Page 1

TJ2PRO LOW PROFILE

TROLLEY JACK

OWNER’S MANUAL

FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.

Page 2

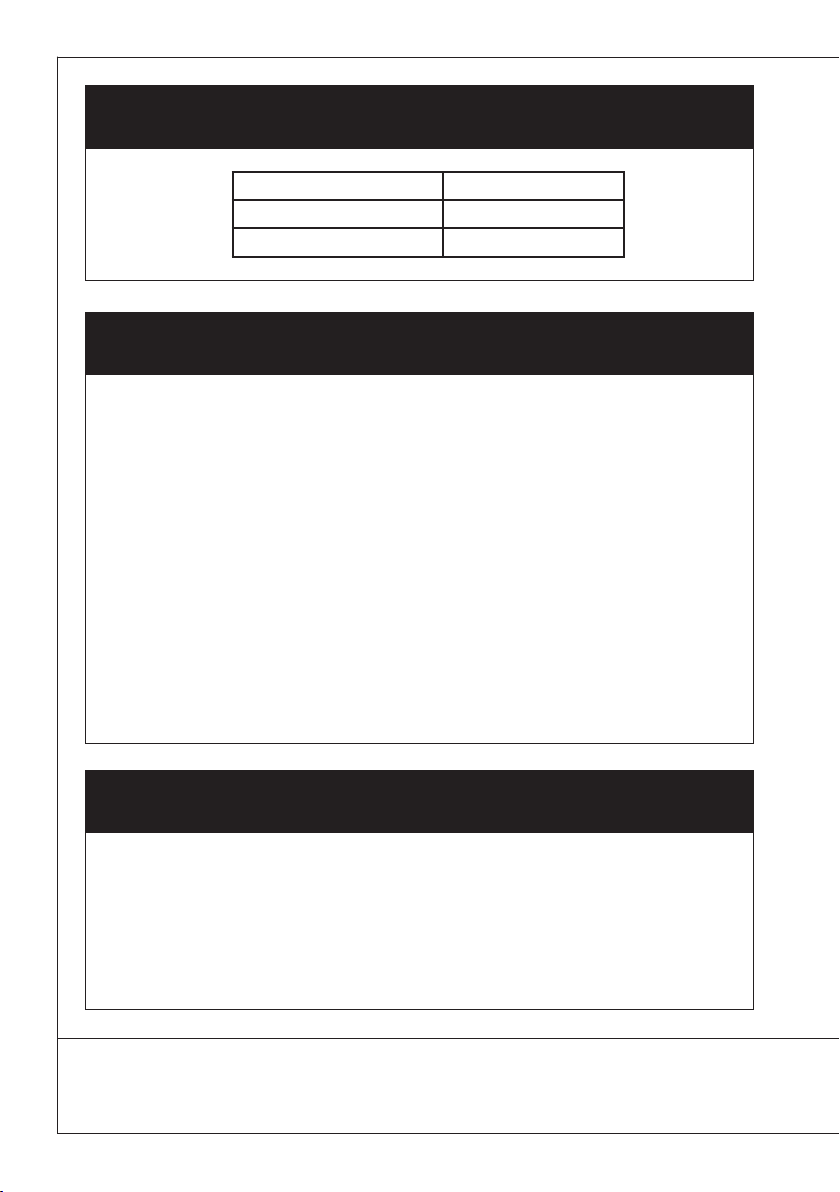

SPECIFICATION

MAXIMUM CAPACITY 2000KG

RETRACTED HEIGHT 70MM

MAXIMUM HEIGHT 500MM

WARNING

• Read and understand all warnings and instructions prior to use.

• Do not overload this jack beyond its rated capacity.

• This jack is a lifting device only.

• This jack is designed for use on hard level surfaces only.

• The load must be supported by jack stands once raised.

• Do not dolly or move the vehicle while it is on the jack.

• Lift only on areas as specified by the vehicle manufacturer.

• Only attachments and/or adaptors supplied by sgs shall be used.

• No alterations to the jack shall be made.

• Failure to heed these warnings may result in damage to the jack

and/or failure resulting in personal injury or property damage.

• Inspect the jack before each use.

INSPECTION BEFORE EACH USE

Before each use a visual inspection shall be made for abnormal

conditions such as cracked welds, damaged, bent, worn, loose or

missing parts.

This jack should be inspected immediately if it is believed to have been

subjected to an abnormal load or shock. Owner/operators should be

aware that repair of this jack requires specialised equipment and

knowledge.

WWW.SGS-ENGINEERING.COM

PAGE 2

Page 3

RAISING A VEHICLE

1. Make sure the jack and vehicle are on a hard level surface.

2. Always set the vehicle handbrake and chock the wheels.

3. Consult the vehicle owner’s manual to ascertain the location of

jacking points and position the jack beneath the lift point.

4. Turn the handle counter clockwise to the closed position.

5. To raise the vehicle pump the handle up and down. Do not over

extend the jack past the maximum height.

6. Place jack stands beneath the vehicle at locations recommended

by the vehicle manufacturer. Do not work under the vehicle

without the use of jack stands. Jacks are not designed to maintain

heavy loads for long periods of time. Do not attempt to place jack

stands simultaneously under both ends of a vehicle or along one

side of a vehicle.

7. Turn the handle slowly clockwise to lower the vehicle onto the jack

stands.

LOWERING A VEHICLE

1. Turn the handle counter clockwise to close the release valve.

2. Pump the handle to lift the vehicle off the jack stands.

3. Remove the jack stands. Do not get under the vehicle while the

vehicle is being lowered.

4. Turn the handle slowly clockwise to lower the vehicle onto the

ground.

PAGE 3

Page 4

MAINTENANCE GUIDE

Daily. See INSPECTION BEFORE EACH USE (page 2).

Monthly. Lubrication is critical to jacks as they support heavy

loads. Any restriction due to dirt, rust or corrosion can cause

either slow movement or rapid jerks damaging the internal

components. The following steps are designed to keep the

jack maintained and operational:

1. Open the release valve by turning the handle knob counter

clockwise and push the ram to its lowest position

2. Remove the filler plug.

3. Fill with clean hydraulic jack oil. Do not use hydraulic brake

fluid.

4. Reinstall the filler plug.

Add lubrication to all moving parts as needed.

Every 6 months. Carry out a thorough inspection for serviceability of component parts Visually inspect for oil leaks (only

a slight oil seepage is permissible). If a leak is found, take the

jack out of service and consult with SGS Engineering.

Annually. Check the ram oil level as follows:

1. Ensure the ram is fully retracted by turning the knob fully

anticlockwise.

2. Remove the cover plate, located at the base of the handle

housing, to gain access the ram, then remove the ram filler

plug.

3. Lift the jack so that it is vertical, resting on its front wheels

and check the oil level. It should be level with the bottom

of the oil filler hole. If necessary, top up with Hydraulic oil.

4. Replace filler plug and purge system of air (see page 5).

WWW.SGS-ENGINEERING.COM

PAGE 4

Page 5

CHECK THE OIL LEVEL

1. Turn the handle clockwise to allow the ram to fully retract. It may

be necessary to apply force to the saddle to lower the ram.

2. Remove the inspection plate.

3. With the jack in the level position remove the oil fill plug. The oil

should be level with the bottom of the fill hole. If not, top up but

do not overfill. Always fill with new, clean hydraulic jack oil.

4. Replace fill plug and inspection plate.

5. Check jack operation.

6. Purge air from the system as required.

SYSTEM AIR PURGE

1. Fully lower the saddle.

2. Turn the handle clockwise one full turn to open.

3. Locate and remove the oil filler plug.

4. Pump the handle eight full strokes to release pressurised air which

may be trapped in the reservoir.

5. Re-install oil filler plug

6. Turn handle counter clockwise one full turn.

FACTORY SERVICE

If this hydraulic jack if found to be damaged in any way, worn or

operating abnormally it should be removed from service until

inspected by an authorised repair centre.

Owner/operators should be aware that the repair of this jack requires

specialised equipment and knowledge. Only factory authorised parts,

labels and decals shall be used on this equipment. An annual

inspection of this jack by an authorised repair centre is recommended

to ensure the jack maintains an optimum operating condition.

PAGE 5

Page 6

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE ACTION

JACK WILL NOT LIFT TO FULL

HEIGHT

JACK WILL NOT HOLD LOAD RELEASE VALVE NOT CLOSING

LOW OIL LEVEL CHECK OIL LEVEL AND REFILL IF

OIL CONTAMINATED

PUMP VALVES NOT SEALING

CYLINDER RAM BINDING

NECESSARY

CONTACT CUSTOMER SERVICE

LIFT ARM WILL NOT LOWER CYLINDER RAM BINDING

JACK FEELS SPONGY WHEN

LIFTING

PARTS WORN

INTERNAL DAMAGE

BROKEN RETURN SPRING

LIFT ARM LINKAGE BENT OR

BINDING

SEE AIR PURGE SECTION PURGE TRAPPED AIR

REPLACEMENT PARTS LIST

ITEM DESCRIPTION QTY

1 SADDLE COVER 1

2 SADDLE 1

3 LIFTING ARM 1

4 UPPER HANDLE 1

5 COTTER PIN 4X50 1

6 CONNECTING BLOCK 1

7 WASHER 2

8 RETURN SPRING 2

9 NUT 18 2

10 SPRING PAD 18 2

11 FLAT PAD 18 2

12 WHEEL FORK SLEEVE 2

13 FRONT WHEEL FORK 2

14 FRONT WHEEL PIN 1

15 SUPPORT SHAFT 1

16 RIGHT PLATE 1

17 LEFT PLATE 1

18 WASHER 20 2

19 NUT 20 2

20 WASHER 14 2

21 NUT 14 2

22 DISK TOOLS 1

23 SCREW 8X16 2

CONTACT CUSTOMER SERVICE

ITEM DESCRIPTION QTY

24 SPRING PAD 8 2

25 SHAFT PIN 1

26 POWER UNIT 1

27 SPRING PAD 12 4

28 SCREW 12X25 2

29 BOLT 6X20 1

30 PAD 10 1

31 PUSHING PLATE 1

32 VALVE 1

33 FLAT PAD 6 1

34 SPRING PAD 6 1

35 NUT 6 1

36 SHAFT PIN 2

37 NUT 12 2

38 FLAT PAD 12 2

39 BUTTERFLY NUT 8 1

40 FLAT PAD 16 2

41 NUT 16 2

42 HANDLE SOCKET PIN 1

43 BACK WHEEL 2

44 SHAFT 1

45 HANDLE SOCKET PIN 1

WWW.SGS-ENGINEERING.COM

PAGE 6

Page 7

REPLACEMENT PARTS DIAGRAM

PAGE 7

Page 8

WARRANTY

This SGS product is covered by a 24 month warranty from the

initial date of purchase. This is a domestic warranty provided

directly by SGS Engineering. Please keep a recipt of your

pucrchase as this may be required as proof of purchase.

You will invalidate your warranty if the product is found to

have been misused, tampered with, modified, overloaded

or used for an application for which it was not designed. The

warranty will also be rendered invalid if the maintenance

prodcedure has not been followed.

You must contact SGS Engineering prior to returning any

product. This warranty does not effect your statutory rights.

CE MARK

SGS ENGINEERING IS COMMITTED TO DESIGNING, MANUFACTURING,

AND MARKETING PRODUCTS THAT MEET OR EXCEED THE NEEDS OF

THE CUSTOMERS WE SERVE. SGS ENGINEERING CAN SUPPLY A LETTER

OF INCORPORATION OR A DECLARATION OF CONFORMITY AND CE

MARKING FOR PRODUCTS THAT CONFORM WITH EUROPEAN COM-

MUNITY DIRECTIVES.

FOR MORE PRODUCTS PLEASE BROWSE OUR WEBSITE: WWW.SGS-ENGINEERING.COM

• GAS STRUTS FOR CARS, DOMESTIC & INDUSTRIAL APPLICATIONS

• HYDRAULIC BOTTLE JACKS, TROLLEY JACKS, AXLE STANDS, FARM JACKS

• WORKSHOP AND INDUSTRIAL HYDRAULIC PRESSES

• HYDRAULIC CYLINDERS, PUMPS, TOOLS & EQUIPMENT

FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.

Page 9

SGS Engineering (UK) Ltd

West Side Park

Derby, DE21 7AZ

EC Declaration of Conformity

This is an important document and should be retained

Raynesway

MANUFACTURER’S NAME:

TYPE OF EQUIPMENT:

PART NUMBER:

APPLICATION OF EC COUNCIL DIRECTIVES / STANDARD:

2006/42/EC Machinery Directive as amended by directive

2009/127/EC

EN1494:2000 + A1:2008 Mobile or movable jacks and associated lifting

equipment

The Supply of Machinery (Safety) Regulations 2008 Statutory instrument 2008

No.1597

The Supply of Machinery (Safety) (Amendment) Regulations 2011 Statutory

instrument 2011 No.2157

SGS Engineering (UK) Ltd

Hydraulic Trolley Jack

TJ2PRO

I, the undersigned, hereby declare that the equipment specied above conforms to the above European Communities Directive(s) and Standard(s).

PLACE:

DATE:

Derby, UK

24th JUNE 2017

(Signature)

Robert Wyatt

Company Secretary

Loading...

Loading...