Page 1

150L BELT DRIVE

AIR COMPRESSOR

OWNER’S MANUAL

FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.

Page 2

SPECIFICATION

ITEM DATA

Model SC90B SC150B

Power 2200W / 3 HP

Voltage 230 V

Frequency 50 Hz

Delivery 14 CFM

Max Discharge Pressure 150 PSI / 10 BAR

Tank Capacity 90 L 150 L

Dimensions

990 x 440 x 880 mm 1400 x 475 x 890 mm

Oil / Oil Free Oil Lubricated

Wheel Mounted Yes

Air Outlets 2

Air Outlet Size 1/4”

Net Weight 69 kg 81 kg

Noise Information LWA 97 dB

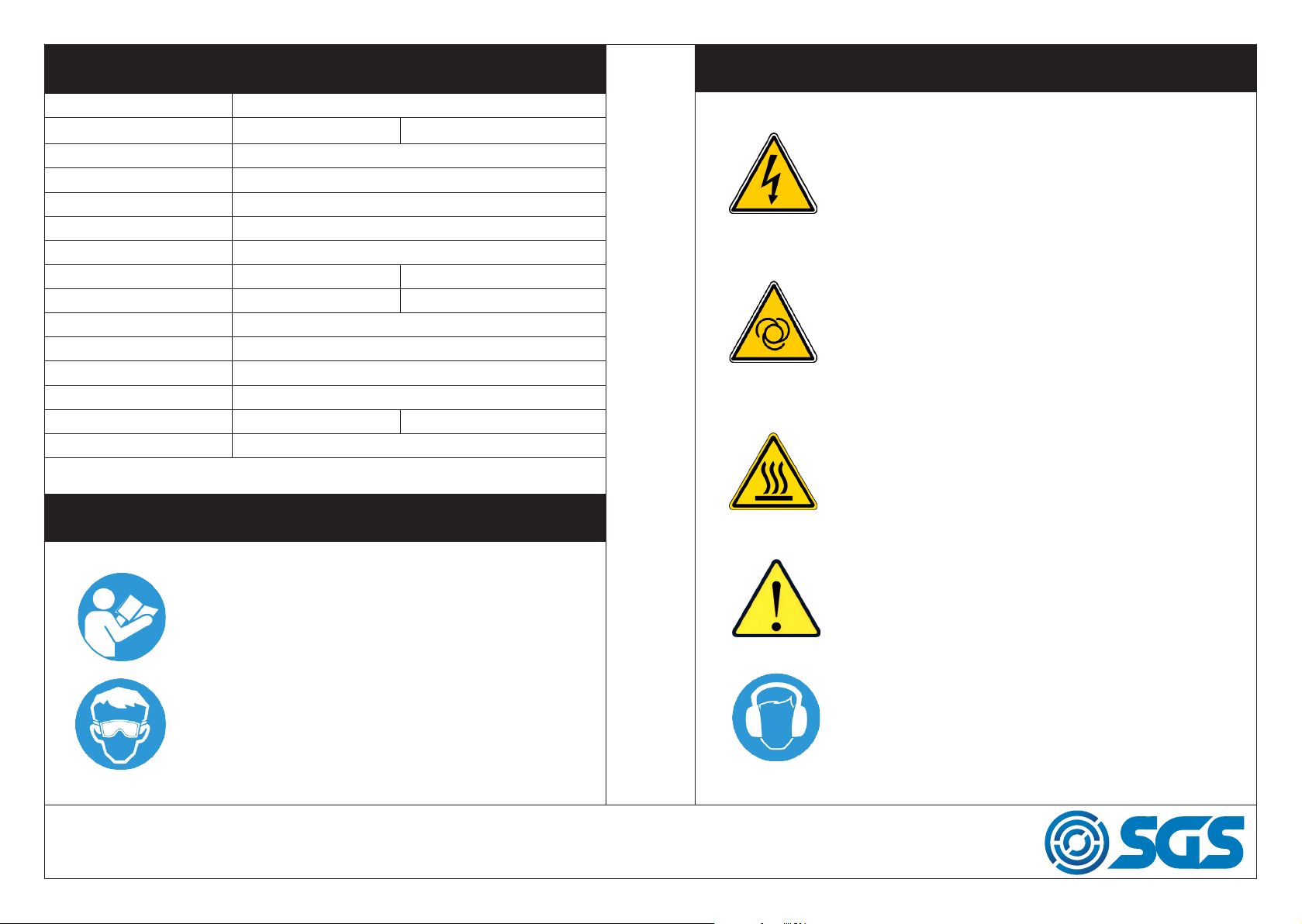

WARNING

WARNING

Risk of electric shock. The compressor must be disconnected from the mains supply before maintenance or removing any covers. Do not use in a damp environment.

Risk of accidental start-up. The compressor could start

automatically in the event of a power cut and subsequent reset. Do not carry the compressor while it is connected to the power source, or when the tank is filled

with compressed air.

This compressor contains surfaces which may reach a

high temperature during operation. Never operate with

the motor housing removed.

Read and understand instructions before use.

Always wear eye/face and hand protection.

WWW.SGS-ENGINEERING.COM

PAGE 2

Air and condensation water can burst from the compressor when the drain plug is removed.

This compressor produces a high sound level during

operation. Ear protection should be worn.

PAGE 3

Page 3

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

KEEP VISITORS/CHILDREN AWAY: Do not allow visitors/children to handle the air compressor or attachments and ensure that any people in the

work area are suitably dressed.

KEEP THE WORK AREA CLEAN: Cluttered areas mean accidents, so

clear the work area of all unnecessary tools, debris and furniture.

DO NOT TOUCH HOT SURFACES: During operation, the motor, connections, compressor body, cylinder head and tubes may get hot, do not

touch.

DO NOT DIRECT AN AIR STREAM AT THE BODY: Do not direct the

air stream at people or animals, as injury may result. Compressed air

can cause soft tissue damage and propel dirt and other particles at high

speed.

BREATHING AIR: This compressor should not be used to supply breathing quality air. Never use it as breathing apparatus.

STAY ALERT: Watch what you are doing, use common sense, and do not

operate the air compressor when you are tired. The air compressor should

not be used if you are under the influence of alcohol, drugs or any medi-

cation that makes you drowsy.

DISCONNECT THE AIR COMPRESSOR: Always disconnect the air compressor from the mains power supply and decompress before performing

maintenance, changing any parts and when not in use.

MAINS POWER CABLE PRECAUTIONS: Never pull on the cable when

removing the plug from the mains socket, or lift the compressor by the

mains cable.

AVOID UNINTENTIONAL STARTING: When connecting the air compressor to the mains supply make sure the red button on top of the air compressor is in the OFF (down) position.

STORE THE AIR COMPRESSOR PROPERLY: When not in use the air

compressor should be stored in a secure, dry place out of the reach of

children. Always lock up the storage area.

MAINTAIN THE AIR COMPRESSOR WITH CARE: If the air compressor is

damaged in any way, have it repaired by a qualified engineer.

DO NOT USE EXTENSION LEADS: Using extension leads can cause your

compressor motor to burn out. Only use extension hoses.

DO NOT WELD TO THE PRESSURE VESSEL

Do not weld or modify the pressure vessel in any manner.

DISPOSAL INFORMATION

The air compressor should be disposed of in a safe an environmentally

friendly manner. Contact your local Council for disposal assistance.

WWW.SGS-ENGINEERING.COM

PAGE 4

PAGE 5

Page 4

QUICK REFERENCE

QUICK REFERENCE

15

14

13

12

16

17

1

2

3

4

5

6

7

1. Guard

2. Capacitor / motor control box

3. Oil breather plug

4. Motor unit

5. Air delivery pipe

6. Air reciever

7. Feet

8. Oil sight glass

9. Drain valve

10. Air reciever pressure gauge

11. Regulated air outlet pressure gauge

12. Air outlet (regulated pressure)

13. Pressure regulator

14. On / off switch

15. Flywheel / fan

WWW.SGS-ENGINEERING.COM

11

10

9

8

PAGE 6

16. Pump unit

17. Air intake filter

PAGE 7

Page 5

SETTING UP THE COMPRESSOR

SETTING UP THE COMPRESSOR

IMPORTANT! Before starting the machine remove all the

travel plugs and attach the Air Filter and the Crank Case

Breather Plug.

The compressor is

equipped with a safety

valve. If the pump were to

continue operating above

the maximum pressure,

the safety valve would

open and eject air from

the vessel. If the safety

valve discharges air, please turn off the compressor and contact the hel-

pline. The safety valve is located to the side of the pressure switch.

Filling the sump with oil

Pour approximately 0.5L of oil into the sump until the oil level reaches the

red spot in the centre of the sight glass (see image below). Once the oil

has reached the correct level re-insert the oil breather plug.

WWW.SGS-ENGINEERING.COM

PAGE 8

PAGE 9

Page 6

OPERATION

OPERATION

Air Pressure Regulator

To adjust the pressure turn the Pressure

Regulator dial anti clockwise to decrease

the pressure and turn the dial clockwise

to increase pressure.

On / off switch

Pressure regulator

Output pressure gauge

Outlet valves

Starting the Air Compressor

Once the air compressor is connected to the mains supply use as follows:

a) Pull up the button on the pressure switch this will ‘click’ up into posi-

tion. The motor/pump will now start to run.

b) Check that the motor/pump automatically stops when the pressure

inside the air receiver reaches approximately (10BAR) (check gauge). Ro-

tate the air regulator to the desired outlet pressure and plug in hose with

chosen air tool connected to the other end. The air is now ready for use.

You may need to finely adjust as the air tool is used.

c) Check that the motor/ pump automatically starts, when the pressure

falls by approximately 2BAR.

When the compressor is running correctly you will hear the following:

a) When the air compressor starts from no pressure within the tank there is

a whistle of ‘leaking’ air from the pressure switch for about 20-30 seconds.

b) Whenever the motor stops there will be a quick sudden discharge of

air. (This is the motor start and stop air unloading system being activated).

WWW.SGS-ENGINEERING.COM

PAGE 10

Shutting down the Air Compressor

Never stop the compressor by unplugging it. The pressure switch must

always be used as this ensures that air is discharged from the head. This

makes the starting easier for the motor and prevents motor damage.

PAGE 11

Page 7

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE ACTION

Motor unable to run,

running slow or getting

hot

Sticking of main compressor

Shaking or abnormal

noise

Pressure insufficient

or discharge capacity

decreased

1. Fault in line or insufficient

voltage

2. Power wire too thin or long

3. Fault in pressure switch

4. Fault in motor

5. Sticking of main compressor

1. Moving parts burnt due to

insufficient oil

2. Moving parts damaged or

stuck by a foreign body

1. Connecting part loose

2. Foreign body in the main

compressor

3. Piston knocking the valve

seat

4. Moving parts seriously

worn

1. Motor running too slow

2. Air filter choked up

3. Leakage of safety valve

4. Leakage of discharge pipe

5. Sealing gasket damaged

6. Valve plate damaged,

stuck or carbon build up

7. Piston ring and cylinder

worn or damaged

1. Check the line

2. Replace the wire

3. Repair or replace

4. Repair or replace

5. Check and repair

Check crankshaft, bearing,

connecting rod, piston, piston ring,

etc. and replace if

necessary

1. Check and retighten

2. Check and clean away

3. Replace with thicker paper

gasket

4. Repair or replace

1. Check and remedy

2. Clean or replace the cartridge

3. Check and adjust

4. Check and repair

5. Check and replace

6. Replace and clean

7. Repair or replace

MAINTENANCE

Changing the oil

Switch off the motor and remove the power plug from the socket outlet.

Release any remaining air pressure and then unscrew the oil drain plug

from the compressor pump and remove. Direct the oil into an appropriate

container. If any oil still remains, tilt the compressor slightly. When all the

old oil has been removed, screw the oil drain plug into place.

Cleaning

Clean the items with a soft brush or a wipe moistened with a suitable bio-

degradable solvent. Do not use flammable liquids like petrol or alcohol,

they are a risk and will damage the finish and plastic parts.

Cleaning/ changing the air filter (Monthly)

Please note: This compressor should not be used in a heavily dusty atmos-

phere. The warranty does not cover damage caused by a blocked air filter.

The air filter must be cleaned or replaced monthly, or more frequently if

the compressor is in regular use. The air filter can be accessed easily by

unscrewing the air filter cover (wing nut) at the side of the pump.

Excessive oil consumption

1. Oil level too high

2. Breather pipe choked up

3. Piston ring and cylinder

WWW.SGS-ENGINEERING.COM

worn or damaged

1. Keep the level within set range

2. Check and clean

3. Repair or replace

PAGE 12

PAGE 13

Page 8

ADJUSTING THE CUT OFF PRESSURE

ADJUSTING THE CUT OFF PRESSURE

If your compressor cuts out before 10 bar:

Your compressor has been tested during manufacture and the cut off

pressure may be set at 6 bar or 8 bar, rather than 10 bar.

Most applications do not require 10 bar air pressure so we recommend

leaving the cut off pressure at the factory setting unless explicitly required.

If you wish to increase the tank pressure to 10 bar first open the switch

box by unscrewing the single screw:

Then turn the 10mm nut clockwise to increase the pressure and counter-

clockwise to decrease the pressure. Make a half turn on the nut in either

direction, then wait for the tank pressure to equalise. Make further half

turns if required.

WWW.SGS-ENGINEERING.COM

PAGE 14

PAGE 15

Page 9

PARTS DIAGRAM PARTS LIST

NO. Description QTY Part No NO. Description QTY Part No

1 Motor Group 1 902689 21 Check Valve 1 902709

2 Pump 1 902690 22 Nut 1 902710

3 Screw 2 902691 23 Aluminum Pipe 1 902711

4 Cylinder Cover 1 902692 24 Tank 1 902712

5 Screw 2 902693 25 Screw 4 902807

6 Air Filter 1 902694 26 Plain Washer 4+5 902808

7 Nut 16 902695 27 Foot Pad 4 902809

8 Screw 4 902696 28 Drain Cock 1 902716

9 Connector 1 902697 29 Pump Board 1 902810

10 Pressure Gauge 1 902698 30 Screw 8 902718

11 Pressure Regulator 1 902699 31 Plain Washer 4 902811

12 Pressure Gauge 1 902700 32 Gasket 4 902812

13 Pressure Switch 1 902701 33 Nut 4 902813

14 Quick Coupler 2 902702 34 Belt 1 902723

15 Safety Valve 1 902703 35 Screw 5 902724

16 Power Wire 1 902704 36 Belt Cover 1 902726

17 Screw 2 902705 37 Screw 1 902727

18 Copper Pipe 1 902706 38 Belt Cover Support 2 902728

19 Cooling Fin 1 902707 39 Elbow 1 902729

20 Elbow 1 902708

WWW.SGS-ENGINEERING.COM

PAGE 16

PAGE 17

Page 10

PARTS DIAGRAM PARTS LIST

NO. Description QTY Part No NO. Description QTY Part No

1 Key 1 902732 20 Gasket 25 902751

2 Motor Wheel 1 902733 21 Nut 11 902752

3 Screw 6 902734 22 Screw 2 902753

4 Washer 6 902735 23 Capacitor 1 902754

5 Washer 6 902736 24 Capacitor 1 902755

6 Front Cover 1 902737 25 Screw 4 902756

7 Gasket 1 902738 26 Wire 1 902757

8 Bearing 2 902739 27 Screw 5 902758

9 Gasket 1 902740 28 Washer 4 902759

10 Screw 2 902741 29 Gasket 1 902760

11 Gasket 1 902742 30 Gasket 1 902761

12 Centrifugal Switch 1 902743 31 Protector 1 902762

13 Rotor 1 902744 32 Unseparated Device 1 902763

14 Stator 1 902745 33 Wire 1 902764

15 Capacitor Cover 1 902746 34 Rear Cover 1 902765

16 Support 2 902747 35 Fan 1 902766

17 Gasket 1 902748 36 Gasket 1 902767

18 Wire Support 1 902749 37 Motor Cover 1 902768

19 Gasket 2 902750 38 Screw 3 902769

WWW.SGS-ENGINEERING.COM

PAGE 18

PAGE 19

Page 11

PARTS DIAGRAM PARTS LIST

NO. Description QTY Part No NO. Description QTY

1 Cylinder Head Bolt 6 902770 19 Oil Gauge 1

2 Cylinder Head 1 902771 20 Seal Ring 1

3 Cylinder Head Gasket 1 902772 21 Screw 1

4 Valve Plate 2 902773 22 Bottom Board 1

5 Gasket 1 902774 23 Screw 12

6 Valve 4 902775 24 Piston Ring 2

7 Pin 2 902776 25 Piston 2

8 Valve Plate gasket 1 902777 26 Circlip 4

9 Cylinder 1 902778 27 Piston Pin 2

10 Cylinder Gasket 1 902779 28 Connecting Rod 2

11 Crankcase 1 902780 29 Gasket 8

12 Screw 8 902781 30 Cylinder Screw 8

13 Gasket 8 902782 31 Oil Seal 1

14 Rear Cover 1 902783 32 Front Cover 1

15 Gasket 2 902784 33 Belt Wheel 1

16 Bearing 2 902785 34 Washer 1

17 Crankshaft 1 902786 35 Screw 1

18 Oil Breath 1 902787

Part No

902788

902789

902790

902791

902792

902793

902794

902795

902796

902797

902798

902799

902800

902801

902802

902803

902804

WWW.SGS-ENGINEERING.COM

PAGE 20

PAGE 21

Page 12

SGS Engineering (UK) Ltd

West Side Park

Derby, DE21 7AZ

EC Declaration of Conformity

This is an important document and should be retained

Raynesway

MANUFACTURER’S NAME:

TYPE OF EQUIPMENT:

PART NUMBER:

APPLICATION OF EC COUNCIL DIRECTIVES / STANDARD:

SGS Engineering (UK) Ltd

AIR COMPRESSOR

SC90B & SC150B

2006/42/EC - Machinery

2004/108/EC - EMC

2006/95/EC - LVD

87/404/EEC - The simple pressure vessel regulations

97/23/EC - Pressure equipment directive

I, the undersigned, hereby declare that the equipment specied above

conforms to the above European Communities Directive(s) and

Standard(s).

PLACE:

Derby, UK

DATE:

24th MAY 2018

(Signature)

Robert Wyatt

Company Secretary

Loading...

Loading...