SGS Thomson Microelectronics M34D64-W Datasheet

M34D64

64 Kbit Serial I²C Bus EEPROM

With Hardware Write Control on Top Quarter of Memory

FEATURES SUMMARY

■ Two Wire I

2

C Serial Interface

Supports 400 kHz Protocol

■ Single Supply Voltage:

– 2.5V to 5.5V for M34D64-W

– 1.8V to 5.5V for M34D64-R

■ Hardware Write Control of the top quarter of

memory

■ BYTE and PAGE WRITE (up to 32 Bytes)

■ RANDOM and SEQUENTIAL READ Modes

■ Self-Tim e d P rogramming Cycle

■ Automatic Address Incrementing

■ Enhanced ESD/Latch-Up Behavior

■ More than 1M Erase/Write Cycles

■ More than 40 Year Data Retention

Figure 1. Packages

8

1

SO8 (MN)

150 mil width

TSSOP8 (DW)

169 mil width

1/21April 2003

M34D64

SUMMARY DESCRIPTION

2

These I

C-compatible electrically erasable

programmable memory (EEPROM) devices are

organized as 8192 x 8.

Figure 2. Logic Diagram

V

CC

3

E0-E2 SDA

SCL

WC

M34D64

V

SS

AI02850B

Table 1. Signal Names

E0, E1, E2 Chip Enable

SDA Serial Data

SCL Serial Clock

WC

V

CC

V

SS

Power On Reset: V

Write Control

Supply Voltage

Ground

Lock-Out Write Protect

CC

In order to prevent data corruption and inadvertent

Write operations during Power-up, a Power On

Reset (POR) circuit is included. The internal reset

is held active until V

has reached the POR

CC

threshold value, and all operations are disabled –

the device will not respond to any command. In the

same way, when V

drops from the operating

CC

voltage, below the POR threshold value, all

operations are disabled and the device will not

respond to any com ma nd. A s table a nd v alid V

CC

must be applied before applying any logic signal.

These devices are compatible with the I

2

memory protocol. This is a two wire serial interface

that uses a bi-directional data bus and serial clock.

The devices carry a built-in 4-bit Device Type

Identifier code (1010) in accordance with the I

2

bus definition.

The device behaves as a slave in the I

2

C protocol,

with all memory operations synchronized by the

serial clock. Read and Write operations are

initiated by a Start condition, generated by the bus

master. The Start condition is followed by a Device

Select Code and RW

bit (as described in Table 2),

terminated by an acknowledge bit.

When writing data to the memory, the device

inserts an acknowledge bit during the 9

th

bit time,

following the bus master’s 8-bit transmission.

When data is read by the bus master, the bus

master acknowledges the receipt of the data byte

in the same way. Data transfers are terminated by

a Stop condition after an Ack for Write, and after a

NoAck for Read.

C

Figure 3. SO and TSSOP Connections

C

M34D64

1

E0 V

2

3

E2

4

SS

Note: 1. See page 17 (onwards) for package dimensions, and how

to identify pin-1.

8

7

6

5

AI02851C

CC

WCE1

SCL

SDAV

2/21

SIGNAL DESCRIPTION

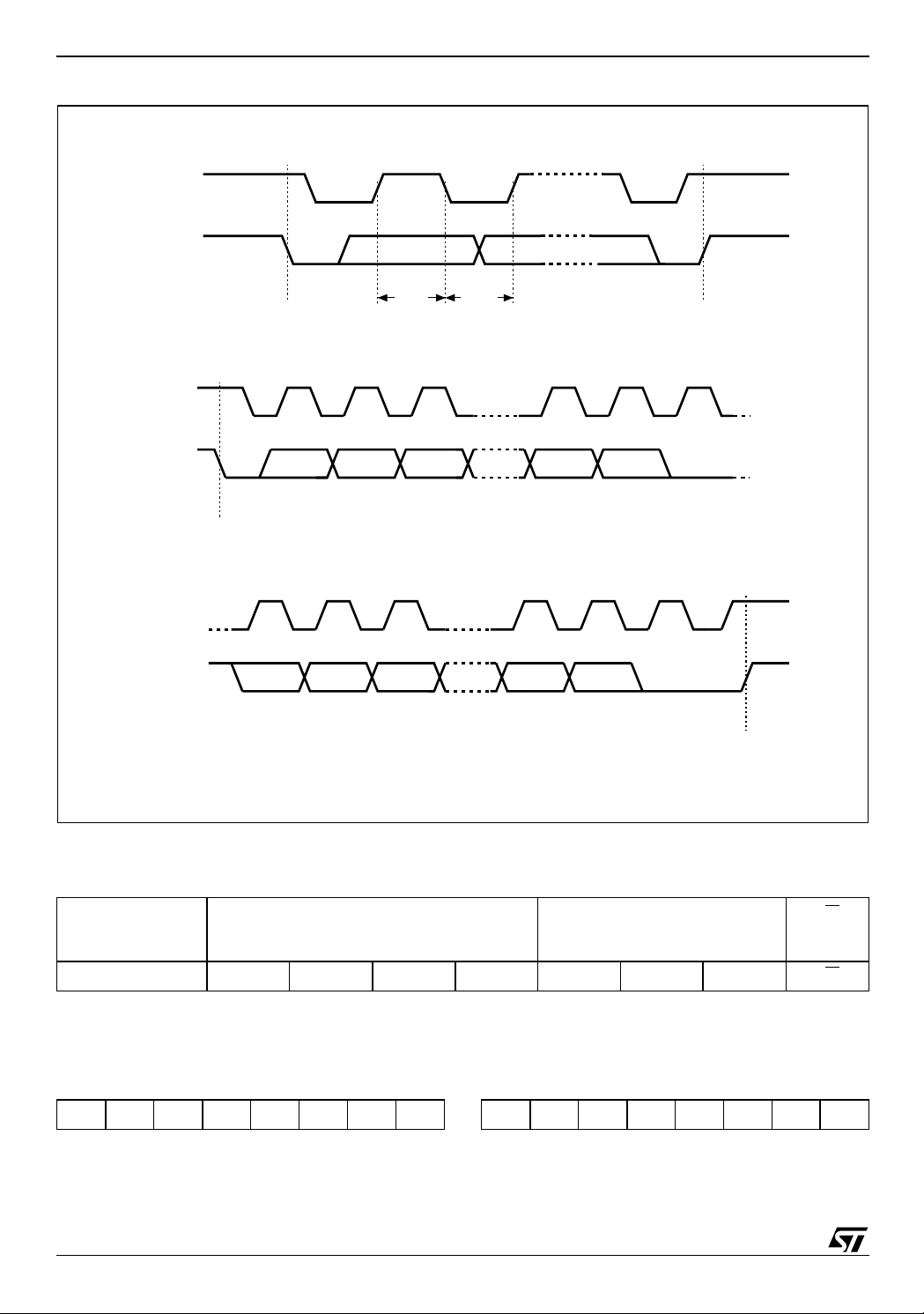

Serial Clock (SCL)

This input signal is used to strobe all data in and

out of the device. In applications where this signal

is used by slave devices to synchronize the bus to

a slower clock, the bus master must have an open

drain output, and a pull-up resistor must be connected from Serial Clock (SCL) to V

. (Figure 5

CC

indicates how the value of the pull-up resist or can

be calculated). In most applications, thoug h, this

method of synchronization is no t employed, and

so the pull-up resistor is not necessary, provided

that the bus maste r has a push-pull (rather than

open drain) output.

Serial Data (SDA)

This bi-directional signal is used to transfer data in

or out of the device. It is an open drain output that

may be wire-OR’ed with other open drain or open

collector signals on the bus. A pull up resistor must

be connected from Serial Data (SDA) to V

CC

. (Figure 5 indicates how the value of the pull-up resistor

can be calculated).

Chip Enable (E0, E1, E2)

These input signals are used to set the value that

is to be looked for on the three least significant bits

(b3, b2, b1) of the 7-bit Device Select Code. These

inputs must be tied to V

or VSS, to establish the

CC

Device Select Code.

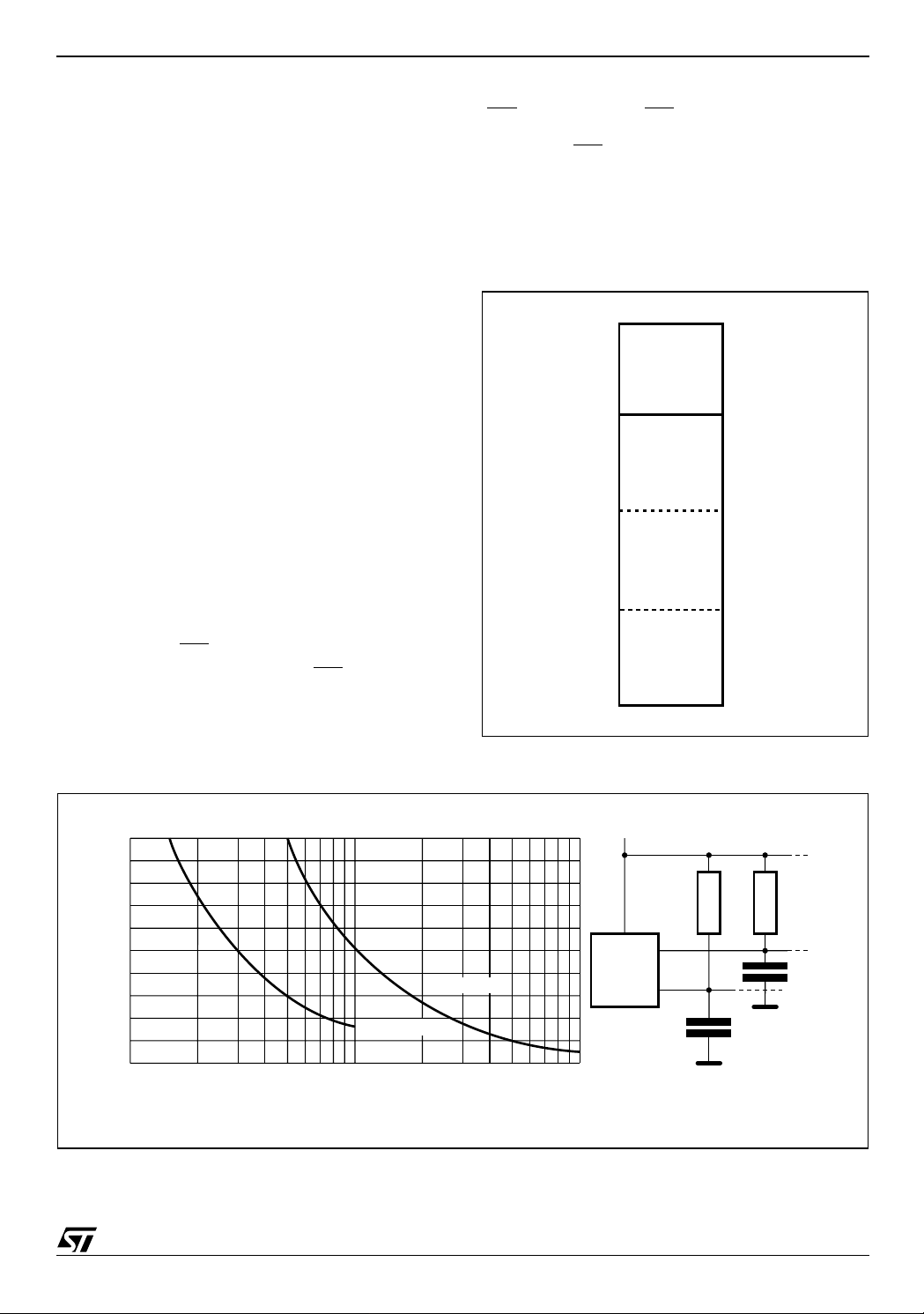

Write Control (WC

The hardware Write Control pin (WC

)

) is useful for

protecting the top quarter of the memory (as

shown in Figure 4) from inadvertent erase or write.

The Write Control signal is used to enable

M34D64

(WC

=VIL) or disable (WC=VIH) write instructions to

the top quarter of the memory area. When unconnected, the WC

write operations are allowed.

Figure 4. Me m ory Map showing Write Cont rol Area

input is internally read as VIL, and

1FFFh

Write Controlled

Area

1800h

1000h

0800h

0000h

AI03114C

Figure 5. Maximum R

20

16

12

8

Maximum RP value (kΩ)

4

0

10 1000

Value versus Bus Capacitance (C

L

fc = 100kHz

fc = 400kHz

100

C

(pF)

BUS

) for an I2C Bus

BUS

MASTER

V

CC

R

SDA

SCL

R

C

BUS

L

C

BUS

AI01665

3/21

L

M34D64

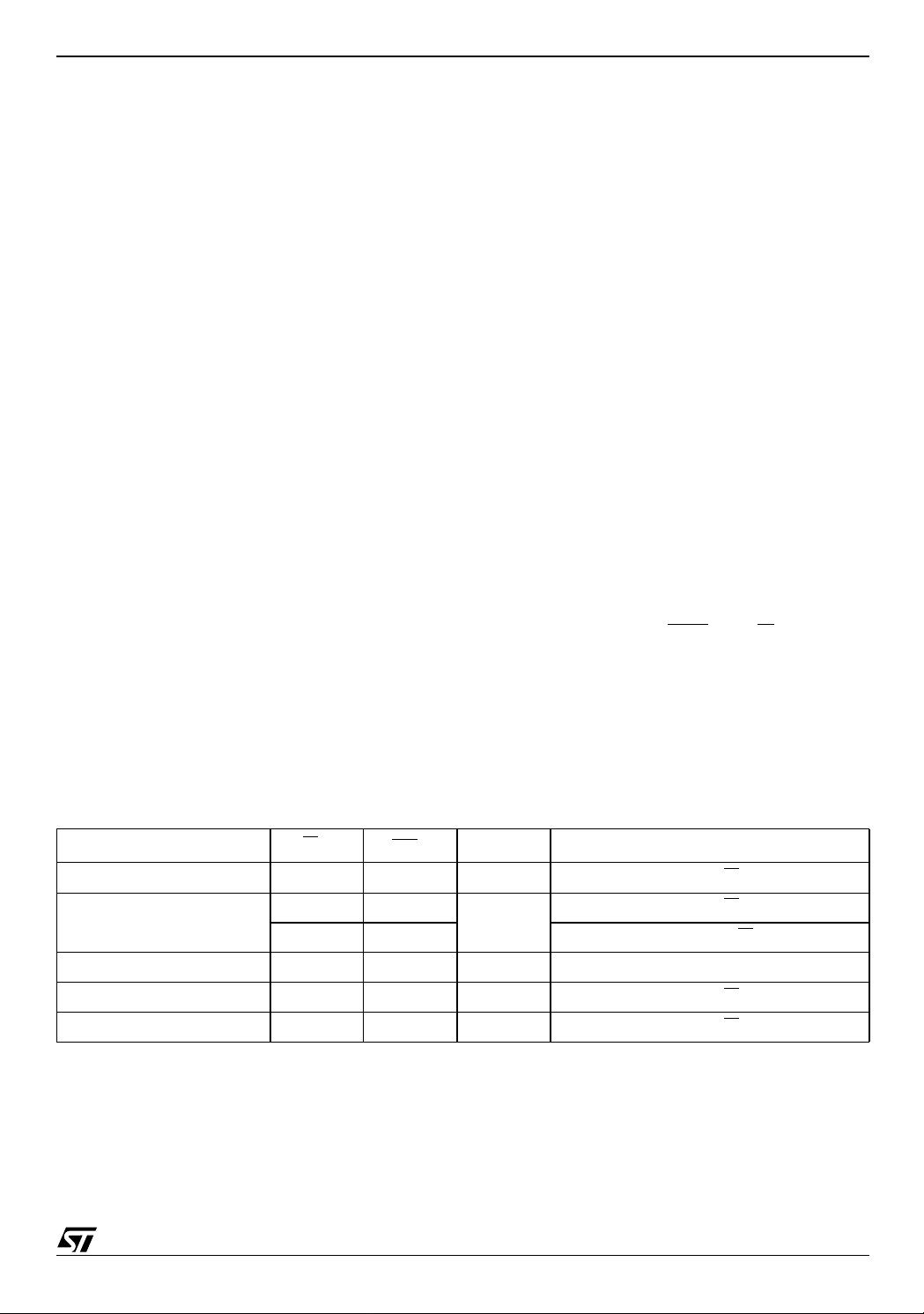

Figure 6. I2C Bus Protocol

SCL

SDA

SCL

SDA

SCL

SDA

START

Condition

START

Condition

1 23 789

MSB

1 23 789

MSB ACK

SDA

Input

SDA

Change

STOP

Condition

ACK

STOP

Condition

AI00792B

Table 2. Device Select Code

Device Type Identifier

1

Chip Enable Address

b7 b6 b5 b4 b3 b2 b1 b0

Device Select Code 1 0 1 0 E2 E1 E0 RW

Note: 1. The most si gnifican t bit, b7, is se nt first.

2. E0 , E 1 and E2 are compared agai nst the respective external pins on the memory device.

2

RW

Table 3. Most Significant Byte Table 4. Least Significant Byte

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

4/21

M34D64

DEVICE OPERATION

2

The device supports the I

C protocol. This is

summarized in Figure 6. Any device that sends

data on to the bus is defined to be a transmitte r,

and any device that reads the data to be a

receiver. The device that controls the data transfer

is known as the bus master, and the other as the

slave device. A data transfer can only be initiated

by the bus master, which will also provide the

serial clock for synchronization. The M34D64

device is always a slave in all communication.

Start Condition

Start is identified by a falling edge of Serial Data

(SDA) while Serial Clock (SCL) is stable in the

High state. A Start condition must precede any

data transfer command. The devi ce continuously

monitors (except duri ng a Write cycle ) Se ri a l Data

(SDA) and Serial Clock (SCL) for a Start condition,

and will not respond unless one is give n.

Stop Condition

Stop is identified by a rising edg e of Serial Data

(SDA) while Serial Clock (SCL) is stable and

driven High. A Stop condition terminates

communication between the device and the bus

master. A Read command that is followed by

NoAck can be followed by a Stop condition to force

the device into the Stand-by mode. A Stop

condition at the end of a Write command triggers

the internal EEPRO M Writ e cycle.

Acknowledge Bit (ACK)

The acknowledge bit is used to indicate a

successful byte transfer. The bus transmitter,

whether it be bus master or slave device, releases

Serial Data (SDA) after sending eight bits of data.

During the 9

th

clock pulse period, the receiver pulls

Serial Data (SDA) Low to acknowledge the receipt

of the eight data bits.

Data Input

During data input, the device samples Serial Data

(SDA) on the rising edge of Serial Clock (SCL).

For correct device operation, Serial Data (SDA)

must be stable during the rising edge of Serial

Clock (SCL), and the Serial Data (SDA) signal

only

must change

when Serial Clock (SCL) is

driven Low.

Memory Addressing

To start communication betwee n the bus master

and the slave device, the bus mas ter mus t initiate

a Start condition. Following this, t he bus master

sends the Device Select Code, shown in Tabl e 2

(on Serial Data (SDA), most significant bit first).

The Device Select Code consists of a 4-bit Device

Type Identifier, and a 3-bit Chip Enable “Address”

(E2, E1, E0). To address the memory array, t he 4bit Device Type Identifier is 1010b.

Up to eight memory devices can be connected on

a single I

2

C bus. Each one is given a uniq ue 3-bit

code on the Chip Enable (E0, E1, E2) inputs.

When the Device Select Code is received on

Serial Data (SDA), the device only responds if the

Chip Enable Address is the s ame as the v alue on

the Chip Enable (E0, E1, E2) inputs.

th

The 8

bit is the Read/Write bit (RW). This bi t is

set to 1 for Read and 0 for Write operations.

If a match occurs on the Device Select code , the

corresponding device gives an acknowledgment

on Serial Data (SDA) during the 9

th

bit time. If the

device does not match the Device Select code, it

deselects itself from the bus, and goes into Standby mode.

Table 5. Operating Modes

Mode RW bit

Current Address Read 1 X 1 START, Device Select, RW

Random Address Read

Sequential Read 1 X

Byte Write 0 V

Page Write 0 V

Note: 1. X = V

IH

or V

.

IL

0X

1 X reSTART, Device Select, RW

WC

1

IL

IL

Bytes Initial Sequence

1

1 Similar to Current or Random Address Read

≥

1 START, Device Select, RW = 0

32 START, Device Select, RW

≤

START, Device Select, RW

= 1

= 0, Address

= 1

= 0

5/21

M34D64

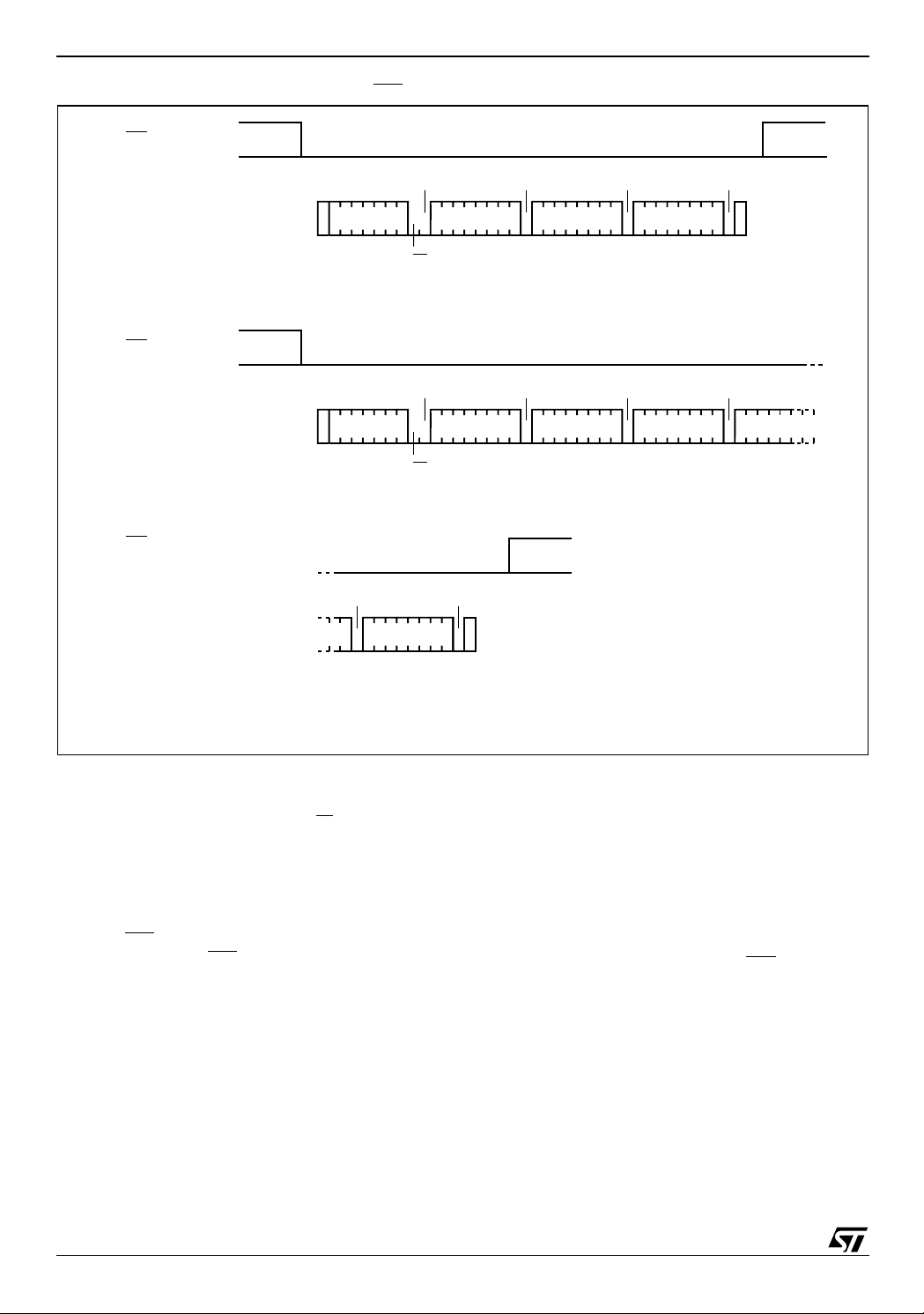

Figure 7. Wri te Mo de S e qu e nces with WC =0 (data wri te enab led)

WC

ACK

BYTE WRITE DEV SEL BYTE ADDR BYTE ADDR DATA IN

R/W

START

WC

ACK ACK ACK ACK

PAGE WRITE DEV SEL BYTE ADDR BYTE ADDR DATA IN 1

R/W

START

WC (cont'd)

ACKACK

PAGE WRITE

(cont'd)

DATA IN N

ACK ACK ACK

STOP

DATA IN 2

Write Operations

Following a Start condition the bus master sends

a Device Select Code with the RW

bit rese t to 0 .

The device acknowledges this, as shown in Figure

7, and waits for two address bytes. The device responds to each address byte with an acknowledge

bit, and then waits for the data byte(s).

Writing to the memory may be inhibited if Write

Control (WC

with Write Control (WC

) is driven High. Any Write instruction

) driven High (during a period of time from the Start condition until the end of

the two address bytes) will not modify the contents

of the top quarter of the memory.

Each data byte in the m emory has a 16-bit (two

byte wide) address. The Most Significant Byte (Table 3) is sent first, followed by the Least Significant

Byte (Table 4). Bits b15 to b0 form t he add ress of

the byte in memory.

When the bus mast er generates a Stop con dition

immediately after the Ack bi t (in t he “10

th

bit” time

slot), either at the end of a Byte Write or a Page

STOP

AI01106C

Write, the internal memory Write cycle is triggered.

A Stop condition at any other time slot does not

trigger the internal Write cycle.

During the internal Write cycle, Serial Da ta (SDA)

is disabled internally, and the devi ce does not respond to any requests.

Byte Write

After the Device Select code and the address

bytes, the bus master sends one dat a byte. If the

addressed location is Write-protected (top quarter

of the memory), by Write Control (WC

) being driven High, the location is not modified. The bus master terminates the transfer by generating a Stop

condition, as shown in Figure 7.

Page Write

The Page Write mode allows u p to 32 by tes to be

written in a single Write cycle, provided that they

are all located in the same ’row’ in the memory:

that is, the most significant m emory address bits

(b12-b5) are the same. If more bytes are sent than

will fit up to t he en d of t he row, a condition known

as ‘roll-over’ occurs. This should be avoided, as

6/21

M34D64

data starts to become overwritten in an implementation dependent way.

The bus master sends fr om 1 to 32 bytes of data.

If Write Control (WC

) is High, the contents of the

addressed top quarter of the m emo ry locatio n are

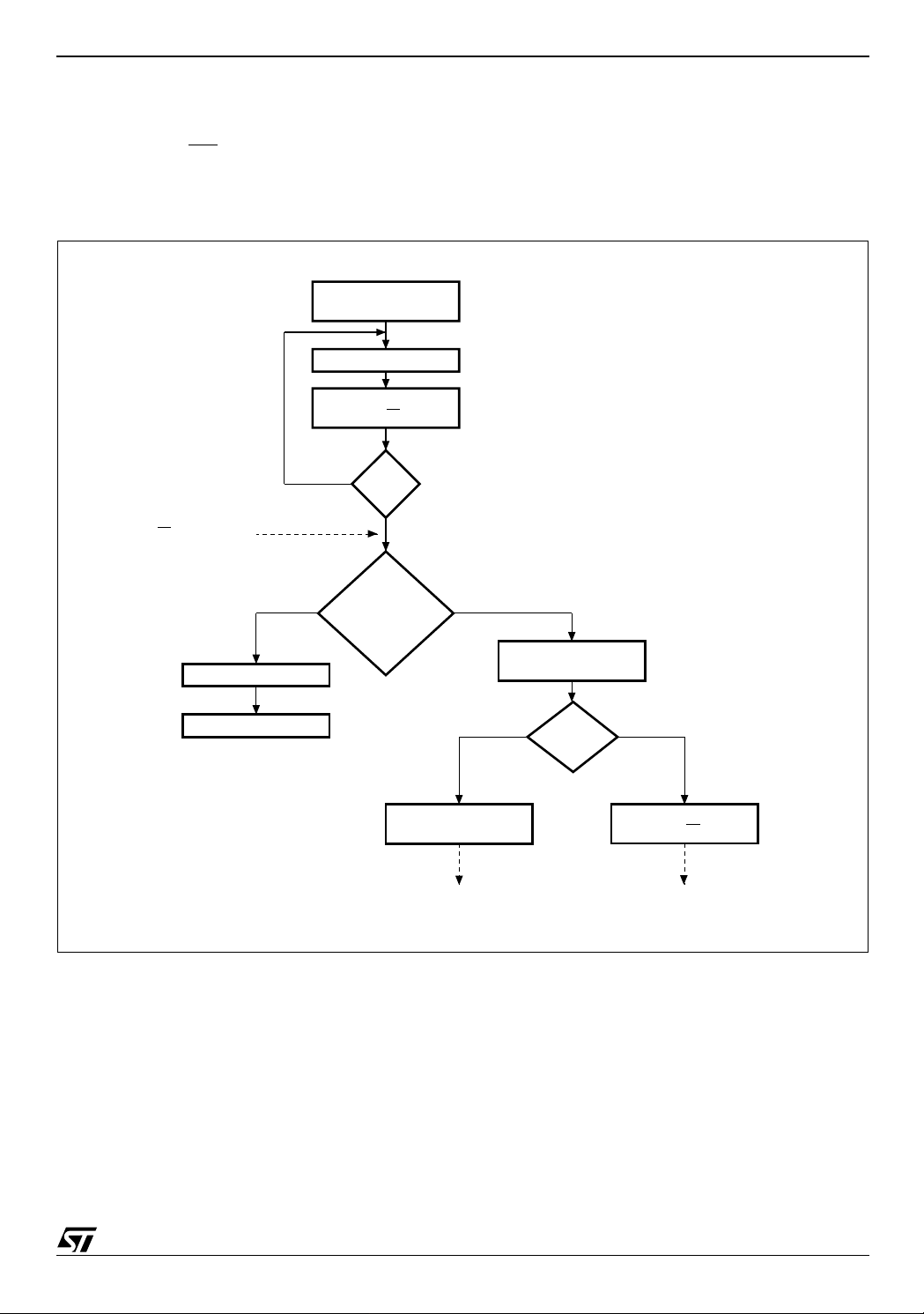

Figure 8. W ri t e C yc le Pol l in g Fl owchart usin g A C K

WRITE Cycle

in Progress

START Condition

DEVICE SELECT

with RW = 0

ACK

NO

Returned

First byte of instruction

with RW = 0 already

decoded by the device

ReSTART

YES

Next

Operation is

Addressing the

Memory

not modified. After each byte is transferred, the internal byte address counter (the 5 least significant

address bits only) is incremented. Th e transfer is

terminated by the bus master generating a Stop

condition.

YESNO

Send Address

and Receive ACK

STOP

DATA for the

WRITE Operation

Continue the

WRITE Operation

Minimizing System Delays by Polling On ACK

During the internal Write cycle, the device

disconnects itself from t he bus , and writes a copy

of the data from its internal latches to the memory

cells. The maximum Write time (t

) is shown in

w

Tables 13 and 14, but the typical time is shorter.

To make use of this, a polling sequence can be

used by the bus master.

The sequence, as shown in Figure 8, is:

– Initial condition: a Write cycle is in progress.

START

Condition

YESNO

DEVICE SELECT

with RW = 1

Continue the

Random READ Operation

AI01847C

– Step 1: the bus master issues a Start condition

followed by a Device Select Code (the first byte

of the new instruction).

– Step 2: if the device is busy with the internal

Write cycle, no Ack will be returned and the bus

master goes back to Step 1. If the device has

terminated the internal Write cycle, it responds

with an Ack, indicating that the device is ready

to receive the second part of the instruction (the

first byte of this instruction having been sent

during Step 1).

7/21

Loading...

Loading...