Page 1

THE

1-34 6 1-HR

SAILPLANE

FJ.ilGllT - ERECTION - MAINTENANCE

MANUAL

Page 2

TABLE

OF

CONTENTS

SECTION ONE -

FLIGHT

PROCEDyrtES

General

Description

Flight

Controls

Retractable

Gear

Control

Pre-Flight

Inspection

Weight

and Balance

Aero Towing

Auto

or

Winch Towing

Take-off

- Spina -

Aerobatics

- Dive

BrakU

- Slipping

Landlnc

Procedures -Normal

and

Emergency

Cold

Weather

Operation

Flight

Envelope

Flight

Envelope Graph (Fig.

Ill)

Performance

Curves (Fig.

IV)

SECTION

TWO

- ERECTION

&r

¥AP!TENANQ!f

Final

AHembly

Hardware

List

Unloading

from

Trailer

Sailplane

AHembly

Generate~

Instructions

Fabric

Covering,

Finish

Lubrication

Chart

- Fig. I

Lubrication

Chart

- Fig.

ll

Lubrication

Chart

- Fig. m

Rigging

Wheel and

Brake

Annual

or

100 Hour lnapectlon

Annual

or

100 Hour Inspection

Record

Sailplane Tie Down

Form

F-116

1-70

Rev. 4-72

1-1

1-2

1-4

1-4

1-5

1-6

1-6

1-7

1-8

1-9

1-11

1-12

1-13

2-1

2-2

2-3

2-7

2-7

2-8

2-9

2-10

2-11

2-12

2-13

2-15

2-16

Page 3

Page 4

GENERAL DESCRIPTION

MODEL

SGS

1-34

The

SGS

1-34

ls a single

place,

high

performance,

all-metal

sailplane

of

monocoque

construction,

built

by

Schweizer

Aircraft

Corp.,

Elmira,

N.

Y.

It

was

designed

and

built

to

meet

the need and demand

for a US

Standard

Class

Sailplane.

Its

many

safety

features

plus

the

excellent

flying and handling

characteristics

serve

to

make

It

an

Ideal

sailplane

for

the

average

soaring

pilot;

as

well

as

for

one with

competition

In

mind.

Pilot

fatigue,

after

long

duration

flights,

has

been

virtually

eliminated

be-

cause

of

the

semi-reclining

adjustable

seat,

adjustable

rudder

pedals

and

adjustable

headrest.

The

rate

of

roll

and

controllability,

while

thermalling,

is

very

good. The

visibllity

out

of

the

cockpit

ln

all

directions

ls

excellent.

The cockpit

is

roomy,

with

all

the

controls

and

instruments

within

easy

reach.

These

features

add

up

to

more

pilot

comfort

and

better

proficiency.

MODEL

SGS

1-34R

The

SGS

1-34R.fllght

and handling

characteristics,

from

lift-off

to touch-

down,are

identical

with

those

of

the

1-34.

The 1-34R

Incorporates a manually-operated

retractable

main

gear

with

doors.

The

retractable

gear

offers

three

advantages

over

the coaventional

gear.

One, obviously

that

of

resulting

in a more

aeroqynamlcally

clean

aircraft.

Second, the

weight

of

the

retraction

mechanism

is

beneficial

from a penetration

standpoint.

Furthermore,

additional ground

clearance

is

provided by the

ex-

tended

gear

for

those

operating

from

uneven

fields.

The

overall

dimensions

re-

main

the

same

except

for

the ground height, which

is

slightly

Increased

on the

1-34R.

In

this

connection, the

gear

for

the

1.,.34

has

a one inch

up

and down

ground

adjustment

through

the

use

of

alternate

axle

holes

in the

gear

plates

and

brake

torque

arm.

overall

Dimensions

Length

Span (15

meters)

Height

Wing

Area

25 ft. 5 In.

49 ft. 2

In.

7 ft. 6 In.

151

sq.ft.

1-1

Other

Characteristics

1-34

Aspect

Ratio

Empty

Weight

Useful Load

Max.

Gross

Weight

16

570

lbs.

270

lbs.

840

lbs.

1-34R

16

595

lbs.

245

lbs.

840

lbs.

Page 5

Caiculatt!d

I)D

Min. Sink

Placard

(red

line) Speed:

dive

brakes

closed

dive

brakes

open

Stall Speed

Opening the Canopy:

PERFORMANCE DATA

SGS

1-34

33

at

55

mph

2.4

fps@

49

mph

800#

GW

840#

GW

135

mph

132

mph

142

mph

132

mph

36 - 38

mph

SGS

1-34R

34

at

55. 5 mph

2.2

fps@

46

mph

800#

GW

840#

GW

135

mph

132

mph

142

mph

132

mph

36 - 38

mph

Access

to the

cockpit

ls

gained

normally

from

the

left

hand

side

of

the

ship.

The

small

window

panel

in

the

lower

section

of

the

canopy

is

pushed

slightly

inward, then

aft.

Reach

across

the

cockpit

to the

ring

on the

latch

handle,

rotate

the

latch by pulling the

handle

ring

inboard and

aft.

The canopy

is

unlatched

when

the handle

is

at

right

angles

to

the longeron. To

latch

the canopy

after

tie-down,

reverse

the above

procedure.

FLIGHT CONTROLS:

1.

Control

Stick:

The

single

bent

control

stick

ls

conventional

for

aileron

and

elevator

control.

2

a.

Rudder

Pedals:

Rudder

pedals

are

conventional

with

a five

position

adjustment.

Ease

of

adjustment

is

provided

for

by a levered

lock-pin

arrangement

and

a

spring

assisted

pedal

retraction.

b.

Rudder

Pedal

Adjustment·Lever:

Located

between

the

bottom

of

the

rudder

pedals.

To

adjust,

depress

lever

with

either

heel

and

relax

pressure

on

rudder

pedals.

The

spring

will

retr.ict

the

pedals

to the full

aft

position.

Push

pedals

for-

ward

to

desired

position

and allow

lever

to

lock in

place

by

removing

heel.

3.

Trim

Control

(longitudinal):

The

cockpit

control

is a lever

with a knurled

lock-knob

located

on

the

right

hand

side

of the

cockpit.

The

lock-knob

must

be

turned

counter-

clockwise to unlock and

clockwise

to

lock.

On

the

first

few

aircraft,

the

cockpit

control

is a T-handle

located

under

the

lower

left

side

of

the

instrument

panel.

To unlock,

turn

T-handle

counterclock-wise.

Pull

to

the

desired

trim

position and

lock by

turning

the

handle

firmly

clockwise.

1-2

Page 6

The

trim

system

is

of

the bungee type which

applies

tension to the

elevator

cable

to

reduce

the

control

stick

back-pressure

required

while flying

at

slower

airspeeds.

Forward

position

for

nose-down

trim

and

aft

positions

for

increasing

amounts

of

nose-up

trim,

for

either

type

of

control.

4.

Tow

Release

Control:

The

release

control

is

a knob located below

center

of the

instrument

panel.

Pull

the knob fully

aft

to

actuate

the

tow

hook

release.

5. Dive

Brake

Control:

The

dive

brakes

are

actuated

by a

lever

located

at

the forward

left

hand

side

of

the

cockpit.

Lever

is

pulled slightly inboard to unlock

and

aft

to the

desired

degree

of

dive

brake

application. To

close

and

lock dive

brakes,

push

the

lever

forward

until

it

snaps

into the locked

position.

Forces

required

to open and

close

the dive

brakes

are

light

at

low

speeds,

but will

require

more

force

to

close

as

speed

is

increased.

6. Main Wheel

Brake:

The

main

wheel

brake

is a hydraulically

actuated

disc

type and is

applied by unlocking the dive

brake

lever

and pulling to the full

aft

position.

The wheel

brake

is

actuated

during the final

few

inches

of

the dive

brake

control

lever

travel.

Extra

pull

force

is

needed to

achieve

wheel-braking

action.

7.

Instrumentation:

An

airspeed

indicator,

sensitive

altimeter

and magnetic

compass

are

required.

Additional

instruments,

up to a full panel,

are

op-

tional

at

the

owner's

discretion.

8.

Static

Line Drain:

Provision

for

draining

of

any

accumulation

of

water

from

the

airspeed

static

line

is

made

by a

spring-loaded

valve located

at

the

lower

left

hand

side

of

center

console.

To

open the

drain

valve, push forward on

the

handle

pins

and

turn

counter-clockwise

approximately

1/ 4 turn.

To

close

valve,

turn

handle

pins

1/4

turn

clockwise and

release.

Factory

flight

tests

have shown

that

with

this

valve open in flight,

air-

speed

readings

are

reduced

slightly.

Flight

with

this

valve

inadver-

tently

in

the

open

position

is

therefore

not

particularly

hazardous,

and,

in

an

emergency,

may

be

used

as

an

alternate

source

of

static

pressure.

1-3

Page 7

9. Canopy Latch:

Located on

right

side

center

bottom canopy

frame.

Push

down and

for-

ward

to

secure

canopy.

Reverse

to

unlatch

- the handle

ls

at

right

angle

to the longeron

ln

the unlatched

posltlon.

10. Cockpit Ventilation:

Located

at

top

left

side

or

right

side

of

console.

Adjust

valve

as

desired.

11.

Clear-vision

Window

Panel:

Located

at

left

or

right

bottom

side

of

canopy

aft

of

center.

To open,

pull

small

knob inward and

slide

panel

aft

to

ventilate

and

remove

con-

densation

from

Internal

canopy

surfaces.

12.

Headrest

Adjustment I.Alver:

Located

at

center

of

aft

hatch

forward

bulkhead.

To

adjust,

pull

spring-loaded

lever

outboard and

set

headrest

to

desired

position.

Release

lever

to lock

In

place.

Six

positions

are

provided

to

comple-

ment

the

various

seat-back

positions.

13.

Seat-back

Adjustment

I.Alvera:

Located

at

top

outboard

sides

of

seat

back.

Depress

both

spring-loaded

levers

Inboard

and

set

seat-back

to

desired

position

in

the

adjustment

racks.

Release

levers

to lock into

position.

14.

Retractable

Gear

Control, 1-34R:

The

gear

retraction/extension

control

has

a

sllde-tube

and

cable

arrru:ige-

ment

with a knob handle,

together

with a squeeze-type

finger

lever

latch,

on the

right

side

of

the cockpit.

For

"Gear

Down", the

control

knob

is

in

the full

forward

position;

for

"Gear

Up", the

control

is

pulled

to

its

full

aft

position.

At

both

"Gear

Up" and

"Gear

Down"

positions,

the

control

is

locked by a

pln

(on the

underside

of

the

latch

lever)

engaging a

ho~e

ln

the

inner

slide

tube. A

"Gear

Down"

safety

pin

is

provided (attached to

a bead chain)

for

insertion

through the

slide

tubes

for

additional

pro-

tection

against

inadvertent

gear

retraction

during

ground-handling

or

tle

down

periods.

PREFLIGHT INSPECTION

CHECK

ALL

POINTS

AS

LISTED

Fuselage

and Cockpit:

a.

Flight

controls

for

free

and

normal

movement.

b.

Rudder

pedal

adjustment.

c.

Seat

and

headrest

adjustments.

d.

Release

hook and linkage.

1-4

Page 8

e.

Instruments,

lines,

pltot-static

openings,

static

line

drain.

f. Canopy - hinges and latch, head

clearance.

g.

Safety

belt

and

shoulder

harness.

h. Wing

pins -main

spar,

and

aft

carry-thru.

i.

Aileron

control

attachment,

fuselage

to

wing.

j.

Tire

condition and inflation (31

psi).

k. Wheel

brake

operation.

I.

Nose

skid

attachment

and condition.

m.

General

condition

exterior

surfaces.

n.

Retractable

gear

safety

pin

removed

-

l-34R

only.

a.

Aileron

hinge and

pushrod

connection.

b.

Dive

brake

and

mechanism.

c.

General

surface

condition.

Empennage:

a.

Stabllizer

attach,

forward

and

aft.

b.

Elevator -hinges,

pushrod

attach.

c.

Rudder

- hinges

and

fabric.

d. Remove inspection

plate -rudder

and

elevator

control

connections.

e.

Tail

wheel.

f.

General

condition

surfaces

and

aft

fuselage.

WEIGHT

AND

BALANCE,

SGS

1-34

The weight

and

balance,

furnished

with

each

sailplane,

should be the

con-

cern

of

each

pilot,

to

familiarize

himself

with the

various

weights, and weight

distribution

limits

shown. The

"placard

limits"

plate

attached

to the

instrument

panel

shows only the

basic

weight

limitations

as

to

maximum

pilot weight to

reach

either

(1)

maximum

gross

weight,

or

forward

CG

limit,

whichever

is

less;

and (2), the

minimum

pilot

weight

to

maintain

the

aft

CG

limit.

However,

be-

cause

of

variables

In loading conditions,

pilot-weight

limits

will

also

vary.

For

instance,

the maximum

pilot

weight (for

forward

CG

limit)

with

the

seat

back in

the fully

forward

position, will

sometimes

calculate

to be

less

than the weight

necessary

to

obtain

the

maximum

gross

weight. See Weight and Balance

Report

for

the

aircraft.

It

should

be

understood

that

the

heavier.pilot

will,

in

most

cases,

be tall enough to

require

that

the

seat-back

be

adjusted

to a position

other

than the fully

forward

position.

In

such

case,

it

is

quite

probable

that

the

maximum

gross

weight figure

ls

applicable,

as

each

succeeding

position

(aft)

of

the

seat

back

adjustment

will

allow a

somewhat

greater

pilot

weight

and

stlll

remain

within

the

forward

limit.

In

any

case,

flight

at,

or

near,

the

forward

1-5

Page 9

CG

llmlt

condltlon

ls

not

as

crltcal

to

controllablllty

as

ls

flight

at

the

aft

CG

limit

condition.

CAUTION: Upon

entering

the

cockpit, the

nose

section

should

be

pushed

down-

ward

so

that

the nose

skid

rests

on

the

ground. Should the

pilot's

own weight

fall

to

keep

the

nose

skid

in

contact

with the ground, the C. G. condltlon

must

be

rechecked,

to

assure

that

the

aft

C. G.

limit

is

not

exceeded,

before

flight

ls

attempted.

This

indication

of

the C. G.

applies

to the fixed

gear

model only.

WEIGHT AND BALANCE.

l-34R

The Datum,

MAC

and C.

G.

llmits

are

identical with

those

for

the

SGS

1-34.

The

1-34R

maximum

Gross

Weight

ls

840

lbs.

This

gross

weight was

also

approved

for

the

model

SGS

1-34

and

was

made

retroactive

to

include

ships

Serial

No. 1 and

Up.

The

main

wheel on the

l-34R,

as

stated

previously,

extends

farther

below

the fuselage than on the

1-34.

The

axle

position

is

also

moved

forward

ap-

proximately

eleven

inches.

This

has

no

effect

on

the

weight and

balance

out-

come

- only

the

figures

used

ln

some

computations.

AERO TOWING

Use

normal

aero

tow

procedures.

The

actual

take-off

should

not

be

at-

tempted until an

IAS

of

40 mph

ls

reached.

Due

to the low angle of

attack,

a

slower

attempt

of

take-off

will

result

in a

series

of

tall

bumps which

wlll

be

severe

lf

the

terrain

or

runway

is

not smooth. The

recommended

aero

tow

speed

is

55 - 60 mph. Towing

slower

than

an

IAS

of

50 mph

is

not

recom-

mended.

AUTO OR WINCH TOWING

Both

the

SGS

1-34

and

SGS

1-34R have

been

flight-tested

and approved

for

auto-winch

towing

at

maximum

gross

weight. However, with the

release

nook

so

far

forward

of

the

CG,

this

manner

of

launch

ls

something

less

than

ideal.

Therefore,

not

recommended

for

any pilot without

proper

instruction

or

equivalent

experience.

Normal auto

or

winch tow

procedures

are

used,

however,

as

the tow hook

is

so

far

forward, the

sailplane

has a porpoising

tendency when too

much

Up-

elevator

is

used

for

the

climb.

Should

this

occur,

reduce

back

pressu:-e on

the

stick

until

the

porpoising

stops.

The

maximum

tow

speed

of

66

mph

must

be

observed.

1-6

Page 10

TAKE-OFF

The

take-off

characteristics

for

the

1-34R

are

different

from

the

1-34

be-

cause

of

the

more

forward

location

of

the

main

landing

gear.

For

this

reason,

a

forward

pressure

on the

stick

ls

required

to

raise

the

tail

off the ground

tCY

attain a level

flying

attitude

for

take-off.

Spin

entries,

rotation

and

recoveries

are

all

normal

throughout the C.

G.

range.

The following

characteristics

occur

as

the

C.

G.

is

moved

rearward.

1.

Entries

will

be

more

difficult.

2.

Rotation

wlll

be

slower

and

flatter.

3.

Control

movements

for

recoveries

more

pronounced.

4.

Slower

recovery,

but

will

not

exceed

3/8 -1/2

turn

at

aft

CG

limit.

5.

Slower

indicated

airspeed

upon

recovery.

6.

Less

loss

of

altitude

per

rotation.

AEROBATICS

The

1-34

is

fully

aerobatic,

but

due

to the

danger

of

easily

exceeding

the

maximum

placard

speed

from a poorly

executed

maneuver,

it

is

highly

recom-

mended

that

pilots

without

aerobatic

experience

either

not

attempt

aerobatics,

or

get

instruction

prior

to

engaging

in

such

flight.

DIVE

BRAKES

Dive

brakes

can

be

used

for

rapid

loss

of

altitude

at

any

time,

including the

normal

landing

procedure

as

described

below.

The

1-34's

dive

brakes

are

extremely

effective

and will

limit

the

aircraft's

speed

to

approximately

142

mph

ln

a

vertical-attitude

dive

at

full

gross

weight.

They

can

be

opened

at

any

IAS up

to

142

mph.

To

maintain

a given

IAS

the

nose

must

be

lowered

as

the dive

brakes

are

pulled

open. The

reverse

ls

true

when

closing

them.

SUPPING

THE

AIRCRAFT

Slips

can

be

executed

normally,

but

with

the

effectiveness

of

the

dive

brakes

lt

ls

unlikely

that

slipping

should

become

necessary.

1-7

Page 11

LANDING PROCEDURES

A.

Normal Landing:

Pattern

It

is

standard

practice

to fly a

normal

traffic

pattern.

Allow

extra

airspeed

as

necessary

depending

on

gust

and wind

conditions.

Approach The

approach

should be

made

high

with

use

of

dive

brakes

as

needed.

They

increase

both

sink

and

drag

which, in

turn,

creates a steeper

and

more

controllable

glide path.

Touch

Down

Can

be

made

with dive

brakes

fully open,

partially

open,

or

fully

closed.

However, the

latter

is

not

recommended

except

for

practice

or

to

stretch

out

a landing

approach.

The

actual

landing should

be

made

at

an

IAS

of

40 - 45 mph. Landing

at

a

slower

speed

will

result

in a

tail

first

landing.

Ground

run

after

landing

Wheel

brake

On the

l-34R

the

main

wheel

is

located

in a

more

forward

position.

For

that

reason

forward

pressure

is

used

during

the

landing

roll

and

stick

movement

increased

as

airspeed

de-

creases,

until

elevator

control

becomes

lost

and the

tail

wheel

contacts

the

ground.

After

touch-down, the

aircraft

should

be

literally

flown to a

stop.

Care

should

be

taken

to

keep

the

wings

level

and the

track

straight.

When taxiing in a

cross

wind, keep the upwind

wing low

for

best

possible

control.

May be

used

at

any time, and to any extent,

for

as

quick a

stop

as

desired

after

touch down. The

aircraft

can

be landed with the

wheel

brake

fully on

..

This

will_!!2!

cause

the

sailplane

to

nose

over,

although

an

abrupt

rotation

will

occur

until the nose

skid

makes

contact

with

the ground.

B. Landing,

Dive-Brakes

Inoperative -

Emergency

Procedure:

In

the

event

that

the dive

brakes

should

become

inoperative,

in which

case

the

wheel

brake

would probably be

also

inoperative,

the

correct

landing

pro-

cedure

is:

1.

Enter

pattern

at

lower

than

normal

altitude.

2. Fly

pattern

at

a slow

but

safe

speed

(45 - 50 mph).

3.

Slip

as

necessary

at

an

indicated

45-50

mph until

sailplane

is

1/2

wing

span

from

the ground.

4.

Raise

low wing

as

altitude

decreases,

but hold

in

full opposite

rudder.

1-8

Page 12

5.

At 2 to 3 feet

above ground, wings should

be

level

and

opposite

rudder

eased

off to

neutral

position

(straight

and level flight).

6.

From

2 to 3

feet

force

the

sailplane

gently but

firmiy

to a flying

touch-down.

7.

Upon touch-down,

immediately

but slowly,

push

the

stick

full

foiward

so

that

the

skid

will

contact

the ground and

assist

in

braking

to a

stop.

It'ls

rather

difficult to

land

a high

performance

sailplane

using the above

pro-

cedure.

Therefore,

some

practice

landings

of

this

type would

be

very

beneficial

for

a future

emergency.

However,

since

an

inoperative

dive

brake

is

considered

to be a

remote

possibility, a pilot

should

not

attempt

to

practice

this

emergency

procedure

until he

has

become

thoroughly

familiar

with the

normal

flight and

handling

characteristics

of

the

sailplane.

COLD WEATHER OPERATION

OF

THE

1-34

Since

the

1-34

may

be

used

in wave and

winter

flying, It Is

recommended

that

a

low-temperature

lubricant

be

used

on

all

pivot points,

bearing

surfaces,

and

other

moving

parts.

To do

this,

the

pins

and

bolts

should be

removed

and

cleaned

of

any

old

grease

or

oil with a

solvent.

Apply

low-temperature

grease,

such

as

Esso

"Beacon

#325",

or

equivalent, which

meets

low-temperature

requirements

of

Spec. MIL-G-3278 (See

QPL-3278).

DIVE BRAKE FREEZING:

Two types

of

1reezing

are

possible

with the dive

brake

system.

The

first

is

the

actual

freezing

down

of

the

dive

brake

doors

and the

second

is

the high

friction

of

the dive

brake

control

system

due to the low

temperature

effect

on

lubricants.

Snow

or

ice

on

the top

surface

of

the wing will

usually

be

melted

by the sun

which

results

in a

water

film in the dive

brake

door

recesses.

In flight,

as

the

air

cools

with altitude,

this

water

freezes

the

doors

into the

recesses

so

that

they

may

not be opened.

It

is

recommended

that

the

doors

and

recesses

be

checked and

dried

off

if

flying

in

freezing

weather

is

expected

or

intended.

The dive

brake

system

should

be

cleaned

and

re-lubricated

with

low-temp-

erature

grease

as

previously

stated.

ICE, FROOT

OR

SNOW

ON

SAILPLANE:

Ice,

frost

or

snow on a

sailplane

can

be

dangerous

in

that

it

greatly

Increases

stalling

speed.

All Ice,

frost

and

snow should be

removed

from

the

sailplane

prior

to flight.

This

can

most

easily

be done by

cleanin11:

off

the

excess

and then

letting

the

sun

melt

the

rest.

If

heated

hangars

or

blowers

are

available,

they

1-9

Page 13

can

be

used.

Be

sure

surfaces

are

dry

before

attempting

flight. Do

not

scrape

ice,

snow

or

frost

from

surfaces

as

this

ls

likely

to

scratch

the finish,

or

possibly

gouge the

skin.

CANOPY PROVISIONS:

Be

sure

that

the

bolts

and

nuts

holding the

plexlglass

to

the

canopy

frame

are

only

snug

so

that

plastic

can

move

as

it

expands

or

contracts.

It

ls

recommended

that

clear-view

panels be

installed

inside

the

canopy to

provide a dead

air

space.

Use

of

the ventilating window

may

not

be

practical

at

ex

remely

low

temperatures.

BATTERIES:

Dry and

wet

cell

batteries

lose

voltage

with

low

temperature.

Insulation

helps

to

reduce

loss

of

voltage. Some

of

the

newer

types

batte>:"les have

improved

cold

weather

performance

and

should

be

considered.

WHEEL FREEZING:

When

operating

through

slush

or

mud,

it

is

possible

that

the

wheel

well

may

become

filled

during

one

or

several

take-offs

and landings. Then

during

flight,

if

temperature

drops

sufficiently,

slush

may

freeze

and lock the

wheel.

There

is

no

remedy

for

this

except

to avoid the

slush

and

mud.

The

consequence

for

landing with a wheel locked

ls

not

severe -at

most,

a blown

tire

could

result.

On the

SGS

1-34R, the above conditions hold

true,

but

with

the

additional

possibility

of

the

retraction

mechanisms

and

doors

becoming

frozen

in

the

"gear

up"

position.

While

this

ls

undesirable, a nearly

normal

landing

can

be

made

on

the

nose

skid

without

necessarily

damaging

the

sailplane.

Allowances should

be

made

to

compensate

for

the

absence

of

the

wheel-brake

In

such

an

instance.

1-10

Page 14

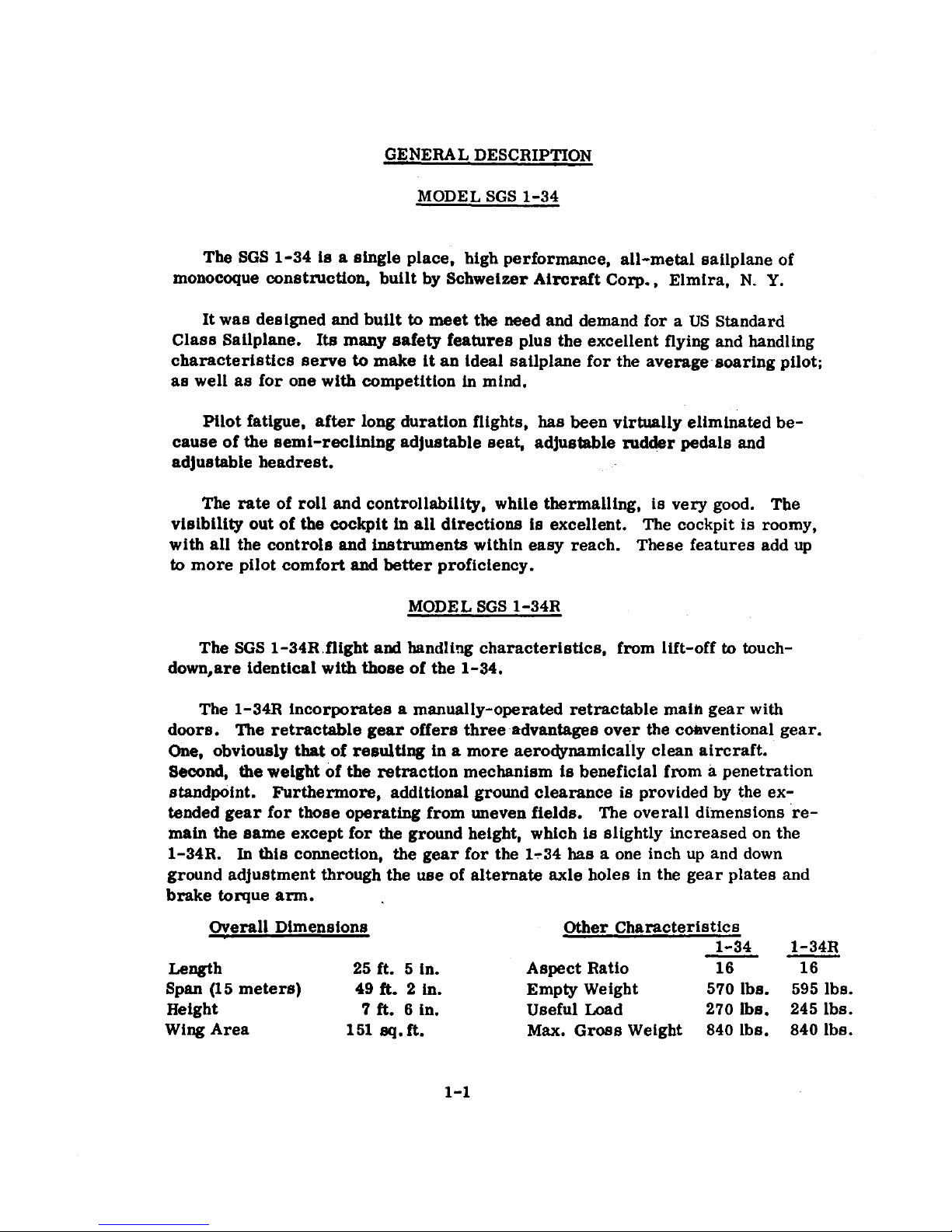

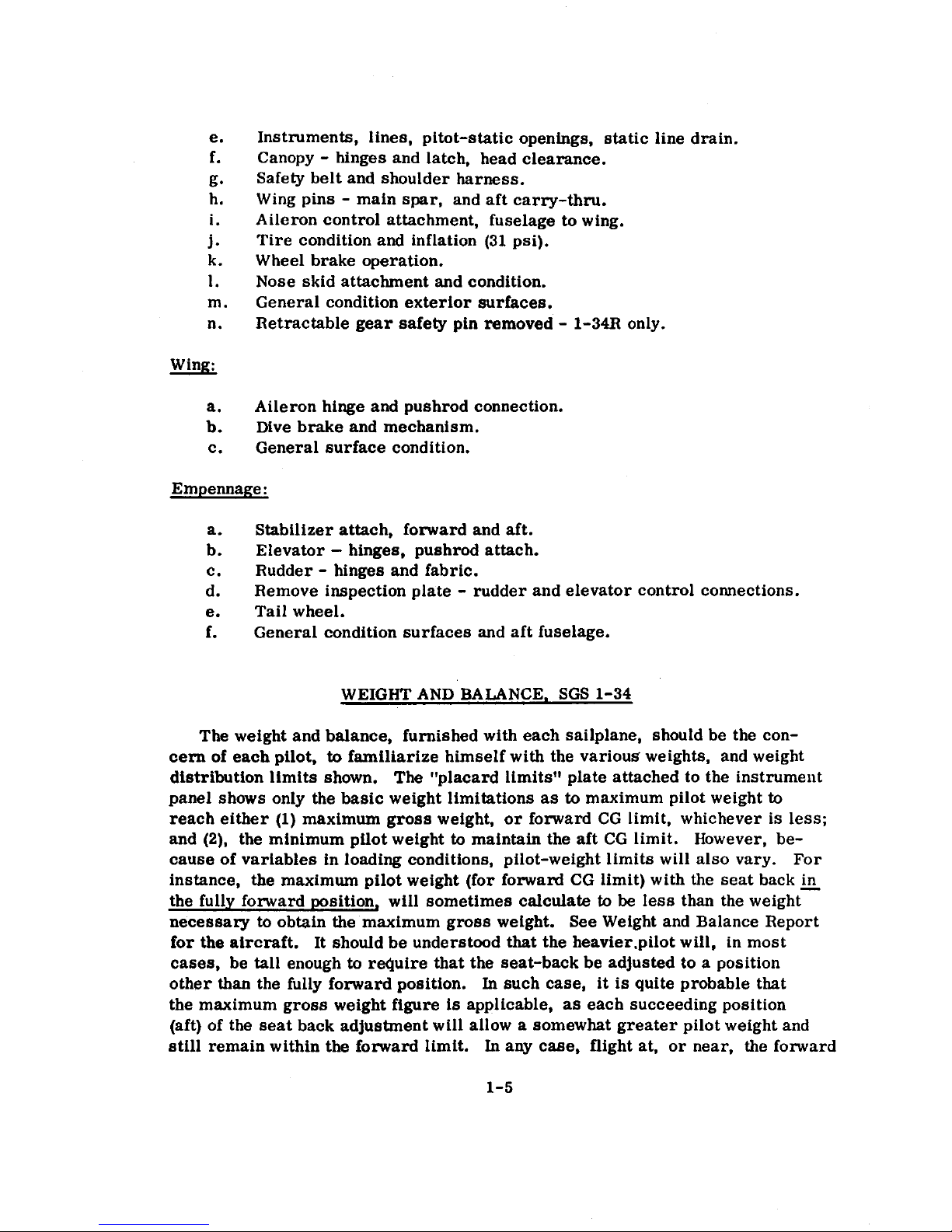

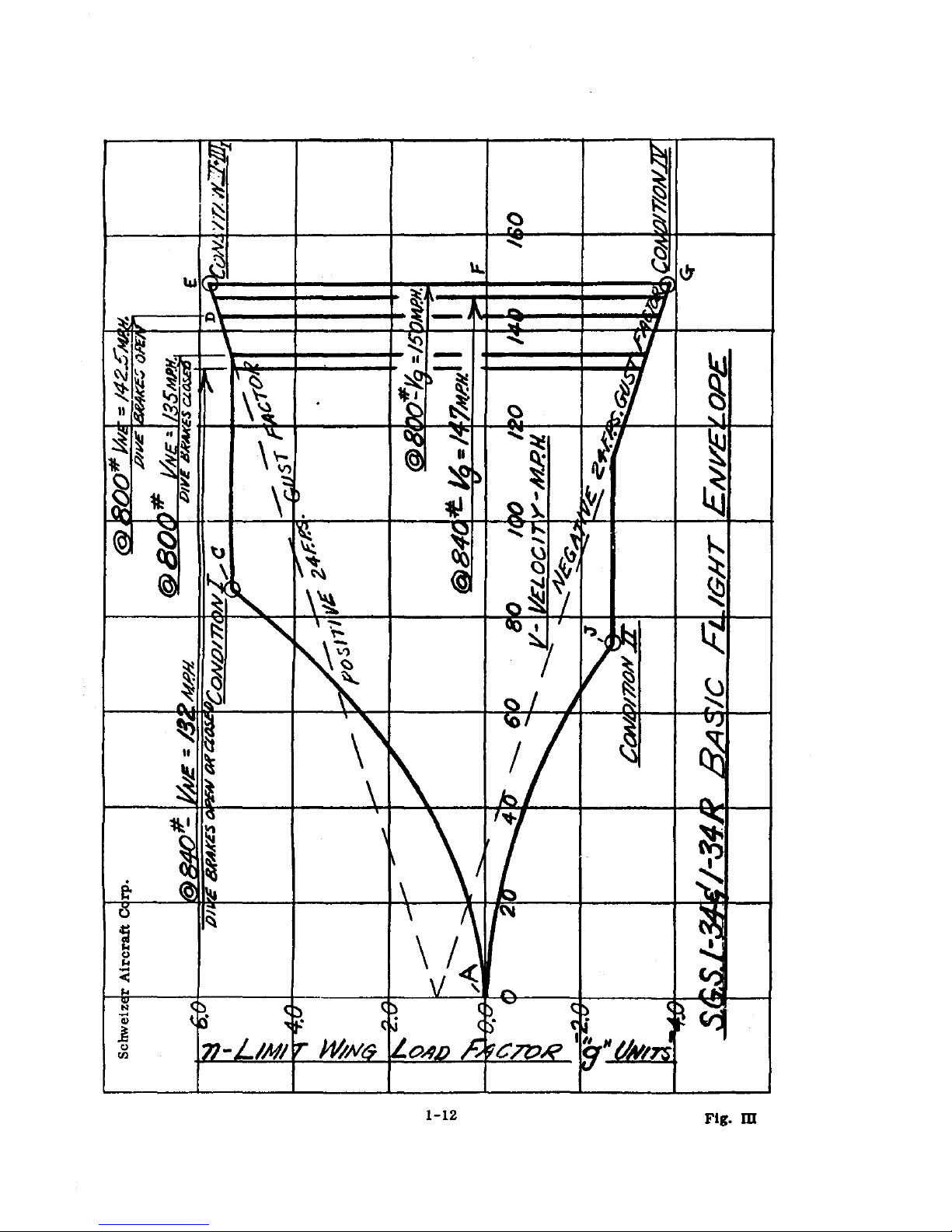

1-34

and

l-34R

FLIGHT ENVELOPE

The

graph

on the following page (Fig. III) shows the

basic

Flight

Envelope.

The

aircraft

should

be

operated

wlthln

the

envelope

limits

at

all

times.

Note

the

different

maximum

speeds

allowable

with

or

without

use

of

the

dive

brakes.

From

points A to

C

and

A to J

abrupt

maneuvers

will

not

exceed

the load

factor

Indicated

by

this

line.

Above C

(83

mph) the

maneuver

must

be

limited

to

avoid

excessive

load

factors.

The

gust

lines

are

based

on the

standard

24

ft/sec.

gust.

In

case

of

extreme

turbulence,

such

as

found

in

wave conditions

and

clouds,

gusts

can

be

much

higher

and

the

aircraft

should

be

operated

as

slowly

as

practicable,

considering

the

fact

that

under

turbulent

conditions a

safe

margin

above

stalling

speed

should

be

maintained.

Keep In

mind

that

while

the load

factors

ln

the

Flight

Envelope

carry a 50%

margin

of

safety,

these

margins

should

not

be

used

intenttonallY -

they

are

for

Inadvertent

conditions

only.

This

is

also

generally

true

for

over-speeding.

A

20%

increase

ln

speed

above the

placard

limit

wlll

use

up the

margin

of

safety.

A

wise

pilot

will

never

use

greater

speed,

or

pull

more

G's

than

the

condition

requires.

A

word

of caution

on

aerobatics.

Sailplane

aerobatics

is a specialized

field

and

requires

instruction

and

experience

to

accomplish

safely.

As

previously

stated

in

this

manual,

it

is

all

too

easy

to

exceed

flight

limits

in

an

improperly

executed

maneuver,

and

for

that

reason

aerobatic

flight

ls

not

recommended.

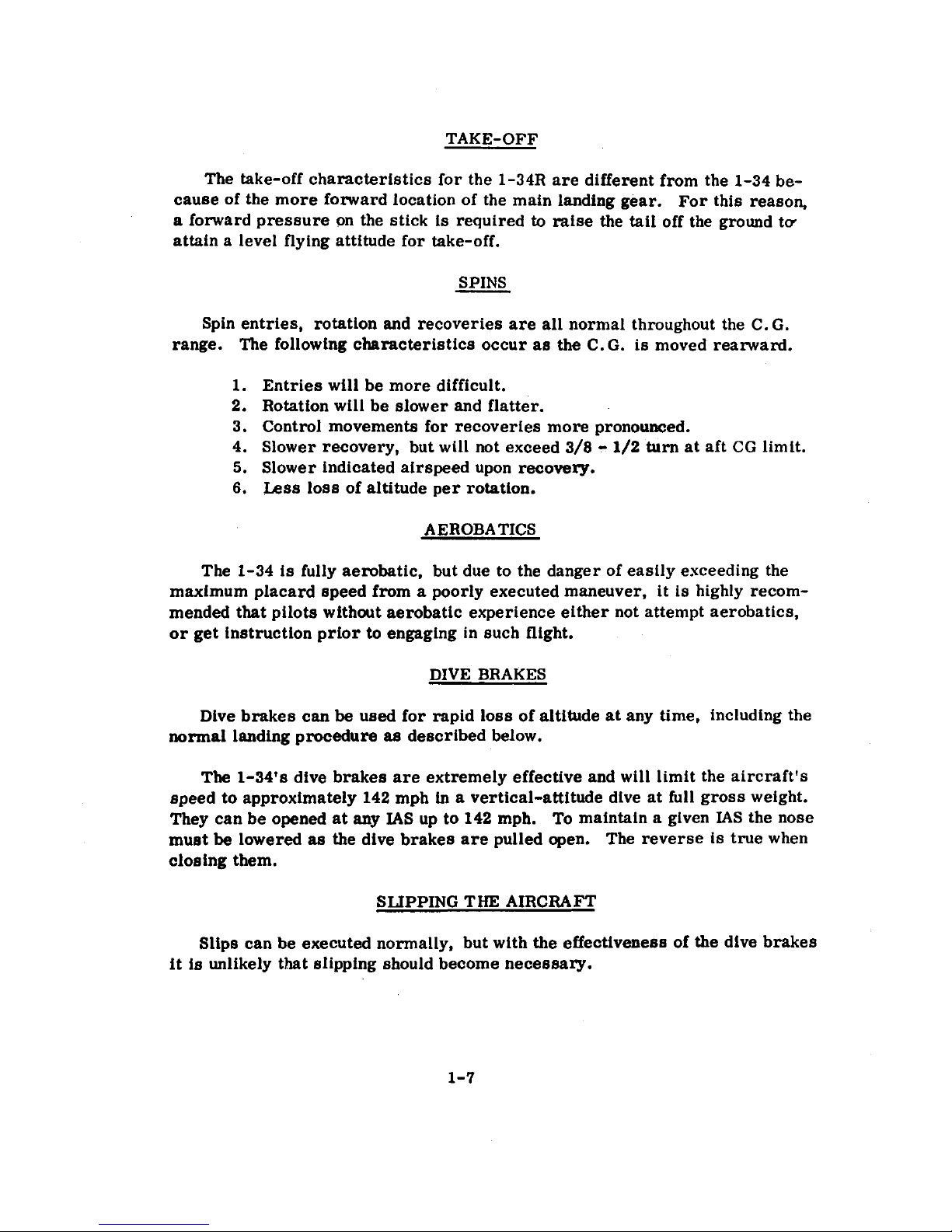

PERFORMANCE CURVES

To

aid

the

serious

pilot

in

becoming

familiar

with

the

various

I/D

vs.

air-

speed

relationships, a graph

of

the

calculated

performance

curves,

at

maximum

gross

weight,

is

provided

for

his

information.

See

Figure

IV.

1-ll

Page 15

rr

~

~

~

~

I "

·~

~

~

:-...

~

.......

~

.~

l.L.

q

&

tu

~

~

''-"

Q.\

~

-

-

J/

~

\

'""

.;L

~

ii!

1

~

'

';:)

~

~

II

-

A.

~

~

~~-

-

C\i

I\~

~

~

~

~

~

~

~~

\

\\

~~

II

~

~

cs

.

.....

~

~

~~

\~

~

~

"~

$''

~

~

1:

~

rq

II

~

~

~

'q

~~

~

n.t

~

11:

~

\"

).

'1

g~

~/

-

@

~

,~

~

,

.....

J1

~

....

~

\'t

~

\.}

~

~

'~

~

f'

~

"

\~

:-.I

~

o~

'/

"'

~

"

I':""

Qt)

I

1

">,I

~

4::

,...

7

~

~

v~

~

~

~

~

()I

J

~

~

::-.....

~

~

,,

!I

~

VJ

~

~

"

\

~

~

~

\

....

1':.'

ll

\

\1

'7

~

t;l

!

~

~

e.

~

~'

~

~

0

'

\

/~

""

~

~

~

"'

~

()

"'

<

v~

~

"'

,...,.

~

<

~

!

I:>

(

D (

~

......

(

D c

~

'1

...

\

~

If'

c

tJ

(

f)

c

Ii '

()

171-L/NI

r WING

ILoA.o

,,&,

~C7l:JR

1

~

11

1.w,r.i

{/)

1-12

Fig. m

Page 16

'

l

!

i

f

I

•

•I

l

r . H

l

t

Ir

'

J

t

•·

.

i.

l

j

I

I

I

ib

'

'I·

.

ih

I

.

i

t

.

I :

'

'

'

r

'

1

~

.

i

i

I

I

t

I

I

I

!

I

c i

I

'

I I

,r;

I

t

i

r

t!

I

i

I

~

.,

l

I

'

!

.

i

.

.

....

t

.

'

I

t

,

..

..

i

!

'

'

~.

I

\,I

ii-·

1-13

Page 17

SCHWEIZER

AmCRAFT

CORP.

Elmira,

New

York

14902

SECTION1WO

ERECTION

AND

MAINTENANCE INSTRUCTIONS

MODEl.8

SGS

1-34

Ir

1-34R

Form

F-116

1-70

Rev.

1-72

Page 18

SGS

1-34 -FINAL

ASSEMBLY HARDWARE LIST

The

following

lists

of

assembly

hardware

are

for a convenient

reference.

Wings to

Fuselage

Attach:

Stabilizer

to

Elevator

Attach

(Ref.):

(2) 34430B-1

Pin

- Main, Wing (2)

AN3-ll

Bolt

(L/R)

(2)

34901B-l

Main Safety

Pin

(2)

AN310-3 Nut

(2) AN393-25

Clevis

Pin

(2) AN960-10

Washer

(6) No.

LSP-1,

Comm'l.

Safety

Pin

(2) AN3-80-2-2

Cotter

Pin

(2) 34237D-1

Pin-Rear

Carry-Thru

(Captive

in

Fuse.)

(2) 34239D-3

Pln

- Main

Spar

(Captive

ln

Fuse.)

Stabilizer

to

Fuselage

Attach:

(2) 34902A Bolt,

Stab.

Attach

(2) AN310-5 Nut

(2) AN380-2-2

Cotter

Pin

(2) AN960-516

Washer

Aileron

to

Push

Rod

Attach

(Ref.):

(1) AN3-11

Bolt

(I./R)

(1) AN960-10

Washer

(1) AN310-3 Nut

(1)

AN380-2-2

Cotter

Pin

Aileron

to Wing

Attach

(Ref.):

(2) 34505B-5 Hinge

Pin

(2) 34505B-7 Hinge

Pln

(I./R)

(I./R)

NOTE:

Items

marked

"(Ref.)"

are

not

normally

disassembled

for

routine

handling

and

trailering.

2-1

Fin

to

Fuselage

Attach

(Ref. ):

(1) AN4-7A

Bolt

(Fwd.)

(5) AN960-416

Washer

(4) AN

4-5A

Bolt

(Rear)

(4) AN365-428 Nut

Rudder

to

Fin

Attach

(Ref.):

(3) AN3-11

Bolt

(3) AN960-10

Washer

(3) AN310-3 Nut

(3)

AN380-2-2

Cotter

Pin

Rudder

to

Horn

Attach

(Ref.):

(1)

AN4-20

Bolt

(1)

A~960-~6

Washer

(1) AN310-4 Nut

(1)

AN380-2-2

Cotter

Pin

Tail

Cone

to

Fuselage

(Ref.

):

(12)

AN509-8R-8

Screw

Page 19

ERECTION PROCEDURES

To

facllltate

disassembly

for

trailering

and

reassembly

at

the launch

site,

the

1-34

le

so

designed

that

this

may

be

accomplished

easily

and quickly.

Unloading

from

Trailer:

A. Unloading

Preparations:

1.

Release

trailer

from

towing

vehicle.

2.

Place

tow-bar

end on ground and block up the

aft

end with a saw

horse,

jack

or

other

convenient

means.

B. Wing Removal:

1.

Unfasten wing

tlp

tle

down.

2. Loosen

and

remove

bolt

that

fastens

the

spar

butt

to the

trailer.

3.

Place

one

person

at

the wing tip, holding

the

wing

by

Its leading

and

trailing

edges.

4.

Place

one

person

at

the

root

end,

lifting

by

the wing leading edge.

5. Both

men

lift

the

wing simultaneously, hlgh enough to

clear

the

trailer.

6. When the wing

ls

clear

of

the

trailer,

carry

to

its

relative

position

near

the

point

of

assembly

and

place

flat

on the ground.

7. Remove

the opposite wing with the

same

procedure

outlined above.

C. Horizontal

Stablllzer:

1. Remove

wing-nuts

from

frame

and swing the holding

straps

down out

of

the way.

2.

Remove

stabilizers

from

trailer

and

carry

to

position.

D.

Fuselage

Removal:

1.

Remove canopy and

set

aside

ln a

safe

place.

2. Remove the blockln¥

means

from

under

the

rear

of

the

trailer,

reverse

the

tilt

of

the

trailer

so

that

the

aft

end

rests

on

the ground

and

place

the

blocking

under

the

forward

end.

2-2

Page 20

3.

Remove the

bolt

attachlng

the

tall

wheel

bracket

to the

trailer.

4. Remove

supports

from

fuselage

attach

polnts

at

rear

.::arry-thru;

at

the

same

tlme

make

sure

that

the

fuselage

ls

supported

manually.

5. With one

person

guldlng the

tall

wheel, and one on

each

slde

of

the

fuselage

at

the cockplt,

lift

fuselage

out

of

the

wheel

chocks

and

carefully

back

the fuselage off the

aft

end of the

trailer.

SAILPLANE ASSEMBLY

A. Wlng to

Fuselage

AHembly:

Before

attachlng

the wlng to the fuselage,

check

to

lnsure

that

no

dlrt

ls

cllnglng to the

spar

butt

or

between the fuselage

carry-thru

plates. A soft

cloth

may

be

used

to wlpe

the

surfaces

clean. The

main

wing pln

holes,

the

holes

ln

the yoke

fltt111g

on

each

side

of the fuselage and the

rear

carry-thru

flttlng should

also

be

checked

for

cleanllness:

'?it

ls

recommended

that a step-by-step

pro-

cedure

be followed to avold

trouble. A light

film

of

grease

applied

to the lnslde

surfaces

of the

right

hand yoke fltting,

also

on the wlng

spar

ln the

area

of

con-

tact,

may

be

beneficial

ln

slldlng

the wlng lnto position.

1.

Support the fuselage ln a

normal

upright

position

wlth the canopy and

wlng

fairing

removed.

2.

Wings should

be

conveniently located

on

the ground,

or

on

racks,

on

their

respective

sides

of

the fuselage

..

Assembly

hardware

should

also

be

placed

near

its

polnt

of

use.

The dive

brake

control

lever

ln the

cockpit

must

be

ln

lts

forward

position

and locked

in

order

for

the dive

brake

slip-fittings

to engage

automatically.

3. Check to

make

sure

that

the four

captive

(3/8"

dia.)

L-shaped

pins

(2

for

the

rear

carry-thru

and one

each

upper

side

of

the fuselage

at

the

U-shaped

yoke fitting),

are

completely

disengaged by

pulllng

the

pins

forWard

against

the

pin

stops.

4.

The

right

hand wing

is

to

be

installed

first,

as

it

has

a wlng

align-

ment

pln

installed

on the

underside

of

the

spar

butt.

Have one

person

level

the fuselage standing on the

right

hand

side

of

fuselage. Two

men

pick up the wing, one

at

the tip and one

at

the

root.

The leadlng

edge

of

the wing

is

handed

to

the

man

supporting

the fuselage and the

man

carrying

the wlng

root

moves

to

support

the

trailing

edge.

5. The

spar

butt

ls

raised

to

clear

the fuselage wlng

attach

yoke fittlng

and wing

alignment

pin

on the

lower

side

of

the

spar

butt. Lower

wing lnto the yoke flttlng and have

tip

man

push

wlng lnboard to

2-3

Page 21

engage wing alignment

pin

In

Its

receiver

block together with the

rear

carry-thru

fitting.

Extreme

care

must

be

exercised

at

this point

so

that

the

man

guiding the

rear

carry-thru

fitting Into position does not

have hie

fingers caught between the

sharp

wing

skin

and the fuselage.

6.

After

engagement

of

rear

fitting and wing alignment pin, rock wing

slightly

and

Insert

3/8"

rear

carry-thru

pin

and safety

each

by

turn-

ing the L-ehaped handle portion to the

vertical

position, lower the

hinged-plate

over

the end

of

the handle and Install a type AN416-1

safety

pin through the hole provided

In

the handle end.

7. Next,

lneert

the forward L-ehaped wing attach pin

at

the yoke fitting

under

the

spar.

Push

the pin aft, through the main

spar

and the

aft

leg

of the yoke fitting, until stopped by the

roll

pin bumping

against

the forward

leg

of

the yoke flttlng. Safety the wing

pin

by Installing a

type AN416-l

safety

pin through the wing pin Just

aft

of

the forward

guide

bracket.

8. The

right

hand

wing tip should

now

be

held,

or

euworted,

ln a

nearly

level position, while the

three

persons

Install the opposite wing

ln a

similar

manner

to that outlined above.

9.

Install

the two

main

wing pine

P/N

34430B-l. A

slight

rocking

at

the

wing

tip wlll

aid

In

Inserting

each

pin

as

will the convenient handle.

Safety both

main

pine using the

P/N

34901B-l

large

safety

pine;

the

two

aileron

puahrode

are

attached

to the

aileron

Idler horn by

en-

gaging

the

quick-disconnect pine (captive In the

Idler

horn), and

are

then

safetied

with

(2)

AN416-l safety pine.

10.

Check

operation

of

dive

brake

doors and

aileron

control

system

to

Insure freedom

of

movement.

B. Horizontal

Tall

Surfaces to Fuselage:

Before

placing

stabilizer

on the fuselage torque tube, check to make

sure

that

the torque

tube le

free

of

dirt

or

grit.

A soft cloth should be used to wipe the

surfaces

clean.

NOTE: The

etabllizere

and

elevators

are

essentially

symmetrical

and

are

capable

of

being Installed on opposite

sides

of

the fuselage. However, the lower

surface

of

each

etablllzer

can

be

Identified by a

rectangular

notch

In

the

aft

Inboard

corner

of

the skin.

2-4

Page 22

1.

Place

stabilizer

on

torque

tube, align the

stabilizer

with forward

line-up

hole and the

elevator

with the

elevator-drive-assembly

pins.

Push

further

inboard untll the (vertical)

attach

hole in the

stabilizer

aligns with

that

in

torque

tube.

Insert

P/N

34902A-1

collared

attach

bolt, add AN960-516

washer,

AN310-6

nut

and (1) AN380-2-3

cotter

pin.

2. Repeat the above

procedure

for opposite hand.

3. Check

operation

of

the

elevator

control

system

for

freedom

of

movement.

C. Control

Surfaces,

Travel:

1.

In the

event

that

the

rigging

of

the

control

surfaces

has

been

disturbed,

the

travel

of

the

moveable

surfaces

must

be

rechecked

to

assure

that

they

are

within

their

respective

specified

tolerances.

Specified

travel

of

the

various

surfaces

are

shown below.

In

case

protractor-type

measuring

devices

are

unavailable

for'

making

this

check, the

chordal

dimensions, min. and

max.

from

neutral,

are

listed

immediately

following the

callout

in

degrees.

Aileron:

30-1/2°

to

33-1/2°

UP

---

4. 96" to 5. 43"

at

inboard

end

10°to

13°

DOWN

--------

1. 64"

to

2.14"

at

inboard

end

Dive

Brake:

Upper 87° to

97°

---

9. 64" to 10. 48"

at

inboard end

Lower

68°

to

7 s

0

---

7. 27"

tO

8. 18" to inboard end

Elevator:

28°

to

31°

UP

---

5. 34" to 5. 90"

at

intersection

of

trailing

edge and

root

rib

24°

to

27°

DOWN

---

4. 58"

to

5.16"

at

intersection

of

trailing

edge and

root

rib.

Rudder: 30°

to

33° L & R

---

8. is

11

to 8. 98"

at

bottom

of

trailing

edge

2. Aileron

control

stops

are

located

on the

under-floor

bulkhead and

contact

the

horn

on

the

control

stick

torque

tube

just

above the

cable

attach

points.

Elevator

control

stops

are

located

beneath

the

control

stick

torque

tube, immediately

forward

and

aft

of

the

control

stick.

Rudder

control

stops

are

bolts,

placed

vertically

through

brackets

in

the

aft

fuselage, which

restrict

rotation

of

the rudder.

horn.

2-5

Page 23

D.

Wing

Fairing

and Canopy:

1.

To

install

the

fiberglass

top wing fairing,

carefully

allgn the

slots

formed

by

the

joggled

strips

on the aft end

of

the canopy

over

the

metal

Up

protruding

forward

from

the

aft

fuselage.

Push

the

fairing

aft

until the

studs

on the fuselage line

up

with the

respective

hole in

the

attach

angle

inside

each

forward

corner

of the fairing.

Push

the

canopy down

over

the

studs.

When

properly

seated,

insert

the two

type AN415-2

pins

thru

the hole

provided

in

each

stud.

Secure

the

ball-type

latches,

one

each

side,

connecting the

upper

and

lower

sections

of

the bulkhead

at

the

forward

end

of

the fairing.

2. Canopy

installation

ls

accomplished

by

placing

the canopy in posltlon

over

the

double studs

on

the

hinges

located on the top of the

left

hand

cockpit

longeron. Lower the canopy, guiding the

studs

through the

holes

in the canopy

frame.

Insert

the

looped-end pins,

P/N

34227R-

15, along the top

side

of

the canopy

frame

member,

through

the

holes

provided

in the

double-studs

at

each

hinge. The canopy

restraint

cord

ls

tied

to the

pin

(AN395-32) located In the

aft

canopy bow, about

six

inches to the

right

of

canopy

center

line.

The S-hook on the opposite

end of the

restrainer

cord

ls

then hooked into the eyebolt,

attached

to

the

bulkhead in the aft,

right

rear

corner

of the cockpit.

Position

the

latch

handle

directly

inboard and

close

canopy.

To lock

the

canopy

from

outside the

sailplane,

pttsh inboard and

aft

on the

small

sliding

vent window

located

in the

lower

left hand

side

of

the canopy

glass.

Reach

across

cockpit and

rotate

latch

handle

forward

until

seating

of the

latch

pin

into

detent

ls

felt.

Reverse

the

above

procedure

to

open canopy

from

outside

the

aircraft.

2-6

Page 24

~ERAL

MAINTENANCE

The

all-metal

construction,

rudder

fabric

covering

excepted,

serves

to

minimize

the line

maintenance

required

for

normal

operation.

LEVELING:

1.

Lateral -using

adjustable

supports

under

the wing tips, level the

aircraft

and

check

with a

spirit

level

along

the

upper

edge

of

the

bulkhead

aft

of

the

seat.

2. Longitudinal -

raise

the

tall

of

the

sailplane,

place

support

under

the

tall

wheel and

check

with a spirit

level

at

the

rivet

line

along

the

side

longeron,

aft

of

the wing

trailing

edge.

LUBRICATION:

The

pulleys

In

the

various

control

systems

are

equipped with

sealed

antl-

frlctlon

bearings

and,

under

normal

operating

conditions,

are

considered

to be

permanently

lubricated.

This

also

applies

to

the

square

slide-tube

for

rudder

pedal

adjustment,

the

main

wheel

bearings,

and the

alleron

push-tube

guide

rollers

Inside the wing.

A good

grade

of engine

lubricating

oll

(SAE #30)

may

be

used

on pivot points

throughout the

control

systems.

However,

under

dry

and.dusty

condltlons,

lt

ls

deslreable

to

use a dry-type

lubrication

such

as a slllcone,

or

solid-film

spray

or

stick

lubricant

to

prevent

retention

of

grit

or

dirt

around

the

bearing.

The

Lubrication

Charts

(Figs.

I, n and III),

indicate

the points

requiring

lubrication

and

the

type

of

lubricant

to

be

used.

The

maximum

interval

for

complete

lubrication

ls

at

annual

inspections.

FABRIC COVERING:

1.

The

rudder

ls

the only

surface

on

the

aircraft

which

Is

fabric

covered.

The

covering

ls a synthetic

fabric,

"Ce::onlte No. 103",

manufactured

and

sold

by

Ceconlte, Inc. , 4677

Worth

Street,

Los Angeles, Calif.

90063. A Ceconlte ProceBB

Procedure

Manual

No.

101

may

be

pro-

cured

from

them

for

guidance

In

maintenance

and

repair

of

this

fabric.

See

front

of

aircraft

logbook

for

finishes

applied.

2. FAA Manual No.

AC43.13-l,

Chapter

3,

also

contains

guidance

information

for

fabric

testing

and

repairs.

2-7

Page 25

LUBRICATION CHART

KEY TO LUBRICATION:

~

Lubricating

OU

(SAE #30)

@

Slllcone

or

Solid-

Film

Spray

(alt. )

<!i)

Hydraulic

Fluid

(MIL-H-5606

or

equiv. l

SGS

1-34

Alleron

& Dive

Brake

Controls:

Wing

2-8

Page 26

LUBRICATION CHART--FUBELAGE

FIG.

ll

2-9

Page 27

Page 28

FINISH:

1.

The

production

aircraft

are

finished with

accyllc

lacquer.

(Ex-

ceptions

are

ship

serial

numbers

7 and 8, which have

enamel

finish).

Colors,

manufacturer

and

manufacturer's

numbers

of

the

material

applied

ls

noted in the

aircraft

desc.rlption

section

In

the

front

of

the

Individual

aircraft

logbook.

RIGGING:

1. The angle

of

incidence and

dihedral

angle

are

built

into the wing and

fuselage and

are

not

adjustable

ln

the field.

2. The

alleron

and

elevator

control

system

cables

are

rigged

to a tension

of

10 to 12

lbs.

The tension should

not

be

exceeded

to

prevent

friction

build-up

In

the

system.

3. The

rudder

control

cables

are

rigged

to

a tension of 10 to

14

lbs.

This

rigging tension Is

to

be

developed

prior

to

attaching

the

rudder

bungee

link

cables,

from

the captive

pretensioned

springs

in

the

aft

fuselage,

to

the

bolt

connection

on

the

rudder

cable

turnbuckles.

4. Control

cables

should

be

rigged with

the

turnbuckle

threads

flush with

the end

of

the

barrel,

although a

maximum

of

three

threads

showing

ls

permissible.

Safety

wiring

of

turnbuckles

ls

done by

the

double-

wrap

method shown ln

Chapter 4 of

FAA Manual AC43.13-1,

or

In

Mllltacy Standard

No.

MS33591.

5. The

dive-brake/wheel-brake

linkage should be

rigged

so

that

there

Is no

lost

motion when the

control

handle

ls

moved. Loosely

rigged

linkage

may

result

in

partial

opening

of

the

dive

brakes

even though

the

control

lever

ls

locked ln

the

closed

posltlon. The wheel

brake

should

be

rigged

to

phase-In

at

the

last

segment

of

the

brake

lever

travel.

The

wheel

brake

should

be

fully on

at

the point when the

dive

brake

doors

have

reached

maximum

travel.

6. The

spring

attached

to the

aft

end

of

the

tow hook

release

arm

should

be

tensioned

to

a point which

requires

a pull (aft)

of

9 to 20

lbs.,

at

the tow hook

slot

ln

the

arm,

to

actuate

the

release

arm

and

release

the hook.

7.

On

the

l-34R,

the

main

gear

up-cable

and

dawn-cable should be

rigged

to

equal

tension

so

that

the

cables

do

not

drag

in

falrleads.

However, avoid

excess

tension

which would

cause

friction

build-up

and consequent difficulty in

operation

of

the

control.

2-11

Page 29

WHEEL

AND

BRAKE:

The

main

wheel

ls a spllt

rlm

type,

wlth

roller

bearing

ln

each

half. The

tlre

ls

a 5.

00

x 5

(aircraft)

Type III, 4 ply

rating

and

takes

a 5.

oo

x 5 tube.

Inflation should

be

maintained

at

31

psl.

The

main

wheel

brake

is

a Cleveland

Aircraft

Products

Co. No. 30-9.

It

is a disc

type,

hydraulically

operated

by a

cylinder,

Scott Aviation,

Part

No.

4408E, mounted in

the

aft

fuselage

section

on the

right

hand

side.

The

brake

system

is

serviced

with

hydraulic

fluid (speclflcatlon MIL-

H-

5606,

or

equivalent)

by

removing

the

filllster

head

screw

from the top

plate

on the

master

cylinder

and

filling through

this

screw

hole.

To

bleed

the

brake

system,

remove

the

bleeder-valve

cap

on

the

brake

·

assembly,

opposite

the

line-attach

point. Actuate

the

brake

cylinder

and,

while

pressure

is

maintained;

crack

the

bleeder-valve

screw

to allow

air

to

escape.

Repeat

this

cycle,

adding hydraulic fluid

as

necessary,

until the

air

is

exhausted. Check

brakes

for

normal

operation

then tight.en

bleeder

valve

screw,

replace

bleeder-valve

cap,

also

replace

the

screw

ln

master

cylinder

filler-hole.

An

"0'

ring

(type AN6290-4)

is

required

in

the

master

cylinder

outlet

and

is

Inserted

ahead

of

the (type AN815-4D) tube union fitting.

MAIN

GEAR RETRACTION MECHANISM. 1-34R:

Retraction

of

the

main

gear

is

effected

by the

knee-action

between the

rear

fork (upper)

and

the

lower

wheel

support

struts.

The

rear

fork (upper)

is

bolted to

trunnion

shafts,

the

right

hand

shaft

being

also

bolted to a

sector

assembly

which, through a

cable

arrangement,

rotates

the

upper

rear

fork

forward and up

together

with the

struts

and forward fork. A

large

spring,

mounted in a

near-vertical

in

the

forward

left

hand

corner

of the wheel well,

compensates

for

most

of

the

weight

of

the wheel and forks

thereby

reducing

control

actuation

effort

to a

reasonable

level.

Adjustable

stop-bolts,

with

jamb

nuts,

are

incorporated

ln

both

lower

struts

to

facilltate

adjustment,

as

need be,

between the

rear

fork and

struts

when the

gear

ls

in the down position.

The

gear

doors

are

linked, with a turnbuckle,

directly

to the

lower

end

of

the

wheel

support

struts.

Adjustment for

proper

closed

position-ls

the only

adjustment

necessary.

The

brake

llne

is

routed

through