SGS SAT103,SAT101 Owner's Manual

SAT103

IMPACT WRENCH

OWNER’S MANUAL

FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.

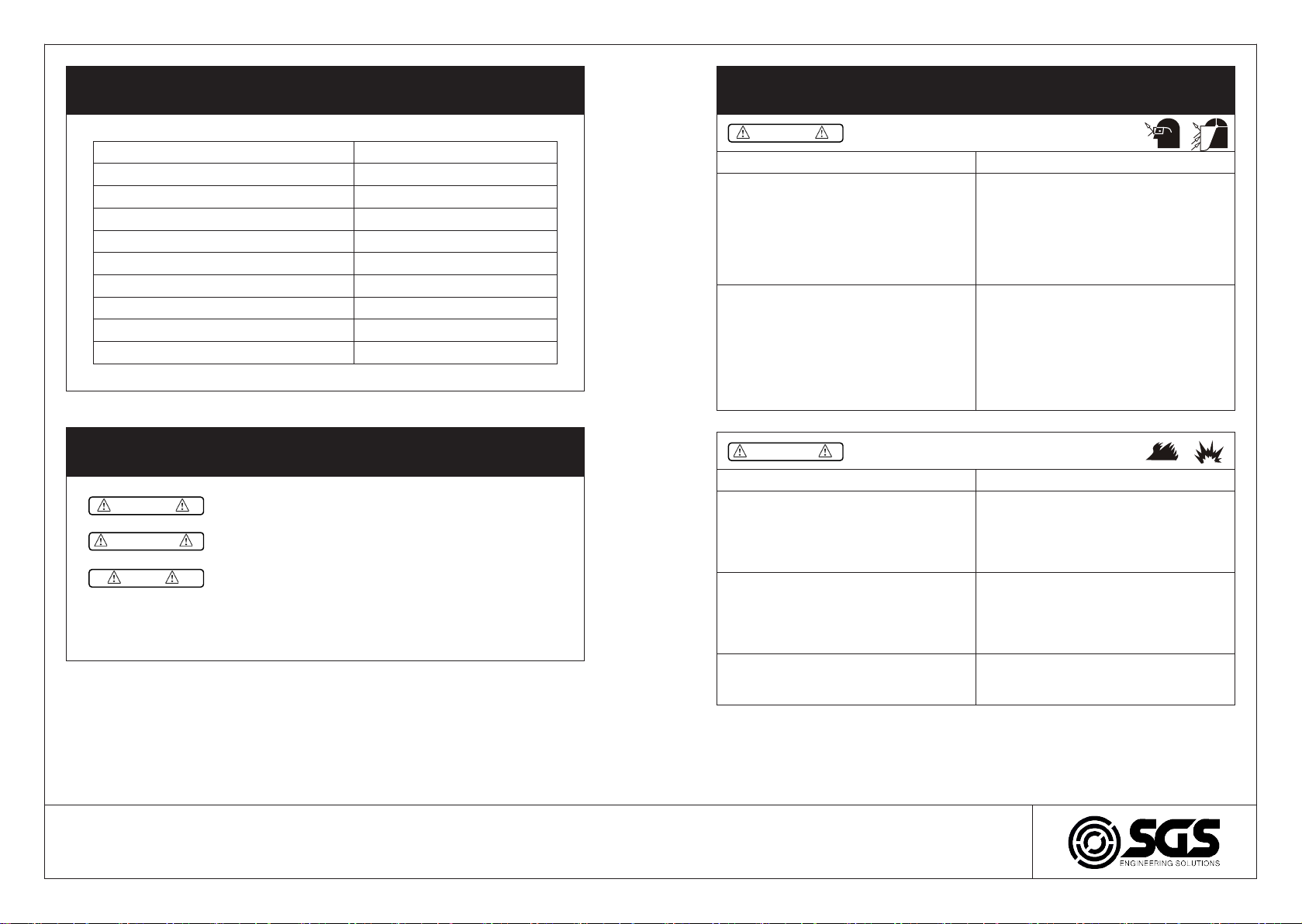

SPECIFICATION

DANGER

WARNING

NOTE

WARNING

DANGER

TOOL MODEL SAT103

CAPACITY 1/2 IN.

FREE SPEED 7000 RPM

MAX TORQUE 250 FT-LB / 340 Nm

AVERAGE AIR CONSUMPTION 8 SCFM

WORKING PRESSURE 90 PSI / 6.3 BAR

AIR INLET 1/4 IN.

AIR HOSE 3/8 IN.

LENGTH x HEIGHT 205 x 200 MM

WEIGHT 2.18 KGS

SAFETY INSTRUCTIONS

RISK OF FIRE OR EXPLOSION

WHAT COULD HAPPEN HOW TO PREVENT IT

Abrasive tools such as sanders and grinders,

rotating tools such as drills and impact tools

such as nailers, staplers, wrenches, hammers

and reciprocating saws are capable of generating sparks which could result in ignition

of flammable materials.

Exceeding the maximum pressure rating of

tools or accessories could cause an explosion resulting in serious injury.

Never operate tools near flammable substances such as petrol, naphtha, cleaning

solvents etc.

Work in a clean, well-ventilated area free of

combustible materials.

Never use oxygen, carbon dioxide or other

bottled gases as a power source for air tools.

Use compressed air regulated to a maximum

pressure at or below the rated pressure of

any attachments.

Never connect to an air source that is capable of exceeding 200 psi.

Always verify prior to using the tools that the

air source has been adjusted to the rated air

pressure range.

SAFETY GUIDELINES

Indicates an immediately hazardous situation which if not

avoided will result in death or serious injury.

Indicates a potentially hazardous situation which if not

avoided could result in death or serious injury.

Alerts the operator to useful information.

Please read and fully understand the manual for information relating to protecting

YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS.

WWW.SGS-ENGINEERING.COM

PAGE 2

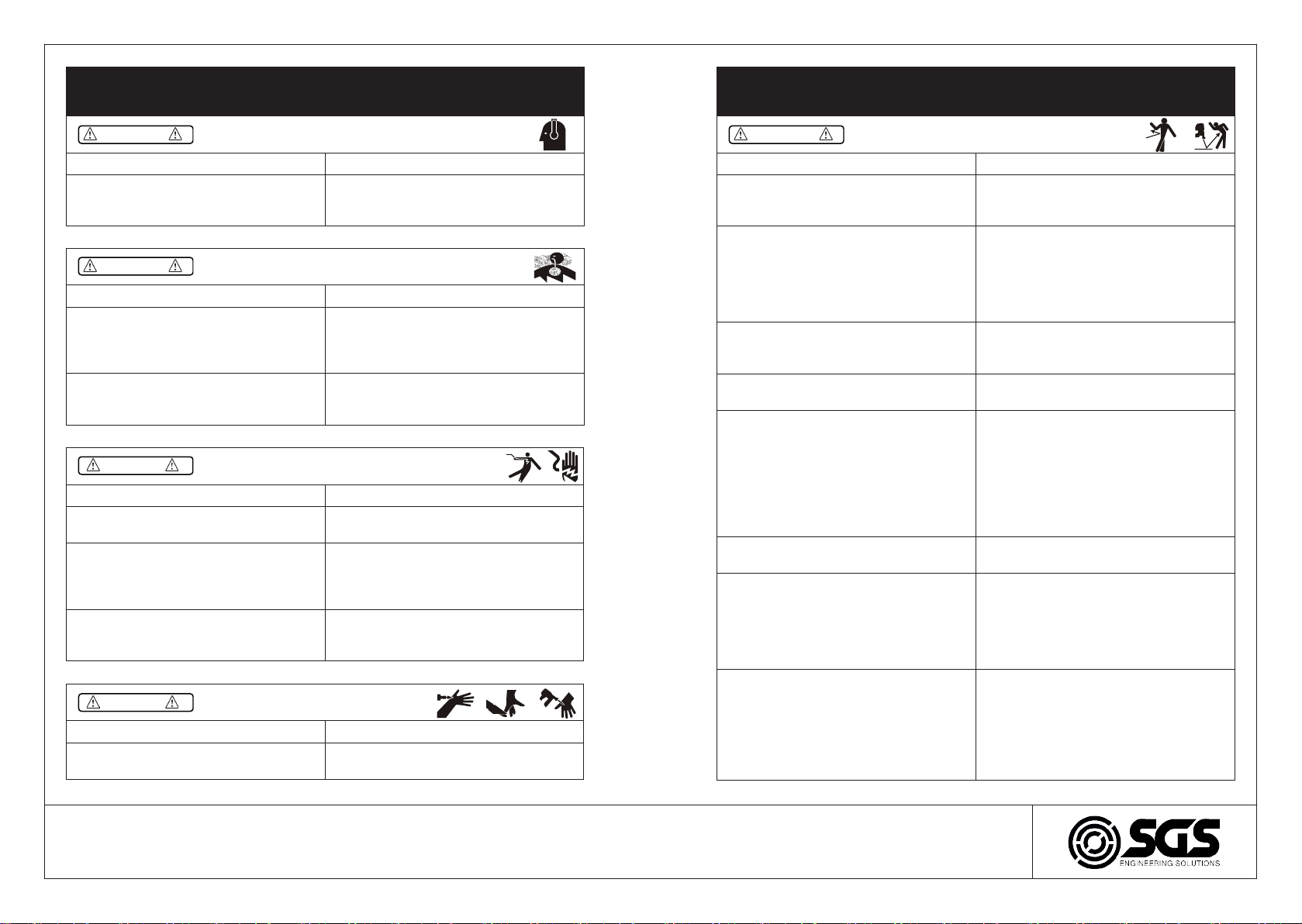

RISK OF EYE OR HEAD INJURY

WHAT COULD HAPPEN HOW TO PREVENT IT

Air powered equipment and power tools

are capable of propelling materials such as

fasteners, metal chips, sawdust and other

debris at high speed which could result in

serious eye injury.

Compressed air can be hazardous.

The air system can cause injury to soft

tissue areas such as eyes and ear. Particles

or objects propelled by the air stream can

cause injury.

Tool attachments can become loose or

break and fly apart, propelling articles at

the operator and others in the work area.

Always wear approved safety glasses with

side shields.

Disconnect air hose when tool is not in use.

For additional protection use an approved

face shield in addition to safety glasses.

Make sure that any attachments are securely

assembled.

PAGE 3

SAFETY INSTRUCTIONS

WARNING

WARNING

DANGER

DANGER

WARNING

SAFETY INSTRUCTIONS

RISK OF LOSS OF HEARING

WHAT COULD HAPPEN HOW TO PREVENT IT

Long term exposure to noise produced

from the operation of air tools can lead to

permanent hearing loss.

INHALATION HAZARD

WHAT COULD HAPPEN HOW TO PREVENT IT

Abrasive tools such as grinders, sanders and

cut-off tools generate dust and abrasive

materials which can be harmful to the lungs

and respiratory system.

Some materials such as adhesives and tar

contain chemicals whose vapours could

cause serious injury with exposure.

RISK OF ELECTRIC SHOCK

WHAT COULD HAPPEN HOW TO PREVENT IT

Using air tools to attach electrical wiring can

result in electrocution or death.

This tool is not provided with an insulated

gripping surface. Contact with a “live” wire

will also make exposed metal parts of the

tool “live” and can result in electrocution.

Fasteners coming in contact with hidden

electrical wiring could cause electrocution

or death.

RISK OF CUT OR BURNS

WHAT COULD HAPPEN HOW TO PREVENT IT

Tools that cut, shear, drill, staple, punch &

chisel are capable of causing serious injury.

Always wear hearing protection.

Always wear a properly fitting facemask or

respirator when using such tools.

Always work in a clean, dry, well-ventilated

area.

Never use nail/staplers to attach electrical

wiring while energized

Avoid body contact with grounded surfaces

such as pipes, radiators and refrigerators.

There is an increased risk of electric shock if

your body is grounded.

Thoroughly investigate the work piece for

possible hidden wiring before performing

work.

Keep the working part of the tool away

from hands and body.

RISK OF INJURY

WHAT COULD HAPPEN HOW TO PREVENT IT

A tool left unattended or with the air hose

attached can be activated by unauthorized

persons leading to injury.

Air tools can inadvertently propel fasteners

or other materials in work area.

A wrench or a key that is left attached to a

rotating part of the tool increases the risk of

personal injury.

Using inflator nozzles for duster applications

can cause serious injury.

Air tools can become activated by accident

during maintenance or tool changes.

Air tools can cause the work piece to move

upon contact, leading to injury.

Loss of control of the tool can lead to injury

to self or others.

Poor quality, improper or damaged tools

such as grinding wheels, chisels, sockets,

drills, nailers, staplers, etc. can fly apart during operation, propelling particles throughout the work area causing serious injury.

Remove air hose when tool is not in use

and store tool in secure location away from

reach of children and untrained users.

Use only parts, fasteners and accessories

recommended by SGS Engineering.

Keep work area clean and free of clutter.

Keep children and others away from tool

while it is in operation.

Keep work area well lit.

Remove adjusting keys and wrenches before turning the tool on.

DO NOT use inflator nozzles for duster applications.

Remove air hose to lubricate or add grinding attachments, sanding discs, drills, etc.

to the tool.

Never carry the tool by the hose.

Avoid unintentional starting. Don’t carry the

tool with a finger on the trigger.

Only an authorised service representative

should perform repair servicing.

Use clamps or other devices to prevent

movement.

Never use tool while using drugs or alcohol.

Don’t over-reach. Keep proper footing and

balance. Keep handles dry, clean and free

from oil/grease. Stay alert. Watch what

you are doing. Use common sense. Do not

operate the tool when you are tired.

Always use tool attachments rated for the

speed of the power tool. Never use tools

which have been dropped, impacted or

damaged by use. Use only impact grade

sockets on an impact wrench. Do not apply

excessive force to the tool; let the tool

perform the work.

WWW.SGS-ENGINEERING.COM

PAGE 4

PAGE 5

Loading...

Loading...