®

FAST RECOVERY RECTIFIER DIODES

LOW SWITCHING LOSSES

LOW PEAK RECOVERY CURRENT I

THE SPECIFICATIONS AND CURVES ENABLE

THE DE TERM INA TIO N OF t

AND IRM A T 100°C

rr

UNDER USERS CONDITIONS

APPLICATIONS

MOTOR CONTROLS (FREE-WHEELING

DIODE)

SWITCH MODE POWER SUPPLIES

SNUBBER DIODES

RM

BY 233-600

Cathode connected to case

A

K

DESCRIPTION

TO220AC

(Plastic)

Fast recovery rectifiers suited for power switching

applications.

ABSOLUTE MAXIMU M RATINGS

Symbol Parameter Value Unit

I

FRM

I

F (RMS

I

F (AV)

I

FSM

P

tot

T

stg

T

Symbol Parameter V alue Unit

V

RRM

V

RSM

Repetive Peak Forward Current

) RMS Forward Current 20 A

Average Forward Current Tc = 115°C

Surge non Repetitive Forward Current tp = 10ms

Power Dissipation

Storage and Junction Temperature Range - 40 to + 150

j

Repetitive Peak Reverse Voltage 600 V

Non Repetitive Peak Reverse Voltage 600 V

(limiting values)

≤ 20µs

t

p

= 0.5

δ

Sinusoidal

= 90°C

T

c

100 A

10 A

100 A

20 W

- 40 to + 150

C

°

THERMAL RESIST ANCE

Symbol Parameter Value Unit

R

th (j - c)

August 1998 Ed : 1A

Junction-case 3

C/W

°

1/5

BY 233-600

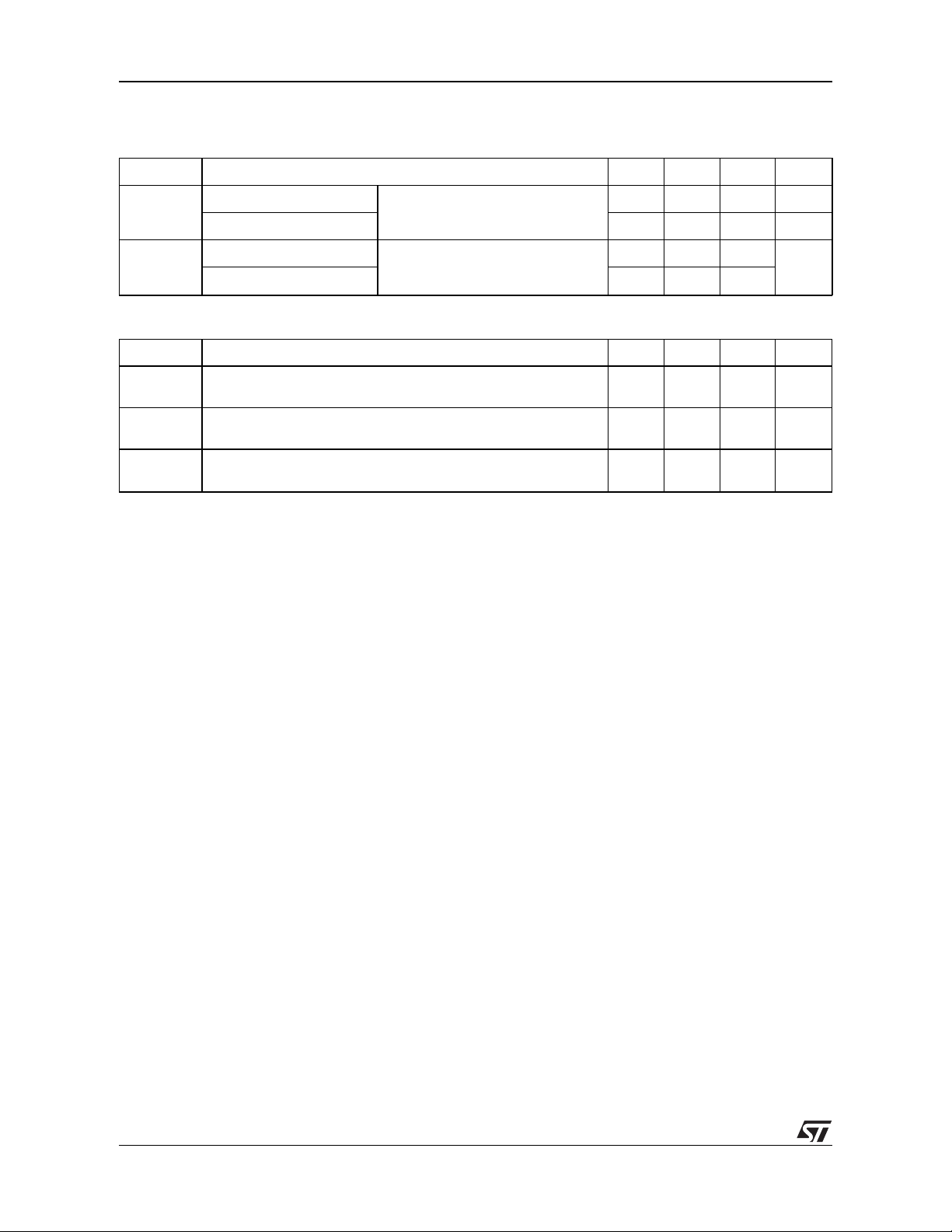

ELECTRICAL CHARACTERISTICS

STATIC CHARACTERISTICS

Synbol Test Conditions Min. Typ. Max. Unit

V

I

R

V

F

Tj = 25°C

= 100°C

T

j

T

= 25°C

j

= 100°C

T

j

= V

R

RRM

1mA

I

= 8A 1.5 V

F

RECOVERY CHARACTERISTICS

Symbol Test Conditions Min. Typ. Max. Unit

20

1.25

A

µ

t

rr

Q

rr

I

RM

Tj = 25°C IF = 1A diF/dt = - 15A/µs

V

= 30V

R

Tj = 25°C IF = 8A diF/dt = - 20A/µs

= 100V

V

R

Tj = 25°C IF = 8A diF/dt = - 20A/µs

V

= 100V

R

To evaluate the conduction losses use the following equations:

V

= 0.95 + 0.012 IF P = 0.95 x I

F

F(AV)

+ 0.012 I

F2(RMS)

2.2

150 ns

C

µ

4A

2/5

BY 233-600

Figure 1. Low frequency power lo sses versus

average current

Figure 3. Non repetitive peak surge current

versus overload duration

Figure 2. Peak current versus form factor

Figure 4. Thermal impedance versus pulse

width

Figure 5. V oltage dro p versus forward current Figure 6. Capacitance versus reverse voltage

3/5

BY 233-600

Figure 7. Recovery time versus diF/d

Figure 9. Peak reverse current versus diF/d

t-

Figure 8. Recovery time versus diF/d

t-

t-

4/5

PACKAGE MECHANICAL DATA

TO220AC (Plastic)

H2

L5

Ø I

L6

L2

AK

L9

F1

L4

F

G

BY 233-600

REF. DIMENSIONS

Millimeters Inches

A

C

L7

A 4.40 4.60 0.173 0.181

C 1.23 1.32 0.048 0.051

D 2.40 2.72 0.094 0.107

E 0.49 0.70 0.019 0.027

F 0.61 0.88 0.024 0.034

F1 1.14 1.70 0.044 0.066

D

G 4.95 5.15 0.194 0.202

H2 10.00 10.40 0.393 0.409

L2 16.40 typ. 0.645 typ.

M

E

L4 13.00 14.00 0.511 0.551

L5 2.65 2.95 0.104 0.116

L6 15.25 15.75 0.600 0.620

L7 6.20 6.60 0.244 0.259

L9 3.50 3.93 0.137 0.154

M 2.6 typ. 0.102 typ.

Diam. I 3.75 3.85 0.147 0.151

Min. Max. Min. Max.

Marking

: type number

Cooling method: by conduction (method C)

Weight: 1.86g

Recommended torque value: 80cm. N

Maximum torque value: 100cm.N

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsIbility for the consequences of

use of such inf orm ation nor for any infringe me nt of paten ts or other rights of third parties which may result from its use. No license is grant ed

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not authorized for use as critical components in life support devices or systems without express written approval

of STM i croel ectr o nics.

The ST logo is a registered trademark of STMicroelectronics

© 1998 STMicroelectronics - Printed in Italy - All rights reserved.

Australia - Brazil - Canada - China - France - Germany - Italy - Japan - Korea - Malaysia - Malta - Mexico - Morocco -

The Netherlands Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

STMicroelectronics GROUP OF COMPANIES

5/5

Loading...

Loading...