512 Kbit (64Kb x8, Bulk) Single Supply Flash Memory

■ SINGLE 5V±10% SUPPL Y VOLTAGE for

PROGRAM, ERAS E and READ O PER AT IONS

■ ACCESS TIME: 45ns

■ PROGRAMMING TIME

– 8µs per Byte typical

■ PROGRAM/E RA SE CONTROLLER

– Embedded Byte Program algorithm

– Embedded Chip Erase algorithm

– Status Register Polling and Toggle Bits

■ UNLOCK BYPASS PROGRAM COMMAND

– Faster Production/Batch Programming

■ LOW POWER CONSUMPTION

– Standby and Automatic Standby

■ 100,000 PROGRAM/ERASE CYCL ES

■ 20 YEARS DATA RETENTI ON

– Defectivity below 1 ppm/year

■ ELECTRONIC SIGNATURE

– Manufacturer Code: 20h

– Device Code: 24h

TSOP32 (NZ)

8 x 14mm

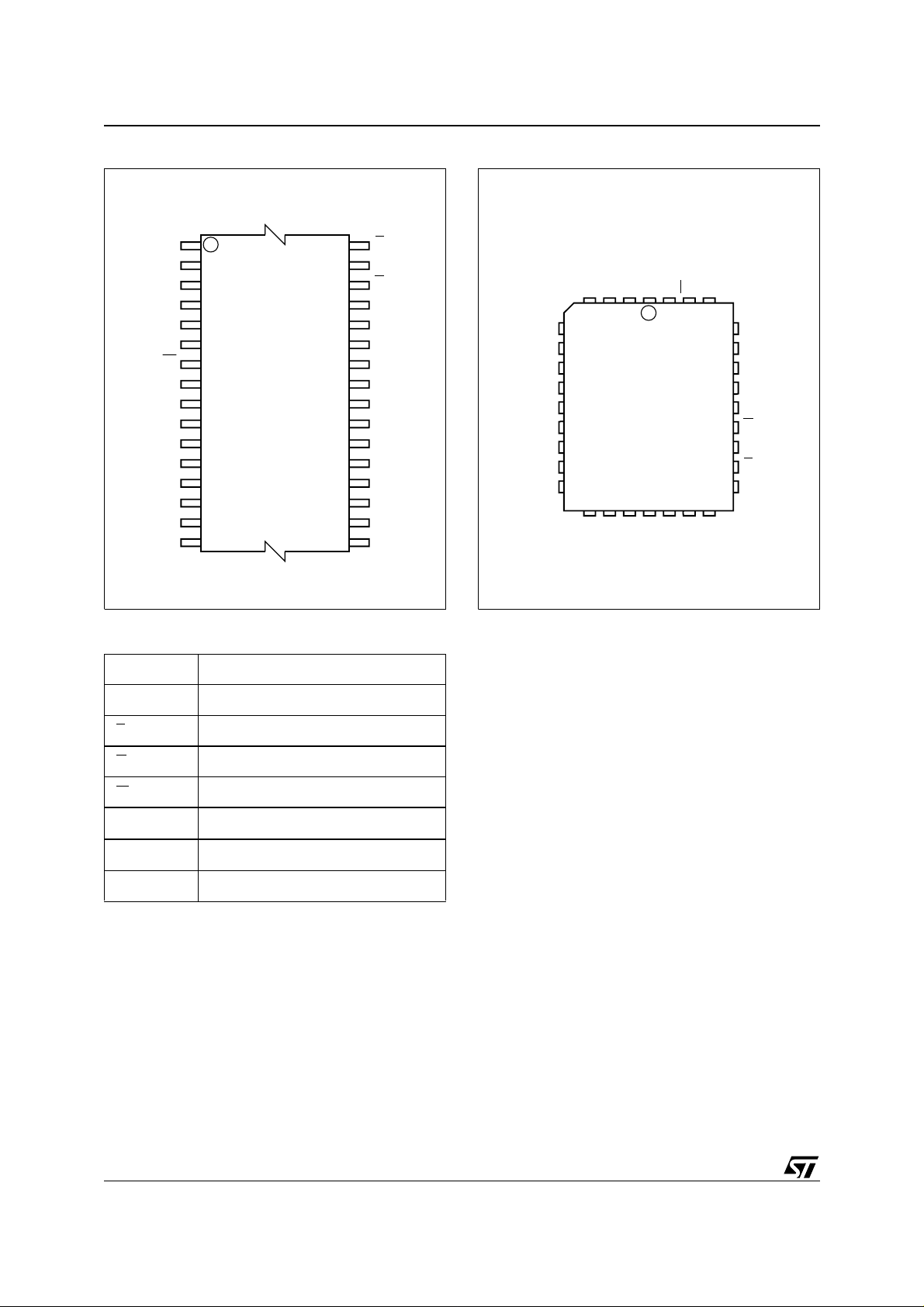

Figure 1. Logic Diagram

V

CC

M29F512B

PRELIMINARY DATA

PLCC32 (K)

16

A0-A15

W

E

G

July 1999

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to change without notice.

M29F512B

V

SS

8

DQ0-DQ7

AI02739

1/16

M29F512B

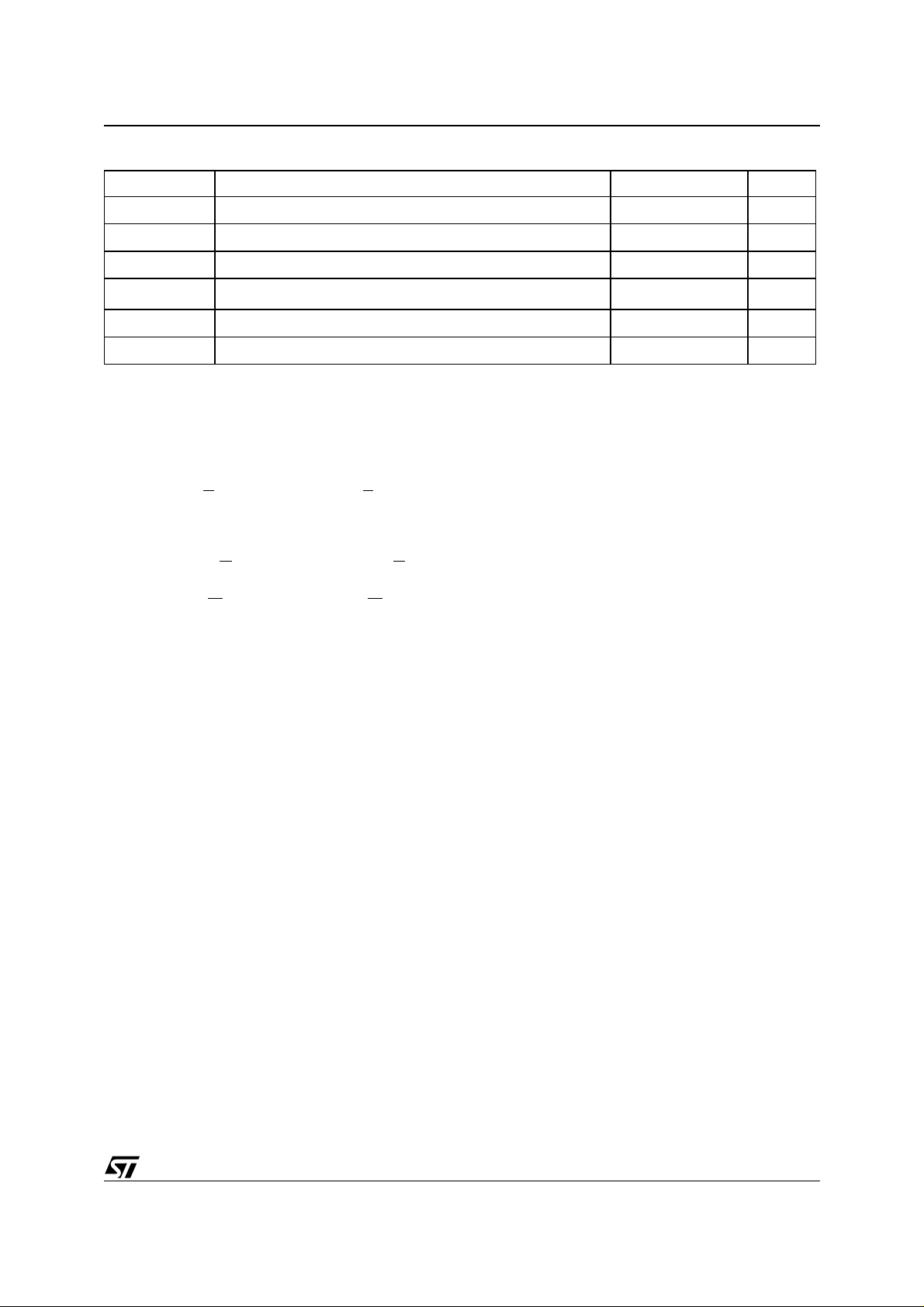

Figure 2A. TSOPConnections

A11 G

A9

A8

A13

A14

NC

V

CC

NC

NC

A15

A12

A7

A6

A5

A4 A3

1

W

8

M29F512B

9

16 17

32

25

24

AI02741

A10

E

DQ7

DQ6

DQ5

DQ4

DQ3

V

SS

DQ2

DQ1

DQ0

A0

A1

A2

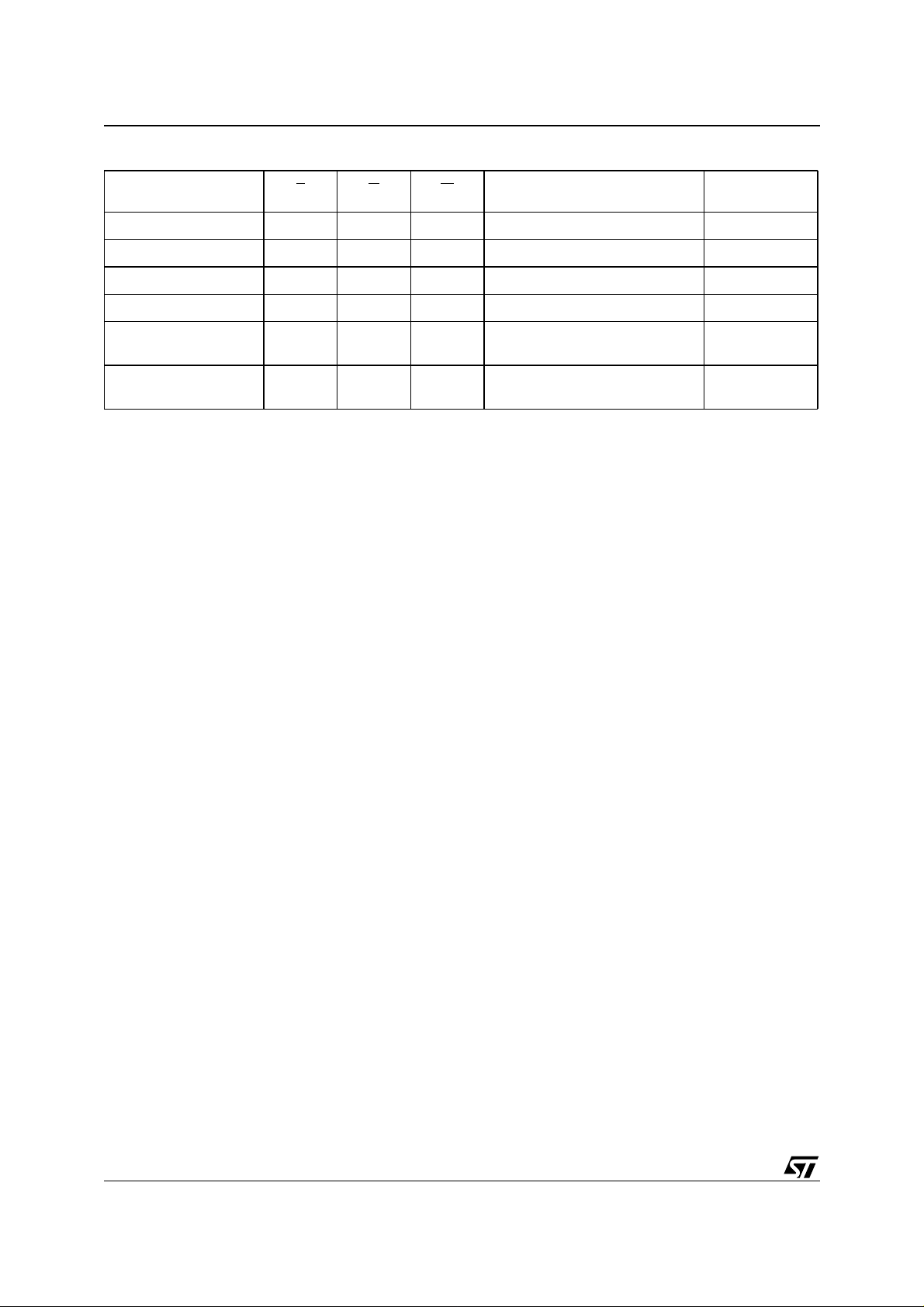

Figure 2B. PLCC Connections

CC

NC

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

A12

9

DQ1

NC

A15

32

1

M29F512B

17

SS

V

DQ2

DQ3

V

DQ4

W

DQ5

NC

25

DQ6

A14

A13

A8

A9

A11

G

A10

E

DQ7

AI02930

Table 1. Signal Names

A0-A15 Address Inputs

DQ0-DQ7 Data Inputs/Outputs

E

G

W

V

CC

V

SS

NC Not Connected Internally

Chip Enable

Output Enable

Write Enable

Supply Voltage

Ground

SUMMARY DESCRIPTION

The M29F512B is a 512 Kbit (64Kb x 8) non-volatile memory that can be read, erased and reprogrammed. These operations can be performed

using a single 5V supply. On power-up the memory defaults to its Read m ode where it can be read

in the same way as a ROM or EPROM.

Program and Erase command s are written to the

Command Interface of the memory. An on-chip

Program/Erase Controller simplifies the process of

programming or erasing the memory by taking

care of all of the special operations that are re-

quired to update the memory contents. The end of

a program or erase operation can be detected and

any error conditions identified. The command set

required to control the memory is consistent with

JEDEC standards.

Chip Enable, Output Enable and Write Enable signals control the bus operation of the memory.

They allow simple conne ction to most m icroprocessors, often without additional logic.

The memory is offered in TSOP32 (8 x 14mm) and

PLCC32 packages. Access times of 45ns and

70ns are available. The m emory is supplied with

all the bits erased (set to ’1’).

SIGNAL DESCRIPTIONS

See Figure 1, Logic Diagram, and Table 1, Sig nal

Names, for a brief overview of the signals connected to this device.

Address Inputs (A0-A15). The Address Inputs

select the cells i n the memory array to a ccess during Bus Read operations. During Bus Write operations they control the commands sent to the

Command Interface of the internal state machine.

Data Inputs/Outputs (DQ0-DQ7). The Data Inputs/Outputs output the data stored at the selected

address during a Bus Read operation. During Bus

Write operations they represent the commands

sent to the Command Interface of the internal state

machine.

2/16

M29F512B

Table 2. Absolute Maximum Ratings

Symbol Parameter Value Unit

T

A

T

BIAS

T

STG

(2)

V

IO

V

CC

V

ID

Note: 1. Except for the rating "Operating Temperature Range", stresses above those listed in the Table "Absolute Maximum Ratings" may

cause permanent damage to the device. These are stress ratings only and operation of the device at these or any other conditions

above those indicated in the Operating section s of this specific at i on is not impli ed. Exposure to Absolu te Maximum Rati ng conditions for extended periods may affect device reliability. Refer also to the STMicroelectronics SURE Program and other relevant

quality documents.

2. Mini m um Voltage may undershoot to –2V duri ng transit i on and for less than 20ns duri ng transitio ns.

Ambient Operating Temperature 0 to 70 °C

Temperature Under Bias –50 to 125 °C

Storage Temperature –65 to 150 °C

Input or Output Voltage –0.6 to 6 V

Supply Voltage –0.6 to 6 V

Identification Voltage –0.6 to 13.5 V

Chip Enable (E). The Chip Enable, E, activates

the memory, allowing Bus Read and Bus Write operations to be performed. When Chip Enable is

High, V

Output Enable (G

, all other pins are ignored.

IH

). The Output Enable, G, con-

trols the Bus Read operation of the memory.

Write Enable (W

). The Write Enable, W, controls

the Bus Write operation of the memory’s Command Interf a c e .

Supply Voltage. The VCC Supply Voltage

V

CC

supplies the power for all operations (Read, Program, Erase etc.).

The Command Interface is disabled when the V

Supply Voltage is less than the L ockout Voltage,

V

. This prevents Bus Write operations from ac-

LKO

cidentally damaging the data during power up,

power down and power surges. If the Program/

Erase Controller is programming or erasing during

this time then the operation aborts and the memory contents being altered will be invalid.

A 0.1µF capacitor should be connected between

the V

Supply Voltage pin and the VSS Ground

CC

pin to decouple the current surges from the power

supply. The PCB track widths must be sufficient to

carry the currents required during program and

erase operations, I

Vss Ground. The V

.

CC3

Ground is the reference

SS

for all voltage measurements.

(1)

CC

BUS OPERATIONS

There are five standard bus operations that control

the device. These are Bus Read, Bus Wri te, Output Disable, Standby and Automatic Standby. See

Table 3, Bus Operations, for a summary. Typically

glitches of less than 5ns are ig nored b y the mem ory and do not affect bus operations.

Bus Read. Bus Read operations read from the

memory cells, or specific registers in the Command Interface. A valid Bus Read operation involves setting the desired address on the Address

Inputs, applying a Low sig nal, V

, to Chip Enable

IL

and Output Enable and keeping Write Enable

High, V

. The Data Inputs/Outputs will output the

IH

value, see Figure 7, Rea d Mode AC Wav eforms,

and Table 10, Read AC Characteristics, for details

of when the output becomes valid.

Bus Write. Bus Write operations write to the

Command Interface. A valid Bus Write operation

begins by setting the des ired address on t he Address Inputs. The Address Inputs are latched by

the Command Interface on the falling edge of Chip

Enable or Write Enable, whichever occurs last.

The Data Inputs/Outputs a re latched by the Command Interface on the rising edge of Chip Enable

or Write Enable, whichever occurs first. Output Enable must remain High, V

, during the whole Bus

IH

Write operation. See Figures 8 an d 9, Write AC

Waveforms, and Tables 11 and 12, Write AC

Characteristics, for details of the timing requirements.

3/16

M29F512B

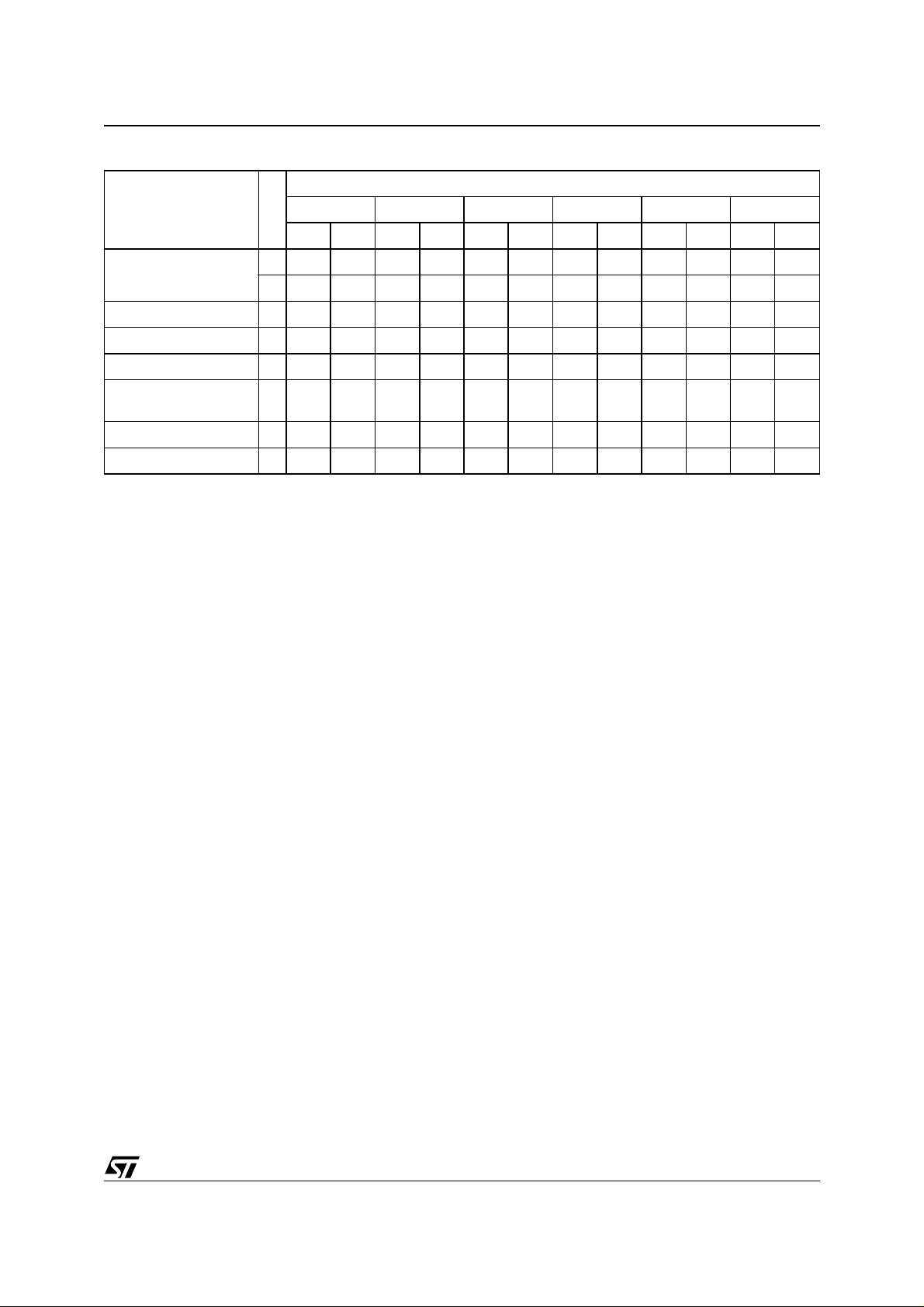

Table 3. Bus Operations

Operation E G W Address Inputs

Bus Read

Bus Write

Output Disable X

Standby

Read Manufacturer

Code

Read Device Code

Note: X = VIL or VIH.

Data

Inputs/Outputs

V

IL

V

IL

V

IH

V

IL

V

IL

V

IL

V

IH

V

IH

XXX Hi-Z

V

IL

V

IL

V

V

V

V

V

Cell Address Data Output

IH

Command Address Data Input

IL

XHi-Z

IH

A0 = VIL, A1 = VIL, A9 = VID,

IH

Others V

A0 = VIH, A1 = VIL, A9 = VID,

IH

Others V

IL

IL

or V

or V

IH

IH

20h

24h

Output Disa bl e . The Data Inputs/Outputs are in

the high impedance s tate when Output Enable is

High, V

Standby. When Chip Enable is High, V

.

IH

, the

IH

memory enters Standby mode and the Data Inputs/Outputs pins are placed in the high-impedance state. To reduce the S upply Current to the

Standby Supply Current, I

be held within V

± 0.2V. For the Standby current

CC

, Chip Enable should

CC2

level see Table 9, DC Characteristics.

During program or erase operations the memory

will continue to use the Program/Erase Supply

Current, I

, for Program or Erase operations un-

CC3

til the operation completes.

Automatic Standby. If CMOS levels (V

± 0.2V)

CC

are used to drive the bus and the bus is inactive for

150ns or more the memory enters Automatic

Standby where the internal Supply Current is reduced to the Standby Supply Current, I

CC2

. The

Data Inputs/Outputs will still output data if a Bus

Read operation is in progress.

Special Bus Operations

Additional bus operations can be performed to

read the Electronic S ignature. These bus operations are intended for use by programming equipment and are not usually used in applications.

They require V

to be applied to some pins.

ID

Electronic Signature. The memory has two

codes, the manufacturer code and the device

code, that can be read to identify the memory.

These codes can be read by applying t he signals

listed in Table 3, Bus Operations.

COMMAND INTERFACE

All Bus Write operations t o the me mory are in terpreted by the Command Interface. Commands

consist of one or more sequential Bus Write operations. Failure to observe a valid sequence of Bus

Write operations will result in the memory returning to Read mode. The long command sequences

are imposed to maximize data security.

The commands are summarized in Table 4, Commands. Refer to Table 4 in conjunction with the

text descriptions below.

Read/Reset Command. The Read/Reset command returns the memory to its Read mode where

it behaves like a ROM or EPROM. It also resets

the errors in the Status Register. Either one or

three Bus Write operations can be u sed to issue

the Read/Reset command.

If the Read/Reset command is issued during a

Chip Erase operation the memory will take about

10µs to abort the Chip Erase. During the abort period no valid data can be read from the memory.

Issuing a Read/Reset command during a Chip

Erase operation will leave invalid data in the memory.

Auto Select Command. The Auto Select command is used to read the Manufacturer Code and

the Device Code. Three consecutive Bus Write operations are required to issue the Auto Select command. Once the Auto Select command is issued

the memory remains in Auto Select mode until another command is issued.

4/16

M29F512B

Table 4. Commands

Bus Write Operations

Command

Read/Reset

Auto Select 3 555 AA 2AA 55 555 90

Program 4 555 AA 2AA 55 555 A0 PA PD

Unlock Bypass 3 555 AA 2AA 55 555 20

Unlock Bypass

Program

Unlock Bypass Reset 2 X 90 X 00

Chip Erase 6 555 AA 2AA 55 555 80 555 AA 2AA 55 555 10

Note: X Don’t Care, PA Program Address, PD Program Data.

All values in the table are in hexadecimal.

The Comman d Interface only uses add ress bits A0-A 10 to verify the comman ds, the upper address bits are Don’t Care.

Read/Re set. After a Read/Reset command, read the memory as normal until another command is issued.

Auto Select. After an Auto Select command, read Manufacturer ID or Device ID.

Program, Un lock Bypa ss Program, Ch ip Erase. After t hese commands read the Sta tus Registe r until the Program/Eras e Controlle r com-

pletes and the memory re turns to Re ad M ode.

Unlock Bypass. After the Unlock Bypass command issue Unlock Bypass Program or Unlock Bypass Reset commands.

Unlock Bypass Reset. After the Unlock Bypass Reset command read the memory as normal until another command is issued.

1X F0

3 555 AA 2AA 55 X F0

2X A0PAPD

1st 2nd 3rd 4th 5th 6th

Length

Addr Data Addr Data Addr Data Addr Data Addr Data Addr Data

From the Auto Select mode the Manufacturer

Code can be read using a Bus Read operation

with A0 = V

may be set to either V

and A1 = VIL. The other address bits

IL

or VIH. The Manufa cturer

IL

Code for STMicroelectronics is 20h.

The Device Code can be read using a B us Read

operation with A0 = V

address bits may be set to e ither V

and A1 = VIL. The other

IH

or VIH. The

IL

Device Code for the M29F512B is 24h.

Program Command. The Program command

can be used to program a value to one address in

the memory array at a time. The command requires four Bus Write operations, the final write operation latches the address and data in the internal

state machine and starts the Program/Erase Controller.

During the program operat ion the memo ry will ignore all commands. I t is n ot poss ible t o iss ue any

command to abort or pause the operation. Typical

program times are given in Table 5. Bus Read operations during the program o peration will output

the Status Register on the Data Inputs/Outputs.

See the section on the S tatus Register for more

details.

After the program operation has completed the

memory will return to the Read mode, unle ss an

error has occurred. When an error occurs the

memory will continue to output the Status Register. A Read/Reset command must be issued to reset the error condition and return to Read mode.

Note that the Program command cannot change a

bit set at ’0’ back to ’1’ and attempting to do so will

cause an error. The Chip Erase command must be

used to set all the bits in the memory from ’0’ to ’1’.

Unlock Bypass Command. The Unlock Bypass

command is used in conjunction with the Unlock

Bypass Program command to program the memory. When the access time to the device is long (as

with some EPROM programmers) considerable

time saving can be made by using these commands. Three Bus Write operations are requ ired

to issue the Unlock Bypass command.

Once the Unlock Bypas s command has bee n issued the memory will only accept the Unloc k Bypass Program command and the Unlock Bypass

Reset command. The memory can be read as if in

Read mode.

5/16

Loading...

Loading...