MK5027

SS7 SIGNALLING

LINK CONTROLLER

August 1989

CMOS

FULLY COMPATIBLE WITH BOTH 8 OR 16

BITSYSTEMS

SYSTEM CLOCK RATE TO 10MHz. DATA

RATE UP TO 2.5Mbps FOR SS7 PROTOCOL

PROCESSING,7Mbps FOR TRANSPARENT

HDLCMODE

COMPLETELEVEL 2 IMPLEMENTATION

COMPATIBLE WITH 1988 CCITT, AT&T,

ANSI, AND BELLCORE SIGNALLING SYSTEMNUMBER 7 LINK LEVELPROTOCOLS

52 PIN PLCC AND 48-PIN DIP PIN-FOR-PIN

COMPATIBLE WITH THE SGS-THOMSON

X.25 CHIP (MK5025)AND NEARLY PIN-FORPIN COMPATIBLE WITH THE SGS-THOMSON VLANCE CHIP (MK5032)

BUFFER MANAGEMENTINCLUDES:

- InitializationBlock

- SeparateReceive and TransmitRings

- VariableDescriptor Ring and Window Sizes.

ON CHIP DMA CONTROL WITH PROGRAM-

MABLEBURST LENGTH

SELECTABLE BEC OR PCR RETRANSMIS-

SION METHODS, INCLUDING FORCED RETRANSMISSIONFOR PCR

HANDLESALL 7 SS7 TIMERS

HANDLESALL SS7 FRAME FORMATTING:

- Zerobit insertand delete

- FCSgeneration and detection

- Framedelimiting with flags

PROGRAMMABLE MINIMUM SIGNAL UNIT

SPACING(number of flags between SU’s)

HANDLES ALL SEQUENCING AND LINK

CONTROL

SELECTABLEFCS OF 16 OR 32 BITS.

TESTINGFACILITIES:

- InternalLoopback

- Silent Loopback

- OptionalInternal Data Clock Generation

- SelfTest

ALL INPUTS AND OUTPUTS ARE TTL COM-

PATIBLE

PROGRAMMABLE FOR FULL OR HALF DU-

PLEX OPERATION

DESCRIPTION

The SGS-THOMSON Signalling System #7 Signalling Link Controller (MK5027) is a VLSI semi-

conductor device which provides a complete link

control function conforming to the 1988 CCITT

version of SS7. This includes frame formatting,

transparency(so called ”bit-stufling”),error recovery by two types of retransmission, error monitoring, sequence number control, link status control, and FISU generation. One of the outstanding

features of the MK5027 is its buffer management

which includes on-chip DMA. Thisfeature allows

users to handlq multiple packets of receive and

transmit data at a time. (A conventional data linkcontrol chip plus a separate DMA chip wouldhandle data for only a single block at a time.) The

MK5027 maybe used with any of severalpopular

16 and 8 bit microprocessors, such as 68000,

6800, Z8000, Z80, LSI-11, 8086, 8088,8080, etc.

DIP48 PLCC52

VSS-GND

DAL07

DAL06

DAL05

DAL04

DAL03

DAL02

DAL01

DAL00

READ

INTR

DALI

DALO

DAS

BMO, BYTE, BUSREL

BMI, BUSAKO

HOLD, BUSRQ

ALE, AS

CS

ADR

READY

RESET

VSS-GND

24

HLDA

1

2

3

4

5

6

7

8

9

10

11

12

13

14

48

47

46

45

44

43

42

41

40

39

38

37

36

23

22

21

20

19

18

17

16

15

35

34

33

32

31

30

29

28

27

26

25

TCLK

A18

A19

A20

A21

A22

A23

RD

DSR, CTS

TD

SYSCLK

RCLK

DTR, RTS

VCC (+5V)

DAL08

DAL09

DAL10

DAL11

DAL12

DAL13

DAL14

DAL15

A16

A17

M

K

5

0

H

2

5

Figure 1: Pin Connection.

1/19

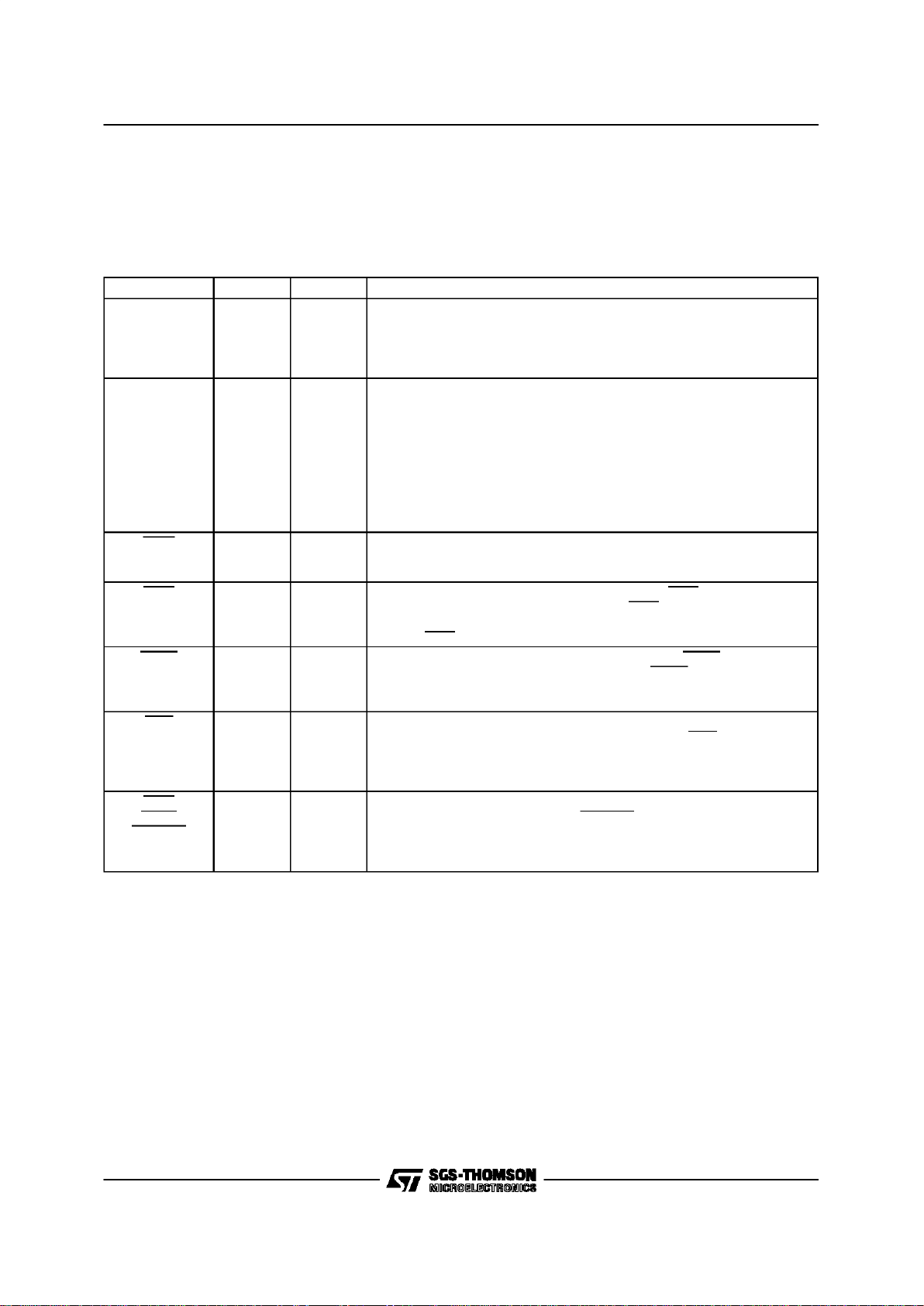

Table 1: PinDescription.

LEGEND:

I Input only O Output only

IO Input/Output 3S 3-State

OD Open Drain(no internal pull-up)

Signal Name Pin(s) Type Descriplion

DAL<15:00> 2-9

40-47

IO/3S The time multiplexedData Address bus.During the address portion of a

memory transfer, DALe15:00 contains the lower 16 bits ofthe memory

address.

Duringthe data portion of a memory transfer, DAL<15:00> contains the

read or write data, depending on thetype of transfer.

READ 10 IO/3S READ indicates the type of operationthat the bus controlleris performing

during a bus transaction. READ is driven by the MK5027 only while it is

the BUS MASTER. READ isvalid during the entire bus transactionand is

tristatedat all othertimes.

MK5027 as a Bus Slave:

READ = HIGH - Data is placed on the DAL lines by the chip.

READ = LOW- Data is taken off theDAL lines by the chip.

MK5027 as a Bus Master:

READ = HIGH- Data is taken off the DAL lines by the chip.

READ = LOW - Data is placed on the DAL lines by the chip.

INTR 11 O/OD INTERRUPT is an attention interruptline that indicates that one or moreof

the following CSR0 status flags isset: MISS, MERR,RINT, TINT or PINT.

INTERRUPT is enabled by CSR0<0.9>, INEA = 1.

DALI 12 O/3S DAL IN is an external bus transceiver control line. DALIis driven by the

MK5027 only whileit is the BUS MASTER. DALIis assertedby the

MK5027 when | ads from the DAL lines during the data portion of a READ

transfer. DALIis not asserted during a WRITE transfer.

DALO 13 O/3S DAL OUT isan external bus transceiver control line. DALOis driven by

the MK5027 onlywhile it is the BUS MASTER. DALOis asserted by the

MK5027 when itdrives the DAL linesduring theaddress portion of a

READ transfer orfor the duration of a WRITE transfer.

DAS 14 IO/3S DATA STROBE defines the dataportio,n ofa transaction. By definition,

data is stable and valid at the low to hightransition of DAS.This signal is

drivenby the MK5027 while it is the BUS MASTER.During the BUS

SLAVE operation, this pin is used as an input.At all other times the signal

is tristated.

BMO

BYTE

BUSREL

15 IO/3S I/O pins 15and 16 are programmable through CSR4. If bit 06 of CSR4 is

set to a one, pin 15 becomes inputBUSRELand is used by the hostto

signalthe MK5027 toterminate a DMA burst after thecurrent bus transfer

has completed. If bit 06 is clear the pin 15 is an output and behaves as

described below for pin16.

Note: Pin out shown is for 48 pin dip.

MK5027

2/19

Table 1: PinDescription (continued)

Signal Name Pin(s) Type Descriplion

BM1

BUSAKO

16 O/3S Pins 15 and 16 are programmable though bit 00 ofCSR4 (BCON).

If CSR4<00> BCON = 0,

I/O PIN 15 = BMO (O/3S)

I/O PIN 16 = BM1 (O/3S)

BYTE MASK<1:0> indicates the byte(s) on the DAL to be read or written

during this bus transaction. MK5027 drives these lines only as a Bus

Master. MK5027 ignores the BM lines whenit is a Bus Slave.

Byte selection is done as outlined inthe following table.

BM1 BM0 TYPE OF TRANSFER

LOW LOW ENTIRE WORD

LOW HIGH UPPER BYTE (DAL<15:08>)

HIGH LOW LOWER BYTE(DAL<07:00>)

HIGH HIGH NONE

If CSR4<00>BCON = 1,

I/O PIN 15 = BYTE (O/3S)

I/O PIN 16 = BUSAKO(O)

Byte selection is done using the BYTE line and DAL<00> latched during

the address portion of the bus transaction. MK5027drives BYTE only a

Bus Master and ignores it whena Bus Slave. Byte selectionis done as

outlined in the followingtable.

BYTE DAL<00> TYPE OF TRANSFER

LOW LOW ENTIRE WORD

LOW HIGH ILLEGAL CONDITION

HIGH LOW LOWER BYTE

HIGH HIGH UPPER BYTE

BUSAKOis a bus request daisy chain output. If MK5027 is notrequesting

the bus andit receives HLDA, BUSAKOwill bedriven low. If MK5027 is

requesting the bus when it receives HLDA, BUSAKOwill remain high.

Note: All transfers are entire word unlessthe MK5027 is configuredfor 8

bit operation.

HOLD

BUSRQ

17 IO/OD Pins 17is configuredthrough bit 0of CSR4.

If CSR4<00> BCON = 0,

I/O PIN 17 = HOLD

HOLD request is asserted by MK5027 when it requires a DMA cycle, if

HLDA is inactive, regardless of the previous state of the HOLD pin.

HOLD is heldlow for the entire ensuing bus transaction.

If CSR4<00> BCON = 1,

I/O PIN 17 = BUSRQ

BUSRQ is asserted by MK5027 when it requires a DMA cycleif the prior

state of theBUSRQpin was high and HLDA is inactive. BUSRQis held

low for the entire ensuing bus transaction.

ALE

AS

18 O/3S The active level of ADDRESS STROBE is programmable throughCSR4.

The address portion of a bustransfer occurs while this signal is at its

asserted level. This signal is driven by MK5027 while itis the BUS

MASTER. At all other times, the signal is tristated.

If CSR4<01> ACON = 0,

I/O PIN 18 = ALE

ADDRESSLATCHENABLE isused to demultiplex the DALlines and define

theaddress portion of thetransferand remains low during the data portion.

If CSR4<01> ACON = 1,

I/O PIN 18 = AS

As AS,the signalpulses lowduring the address portion of the bus

transfer. The low to hightransition of AScan be used by a slavedevice to

strobe the address into a register.

AS is effectively the inversion of ALE.

HLDA 19 I HOLD AKNOWLEDGE is theresponse to HOLD. Whe nHLDAis low inresponse

to MK5027’s assertion of HOLD, theMK5027 isthe BusMaster . HLDA should be

desasse rted ONLY a fter HOLDhas been re leased by the MK 5027.

MK5027

3/19

Table 1: PinDescription (continued)

Signal Name Pin(s) Type Descriplion

CS 20 I CHIP SELECT indicates, when low, that the MK5027 is the slave device

for the data transfer.CS must be valid througoutthe enture transaction.

ADR 21 I ADDRESS selects the Register Address Port or the Register Data Port. It

must be validthroughout thedata portion of thetransfer and is onlyused

by the chipwhen CS is low.

ADR PORT

LOW REGISTER DATA PORT

HIGH REGISTER ADDRESS PORT

READY 22 IO/OD When the MK5027 is a Bus Master, READYis an asynchronous

acknowledgement from the bus memory that memory will accept data in a

WRITE cycle or that memory has put data on the DAL lines in a READ

cycle.

As a bus Slave, the MK5027 asserts READYwhen it hasput data on the

DAL lines during a READcycle oris about to take datafrom the DAL lines

during WRITE cycle.READY is a response to DAS and it will be released

after DASor CS is negated.

RESET 23 I RESET isthe Bus signal that will cause MK5027 to cease operation, clear

its internal logic and enter an idle state with the Power Off bit of CSR0 set.

TCLK 25 I TRANSMIT CLOCK. A 1xclock input for transmitter timing. TD changes

on the falling edge of TCLK. The frequency of TCLKmay not be greater

than the frequency of SYSCLK.

DTR

RTS

26 IO DATA TERMINAL READY, REQUEST TO SEND. Modem controlpin. Pin

26 is configurablethrough CSR5. This pin can be programmed to behave

as output RTS or as programmable IO pin DTR. If configured as RTS, the

MK5027 will assert this pin if it has data to send and throughout the

transmission of a signal unit.

RCLK 27 I RECEIVE CLOCK. A 1x clock input for receiver timing. RD is sampled on

the rising edge of RCLK. The frequency of RCLK may not be greater than

the frequency of SYSCLK.

SYSCLK 28 I SYSTEM CLOCK. System clock used for internaltiming of the MK5027.

SYSCLK should be a square wave, of frequency up to 10MHz.

TD 29 O TRANSMIT DATA. Transmit serial dataoutput.

DSR

CTS

30 IO DATA SET READY, CLEAR TOSEND. Modem Control Pin. Pin 30 is

configurablethrough CSR5. This pin can beprogrammed to behave as

input CTS or as programmable IO pin DSR. If configured asCTS, the

MK5027 will transmit allones while CTS is high.

RD 31 I RECEIVE DATA. Received serialdata input.

A<23:16> 32-39 O/3S Address bits <23:16> used in conjunctionwith DAL <15:00> to produce a

24 bit address. MK5027 drives these lines only as a Bus Master.

A23-A20may be driven continuouslyas described in the CSR4<7>BAEN

bit.

VSS-GND 1, 24 GroundPins

VCC 48 Power Supply Pin

+5.0 VDC ± 5%

MK5027

4/19

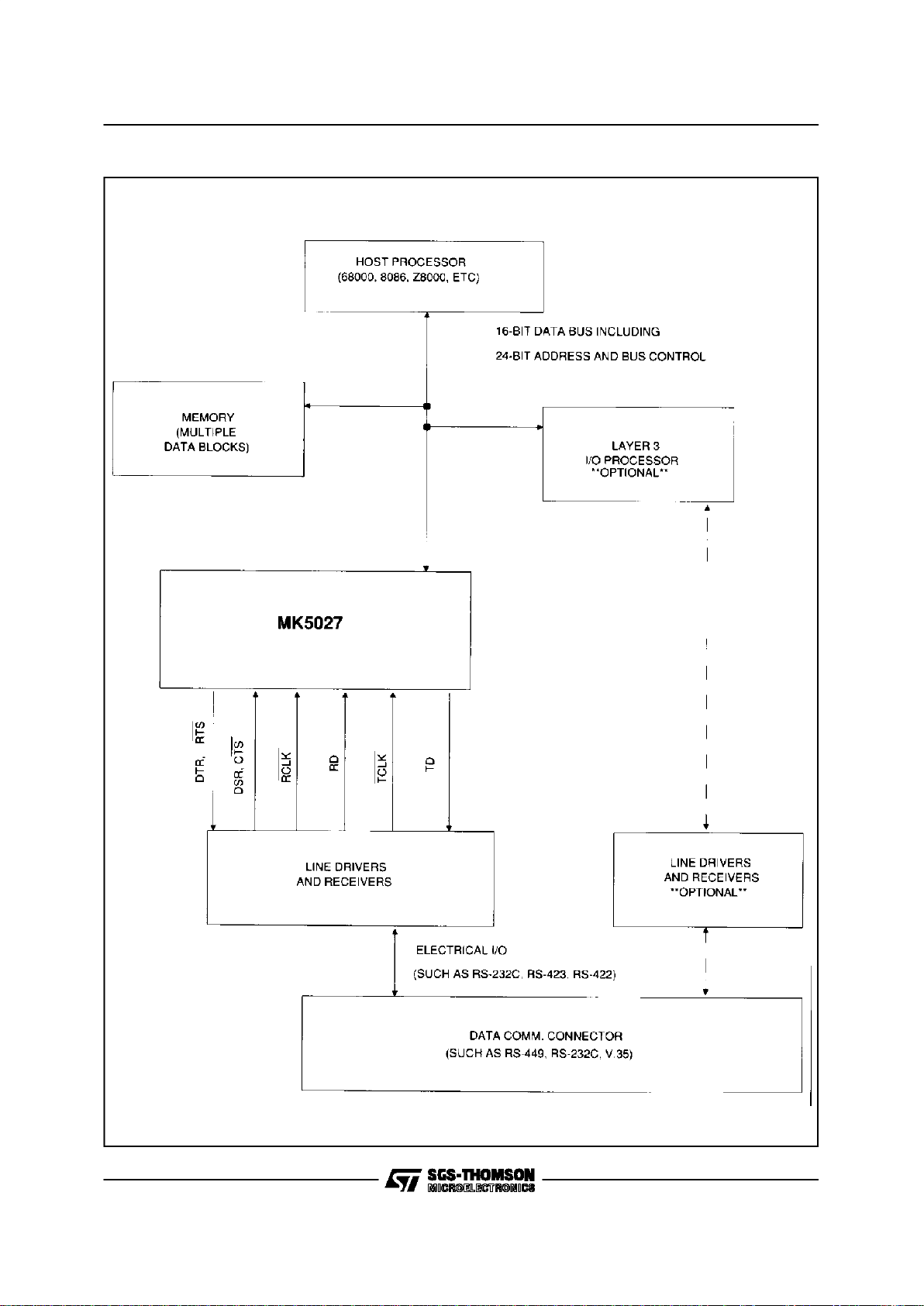

Figure2: PossibleSystem Configurationfor the MK5027.

MK5027

5/19

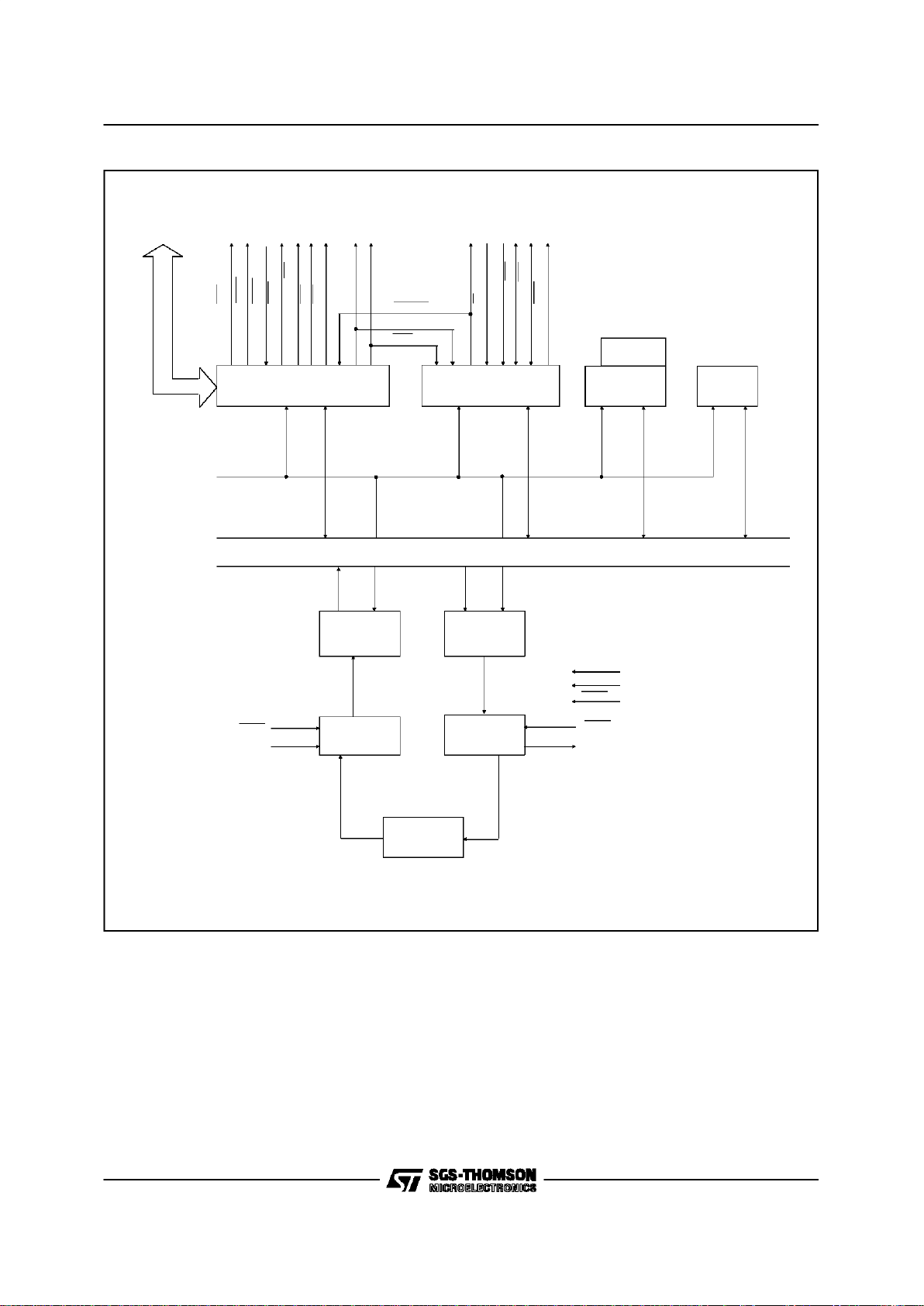

OPERATIONALDECRIPTION

The SGS-THOMSON Signalling System #7 Signalling Link Controller (MK5027) device is a VLSI

product intended for data communicationapplicationsrequiring SS7link level control. The MK5027

will perform all frame formatting, such as: frame

delimiting with flags, FCS generation and detection. It will also perform all error recovery and link

control. The MK5027 also includes a buffer management mechanism that allow the user to transmit and/or receive multiple MSU’s. Contained in

the buffer management is an on-chip dual chan-

nel DMA: one channel for receive and one channel for transmit. The MK5027handles error recovery andlink statussignalling.

The MK5027 is intended to be used with any

popular 16 or 8 bit microprocessor. Possible system configurationfor the MK5027 is shown in Figure 2. The MK5027 will move multiple blocks of

receive and transmit data directly into and out of

memory through the host’s bus. An I/O acceleration processor in Figure 2 is recommended, but

not required.

DALI

DALO

HLDA

HOLD

ALE, AS

BM0

BM1

DAS

READ

INTR

ADR

READY

DTR, RTS

DSR, CTS

CS

FIRMWARE

ROM

MICRO

CONTROLLER

TIMERS

DMA

CONTROLLER

CONTROL / STATUS

REGISTERS 0 - 5

SYSCLK

INTERNAL BUS

RECEIVER

FIFO

TRANSMITTER

FIFO

RECEIVER TRANSMITTER

LOOPBACK

TEST

RD

RCLK

TCLK

TD

VSS - GND

RESET

VCC

DAL<15:00>

A <23:16>

Figure3: MK5027 SimplifiedBlockDiagram.

MK5027

6/19

All signal pins on the MK5027 are TTL compatible. This has the advantage of making the

MK5027 in- dependent of the physical interface.

As shown in Figure 2. Iine drivers and receivers

are used for electrical- connectionto the physical

layer.

SERIALINTERFACE

The MK5027 provides two separate serial channels: one for received data and one for transmitted data. These serial channels are completely

separate and may be run at different clock frequenciesThe receiver is responsible for recognizing frame boundries. removal of inserted zeroes

(for transparency) and checking the incoming

FCS. Signal units with in correct FCS values are

discarded. The receiver also parallelizes the incoming data which is placed into the receive data

buffers within the receive descriptor ring The

transmitteris responsiblefor framing and serializing the data frames placed in the transmit descriptor ring. The transmitter calculates the FCS

of the outgoing data and appends it to the data

The transmitter generates flag sequences for inter-signal unit fill, at least two flags are transmitted between adjacent signal units. The FCS calculations for both directions of serial data

optionally follow either the 16 bit CRC CCITT or

the 32-bit CRC32 algorithmsFCS generationand

checkingcan also be optionallydisabled if necessary.

MICROPROCESSOR INTERFACE

The MK5027 contains a dual channel DMA on

chip to handle data transfers to and from the host

mem-ory. Allaccess to the initializationblock and

descriptor rings is handled in this way The address bus is 24 bits wide and does not use any

segmentation or paging methods. Data transfers

can optionally be 8 and 16 bit operations. this allows easy interfacingwith both 8 and 16 bit processors DMA transfers can be up to 1. 8 or an unlimited number of words per transfer under

program control During bus slave operation the

MK5027 allows access to its 6 control/status registers which are used to monitor and control the

chip. These registers are used to control link procedures, configure interface options, control and

monitor interrupt status. and more. Bus slave

mode also allows both 8 and 16 bit accesses.

BUFFERMANAGEMENT

The basic organization of the buffer management

is a circular queue of tasks in memory called descriptor rings. There are separate rings to describe the transmit and receive operations. Up to

128 buffers may be queued-up on a descriptor

ring awaiting execution by the MK5027 The descriptor ring has a segment assigned to each

buffer. Each segmentholds a pointer for the starting address of the buffer. and holds a value for

the lengthof the bufferin bytes.

Each segment also contains two control bits

called OWNA and OWNB, which denote whether

the MK5027. the HOST. or the l/O ACCELERATION PROCESSOR (if present) ”owns” the buffer. For transmit. when the MK5027owns the buffer. the MK5027 is allowed and commanded to

transmit the buffer When the MK5027 does not

own the buffer, it will not transmit that buffer. For

receive. when the MK5027 owns a buffer. it may

place received data into that buffer. Conversely.

when the MK5027 does not own a receive buffer, it will not place received data in that buffer.

The MK5027 buffer managementmechanism will

handly signal units which are longer than the

length of an individual buffer. This is done by a

chaining method which utilizes multiple buffers.

The MK5027 tests the next segment in the descriptor ring in a ”look ahead” manner. If the

packet is too long for one buffer, the next bufferwill be used after filling the first buffer: that is,

”chained”. The MK5027 will then ”look ahead” to

the next buffer, and chain that buffer if necessary,

and so on The operational parameters for the

buffer management are defined by the user

in the initialization block The parameters defined

include the basic mode of operation. the number

of entries for the transmitter and receiver descriptor rings.etc.

MK5027

7/19

RECEIVERDESCRIPTOR RINGS

DESCRIPTOR 0

BUFFERSTATUS

BUFFERADDRESS

BUFFER SIZE

BUFFER MSGCOUNT

DESCRIPTOR 1

DESCRIPTOR M

TRANSMITDESCRIPTOR RINGS

DESCRIPTOR 0

BUFFER STATUS

BUFFER ADDRESS

BUFFER SIZE

BUFFER MSG COUNT

DESCRIPTOR 1

DESCRIPTOR N

BUFFER

N

BUFFER

1

BUFFER

0

TRANSMIT BUFFER

BUFFER

M

BUFFER

1

BUFFER

0

RECEIVE BUFFER

CSR 2, CSR3

POINTER TO

INITIALIZATI ON BLOCK

INITIALIZATI ON BLOCK

MODE

TIMER VALUES

RX DESCRIPTOR

TX DESCRIPTOR

POINTER

POINTER

FRAME ADDRESS

FIELDS

STATUS

BUFFER ADDRESS

STATUS BUFFER

ERROR COUNTERS

XID/TEST TRANSMIT

DESCRIPTOR POINTER

XID/TEST RECEIVE

DESCRIPTORPOINTER

RECEIVE BUFFER

TRANSMIT BUFFER

XID/TEST

XID/TEST

Figure4: MK5027 Buffer Management.

MK5027

8/19

SIGNALLING UNIT REPERTOIRE

Thesignal unitrepertoire of theMK5027 is shown

in Table 1. This set conforms to the 1988 CCITT

specificationfor level2 of SignallingSystem #7.

The definitions for the symbols for the frame

types are:

Name Definition

F

FSN

BSN

FIB

BIB

LI

X

SIO

SIF

SF

FCS

Flag Sequence

Forward Sequence Number

Backward Sequences Number

Forward Indicator Bit

Backward Indicator Bit

Lenght Indicator

Programmed As Zeroes

Signalling Information Octet

Service Information Field

Satus Field

Frame Check Sequence

Table 1: MK5027Signal Unit Repertoire.

MK5027

9/19

MK5027ELECTRICAL SPECIFICATIONS

ABSOLUTE MAXIMUM RATINGS

Temperature under Bias –25°Cto +100°C

Storage Temperature –65°Cto +150°C

Voltage on AnyPin with Respect to Ground –0.5V to VCC +0.5V

Power Dissipation 0.50W

Stresses above those listed under ”Absolute Maximum Ratings” may cause permanent damage to the above device. This isa stress rating only

and functional operation of the device atthese or any other condition above those indicated in the operationalsections of this specification is

not implied. Exposure to absolutemaximum rating conditions for extended periods may affectdevice reliability.

DC CHARACTERISTICS

T

A

=0 °Cto70°C, VCC= +5V±5 percentunlessotherwise specified.

Symbol Parameter Min. Typ. Max. Units

V

IL

-0.5 +0.8 V

V

IH

+2.0 VCC+0.5 V

V

OL

@ IOL = 3.2 mA +0.5 V

V

OH

@ IOH= -0.4 mA +2.4 V

I

IL

@ VIN = 0.4 to V

CC

+10 mA

I

CC

@ TSCT = 100 ns 50 µA

CAPACITANCE

f = 1MHz

Symbol Parameter Min. Typ. Max. Units

C

IN

Capacitance on Input pins 10 pF

C

OUT

Capacitance on Output Pins 10 pF

C

IO

Capacitance on I/O pins 20 pF

AC TIMING SPECIFICATIONS

T

A

=0°Cto70°C, VCC= +5V ±5 percent,unless otherwisespecified.

No Signal Symbol Parameter

Test

Condition

Min. Typ. Max. Units

1 SYSCLK T

SCT

SYSCLK period 100 20000 ns

2 SYSCLK T

SCL

SYSCLK low time 45 ns

3 SYSCLK T

SCH

SYSCLK hightime 45 ns

4 SYSCLK T

SCR

Rise time of SYSCLK 0 8 ns

5 SYSCLK T

SCF

Fall time of SYSCLK 0 8 ns

6 TCLK T

TCT

TCLKperiod 140 ns

7 TCLK T

TCL

TCLK low time 63 ns

8 TCLK T

TCH

TCLKhigh time 63 ns

9 TCLK T

TCR

Rise time of TCLK CL = 50 pF 0 8 ns

10 TCLK T

TCF

Fall time of TCLK 0 8 ns

11 TD T

TDP

TD datapropagation delay after the

falling edge of TCLK

CL = 50 pF 40 ns

12 TD T

TDH

TD datahold time after the falling edge

of TCLK

5ns

MK5027

10/19

AC TIMING SPECIFICATIONS (Continued)

T

A

=0°Cto70°C, VCC= +5V ±5 percent,unless otherwisespecified.

No Signal Symbol Parameter

Test

Conditions

Min. Typ. Max. Units

13 RCLK T

RCT

RCLK period 140 ns

14 RCLK T

RCH

RCLK high time 63 ns

15 RCLK T

RCL

RCLK low time 63 ns

16 RCLK T

RCR

Rise time of RCLK 0 8 ns

17 RCLK T

RCF

Fall time of RCLK 0 8 ns

18 RD T

RDR

RD datarise time 0 8 ns

19 RD T

RDF

RD datafall time 0 8 ns

20 RD T

RDH

RD holdtime after rising edge of

RCLK

5ns

21 RD T

RDS

RD setuptime prior to rising edge of

RCLK

30 ns

22 A/DAL T

DOFF

Bus Master driver disable after rising

edge of HOLD

050ns

23 A/DAL T

DON

Bus Master driver enable after falling

edge of HLDA

TSCT =100ns 0 200 ns

24 HLDA T

HHA

Delay to fallingedge of HLDAfrom

falling edge of HOLD (Bus Master)

0ns

25 RESET T

RW

RESET pulse width 30 ns

26 A/DAL T

CYCLE

Read/write, address/data Cycle Time TSCT =100ns 600 ns

27 A T

XAS

Address setup time to falling edge

of ALE

100 ns

28 A T

XAH

Address hold time after the rising

edge of DAS

50 ns

29 DAL T

AS

Address setup time to falling edge

of ALE

75 ns

30 DAL T

AH

Address hold time after the falling

edge ofALE

20 ns

31 DAL T

RDAS

Data setup time to thefalling edge

of DAS(Bus Master read)

55 ns

32 DAL T

RDAH

Data holdtime afterthe risingedge

of DAS(bus master read)

0ns

33 DAL T

DDAS

Data setup time to the falling edgeof

DAS (bus master write)

0ns

34 DAL T

WDS

Data setup time to the rising edgeof

DAS (bus master write)

250 ns

35 DAL T

WDH

Data holdtime tothe rising edge of

DAS (bus slave write)

35 ns

36 DAL T

SRDH

Data holdtime afterthe risingedge

of DAS (bus slave read)

TSCT =100ns 0 35 ns

37 DAL T

SWDH

Data holdtime afterthe risingedge

of DAS (bus slave write)

0ns

38 DAL T

SWDS

Data setup time to the falling edgeof

DAS (bus slave write)

0ns

39 ALE T

ALEW

ALE width high 110 ns

40 ALE T

DSW

Delay from rising edge od DASto

the rising edge of ALE

70 ns

41 DAS T

DSW

DAS width low 200 ns

MK5027

11/19

AC TIMING SPECIFICATIONS (Continued)

T

A

=0°Cto70°C, VCC= +5V ±5 percent,unless otherwisespecified.

No Signal Symbol Parameter

Test

Conditions

Min. Typ. Max. Units

42 DAS T

ADAS

Delay from the falling edge ofALE to

the falling edge of DAS

80 ns

43 DAS T

RIDF

Delay from the rising edge of DALO

to the fallingedge of DAS(bus

master read)

35 ns

44 DAS T

RDYS

Delay from the falling edge of

READYto the fallingedge of DAS

T

ARYD

= 300ns

T

SCT

= 100ns

120 200 ns

45 DALI T

ROIF

Delay from the rising edge of DALO

to the fallingedge of DALI(bus

master read)

70 ns

46 DALI T

RIS

DALIsetup time to the rising edge of

DAS (bus master read)

150 ns

47 DALI T

RIH

DALIhold time afterthe risingedge

of DAS(bus master read)

0ns

48 DALI T

RIOF

Delay from the rising edge of DALI

to the fallingedge of DALO(bus

master read)

70 ns

49 DALO T

OS

DALOsetup time to the falling edge

of ALE (bus master read)

110 ns

50 DALO T

ROH

DALOhold time afterthe falling

edge ofALE (busmasterread)

35 ns

51 DALO T

WDSI

Delay from the rising edge of DAS to

the rising edge of DALO(bus master

write)

50 ns

52 CS T

CSH

CS hold time after the risingedge of

DAS (bus slave)

0ns

53 CS T

CSS

CS setup time to the fallingedge of

DAS (bus slave)

0ns

54 ADR T

SAH

ADR hold time after the rising edge

of DAS (bus slave)

0ns

55 ADR T

SAS

ADR setup time to the falling edge of

DAS (bus slave)

0ns

56 READY T

ARYD

Delay from the falling edge ofALE to

the falling edge of READYto Insure

a Minimum Bus Cycle Time (600ns)

T

SCT

= 100ns 150 ns

57 READY T

SRDS

Data setup time to the falling edgeof

READY(bus slave read)

75 ns

58 READY T

RDYH

READYhold time after the rising

edge of DAS (bus master)

0ns

59 READY T

SRYH

READYhold time after the rising

edge of DAS (bus slave)

T

SCT

= 100ns 0 35 ns

60 READY T

RSH

READ holdtime afterrhe rising edge

of DAS(bus slave)

0ns

61 READ T

SRS

READ setup time after rhe rising

edge of DAS (bus slave)

0ns

62 READY T

RDYD

Delay from falling edge of DASto

falling edge of READY(bus slave)

T

SCT

= 100ns 200 ns

MK5027

12/19

C

L

0.4 mA

CR

CR

CR

CR

1

2

3

4

R1 = 1.2K

CR1 - CR4 = 1N914 or EQUIV

TEST

POINT

FROM

OUTPUT

UNDER

TEST

R1 = 1.4K

C

L

VccVcc

C =50pF min @ 1 MHz

L

FROM

OUTPUT

UNDER

TEST

NOTE: This load is used on all outputs except INTR, HOLD, READY.

NOTE: This load is used on open

drain outputs INTR, HOLD,READY.

RCLK

13

15

14

16 17

21

20

19

18

RD

12

6

87

10

11

9

TD

TCLK

”0”

O.8 V

O.8 V

90 %

”1”

2.0 V

2.0 V

10 %

OUTPUT

INPUT

FLOAT

TIMING MEASUREMENTS ARE MADE AT THE FOLLOWING VOLTAGES,

UNLESS OTHERWISE SPECIFIED:

Figure 6: MK5027Serial Link Timing Diagram

Figure5A: TTL Output Load Diagram. Figure5B: Open Drain OutputLoad Diagram.

MK5027

13/19

Figure7: MK5027 Bus Master Timing Diagram (read).

Note: The BusMaster cycle time willincrease from a minimum of 600ns in 100ns steps until the slave device return READY.

MK5027

14/19

Figure8: MK5027 Bus Master Timing Diagram (write).

Note: The BusMaster cycle time willincrease from a minimum of 600ns in 100ns steps until the slave device return READY.

MK5027

15/19

Figure9: MK5027 Bus Slave Timing Diagram (read)

Figure10: MK5027Bus Slave Timing Diagram (write)

MK5027

16/19

DIP48PACKAGE MECHANICAL DATA

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

a1 0.63 0.025

b 0.45 0.018

b1 0.23 0.31 0.009 0.012

b2 1.27 0.050

D 62.74 2.470

E 15.2 16.68 0.598 0.657

e 2.54 0.100

e3 58.42 2.300

F 14.1 0.555

I 4.445 0.175

L 3.3 0.130

MK5027

17/19

PLCC52PACKAGE MECHANICAL DATA

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 4.20 5.08 0.165 0.20

A1 0.51 0.020

A3 2.29 3.30 0.090 0.13

B 0.33 0.53 0.013 0.021

B1 0.66 0.81 0.026 0.032

C 0.25 0.01

D 19.94 20.19 0.785 0.795

D1 19.05 19.20 0.750 0.756

D2 17.53 18.54 0.690 0.730

D3 15.24 0.60

E 19.94 20.19 0.785 0.795

E1 19.05 19.20 0.750 0.756

E2 17.53 18.54 0.690 0.730

E3 15.24 0.60

e 1.27 0.05

L 0.64 0.025

L1 1.53 0.060

M 1.07 1.22 0.042 0.048

M1 1.07 1.42 0.042 0.056

MK5027

18/19

Information furnished is believed to be accurate and reliable. However,SGS-THOMSON Microelectronics assumes no responsibility for the

consequences of use ofsuch information nor for any infringement of patents or other rights of third parties which may result from its use. No

license is granted by implication or otherwiseunder any patent or patent rightsof SGS-THOMSONMicroelectronics. Specification mentioned

in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied.

SGS-THOMSON Microelectronics products arenotauthorizedfor use as critical components in life support devices orsystems without express

written approval of SGS-THOMSON Microelectronics.

1996 SGS-THOMSON Microelectronics – Printed in Italy– All RightsReserved

SGS-THOMSON Microelectronics GROUP OFCOMPANIES

Australia - Brazil - Canada- China - France - Germany - Hong Kong - Italy - Japan - Korea- Malaysia - Malta - Morocco - The Netherlands -

Singapore- Spain- Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

MK5027

19/19

Loading...

Loading...