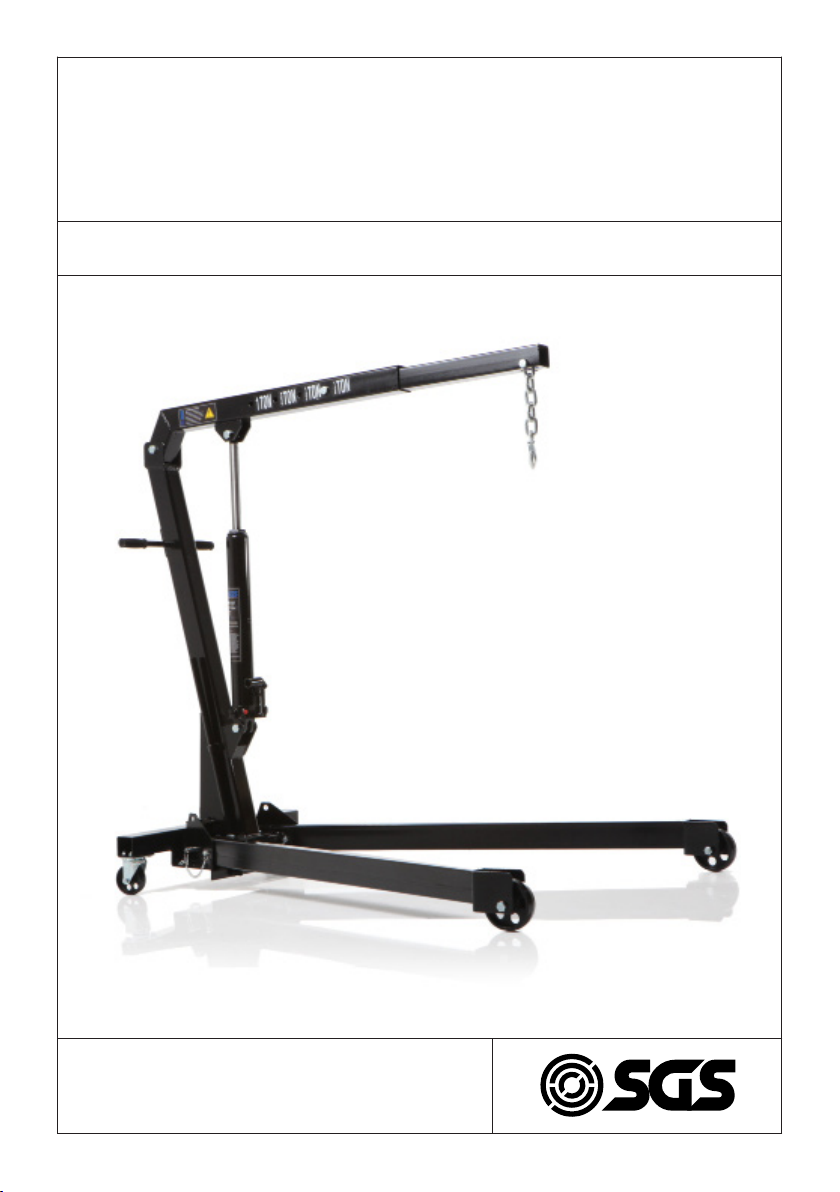

SGS EC1000 Owner's Manual

EC1000

ENGINE CRANE

OWNER’S MANUAL

1 TONNE MAX CAPACITY

FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.

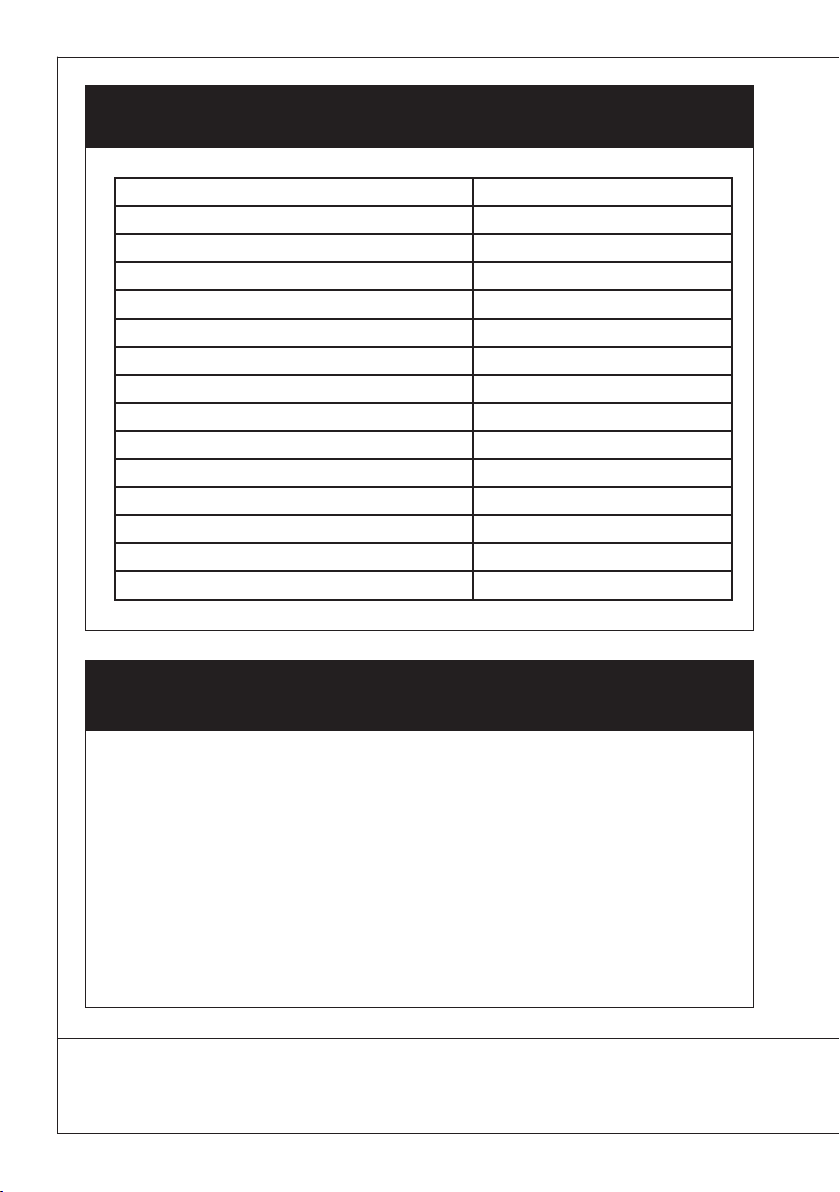

SPECIFICATION

Lifting capacity position 1 1000kg

Lifting capacity position 2 750kg

Lifting capacity position 3 500kg

Lifting capacity position 4 250kg

Maximum lifting height min. jib ext. 2020mm

Maximum lifting height max. jib ext. 2248mm

Length of jib position 1 902mm

Length of jib position 2 990mm

Length of jib position 3 1080mm

Length of jib position 4 1168mm

Height of frame 159mm

Length of frame 1251mm

Overall height 1400mm

Width of frame max 952mm

Distance between centre of rear wheels 597mm

WARNING

Do not overload. Overloading could cause damage or failure of the crane. Never exceed

the safe working loads indicated on the jib.

Never use the crane on an uneven floor surface as this could result in the crane tipping

over.

Always lock the legs and jib in position before lifting a load.

The nuts and bolts supplied with the crane are all high strength and should not be substituted for inferior types. Before each use ensure that all nuts and bolts are correctly

fitted and tight.

WWW.SGS-ENGINEERING.COM PAGE 2

OPERATING INSTRUCTIONS

WARNING: This double pump long ram is designed for lifting purposes only – not for

supporting loads. Do not load beyond its rated capacity.

IMPORTANT: It is possible that air has got into the hydraulic system causing poor

lifting performance. Purge any air from the system by fully opening the release valve

(turn handle counter-clockwise) then while holding the boom down operate the pump

handle rapidly several times.

TO RAISE LOAD: Close release valve by turning handle clockwise to a snug-tight position. Do not over-tighten.

TO LOWER LOAD: Open release valve by turning handle counter-clockwise very

slowly. The speed of the lowering is controlled by how much the handle is turned.

NOTE: Before raising the legs to the storage position bolt (No. 6) and nut (No. 7) must

be inserted into the base support and tightened. If this procedure is not followed the

unit may fall over.

MAINTENANCE

IMPORTANT: When adding or replacing oil always use high grade hydraulic jack oil.

Avoid mixing different grades/types of oil. Do not use brake fluid, alcohol, glycerine,

detergent motor oil or dirty oil. Improper fluid can cause serious internal damage to

the ram.

When adding oil be very careful not to permit dirt or foreign matter to enter the system. Check ram and plunger every 3 months for any signs of rust or corrosion. Clean

as needed and wipe with an oily cloth.

When not using the ram always leave the jib in the fully lowered position.

PAGE 3

Loading...

Loading...