■ Compatible with SPI Bus Serial Interface

(Positive Clock SPI Modes)

■ Single Supply Voltage: 4.5 V to 5.5 V

■ 5 MHz Clock Rate (maximum)

■ Sixteen 16-bit Increment al Regist ers

■ BYTE and PAGE WRITE (u p to 32 Bytes)

(except for the Incremental Registers)

■ Self-Tim e d P ro g r amming Cycle

■ Hardware Protection of the Status Register

■ Resizeable Read-Only EEPROM Area

■ Enhanced ESD Protection

■ 1 Million Erase/Write Cycles (minimum)

■ 40 Year Data Retention (minimum)

DESCRIPTION

The M35080 device consists of 1024x8 bits of low

power EEPROM, fabricated with

STMicroelectronics’ proprietary High Endurance

Double Polysilicon CMOS technology.

The device is accessed by a simple SPI-compatible serial interface. The bus signals consist of a

serial clock input (C), a serial data input (D) and a

serial data output (Q), as shown in Table 1.

The device is selected when t he chip s elect input

) is held low. Data is clocked in during the low to

(S

high transition of the clock, C. Data is clocked out

during the high to low transition of the clock.

M35080

8 Kbit Serial SPI Bus EEPROM

With Incremental Registers

PRELIMINARY DATA

8

1

PSDIP8 (BN)

0.25 mm frame

8

1

SO8 (MN)

150 mil width

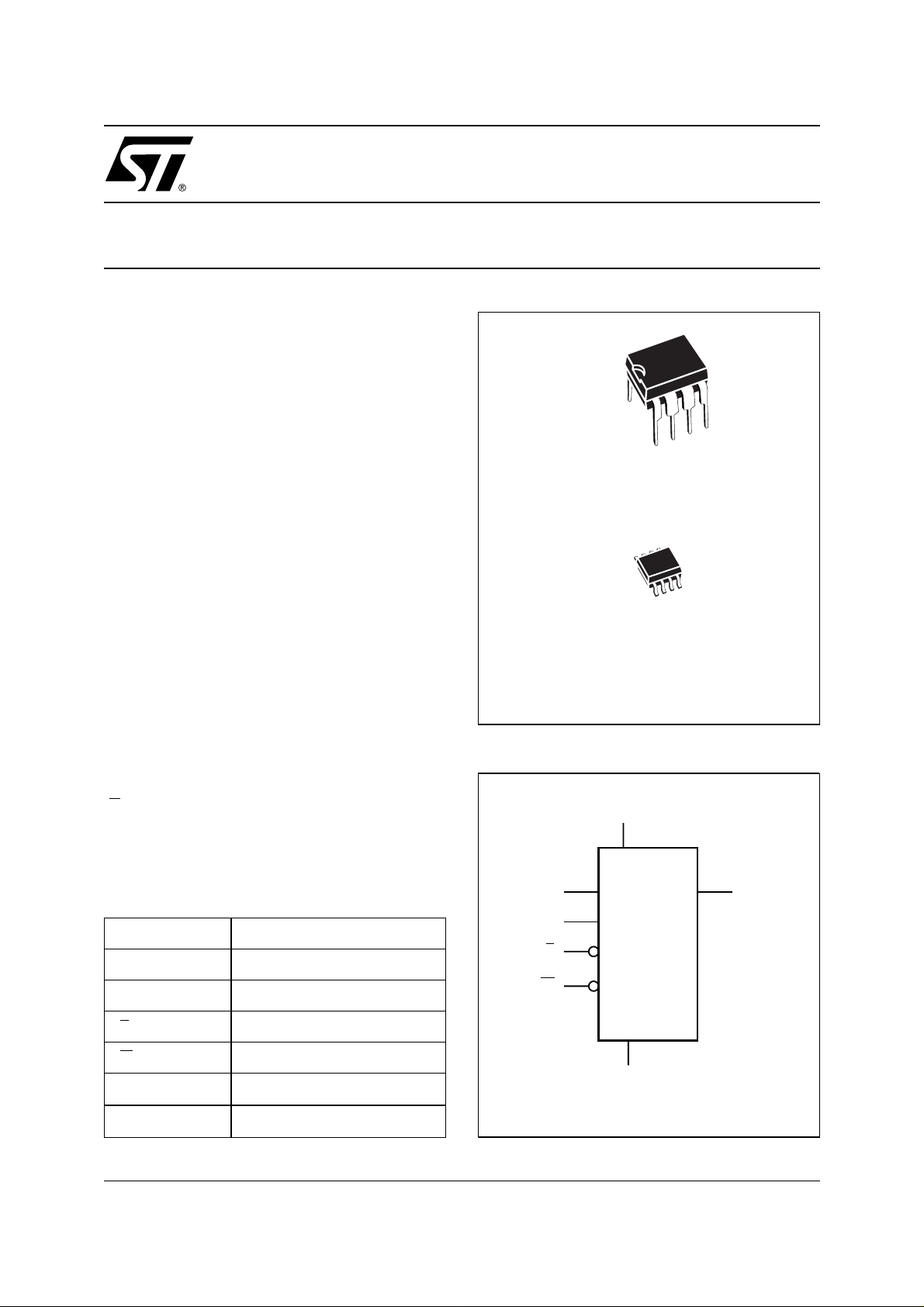

Figure 1. Logic Diagram

V

CC

D

Q

Table 1. Signal Names

W

C

S

M35080

V

SS

C Serial Clock

D Serial Data Input

Q Serial Data Output

S

W

V

CC

V

SS

June 1999

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to change without notice.

Chip Select

Write Protect

Supply Voltage

Ground

AI02143

1/18

M35080

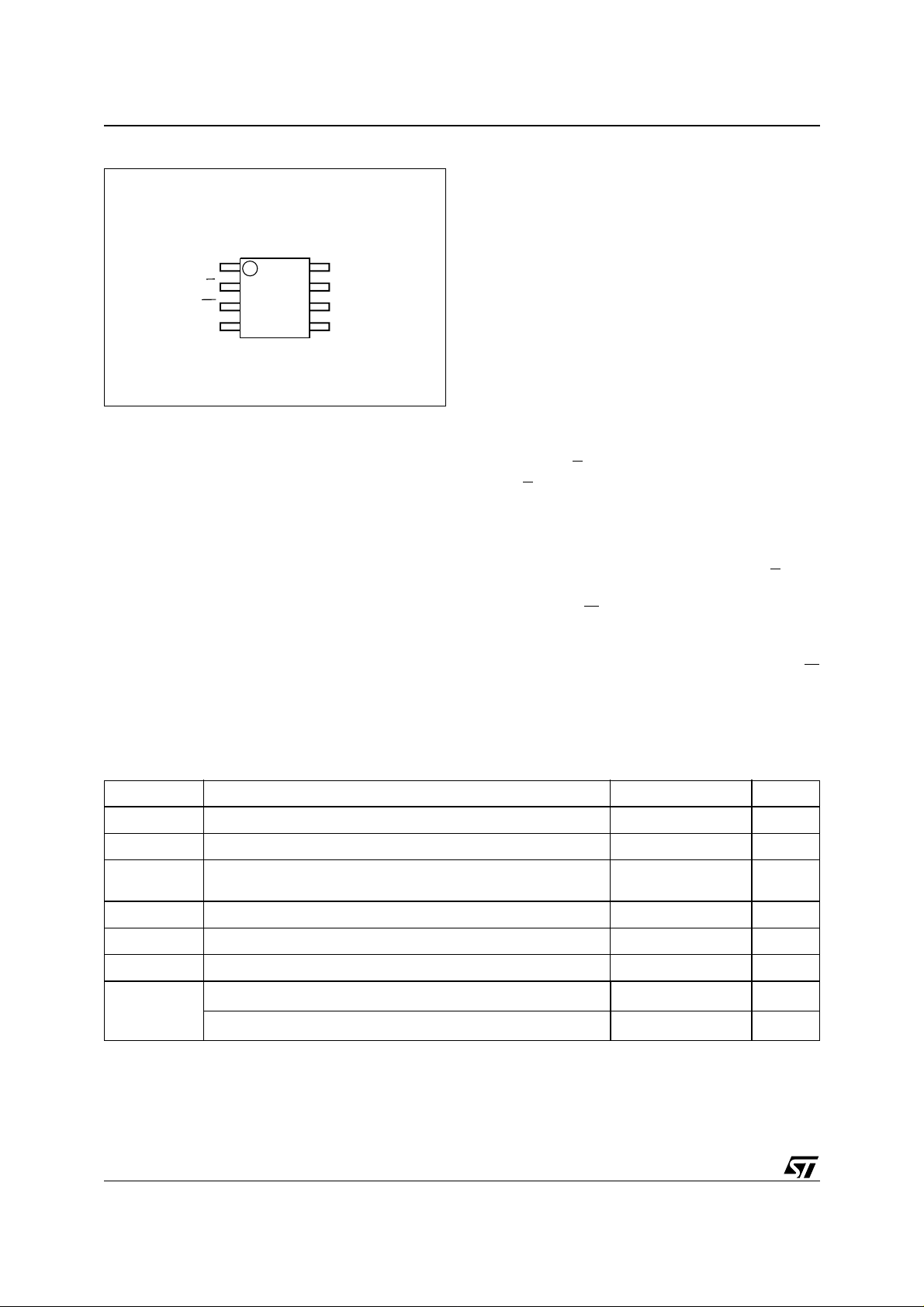

Figure 2. DIP and SO Connections

M35080

V

SS

Note: 1. NC = Not Connected.

W

1

S

2

3

4

Q

8

7

6

5

AI02144B

V

D

C

NC

CC

The memory is organized in pages of 32 bytes.

However, the first page is not treated in the sam e

way as the others. Instead, it is considered to consist of sixteen 16-bit incremental registers. Each

register can be modified using the conventional

write instructions, but the new value will only be

accepted if it is greater than the current value.

Thus, each register is restricted t o b eing mo dified

monotonically upwards.

This is useful in applications where it is necessary

to implement a counter that is protected from

fraudulent tampering (such as in a car odometer,

an electricity meter, or a tally for remaining credit).

SIGNAL DESCRIPTION

Seria l O utput ( Q )

The output pin is used to transfer data serially out

of the Memory. Data is shifted out on the falling

edge of the serial clock.

Serial Inpu t ( D )

The input pin is used to transfer data serially into

the device. Instructions, addresses, and the data

to be written, are each received t his way. Input is

latched on the rising edge of the serial clock.

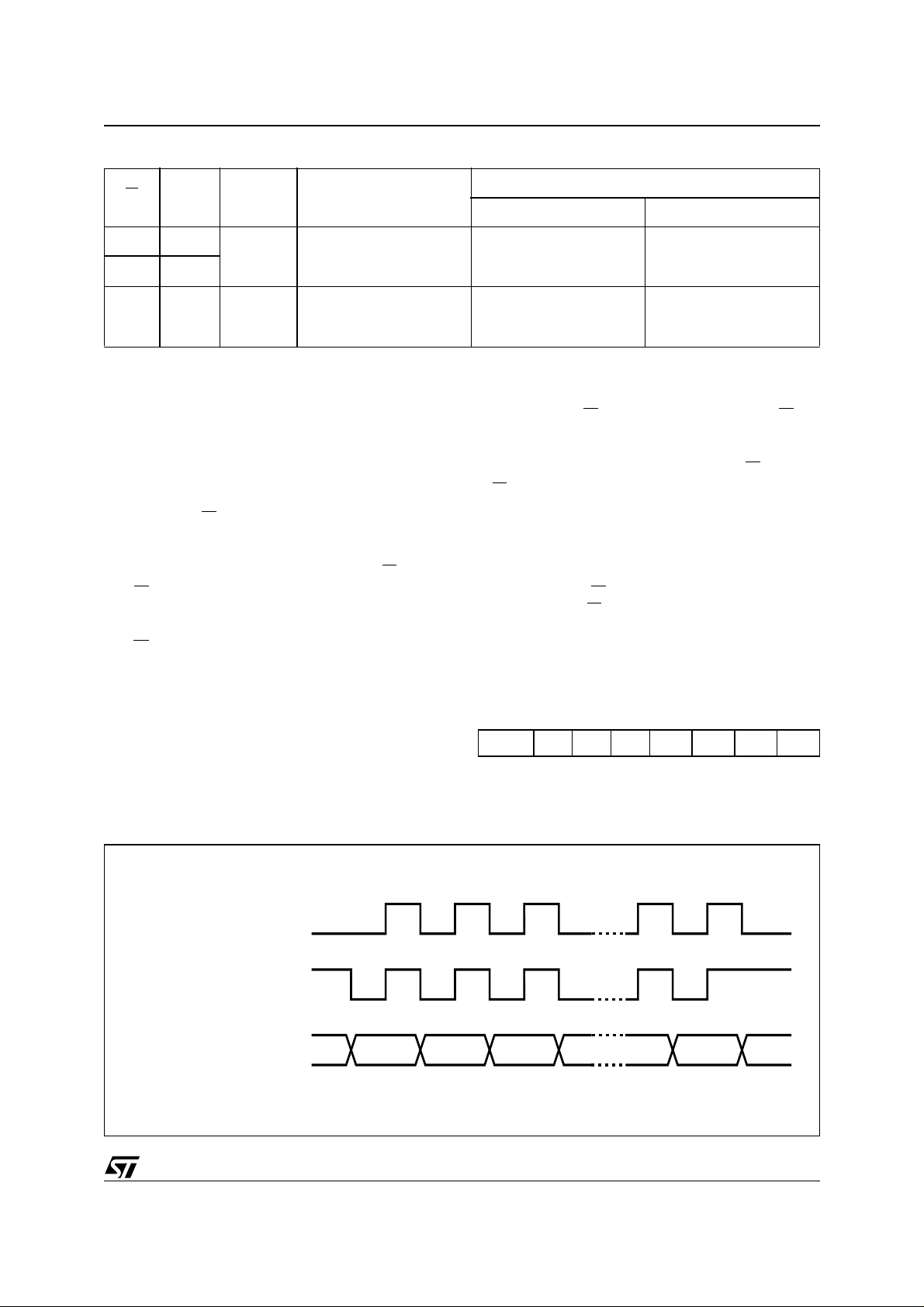

Serial Clock (C)

The serial clock provides the timing for the serial

interface (as shown in Figure 3). Instructions, addresses, or data are latched, from the input pin, on

the rising edge of the clock input. The output dat a

on the Q pin changes state after the falling edge of

the clock input.

Chip Select (S

When S

is high, the memory device is deselected,

)

and the Q output pin is held in its high impe dance

state. Unless an internal write operation is underway, the memory device is placed in its stand-by

power mode.

After power-on, a high-to-low transition on S

is re-

quired prior to the start of any operation.

Write Protect (W

)

The protection features of t he m em ory device are

summarized in Table 3.

The hardware write protection, controlled by the W

pin, restricts write access to the Status Register

Table 2. Absolute Maximum Ratings

Symbol Parameter Value Unit

T

A

T

STG

T

LEAD

V

O

V

I

V

CC

V

ESD

Note: 1. Except for the rating “Operating Temperature Ra nge”, stres ses above those listed in the Table “Absolute Maximum Ratings” may

2/18

cause perm anent damage to the device. These are stress ratings only and op eration of th e device at these or any othe r

conditions above thos e i ndi cated in the O perating sec tions of this specificat i on i s not implied. Exposure to Absolute Ma xim um

Rating conditions for extended periods may affect device reliability. Refer also to the ST SURE Program and

other relevant quality documents .

2. MIL-STD-883C, 3015.7 (100 pF , 1500W).

3. EIAJ IC- 121 (Condi tion C) (200pF , 0W).

Ambient Operating Temperature -40 to 125 °C

Storage Temperature -65 to 150 °C

Lead Temperature during Soldering

Output Voltage Range

Input Voltage Range -0.3 to 6.5 V

Supply Voltage Range -0.3 to 6.5 V

Electrostatic Discharge Voltage (Human Body model)

Electrostatic Discharge Voltage (Machine model)

1

PSDIP8: 10 sec

SO8: 40 sec

2

3

260

215

-0.3 to V

+0.6

CC

4000 V

400 V

°C

V

Table 3. Write Protection Control

SRWD

W

Bit

Mode Status Register

M35080

Data Bytes

Protected Area Unprotected Area

0 or 1 0 Software

11

01

Protected

(SPM)

Hardware

Protected

(HPM)

Writeable (if the WREN

instruction has set the

WEL bit)

Hardware write protected

(though not to the WIP and WEL bits, which are

set or reset by the device’s internal logic).

Bit 7 of the status register (as shown in Table 4) is

the Status Register Write Disable bit (SRWD).

When this is set to 0 (its initial delivery state) it is

possible to write to the status register if the WEL

bit (Write Enable Latch) has been set by the

WREN instruction (irrespective of the l evel being

applied to the W

input).

When bit 7 (SRWD) of the status reg ister is set to

1, the ability to write to the status register depends

on the logic level being presented at pin W

pin is high, it is possible to write to the sta-

–If W

:

tus register, after having set the WEL bit using

the WREN instruction (Write Enable Latch).

–If W

pin is low, any attempt to modify the status

register is ignored by the device, even if the

WEL bit has been set. As a consequence, all the

data bytes in the EE PROM area, protected by

the BP1 and BP0 bits of the status register, are

also hardware protected against data corruption, and appear as a Read Only EEPROM area

for the microcontroller. This mode is called the

Hardware Protected Mode (HPM).

Software write protected

by the BP0 and BP1 bits

of the status register

Hardware write protected

by the BP0 and BP1 bits

of the status register

Writeable (if the WREN

instruction has set the

WEL bit)

Writeable (if the WREN

instruction has set the

WEL bit)

It is possible to enter the Hardware Protected

Mode (HPM) either by s etting the SRWD bi t after

pulling low the W

pin, or by pulling low the W pin

after setting the SRWD bit.

The only way to abort the Hardware Protected

Mode, once entered, is to pull high the W

pin is permanently t ied to the hi gh level, the

If W

pin.

Hardware Protected Mode is never activated, and

the memory device only allows the user to protect

a part of the memory, using the BP1 and BP0 bits

of the status register, in the Software Protected

Mode (SPM).

IMPORTANT: if W pin is left floating, not driven by

the application, W

is read as a logical ’0’.

Table 4. Status Register Format

b7 b0

SRWD UV X INC BP1 BP0 WEL WIP

Note: 1. BP0, BP1: Read and wri te bits

2. UV, INC, WEL, WIP: Read only bits.

3. SRWD: Read and Write bit.

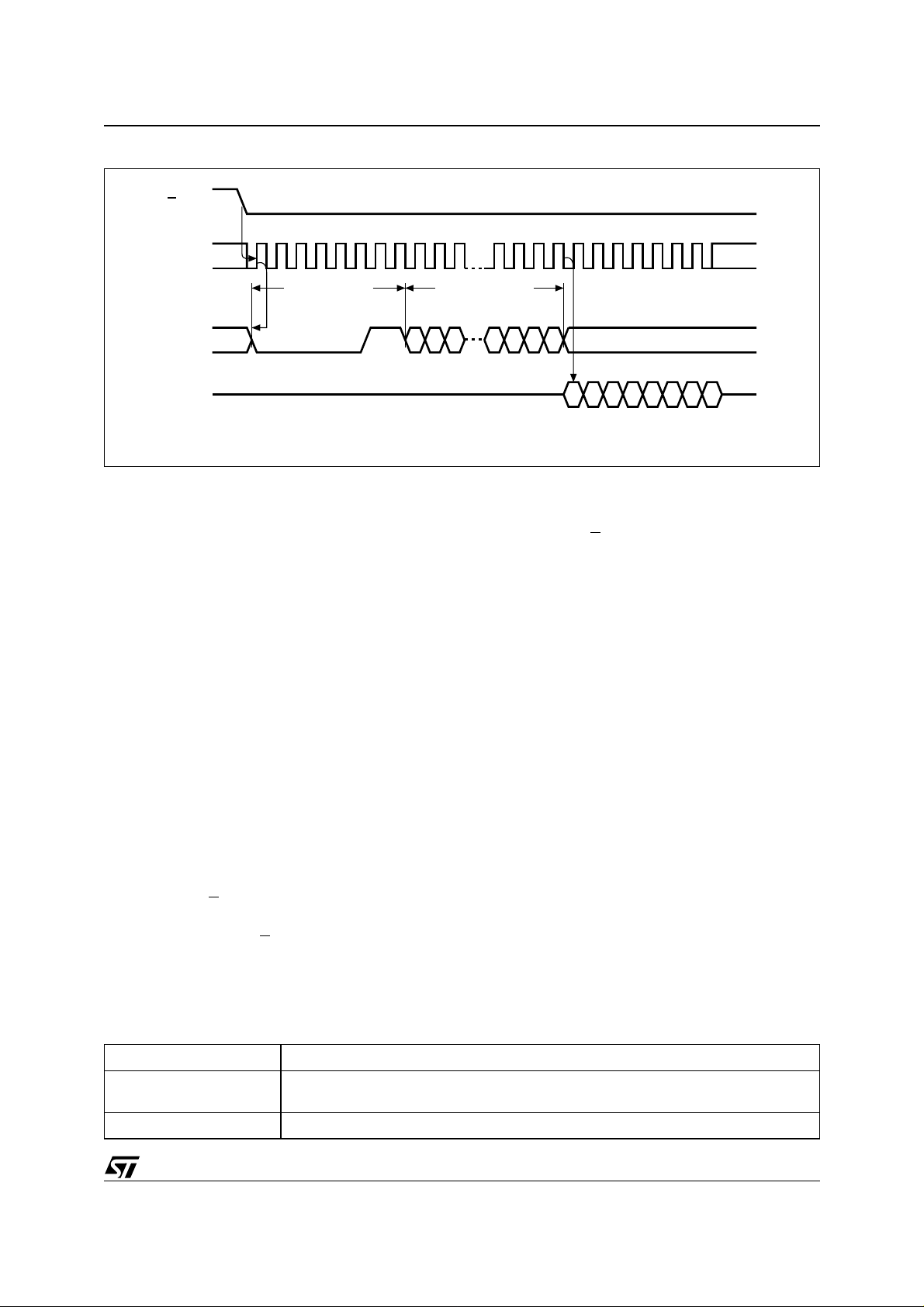

Figure 3. Dat a and Clock Timi ng

CPOL

CPHA

0

1

0

1

C

C

D or Q

MSB LSB

AI01438

3/18

M35080

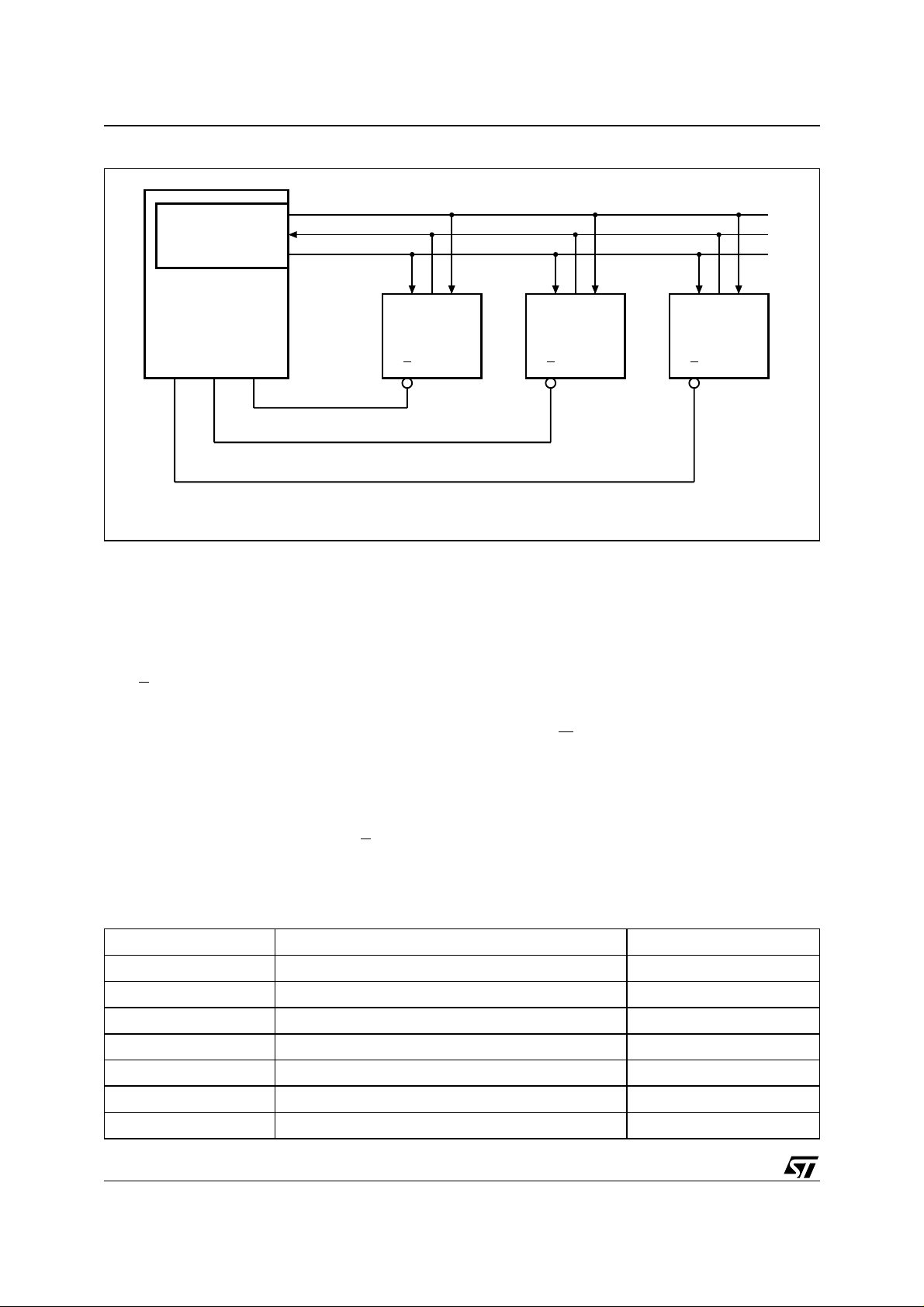

Figure 4. EEPR OM and SPI Bus

SPI Interface with

(CPOL, CPHA) =

('0', '0') or ('1', '1')

Master

(ST6, ST7, ST9,

ST10, Others)

CS3 CS2 CS1

D

Q

C

CQD

M35xxx

S

OPERATIONS

All instructions, addresses and data are shifted serially in and out of the chip (along the bus, as

shown in Figure 4). The most significant bit is presented first, with the data input (D) sampled on the

first rising edge of the clock (C) after the chip se-

) goes low (as shown in Figure 5, Figure 9,

lect (S

and Figure 12).

Every instruction, as summarized in Table 5, starts

with a single -byte cod e. If an invalid instructio n is

sent (one not contained in Table 5), the chip automatically deselects itself.

The instruction code is entered via the data input

(D), and latched on the rising edge of the clock input (C). To enter an instruction code, the device

must have been previously selected (S

held low).

CQD

M35xxx

S

CQD

M35xxx

S

AI02148C

Protection of the First 32 Bytes

The first 32-byte page is organized as 16 words

(two bytes each). The initial content of each word

on this page is 0000h. When writing to byt e-pair, a

logic comparator verifies that the new two-byte

value is larger than the val ue currently stored. If

the new value is sm aller than the current on e, no

operation is performed. It is impossible to write a

value lower than the previous one, irrespective of

the state of W

pin and status register, as indicated

in Table 6.

Write Enable (WREN) and Write Disable (WRDI)

The write enable latch, inside the memory device,

must be set prior to each WRITE and WRSR operation. The WREN instruction (write enable) sets

this latch, and the WRDI instruction (write disable)

resets it.

Table 5. Instruction Set

Instruction Description Instruction Format

WREN Set Write Enable Latch 0000 0110

WRDI Reset Write Enable Latch 0000 0100

RDSR Read Status Register 0000 0101

WRSR Write Status Register 0000 0001

READ Read Data from Memory Array 0000 0011

WRITE Write Data to Memory Array 0000 0010

WRINC Write Data to Secure Array 0000 0111

4/18

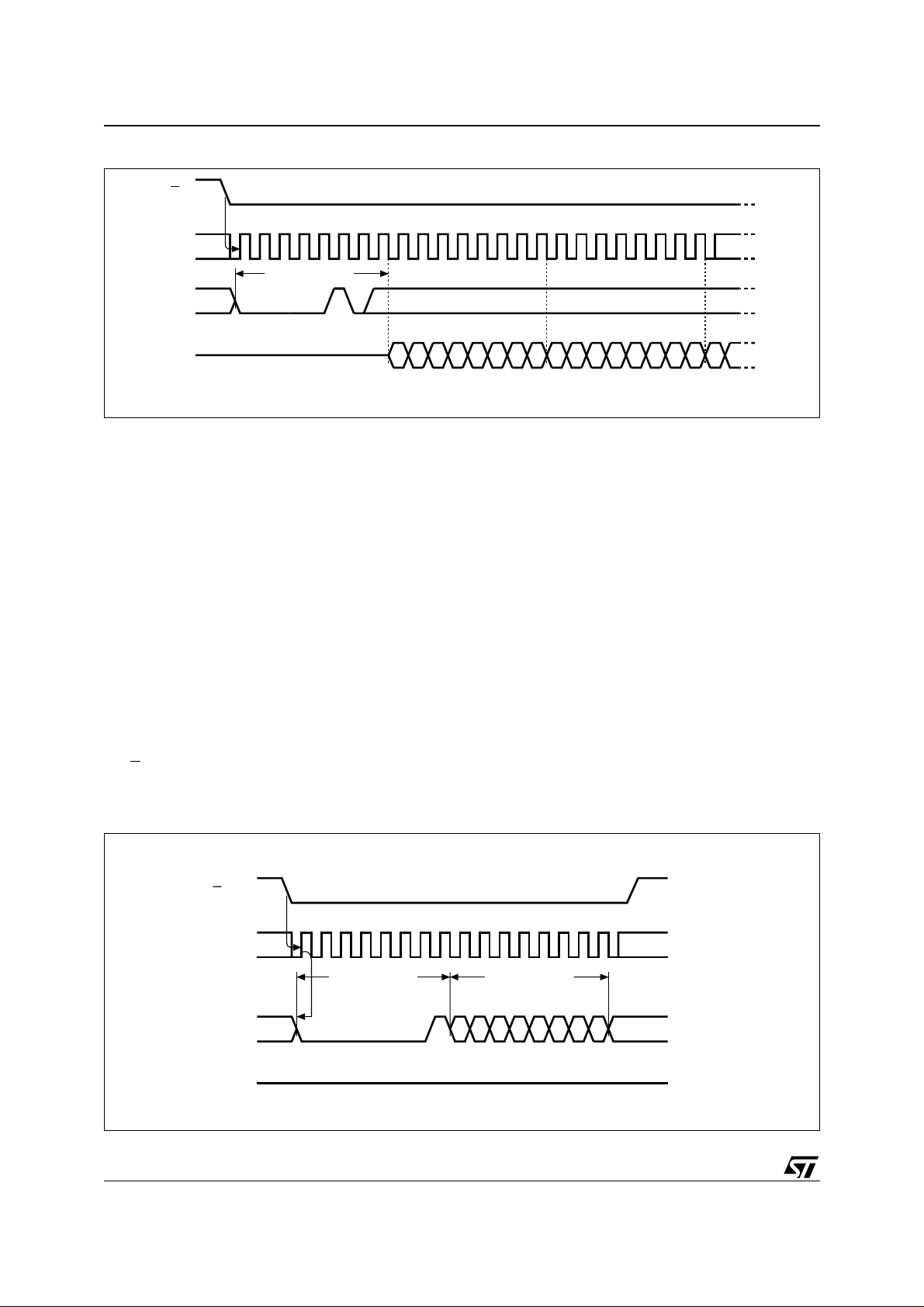

Figure 5. Rea d EEPRO M Arr a y Oper a t ion Sequence

S

21 345678910 2021222324252627

0

C

INSTRUCTION 16 BIT ADDRESS

15

D

1413 3210

M35080

28 29 30

HIGH IMPEDANCE

Q

Note: 1. The most signific ant address bi ts, A15-A 10, are treated as Don’t Care.

The latch becomes reset by any of the f ollowing

events:

– Power on

– WRDI instruction completion

– WRSR in s t ru ctio n completio n

– WRITE instruction completion.

As soon as the WREN or WRDI instruction is re-

ceived, the memory device first executes the instruction, then enters a wait mode until the device

is deselected.

Read Status Register (RDSR)

The RDSR instruction allows the status register to

be read, and can be sent at any time, even during

a Write operation. Indeed, when a Write is in

progress, it is recommended th at the value of t he

Write-In-Progress (WIP) bit be checked. The value

in the WIP bit (whose position in the status register

is shown in Table 4) can be continuously p olled,

before sending a new WRITE instruction. This can

be performed in one of two ways:

■ Repeated RDSR instructions (each one

consisting of S

being taken low, C being clocked

8 times for the instruction and 8 times for the

read operation, and S

being taken high)

■ A single, prolonged RDSR instruction

(consisting of S

clocked 8 times for the instruction and kept

running for repeated read operations), as

shown in Figure 6.

The Write-In-Process (WIP) bit is read-only, and

indicates whether the memory is busy with a Write

operation. A ’1’ indicates that a write is in progress,

and a ’0’ that no write is in progress.

The Write Enable Latch (WEL) bit indicates the

status of the write enable latch. It, too, is read-only.

Its value can only be changed by one of the events

listed earlier, or as a result of executing WREN or

WRDI instruction. It cannot be changed using a

WRSR instruction. A ’1’ i ndicates that the latch is

set (the forthcoming Write instruction will be executed), and a ’0’ that it is reset (and any forthcoming Write instructions will be ignored).

The Block Protect (BP0 and BP1) bits indicate the

amount of the memory that is to be write-protected. These two bits are non-volatile. They are set

using a WRSR instruction.

During a Write operation (whether it be to the

memory area or to the status register), all bits of

the status register remain valid, and can be read

using the RDSR instruction. However, during a

Write operation, the values of the no n-vo latile bits

DATA OUT

765432 0

MSB

1

being taken low, C being

AI01793

Table 6. Memory Mapping

Address Protection

000h-01Fh

020h-3FFh No specific protection except the one as of Table 7

Incremental area: a word (2 bytes) can be written only if the new value to write is larger

than the value already stored

5/18

M35080

Figure 6. RDSR: Read Status Register Sequence

S

21 3456789101112131415

0

C

INSTRUCTION

D

Q

HIGH IMPEDANCE

STATUS REG. OUT

7 6543210

MSB

(SRWD, BP0, BP1) be come frozen at a constant

value. The updated value of these bi ts becomes

available when a new RDSR instruction is executed, after completion of the write cycle. On the other hand, the two read-only bits (WEL, WIP) are

dynamically updated during internal write cycles.

Using this facility, it is possible to poll the WIP bit

to detect the end of the internal write cycle.

The Comparator bit (INC) indicates if the new val-

ue written in the 16 first word is lower ‘1’ or higher

‘0’ than the previous stored value.

The UV bit indicates if the memory chip has been

erased.

Write Status Register (WRSR)

The format of the WRSR instruction is shown in

Figure 7. After the instruction and the eigh t bits of

the status register have been latched-in, the internal Write cycle is triggered by the rising edge of

line. This must occur after the falling edge of

the S

STATUS REG. OUT

the 16

the 17

7 6543210

MSB MSB

th

clock pulse, and before the rising edge of

th

clock (as indicated in Figure 7), otherwise

7

AI02031

the internal write sequence is not performed.

The WRSR instruction is used for the following:

■ to select the size of memory area that is to be

write-protected

■ to select between SPM (Software Protected

Mode) and HPM (Hardware Protected Mode).

The size of the write-protection area applies equally in SPM and HPM. The BP 1 and BP0 b its of the

status register have the appropriate value (see Table 7) written into them after the contents of the

protecte d ar ea of t he EEPROM have been written.

The initial delivery state of the BP1 and BP0 bits is

00, indicating a write-protection size of 0.

Figure 7. WRSR: Write Status Register Sequence

S

21 3456789101112131415

0

C

INSTRUCTION STATUS REG.

D

MSB

HIGH IMPEDANCE

Q

6/18

765432 0

1

AI01797

Loading...

Loading...