512 bit (64b x8) Serial Access TIMEKEEPER® SRAM

■ 5V ±10% SUPPLY VOLTAG E

■ COUNTERS for SECONDS, MINUTES,

HOURS, DAY, DATE , MONTH, YEARS and

CENTURY

■ YEAR 2000 COMPLIANT

■ SOFTWARE CLOCK CALIBRATION

■ AUTOMATIC POWER-FAIL DETECT and

SWITCH CIRCUITRY

2

■ I

C BUS C O MPATI BLE

■ 56 BYTES of GENERAL PURPOSE RAM

■ ULTRA-LOW BATTER Y SU PPL Y CU RRE N T

of 500nA

■ LOW OPERATING CURRENT of 300µA

■ OPERATING TEMP ERATURE of –40 to 85°C

■ AUTOMATIC LEAP YEAR COMPENSATION

■ SPECIAL SOFTWARE PROGRAMMABLE

OUTPUT

■ PACKAGING INCLUDES a 28-LEAD SOIC and

SNAPHAT

®

TOP (to be Ordered Separately)

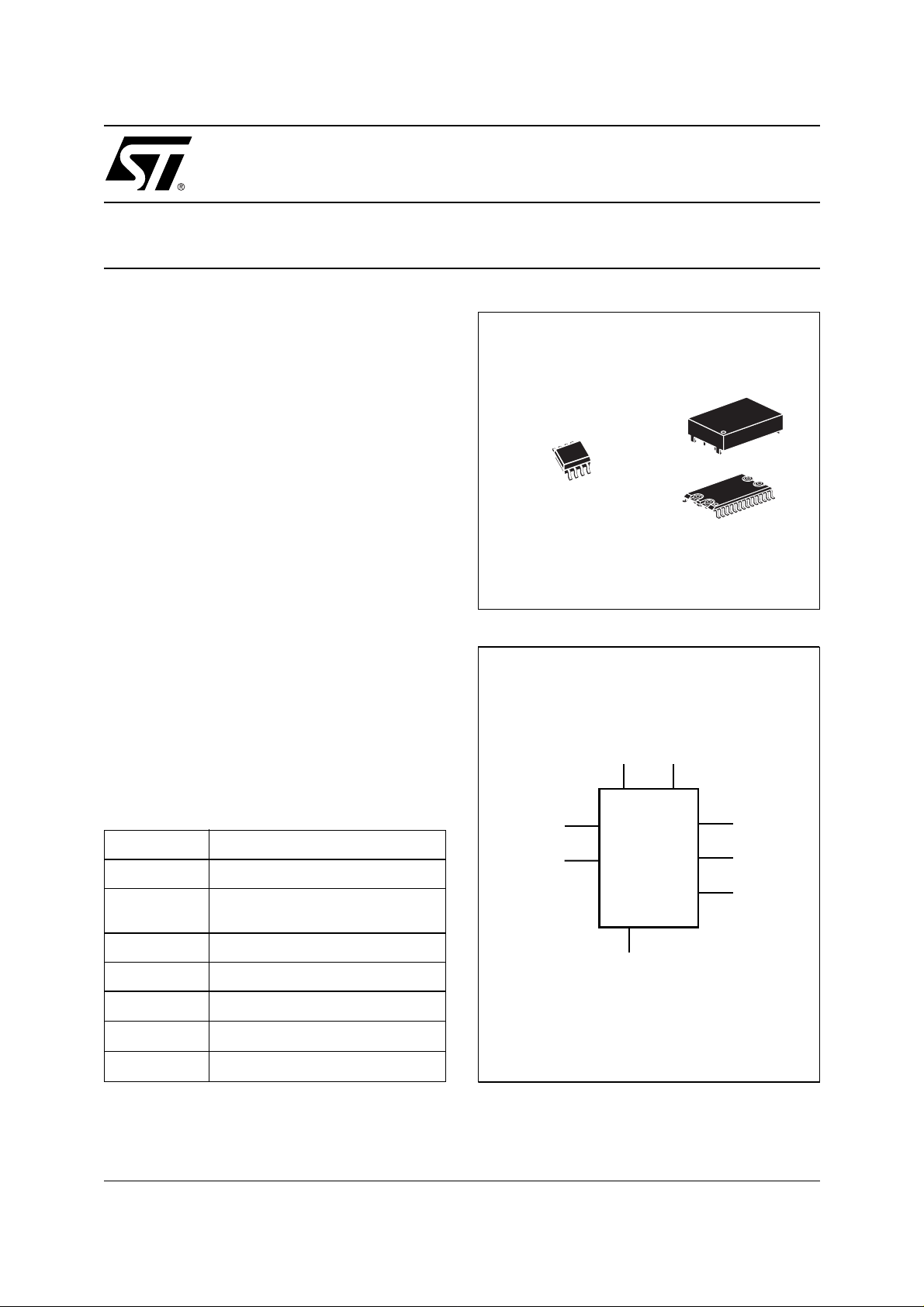

8

1

SO8 (M)

150mil Width

Figure 1. Logic Diagram

M41T56

SNAPHAT (SH)

Battery & Crystal

28

1

SOH28 (MH)

Table 1. Signal Names

OSCI Oscillator Input

OCSO Oscillator Output

FT/OUT

SDA Serial Data Address Input / Output

SCL Serial Clock

V

BAT

V

CC

V

SS

Frequency Test / Output Driver

(Open Drain)

Battery Supply Voltage

Supply Voltage

Ground

OSCI

SCL

V

CC

M41T56

V

SS

V

BAT

OSCO

SDA

FT/OUT

AI02304B

1/19March 2000

M41T56

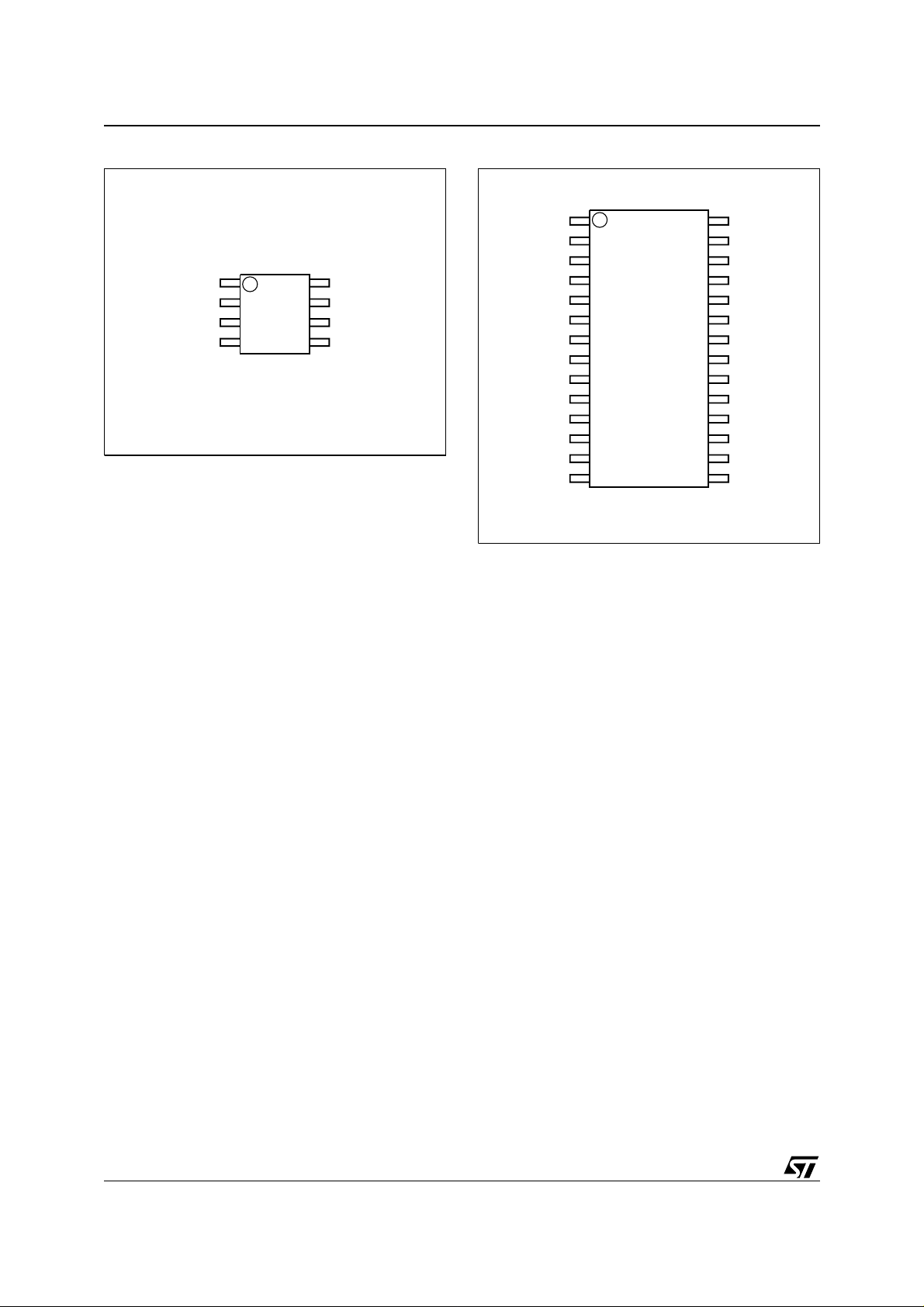

Figure 2A. SO8 Pin Connections

M41T56

OSCI V

V

BAT

SS

1

2

3

4

8

7

6

5

AI02306B

CC

FT/OUTOSCO

SCL

SDAV

DESCRIPTION

®

The M41T56 TIMEKEEPER

is a low power 512

bit static CMOS RAM organized as 64 words by 8

bits. A built-in 32.768 kHz oscillator (external cry stal controlled) and the first 8 bytes of the RAM are

used for the clock/calendar function and are configured in binary coded decimal (BCD) format. Addresses and data are transferred serially via a twoline bi-directional bus. The built-in address register

is incremented automatically after each write or

read data byte.

The M41T56 clock has a built-in power sense circuit which detects power failures and automatically switches to the battery supply during power

failures. The energy needed to sustain the RAM

and clock operations can be supplied from a small

lithium co in cell.

Typical data retention time is in excess of 10years

with a 50mAh 3V lithium cell. The M41T56 is supplied in 8 lead Plastic SOIC package or 2 8 lead

SNAPHAT package.

The 28 pin 330mil SOIC provides sockets with

gold plated contacts at both ends for direct con-

Figure 2B. SOH28 Connections

NC V

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

NC

V

SS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

M41T56

28

27

26

25

24

23

22

21

20

19

18

17

16

15

AI03607

CC

NC

FT/OUT

NC

NC

NC

NC

NC

SCL

NC

NC

NC

SDA

NC

nection to a separate SNAPHAT housing cont aining the battery and crystal. The unique design

allows the SNAPHAT battery package to be

mounted on top of the SOIC package after the

completion of the surface mount process. Insertion of the SNAPHAT housing after reflow prevents potential battery and c rystal dam age due to

the high temperatures required for device surfacemounting. The SNAPHAT housing is keyed to prevent reverse insertion. The SOIC and battery/crystal packages are shipped separately in plastic antistatic tubes or in Tape & Reel form.

For the 28 lead SOIC, the battery/crystal package

(i.e. SNAPHAT) part number is "M4TxxBR12SHx".

Caution: Do not place the SNAPHAT battery/crystal package "M4Txx-BR12SHx" in conductive

foam since this will drain the lithium button-cell

battery.

2/19

M41T56

Table 2. Absolute Maximum Ratings

Symbol Parameter Value Unit

T

A

T

STG

(2)

T

SLD

V

IO

V

CC

I

O

P

D

Note: 1. Stresses greater than those listed under "Absolute Maximum Ratings" may cause permanent damage to the device. This is a stress

rating only and function al operation of th e device at thes e or any other conditions above those indic at ed in the operational section

of this spec ification is not im plied. Exposure t o the abso lute max imum rat ing cond itions for extende d period s of tim e may affe ct

reliability.

2. Soldering temperature not to exceed 260°C for 10 seconds (total thermal budget not to exceed 150°C for longer than 30 seconds).

CAUTION: Negative undershoo ts bel ow –0.3V are not al l owed on any pin whil e i n the Battery Back-up mode.

CAUTION: Do NOT wave solder SOIC to avoid damaging SNAPHAT sockets.

Ambient Operating Temperature –40 to 85 °C

Storage Temperature (VCC Off, Oscillator Off)

Lead Solder Temperature for 10 seconds 260 °C

Input or Output Voltages –0.3 to 7 V

Supply Voltage –0.3 to 7 V

Output Current 20 mA

Power Dissipation 0.25 W

OPERATION

The M41T56 clock operates as a slave device on

the serial bus. Access is obtained by implementing

a start condition followed by the correct slave address (D0h). The 64 bytes contained in the device

can then be accessed sequentially in the following

order:

1. Seconds Register

2. Minutes Register

3. Century/Hours Register

4. Day Register

5. Date Register

(1)

SNAPHAT –40 to 85

SOIC –55 to 125

The clock continually monitors V

tolerance condition. Should V

CC

CC

fall below V

°C

for an out of

PFD

the device terminates a n access in progress and

resets the device address counte r. Inputs to the

device will not be recognized at this time to prevent erroneous data fr om being writt en to the device from an out of tolerance system. W hen V

falls below V

, the device automatically switch-

BAT

CC

es over to the battery and powers down into an ultra low current mode of operation to conserve

battery life. Upon power-up, the device switches

from battery to V

when V

goes above V

CC

CC

at V

and recognizes inputs

BAT

volts.

PFD

6. Month Register

7. Years Register

8. Control Register

9 to 64.RAM

,

3/19

M41T56

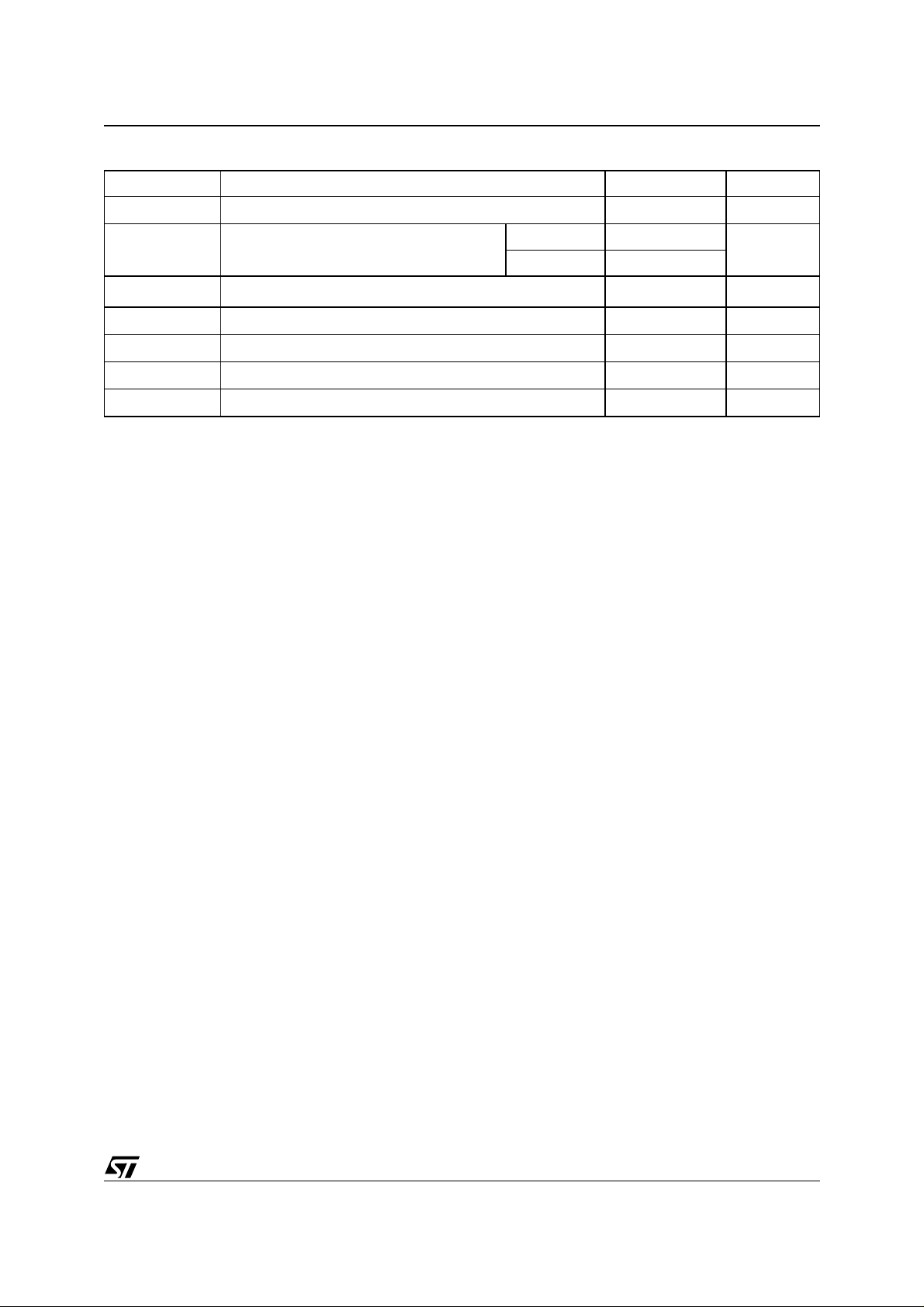

Figure 3. Block Diagram

OSCI

OSCO

FT/OUT

V

CC

V

SS

V

BAT

SCL

SDA

OSCILLATOR

32.768 kHz

VOLTAGE

SENSE

and

SWITCH

CIRCUITRY

SERIAL

BUS

INTERFACE

DIVIDER

CONTROL

LOGIC

ADDRESS

REGISTER

1 Hz

SECONDS

MINUTES

CENTURY/HOURS

DAY

DATE

MONTH

YEAR

CONTROL

RAM

(56 x 8)

AI02566

Table 3. Register Map

Address

Data

D7 D6 D5 D4 D3 D2 D1 D0

0 ST 10 Seconds Seconds Seconds 00-59

1 X 10 Minutes Minutes Minutes 00-59

(1)

2

CEB

CB 10 Hours Hours Century/Hour 0-1/00-23

3 XXXXX Day Day 01-07

4 X X 10 Date Date Date 01-31

5 X X X 10 M. Month Month 01-12

6 10 Years Years Year 00-99

7 OUT FT S Calibration Control

Note: 1. When CEB is set to ’1’, CB will toggle from ’0’ to ’1’ or from ’1’ to ’0’ every 100 years (dependent upon the initial value set).

Keys: S = SIGN Bit;

When CEB is set to ’0’, CB will not toggle.

FT = FREQUENCY TEST Bit;

ST = STOP Bit;

OUT = Output level;

X = Don’t care;

CEB = Century Enable Bit;

CB = Centur y B i t.

Function/Ran ge

BCD Format

4/19

M41T56

Table 4. AC Measurement Conditions

Input Rise and Fall Times ≤ 5ns

Input Pulse Voltages 0 to 3V

Input and Output Timing Ref. Voltages 1.5V

Note that Output Hi-Z is defined as the point where data is no longer

driven.

2-WIRE BUS CHARACTERISTICS

This bus is intended for communication between

different ICs. It consists of two lines: one bi-directional for data signals (SDA) and one for clock signals (SCL). Both the SDA and the SCL lines must

be connected to a positive supply voltage via a

pull-up resistor.

The following protocol has been defined:

– Data transfer may be initiated only when the bus

is not busy.

– During data trans fer, the dat a line mus t remain

stable whenever the clock line is High.

– Changes in the dat a line while the clock line is

High will be interpreted as control signals.

Accordingly, the following bus conditions have

been defined:

Bus not busy. Both data and clock lines remain

High.

Start data transfer. A change in the state of t he

data line, from High to Low, while the clock is High,

defines the START condition.

Stop data transfer. A change in the state of the

data line, from Low to High, while the clock is High,

defines the STOP condition.

Figure 4. AC Testing Load Circuit

0.8V

0.2V

CC

CC

0.7V

0.3V

AI02568

CC

CC

Data valid. The state of the data line represents

valid data when after a start condition, the data line

is stable for the duration of the High period of the

clock signal. The data on the line may be changed

during the Low period of the clock signal. There is

one clock pulse per bit of data.

Each data transfer is initiated with a start condition

and terminated with a stop condition. The number

of data bytes transferred between the start and

stop conditions is not limited. The information is

transmitted byte-wide and each receiver acknowledges with a ninth bit.

By definition, a device that gives out a message is

called "transmitter", the receiving de vice t hat g ets

the message is called "rece iver". The device that

controls the message is called "master". The devices that are controlled by the master are cal led

"sla ve s".

Table 5. Capacitance

(T

= 25 °C, f = MHz)

A

Symbol Parameter Min Ma x Unit

C

IN

C

OUT

t

LP

Note: 1. Effectiv e capacitan ce measured with power supply at 5V.

2. Sampled, not 100% tested.

3. Outputs deselect ed.

Input Capacitance (SCL) 7 pF

(3)

Output Capacitance (SDA, FT/OUT) 10 pF

Low-pass filter input time constant (SDA and SCL) 0.25 1 µs

(1, 2)

5/19

M41T56

Table 6. DC Characteristics

(T

= –40 to 85 °C; VCC = 4.5V to 5.5V)

A

Symbol Parameter Test Condition Min Typ Max Unit

I

I

I

CC1

I

CC2

V

V

V

V

BA T

I

BA T

Note: 1. STMicro el ectronics recommend s t he RAYOVAC BR 1225 or BR1632 (or equivalent) as the battery supply.

Input Leakage Current

LI

Output Leakage Current

LO

Supply Current Switch Frequency = 100kHz 300 µA

Supply Current (Standby)

Input Low Voltage –0.3

IL

Input High Voltage

IH

Output Low Voltage

OL

(1)

Battery Supply Voltage 2.5 3 3.5 V

Battery Supply Current

0V ≤ V

0V ≤ V

SCL, SDA = V

I

= 5mA, VCC = 4.5V

OL

T

= 25°C, VCC = 0V,

A

Oscillator ON, V

Table 7. Power Down/Up Trip Points DC Characteristics

IN

OUT

≤ V

≤ V

CC

CC

CC

– 0.3V

= 3V

BAT

±1 µA

±1 µA

100 µA

1.5

3V

CC

0.4 V

450 550 nA

(1)

+ 0.8

(TA = –40 to 85 °C)

Symbol Parameter Min Typ Max Unit

V

PFD

V

SO

Note: 1. All voltages referenced to VSS.

Power-fail Deselect Voltage

Battery Back-up Switchover Voltage

1.2 V

BA T

1.25 V

V

BAT

BA T

1.285 V

BA T

V

V

V

V

Table 8. Crystal Electrical Characteristics

(Externally Supplied if using the SO8 package)

Symbol Parameter Min Typ Max Unit

f

O

R

S

C

L

Note: L oad cap acitors are inte grated w ithin the M 41T56 . Circuit b oard lay out consi deration s for the 32.768 kH z crysta l of minimu m trace

lengths and isolation from RF generating signals should be taken into account .

STMicroelectron i cs recommends the KDS DT-38 Tuning Fork Type quartz crystal for industrial temperature op erat i ons.

KDS can b e contacted at 9 13-491-6825 or http://w ww.kd sj.co.jp for furt her information on this crystal type.

All SNAP HA T battery/cry st al tops meet thes e specifications.

Resonant Frequency 32.768 kHz

Series Resistance 35 kΩ

Load Capacitance 12.5 pF

6/19

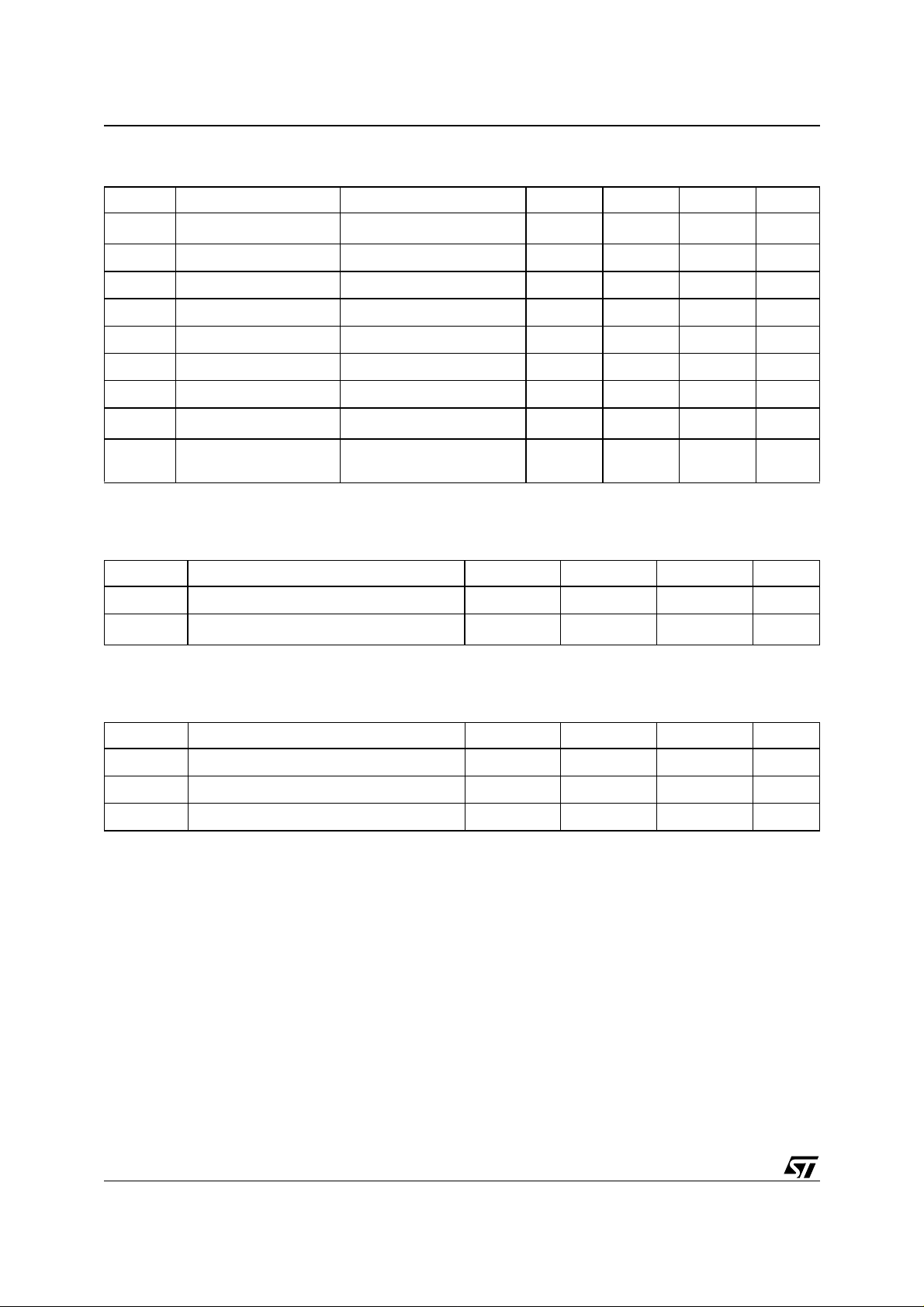

Table 9. Power Down/Up AC Characteristics

(T

= –40 to 85 °C)

A

Symbol Parameter Min Max U nit

M41T56

t

PD

t

FB

t

RB

t

REC

SCL and SDA at VIH before Power Down

V

(min) to VSS VCC Fall Time

PFD

VSS to V

SCL and SDA at VIH after Power Up

(min) VCC Rise Time

PFD

Figure 5. Power Down/Up Mode AC Waveforms

V

CC

V

PFD

VSO

SDA

SCL

I

BAT

tPD

tFB

DATA RETENTION TIME

0ns

300 µs

100 µs

10 µs

tRB

tREC

AI00595

Acknowledge. Each byte of eight bits is followed

by one acknowledge bit. This acknowledge bit is a

low level put on the bus b y the receiver, whereas

the master generates an extra acknowledge related clock pulse.

A slave receiver which is addressed is obliged to

generate an acknowledge after the reception of

each byte. Also, a master receiver must generate

an acknowledge a fter the reception of e ach byte

that has been clocked out of the slave transmitter.

The device that acknowledges has to pull down

the SDA line during the acknowledge clock pulse

in such a way that the SDA line is a stable Low during the High period of the acknowledge related

clock pulse. Of course, setup and hold times must

be taken into account. A master receiver must signal an end-of-data to the slave transm itter by not

generating an acknowledge on t he last byte that

has been clocked out of the slave. In this case, the

transmitter must leave the data line High to enable

the master to generate the STOP condition.

7/19

M41T56

Table 10. AC Characteristics

(T

= –40 to 85 °C; VCC = 4.5V to 5.5V)

A

Symbol Parameter Min Max Unit

f

SCL

t

LOW

t

HIGH

t

R

t

t

HD:STA

t

SU:STA

t

SU:DA T

t

HD:DAT

t

SU:STO

t

BUF

Note: 1. Transmitter must internally provide a hold time to bridge the undefined region (300ns max.) of the falling edge of SCL.

WRITE MODE

In this mode the master transmitter transmits to

the M41T56 slave receiver. Bus protocol is shown

in Figure 10. Following the START condition and

slave address, a logic ’0’ (R/W

bus and indicates to the addressed device that

word address An will follow and is to be written to

the on-chip address p ointer. Th e data wo rd to be

written to the memory is strobed in next and the internal address pointer is incremented to the next

memory location within the RAM on the reception

of an acknowledge clock. The M 41T56 slave receiver will send an acknowledge clock to the master transmitter after it has received the slave

address and again after it has received the word

address and each data byte (see Figure 9).

READ MODE

In this mode, the master reads the M41T56 s lave

after setting the slave address (see Figure 11).

Following the write mode control bit (R/W

the acknowledge bit, the word address A

SCL Clock Frequency 0 100 kHz

Clock Low Period 4.7 µs

Clock High Period 4 µs

SDA and SCL Rise Time 1 µs

SDA and SCL Fall Time 300 ns

F

START Condition Hold Time

(after this period the first clock pulse is generated)

START Condition Setup Time

(only relevant for a repeated start condition)

Data Setup Time 250 ns

(1)

Data Hold Time 0 µs

STOP Condition Setup Time 4.7 µs

Time the bus must be free before a new transmission can start 4.7 µs

4µs

4.7 µs

ten to the on-chip address pointer. Next the

START condition and slave address are repeated,

followed by the READ mode control bit (R/W

At this point, the master transmitter becomes the

= 0) is placed on the

master receiver. The data byte which was addressed will be transmitted and the master receiver will send an acknowledge bit to the slave

transmitter. The address pointer is only incremented on reception of an acknowledge bit. The

M41T56 s lave tr ansmitt er will now place the data

byte at address A

+ 1 on the bus. The master re-

n

ceiver reads and acknowledges the n ew byte and

the address pointer is incremented to A

This cycle of reading con secutive addresses will

continue until the mast er receiver sends a STOP

condition to the slave transmitter.

An alternate READ mode may also be implemented, whereby the master reads the M41T56 slave

without first writing to the (volatile) a ddress pointer. The first address that is read is the last one

= 0) and

is writ-

n

stored in the pointer, see Figure 12.

n

= 1).

+ 2.

8/19

Figure 6. Serial Bus Data Transfer Sequence

DATA LINE

STABLE

DATA VALID

CLOCK

DATA

M41T56

START

CONDITION

Figure 7. Acknowledgment Sequen ce

START

SCLK FROM

MASTER

DATA OUTPUT

BY TRANSMITTER

DATA OUTPUT

BY RECEIVER

12 89

MSB LSB

CLOCK OPERATION

The eight byte clock register (see Table 3) is used

to both set the clock and to read the date and time

from the clock, in a binary coded decimal form at.

Seconds, Minutes, and Hours are contained within

the first three registers. Bits D6 and D7 of clock

register 2 (Hours Register) contain the CENTURY

ENABLE Bit (CEB) and the CENTURY Bit (CB).

Setting CEB to a ’1’ will cause CB to toggle, either

from ’0’ to ’1’ or from ’1’ to ’0’ at the turn of the century (depending upon its initial state). If CEB is set

to a ’0’, CB will not toggle. Bits D0 through D2 of

register 3 contain the Day (day of week). Registers

4, 5 and 6 contain the Date (day of month), Month

and Years. The final register is the Control Register (this is described in the Clock Calibration section). Bit D7 of register 0 contains the STOP Bit

(ST). Setting this bit to a ’1’ will cause the oscillator

CHANGE OF

DATA ALLOWED

STOP

CONDITION

AI00587

CLOCK PULSE FOR

ACKNOWLEDGEMENT

AI00601

to stop. If the device is expected to spend a significant amount of time on the shelf, the oscillator

may be stopped to reduce current drain. When reset to a ’0’ the oscillator restarts within one second.

The seven Clock Registers may be read one byte

at a time, or in a sequential block. The Control

Register (Address location 7) may be accessed independently. Provision has been made to assure

that a clock update does not occur while any of the

seven clock addresses are being read. If a clock

address is being read, an update of the clock registers will be delayed by 250ms to allow the read

to be completed before the update occurs. This

will prevent a tran s it ion of da t a d ur ing t he re ad .

Note: This 250ms delay affects only the clock register update and does not alter the actual clock

time.

9/19

M41T56

Figure 8. Bus Timing Requirements Sequence

SDA

tHD:STAtBUF

tR

SCL

SP

Note: P = STOP and S = START

tF

tHIGH

tLOW

Figure 9. Slave Address Location

R/W

START A

SLAVE ADDRESS

MSB

0100011

LSB

AI00602

CLOCK CALIBRATION

The M41T56 is driven by a quartz controlled oscillator with a nominal frequency of 32,768Hz. The

devices are tested not to exceed 35ppm (parts per

million) oscillator frequency error at 25°C , which

equates to about ±1.53 m inutes per month. With

the calibration bits properly set, the accuracy of

each M41T56 im proves to better than +1/–2 ppm

at 25°C.

The oscillation rate of any crystal changes with

temperature (see Figure 14). Most clock chips

compensate for crystal frequency and temperature shift error with cumbersome trim capacitors.

The M41T56 design, however, employs periodic

tHD:STA

tSU:DAT

tHD:DAT

SR

tSU:STOtSU:STA

P

AI00589

counter correction. The calibration c ircuit adds or

subtracts counts from the o scillator divider circuit

at the divide by 256 stage, as shown in Figure 13.

The number of times pulses are blanked (subtracted, negative calibration) or split (added, positive

calibration) depends upon the value loaded into

the five bit Calibration byte found in the Control

Register. Adding counts speeds the clock up, subtracting counts slows the clock down.

The Calibration byte occupies the five lower order

bits (D4-D0) in the Control register (Addr 7). This

byte can be set to represent any value between 0

and 31 in binary form. Bit D5 is a Sign bit; '1' indicates positive calibration, '0' indicates negative

calibration. Calibration occurs within a 64 m inute

cycle. The first 62 m inutes i n t he c ycle m ay , onc e

per minute, have one second either shortened by

128 or lengthened by 256 oscillator cycles. If a binary '1' is loaded into the register, only the first 2

minutes in the 64 minutes cycle will be modified; if

a binary 6 is loaded, t he first 12 will be affected,

and so on.

Therefore, each cal ibration step has the effect of

adding 512 or subtracting 256 oscillator cycles for

every 125,829,120 actual oscillator cycles, that is

+4.068 or –2.034 ppm of adjustment per calibration step in the cal ibration registe r. Ass um ing that

the oscillator is in fact running at exactly 32,768Hz,

each of the 31 in crements in the Calibration b yte

would represent +10.7 or –5.35 seconds per

month which corresponds to a total range of +5.5

or –2.75 minutes per month.

10/19

Figure 10. Wri t e Mode Sequence

M41T56

BUS ACTIVITY:

MASTER

BUS ACTIVITY:

START

S

SLAVE

ADDRESS

Figure 11. Read Mode Sequence

BUS ACTIVITY:

MASTER

SDA LINE

BUS ACTIVITY:

START

S

SLAVE

ADDRESS

R/W

WORD

ADDRESS (n)

ACK

R/W

WORD

ADDRESS (n)

ACK

DATA n DATA n+1 DATA n+X

ACK

START

S

ACK

SLAVE

ADDRESS

ACK

R/W

DATA n DATA n+1

ACK

ACK

ACK

STOP

PSDA LINE

ACK

AI00591

ACK

DATA n+X

Figure 12. Alternate Read Mode Sequence

BUS ACTIVITY:

MASTER

BUS ACTIVITY:

START

S

SLAVE

ADDRESS

R/W

DATA n DATA n+1 DATA n+X

ACK

STOP

P

NO ACK

ACK

ACK

AI00899

STOP

PSDA LINE

ACK

NO ACK

AI00895

11/19

M41T56

Figure 13. Cloc k C al ib rat i on

NORMAL

POSITIVE

CALIBRATION

NEGATIVE

CALIBRATION

AI00594B

Two methods are available for ascertaining how

much calibration a given M41T56 may require.

The first involves simply setting the clock, letting it

run for a month and comparing it to a known accurate reference (like WWV broadcasts). While that

may seem crude, it allows the designer to give the

end user the ability to calibrate his clock as his environment may require, even after the final product

is packaged in a non-user serviceable enclosure.

All the designer has to do is provide a simple utility

that accessed the Calibration byte.

The second approach is better suit ed to a manufacturing environment, and involves the use of

some test equipment. When the F requency Test

(FT) bit, the seventh-most significant bit in the

Control Register, is set to a '1', and the oscillator is

running at 32,768Hz, the FT/OUT pin of the device

will toggle at 512Hz. Any deviation from 512Hz indicates t he degre e and direc tion of o scillator frequency shift at the test temperature.

For example, a reading of 512.01024Hz woul d indicate a +20ppm oscillator frequency error, requir-

ing a –10(XX001010) to be loaded into the

Calibration Byte for correction. Note that setting or

changing the Calibration Byte does n ot affect the

Frequency test output frequency.

OUTPUT DRIVER PIN

When the FT bit is not set, the FT/OUT pin becomes an output driver that reflects the contents of

D7 of the control register. In other words, when D6

of location 7 is a zero and D7 of location 7 i s a zero

and then the FT/OUT pin will be driven low.

Note: The FT/OUT pin is open drain which requires an external pull-up resistor.

POWER-ON DEFAULTS

Upon initial application of power to the device, the

FT bit will be set to a '0' and the OUT bit will be set

to a '1'. All other Register bits will initially power-on

in a random state.

12/19

Figure 14. Crystal Accuracy Across Temp eratur e

Frequency (ppm)

20

0

–20

–40

–60

–80

∆F

–100

–120

–140

–160

0 10203040506070

Temperature °C

= -0.038 (T - T

F

ppm

C

T0 = 25 °C

M41T56

)2 ± 10%

0

2

80–10–20–30–40

AI00999

13/19

M41T56

Table 11. Ordering Information Scheme

Example: M41T56 M 6 TR

Device Type

M41T

Package

M = SO8 150mils width

MH = SOH28

Temperature Range

6 = –40 to 85 °C

Shipping Method for SO

blank = Tubes

TR = Tape & Reel

Note: T he SOIC package (SOH28) requires the batt ery package (S NAPHAT) whi ch is ordered separately un der the part number

"M4Txx-BR12SHx " in pl astic tube or "M 4T xx-BR12SHxTR" in Tape & Reel form.

Cautio n: Do not place the SNAPHAT battery package "M4Txx-BR12SHx" in conductive foam since thi s will drain the lit hium butt on-cell battery.

For a list of available options or for further inform ation on any aspect of this device, please contact the

STMicroelectronics Sales Office near e st to you.

Table 12. Revision History

Date Revision Details

March 1999 F irst Issue

12/23/99 SOH28 package added

03/21/00 Series Resistance Max Value Changed (Table 8)

14/19

M41T56

Table 13. SO8 - 8 pin Plastic Small Outline, 150 mils body width, Packag e Mechani cal Data

Symb

Typ Min Max Typ Min Max

A 1.35 1.75 0.053 0.069

A1 0.10 0.25 0.004 0.010

B 0.33 0.51 0.013 0.020

C 0.19 0.25 0.007 0.010

D 4.80 5.00 0.189 0.197

E 3.80 4.00 0.150 0.157

e 1.27 – – 0.050 – –

H 5.80 6.20 0.228 0.244

h 0.25 0.50 0.010 0.020

L 0.40 0.90 0.016 0.035

α 0° 8° 0° 8°

N8 8

CP 0.10 0.004

mm inches

Figure 15. SO8 - 8 pin Plastic Small Outline, 150 mils body width, Package Outline

h x 45˚

A

C

B

e

CP

D

N

E

H

1

LA1 α

SO-a

Drawing is not to scale.

15/19

M41T56

Table 14. SOH28 - 28 lead Plastic Small Outline, 4-socket battery SNAPHAT,

Package Mechanical Data

Symb

Typ Min Max Typ Min Max

A 3.05 0.120

A1 0.05 0.36 0.002 0.014

A2 2.34 2.69 0.092 0.106

B 0.36 0.51 0.014 0.020

C 0.15 0.32 0.006 0.012

D 17.71 18.49 0.697 0.728

E 8.23 8.89 0.324 0.350

e 1.27 – – 0.050 – –

eB 3.20 3.61 0.126 0.142

H 11.51 12.70 0.453 0.500

L 0.41 1.27 0.016 0.050

α 0° 8° 0° 8°

N 28 28

CP 0.10 0.004

mm inches

Figure 16. SOH28 - 28 lead Plastic Small Outline, 4-socket battery SNAPHAT, Package Outline

A2

A

C

Be

eB

CP

D

N

E

H

LA1 α

1

SOH-A

Drawing is not to scale.

16/19

M41T56

Table 15. SH - 4-pin SNAPHAT Housing for 48 mAh Battery & Crystal, Package Mechanical Data

Symb

Typ Min Max Typ Min Max

A 9.78 0.385

A1 6.73 7.24 0.265 0.285

A2 6.48 6.99 0.255 0.275

A3 0.38 0.015

B 0.46 0.56 0.018 0.022

D 21.21 21.84 0.835 0.860

E 14.22 14.99 0.560 0.590

eB 3.20 3.61 0.126 0.142

L 2.03 2.29 0.080 0.090

mm inches

Figure 17. SH - 4-pin SNAPHAT Housing for 48 mAh Battery & Crystal, Package Outline

A1

eA

D

A

B

eB

A3

L

E

SHTK-A

Drawing is not to scale.

A2

17/19

M41T56

Table 16. SH - 4-pin SNAPHAT Housing for 120 mAh Battery & Crystal, Package Mechanical Data

Symb

Typ Min Max Typ Min Max

A 10.54 0.415

A1 8.00 8.51 0.315 0.335

A2 7.24 8.00 0.285 0.315

A3 0.38 0.015

B 0.46 0.56 0.018 0.022

D 21.21 21.84 0.835 0.860

E 17.27 18.03 0.680 0.710

eB 3.20 3.61 0.126 0.142

L 2.03 2.29 0.080 0.090

mm inches

Figure 18. SH - 4-pin SNAPHAT Housing for 120 mAh Battery & Crystal, Package Outline

A1

eA

D

A

B

eB

A3

L

E

SHTK-B

Drawing is not to scale.

A2

18/19

M41T56

Information furnishe d is bel i eved to be accurate and reliable. However, STMicroelectroni cs assumes no responsibility for t he consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or oth erwise unde r any patent or patent rights of STMi croelectronics. Speci fications me ntioned in th i s publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as crit i cal component s i n l i f e support devices or systems wi thout expre ss written appr oval of STMicroelectronics.

The ST log o i s registered trademark of STM i croelectronics

2000 STMicroel e ctronics - All Ri ghts Reserved

All other names are the property of their respectiv e owners.

Australi a - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta - Moroc co -

Singapor e - Spain - Sweden - Switzerla nd - United Kingdom - U.S.A.

STMicroelect ro n ics GRO UP OF COMPANI ES

http://www.st.com

19/19

Loading...

Loading...