SGS Thomson Microelectronics M24C04-DW6T, M24C04-BN6, M24C04, M24C02-W, M24C02-RMN6T Datasheet

...

1/20May 2000

M24C16, M24C08

M24C04, M24C02, M24C01

16/8/4/2/1 Kbit Serial I²C Bus EEPROM

■ Two Wire I

2

C Serial Interface

Supports 400 kHz Protocol

■ Single Supply Voltage:

– 4.5V to 5.5V for M24Cxx

– 2.5V to 5.5V for M24Cxx-W

– 1.8V to 3.6V for M24Cxx-R

■ Hardware Write Control

■ BYTE and PAGE WRITE (up to 16 Bytes)

■ RANDOM and SEQUENTIAL READ Modes

■ Self-Tim ed P ro g ra m ming Cycle

■ Automatic Address Incrementing

■ Enhanced ESD/Latch-Up Behavior

■ 1 Million Erase/Write Cycles (minimum)

■ 40 Year Data Retention (minimum)

DESCRIPTION

These I

2

C-compatible electrically erasable

programmable memory (EEPROM) devices are

organized as 2048/1024/512/256/128 x 8 bit

(M24C16, M24C08, M24C04, M24C02, M24C01),

and operate with a power supply down to 2.5 V (for

the -W version of each device), and down to 1.8 V

(for the -R version of each device).

The M24C16, M24C08, M24C04, M24C02,

M24C01 are available in Plastic Dual-in-Line,

Plastic Small Outline and Thin Shrink Small

Outline packages. The M24C16-R is also

available in a chip-scale (SBGA) package.

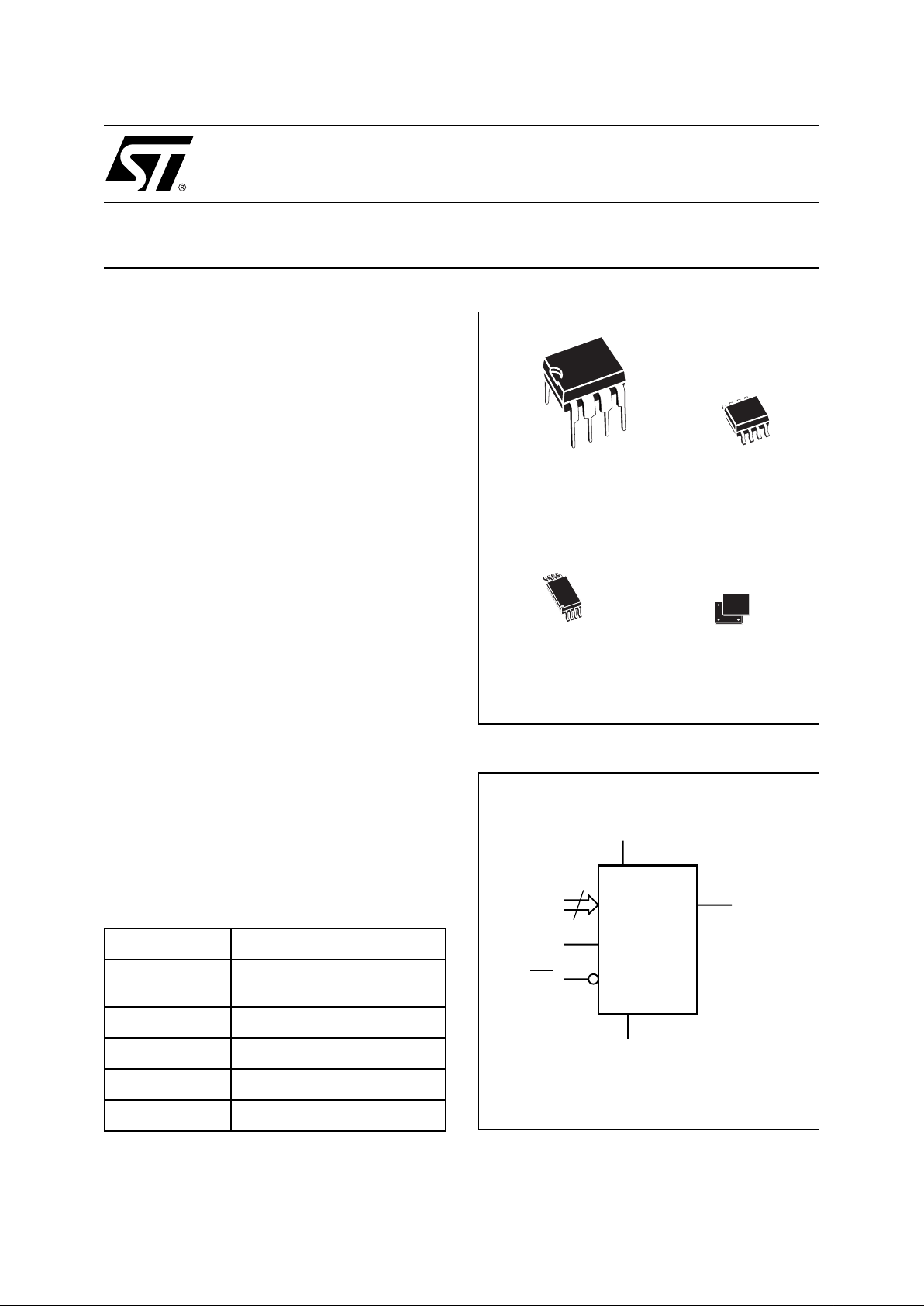

Figure 1. Logic Diagram

AI02033

3

E0-E2 SDA

V

CC

M24Cxx

WC

SCL

V

SS

Table 1. Signal Names

E0, E1, E2 Chip Enable Inputs

SDA Serial Data/Address Input/

Output

SCL Serial Clock

WC Write Control

V

CC

Supply Voltage

V

SS

Ground

PSDIP8 (BN)

0.25 mm frame

SO8 (MN)

150 mil width

TSSOP8 (DW)

169 mil width

8

1

8

1

8

1

SBGA

SBGA5 (EA)

75 mil width

M24C16, M24C08, M24C04, M24C02, M24C01

2/20

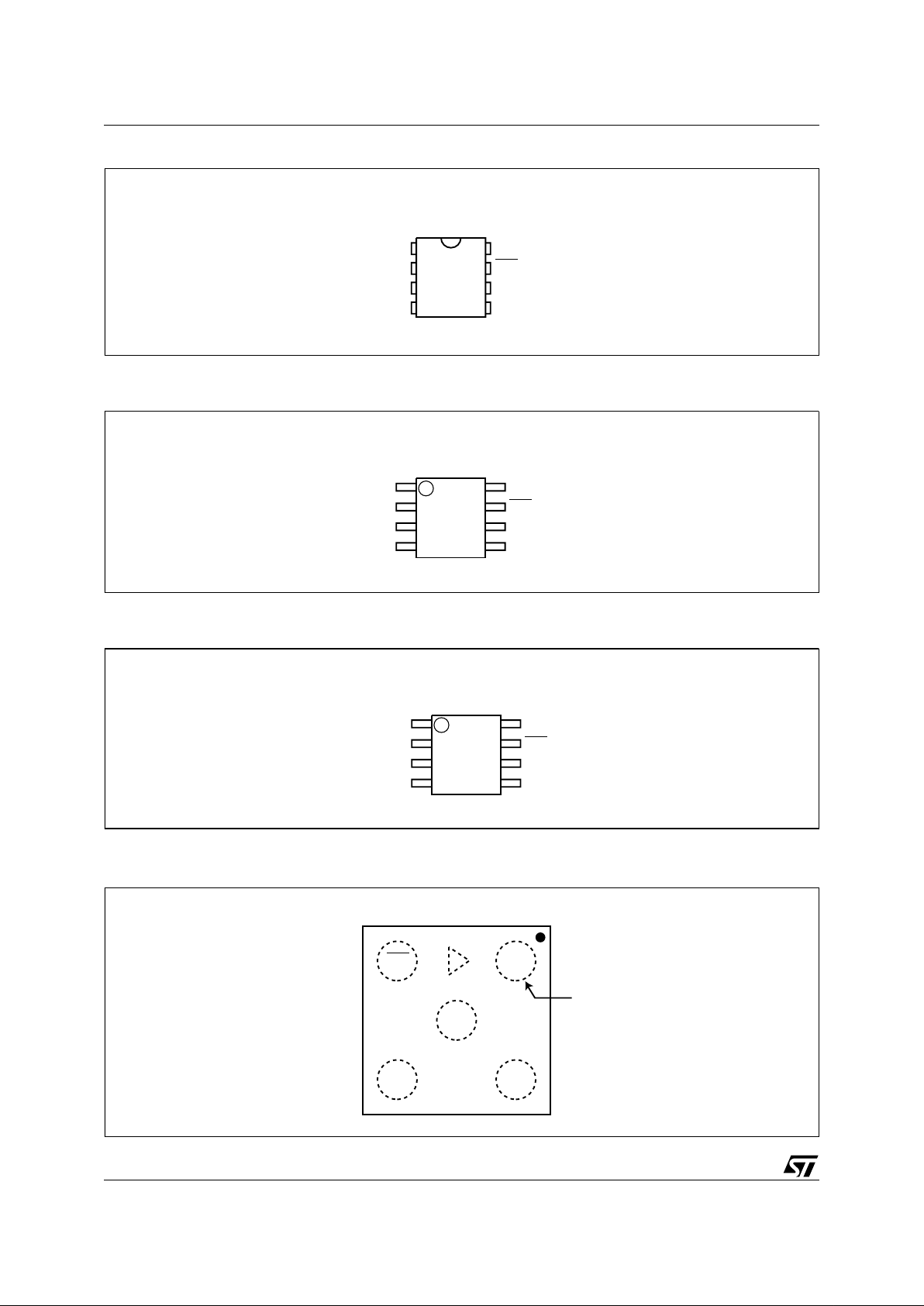

Figure 2A. DIP Connections

Note: 1. NC = Not Connected

Figure 2B. SO Connections

Note: 1. NC = Not Connected

Figure 2C. Standard-TSSOP Connections

Note: 1. NC = Not Connected

SDAV

SS

SCL

WC

V

CC

/ E2

AI02034D

M24Cxx

1

2

3

4

8

7

6

5

/ E2/ E2/ E2NC

/ E1

/ E1/ E1/ NCNC

/ E0

/ E0/ NC/ NCNC

/1Kb

/2Kb/4Kb/8Kb16Kb

1

AI02035D

2

3

4

8

7

6

5

SDAV

SS

SCL

WC

V

CC

/ E2

M24Cxx

/ E2/ E2/ E2NC

/ E1

/ E1/ E1/ NCNC

/ E0

/ E0/ NC/ NCNC

/1Kb

/2Kb/4Kb/8Kb16Kb

1

AI02036D

2

3

4

8

7

6

5

SDAV

SS

SCL

WC

V

CC

/ E2

M24Cxx

/ E2/ E2/ E2NC

/ E1

/ E1/ E1/ NCNC

/ E0

/ E0/ NC/ NCNC

/1Kb

/2Kb/4Kb/8Kb16Kb

Figure 2D. SBGA Connections (top view, marking side, with balls on the underside)

AI02796E

SCL V

SS

SDA

WC V

CC

M24C16

Ball "1"

3/20

M24C16, M24C08, M24C04, M24C 02, M24C01

These memory devices are compatible with the

I

2

C memory standard. This is a two wire serial

interface that uses a bi-directional data bus and

serial clock. The memory carries a built-in 4-bit

unique Device Type Identifier code (1010) in

accordance with the I

2

C bus definition.

The memory behaves as a slave device in the I

2

C

protocol, with all memory operations synchronized

by the serial clock. Read and Write operations are

initiated by a START condition, gene rated by the

bus master. The START condition is followed by a

Device Select Code and RW

bit (as described in

Table 3), terminated by an acknowledge bit.

When writing data to the memory, the memory

inserts an acknowledge bit during the 9

th

bit time,

following the bus master’s 8-bit transmission.

When data is read by the bus master, the bus

master acknowledges the receipt of the data b yte

in the same way. Data transfers are terminated by

a STOP condition after an Ack for WRITE, and

after a NoAck for READ.

Power On Reset: V

CC

Lock-Out Write Protect

In order to prevent data corruption and inadvertent

write operations during power up, a Power On

Reset (POR) circuit is included. The internal reset

is held active until the V

CC

voltage has reached

the POR threshold value, and all operations are

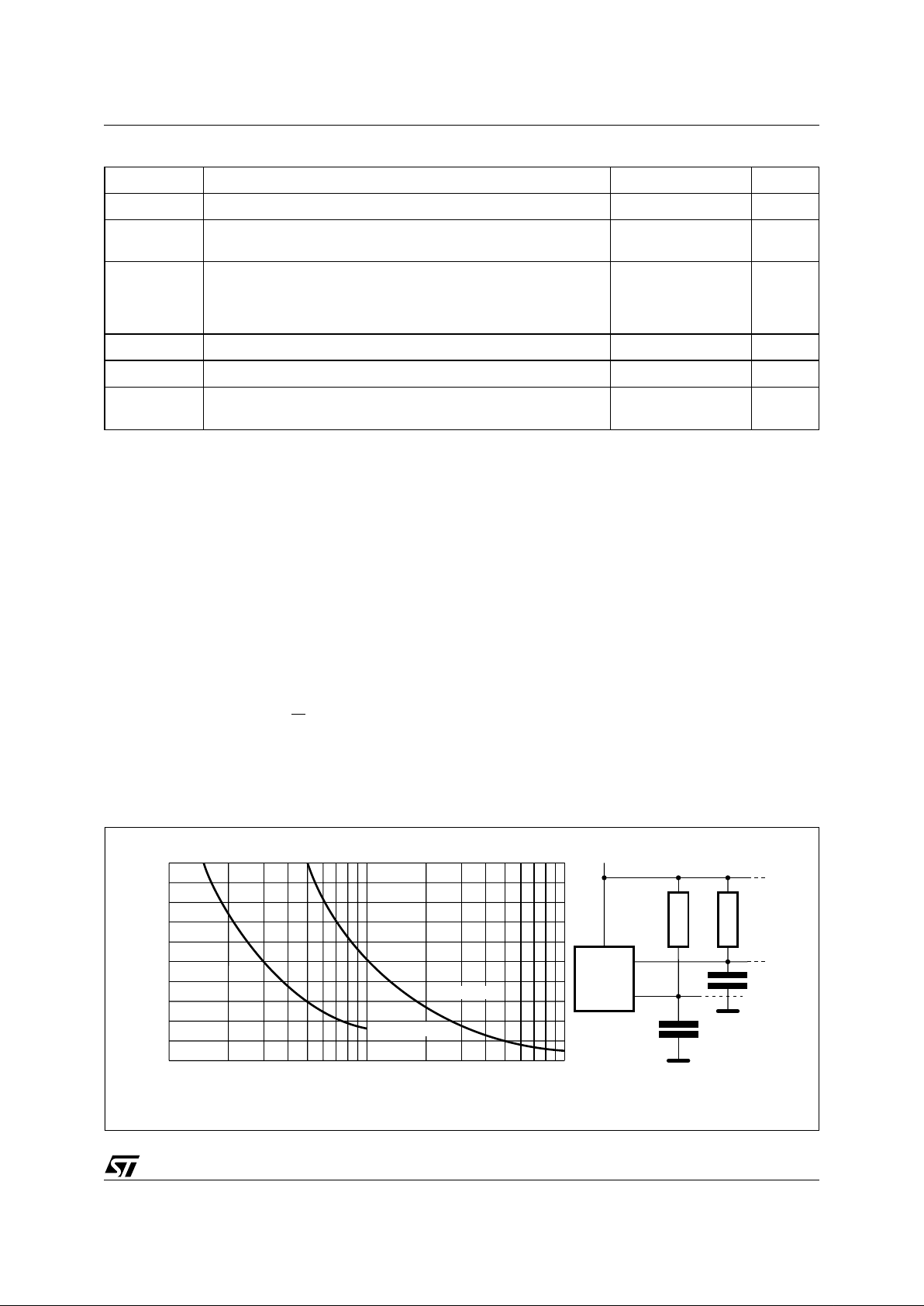

Figure 3. Maximum R

L

Value versus Bus Capacitance (C

BUS

) for an I2C Bus

AI01665

V

CC

C

BUS

SDA

R

L

MASTER

R

L

SCL

C

BUS

100

0

4

8

12

16

20

C

BUS

(pF)

Maximum RP value (kΩ)

10 1000

fc = 400kHz

fc = 100kHz

Table 2. Absolute Maximum Ratings

1

Note: 1. Exc ept for the r ating “Oper ating Tempe rature Range”, stresses above th ose listed in the Table “Absolute M aximum Rati ngs” may

cause permanent damage to the device. These are stress ratings only, and operation of the device at these or any other conditions

above those indicated in the Operating sections of this s pecificatio n is not implied. Ex posure to A bsolute Maximum Rating cond i tions for extended periods may affect device reliability. Refer also to the ST SURE Program and other relevant quality documents.

2. MIL -STD-883C , 3015.7 (100 pF, 1500 Ω)

Symbol Parameter Value Unit

T

A

Ambient Operating Temperature -40 to 125 °C

T

STG

Storage

Temperature

-65 to 150 °C

T

LEAD

Lead Temperature

during Soldering

PSDIP8: 10 sec

SO8: 40 sec

TSSOP8: 40 sec

SBGA5: t.b.c.

260

215

215

t.b.c.

°C

V

IO

Input or Output range -0.6 to 6.5 V

V

CC

Supply Voltage -0.3 to 6.5 V

V

ESD

Electrostatic Discharge Voltage (Human Body model2)

4000

V

M24C16, M24C08, M24C04, M24C02, M24C01

4/20

disabled – the device will not respond to any

command. In the same way, when V

CC

drops from

the operating voltage, below the POR threshold

value, all operations are disabled an d the device

will not respond to any command. A stable and

valid V

CC

must be applied before applying any

logic signal.

SIGNAL DESCRIPTION

Serial Clock (SCL)

The SCL input pin is used to strobe all data in and

out of the memory. In applications where this line

is used by slaves to synchronize the bus to a

slower clock, the master must have an open drain

output, and a pull-up resistor must be c onnected

from the SCL line to V

CC

. (Figure 3 indicates how

the value of the pull-up resistor can be calculated).

In most applications, though, this method of

synchronization is not employed, and so the pullup resistor is not necessary, provided that the

master has a push-pull (rather than open drain)

output.

Serial Data (SDA)

The SDA pin is bi-directional, and is used to

transfer data in or out of the memory. It is an open

drain output that may be wire-OR’ed with other

open drain or open collector signals on the bus. A

pull up resistor must be connected f rom the SDA

bus to V

CC

. (Figure 3 indicates how t he value of

the pull-up resistor can be calculated).

Chip Enable (E2, E1, E0)

These chip enable inputs are used to set the value

that is to be looked for on the three least significant

bits (b3, b2, b1) of the 7-bit device select code (but

see the description of memory addressing, on

page 6, for more details). These inputs may be

driven dynamically or tied to V

CC

or VSS to

establish the device select code (but note that the

V

IL

and VIH levels for the inputs are CMOS

compatible, not TTL compatible).

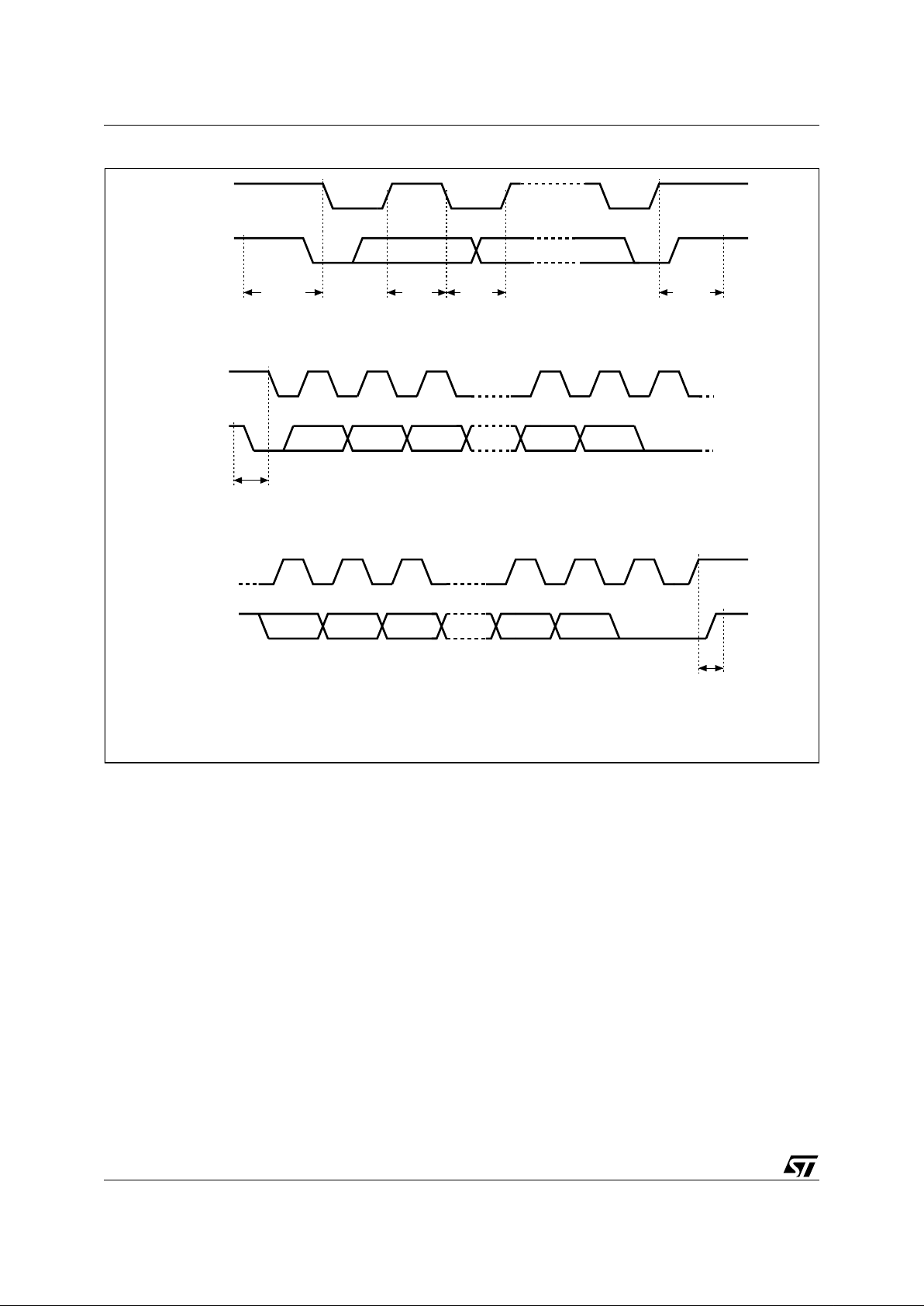

Figure 4. I

2

C Bus Protocol

SCL

SDA

SCL

SDA

SDA

START

CONDITION

SDA

INPUT

SDA

CHANGE

AI00792

STOP

CONDITION

1 23 789

MSB

ACK

START

CONDITION

SCL

1 23 789

MSB ACK

STOP

CONDITION

5/20

M24C16, M24C08, M24C04, M24C 02, M24C01

Write Control (WC)

The hardware Write Control pin (WC

) is useful for

protecting the entire contents of the memory from

inadvertent erase/write. The Write Control signal is

used to enable (WC

=VIL) or disable (WC=VIH)

write instructions to the entire memory area. When

unconnected, the WC

input is internally read as

V

IL

, and write operations are allowed.

When WC

=1, Device Select and Address bytes

are acknowledged, Data bytes are not

acknowledged.

Please see the Application Note

AN404

for a more

detailed description of the Write Control feature.

DEVICE OPERATION

The memory device supports the I

2

C protocol.

This is summarized in Figure 4, and is compared

with other serial bus protocols in Application Note

AN1001

. Any device that sends data on to the bus

is defined to be a transm itter, and any device that

reads the data to be a receiver. The device that

controls the data transfer is k nown as the master,

and the other as the slave. A data transfer can only

be initiated by the mas ter, which wi ll also provide

the serial clock for synchronization. The memory

device is always a slave device in all

communication.

Start Condition

START is identified by a high t o low transition of

the SDA line while the clock, SCL, is stab le in t he

high state. A START condition must precede any

data transfer command. The memory device

continuously monitors (except during a

programming cycle) the SDA and SCL lines for a

START condition, and will not respond unless one

is given.

Stop Condition

STOP is identified by a low to high transition of the

SDA line wh ile th e clock S CL is sta ble in the h igh

state. A STOP condition terminates

communication between the m emory device and

the bus master. A STOP condition at the end of a

Read command, after (and only after) a NoAck,

forces the memory device into its standby state. A

STOP condition at the end of a Write com mand

triggers the internal EEPROM write cycle.

Acknowledge Bit (ACK)

An acknowledge signal is used to indicate a

successful byte transfer. The bus transmitter,

whether it be master or slave, releases the SDA

bus after sending eight bits of data. During the 9

th

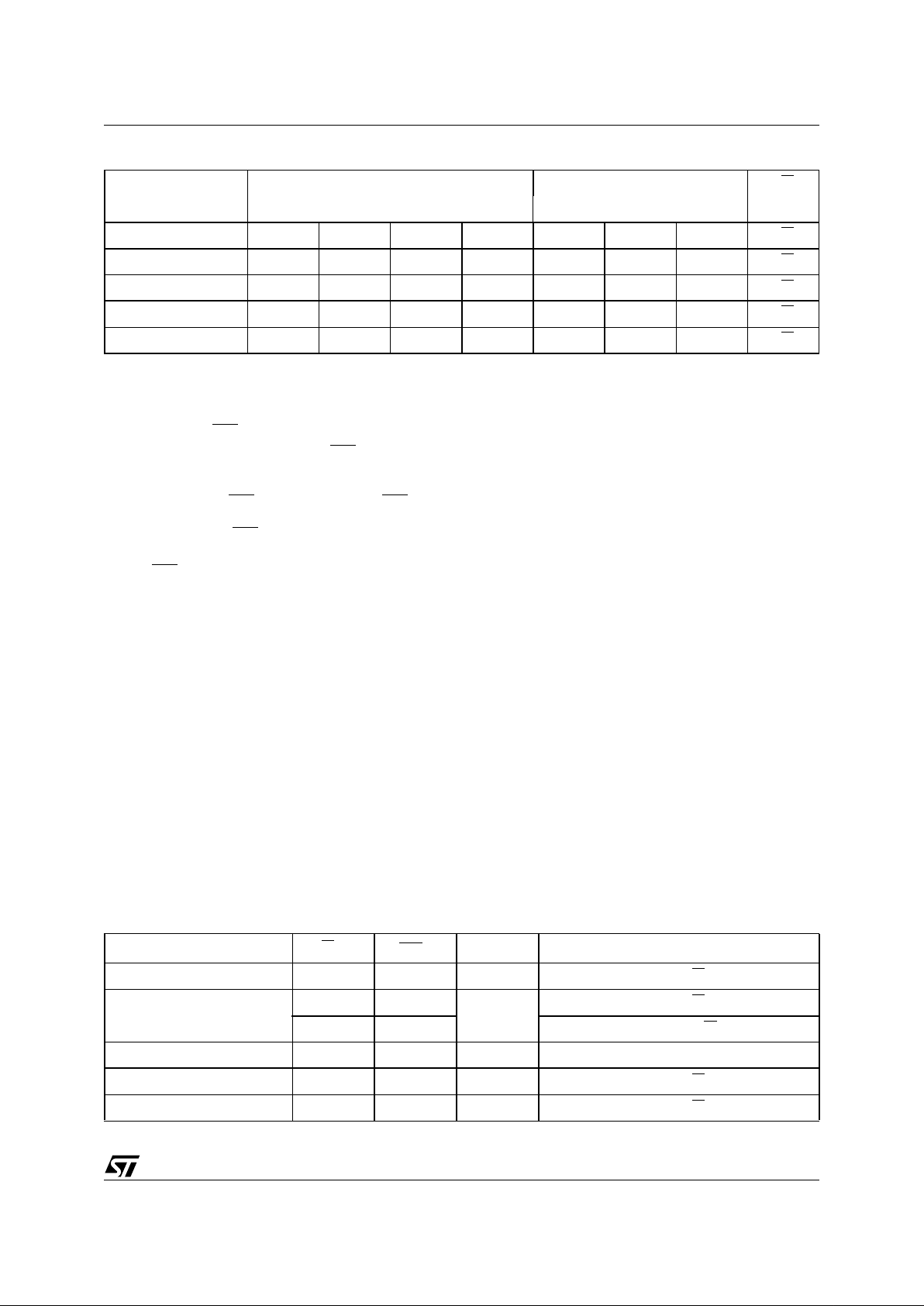

Table 3. Device Select Code

1

Note: 1. The most significant bit, b7, is sent first.

2. E0, E1 and E2 are comp ared against the respective ext ernal pins on the memory device.

3. A10, A9 and A8 repres ent high significant bits of the address.

Device Type Identifier Chip Enable RW

b7 b6 b5 b4 b3 b2 b1 b0

M24C01 Select Code 1010E2E1E0RW

M24C02 Select Code 1010E2E1E0RW

M24C04 Select Code 1010E2E1A8RW

M24C08 Select Code 1010E2A9A8RW

M24C16 Select Code 1010A10A9A8RW

Table 4. Operating Modes

Note: 1. X = V

IH

or V

IL

.

Mode RW bit

WC

1

Bytes Initial Sequence

Current Address Read 1 X 1 START, Device Select, RW

= ‘1’

Random Address Read

0X

1

START, Device Select, RW

= ‘0’, Address

1 X reSTART, Device Select, RW

= ‘1’

Sequential Read 1 X

≥

1 Similar to Current or Random Address Read

Byte Write 0 V

IL

1 START, Device Select, RW = ‘0’

Page Write 0 V

IL

≤

16 START, Device Select, RW

= ‘0’

M24C16, M24C08, M24C04, M24C02, M24C01

6/20

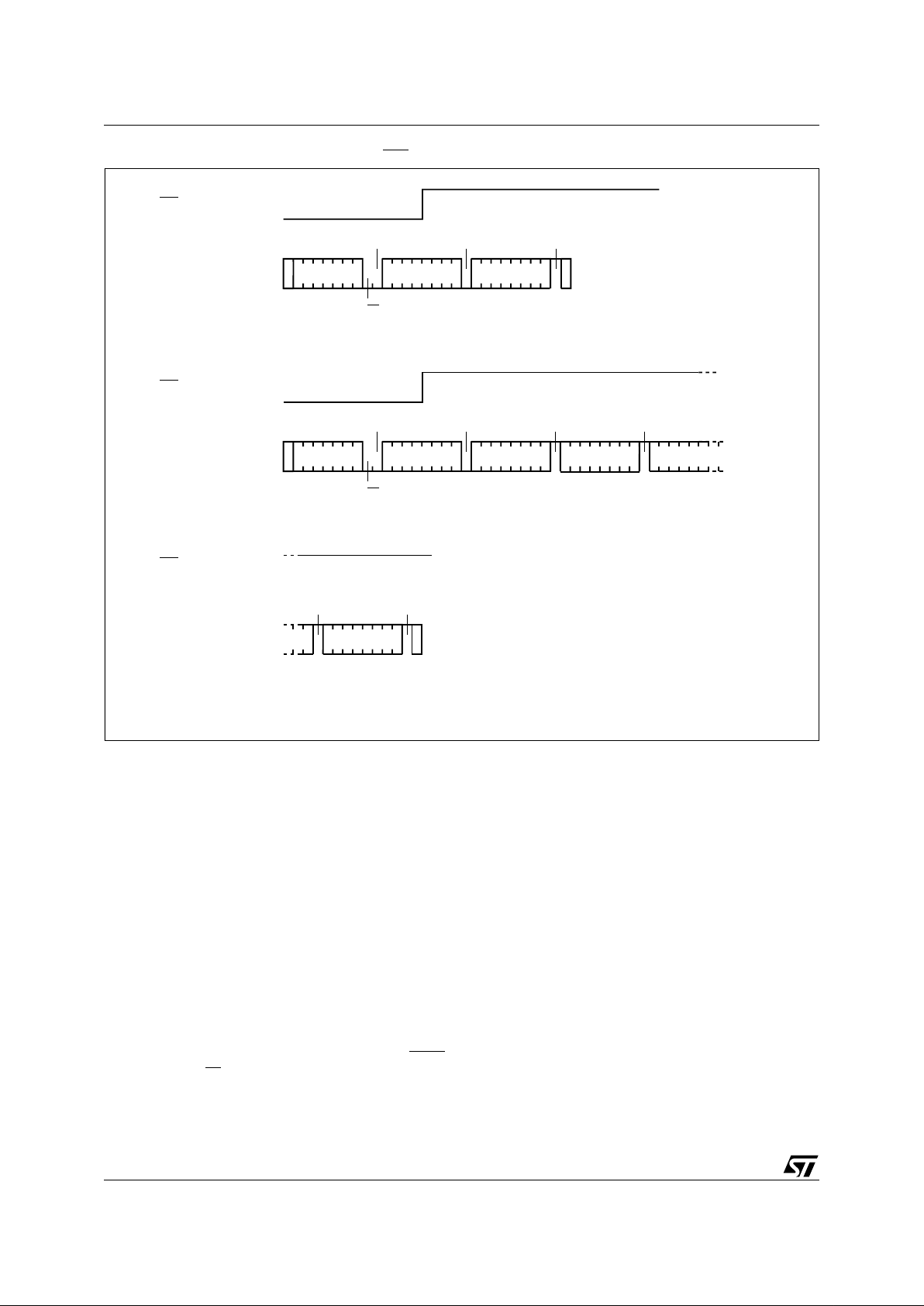

Figure 5. Wri te Mo de S e qu e nces with WC=1 (data wri te inhibi ted)

STOP

START

BYTE WRITE DEV SEL BYTE ADDR DATA IN

WC

START

PAGE WRITE DEV SEL BYTE ADDR DATA IN 1 DATA IN 2

WC

DATA IN 3

AI02803B

PAGE WRITE

(cont'd)

WC (cont'd)

STOP

DATA IN N

ACK ACK NO ACK

R/W

ACK ACK NO ACK NO ACK

R/W

NO ACK NO ACK

clock pulse period, the receiver pulls the SDA bus

low to acknowledge the receipt of the eight data

bits.

Data Input

During data input, the memory device samples the

SDA bus signal on the rising edge of the clock,

SCL. For correct device operation, the SDA signal

must be stable during the clock low-to-high

transition, and the data must change

only

when

the SCL line is low .

Memory Addressing

To start communication betwee n the bus master

and the slave memory, the master must initiate a

START condition. Following this, the master sends

the 8-bit byte, shown in Table 3, on the SDA bus

line (most significant bit first). This consists of the

7-bit Device Select Code, and the 1-bit Read/Write

Designator (RW). The Device Select Code is

further subdivided into: a 4-bit Device Type

Identifier, and a 3-bit Chip Enable “Address” (E2,

E1, E0 ) .

To address the memory array, the 4-bit Device

Type Identifier is 1010b.

Up to eight memory devices can be connected on

a single I

2

C bus. Each one is given a uniq ue 3-bit

code on its Chip Enable inputs. W hen the Device

Select Code is received, the memory only

responds if the Chip Enable Code (shown in Table

3) is the same as the pattern applied to its Chip

Enable pins.

Those devices with larger memory capacities (the

M24C16, M24C08 and M24C04) need more

address bits. E0 is not available for use on devices

that need to use address line A8; E1 is not

available for devices that need to use address line

A9, and E2 is not available for devices that need to

use address line A10 (see Figure 2A to Figure 2D

and Table 3 for details). Using the E0, E1 and E2

inputs pins, up to eight M24C02 (or M24C01), four

M24C04, two M24C08 or one M24C16 device can

be connected to one I

2

C bus. In each case, and in

the hybrid cases, this gives a total memory

Loading...

Loading...