Page 1

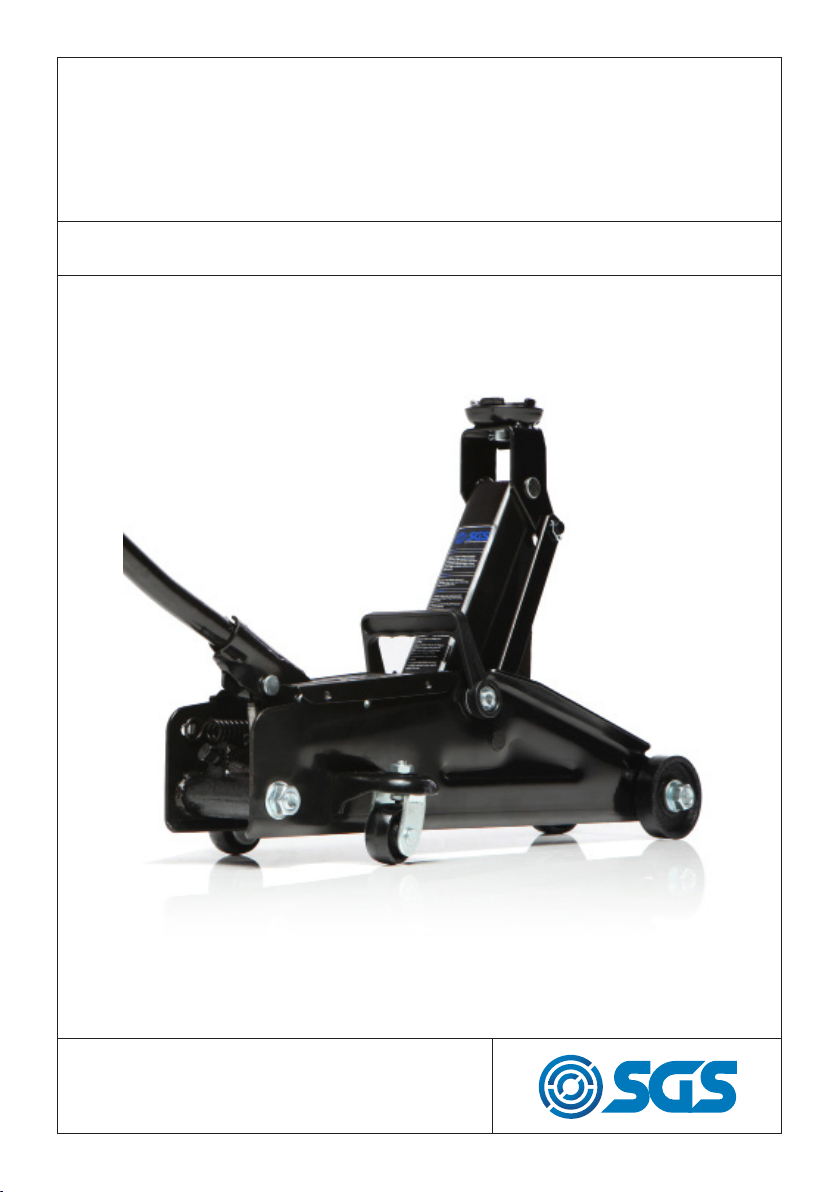

TJ2

TROLLEY JACK

OWNER’S MANUAL

FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.

Page 2

SPECIFICATION

Maximum weight capacity: 2 Ton/2000kg

Retracted (closed) height: 130mm

Maximum extended height: 345mm

Base length: 470mm

Base width: 210mm

Saddle diameter: 44mm

Product weight: 9.6kg

Product code: TJ2

WARNINGS

Read and understand all instructions and warnings prior to use.

Never overload beyond its capacity (10 tons/10000kg).

Ensure the vehicle handbrake is engaged, and in first gear (or

‘park’ for automatic vehicles) before lifting it with this product.

It is also advised to use wheel chocks when lifting a vehicle.

Never have people inside the vehicle when it is being raised by

the trolley jack.

This jack is designed for use on hard level surfaces only. Do not

use on concrete substituted surfaces such as ‘tarmacadan’ etc.

Do not move the vehicle while it is lifted by this trolley jack.

WWW.SGS-ENGINEERING.COM

PAGE 2

Page 3

WARNINGS

• Do not operate this product if it is damaged.

• This jack is a lifting device only, it is not intended for holding weight - always use axle stands where necessary to

support the vehicle.

• No after market alterations must be made to this jack.

• Only designated attachments and adaptors supplied by sgs

engineering should be used.

• Ensure minimum distance of 50cm between static objects

such as doors, walls etc to allow for vehicle tilting.

• Never adjust the safety overload valve.

• Never top up the hydraulic system of this trolley jack using

brake fluid.

• Always lift in areas of the vehicle assembly as advised by

the vehicle manufacturer, e.g in proper jacking points etc

• Always store this trolley jack in a safe area when not in use,

away from adverse weather conditions, away from extreme

temperatures, where it cannot be tampered with, and

where children cannot play with it.

• Never use a ‘cheater’ pipe, or any other device to extend

the handle.

PAGE 3

Page 4

INSPECTION BEFORE EACH USE

Before each use, it’s highly advised to visually inspect this trolley jack.

Abnormalities that should be checked for every time:

• cracked welds

• leaking fluid anywhere on the trolley jack

• bent parts

• missing parts

• loose parts

• damaged parts

This trolley jack should be taken out of service if it is believed

to have been subjected to an abnormal load or shock.

Owner/operators should be aware that repair of this trolley jack

requires specialist attention in the form of suitable repair

equipment and knowledge.

WWW.SGS-ENGINEERING.COM

PAGE 4

Page 5

PURGING YOUR TROLLEY JACK

Sometimes during transport and handling, air gets into the

hydraulic system causing poor lifting performance. Before the

initial operation purge any air from the system by following

these steps:

1. The jack handle should be placed

on the release valve and turned anticlockwise to open the valve.

2. Place the handle back into the

receiver and pump the jack handle up

and down 20 times.

This should force any air from the

system and lubricate the seals.

3. Close the release valve by turning

clockwise.

PAGE 5

4. Test the jack. If the jack won’t lift, or

lifts but won’t hold a load, then repeat

the procedure. If the problem persists

then please contact us.

Page 6

RAISING THE VEHICLE

1. Make sure the jack and vehicle are on

a hard level surface.

2. Always set the vehicle handbrake and

chock the wheels.

3. Consult the vehicle owner’s manual to

ascertain the location of jacking points

and position the jack beneath the lifting

point.

4. Raise your vehicle by closing the

release valve and pumping the handle.

WWW.SGS-ENGINEERING.COM

PAGE 6

Page 7

LOWERING THE VEHICLE

1. Place the handle onto the release valve

and turn it slowly anti-clockwise to open

the release valve.

2. The vehicle will lower.

PAGE 7

Page 8

MAINTENANCE GUIDE

Daily. See INSPECTION BEFORE EACH USE (page 4).

Monthly. Lubrication is critical to jacks as they support heavy

loads. Any restriction due to dirt, rust or corrosion can cause

either slow movement or rapid jerks damaging the internal

components. The following steps are designed to keep the

jack maintained and operational:

1. Open the release valve by turning the handle knob counter

clockwise and push the ram to its lowest position

2. Remove the filler plug.

3. Fill with clean hydraulic jack oil. Do not use hydraulic brake

fluid.

4. Reinstall the filler plug.

Add lubrication to all moving parts as needed.

Every 6 months. Carry out a thorough inspection for serviceability of component parts Visually inspect for oil leaks (only

a slight oil seepage is permissible). If a leak is found, take the

jack out of service and consult with SGS Engineering.

Annually. Check the ram oil level as follows:

1. Ensure the ram is fully retracted by turning the knob fully

anticlockwise.

2. Remove the cover plate, located at the base of the handle

housing, to gain access the ram, then remove the ram filler

plug.

3. Lift the jack so that it is vertical, resting on its front wheels

and check the oil level. It should be level with the bottom

of the oil filler hole. If necessary, top up with Hydraulic oil.

4. Replace filler plug and purge system of air (see page 5).

WWW.SGS-ENGINEERING.COM

PAGE 8

Page 9

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE ACTION

Jack will not lift to

full height

Jack will not hold

load

Lift arm will not

lower

Jack feels spongy

when lifting

Low oil level Check oil level and

refill if necessary

Release valve not

closing, oil may be

contaminated- pump

Contact customer

service:

(+44) 01332 576 850

valves not sealing,

cylinder ram may be

binding

Cylinder ram

binding,

parts may be worn,

Contact customer

service:

(+44) 01332 576 850

and/or internal damage- or a broken

return springor a lift arm linkage

bent or binding

Trolley jack may

Purge trapped air

require an air purge

PAGE 9

Page 10

SERVICING

If this hydraulic jack if found to be damaged in any way, worn or

operating abnormally it should be removed from service until

inspected by an authorised repair centre.

Owner/operators should be aware that the repair of this jack

requires specialised equipment and knowledge. Only factory

authorised parts, labels and decals shall be used on this

equipment. An annual inspection of this jack by an authorised

repair centre is recommended to ensure the jack maintains an

optimum operating condition.

Should the trolley jack ever become unservicable, drain off all

fluid and dispose of in a proper manner, paying heed to any

environmental preservation regulations.

WARRANTY

This SGS product is covered by a 24 month warranty from the

initial date of purchase. This is a domestic warranty provided

directly by SGS Engineering. Please keep a recipt of your

pucrchase as this may be required as proof of purchase.

You will invalidate your warranty if the product is found to

have been misused, tampered with, modified, overloaded

or used for an application for which it was not designed. The

warranty will also be rendered invalid if the maintenance

prodcedure has not been followed.

You must contact SGS Engineering prior to returning any

product. This warranty does not effect your statutory rights.

WWW.SGS-ENGINEERING.COM

PAGE 10

Page 11

TECHNICAL DIAGRAM

PAGE 11

Page 12

TECHNICAL DIAGRAM - PARTS LIST

Part Description Qty

1. Cap 1

2. Handle 1

3. Saddle - A 1

4. Saddle - B 1

5. Mount, Saddle 1

6. Pin, Mount, Saddle 1

7. Radius link 2

8. Shaft link 1

9. Pin link 2

11. Retaining ring 4

12. Retaining ring 2

13. Front wheel 2

14. Spindle, Front wheel 1

15. Spacer, Front wheel 2

16. Nut 6

17. Flat washer 2

18. Castor wheel 2

19. Spindle, Castor wheel 2

20. Fork, Castor wheel 2

21. Bolt, Castor wheel 2

22. Nut 2

23. Lock washer 2

24. Flat washer 2

Part Description Qty

25. Steel ball bearing 12

26. Side member LH 1

27. Side member RH 1

28. Anchor bolt 1

29. Spacer tube 2

30. Spindle side member 1

31. Lifting arm 1

32. Spindle lifting arm 1

33. Return spring 1

34. Cross head pin 1

35. Retaining ring 2

36. Cover plate 1

37. Hydraulic unit

assembly

38. Top nut 1

39. O-ring, Seal ram 1

40. Body, Hydraulic unit 1

41. Screer filler, Body 1

42. Release valve 1

43. O-ring seal, Release

valve

45. Steel ball 2

46. Steel ball 1

47. Cylinder, Pump 1

48. O-ring seal, pump

cylinder

1

1

1

Part Description Qty

49 Washer 1

50 Sereen,

Washer pump

51 Handle sleeve 1

52 Link piston 1

53 Piston pin 1

54 Connector pin 1

55 Piston 1

56 Backup ring 1

57 Backup ring 1

58 Set pin 2

59 Set pin 1

60 Cap ring 1

61 Collar, Ram 1

62 Ram 1

63 Cylinder, Ram 1

64 Oil chamber 1

65 Fiber washer,

Oil chamber

66 Overload valve

adjusting screw

67 O-ring seal 1

68 Spring 1

69 Spring guide

overload valve

71 Filler plug 1

74 Covering 1

75 Spring washer 6

77 Fiber washer,

Oil chamber

1

2

1

1

1

WWW.SGS-ENGINEERING.COM

PAGE 12

Page 13

SGS Engineering (UK) Ltd

West Side Park

Derby, DE21 7AZ

EC Declaration of Conformity

This is an important document and should be retained

Raynesway

MANUFACTURER’S NAME:

TYPE OF EQUIPMENT:

PART NUMBER:

APPLICATION OF EC COUNCIL DIRECTIVES / STANDARD:

2006/42/EC Machinery Directive as amended by directive

2009/127/EC

EN1494:2000 + A1:2008 Mobile or movable jacks and associated lifting

equipment

The Supply of Machinery (Safety) Regulations 2008 Statutory instrument 2008

No.1597

The Supply of Machinery (Safety) (Amendment) Regulations 2011 Statutory

instrument 2011 No.2157

SGS Engineering (UK) Ltd

Hydraulic Trolley Jack

TJ2

I, the undersigned, hereby declare that the equipment specied above conforms to the above European Communities Directive(s) and Standard(s).

PLACE:

DATE:

Derby, UK

24th JUNE 2017

(Signature)

Robert Wyatt

Company Secretary

Loading...

Loading...