SGS SCT501 Owner's Manual

FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.

OWNER’S MANUAL

5 IN 1 MULTI- TOOL

PAGE 2

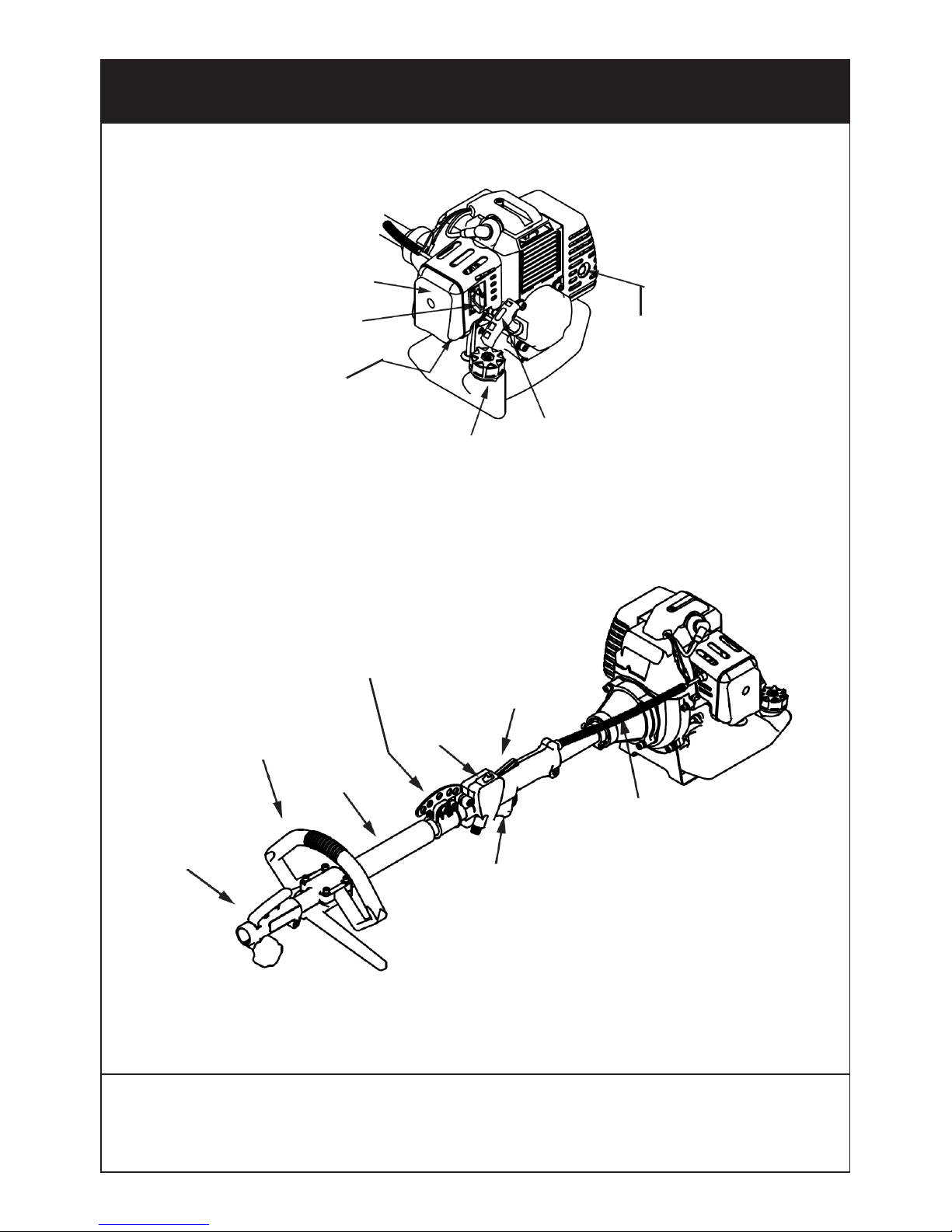

PARTS LOCATION

Air

filter

cover

Choke

lever

Primer

bulb

Fuel tank

Pull start

Muffler

Throttle

cable

Throttle

control

Throttle

trigger

On/off

switch

Harness

suspension

point

Main

shaft

tube

Loop

handle

Split shaft

connector

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE: 01332 576 850

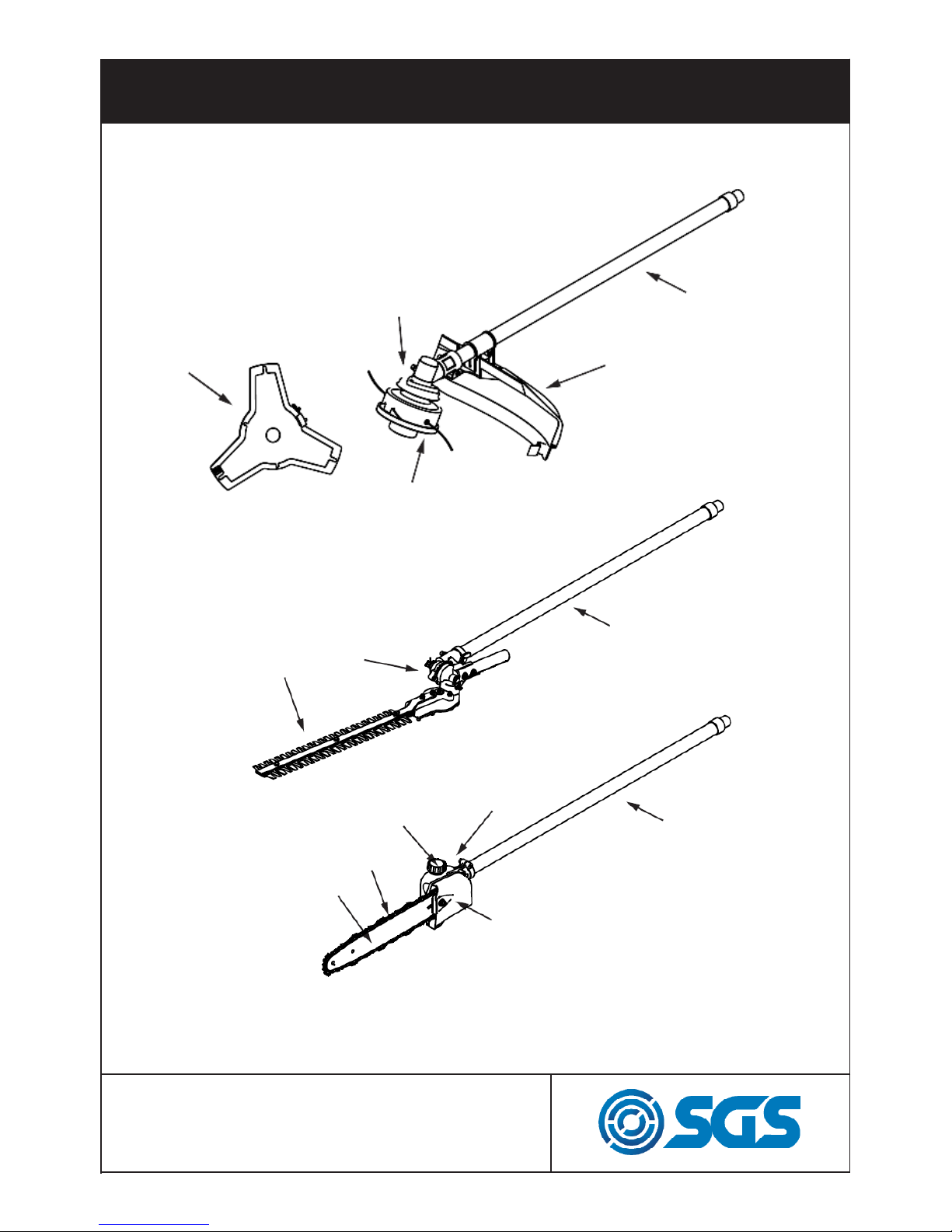

PAGE 3

Attachment

guard

Brush

cutter gear

case

Nylon

trimmer

Three point

blade

Working

shaft tube

PARTS LOCATION

Working

shaft tube

Working

shaft tube

Hedge

trimmer

gear case

Hedge trimmer

attachment

Pruner guide bar

Pruner saw

Chain cover

Pruner

gear case

Oil tank

PAGE 4

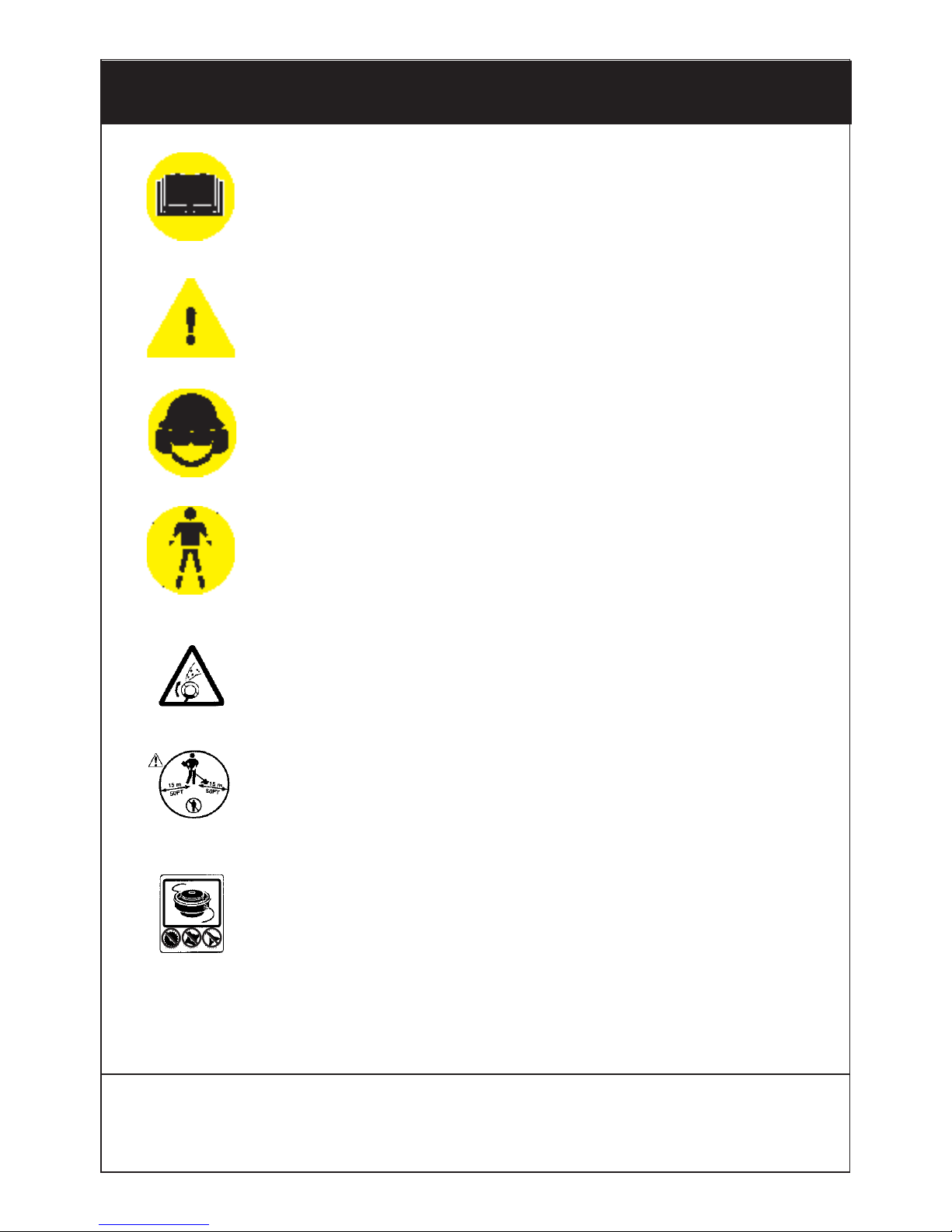

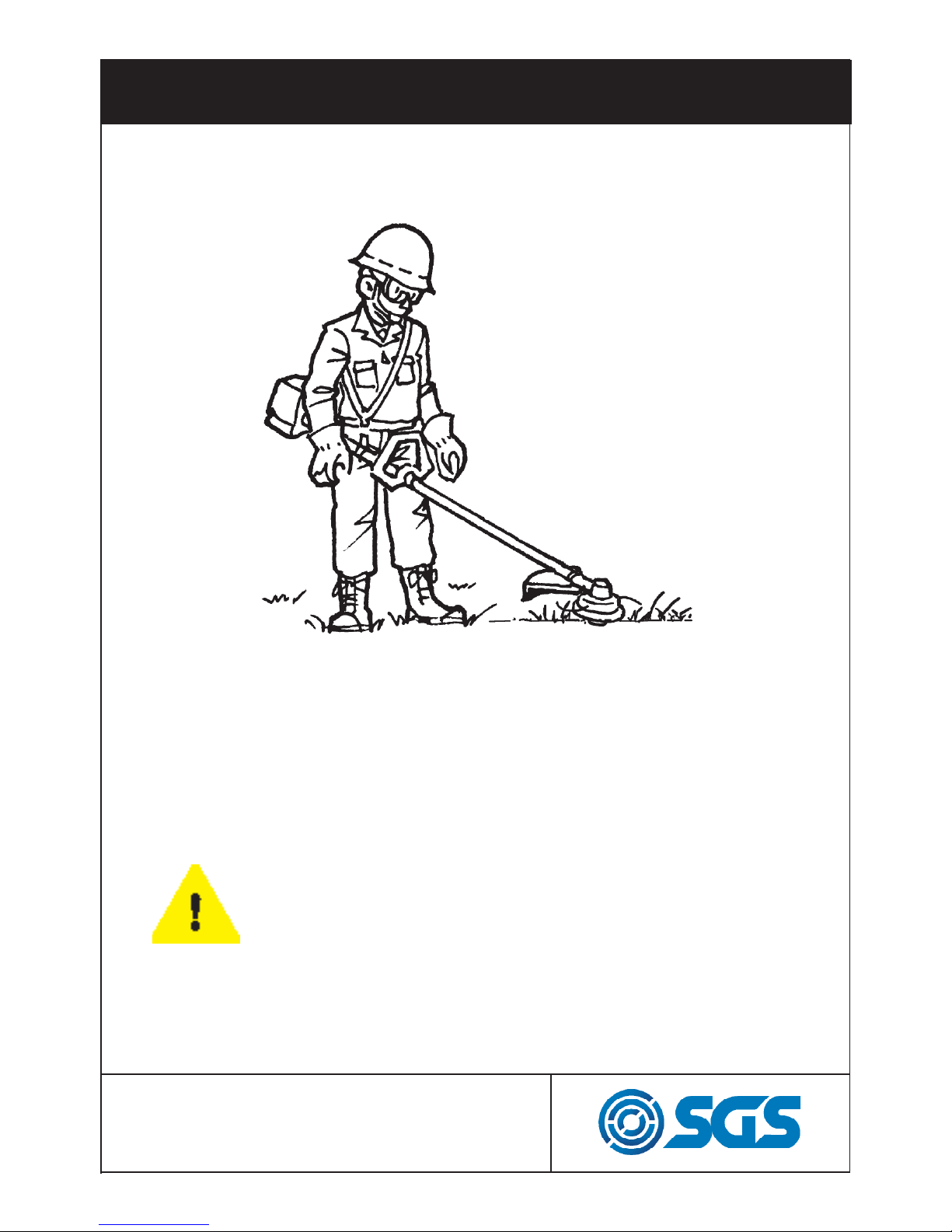

FOR SAFE OPERATION

Read operator’s instruction book before

operating this machine.

Read, understand and follow all warnings.

Wear head, eye and ear protection.

Use suitable work-wear to protect yourself.

Watch out for thrown objects & ricochets

The operator of the machine must ensure,

while working, that no persons or animals

come closer than 50 feet (15 meters).

Only use non--metallic, flexible

cutting attachments, i.e. trimmer

heads with trimmer line.

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE: 01332 576 850

PAGE 5

FOR SAFE OPERATION

GLOVES

Gloves should be worn when necessary, e.g., when

fitting cutting attachments.

HEARING PROTECTION

Wear hearing protection that provides adequate

noise reduction.

EYE PROTECTION

Always wear approved eye protection. If you use a

visor then you must also wear approved protective

goggles. Approved protective goggles must comply with your countries relevent safety standard.

BOOTS

Wear sturdy, non--slip boots.

CLOTHING

Wear clothes made of a strong fabric and

avoid loose clothing that can catch on twigs and

branches. Always wear heavy, long pants. Do not

wear jewellery, shorts sandals or go barefoot. Secure hair so it is above shoulder level.

PAGE 6

FOR SAFE OPERATION

The only accessories you can operate with this engine unit are the cutting attachments we recommend.

Never use wire, rope, string, etc.

Never use the machine if you are tired, if you have

drunk alcohol, or if you are taking medication that

could affect your vision, your judgment or your coordination.

Never use the machine in extreme weather conditions

such as severe cold, very hot and/or humid climates.

Never use a machine that has been modified in any

way from its original specification.

Wear personal protective equipment.

Never use a machine that is faulty. Carry out the

checks, maintenance and service instructions described in this manual. Some maintenance and service

measures must be carried out by trained and qualified

specialists.

The strimmer attachment is only designed for

trimming grass.

PAGE 7

FOR SAFE OPERATION

All covers and guards must be fitted before starting.

Make sure the spark plug cap and lead are not damaged. Otherwise you could get an electric shock.

The machine operator must ensure that no people

or animals come closer than 50 feet (15 meters) while

working. Stay clear of spinning line.

Secure or remove loose clothing or clothing with

loosely hanging ties, straps, tassels, etc. They can be

caught in moving parts.

Being fully covered also helps protect you from debris

and pieces of toxic plants thrown by spinning line.

Keep handles free of oil and fuel.

Always keep the engine on the right hand side of your

body. Hold the unit firmly with both hands.

Keep trimmer head below waist level.

PAGE 8

- Make sure the chain and sprocket are correctly adjusted

before operating the pruner. Never attempt chain

adjustment with the engine running!

• Always make sure the cutting attachment

is properly installed and firmly tightened before operation.

• Never use a cracked or warped guide bar: replace it

with a serviceable one and make sure it fits properly.

• If a saw blade should bind fast in a cut, shut off the

engine immediately. Push the branch or tree to ease the

bind and free the blade.

• Do not operate the pole pruner with the muffler removed.

• When cutting a limb that is under tension, be alert for springback

so that you will not be struck by the moving

limb.

• Always stop the engine immediately and check for damage if you

strike a foreign object or if the machine becomes tangled.

Do not operate with broken or damaged equipment.

• Do not make unauthorized modifications or substitutions to

the guide bar or chain.

• Never allow the engine to run at high RPM without a load.

Doing so could damage the engine.

• Keep the pruner as clean as possible.

FOR SAFE OPERATION

IMPORTANT

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE: 01332 576 850

PAGE 9

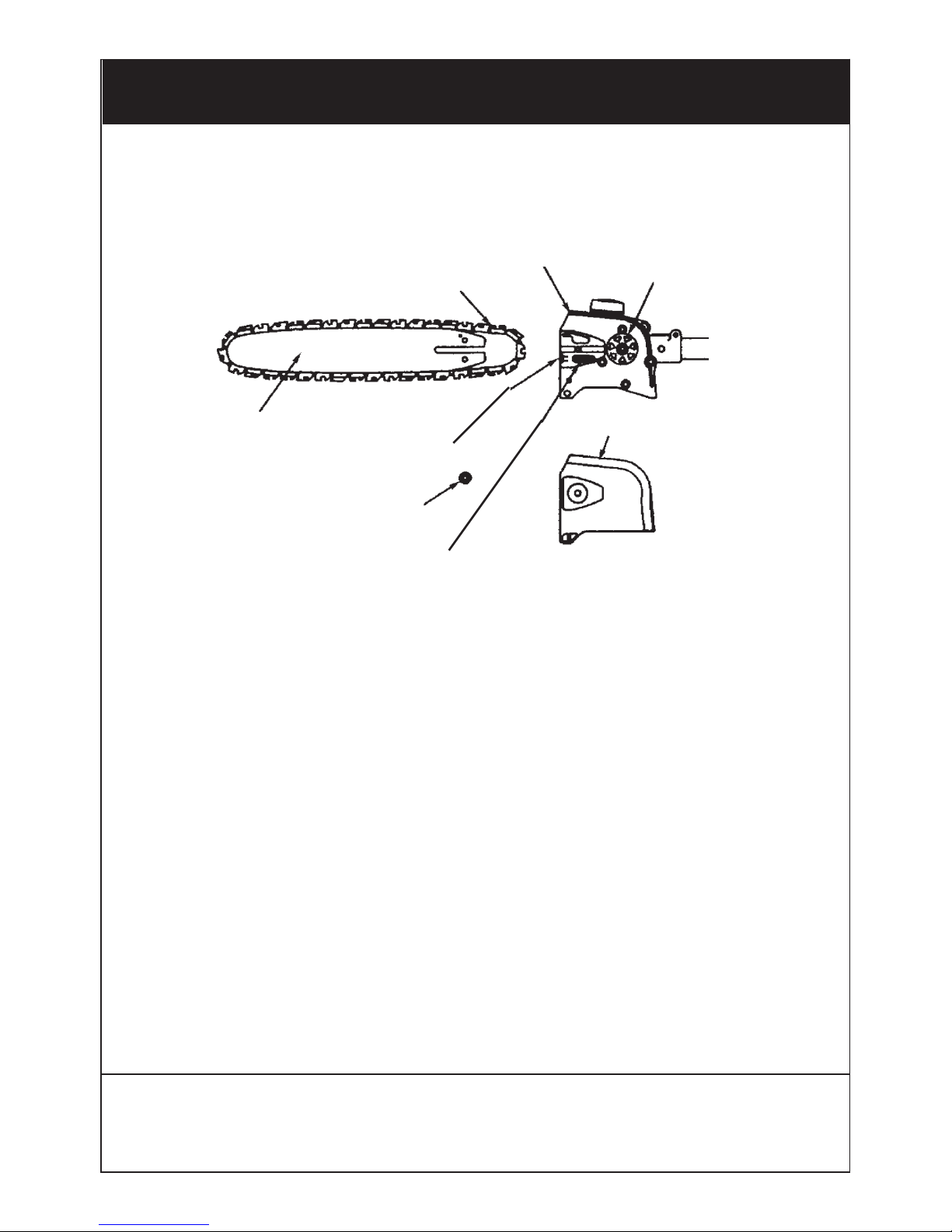

A standard package contains the items as shown below.

SET UP

(1) Guide bar

(2) Saw chain

(3) Transmission

(4) Sprocket

(5) Chain tension adjust screw

(6) Nut

(7) Chain tensioner nut

(8) Chain cover

The saw chain has very sharp edges. Use protective

gloves for safety.

WARNING

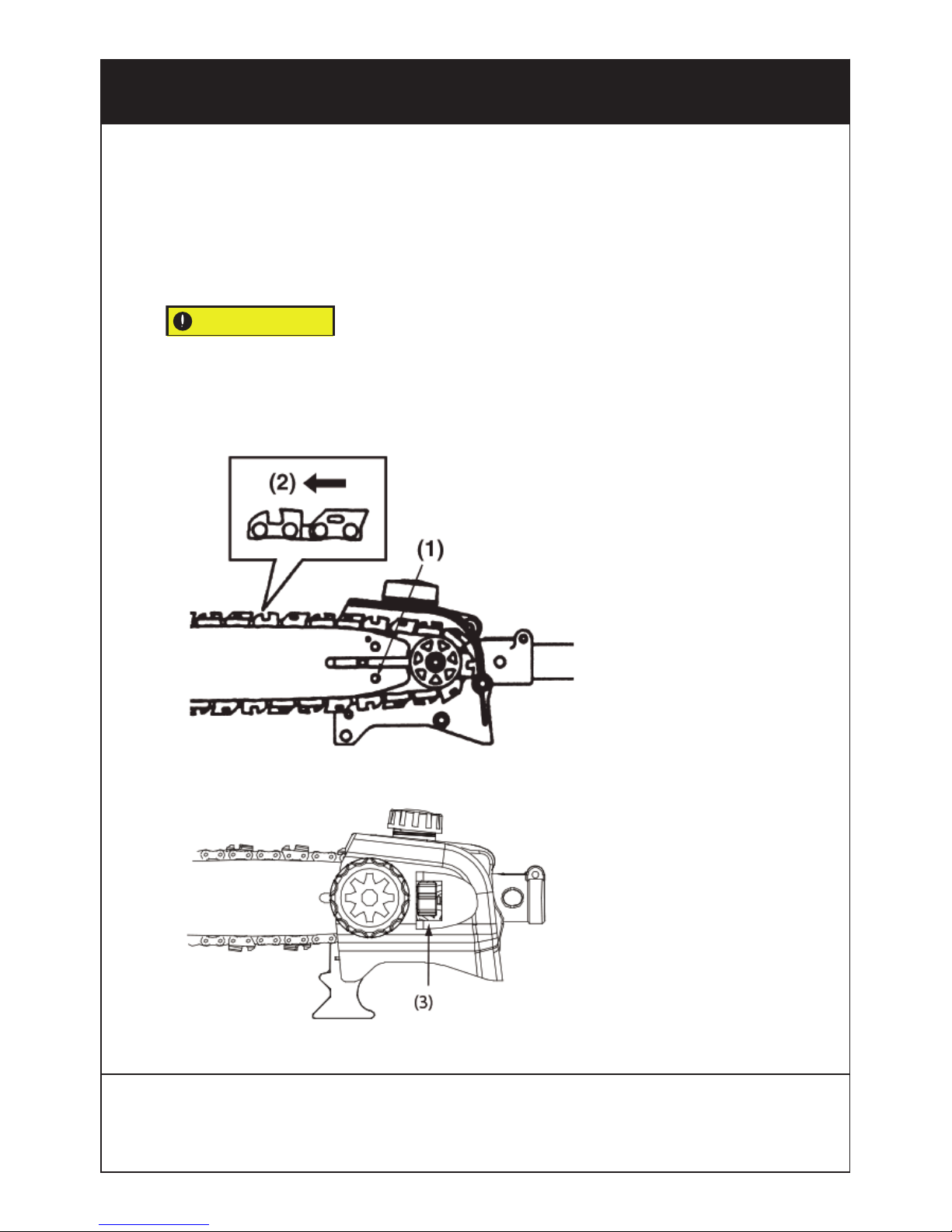

PAGE 10

1. Loosen the nut and remove the chain cover.

2. Mount the guide bar then fit the saw chain around the

bar and sprocket.

3. Fit the chain tensioner nut into the lower hole of the

guide bar, then install the chain cover, and fasten the

mounting nut to finger tightness.

Pay attention to the correct direction of

the saw chain.

SET UP

IMPORTANT

(1) Hole

(2) Moving direction

(3) Toolless chain tensioner roller

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE: 01332 576 850

PAGE 11

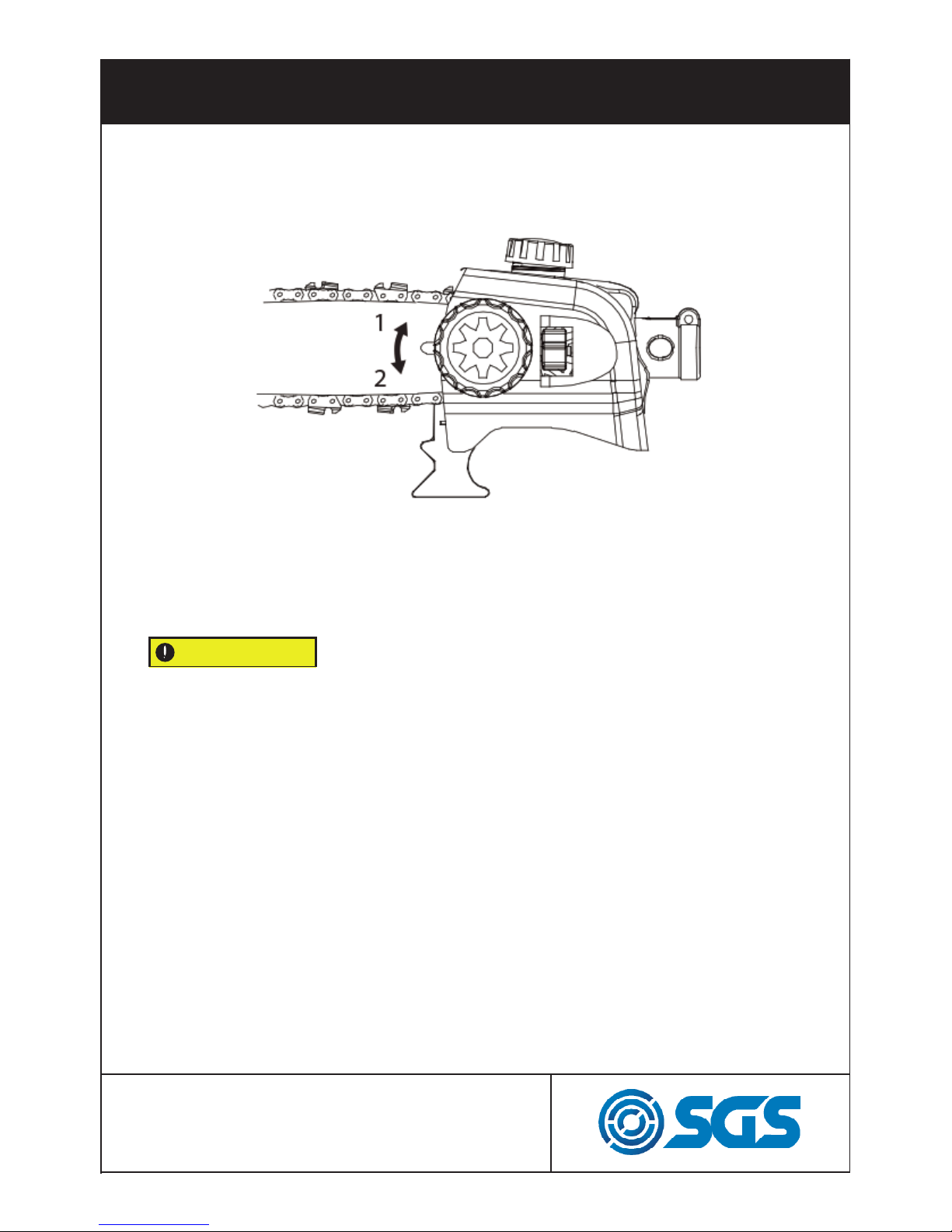

4. Adjust the chain tension by turning the tensioner screw until

the tie straps just touch the bottom side of the bar rail.

SET UP

5. Tighten the mounting nut securely with the bar tip

held up (TORQUE: 8.9 ~ 11.7 N.m./90 ~ 120 kg-cm). Then

check the chain for smooth rotation and correct tension

while moving it by hand. If necessary, readjust.

Balance Unit

1. Put on harness strap and attach it to the unit suspension

point.

2. Depending on the working posture, insert hook up or down

the suspension point until the unit balances and the strap fits

your body.

It is very important to maintain the proper chain tension.

Rapid wear of the guide bar or the chain coming off easily

can be caused by improper tension.

IMPORTANT

(a) Loosen (b) Tighten

PAGE 12

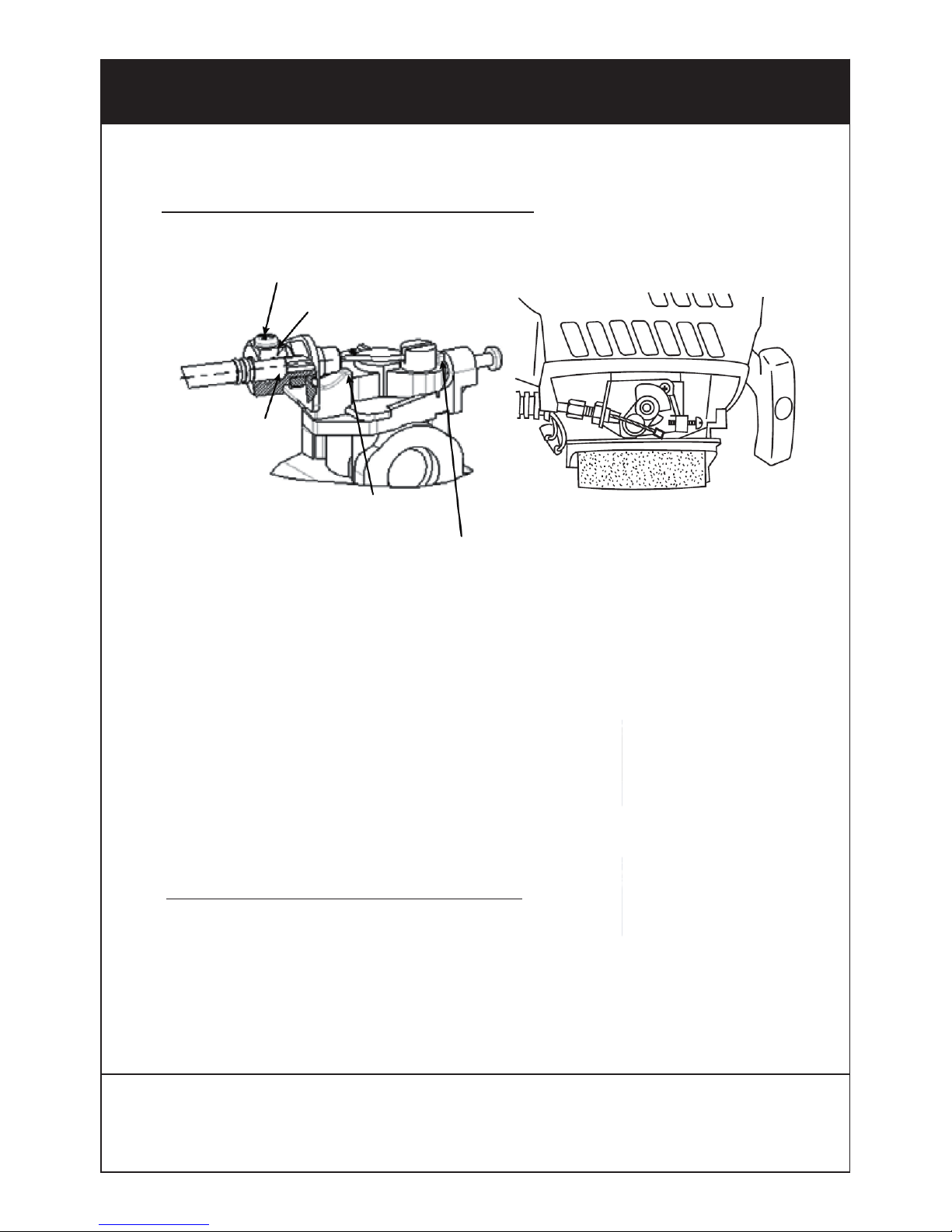

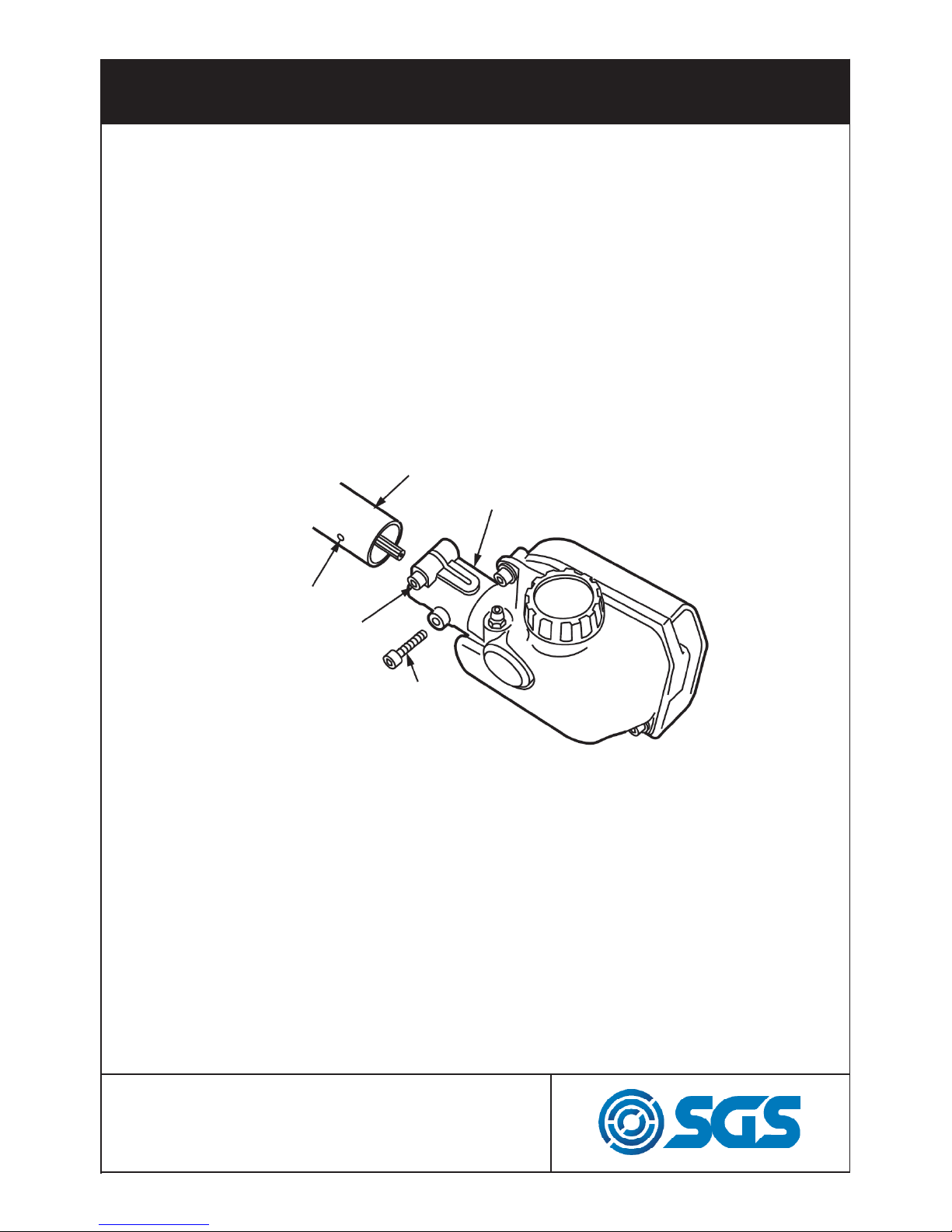

SET UP

CONNECTING THROTTLE WIRE

M3 screw

Insert the

cable

to the end

of

adjuster

Full on

stopper

Idling adjust screw

1. Connect throttle wire with carburettor. Insert the cable

to the end of adjuster fix the throttle cable by tightening the

M3 screw. (Tightening torque: 0.4 ~ 0.8 N.m.)

2. Make sure the ‘STOPPER-PLATE’ of carburettor moves

to contact with ‘IDLING ADJUST SCREW’ and the ‘SWINGARM’ of carburettor moves to contact with ‘FULL ON STOPPER’ by gripping throttle lever.

CONNECTING SWITCH WIRES

Connect the switch wires between the engine and the main

unit. Pair wires of the same colour.

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE: 01332 576 850

PAGE 13

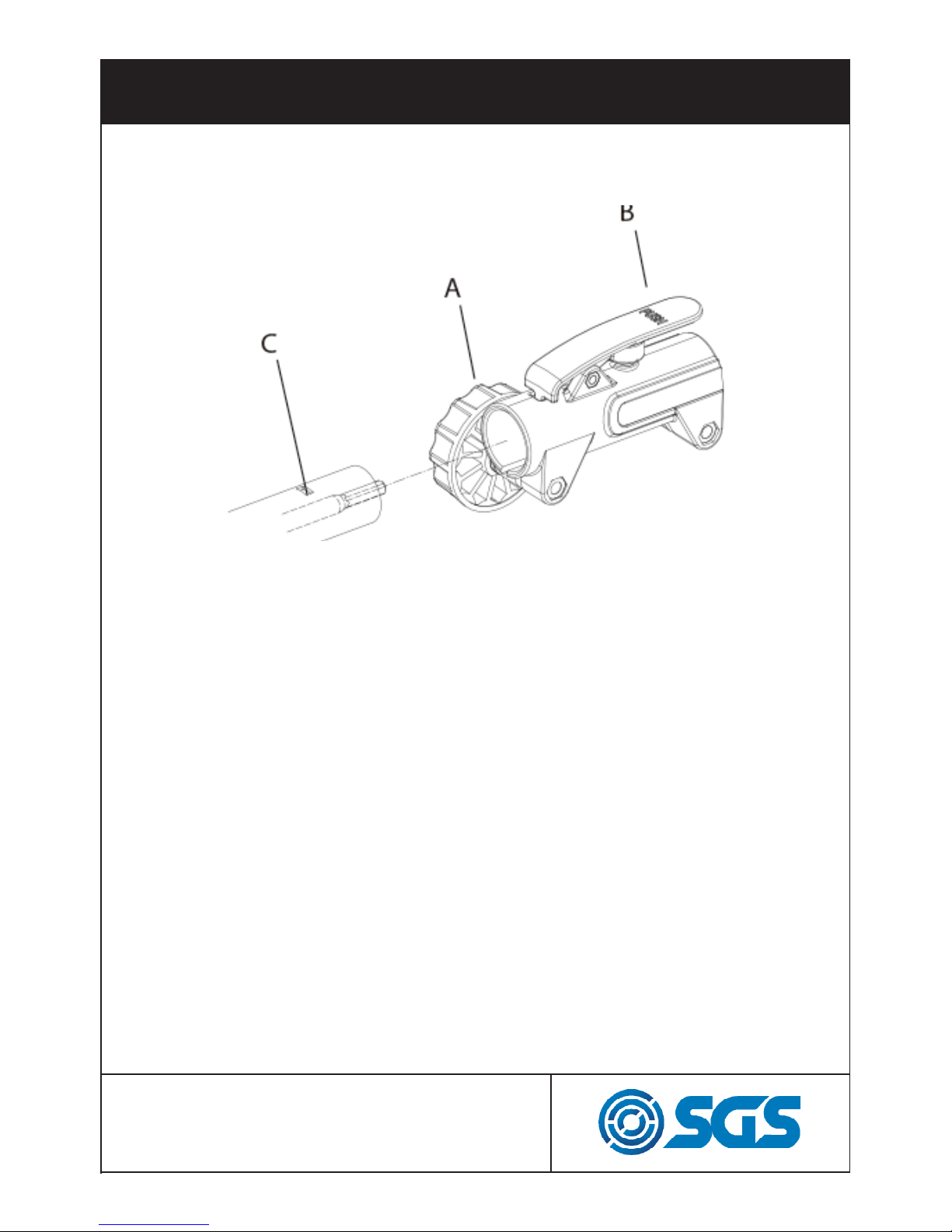

SET UP

Connecting the shaft

To connect the working shaft to the main shaft with the

coupler:

1. Loosen the Locking Knob (A) counter clockwise so the

working shaft can be inserted into the tube coupler.

2. Press the Push Button (B) and gently rotate the working

shaft back and forth while inserting to make sure the drive

shaft is placed in position.

3. Release the Push Button to lock the hole (C) of the

working shaft tube. The Push Button is connected to a

spring-loaded detent that can snap the working tube in

position

4. Turn the Locking Knob clock-wise to secure the

connection.

PAGE 14

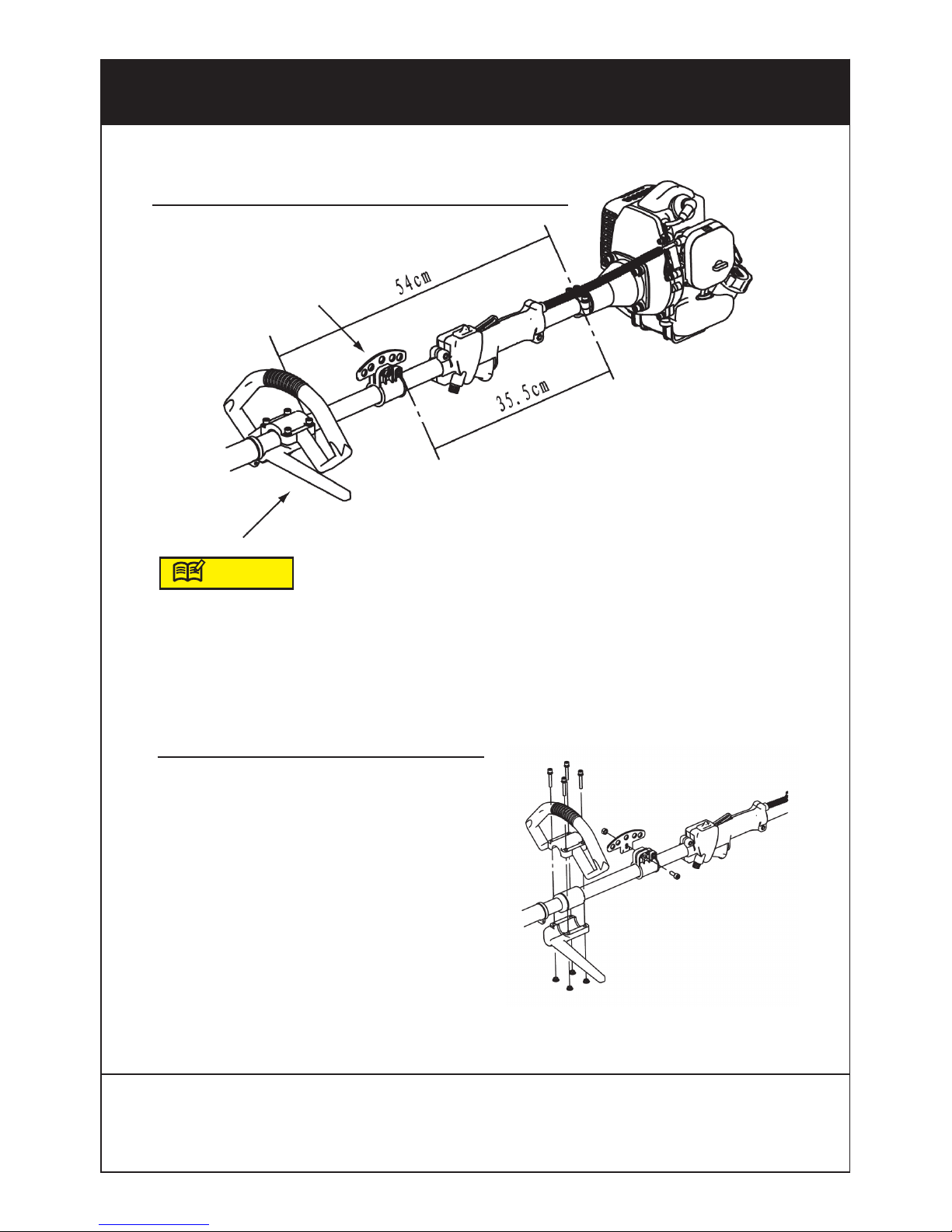

SET UP

Loop

handle

Suspension

point

HANDLE AND SUSPENSION POINT

The recommended position of the handle and suspension

point is marked above. However you may adjust the position

to make sure it is comfortable for you.

INSTALLATION OF HANDLE

Set the upper part and lower part of

the handle at the right position.

Tighten the loop handle with the

screw and nut.

Insert the nuts (4) into the countersunk holes in the lower handle and

secure the top part of the

handle with the bolts supplied (4).

ZZ

NOTE

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE: 01332 576 850

PAGE 15

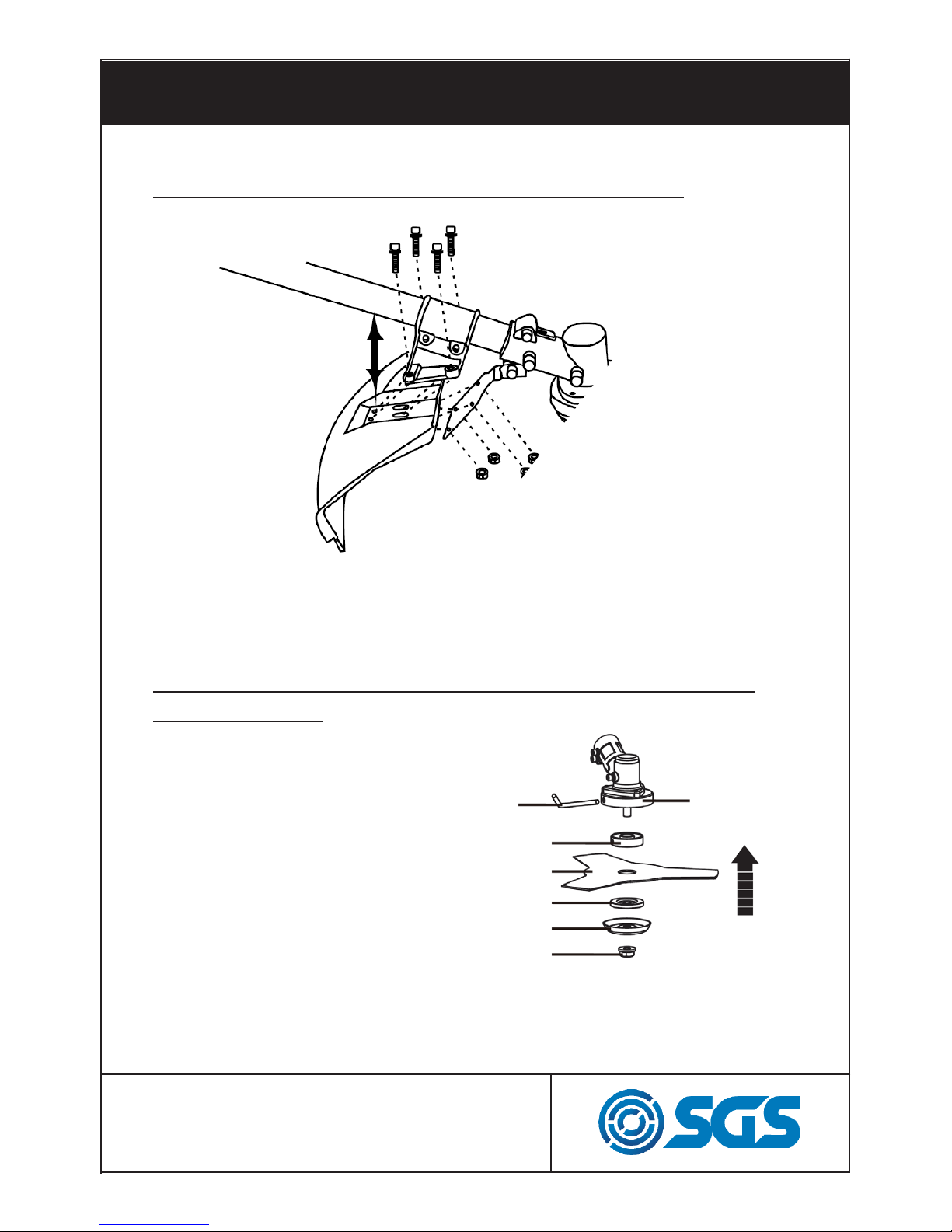

SET UP

INSTALLING CUTTING ATTACHMENT GUARD

Put the cutting attachment guard on the gearbox,

attach it with the nuts and bolts provided.

BRUSH CUTTER AND EDGE TRIMMER INSTALLING

METAL BLADE

Key

Gear case

Collar ring

Metal blade

Washer

Washer

Nut

1- Insert the key wrench

into the gear case locking

hole.

2- Screw the collar ring on

the shaft thread.

3- Secure metal blade

between collar ring and

washer.

4- Place the washer.

5- Screw the nut.

PAGE 16

SET UP

INSTALLING THE NYLON LINE (NYLON CUTTER HEAD)

Gear case

Key

Collar ring

Nylon spool

1- Insert the key wrench into the gear case locking hole.

2- Screw the collar ring on the shaft thread.

3- Screw the nylon spool on the shaft thread.

4- Check the spool is secured tightly.

ATTACHING THE TRIMMING MECHANISM

Attachment

tube

Screw

hole

Fastening

bolt

Screw

Gear

case

(Instructions to follow on page 10)

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE: 01332 576 850

PAGE 17

SET UP

1. Remove the plastic cap on the end of the tube.

2. Remove the screw.

3. Insert the end of the tube into the gear case, and make sure

to align the transmission shaft of the tube with the transmission

shaft of the gear case.

4. Line up the hole on the tube with the hole on the gear case

and insert the screw through the hole and tighten firmly.

ATTACHING THE PRUNING MECHANISM

Attachment tube

Bolt hole

Fastening bolt

Bolt

Gear case

1. Remove the plastic cap on the end of the tube.

2. Remove the bolt.

3. Insert the end of the tube into the gear case, make sure to

align the transmission shaft of the tube with the transmission

shaft of the gear case.

4. Line up the hole on the tube with the hole on the gear

case and insert the bolt through the hole and tighten firmly.

5. Using a wrench, screw in the fastening bolt provided to fix

the mechanism into place.

PAGE 18

SET UP

INSTALLING GUIDE BAR AND SAW CHAIN

Guide bar

Saw chain

Transmission

Sprocket

Chain tension adjust screw

Nut

Chain tensioner nut

Chain cover

1. Loosen the nut and remove the chain cover.

2. Mount the guide bar, then fit the saw chain around the bar

and sprocket.

3. Fit the chain tensioner nut into the lower hole of the guide

bar, then install the chain cover, and fasten the mounting nut

to finger tightness.

4. Adjust the chain tension by turning the tensioner screw

until the tie straps just touch the bottom side of the bar rail.

5. Tighten the mounting nut securely with the bar tip held

up (TORQUE: 8.9 ~ 11.7 N.m./90 ~ 120 kg-cm). Then check

the chain for smooth rotation and correct tension while moving it by hand. If necessary, readjust.

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE: 01332 576 850

PAGE 19

ASSEMBLY

Balancing the strimmer

1. Put the harness on and attach your strimmer to it.

2. Slide clamp up and down, till you feel comfortable with how

the strimmer balances, and how you can manoeuvre it whilst

working.

Make sure the strimmer unit is off, whilst doing

this procedure, to ensure accurate balancing.

PAGE 20

• Always use a fuel container with an anti-spill valve.

• Never refuel the machine while the engine is running.

• Always stop the engine and let it cool for a few minutes before refilling with mixed fuel.

• Make sure there is plenty of ventilation when refilling or mixing fuel (petrol and 2--stroke oil).

• Move the machine at least 10 feet (3 meters) from the refueling point before starting it.

Never start the machine:

• If you have spilt fuel on it. Wipe off the spillage and allow

remaining fuel to evaporate.

• If you have spilt fuel on yourself or your clothes, change your

clothes. Wash any part of your body that has come in contact

with fuel. Use soap and water.

• If the machine is leaking fuel. Check regularly for leaks from

the fuel cap and fuel lines.

• Avoid all skin contact with fuel. Fuel is a skin irritant.

FUEL SAFETY

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE: 01332 576 850

Loading...

Loading...