16 Mbit (1Mb x16) 3V Supply FlexibleROM™ Memory

FEATURES SUMMARY

■ ONE TIME PROGRAMMABLE

■ SUPPLY VOLTAGE

–V

–V

■ ACCESS TIME

– 90ns at V

– 10 0, 110ns at V

■ PROGRAMMING TIME

– 9µs per Word typical

– Multiple Word Programm ing Option

■ SUITABLE FOR ON-BOARD PROGRAMMING

■ PROGRAM CONTROLLER

– Embedded Word Program algorithms

■ ELECTRONIC SIGNATURE

– Manufacturer Code: 0020h

– Device Code : 888Dh

2.7 to 3.6V for Read

CC =

11.4 to 12.6V for Program

PP =

3.0 to 3.6V

CC =

2.7 to 3.6V

CC =

(2s typical Chip Program)

Figure 1. Packages

SO44 (M)

42

1

M27W016

TSOP48 (N)

12 x 20mm

PDIP42 (B)

42

1

SDIP42 (S)

1/26March 2003

M27W016

TABLE OF CONTENTS

FEATURES SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 1. Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Logic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 1. Signal Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3. PDIP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 4. SDIP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 5. SO Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 6. TSOP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SIGNAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Address Inputs (A0-A19). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Data Inputs/Outputs (DQ0-DQ7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Data Inputs/Outputs (DQ8-DQ15 ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chip Enable (E). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Output Enable (G). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

V

Supply Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CC

Program Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

V

PP

Vss Ground.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

BUS OPERATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Bus Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Bus Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Output Disable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Automatic Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electronic Signature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Table 2. Bus Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

COMMAND INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Read/Reset Command.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Auto Select Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Word Program Command.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Multiple Word Program Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Setup Phase.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Program Phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Verify Phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 0

Exit Phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 3. Standard Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

Table 4. Multiple Word Program Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 5. Program Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 7. Multiple Word Program Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2/26

M27W016

STATUS REGISTER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Data Polling Bit (DQ7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Toggle Bit (DQ6).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Error Bit (DQ5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

V

Status Bit (DQ4). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

PP

Multiple Word Program Bit (DQ0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Multiple Word Program Bit (DQ0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 6. Status Register Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 8. Data Polling Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 4

Figure 9. Data Toggle Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 4

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 7. Absolute Maximum Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

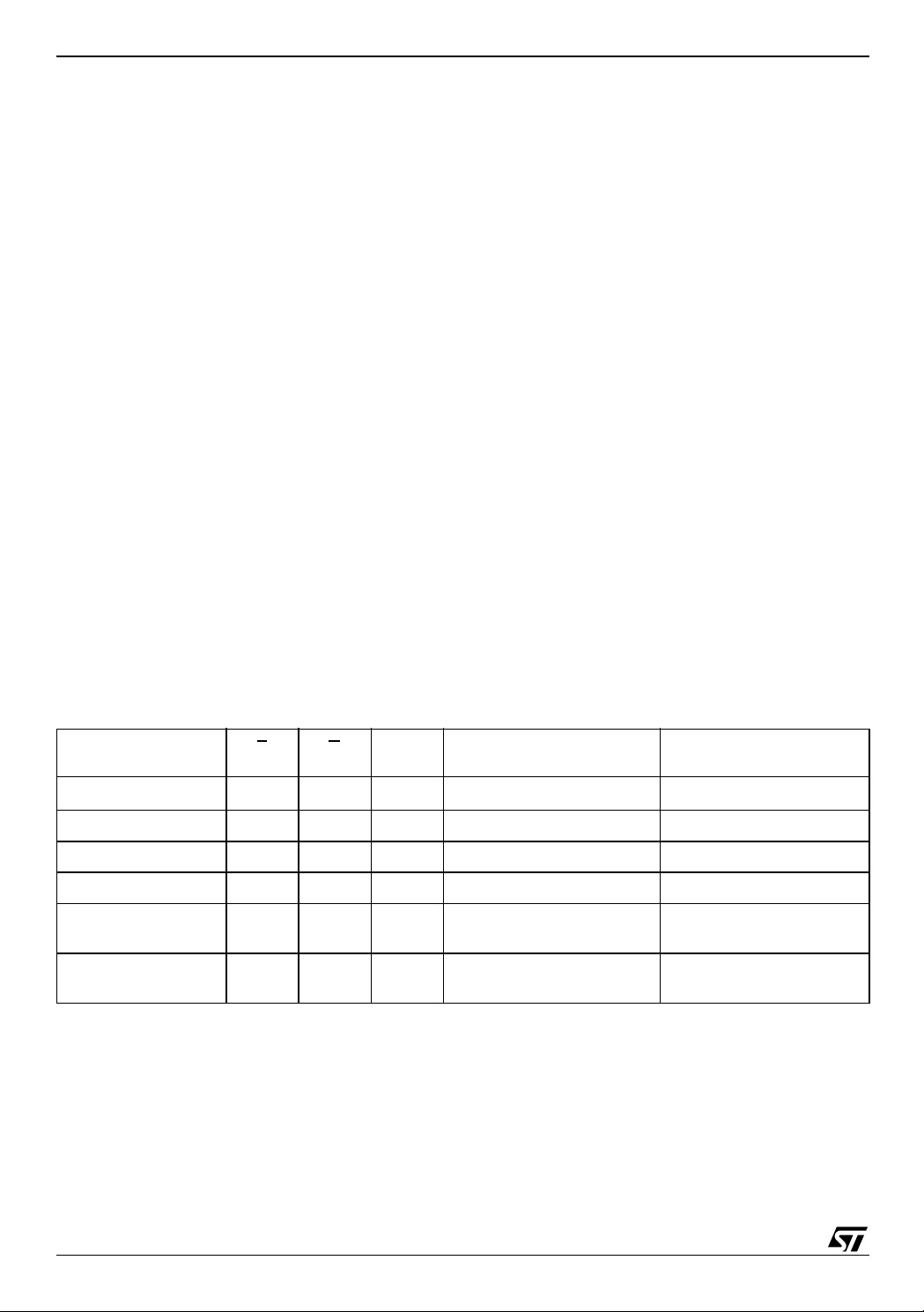

DC and AC PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 6

Table 8. Operating and AC Measurement Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

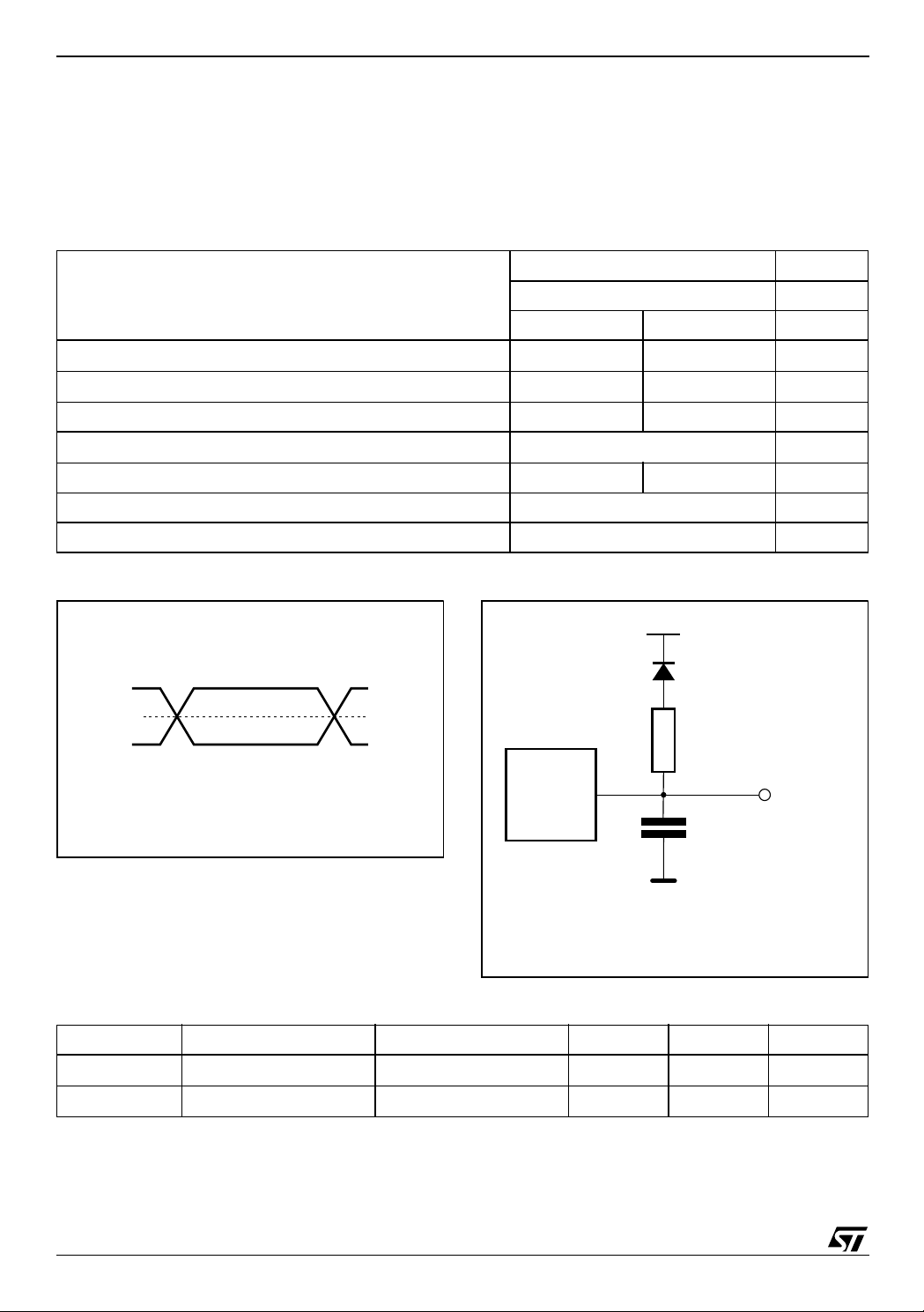

Figure 10. AC Measurement I/O Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 11. AC Measurement Load Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 9. Device Capacitance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 10. DC Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 12. Read AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 11. Read AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 13. Chip Enable Controlled, Write AC Waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 12. Chip Enable Controlled, Write AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

PACKAGE MECHANICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SO44 - 44 lead Plastic Small Outline, 500 mils body width, Package Outline . . . . . . . . . . . . . . . . 20

SO44 - 44 lead Plastic Small Outline, 500 mils body width, Package Mechanical Data . . . . . . . . . 20

TSOP48 - 48 lead Plastic Thin Small Outline, 12 x 20mm, Package Outlin e . . . . . . . . . . . . . . . . . 21

TSOP48 - 48 lead Plastic Thin Small Outline, 12 x 20mm, Package Me chanical Data . . . . . . . . . 21

PDIP42 - 42 pin Plastic DIP, 600 mils width, Bottom View Package Outline . . . . . . . . . . . . . . . . . 22

PDIP42 - 42 pin Plastic DIP, 600 mils width, Package Mechanical Data . . . . . . . . . . . . . . . . . . . . 22

SDIP42 - 42 pin Shrink Plastic DIP, 600 mils width, Package Outline . . . . . . . . . . . . . . . . . . . . . . 23

SDIP42 - 42 pin Shrink Plastic DIP, 600 mils width, Package Mechanical Data. . . . . . . . . . . . . . .23

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 17. Ordering Information Scheme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

REVISION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 18. Document Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3/26

M27W016

SUMMARY DESCRIPTION

The M27W016 is a 16 Mbit (2Mb x16) non-volatile,

One Time Programmable (OT P), FlexibleROM™

Memory. Read operations can be performed using

a single low voltage (2.7 to 3.6V) supply. Program

operations require an additional V

(11.4 to

PP

12.6V) power supply. On power-up the memory

defaults to Read mode where it can be read in the

same way as a ROM or EPROM.

Program commands are written to t he Command

Interface of the memory. An on-chip Program Controller (PC) simplifies the process of programming

the memory by taking care of all of the special operations that are required to update the memory

conte nts.

The M27W016 features an in novative command,

Multiple Word Program, used to program large

streams of data. It greatly reduces the total pro-

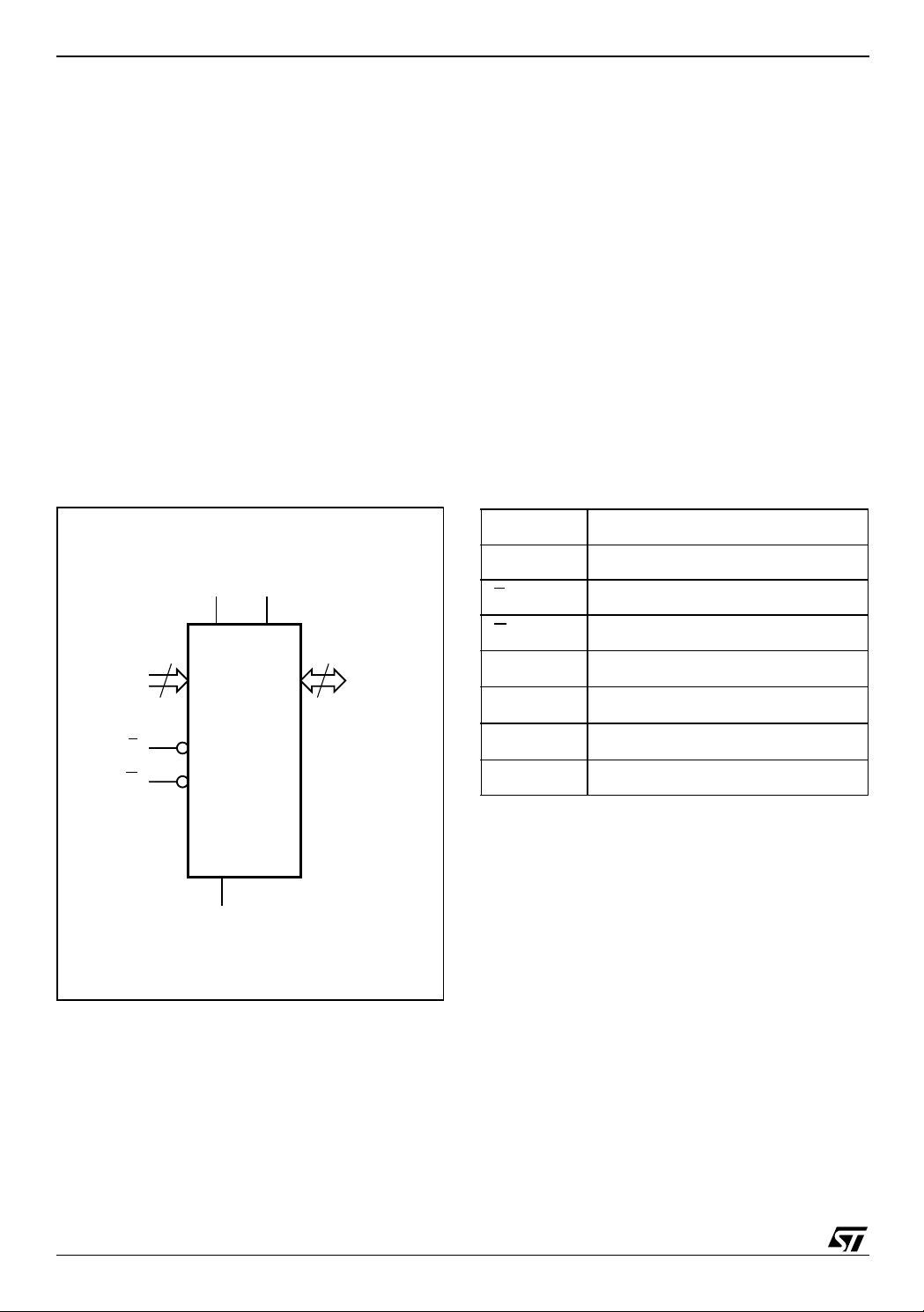

Figure 2. Logic Diagram Table 1. Signal Names

gramming time when a large number of Words are

written to the memory at any one time. Using this

command the entire memory can be program m ed

in 2s, compared to 9s using the standard Word

Progra m.

The end of a program operation can be de tected

and any error conditions identified. The command

set required to control the memory is consistent

with JEDEC standards.

Chip Enable and Output Enable signals control the

bus operation of the memory. They allo w simple

connection to most microprocessors, often without

additional logic.

The memory is offered in SO44, TSOP48 (12 x

20mm), PDIP42 and SDIP42 packages. The

memory is supplied with all the bits set to ’1’.

A0-A19 Address Inputs

V

V

20

A0-A19 DQ0-DQ15

E

G

M27W016

V

CC

SS

PP

16

AI05906

DQ0-DQ15 Data Inputs/Outputs

E

G

V

CC

V

PP

V

SS

NC Not Connected Internally

Chip Enable

Output Enable

Supply Voltage read

Supply Voltage program

Ground

4/26

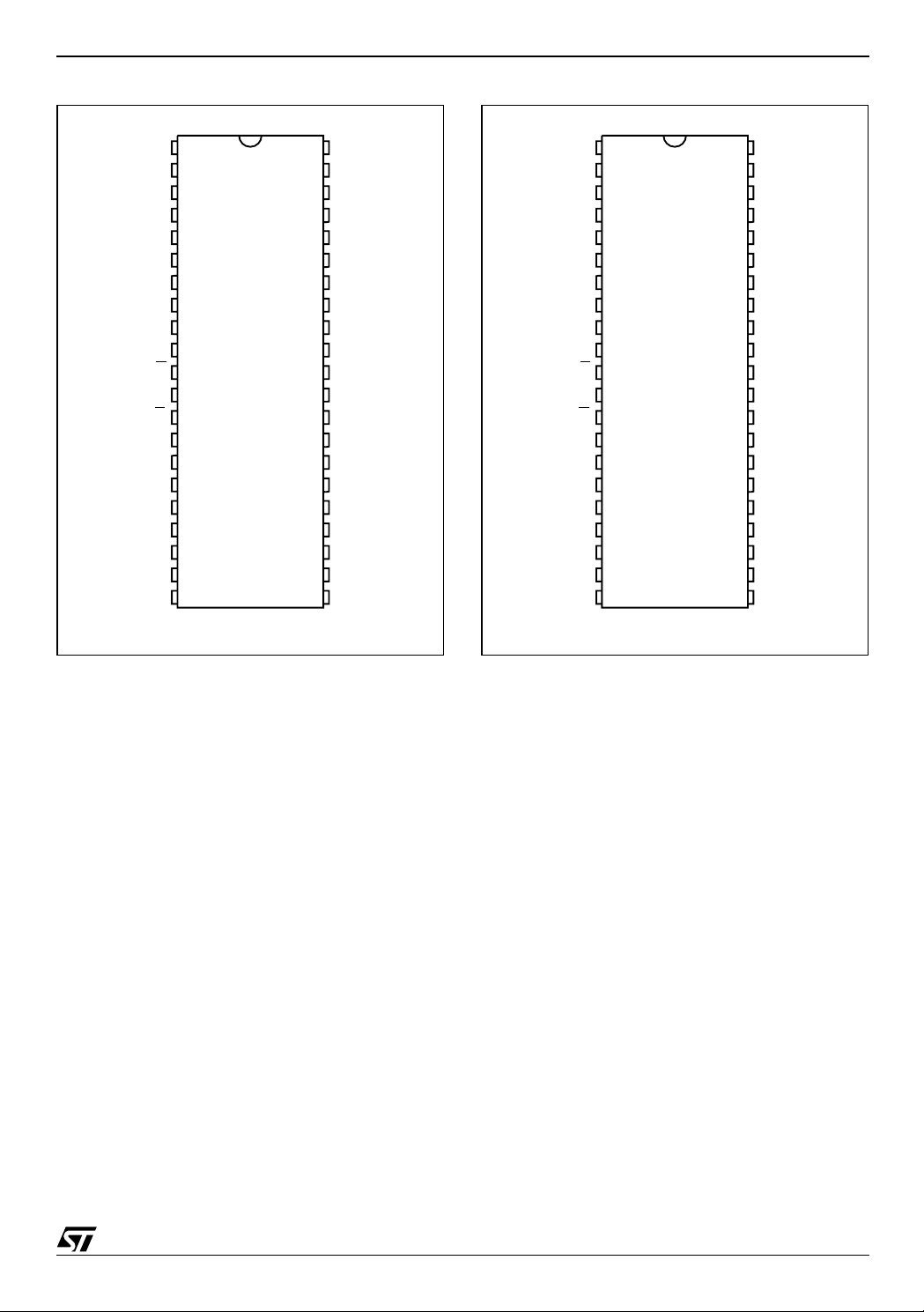

Figure 3. PDIP Connection s Figure 4. SDIP Connection s

M27W016

A18

A17

A7

A6

A5

A4

A3

A2

A1

A0

V

SS

DQ0

DQ8

DQ1

DQ9

DQ2

DQ10

DQ3

DQ11

1

2

3

4

5

6

7

8

9

10

M27W016

11

E

12

13

G

14

15

16

17

18

19

20

21

AI05907

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

A19

A8

A9

A10

A11

A12

A13

A14

A15

A16

V

PP

V

SS

DQ15

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

A18

A17

A7

A6

A5

A4

A3

A2

A1

A0

V

SS

DQ0

DQ8

DQ1

DQ9

DQ2

DQ10

DQ3

DQ11

1

2

3

4

5

6

7

8

9

10

M27W016

11

E

12

13

G

14

15

16

17

18

19

20

21

AI05907

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

A19

A8

A9

A10

A11

A12

A13

A14

A15

A16

V

PP

V

SS

DQ15

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

5/26

M27W016

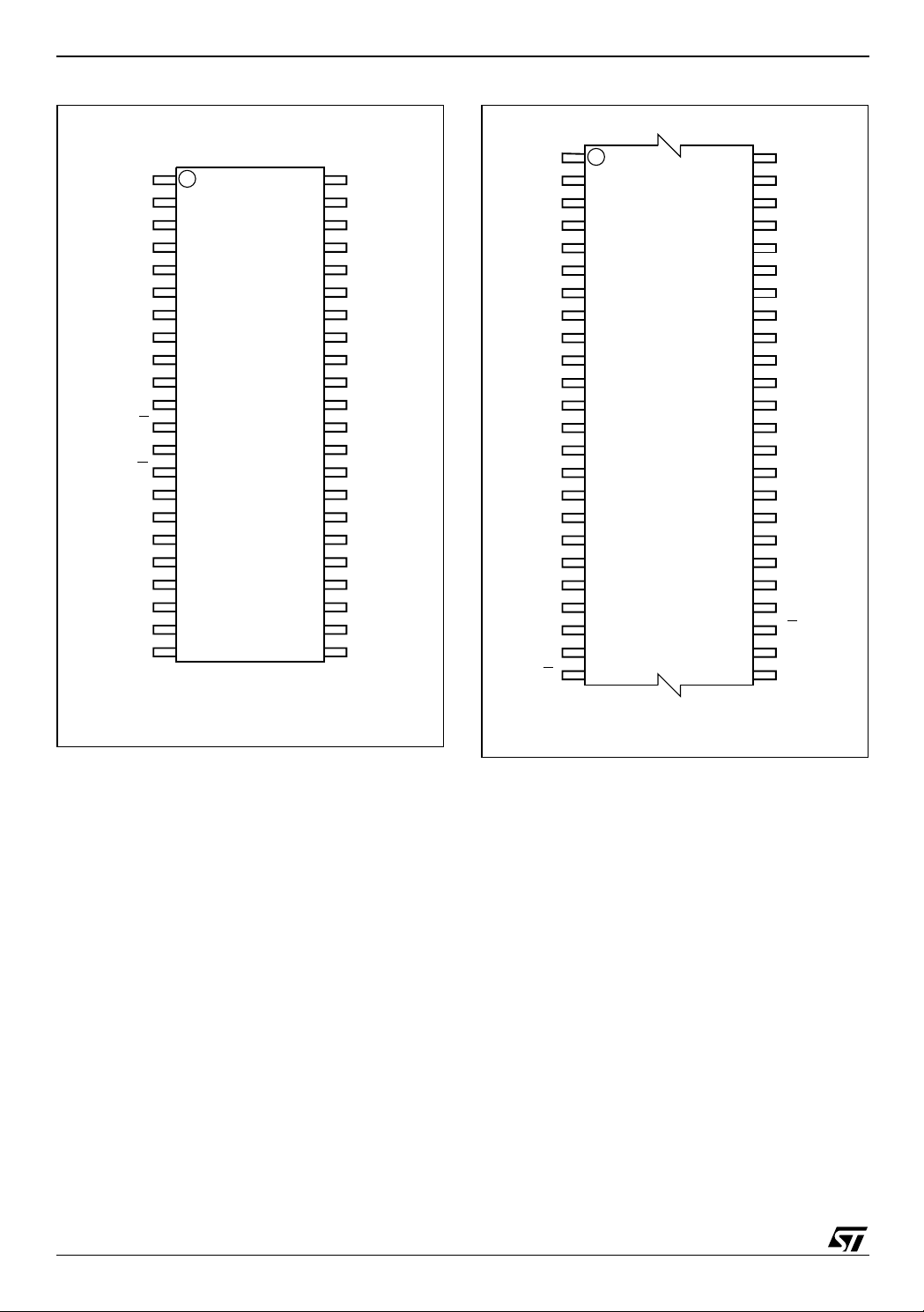

Figure 5. SO Connection s Figure 6. TSOP Connection s

NC

A18

A17 A8

A7

A6

A5

A4

A3

A2

A1

A0

V

SS

DQ0

DQ8

1

2

3

4

5

6

7

8

9

10

11

M27W016

12

E

13

14

G

15

16

17DQ1

DQ9

18

19

DQ10

DQ3

20

21

DQ11

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

2322

NC

A19

A9

A10

A11

A12

A13

A14

A15

A16

V

PP

V

SS

DQ15

DQ7

DQ14

DQ6

DQ13

DQ5DQ2

DQ12

DQ4

V

CC

AI05909

V

PP

A16

A15

A14

A13

A12

A11

A10

A9

A8

A19

V

SS

NC

A18

A17

A5

A0

A7

A6

A4

A3

A2

A1

1

12

M27W016

13

24 25

E

48

37

36

V

SS

V

SS

DQ15

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

V

CC

NC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

G

V

SS

V

SS

AI05917

6/26

SIGNAL DESCRIPTIONS

See Figure 2, Logic Diagram, and Table 1, Sign al

Names, for a brief overview of the signals connected to this device.

Address Inputs (A0-A19). The Address Inputs select the cells i n the memory array to a ccess during Bus Read operations. During Bus Write operations they control the commands sent to the Command Interface of the Program Controller.

Data Inputs/Outputs (DQ0-DQ7). The Data Inputs/Outputs output the data stored at the selected address during a Bus Read operation. During Bus Write operations they represent the command sent to the Command Interface of the Program Controller. When reading the Status Register they report the status of the ongoing algorithm.

Data Inputs/Outputs (DQ8-DQ15). The Data Inputs/Outputs output the data stored at the selected address during a Bus Read operation. During Bus Write operations the Command Interface does not use these bits. When reading t he Status Register these bits should be ignored.

Chip Enable (E

). The Chip Enable, E, activates

the memory, allowing Bus Read operat ions to be

performed. It also controls the B us Write operations, when V

Output Enable (G

is in the VHH range.

PP

). The Ou tput Enable, G, con-

trols the Bus Read operations of the memory. It

M27W016

also allows Bus Write operations, when V

the V

V

range.

HH

Supply Voltage. The VCC Supply Voltage

CC

supplies the power for Read operations.

A 0.1µF ca pacitor should be connected between

the V

Supply Voltage pin and the VSS Ground

CC

pin to decouple the current surges from the power

supply. The PCB track widths must be sufficient to

carry the currents required during program operations, I

V

PP

.

CC3

Program Supply Voltage. VPP is both a

power supply and Write Protect pin. The two functions are selected by t he voltage range a pplie d to

the pin.

When the V

is in the VHH range (see Table 10,

PP

DC Characteristic, for the relevant values) the Program operation is enabled. During such operations the V

If the V

must be stable in the VHH range.

PP

is kept under the VHH range, particularly

PP

in the voltage range 0 to 3.6V, any Program operation is disabled or stopped.

Note that V

must not be left floating o r uncon-

PP

nected as the device may become unreliable. Vss Ground. The V

Ground is the reference

SS

for all voltage measurements.

PP

is in

7/26

M27W016

BUS OPERATIONS

There are six standard bus operations that control

the device. These are Bus Read, Bus Wri te, Output Disable, Standby, Automatic Standby and

Electronic Signature. See Tables 2, Bus Operations, for a summary. Typically glitches of less

than 5ns on Chip Enable or Write Enable are ignored by the memory and do not affect bus operations.

Bus Read. Bus Read operations read from the memory cells, or specific registers in the Command Interface. A valid Bus Read operation involves setting the desired address on the Address Inputs and applying a Low signal, V able and Output Enable. The Data Inputs/Outpu ts will output the value, see Figure 12, Read AC Waveforms, and Table 11, Read AC Ch aracteristics, for details of when the output becomes valid.

Bus Write. Bus Write operations write to the Command Interface. Bus Write is enabled only when V

is set to VHH. A valid Bus W rite opera-

PP

tion begins by setting the desired addres s on the

Address Inputs. The Address Inputs are latched by

the Command Interface on the falling edge of Chip

Enable. The Data I nputs/Outputs are latched by

the Command Interface on the rising edge of Chip

Enable. Output Enable must remain High, V

during the whole Bus W rite operat ion . See Fi gure

13, Write AC Waveforms, and Table 12, Write AC

Characteristics, for details of the timing requirements.

, to Chip En-

IL

IH

Output Disa bl e . The Data Inputs/Outputs are in the high impedance s tate when Output Enable is High, V

.

IH

Standby. When Chip Enable is High, V memory enters Standby mode and the Data Inputs/Outputs pins are placed in the high-impedance state. To reduce the S upply Current to the Standby Supply Current, I be held within V

± 0.2V. For the Standby current

CC

, Chip Enable should

CC2

level see Table 10, DC Characteristics.

During program operation the mem ory will cont in-

ue to use the Program Supply Current, I

Program operation until the operation completes.

Automatic Standby. If CMOS levels (V are used to drive the bus and the bus is inactive for 150ns or more the memory enters Automatic Standby where the internal Supply Current is reduced to the Standby Supply Current, I Data Inputs/Outputs will still output data if a Bus Read operation is in progress.

Electronic Signature. The memory has two codes, the manufacturer code and the device code, that can be read to identify the memory. These codes can be read by applying t he signals listed in Tables 2, Bus Operat ions, once the A uto

,

Select Command is executed. To exit Electronic

Signature mode, the Read/Reset c ommand must

be issued.

CC3

± 0.2V)

CC

CC2

, the

IH

. The

, for

Table 2. Bus Operations

Operation E G

HH

V

IL

V

IL

V

IH

V

IL

V

IL

Bus Read

Bus Write

Output Disable X

Standby

Read Manufacturer

Code

Read Device Code

Note: 1. X = VIL or VIH.

2. XX = V

3. When reading Statu s Register during Program algori thm execution VPP must be kept at VHH.

, V

or V

IL

IH

V

IL

V

IH

V

IH

X X X Hi-Z

V

IL

V

IL

V

PP

(3)

XX

V

HH

X X Hi-Z

V

HH

V

HH

Address Inputs

A0-A19

Cell Address Data Output

Command Address Data Input

A0 = VIL, A1 = VIL,

Others VIL or V

A0 = VIH, A1 = VIL,

Others VIL or V

IH

IH

Data Inputs/Outputs

DQ15-DQ0

0020h

888Dh

8/26

COMMAND INTERFACE

All Bus Write operations t o the me mory are in terpreted by the Command Interface. Commands

consist of one or more sequential Bus Write operations. Failure to observe a valid sequence of Bus

Write operations will result in the memory returning to Read mode. The long command sequences

are imposed to maximize data security.

Refer to Tables 3 and 4, for a summary of the commands.

Read/Reset Command.

The Read/Reset command returns the memory to

its Read mode where it behaves like a ROM or

EPROM, unless otherwise stated. It also resets

the errors in the Status Register. Either one or

three Bus Write operations can be u sed to issue

the Read/Reset command.

must be set to VHH during the Read/Reset

V

PP

command. If V

is set to either V

PP

IL

or V

the com-

IH

mand will be ignored. The command can be issued, between Bus Write cycles before the start of

a program operation, to return the device to read

mode. Once the program operation has started the

Read/Reset command is no longer accepted.

Auto Select Command.

The Auto Select command is used to read the

Manufacturer Code and the Device Code. V

PP

must be set to VHH during the Auto Select command. If V

is set to either V

PP

IL

or V

the com-

IH

mand will be ignored. Three consecutive Bus

Write operations are required to issue the Auto Select command. Once the Auto Select command is

issued the memory remai ns in Auto Select m ode

until a Read/Reset com mand is issued, all other

commands are ignored.

From the Auto Select mode the Manufacturer

Code can be read using a Bus Read operation

with A0 = VIL and A1 = VIL. The other address bits

may be set to either V

or VIH.

IL

The Device Code can be read using a B us Read

operation with A0 = V

address bits may be set to either V

and A1 = VIL. The other

IH

or VIH.

IL

Word Progr a m Com m a n d.

The Word Program command can be used to program a Word to the memory array. V

set to V

ther V

during Word Program. If VPP is set to ei-

HH

or VIH the command will be ignored, the

IL

must be

PP

data will remain unchanged and the device will revert to Read/Reset mode. The command requires

four Bus Write operations, the final write operation

latches the address and data in the internal state

machine and starts the PC.

During the program operat ion the memo ry will ignore all commands. I t is n ot poss ible t o iss ue any

command to abort or pause the operation. Typical

program times are given in Table 5. Bus Read op-

M27W016

erations during the program o peration will output

the Status Register on the Data Inputs/Outputs.

See the section on the S tatus Register for more

details.

After the program operation has completed the

memory will return to the Read mode, unle ss an

error has occurred. When an error occurs the

memory will continue to output the Status Register. A Read/Reset command must be issued to reset the error condition and return to Read mode.

Note that the Program command cannot change a

bit set at ’0’ back to ’1’.

Multiple Word Program Command

The Multiple Word Program command can be

used to program large streams of data. It greatly

reduces the total programming time when a l arge

number of Words are written in the memory at

once. V

Program. If V

mand will be ignored, the data will remain unchanged and the device will revert to Read mode.

It has four phases: the Setup P hase to initiate the

command, the Program Phase to program the

data to the memory, the Verify Phase to check that

the data has been correctly programmed and reprogram if necessary and the Exit Phase.

Setup Phase. The M ultiple Word Program command requires three Bus Write operations to initiate the command (refer to Table 4, Multiple Word Program Command and Figure 8, Multiple Word Program Flowchart).

The Status Register must be read in order to

check that the PC has started (see Table 6 and

Figure 8).

Program Phase. The Program Phase requires n+1 Bus Write operations, where n is the num ber of Words, to execute t he program mi ng p has e (refer to Table 4, Multiple Word Program and Figure 7, Multiple Word Program Flowchart).

Before any Bus Write operation of the Program

Phase, the Status Register m ust be read i n order

to check that the PC is ready to accept the operation (see Table 6 and Figure 8).

The Program Phase is executed in three different

sub-phases:

1. The first Bus Write operation of the Program

Phase (the 4th of the command) latches the

Start Address and the first Word to be

programmed.

2. Each subs equent Bus Write operation latches

the next Word to be programmed and

automatically increments the internal Address

Bus. It is not necessary to provide the address

of the location to be programmed but only a

Continue Address, CA (A17 to A19 equal to the

must be set to VHH during Multiple Word

PP

is set either VIL or VIH the com-

PP

9/26

M27W016

Start Address), that indicates to the PC that the

Program Phase has to continue. A0 to A16 are

‘don’t car e’.

3. Finally, after all Words have been programmed,

a Bus Write operation (the (n+1)

th

) with a Final

Address, FA (A17 or a higher address pin

different from the Start Address), ends the

Program Phase.

The memory is now set to enter the Verify Phase. Verify Phase. Th e Verify Phase is s imilar to the

Program Phase in that all Words must be resent to

the memory for them to be che cked against the

programmed data.

Before any Bus Write Operation of the Verify

Phase, the Status Register m ust be read i n order

to check that the PC is ready for the next operation

or if the reprogram of the location has failed (see

Table 6 and Figure 8).

Three successive steps are required to execute

the Verify Phase of the command:

1. The first Bus Write operation of the Verify Phase

latches the Start A ddress and the Word t o be

verified.

2. Each subs equent Bus Write operation latches

the next Word to be verified and automatically

increments the internal Address Bus. As in the

Program Phase, it is not necessary to provide

the address of the location to be program med

but only a Continue Address, CA (A17 to A 19

equal to the Start Address).

3. Finally, after all Words have been verified, a Bus

Write cycle with a Final Address, FA (A17 or a

higher address pin different from the Start

Address) ends the Verify Phase.

Exit Phase. After the Verify Phase ends, the Status Register must be read to check if the command has successfully completed or not (see Table 6 and Figure 8).

If the Verify Phase is suc cessful, the memory returns to Read mode and DQ6 stops toggling.

If the PC fails to reprogram a given location, the

Verify Phase terminates, DQ6 continues toggl ing

and error bit DQ5 is set in the Statu s Register. If

the error is due to a V

failure DQ4 is also set.

PP

When the operation fails a Read/Reset command

must be issued to return the device to Read mode.

During the Multiple Word Program operation the

memory will ignore all commands. It is not possible

to issue any command to abort or pause the operation. Typical program times are give n in T able 5.

Bus Read operations during the program operati on will output the Status Register on the Data Inputs/Outputs. See the section on the Status

Register for more details.

Note that the Multiple Word Program command

cannot change a bit set to ’0’ back to ’1’.

10/26

Table 3. Standard Commands

M27W016

Bus Write Operations

Command

Length

1st 2nd 3rd 4th

Add Data Add Data Add Data Add Data

1X F0

Read/Reset

3 555 AA 2AA 55 X F0

Auto Select 3 555 AA 2AA 55 555 90

Word Program 4 555 AA 2AA 55 555 A0 PA PD

Note: X Don’t Care, PA Program Address, PD Program Data. All values in the table are in hexadecimal. The Command Interface only uses

A0-A10 and DQ0-DQ7 to verify the commands; A11-A19, DQ8-D Q 15 are Don’t Care.

Table 4. Multiple Word Program Command

Bus Write Operations

Phase

Length

1st 2nd 3rd 4th 5th nth Final

Add Data Add Data Add Data Add Data Add Data Add Data Add Data

Set-Up 3 555 AA 2AA 55 555 20

Program n+1 SA PD1 CA PD2 CA PD3 CA PD4 CA PD5 CA PAn FA X

Verify n+1 SA PD1 CA PD2 CA PD3 CA PD4 CA PD5 CA PAn FA X

Note: A Bus Read must be done between each Write cycle where the data is programmed or verified, to Read the Status Register and check

that the memory is ready to accept the next data. SA is the Start Address. CA is the Continue Address. FA is the Final Address. X Don’t

Care, n = number of Words to be programmed.

Tabl e 5. Program Time s

Parameter

Typ

(1)

Max U nit

Program (Word) 9 200 µs

Chip Program (Multiple Word) 2 35 s

Chip Program (Word by Word) 9 35 s

Note: 1. TA = 25°C, VPP = 12V.

11/26

M27W016

Figure 7. Mul ti pl e W or d Program Fl owchart

Setup

Phase

NO

Setup time

exceeded?

EXIT (

Program

Phase

YES

setup failed)

Start

Write AAh

Address 555h

Write 55h

Address 2AAh

Write 20h

Address 555h

Read Status

Register

NO

DQ6

toggling?

YES

NO

DQ0 = 0?

YES

Write Data1

Start Address

Read Status

Register

DQ0 = 0?

YES

Write Data 2

Continue Address

Read Status

Register

DQ0 = 0?

Write Data n

Continue Address

Read Status

Register

DQ0 = 0?

YES

Write XX

Final Address

YES

NO

NO

NO

Read Status

Register

DQ0 = 0?

Write Data1

Start Address

Read Status

Register

DQ0 = 0?

YES

Write Data 2

Continue Address

Read Status

Register

DQ0 = 0?

YES

Write Data n

Continue Address

Read Status

Register

DQ0 = 0?

YES

Write XX

Final Address

Read Status

Register

DQ6

toggling?

NO

NO

NO

DQ5 = 1 ?

NO

DQ5 = 1?

NO

YES

DQ5 = 1?

Fail error

Exit (read mode)

Verify

Phase

NO

NO

NO

YES

YES

YES

YES

Read Status

Register

DQ4 = 0?

Write F0h

Address XX

Exit

Phase

NO

Fail, VPP error

12/26

AI05954b

STATUS REGISTER

Bus Read operations from any address always

read the Status Register during Program operations. The bits in the Status Regi ster are summ arized in Table 6, Status Register Bits.

Data Polling Bit (DQ7). The Data Polling Bit can be used to identify whether the Program Controller has successfully completed its operation. The Data Polling Bit is output on DQ7 when the Status Register is read.

During a Word Program operation the Data Polling

Bit outputs the complement of the bit being programmed to DQ7. After successful completion of

the Word Program ope ration the memory ret urns

to Read mode and Bus Read operations from the

address just programmed output DQ7, not its complement.

Figure 8, Data Polling Flowchart, gives an example of how to use the Data Polling Bit. A Valid Address is the address being programmed.

Toggle Bit (DQ6). The Toggle Bit can be used to identify whether the Program Con troller has successfully completed its operation. The Toggle Bit is output on DQ6 when the Status Register is read.

During Program operations the Toggle Bit changes from ’0’ to ’1’ to ’0’, etc., with successive Bus

Read operations at any address. After successful

completion of the operation the memory returns to

Read mode.

M27W016

Figure 9, Data Toggle Flowchart, g ives an example of how to use the Data Toggle Bit.

Error Bit (DQ5). The Error Bit can be used to identify errors detected by the Program Controller. The Error Bit is set to ’1’ when a Program operation fails to write the correct data to the memory. If the Error Bit is set a Re ad/Reset command m ust be issued before other commands are issued. The Error bit is output on DQ5 when the Status Register is read.

Note that the Program command cannot change a

bit set to ’0’ back to ’1’ and attempting to do so will

set DQ5 to ‘1’. A Bus Read operation to that address will show the bit is still ‘0’.

Status Bit (DQ4). The VPP Status Bit can be

V

PP

used to identify if any Program operation has failed

due to a V

any Program operation, the operation a borts and

DQ4 is set to ‘1’. If V

the Program operation, the operation completes

and DQ4 is set to ‘0’.

Multiple Word Program Bit (DQ0). The Multiple

Word Program Bit can be used to indicate whether

the Program Controller is active or inactive during

Multiple Word Program. When the P rogram Controller has written one Word and is ready to accept

the next Word, the bit is set to ‘0’.

Status Register Bit DQ1 is reserved.

error. If V

PP

falls below VHH during

PP

remains at V

PP

throughout

HH

13/26

M27W016

Table 6. Status Register Bits

Command

(1)

P.C. Status DQ7 DQ6 DQ5 DQ4 DQ3 DQ0

Programming – Toggle 0 – 0 1

Multiple Word Program

Word Program

Note: 1. Unspecified data bits shou l d be ignored.

2. DQ4 = 0 if V

≥ VHH during Pr ogram algori t hm executi on; DQ4 = 1 if VPP < VHH during Progr am al gorithm execution.

PP

Waiting for data – Toggle 0 – 0 0

Program fail – Toggle 1

Programming DQ7

Program error DQ7

Toggle 0 – 0 –

Toggle 1

(2)

(2)

Figure 8. Dat a Po ll i ng Fl o wc h a rt Figure 9. Dat a Toggle Flow c hart

DQ5 & DQ6

READ DQ6

TOGGLE

NO

READ DQ6

TOGGLE

START

READ

DQ6

=

DQ5

= 1

TWICE

DQ6

=

NO

YES

YES

NO

YES

START

READ DQ5 & DQ7

at VALID ADDRESS

DQ7

YES

=

DATA

NO

NO

DQ5

= 1

YES

READ DQ7

at VALID ADDRESS

DQ7

YES

=

DATA

NO

FAIL PASS

01

0–

14/26

AI03598

FAIL PASS

AI01370B

MAXIMUM RATI N G

Stressing the device ab ove the rating listed in t he

Absolute Maximum Ratings" table may cause permanent damage to the device. Exposure to Absolute Maximum Rating conditions for extended

periods may affect device reliability. These are

these or any other conditions above those indicated in the Operating sections of this specification is

not implied. Refer also to the STMicroelectronics

SURE Program and ot her relevant quality documents.

stress ratings only and operation of the dev ice at

Table 7. Absolute Maximum Ratings

Symbol Parameter Min Max Unit

T

BIAS

T

STG

V

IO

V

CC

V

PP

Note: 1. Minimum vol tage may un dershoot t o –2V for less than 20ns duri ng transitions.

2. Maximum voltage may overshoot to V

3. Maximum voltage m ay oversh oot to 14.0V for less t han 20ns during transitions. V

of 80hrs.

Temperature Under Bias –50 125 °C

Storage Temperature –65 150 °C

Input or Output Voltage

(1,2)

–0.6

V

+0.6

CC

Read Supply Voltage –0.6 4 V

Program Supply Voltage

CC

(3)

+2V for less than 20ns during transitions.

–0.6 13.5 V

must not remain at VHH for more than a total

PP

M27W016

V

15/26

M27W016

DC AND AC PARAMETERS

This section summarizes t he operating m easurement conditions, and the DC and AC characteristics of the device. The parameters in the DC and

AC characteristics Tables that follow, are derived

from tests performed under the Measurement

Table 8. Operating and AC Measurement Conditions

Conditions summarized in Table 8, Operating and

AC Measurement Conditions. Designers should

check that the operating cond itions in their circuit

match the operating conditions when relying on

the quoted parameters.

M27W016 Unit

Parameter

100, 110

Min Max

V

Read Supply Voltage

CC

Program Supply Voltage

V

PP

2.7 3.6 V

11.4 12.6 V

Ambient Operating Temperature 0 70 °C

Load Capacitance (C

)

L

30 pF

Input Rise and Fall Times 10 ns

Input Pulse Voltages 0 to 3 V

Input and Output Timing Ref. Voltages 1.5 V

Figure 10. AC Measurem ent I/O W av eform Figure 11. AC Me a surement Lo a d Circuit

1.3V

3V

0V

1.5V

AI05546

DEVICE

UNDER

TEST

1N914

3.3kΩ

OUT

CL

CL = 30pF

CL includes JIG capacitance

Table 9. Device Capacitance

Symbol Parameter Test Condition Min Max Unit

C

IN

C

OUT

Note: Sampled only, not 100% tested.

Input Capacitance

Output Capacitance

16/26

V

V

OUT

IN

= 0V

= 0V

6pF

12 pF

AI05447

Table 10. DC Characteristics

Symbol

Parameter

(1)

M27W016

Test Condition Min Max Unit

0V ≤ V

I

OUT

0V ≤ V

E

E

I

I

LI

I

LO

I

CC1

I

CC2

I

CC3

V

IL

V

IH

V

OL

V

OH

V

HH

I

HH

Note: 1. VCC must be ap pl i ed simultaneously or before VPP and removed simult aneously or after VPP.

2. Average Va l ue.

Input Leakage Current

Output Leakage Current

Supply Current (Read)

(2)

Supply Current (Standby)

Supply Current (Program) PC active 20 mA

Input Low Voltage –0.5 0.8 V

Input High Voltage

Output Low Voltage

Output High Voltage

V

Program Voltage

PP

VPP Current (Program)

≤ V

IN

CC

≤ V

OUT

CC

= VIL, G = VIH,

= 0mA, f = 6MHz

= VCC ±0.2V

0.7V

I

= 1.8mA

OL

= –100µA

OH

V

CC

PC Active 10 mA

±1

µA

±1 µA

10 mA

CC

100

VCC +0.3

µA

0.45 V

–0.4

11.4 12.6 V

V

V

17/26

M27W016

Figure 12. Read AC Waveforms

A0-A19

tAVQV tAXQX

E

tELQV

G

DQ0-DQ15

VALID

tGLQV

Table 11. Read AC Characteristics

Symbol Alt

t

AVQVtACC

t

ELQVtCE

t

GLQVtOE

(2)

t

EHQZ

t

GHQZ

t

AXQXtOH

Note: 1. VPP must be applied after VCC and with the Chip Enable (E) at VIH.

t

HZ

(2)

t

DF

2. Sampled only, not 100% tested.

Parameter

Address Valid to

Output Valid

Chip Enable Low to

Output Valid

Output Enable Low to

Output Valid

Chip Enable High to

Output Hi-Z

Output Enable High to

Output Hi-Z

Address Transition to

Output Transition

(1)

T est Condition

= VIL,

E

G = V

= V

G

= V

E

= V

G

= V

E

Max 90 100 110 ns

IL

Max 90 100 110 ns

IL

Max353535ns

IL

Max303030ns

IL

Max303030ns

IL

Min 0 0 0 ns

VCC= 3.0 to 3.6V VCC = 2.7 to 3.6V VCC = 2.7 to 3.6V

tEHQZ

tGHQZ

VALID

AI05812

M27W016

Unit100 110

18/26

Figure 13. Chip Enable Controlled, Write AC Waveforms

M27W016

A0-A19

G

E

DQ0-DQ15

V

CC

V

PP

tAVEL

tVCHEL

tVPHEL

VALID

tELEHtGHEL

VALID

Table 12. Chip Enable Controlled, Write AC Characteristics

Symbol Alt

t

ELEH

t

DVEH

t

EHDX

t

EHEL

t

AVEL

t

ELAX

t

GHEL

t

EHGL

t

VCHEL

(2)

t

VPHEL

Note: 1. TA = 25°C; VPP = 11.4 to 12.6V. VCC = 2.7 to 3. 6V.

V

PP

Sampled only, not 100% tested.

2. Not requir ed i n Auto Selec t or Read/R eset comm and sequen ces.

t

t

t

t

CPH

t

t

Chip Enable Low to Chip Enable High Min 50 ns

CP

Input Valid to Chip Enable High Min 50 ns

DS

Chip Enable High to Input Transition Min 0 ns

DH

Chip Enable High to Chip Enable Low Min 50 ns

Address Valid to Chip Enable Low Min 0 ns

AS

Chip Enable Low to Address Transition Min 100 ns

AH

Output Enable High Chip Enable Low Min 10 ns

t

OEH

t

VCS

t

VCS

must be applied after VCC and with the Chip Enable (E) at VIH.

Chip Enable High to Output Enable Low Min 10 ns

VCC High to Chip Enable Low

VPP High to Chip Enable Low

Parameter

(1)

tELAX

tEHGL

tEHEL

tEHDXtDVEH

AI05583

M27W016 Unit

Min 50 µs

Min 500 ns

19/26

M27W016

PACKAGE MECHANICAL

Figure 14. SO44 - 44 lead Plastic Small Outline, 500 mils body width, Package Outline

D

44

23

c

E1

E

θ

1 22

LA1

A2

A

L1

ddd

b

e

SO-F

Note: Drawing is not to scale.

Table 13. SO44 - 44 lead Plastic Small Outline, 500 mils body width, Package Mechan ical Data

Symbol

Typ Min Max Typ Min Max

A 3.00 0.118

A1 0.10 0.004

millimeters inches

A2 2.69 2.56 2.79 0.1 06 0.101 0.110

b 0.35 0.50 0.014 0.020

c 0.18 0.28 0.007 0.011

D 28.50 28.37 28.63 1.122 1.117 1.127

ddd 0.10 0 .004

E 16.03 15.77 16.28 0.631 0.621 0.641

E1 12.60 12.47 12.73 0.4 96 0.491 0.501

e 1.27 – – 0.050 – –

L 0.79 0.031

L1 1.73 0.0 68

θ 8° 8°

N44 44

20/26

Figure 15. TSOP48 - 48 lead Plastic Thin Small Outline, 12 x 20mm, Package Outline

A2

1 N

e

E

B

N/2

M27W016

D1

D

DIE

A

CP

C

TSOP-a

Note: Drawing is not to scale.

LA1 α

Table 14. TSOP48 - 48 lead Plastic Thin Small Outline, 12 x 20mm, Package Mechanical Data

Symbol

Typ Min Max Typ Min Max

A 1.20 0.0472

A1 0.05 0.15 0.0020 0.0059

A2 0.95 1.05 0.0374 0.0413

B 0.17 0.27 0.0067 0.0106

C 0.10 0.21 0.0039 0 .0083

CP 0.10 0.0039

millimeters inches

D 19.80 20.20 0.7795 0 .7953

D1 18.30 18.50 0.7205 0.7283

E 11.90 12.10 0.4685 0.4764

e 0.50 – – 0.0197 – –

L 0.50 0.70 0.0197 0.0276

α 0° 5° 0° 5°

N48 48

21/26

M27W016

Figure 16. PDIP42 - 42 pin Plastic DIP, 600 mils width, Bottom View Package Outline

A2

A1AL

B1 B e1

D2

α

C

eA

eB

D

S

N

E1 E

1

Note: Drawing is not to scale.

PDIP

Table 15. PDIP42 - 42 pin Plastic DIP, 600 mils width, Package Mechanical Data

Symbol

Typ Min Max Typ Min Max

A – 5.08 – 0.200

A1 0.25 – 0. 010 –

A2 3.56 4.06 0.140 0.160

B 0.38 0.53 0. 015 0.021

B1 1.27 1.65 0.050 0.065

C 0.20 0.36 0.008 0.014

D 52.20 52.71 2.055 2.075

D2 50.80 – – 2.000 – –

E 15.24 – – 0.600 – –

E1 13.59 13.84 0.535 0.545

e1 2.54 – – 0.100 – –

eA 14.99 – – 0.590 – –

eB 15.24 17.78 0.600 0.700

L 3.18 3.43 0.125 0 .135

S 0.86 1.37 0. 034 0.054

α 0° 10° 0° 10°

N42 42

millimeters inches

22/26

Figure 17. SDIP42 - 42 pin Shrink Plastic DIP, 600 mils width, Package Outline

A2

A1AL

M27W016

b2 b e

D2

c

eA

eB

D

S

N

E1 E

1

Note: Drawing is not to scale.

SDIP

Table 16. SDIP42 - 42 pin Shrink Plastic DIP, 600 mils width, Package M echa nical Data

Symbol

Typ Min Max Typ Min Max

A 5.08 0 .200

A1 0.51 0.020

A2 3.81 3.05 4.57 0.1 50 0.120 0.180

millimeters inches

b 0.46 0.38 0.56 0.018 0.015 0.022

b2 1.02 0.89 1.14 0.0 40 0.035 0.045

c 0.25 0.23 0.38 0.010 0.009 0.015

D 36.83 36.58 37.08 1.450 1.440 1.460

e 1.78 – – 0.070 – –

E 15.24 16.00 0.600 0.630

E1 13.72 12.70 14.48 0.5 40 0.500 0.570

eA 15.24 – – 0.600 – –

eB 18.54 0.730

L 3.30 2.54 3.56 0.130 0.100 0.140

S 0.64 0.025

N42 42

23/26

M27W016

PART NUMBERING

Table 17. Ordering Information Scheme

Example: M27W016 100 N 1 T

Device Type

M27 = FlexibleROM™ Memory

Operating Voltage

W = V

Device Function

016 = 16 Mbit (x16)

Speed

100 = 100 ns

110 = 110 ns

Package

M = SO44, 500mils body width

N = TSOP48: 12 x 20 mm

B = PDIP42

S = SDIP42

= 2.7 to 3.6V

CC

(1)

Temperature Rang e

1 = 0 to 70 °C

Option

T = Tape & Reel Packing

Note: 1. This speed als o guarantees 90ns acc ess time at VCC = 3.0 to 3.6V.

Devices are shipped from the factory with all the bits set to ’1’.

For a list of available options (Speed, Pac kage, etc...) or for furthe r information on any aspect of this de-

vice, please contact the ST Sales Office nearest to you.

24/26

REVISION HIST ORY

Table 18. Document Revision History

Date Version Revision Details

28-Jan-2002 1.0 First Issue

Output Enable paragraph clarified

Electronic Signature paragraph clarified

Multiple Word Command paragraph clarified (Paragraph rewritten, Table 4, Figure 7)

15-May-2002 2.0

17-Jun-2002 3.0

Status Register Bits table clarified (Table 6)

SO44 package mechanical data and drawing clarified (Figure 14, Table 13)

PLCC44 package removed

Document status changed to Product Preview

Device classification changed to Fast OTP

Program Phase and Verify Phase paragraphs clarified

Standard Commands table clarified (Table 3)

Multiple Word Program Command table and Flowchart clarified (Table 4, Figure 7)

AC Measurement Load Circuit clarified (Figure 11)

Read AC parameters clarified (Figure 12, Table 11)

Chip Enable Controlled, Write AC parameters clarified (Figure 13, Table 12)

M27W016

28-Jun-2002 4.0

09-Jul-2002 5.0

31-Jul-2002 5.1

Document status changed to Preliminary Data

Document title clarified

100ns speed class added (90ns at V

= 3.0 to 3.6V)

CC

Product Name changed

Multiple Word Program Command Table clarified (Table 4)

I

, I

CC1

clarified (Table 10)

CC2

27-Sep-2002 5.2 Product Naming revised

Document status changed to Datasheet

OTP specification added

14-Nov-2002 5.3

SO44 package changed to 500mils body width

Bus Operation table clarified (Table 2)

Read/Reset , Auto Select and Multiple Word Program commands clarified

29-Nov-2002 5.4

90ns speed class obtained from the 100ns at V

and 12)

20-Feb-2003 5.5 T SOP Conn ection s diagram updat ed (Figure 6)

05-Mar-2003 5.6 Typing error on page 1 corrected

= 3.0 to 3.6V - clarifiication (T able 11

CC

25/26

M27W016

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the cons equences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or o therwise under any patent or patent rights of STMicroelectron i cs. Speci fications mentioned i n this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as c ri t i cal components in life support dev i ces or systems wi thout exp ress written approval of STMicroel ectronics.

The ST log o i s a registered tradema rk of STMicroelectronics

FlexibleR O M i s a pending trademark of S T M i croelectronics

All other nam es are the property of th ei r respect ive owners

© 2003 STMicroelectronics - All Rights Reserved

Australi a - Brazil - Canada - China - Finland - F rance - Germany - Hong Kong - India - Is rael - Italy - Japan - Malaysia - Malta -

Morocc o - Singapor e - Spain - Sweden - Switz erl and - Unit ed Kingdom - United States

STMicroelectron ics GROUP OF COMPANIES

www.st.com

26/26

Loading...

Loading...