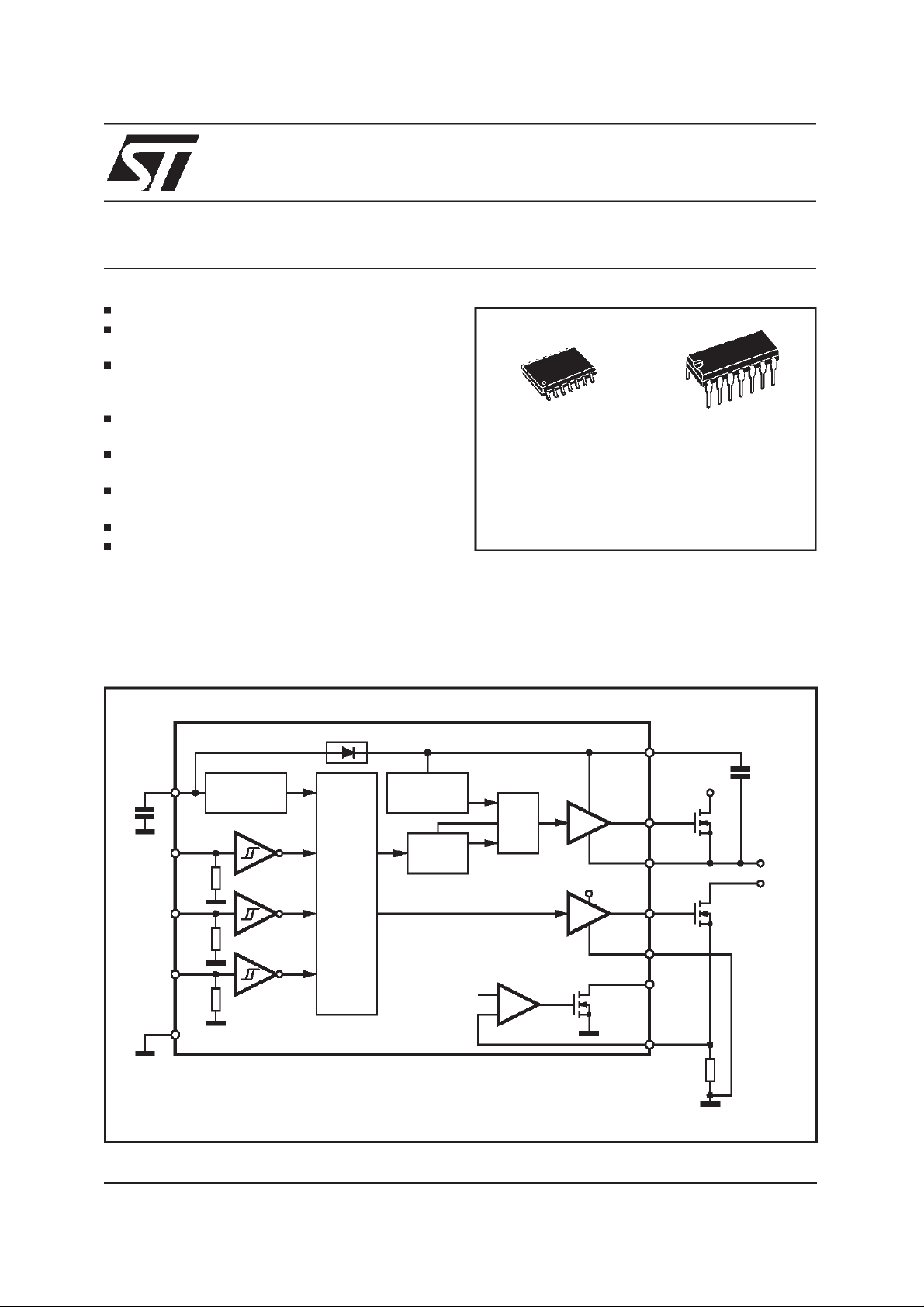

HIGH-VOLTAGE HIGH AND LOW SIDE DRIVER

HIGHVOLTAGERAIL UP TO 600V

dV/dt IMMUNITY +- 50 V/nsec iN FULL TEM-

PERATURERANGE

DRIVER CURRENTCAPABILITY:

400 mASOURCE,

650 mASINK

SWITCHING TIMES 50/30 nsec RISE/FALL

WITH 1nF LOAD

CMOS/TTL SCHMITT TRIGGER INPUTS

WITH HYSTERESISANDPULL DOWN

UNDER VOLTAGE LOCK OUT ON LOWER

AND UPPERDRIVING SECTION

INTEGRATEDBOOTSTRAPDIODE

OUTPUTSIN PHASEWITH INPUTS

DESCRIPTION

The L6386 is an high-voltage device, manufactured with theBCD ”OFF-LINE”technology. It has

a Driver structure that enables to drive inde-

L6386

SO14 DIP14

ORDERING NUMBERS:

L6386D L6386

pendent referenced Channel Power MOS or

IGBT. The Upper (Floating) Section is enabled to

work with voltage Rail up to 600V. The Logic Inputs are CMOS/TTL compatible for ease of interfacing with controlling devices.

BLOCK DIAGRAM

V

CC

DETECTION

4

3

HIN

2

SD

1

LIN

SGND

7 6

UV

BOOTSTRAP DRIVER

LOGIC

UV

DETECTION

LEVEL

SHIFTER

VREF

R

R

S

-

+

LVG

DRIVER

DRIVER

V

CC

D97IN520D

HVG

14

13

12

Vboot

C

H.V.

HVG

OUT

LVG

9

PGND

8

DIAG

5

CIN

BOOT

TO LOAD

July 1999

1/10

L6386

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

Vout Output Voltage -3 toVboot - 18 V

Vcc Supply Voltage - 0.3 to +18 V

Vboot Floating Supply Voltage -1 to 618 V

Vhvg Upper Gate Output Voltage - 1 to Vboot V

Vlvg Lower Gate Output Voltage -0.3 toVcc +0.3 V

Vi Logic Input Voltage -0.3 toVcc +0.3 V

Vdiag Open Drain Forced Voltage -0.3 to Vcc +0.3 V

Vcin Comparator InputVoltage -0.3 toVcc +0.3 V

dVout/dt Allowed Output Slew Rate 50 V/ns

Ptot Total Power Dissipation (Tj = 85 °C) 750 mW

Tj Junction Temperature 150 °C

Ts Storage Temperature -50 to 150 °C

Note:

ESD immunity for pins 12, 13 and 14 is guaranteed up to900V (Human Body Model)

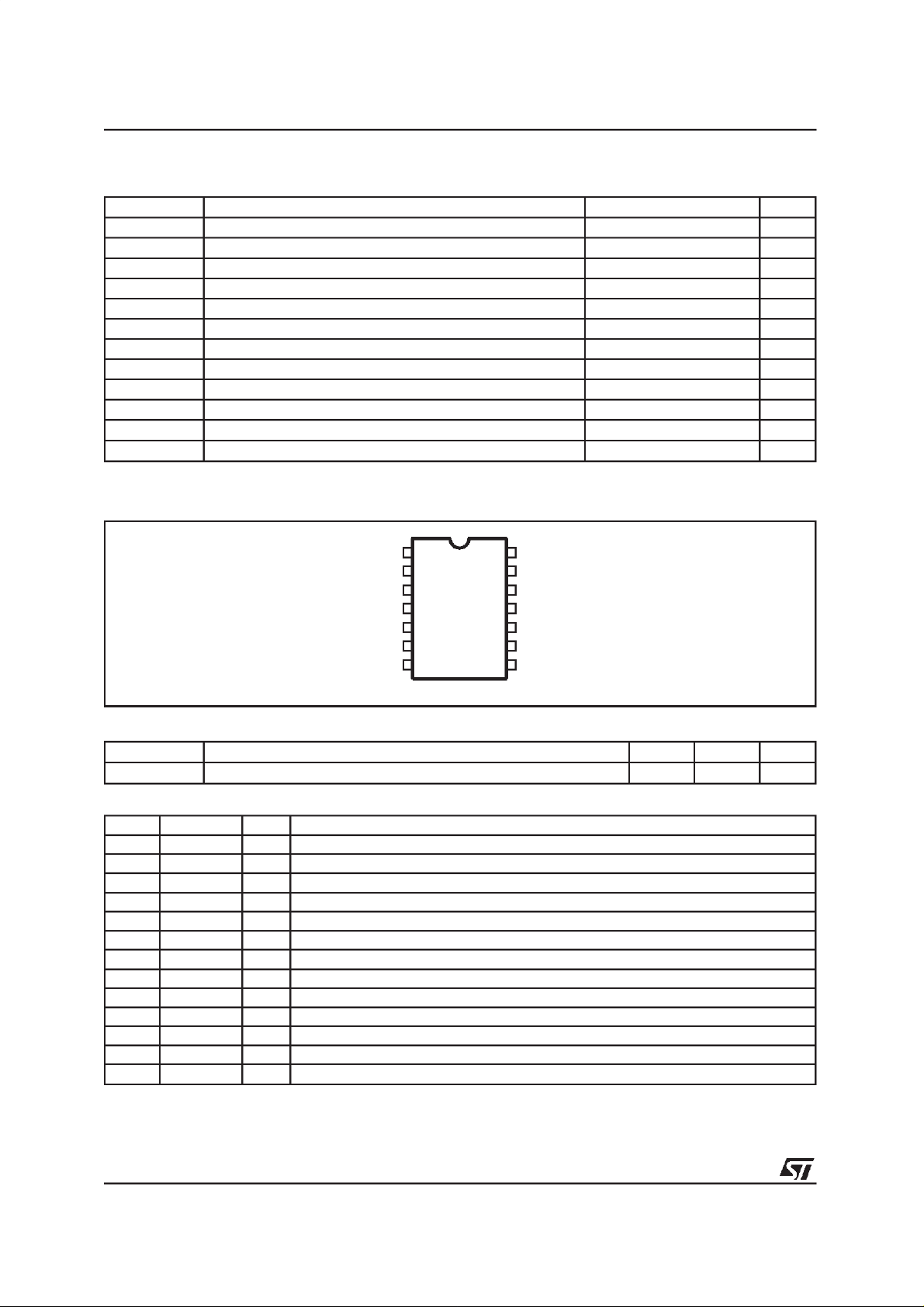

PIN CONNECTION

LIN

SD

HIN

V

DIAG

CIN

SGND

1

2

3

4

CC

5

6

7 PGND

D97IN521A

14

V

boot

13

HVG

12

OUT

11

N.C.

10

N.C.

9

LVG

8

THERMAL DATA

Symbol Parameter SO14 DIP14 Unit

R

th j-amb

Thermal ResistanceJunction to Ambient 165 100 °C/W

PIN DESCRIPTION

N. Name Type Function

1 LIN I Lower Driver Logic Input

2 SD (*) I Shut Down Logic Input

3 HIN I UpperDriver Logic Input

4 VCC I Low Voltage Supply

5 DIAG O Open Drain Diagnostic Output

6 CIN I Comparator Input

7 SGND Ground

8 PGND Power Ground

9 LVG (*) O LowSide Driver Output

10, 11 N.C. NotConnected

12 OUT O Upper Driver Floating Driver

13 HVG (*) O HighSide Driver Output

14 Vboot BootstrappedSupply Voltage

(*) The circuit guarantees 0.3V maximum on the pin (@ Isink = 10mA),with VCC >3V.This allows toomit the ”bleeder” resistor connected

betweenthegate and the source of the externalMOSFET normally used to hold the pin low; the gate driver assures low impedance also

in SD condition.

2/10

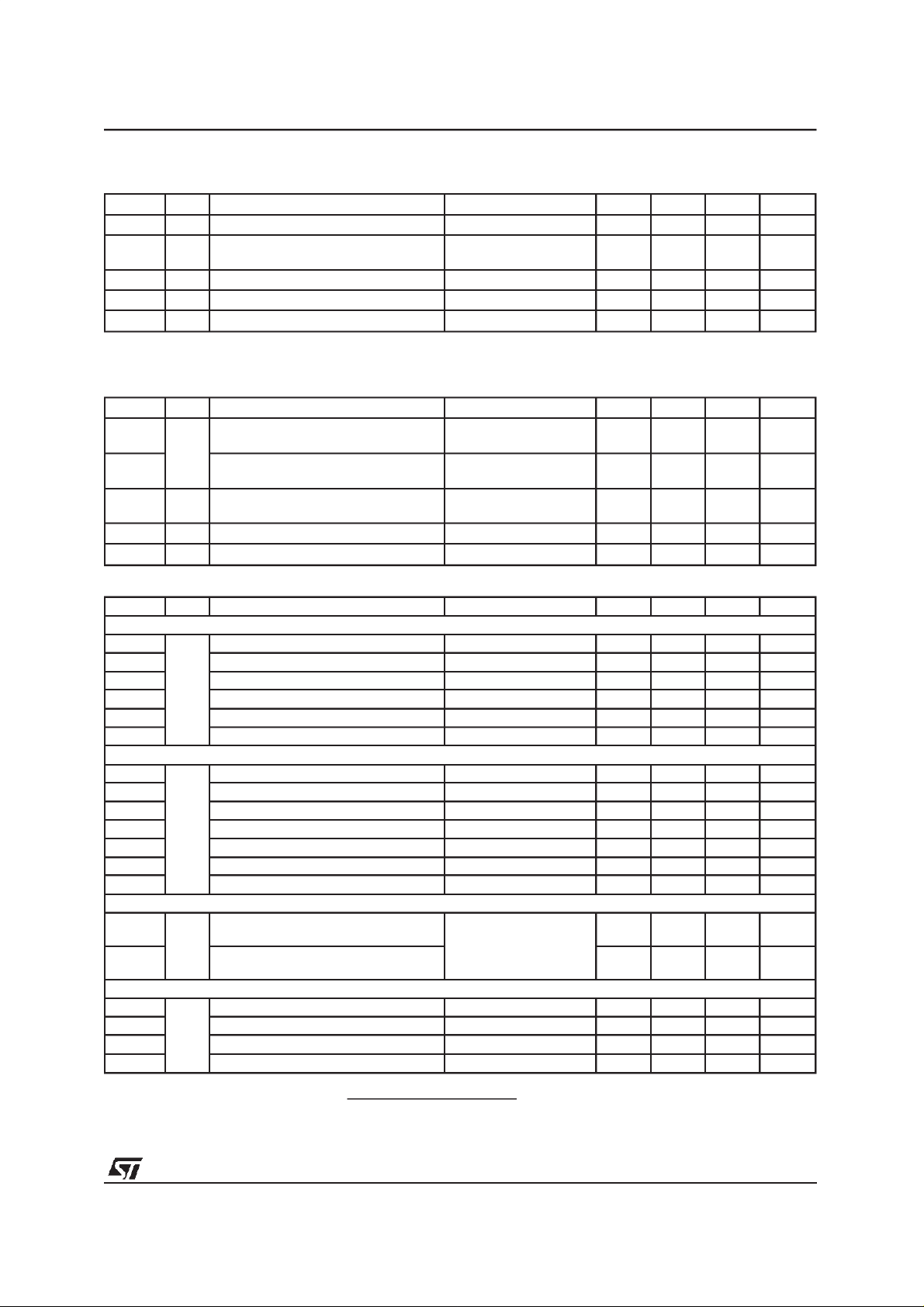

L6386

RECOMMENDED OPERATINGCONDITIONS

Symbol Pin Parameter Test Condition Min. Typ. Max. Unit

Vout 12 Output Voltage Note1 580 V

Vboot-

Vout

fsw Switching Frequency HVG,LVGloadCL= 1nF 400 kHz

Vcc 4 Supply Voltage 17 V

T

Note 1:

ELECTRICALCHARACTERISTICS

AC Operation(Vcc = 15V; Tj = 25°C)

Symbol Pin Parameter Test Condition Min. Typ. Max. Unit

ton 1.3

toff High/Low SideDriver Turn-Off

tsd 2 vs

tr 13,9 Rise Time CL = 1000pF 50 ns

tf 13,9 Fall Time CL = 1000pF 30 ns

DC Operation(Vcc = 15V; Tj = 25°C)

14 Floating Supply Voltage Note1 17 V

j

if the condition Vboot - Vout < 18V is guaranteed,Vout can range from -3 to580V.

Junction Temperature -45 125 °C

High/Low SideDriver Turn-On

Propagation Delay

vs 9,

13

Vout = 0V 110 150 ns

Vout = 0V 105 150 ns

Propagation Delay

Shut Down to High/Low Side

9,13

Propagation Delay

Vout = 0V 105 150 ns

Symbol Pin Parameter Test Condition Min. Typ. Max. Unit

Low Supply Voltage Section

Vcc 4 Supply Voltage 17 V

Vccth1 Vcc UV Turn On Threshold 11.5 12 12.5 V

Vccth2 Vcc UV Turn Off Threshold 9.5 10 10.5 V

Vcchys Vcc UV Hysteresis 2 V

Iqccu UndervoltageQuiescentSupplyCurrent Vcc ≤ 11V 200 µA

Iqcc Quiescent Current Vcc = 15V 250 320 µA

Bootstrapped Supply Section

Vboot 14 Bootstrapped Supply Voltage 17 V

Vbth1 Vboot UV TurnOn Threshold 10.7 11.9 12.9 V

Vbth2 Vboot UV TurnOff Threshold 8.8 9.9 10.7 V

Vbhys Vboot UV Hysteresis 2 V

Iqboot Vboot QuiescentCurrent Vout = Vboot 200

Ilk Leakage Current Vout = Vboot = 600V 10 µA

Rdson Bootstrap Driver on Resistance (*) Vcc≥12.5V;Vin = 0V 125

Driving Buffers Section

Iso 9, 13 High/Low SideDriver Short Circuit

VIN = Vih (tp < 10µs) 300 400 mA

Source Current

Isi High/Low SideDriver Short Circuit

500 650 mA

Sink Current

Logic Inputs

Vil 1,2,3 Low Level Logic Threshold Voltage 1.5 V

Vih High LevelLogic Threshold Voltage 3.6 V

Iih High LevelLogic Input Current VIN = 15V 50 70

Iil Low LevelLogic Input Current VIN = 0V 1 µA

−(V

(*)

R

where I

is tested in thefollowing way: R

DSON

ispin 8 current whenV

1

(V

=

DSON

I

CBOOT=VCBOOT1,I2

CC−VCBOOT1)

1(VCC,VCBOOT1

whenV

CBOOT=VCBOOT2

− V

CC

)−I2(VCC,V

CBOOT2

CBOOT2

.

)

)

A

µ

Ω

A

µ

3/10

L6386

DC OPERATION(continued)

Symbol Pin Parameter Test Condition Min. Typ. Max. Unit

Sense Comparator

Vio Input OffsetVoltage -10 10 mV

Iio 6 Input Bias Current Vcin ≥ 0.5 0.2 µA

Vol 2 Open Drain Low Level Output

Voltage, Iod = -2.5mA

Vref Comparator Reference voltage 0.460 0.5 0.540 V

Figure 1. TimingWaveforms

HIN

LIN

SD

HOUT

LOUT

0.8 V

V

REF

V

CIN

DIAG

Note: SD active condition is latched until next negative IN edge.

Figure 2. TypicalRise and Fall Times vs.

Load Capacitance

time

(nsec)

250

200

150

100

50

D99IN1054

Tr

Tf

D97IN522A

Figure 3. QuiescentCurrent vs. Supply

Voltage

Iq

(µA)

4

10

3

10

2

10

D99IN1057

0

0 1 2 3 4 5 C (nF)

For both high and low side buffers @25°C Tamb

4/10

10

0 2 4 6 8 10121416VS(V)

L6386

BOOTSTRAPDRIVER

A bootstrap circuitryis needed to supply the high

voltage section. This function is normally accomplished by a high voltage fast recovery diode (fig.

4a). In the L6386 a patented integrated structure

replaces the external diode. It is realized by a

high voltage DMOS, driven synchronously with

the low side driver (LVG), with in series a diode,

as shownin fig. 4b

An internal charge pump (fig. 4b) provides the

DMOS driving voltage .

The diode connected in series to the DMOS has

been added to avoid undesirable turn on of it.

CBOOT selection and charging

To choose the proper C

BOOT

:

value the external

MOS can be seen as an equivalent capacitor.

This capacitor C

is related to the MOS total

EXT

gate charge :

Q

gate

=

C

EXT

V

gate

The ratio betweenthecapacitorsC

EXT

andC

BOOT

is proportionalto the cyclicalvoltage loss .

It has to be:

C

>>>C

BOOT

EXT

supply 1µCtoC

. This charge on a 1µFca-

EXT

pacitormeans a voltagedrop of 1V.

The internal bootstrap driver gives great advantages: the external fast recovery diode can be

avoided (it usually has great leakage current).

This structure can work only if V

OUT

is close to

GND (or lower) and in the meanwhile the LVG is

on. The charging time (T

charge

) of the C

BOOT

the time in whichboth conditions are fulfilledand

it has to be long enough to chargethe capacitor.

The bootstrap driver introduces a voltage drop

due to the DMOS R

(typical value: 125

DSON

Ohm). At low frequency this drop can be neglected. Anyway increasing the frequency it

must be taken in to account.

The following equation is useful to compute the

drop on the bootstrap DMOS:

Q

= I

V

drop

chargeRdson

where Q

power MOS, R

is the gate charge of the external

gate

is the on resistance of the

dson

bootstrap DMOS, and T

→V

charge

drop

gate

=

T

charge

R

dson

is the chargingtime

of the bootstrapcapacitor.

For example: using a power MOS with a total

gate charge of 30nC the drop on the bootstrap

DMOSis about1V, if the T

charge

is 5µs. In fact:

is

e.g.: if Q

3nF. With C

is 30nC and V

gate

BOOT

is 10V, C

gate

EXT

= 100nF the drop would be

300mV.

If HVG has to be supplied for a long time, the

C

selectionhas to take into account also the

BOOT

leakage losses.

e.g.: HVG steady state consumptionis lower than

200µA, so if HVG T

is 5ms, C

ON

BOOT

has to

Figure 4. Bootstrap Driver.

D

BOOT

V

S

HVG

LVG

ab

V

V

BOOT

OUT

H.V.

C

BOOT

TO LOAD

is

V

age drop on C

V

has to be taken into account when the volt-

drop

drop

30nC

=

BOOT

⋅

125Ω~0.8V

5µs

is calculated: if this drop is

too high, or the circuit topology doesn’t allow a

sufficient charging time, an external diode can be

used.

V

V

S

HVG

LVG

BOOT

H.V.

V

OUT

C

BOOT

TO LOAD

D99IN1056

5/10

L6386

Figure 5. Turn On Time vs. Temperature

250

@ Vcc = 15V

200

150

Typ.

100

Ton(ns)

50

0

-45 -25 0 25 50 75 100 125

Tj (°C)

Figure 6. Turn Off Time vs. Temperature

250

@ Vcc= 15V

200

150

Typ.

100

Toff(ns)

50

0

-45 -25 0 25 50 75 100 125

Tj (°C)

Figure 8. V

UV TurnOn Thresholdvs.

BOOT

Temperature

15

14

13

Typ.

12

11

10

Vbth1 (V)

9

8

7

-45 -25 0 25 50 75 100 125

Tj (°C)

Figure 9. V

UV TurnOff Thresholdvs.

BOOT

@ Vcc = 15V

Temperature

15

14

13

12

11

Typ.

10

Vbth2 (V)

9

8

7

-45 -25 0 25 50 75 100 125

Tj (°C)

@ Vcc = 15V

Figure 7. Shutdown Time vs. Temperature

250

@ Vcc = 15V

200

150

Typ.

100

tsd (ns0

50

0

-45-250 255075100125

Tj (°C)

6/10

Figure 10. V

3

UV Hysteresis

BOOT

@ Vcc = 15V

2.5

Typ.

2

Vbhys (V)

1.5

1

-45 -25 0 25 50 75 100 125

Tj (°C)

L6386

Figure 11. Vcc UV Turn On Thresholdvs. Tem-

perature

15

14

13

Typ.

12

Vccth1(V)

11

10

9

-45 -25 0 25 50 75 100 125

Tj (°C)

Figure 12. Vcc UV Turn Off Thresholdvs.

Temperature

12

11

Figure 14. Output SourceCurrent vs. Tem-

perature

1000

@ Vcc = 15V

800

600

Typ.

400

current (mA)

200

0

-45 -25 0 25 50 75 100 125

Tj(°C)

Figure 15. Output SinkCurrent vs. Tempera-

ture

1000

@ Vcc =15V

800

Typ.

10

Typ.

9

Vccth2(V)

8

7

-45 -25 0 25 50 75 100 125

Tj (°C)

Figure 13. Vcc UV Hysteresisvs. Tempera-

ture

3

2.5

Typ.

2

Vcchys (V)

1.5

600

400

current (mA)

200

0

-45 -25 0 25 50 75 100 125

Tj (°C)

1

-45 -25 0 25 50 75 100 125

Tj (°C)

7/10

L6386

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

a1 0.51 0.020

B 1.39 1.65 0.055 0.065

b 0.5 0.020

b1 0.25 0.010

D 20 0.787

E 8.5 0.335

e 2.54 0.100

e3 15.24 0.600

F 7.1 0.280

I 5.1 0.201

L 3.3 0.130

Z 1.27 2.54 0.050 0.100

mm inch

OUTLINE AND

MECHANICAL DATA

DIP14

8/10

L6386

DIM.

MIN.. TYP. MAX.. MIN.. TYP.. MAX..

A 1.75 0.069

a1 0.1 0.25 0.004 0.009

a2 1.6 0.063

b 0.35 0.46 0.014 0.018

b1 0.19 0.25 0.007 0.010

C 0.5 0.020

c1 45°(typ.)

D (1) 8.55 8.75 0.336 0.344

E 5.8 6.2 0.228 0.244

e 1.27 0.050

e3 7.62 0.300

F (1) 3.8 4 0.150 0.157

G 4.6 5.3 0.181 0.209

L 0.4 1.27 0.016 0.050

M 0.68 0.027

S8°

(1) D and F donot include mold flash or protrusions. Mold flash or

potrusions shall not exceed 0.15mm (.006inch).

mm inch

(max. )

OUTLINE AND

MECHANICAL DATA

SO14

9/10

L6386

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is

granted by implication or otherwise under any patent or patent rights of STMicroelectronics. Specification mentioned in this publication are

subject to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products

are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registeredtrademark of STMicroelectronics

1999 STMicroelectronics – Printed in Italy – All Rights Reserved

STMicroelectronics GROUP OFCOMPANIES

Australia - Brazil - China- Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta - Morocco -

Singapore - Spain - Sweden - Switzerland - UnitedKingdom - U.S.A.

http://www.st.com

10/10

Loading...

Loading...