2 Kbit Serial SPI EEPROM with High Speed Clock

HIGH SPEED CLOCK RATE:

– 2.1 MHz Max

1,000,000 ERASE/WRITE CYCLES

40 YEARS DA TA RETE NT ION

SINGLE 4.5V to 5.5V SUPPLY VOLTAGE

SPI BUS COMPATIBLE SERIAL INTERFACE

BLOCK WRITE PROTECTION

STATUS REGISTER

16 BYTE PAGE MODE

WRITE PROTECT

SELF-TIMED PROGRAMMING CY CLE

E.S.D.PROTECTION GREATER than 4000V

SUPPO RTS POSITIVE CLOCK SPI MODES

ST95022

8

1

SO8 (M)

150mil Width

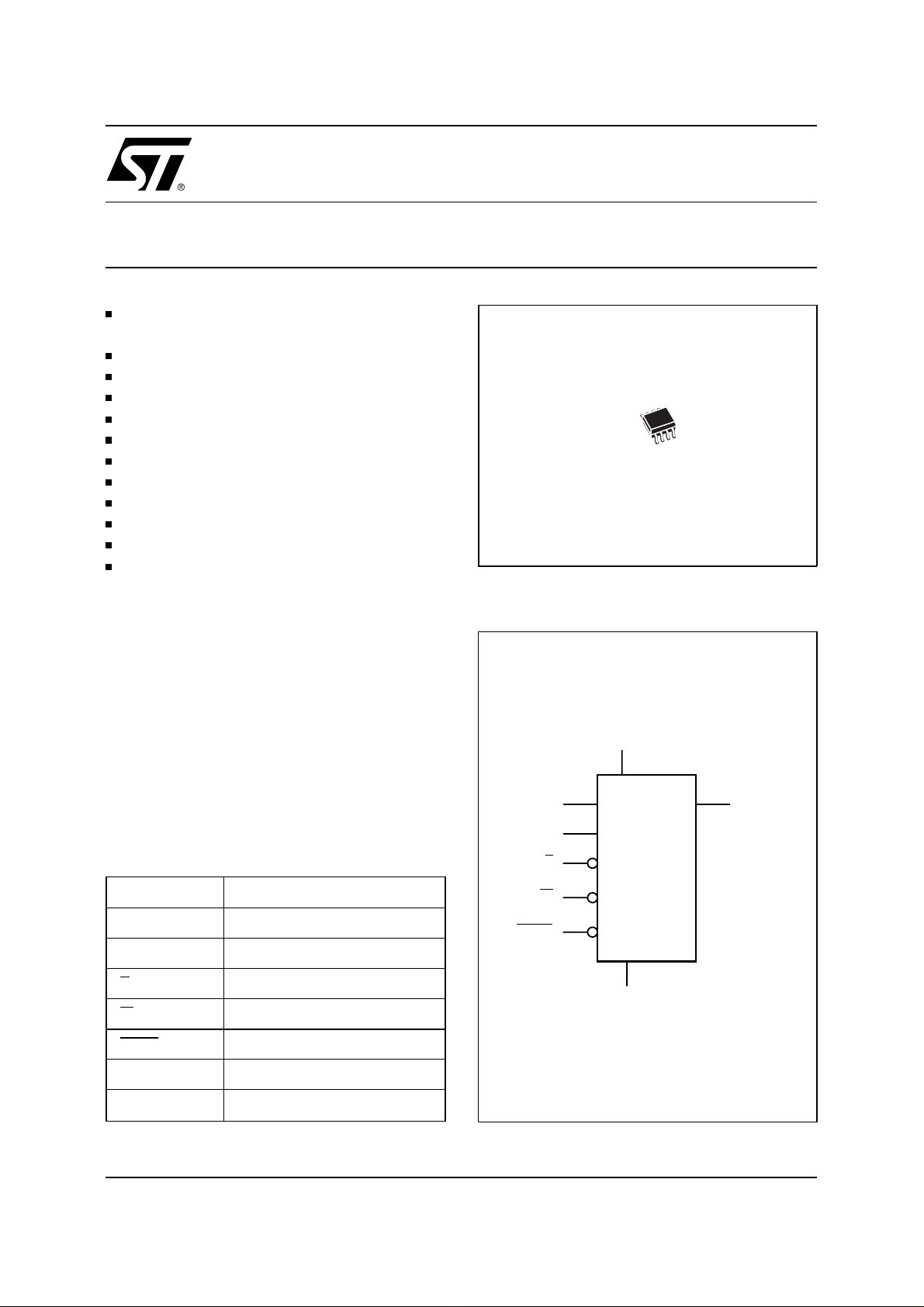

Figure 1. Logic Diagram

DESCRIPTION

The ST95022 is an high speed 2 Kbit Electrically

Erasable Programmable Memory (EEPROM) fabricated with STMicroelectronics’s High Endurance

Single Polysilicon CMOS technology. The memory

is accessed by a simple SPI bus compatible serial

interface. The bus signals are a serial clock input

(C), a serial data input (D) and a serial data output

(Q).

T ab le 1. Signal Names

C Serial Clock

D Serial Data Input

Q Serial Data Output

S Chip Select

W Write Protect

HOLD Hold

V

CC

Supply Voltage

W

HOLD

V

CC

D

C

S

ST95022

V

SS

Q

AI01722

V

SS

February 1999 1/16

Ground

ST95022

T ab le 2. Absolute Maximum Ratings

Symbol Parameter Value Unit

T

A

T

STG

T

LEAD

V

O

V

V

CC

V

ESD

Notes:

1. Except for the rating "Operating T emperature Range", stresses above those listed in the Table "Absolute Maximum Ratings"

2. Depends on range.

3. MIL-STD-883C, 3015.7 (100pF, 1500Ω)

4. EIAJ IC-121 (Condition C) (200pF , 0Ω)

Ambient Operating Temperature

Storage Temperature –65 to 150 °C

Lead Temperature, Soldering (SO8 package) 40 sec 215 °C

Output Voltage –0.3 to VCC +0.6 V

Input Voltage with respect to Ground –0.3 to 6.5 V

I

Supply Voltage –0.3 to 6.5 V

Electrostatic Discharge Voltage (Human Body model)

Electrostatic Discharge Voltage (Machine model)

may cause permanent damage to the device. These are stress rating s only and operation of the device at these or any other

conditions above those indicated in the Operating sections of this specification is not implied. Exposure to Absolute Maximum

Rating conditions for extended periods may affect device reliability. Refer also to the STMicroelectronics SURE Program and

other relevant quality documents.

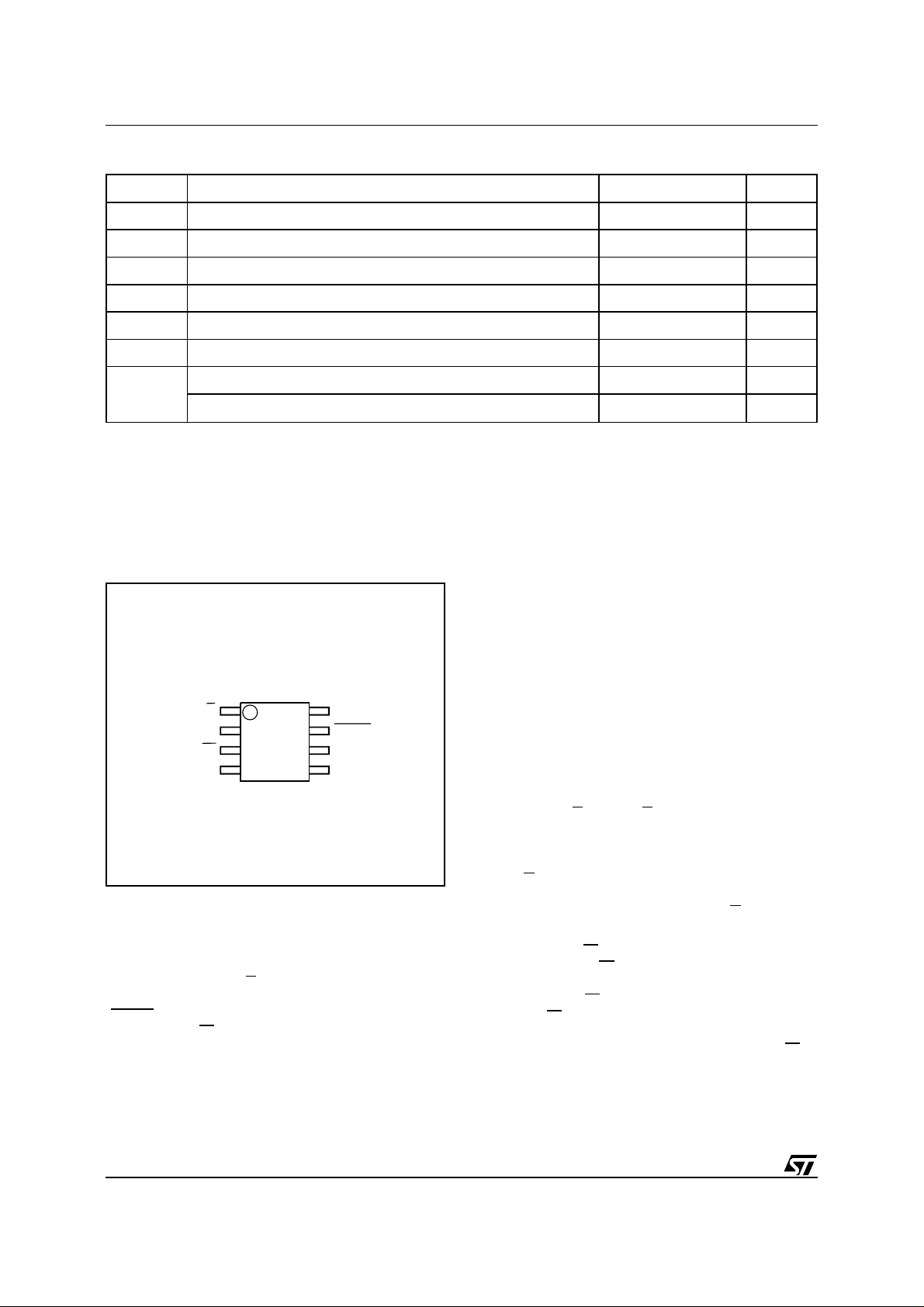

Figure 2B. SO Pin Connections

(1)

(2)

(3)

(4)

–40 to 125 °C

4000 V

500 V

SIGNALS DESCRIPTION

Serial Output (Q).

The output pin is used to transfer data serially out of the ST95022. Data is shifted

out on the falling edge of the serial clock.

Serial Input (D).

The input pin is used to transfer

data serially into the device. It r eceives instructions,

ST95022

1

SV

2

3

W

SS

4

8

7

6

5

AI01723

CC

HOLDQ

C

DV

addresses, and the data to be written. Input is

latched on the rising edge of the serial clock.

Serial Clock (C).

The serial clock provides the

timing of the serial interface. Instructions, addresses, or data present at the input pin are latched

on the rising edge of the clock input, while data on

the Q pin changes after the falling edge of the clock

input.

Chip Select (

S).

When

S is high, the ST95022 is

deselected and the D output pin is at high impedance and, unless an internal write operation is

underway the ST95022 will be in the standby power

S low enables the ST95022, placing it in the

mode.

active power mode. It should be noted that af ter

S is required

DESCRIPTION

(cont’d)

The device connected to the bus is selected when

the chip select input (

S) goes low. Communications

with the chip can be interrupted with a hold input

HOLD). The write operation is disabled by a write

(

protect input (

W).

Data is clocked in during the low to high transition

of clock C, data is clocked out during the high to

low transition of clock C.

power-on, a high to low transition on

prior to the start of any operation.

Write Protect (

protection. When

W).

This pin is for hardware write

W is low, writes to the ST95022

memory are disabled but any other operations stay

enabled. When

available.

W is high, all writes operations are

W going low at any time before the last

bit D0 of the data stream will reset the write enable

latch and prevent programming. No action on

on the write enable latch can interrupt a write cycle

which has commenced.

W or

2/16

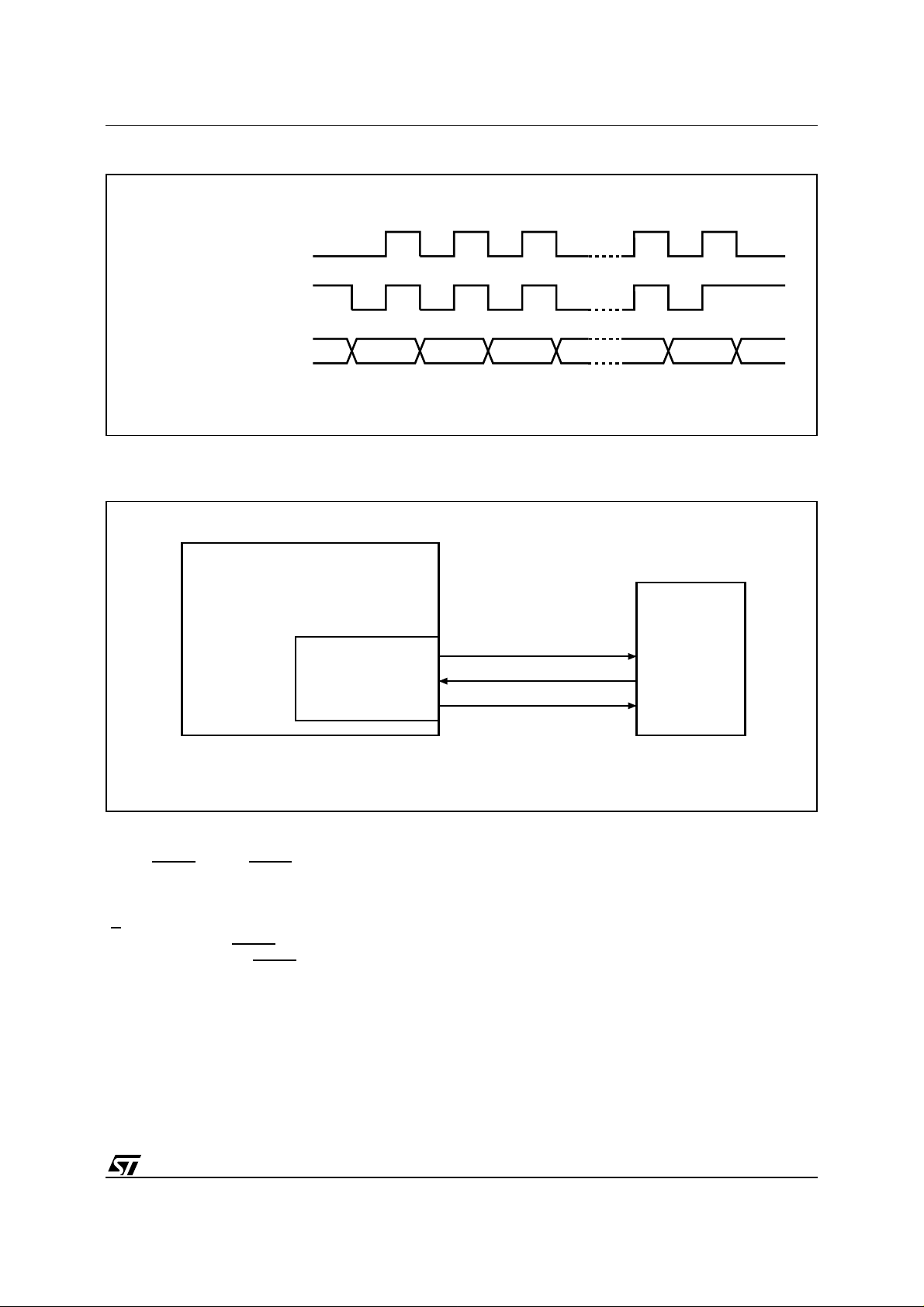

Figure 3. Data and Clock Timing

ST95022

CPOL

CPHA

0

1

0

1

C

C

D or Q

MSB LSB

Figure 4. Microcontroller and SPI Interface Set-up

MICROCONTROLLER

(ST6, ST7, ST9)

SPI Interface with

(CPOL, CPHA) =

('0', '0') or ('1', '1')

SCK

SDI

SDO

C

Q

D

AI01438

ST95xx0

HOLD ).

Hold (

HOLD pin is used to pause

The

serial communications with a ST95022 without resetting the serial sequence. To take the Hold condition into account, the product must be selected

(

S = 0). Then the Hold state is validated by a high

to low transition on

the communications,

HOLD when C is low . T o r esume

HOLD is brought high while

C is low. During the Hold condition D, Q , and C are

at a high impedance state.

When the ST95022 is under the Hold condition, it

is possible to deselect the device. However, the

serial communications will remain paused after a

reselect, and the chip will be reset.

AI01439

The ST95022 can be driven by a microcontroller

with its SPI peripheral running in either of the two

following modes: (CPOL, CPHA) = (’0’, ’0’) or

(CPOL, CPHA) = (’1’, ’1’).

For these two modes, input data is latched in by the

low to high transition of clock C, and output data is

available from the high to low transition of Clock

(C).

The difference between (CPOL, CPHA) = (0, 0) and

(CPOL, CPHA) = (1, 1) is the stand-by polarity: C

remains at ’0’ for (CPOL, CPHA) = (0, 0) and C

remains at ’1’ for (CPOL, CPHA) = ( 1, 1) when there

is no data transfer.

3/16

ST95022

OPERATIONS

All instructions, addresses and data are shifted in

and out of the chip MSB first. Data input (D) is

sampled on the first rising edge of clock (C) after

the chip select (

S) goes low. Prior to any operation,

a one-byte instruction code must be entered in the

chip. This code is entered via the data input (D),

and latched on the rising edge of the clock input

(C). T o enter an instruction code, the product must

have been previously selected (

S = low). Table 3

shows the instruction set and format for device

operation. If an invalid instruction is sent (one not

contained in Table 3), the chip is automatically

deselected.

Write Enable (WREN) and Write Disable (WR DI)

The ST95022 contains a write enable latch. This

latch must be set prior to every WRITE or WRSR

operation. The WREN instruction will set the latch

and the WRDI instruction will reset the latch. The

latch is reset under the following conditions:

W pin is low

–

– Power on

– WRDI instruction executed

– WRSR instruction executed

– WRITE instruction executed

As soon as the WREN or WRDI instruction is

received by the ST95022, the circuit executes the

instruction and enters a wait mode until it is deselected.

Read Status Register (RDSR)

The RDSR instruction provides access to the status

register. The status register may be read at any

time, even during a write to the memory operation.

As soon as the 8th bit of the status register is read

out, the ST95022 enters a wait mode (data on D is

not decoded, Q is in Hi-Z) until it is deselected.

The status register format is as follows:

b7 b0

1 1 1 1 BP1 BP0 WEL WIP

BP1, BP0: Read and write bits.

WEL, WIP: Read only bits.

b7 to b4: Read only bits.

During a write to the memory operation to the

memory array, all bits BP1, BP0, WEL, WIP are

valid and can be read. During a write to the status

register, only the bits WEL and WIP are valid and

can be read. The values of BP1 and BP0 read at

that time correspond to the previous contents of the

status register.

The Write-In-Process (WIP) read-only bit indicates

whether the ST95022 is busy with a write operation. When set to a ’1’ a write is in progress, when

set to a ’0’ no write is in progress.

The Write Enable Latch (WEL) read-only bit indicates the status of the write enable latch. When set

to a ’1’ the lat ch is set, when set t o a ’0’ the latch is

reset. The Block Protect (BP0 and BP1) bits indicate the extent of the protection employed. These

bits are set by the user issuing the WRSR instruction. These bits are non-volatile.

Write Status Register (WRSR)

The WRSR instruction allows the user to select the

size of protected memory. The ST95022 is divided

into four 512 bit blocks. The user may read the

blocks but will be unable to write within the pro-

T ab le 3. Instruction Set

Instruction Description Instruction Format

WREN Set Write Enable Latch 0000 0110

WRDI Reset Write Enable Latch 0000 0100

RDSR Read Status Register 0000 0101

WRSR Write Status Register 0000 0001

READ Read Data from Memory Array 0000 0011

WRITE Write Data to Memory Array 0000 0010

Notes:

A = 1, Upper page selected

A = 0, Lower page selected

4/16

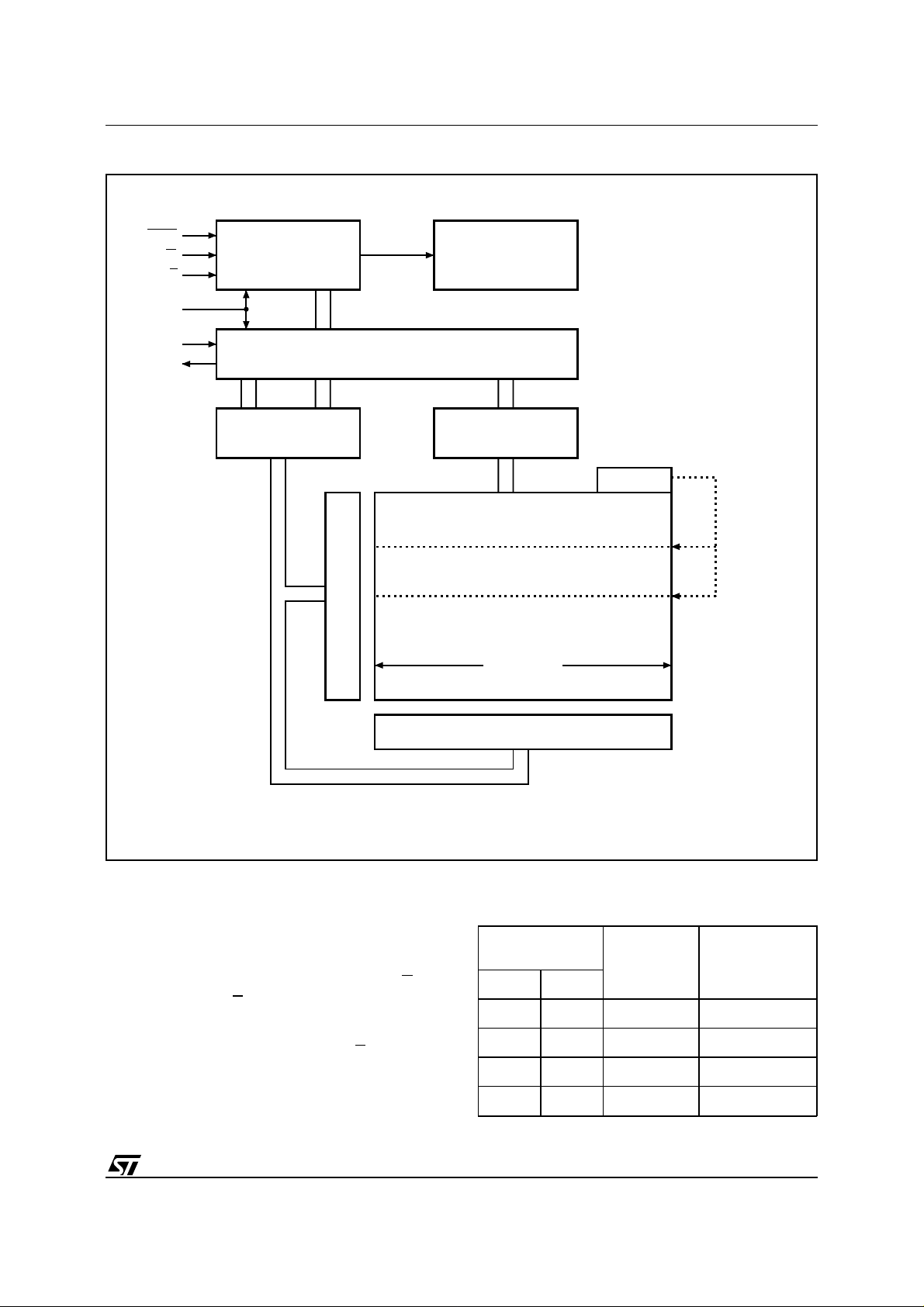

Figure 5. Block Diagram

ST95022

HOLD

W

S

C

D

Q

Control Logic

I/O Shift Register

Address Register

and Counter

Y Decoder

High Voltage

Generator

Data

Register

Status

Block

Protect

16 Bytes

tected blocks. The blocks and respective WRSR

control bits are shown in Table 4.

When the WRSR instruction and the 8 bits of the

Status Register are latched-in, the internal write

cycle is then triggered by the ris ing edge of

This rising edge of

S must appear no later than the

S.

16th clock cycle of the WRSR instruction of the

Status Register content (it must not appear a 17th

clock pulse before the rising edge of

S), otherwise

the internal write sequence is not performed.

X Decoder

T ab le 4. Write Protected Block Size

Status Register

Bits

BP1 BP0

0 0 none none

0 1 C0h - FFh Upper quarter

1 0 80h - FFh Upper half

1 1 00h - FFh Whole memory

Array

Addresses

Protected

Protected

AI01272

Block

5/16

Loading...

Loading...