SGS GPA520 Owner's Manual

GPA520

PETROL AUGER

OWNER’S MANUAL

FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.

SPECIFICATION

GENERAL SAFETY PRECAUTIONS

MODEL No GPA520

ENGINE SIZE 52 cc

MAX POWER 1.8 kW

MAX SPEED 7500 RPM

FUEAL TANK CAPACITY 800 ml

NOISE LEVEL 116 dB

WEIGHT 19.20 kg

WARNING

Read and understand the instruction manual before

using the blower. Restrict unit to users who understand

and will follow all warnings and safety rules in this

manual.

Approved protective goggles or visor, ear protection,

gloves, and face mask in dusty environments must be

worn.

WARNING: Fire hazard - keep fuel away from all

sources of ignition.

You MUST STOP using the machine if:

• The engine speed changes with no control.

• In case of misfire

• In case of high vibration.

• When flames or smoke appear.

• In rain or stormy weather.

DO NOT attempt to lift or move the machine while the

engine is running. DO NOT put hands or feet near rotating parts.

DO NOT touch or allow clothing and other flammable

materials to come into contact with the engine or

muffler. These parts get extremely hot from operation.

WARNING: Danger of inhaling carbon monoxide - To

avoid poisoning operate this machine only in well

ventilated areas. Never start or run the engine inside a sealed room or building.

WWW.SGS-ENGINEERING.COM

PAGE 2

If the machine should start to make an unusual noise or

vibration, immediately shut off the engine, disconnect

the spark plug HT lead, and check for the cause.

PAGE 3

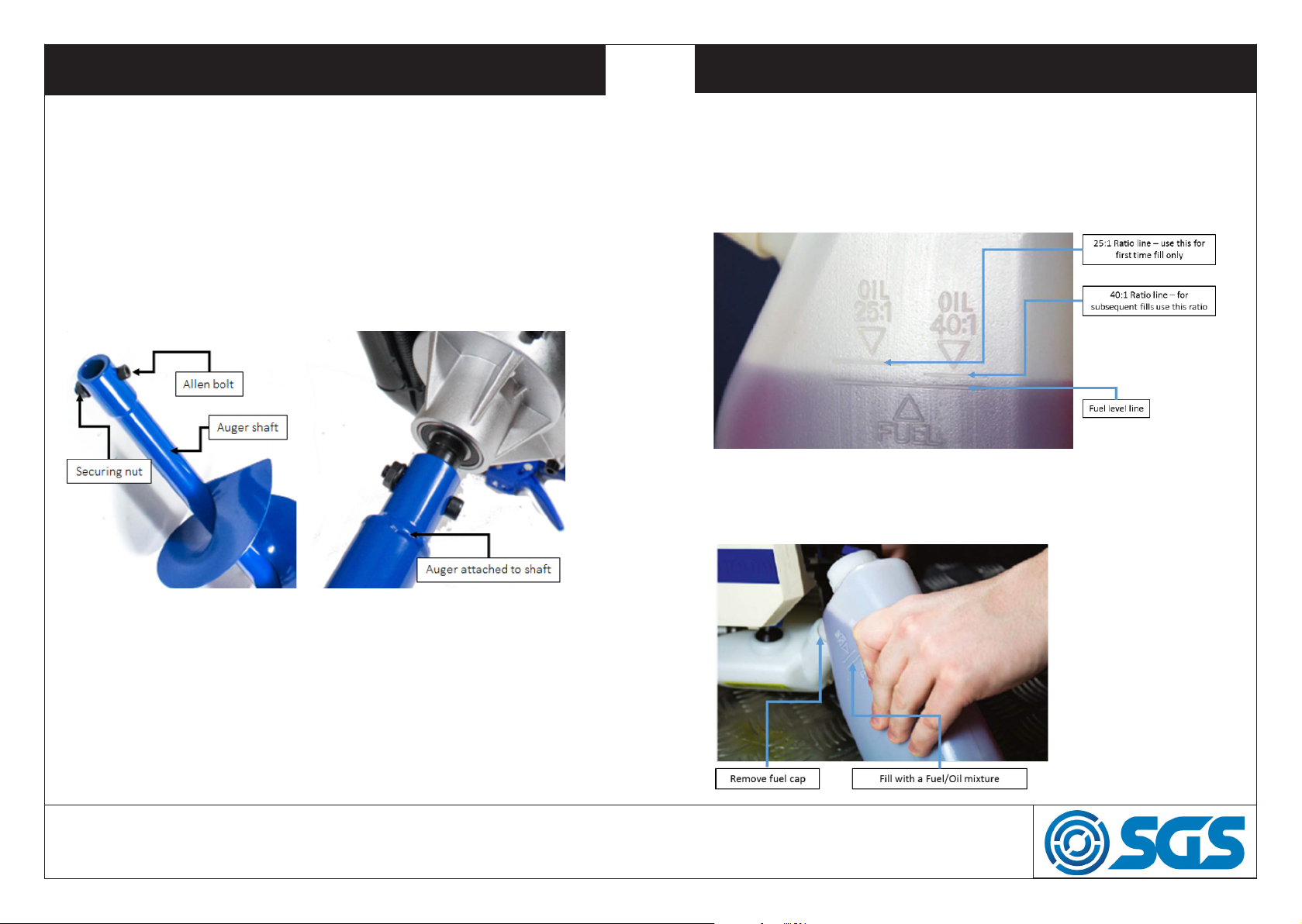

AUGER BIT ASSEMBLY

1. Take the Allen key and box spanner (small end) and undo the bolt that

passes through the end of the auger bit.

2. Once the bolt is removed you can slot the auger over the end of the

power unit drive shaft.

3. Align the hole in the shaft with the holes in the auger bit.

4. Pass the bolt through the auger and shaft then fit the nut and fully

tighten.

FUELING

1. Fill the mixing bottle with fresh unleaded petrol to the fuel level line. You

MUST only use fresh unleaded fuel and 2 stroke engine oil mixture.

2. For the first time ONLY a mixing ratio of 25:1 should be used to

lubricate all engine parts to an optimum level. Thereafter the mix is 40:1.

3. Unscrew the fuel tank cap and carefully add the fuel/2 stroke mixture as

in section 2. DO NOT overfill and allow a 25mm gap at the top of the tank.

Once full replace and correctly tighten the fuel cap. DO NOT use straight

unleaded petrol. From empty the fuel tank holds 800ml.

WWW.SGS-ENGINEERING.COM

PAGE 4

PAGE 5

Loading...

Loading...