Sewerin Variotec 9-EX, SR 6 User Manual

Operating

Instructions

|

6, |

EX |

|

|

|

9 |

|

||

|

|

|

- |

|

EX |

SR |

VARIOTEC® |

|

|

|

|

|

||

TEC® |

|

|

|

|

- |

|

|

|

|

103992

Measurable success by Sewerin equipment

You settled on a precision instrument.

A good choice!

Our equipment stands out for guaranteed safety, optimal output and efficiency.

They correspond with the national and international guide-lines.

These operating instructions will help you to handle the instrument quickly and competently.

Please pay close attention to our operating instructions before usage.

In case of further queries our staff is at your disposal at any time.

Yours

Hermann Sewerin GmbH

Robert-Bosch-Straße 3 D-33334 Gütersloh

: +49 - (0) - 52 41/9 34-0 FAX : +49 - (0) - 52 41/9 34-4 44 www.sewerin.com info@sewerin.com

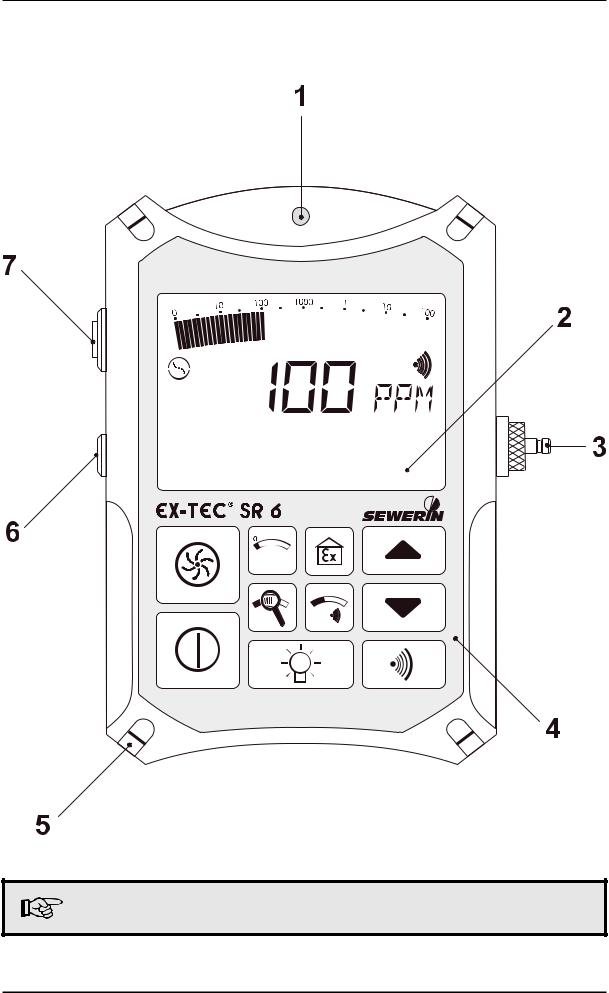

EX-TEC SR 6: illustration

See page 15 for an explanation of individual items

1

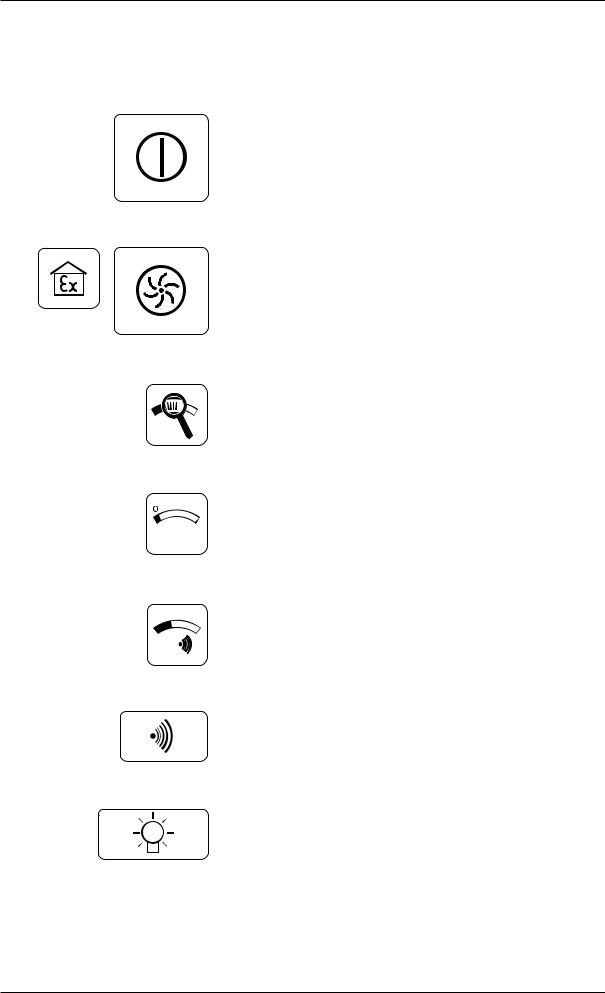

Brief operating instructions

Brief operating instructions: EX-TEC SR 6, VARIOTEC 9-EX

switches the detector on and off

toggles between GAS-WARNING / GASMEASURING modes

toggles between total and optimum measuring ranges

zero-point correction

displays the alarm threshold value

acoustic clearance of the alarm signal

switches LC display illumination on and off (... switches off automatically after about 4 minutes)

2

Operating manual

EX-TEC® SR 6, VARIOTEC® 9-EX

103992 - 04.12.2002

3

For your safety

This product may only be used after the operating instructions have been read and understood and only by appropriately trained operators.

This product may only be used for its designated purpose, and only in industry and trade.

Repair work may only be carried out by appropriately trained persons.

Changes and modifications to the product may only be carried out with the consent of Hermann Sewerin GmbH. Unauthorised modifications to the product render the warranty null and void.

Only accessories from Hermann Sewerin GmbH may be used with this product.

Only spare parts approved by us may be used for repairs.

Hermann Sewerin GmbH bears no liability for damage attributable to noncompliance with these instructions. The terms of warranty and liability of the conditions of sale and delivery of Hermann Sewerin GmbH are not extended by the above.

We reserve the right to make technical modifications in the interests of further development.

Please comply with general safety rules in addition to these instructions!

Symbols used:

CAUTION!

This symbol warns of dangers to the user or product.

Note:

This symbol indicates information and tips that go beyond actual operation for the product.

4

Contents |

page |

|

1 |

EX-TEC SR 6, VARIOTEC 9-EX system |

|

1.1 |

Models .......................................................................................... |

7 |

1.2 |

Test certificates ............................................................................ |

8 |

1.3 |

Charging equipment ..................................................................... |

9 |

1.4 |

Carrying equipment .................................................................... |

10 |

1.5 |

Probe systems ............................................................................. |

11 |

1.6 |

Test equipment ........................................................................... |

13 |

2 Safety

2.1 Safety instructions ....................................................................... |

14 |

3 |

Measuring operation |

|

3.1 |

Model overview........................................................................... |

15 |

3.2 |

Switching on ............................................................................... |

16 |

3.3 |

Illumination and contrast ............................................................. |

17 |

3.3.1 |

Operating hours in measuring operation .................................... |

18 |

3.4 |

Pump operation .......................................................................... |

19 |

3.5 |

Alarm signal and volume ............................................................ |

20 |

3.5.1 |

Automatic alarm reactivation....................................................... |

20 |

3.6 |

Alarm threshold value ................................................................. |

21 |

3.7 |

Switching measuring ranges ...................................................... |

22 |

3.8 |

Location / gas injection / blanketing ............................................ |

23 |

3.9 |

Delayed-action indicator ............................................................. |

24 |

3.10 |

Zero-point correction .................................................................. |

25 |

3.11 |

Gas-warning mode ..................................................................... |

25 |

3.12 |

Battery alarm ............................................................................... |

27 |

3.13 |

Switching off ............................................................................... |

27 |

4 |

Charging operation |

|

4.1 |

Charging and charge maintenance............................................. |

28 |

4.2 |

Spontaneous discharge ............................................................. |

29 |

5

Contents |

page |

|

5 |

Testing and maintenance |

|

5.1 |

Function testing, testing display accuracy .................................. |

30 |

5.2 |

Test equipment ........................................................................... |

33 |

5.3 |

Test gases .................................................................................. |

35 |

5.4 |

Function testing .......................................................................... |

36 |

6 |

Settings menu |

|

6.1 |

Setting the ppm sensor .............................................................. |

38 |

6.2 |

Setting the LEL sensor ............................................................... |

40 |

6.3 |

Setting the VOL sensor .............................................................. |

41 |

6.4 |

Setting the measurement unit (%LEL range language) .............. |

43 |

6.5 |

Setting 10 ppm sensitivity .......................................................... |

45 |

6.6 |

Activating the ETHANE box........................................................ |

46 |

6.7 |

Interface mode ........................................................................... |

46 |

6.8 |

Checking the LC display............................................................. |

47 |

6.9 |

Leaving the settings menu ......................................................... |

47 |

7 |

Technical aspects |

|

7.1 |

Technical notes........................................................................... |

48 |

7.2 |

Technical data ............................................................................. |

49 |

7.3 |

Error messages .......................................................................... |

52 |

7.4 |

Wearing parts ............................................................................. |

54 |

Appendix |

|

|

EC-type-examination certificates ......................................................... |

55 |

|

Declarations of conformity ................................................................... |

60 |

|

Test report ............................................................................................ |

62 |

|

6

1 EX-TEC SR 6, VARIOTEC 9-EX system

1 EX-TEC SR 6, VARIOTEC 9-EX system

1.1 Models

EX-TEC SR 6 (explosion-proof)

Gas detection

above-ground gas detection for pipeline monitoring (ppm range)

Interior installations

leak detection for pipelines in buildings (ppm range)

Gas warning

monitoring proximity to the lower explosion limit (%LEL range)

Location

concentration measurement in probe holes (vol.% range)

Gas injection and blanketing concentration measurement in pipelines (vol.% range)

VARIOTEC 9-EX (explosion-proof)

Gas detection

above-ground gas detection for pipeline monitoring (ppm range)

Interior installations

leak detection for pipelines in buildings (ppm range)

Location

concentration measurement in probe holes (vol.% range)

Gas injection and blanketing concentration measurement in pipelines (vol.% range)

7

1 EX-TEC SR 6, VARIOTEC 9-EX system

1.2Test certificates

Passive explosion protection

The EX-TEC SR 6 and VARIOTEC 9-EX models are explosion-proof in accordance with European norms (CENELEC):

EC prototype test certificate: PTB 96 ATEX 2166

Identification mark: |

II 2 G EEx ib d IIB T3 |

Testing institution: |

Physikalische-Technische |

|

Bundesanstalt, Brunswick |

Active explosion protection

The EX-TEC SR 6 has also been tested for functional safety in the gaswarning field:

Test report: |

PFG no. 41300897 |

Testing institution: |

DMT - Gesellschaft for Forschung |

|

und Prüfung mbH, Essen |

The test certificates can be found on and after page 55.

8

1 EX-TEC SR 6, VARIOTEC 9-EX system

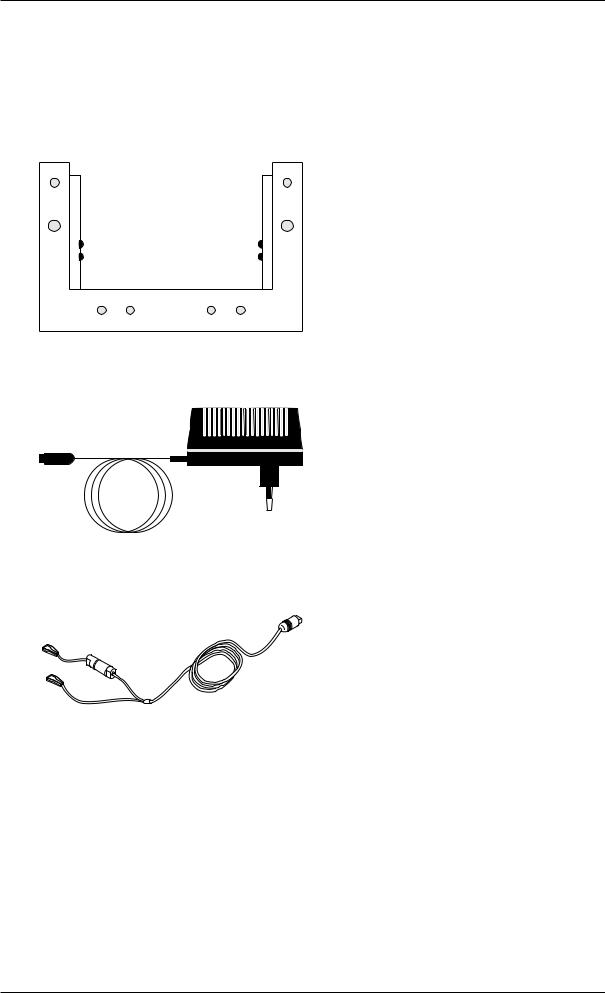

1.3Charging equipment

The EX-TEC SR 6 and the VARIOTEC 9-EX can be charged either in the workshop or in the standby vehicle:

HS charging adapter

to hold the detector, with a connection socket for the plug-in power pack or a vehicle adapter

230V plug-in power pack

to connect the HS HS charging adapter to a 230-volt mains supply

12V vehicle adapter

to connect the HS charging adapter to a 12-volt vehicle battery

24V vehicle adapter

(not shown) to connect the HS charging adapter to a 24-volt vehicle battery

9

1 EX-TEC SR 6, VARIOTEC 9-EX system

1.4Carrying equipment

TRIANGEL carrying system

a quick and easy way of carrying the detector, consisting of a carrying strap and neck-pad

front view |

side view |

rear view |

CROSS-STRAP carrying system

a comfortable way to carry the detector for longer periods, consisting of 2 carrying straps crossed at the back

front view |

side view |

rear view |

10

1 EX-TEC SR 6, VARIOTEC 9-EX system

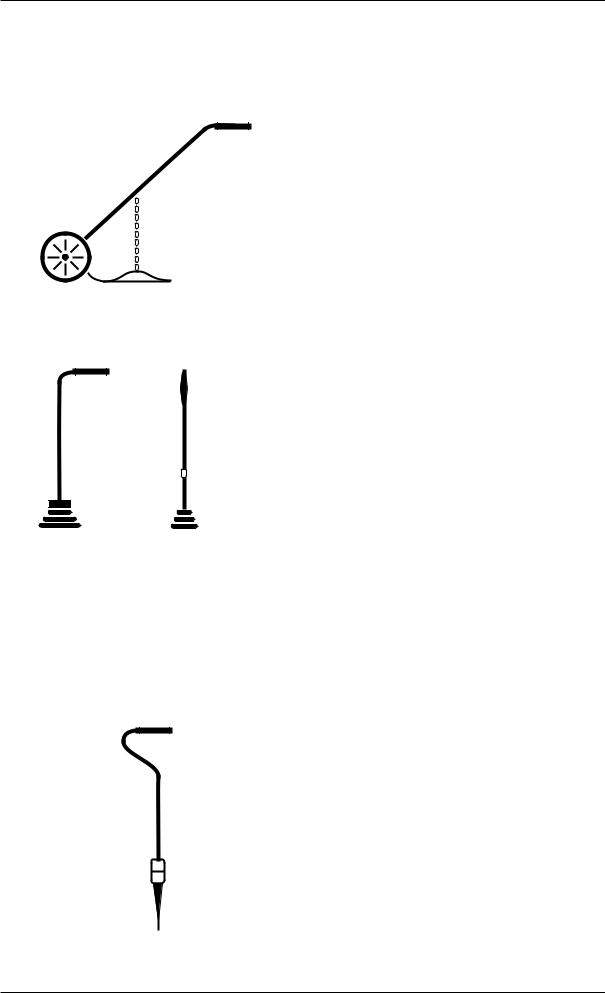

1.5Probe systems

- Pipe-monitoring probes -

Carpet probe

for checking stable surfaces. The sample is drawn into an excrescence in a neoprene mat in contact with the surface with no extraneous emissions

Bell probe, telescopic bell probe

for checking unstable and overgrown surfaces.

It can be used in confined spaces, e.g. between parked cars or in front gardens

- Location probes-

Location probe

for measuring concentrations in probe holes,

with a rigid rubber cone to seal off the probe hole and

2 different probe tips (length 245 mm or 345 mm)

11

1 EX-TEC SR 6, VARIOTEC 9-EX system

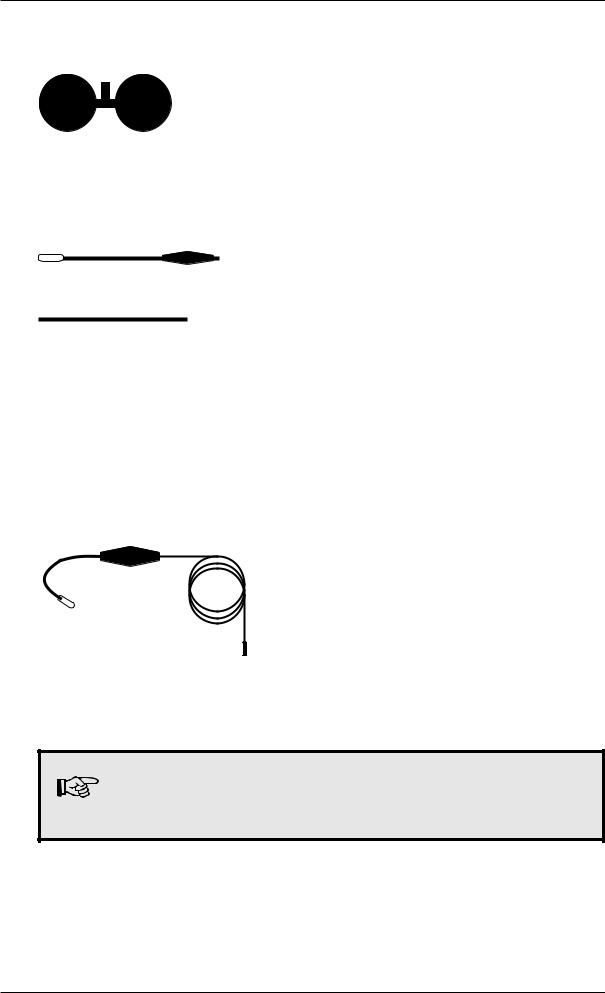

- Probes for use in enclosed spaces -

Floater probe

for measuring concentrations in shafts,

floater with intake orifice and hose connection

Divisible manual probe

for use with unenclosed pipes or at inaccessible locations, measuring concentrations in containers, overall length 900 mm

- Probes for interior installations -

Flexible manual probes for use with interior pipework,

grip with flexible swan-neck and probe hose, overall lengths 360 mm or 660 mm

Except with the carpet probe, a probe hose should always be used with a hydrophobic filter.

12

1 EX-TEC SR 6, VARIOTEC 9-EX system

1.6Test equipment

The following equipment is available for monitoring and testing the pump power and sensitivity of the EX-TEC SR 6 and VARIOTEC 9-EX:

SPE1 and SPE3 testers

for mobile use including in-vehicle use,

with connections for SEWERIN test-gas bottles, flow meter, release button and connection hose

Test-gas bottles

for testing and adjusting display sensitivity,

various test-gas concentrations in 1-litre bottles at pressures of about 12 bar

SPE2 tester

for non-mobile use in the workshop, with connections for several SEWERIN pressure cylinders, pressure and flow meter, release button and connection hoses

Pressure cylinders

(not shown) for testing and adjusting display sensitivity, various test-gas concentrations in 0.4 / 2.0 / 10.0 litre steel cylinders at pressures of 100-150 bar

13

2 Safety

2 Safety

2.1 Safety instructions

Always use original SEWERIN accessories with the EX-TEC SR 6 and VARIOTEC 9-EX

Always use a probe hose with a hydrophobic filter

Observe the permissible operating temperature range of minus 10 °C to plus 40 °C

The EX-TEC SR 6 and VARIOTEC 9-EX must not be recharged in areas exposed to the danger of explosion

Test gases may only be used in well-ventilated spaces

The EX-TEC SR 6 and VARIOTEC 9-EX satisfy the limits of the EMV regulation. When using it near (mobile) radio equipment please also follow the instructions in the manuals for that equipment

14

3 Measuring operation

3 Measuring operation

3.1 Model overview

Fold out the illustration inside the front cover

Item |

description |

function |

|

|

|

1 |

alarm lamp |

optical warning on: |

|

|

breaching alarm thresholds |

|

|

display of error messages |

|

|

|

2 |

LC display |

display of: |

|

|

gas concentrations |

|

|

menu items |

|

|

operating conditions |

|

|

error messages |

|

|

|

3 |

probe connection |

connection for: |

|

|

probe hose |

|

|

tester |

|

|

|

4 |

keypad |

detector operation |

|

|

|

5 |

attachment |

for carrying systems: |

|

|

Triangel |

|

|

cross-strap |

|

|

|

6 |

outlet |

for the gas sample |

|

|

|

7 |

buzzer |

acoustic warning on: |

|

|

reaching alarm thresholds |

|

|

display of error messageses |

15

3 Measuring operation

3.2 Switching on

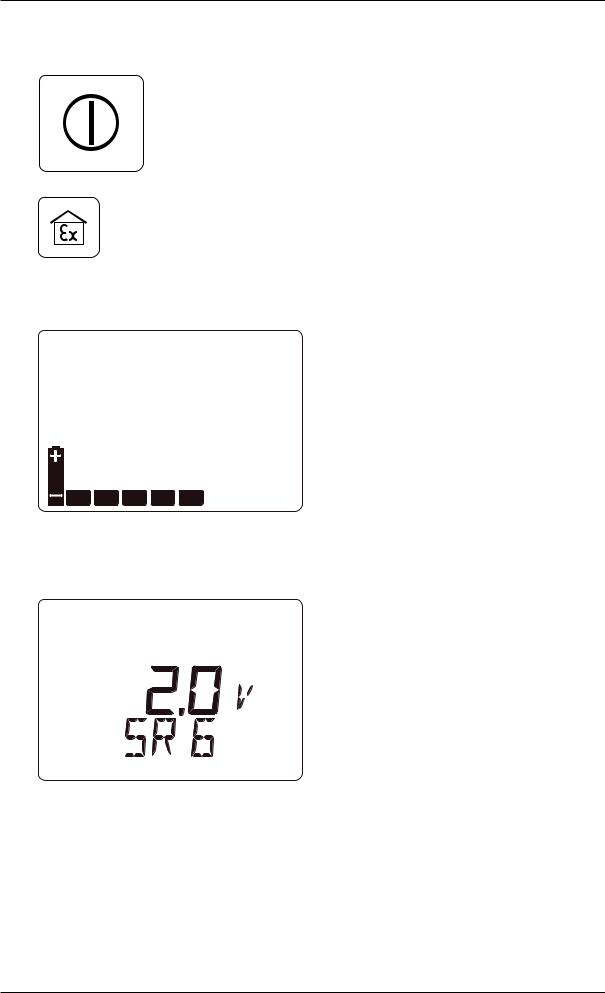

hold the on/off button down for about 2 seconds

or, on the SR 6 only, hold the gaswarning button down for about 2 seconds to start the detector in gas-warning mode (see p. 25 ff.)

the optical and acoustic control signals (items 1 and 7) operate for about 2 seconds

available operating hours are displayed in the form of bars (e.g. 5 hours)

theintegralpumprunsatfullpower

the software version number (e.g. 2.0) and detector type (SR 6) are displayed

16

3 Measuring operation

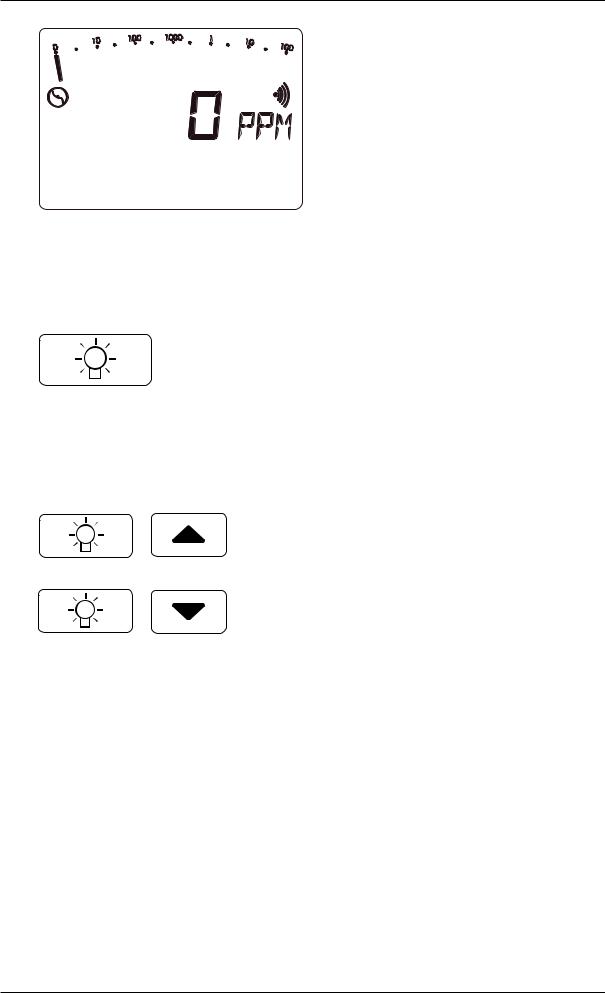

wait for the zero point to establish itselfinfreshair(approx.1minute):

display:  0 PPM

0 PPM

(after flashing stops)

3.3 Illumination and contrast

pressing the light button switches the LC DISPLAY illumination on and off

the illumination automatically switches off approx. 4 minutes after being switched on

simultaneously pressing the light button and a cursor button increases or reduces the contrast of the LC display

17

3 Measuring operation

3.3.1 Operating hours in measuring operation

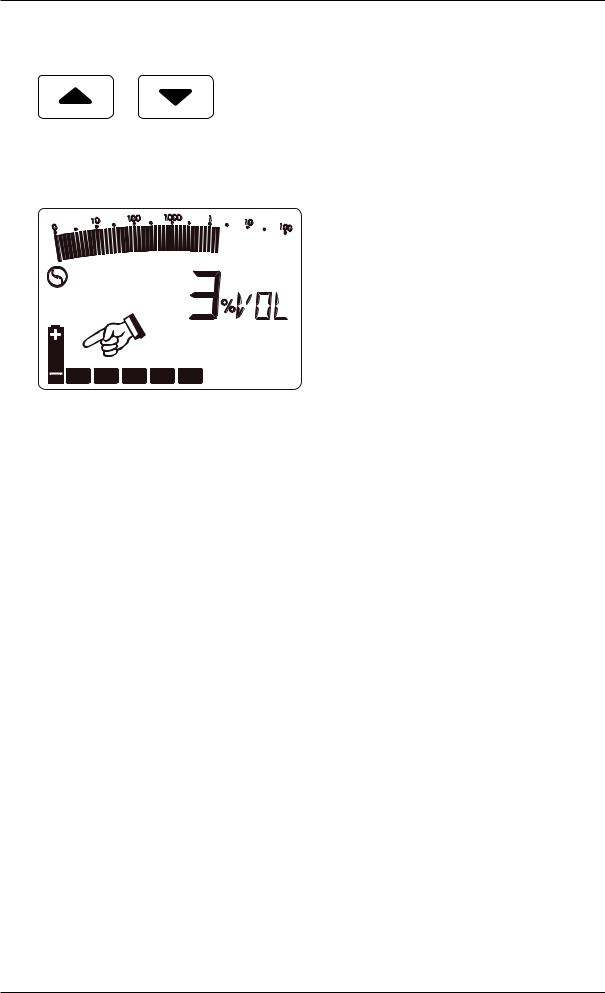

simultaneously pressing both cursor buttons in measuring operation displays the operating hours still available (e.g. 5 hours)

this display (battery symbol and bars) disappears automatically after about 10 seconds

18

Loading...

Loading...