SGS SAT403, SAT401 Owner's Manual

FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.

OWNER’S MANUAL

SAT403

BRAD NAILER & STAPLER

PAGE 3

PAGE 2

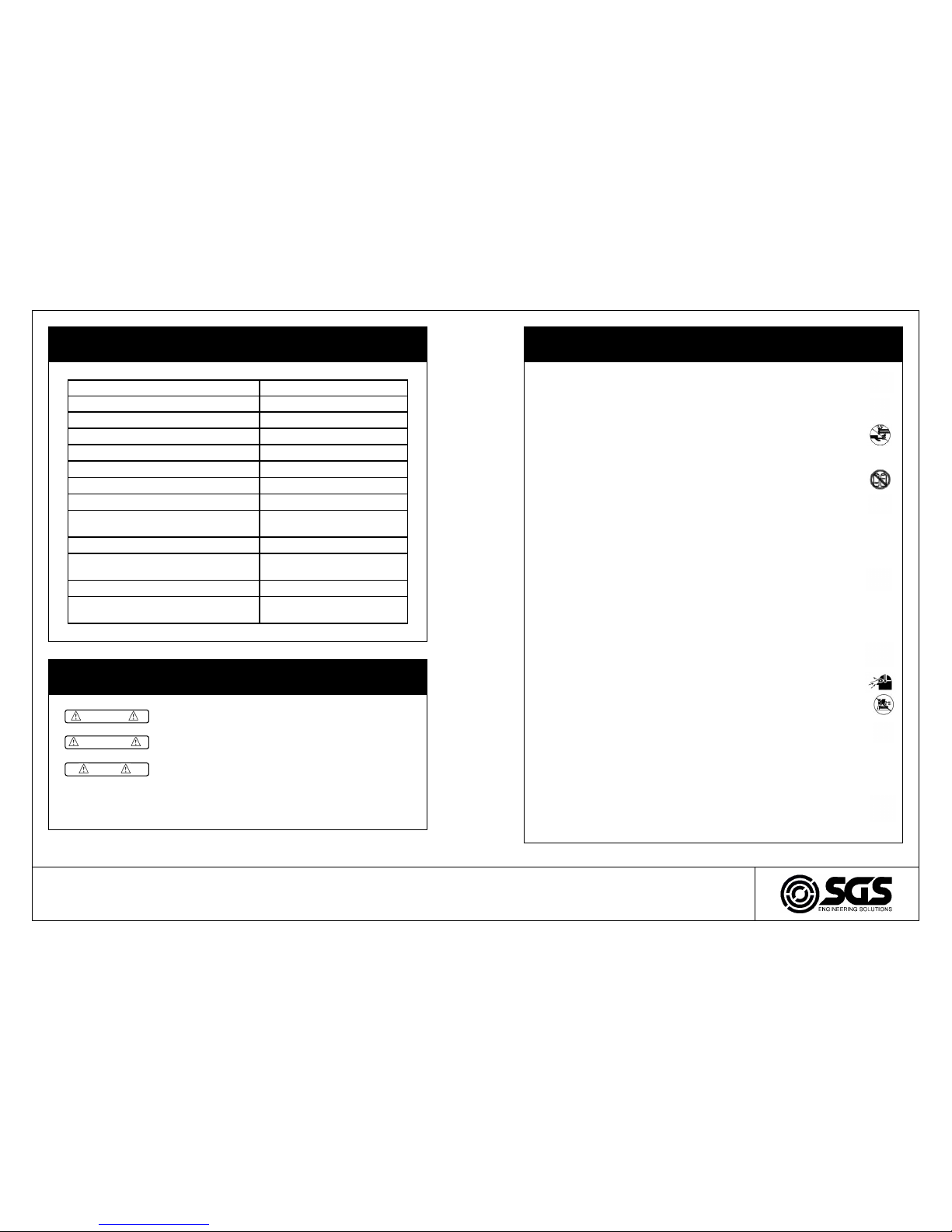

SPECIFICATION

TOOL MODEL SAT403

TOOL LENGTH 250 MM

TOOL HEIGHT 240 MM

TOOL WIDTH 55 MM

TOOL WEIGHT 1.46 KG

MAXIMUM OPERATING PRESSURE 115 PSI

RECOMMENDED OPERATING PRESSURE 75-100 PSI

MAGAZINE CAPACITY 100 NAILS / 80 STAPLES

FASTNER GAUGE 18 GAUGE BRAD NAILS

18 GAUGE CROWN STAPLES

FASTNER LENGTHS NAILS (MM) 15, 20, 25, 30, 35, 40, 45, 50

FASTNER LENGTHS NAILS (IN.) 5/8, 3/4, 1, 1-1/4, 1-3/8, 1-1/2,

1-3/4, 2

FASTNER LENGTHS STAPLES (MM) 13, 16, 19, 25, 32, 38, 40

FASTNER LENGTHS STAPLES (IN.) 1/2, 5/8, 3/4, 1, 1-1/4,

1-1/2

SAFETY GUIDELINES

Please read and fully understand the manual for information relating to protecting

YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS.

Indicates an immediately hazardous situation which if not

avoided will result in death or serious injury.

DANGER

WARNING

NOTE

Indicates a potentially hazardous situation which if not

avoided could result in death or serious injury.

Alerts the operator to useful information.

SAFETY INSTRUCTIONS

1. Read and understand tool labels and manual. Failure to follow warnings

could result in DEATH or SERIOUS INJURY.

2. Operator and others in work area MUST wear safety glasses.

3. Keep fingers AWAY from trigger when not driving fasteners to avoid ac-

cidental firing.

4. Never point tool at any part of your body or others.

5. Never use oxygen or other bottled gasses. Explosion and serious per-

sonal injury could result.

6. Wear ear protection to safe-guard against possible hearing loss.

7. Use clean, dry, regulated, compressed air at 75 to 100 PSI.

8. Only use air hose that is rated for a maximum working pressure of at least

150 PSI or 150% of the maximum system pressure, which ever is greater.

9. Disconnect tool from air supply hose before performing tool maintenance, clearing a jammed fastener, leaving work area, moving tool to another

location or handing the tool to another person.

10. Never use tool if safety, trigger or springs are inoperable, missing or

damaged. Do not alter or remove safety, trigger or springs. Make daily inspections for free movement of trigger and safety mechanism.

11. Connect tool to air supply before loading fasteners to prevent a fastener from being fired during connection.

12. Operator and bystanders to wear helmets to safeguard against injuries.

13. Do not load fasteners with trigger or safety depressed to prevent

unintentional firing of a fastener.

14. Do not drive fasteners close to the edge of the work-piece. The workpiece is likely to split allowing the fasteners to fly free or ricochet.

15. Fire fasteners into work-piece only - never into materials too hard to

penetrate. Do not drive fasteners on top of other fasteners, or with the tool

at too steep an angle; the fasteners can ricochet causing personal injury.

16. Always carry a fastener-driving tool using only the handgrip and never

with the trigger actuated. Never carry the tool by the hose or pull the hose to

move the tool.

WWW.SGS-ENGINEERING.COM

PAGE 5

PAGE 4

SAFETY MECHANISM

OPERATING A CONTACT TRIP SAFETY TOOL

The operator requires finger to be off the trigger and the work contact element (WCE) of the tool to be placed on the work-piece.

The work contact element (WCE) is then depressed against the work-piece

and the trigger is pulled to drive a fastener.

The trigger is released after each fastener is driven.

Move the tool to next location and repeat the above procedure.

CHECKING A CONTACT TRIP SAFETY TOOL

Disconnect the air supply from the tool.

Empty the magazine.

Make sure the trigger and the safety move up and down without sticking.

Connect the air supply to the tool.

Depress the safety tip against the work-piece without pulling the trigger.

The tool must not cycle. Never use the tool if a cycle occurs.

Hold the tool clear of the work-piece. The WCE should return to its original

down position. Pull the trigger. The tool must not cycle. Never use the tool

if a cycle occurs.

WARNING

CHECK AND REPLACE ANY DAMAGED OR WORN COMPONENTS. SAFETY WARNING LABELS ON THE TOOL MUST ALSO BE REPLACED IF THEY ARE NOT LEGIBLE.

LOADING THE TOOL

Connect the air hose.

Depress the magazine latch. Pull back on the magazine cover.

Insert a stick of fasteners into the magazine. Make sure the pointed ends of

the fasteners are loaded with the points downward. Also make sure fasteners are not dirty or damaged.

Push the magazine cover forward until the latch catches.

OPERATING THE TOOL

Add a few drops of tool oil

Attach a high flow quick connector fitting to the tool. Empty the magazine.

Regulate the air pressure to obtain air pressure within the working pressure

range at the tool.

Load fasteners into your tool following the instructions in this manual.

Test for proper fastener penetration by driving nails into a sample piece of

wood. If the fasteners do not achieve the desired penetration, adjust the

air pressure to a higher setting until the desired penetration is achieved. If

you are using a tool with a depth control device, turn the thumb wheel to

achieve the desired penetration.

WWW.SGS-ENGINEERING.COM

Loading...

Loading...