SGS SSB100 Owner's Manual

SSB100

SHOT BLAST CABINET

OWNER’S MANUAL

FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.

SPECIFICATION

TOOL MODEL SSB100

TYPE BENCH MOUNTED

VOLTS 12V

MIN AIR REQUIREMENT 10 CFM

MIN AIR REQUIREMENT 80-100 PSI

WARNING

Read and understand instructions before use.

Always wear eye/face and hand protection.

Do not use any silica based abrasives with this cabinet.

Silica based abrasives have been linked to severe res-

piratory disease. Always use recommended abrasives.

Abrasives used in this unit may be covered by COSHH.

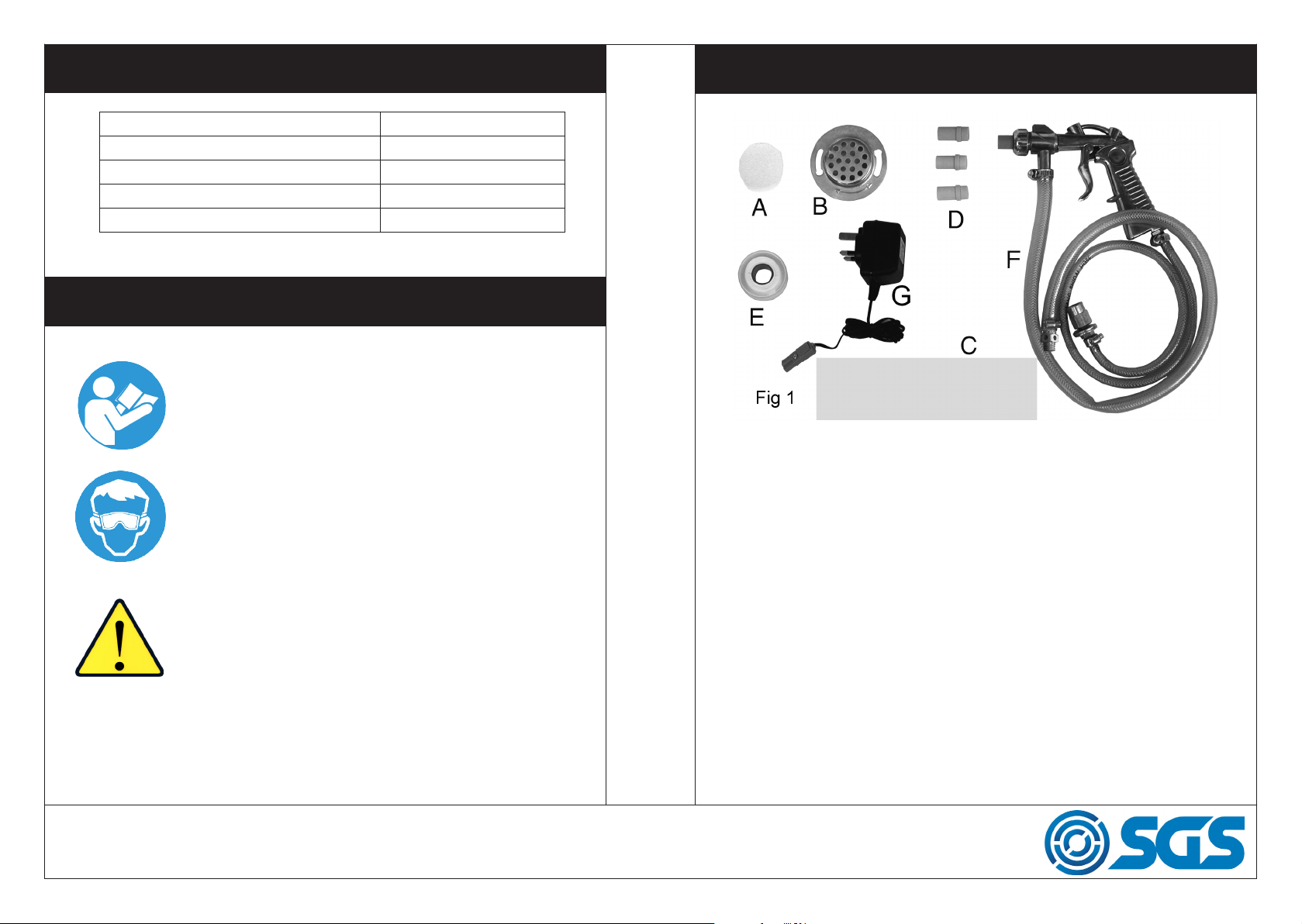

INVENTORY

A - Foam Vent Filter

B - Air Vent Cover

C - Spare protective film

D - Ceramic Nozzles 4, 5, 6 & 7mm (one nozzle is fitted)

E - PTFE tape

F - Gun c/w air and pickup hoses

G - 12V transformer & cable

WWW.SGS-ENGINEERING.COM

PAGE 2

PAGE 3

ASSEMBLY

ASSEMBLY

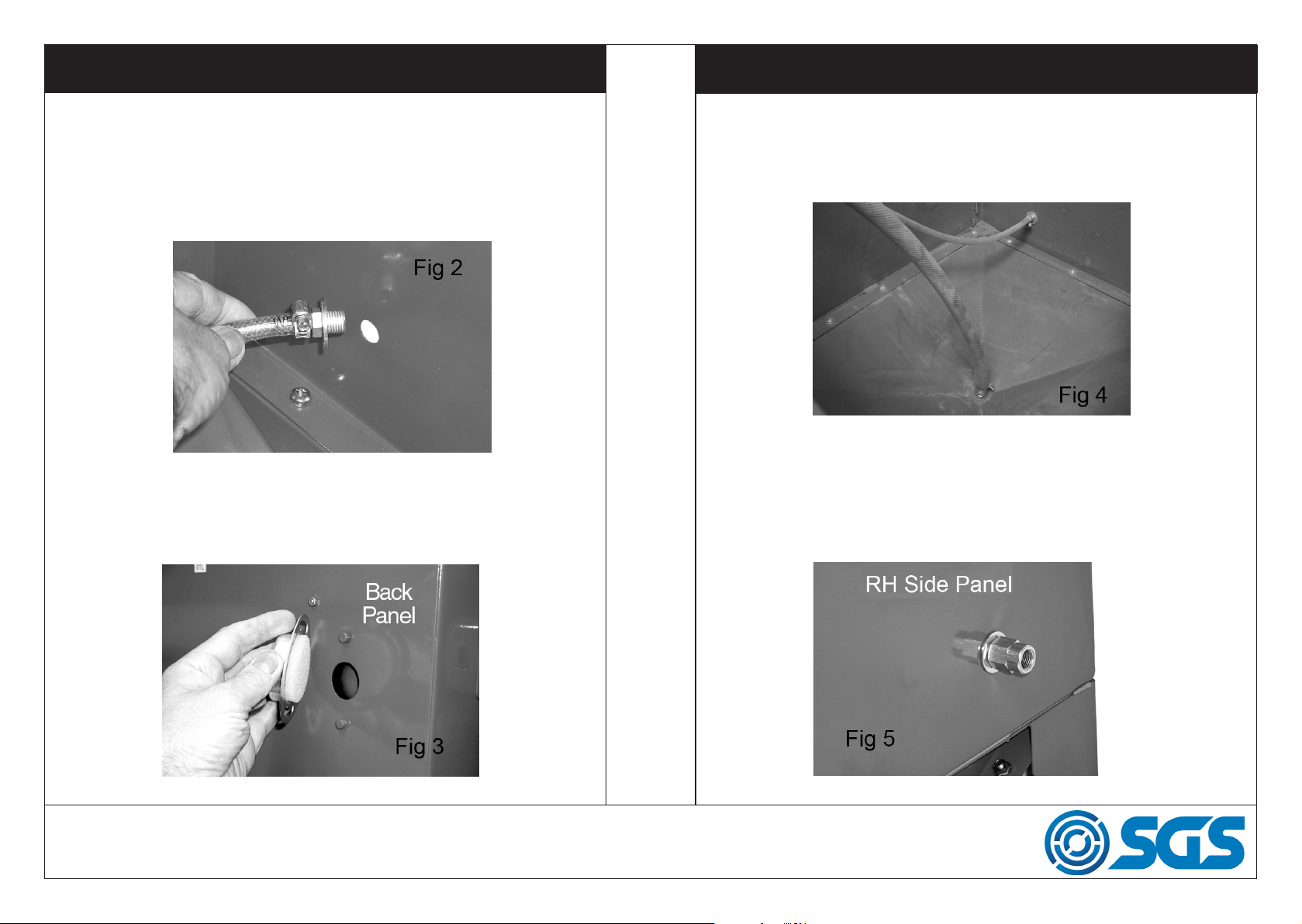

The unit is shipped fully assembled, except for the air vent filter and the

gun with attached hoses. First, remove the grid and all the various loose

components from within the cabinet.

The end of the air inlet hose, connected to the gun, is inserted through

the 16mm dia. hole in the cabinet from the inside, as shown in Fig 2. Ensure a flat washer is threaded on to the adapter as shown.

Thread a flat washer, followed by the extended nut, onto the adapter,

from the outside of the cabinet, and tighten. Insert the circular foam filter

into the recess in the Air Vent Cover, and attach the cover to the rear of

the cabinet as shown in Fig 3, having first prised out the plastic bung from

the vent hole.

The pick up hose should be attached to the bottom of the cabinet as

shown in Fig 4, using the large washer and nut underneath.

Replace the grid, ensuring the feet face downwards with the cut away

section at the rear of the cabinet.

Finally, connect the air supply to the extended nut shown in Fig 5. Use of

the PTFE tape supplied with ensure an airtight seal.

• The air supply should be dry and capable of delivering a minimum

of 10 cu ft/min at 100 lbf/in.

WWW.SGS-ENGINEERING.COM

PAGE 4

PAGE 5

Loading...

Loading...