Page 1

FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.

OWNER’S MANUAL

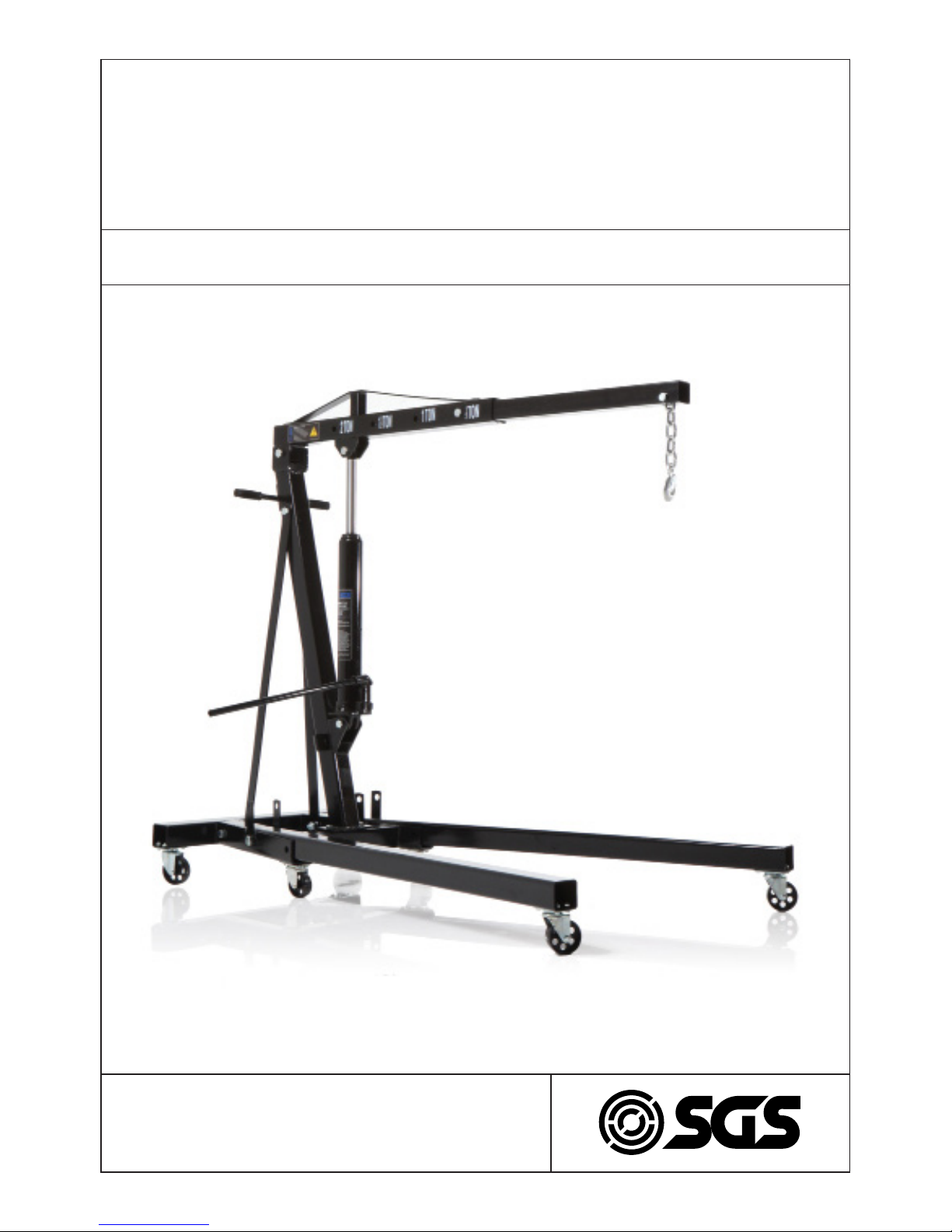

EC2000

ENGINE CRANE

2 TONNE MAX CAPACITY

Page 2

WARNING

Do not overload. Overloading could cause damage or failure of the crane. Never exceed the safe working loads indicated on the jib.

Never use the crane on an uneven floor surface as this could result in the crane tipping over.

Always lock the legs and jib in position before lifting a load.

The nuts and bolts supplied with the crane are all high strength and should not be

substituted for inferior types. Before each use ensure that all nuts and bolts are correctly fitted and tight.

WARNING: This double pump long ram is designed for lifting purposes only – not for

supporting loads. Do not load beyond its rated capacity.

IMPORTANT: It is possible that air has got into the hydraulic system causing poor

lifting performance. Purge any air from the system by fully opening the release valve

(turn handle counter-clockwise) then while holding the boom down operate the pump

handle rapidly several times.

Note: Before raising the legs to the storage position bolts must be inserted into the

base support and tightened each time. If this procedure is not followed the unit may

fall over.

MAINTENANCE

IMPORTANT: When adding or replacing oil always use high grade hydraulic jack oil.

Avoid mixing different grades/types of oil. Do not use brake fluid, alcohol, glycerine,

detergent motor oil or dirty oil. Improper fluid can cause serious internal damage to

the ram.

When adding oil be very careful not to permit dirt or foreign matter to enter the system. Check ram and plunger every 3 months for any signs of rust or corrosion. Clean

as needed and wipe with an oily cloth.

When not using the ram always leave the jib in the fully lowered position.

WWW.SGS-ENGINEERING.COM

PAGE 2

Page 3

OPERATING INSTRUCTIONS

TO RAISE LOAD: Close release valve by turning handle clockwise to a snug-tight posi-

tion. Do not over-tighten.

TO LOWER LOAD: Open release valve by turning handle counter-clockwise very

slowly. The speed of the lowering is controlled by how much the handle is turned.

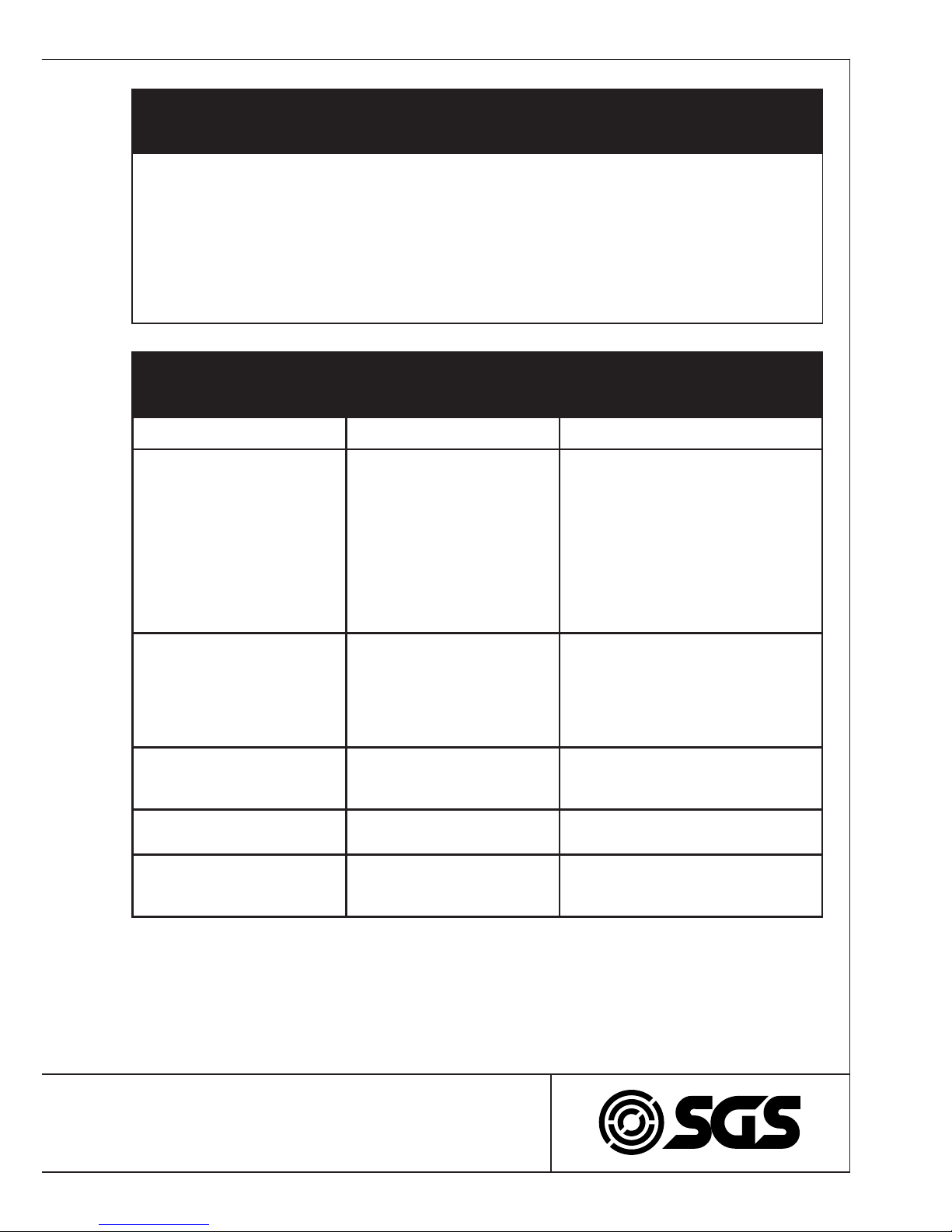

TROUBLE SHOOTING

TROUBLE PROBABLE CAUSE REMEDY

Will not hold load. Dirt on valve seats. 1. Lower lifting boom. Close the

release valve and remove oil

filler plug.

2. Place one foot on the leg and

pull up the lifting boom to its

full height by hand.

3. Open the release valve to lower

the lifting boom.

4. Replace worn seals.

Will not lift load.

Will not lift to its full height.

Pump feels unsteady under

load. Pump will not lower

completely.

Air block. 1. Open the release valve and

remove oil filler plug.

2. Pump handle a couple of full

strokes and close the release

valve.

Pump will not lift to its full

height. Pump feels unsteady

under load.

The reservoir could be overfilled. Low hydraulic oil level.

Check the oil level. Remove the filler

plug.

Top up oil to correct level.

Pump feels unsteady under

load.

The cup seal could be worn

out.

Replace cup seal.

Will not lower completely. Air block. Unit requires

lubrication.

Release air from the hydraulic pump

by removing filler plug.

Oil external moving parts.

PAGE 3

Page 4

ITEM DESCRIPTION QTY

H1 SPRING WASHER 8 24

H2 NUT M8 16

H3 BOLT M8X20 16

H4 BOLT M8X12 8

H5 BOLT M14X95 2

H6 WASHER 14 3

H7 NUT M14 3

H8 SPRING WASHER 16 2

H9 NUT M16 6

H10 BOLT M16X100 1

H11 BOLT M16X115 2

H12 BOLT M18X125 2

H13 SPRING WASHER 18

2

H14

NUT M18 3

H15 PIN 18X110 2

H16 SPLIT PIN 2

H17 BOLT M16X90 2

H18 WASHER 16 4

H19 BOLT M18X110 1

H20 WASHER 18 1

H21 BOLT M16X75 1

H22 BOLT M14X75 1

WWW.SGS-ENGINEERING.COM

PAGE 4

Page 5

ITEM DESCRIPTION QTY

1 BASE 1

2 LARGE CASTER 4

3 SMALL CASTER 2

4 POST 1

5 SUPPORT 2

6 LEG 2

7 JACK 1

8 BOOM 1

9 EXTENSION 1

10 JACK HANDLE 1

11 CHAIN/HOOK 1

PAGE 5

Page 6

ITEM DESCRIPTION QTY

1 VALVE BLOCK 1

2 COPPER WASHER 1

3 CYLINDER 1

4 O-RING 1

5 O-RING RETAINER 1

6 RAM 1

7 TOP NUT 1

8 O-RING 1

9 SEALING GASKET 1

10 OIL TANK 1

11 OIL PLUG 1

12 SEAL RING 1

13 TUBE 1

14 BOLT 1

15 SCREW 2

16 BALL 1

17 SEAL RING 1

18 RELEASE SPINDLE 1

19 BALL 1

20 COPPER WASHER 1

21 PUMP CYLINDER 1

22 O-RING 1

23 BACK UP RING 1

24 PLUNGER 1

25 PUMP LINK 1

26 HANDLE 1

27 HANDLE SOCKET 1

28 SHAFT 2

29 COTTER PIN 2

FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.

Page 7

EC Declaration of Conformity

This is an important document and should be retained

MANUFACTURER’S NAME:

TYPE OF EQUIPMENT:

PART NUMBER:

I, the undersigned, hereby declare that the equipment specied above

conforms to the above European Communities Directive(s) and

Standard(s).

PLACE:

DATE:

(Signature)

Robert Wyatt

Company Secretary

Derby, UK

24th JUNE 2017

SGS Engineering (UK) Ltd

SGS Engineering (UK) Ltd

West Side Park

Raynesway

Derby, DE21 7AZ

Engine Crane

EC2000

EN 1494:2000+A1:2008 Mobile or movable jacks and

associated lifting equipment

EN ISO 12100:2010 Risk assessment & risk reduction

EN ISO 13857:2008 Safety distances & hazard zone

EN 349:1993+A1:2008 Minimum safety gaps

2006/42/EC Machinery Directive (MD)

APPLICATION OF EC COUNCIL DIRECTIVES / STANDARD:

Loading...

Loading...