Page 1

Operating

Instructions

EX-TEC® SR 6,

VARIOTEC® 9-EX

103992

Page 2

Measurable success by Sewerin equipment

You settled on a precision instrument.

A good choice!

Our equipment stands out for guaranteed safety, optimal output and efficiency.

They correspond with the national and international guide-lines.

These operating instructions will help you to handle the instrument quickly and

competently.

Please pay close attention to our operating instructions before usage.

In case of further queries our staff is at your disposal at any time.

Yours

Hermann Sewerin GmbH

Robert-Bosch-Straße 3

D-33334 Gütersloh

: +49 - (0) - 52 41/9 34-0

FAX : +49 - (0) - 52 41/9 34-4 44

www.sewerin.com

info@sewerin.com

Page 3

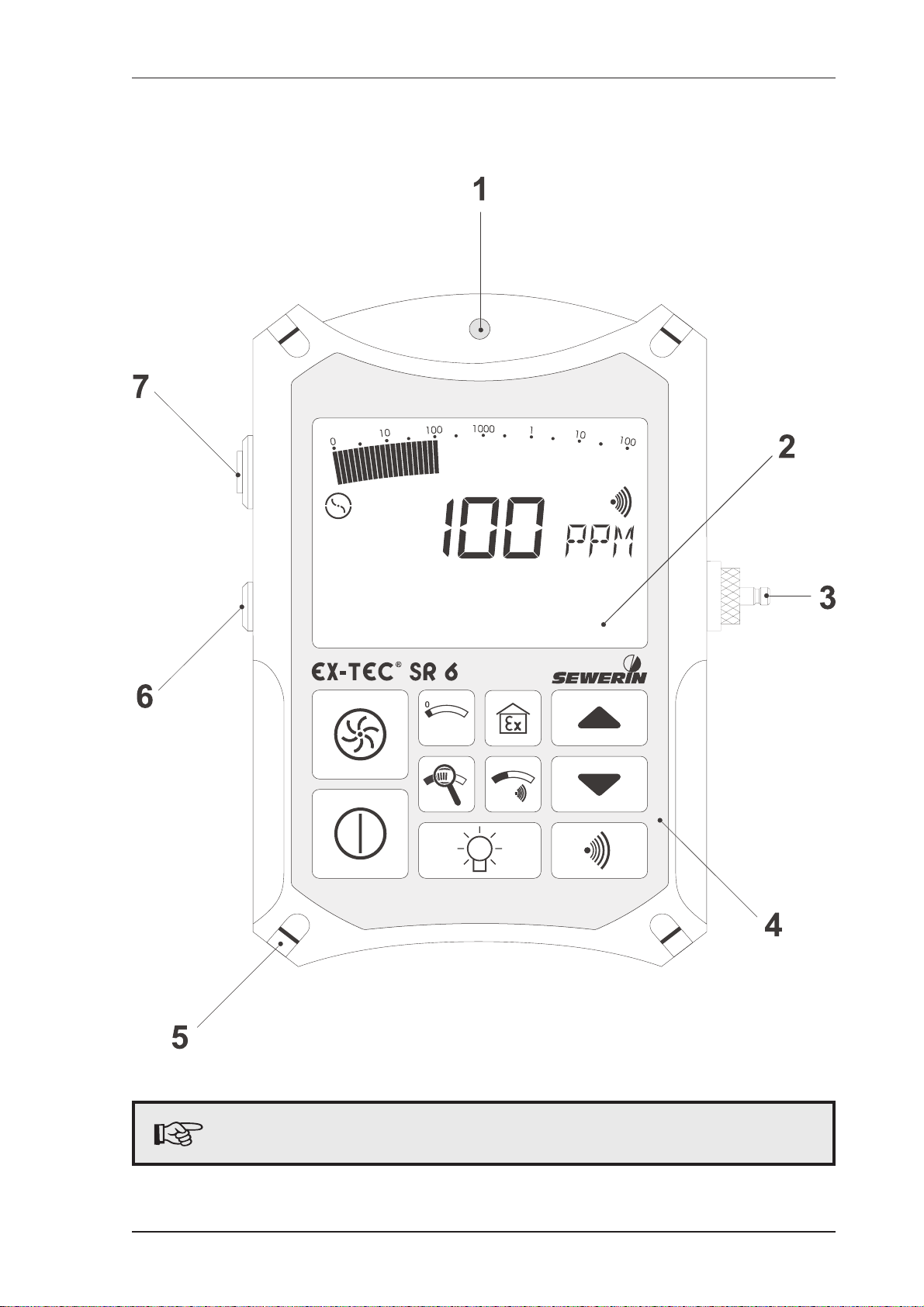

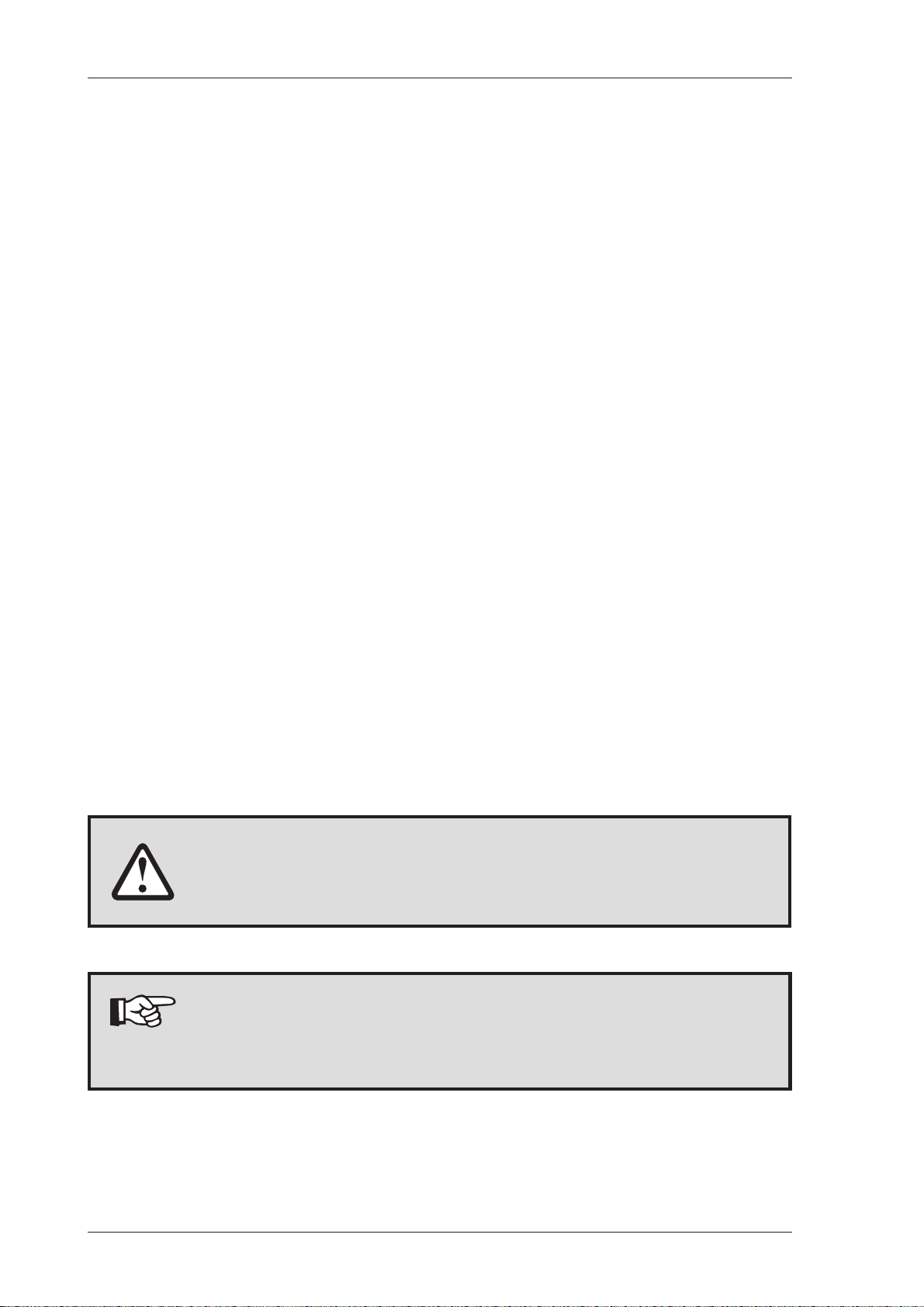

EX-TEC SR 6: illustration

See page 15 for an explanation of individual items

1

Page 4

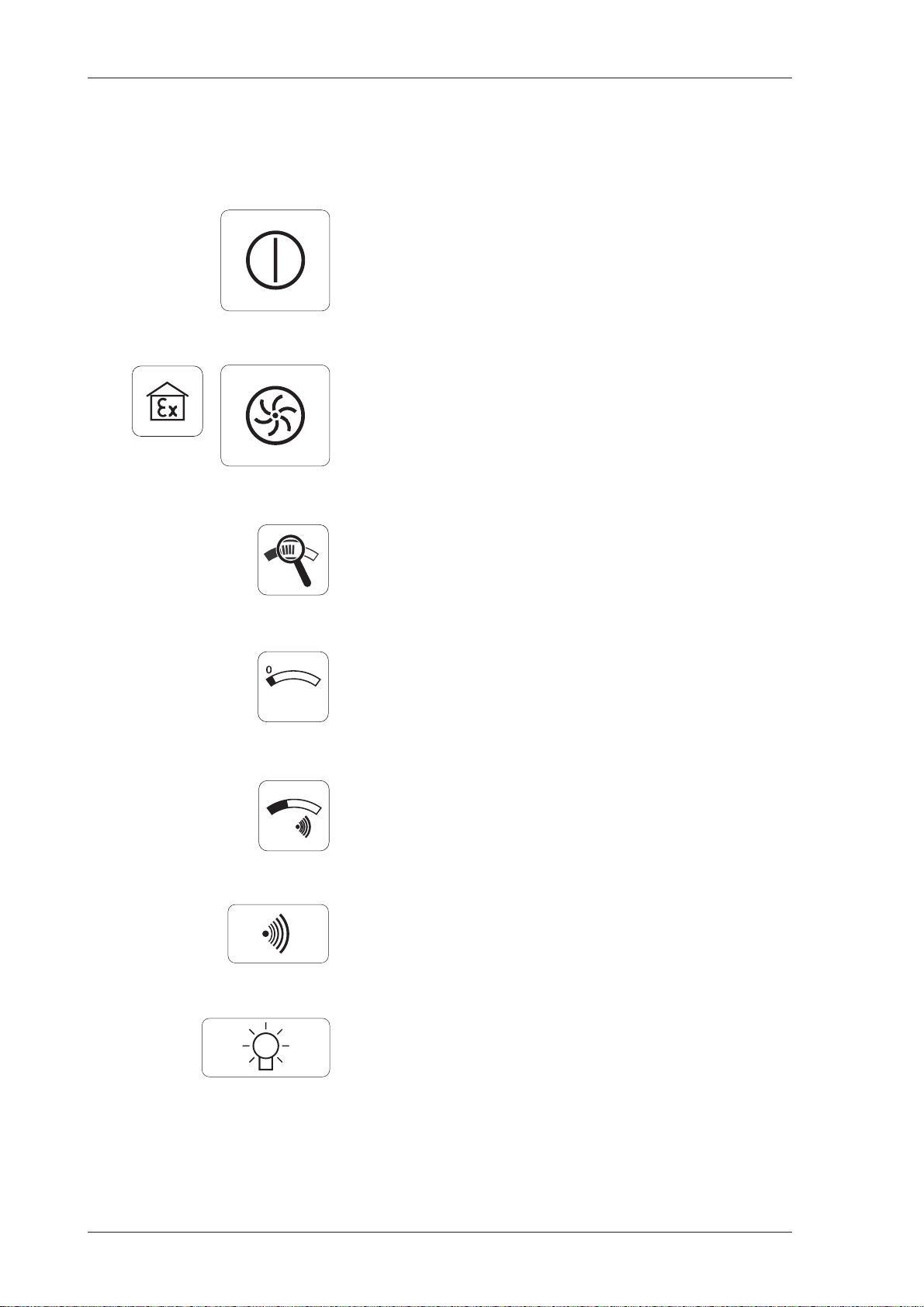

Brief operating instructions

Brief operating instructions:EX-TEC SR 6, VARIOTEC 9-EX

switches the detector on and off

toggles between GAS-WARNING / GASMEASURING modes

toggles between total and optimum

measuring ranges

zero-point correction

displays the alarm threshold value

acoustic clearance of the alarm signal

switches LC display illumination on and off

(... switches off automatically after about 4

minutes)

2

Page 5

Operating manual

EX-TEC® SR 6,

VARIOTEC® 9-EX

103992 - 04.12.2002

3

Page 6

For your safety

This product may only be used after the operating instructions have been

read and understood and only by appropriately trained operators.

This product may only be used for its designated purpose, and only in

industry and trade.

Repair work may only be carried out by appropriately trained persons.

Changes and modifications to the product may only be carried out with

the consent of Hermann Sewerin GmbH. Unauthorised modifications to

the product render the warranty null and void.

Only accessories from Hermann Sewerin GmbH may be used with this

product.

Only spare parts approved by us may be used for repairs.

Hermann Sewerin GmbH bears no liability for damage attributable to non-

compliance with these instructions. The terms of warranty and liability of

the conditions of sale and delivery of Hermann Sewerin GmbH are not

extended by the above.

We reserve the right to make technical modifications in the interests of

further development.

Please comply with general safety rules in addition to these instructions!

Symbols used:

CAUTION!

This symbol warns of dangers to the user or product.

Note:

This symbol indicates information and tips that go beyond

actual operation for the product.

4

Page 7

Contents page

1 EX-TEC SR 6, VARIOTEC 9-EX system

1.1 Models.......................................................................................... 7

1.2 Test certificates ............................................................................ 8

1.3 Charging equipment ..................................................................... 9

1. 4 Carrying equipment .................................................................... 10

1.5 Probe systems .............................................................................11

1.6 Test equipment........................................................................... 13

2 Safety

2. 1 Safety instructions ....................................................................... 14

3 Measuring operation

3. 1 Model overview ........................................................................... 15

3. 2 Switching on ............................................................................... 16

3.3 Illumination and contrast ............................................................. 17

3.3.1 Operating hours in measuring operation .................................... 18

3.4 Pump operation .......................................................................... 19

3. 5 Alarm signal and volume ............................................................ 20

3.5.1 Automatic alarm reactivation....................................................... 20

3. 6 Alarm threshold value ................................................................. 21

3. 7 Switching measuring ranges ...................................................... 22

3. 8 Location / gas injection / blanketing............................................ 23

3.9 Delayed-action indicator ............................................................. 24

3.10 Zero-point correction .................................................................. 25

3. 11 Gas-warning mode ..................................................................... 25

3.12 Battery alarm............................................................................... 27

3.13 Switching off............................................................................... 27

4 Charging operation

4. 1 Charging and charge maintenance............................................. 28

4.2 Spontaneous discharge ............................................................. 29

5

Page 8

Contents page

5 Testing and maintenance

5. 1 Function testing, testing display accuracy.................................. 30

5.2 Test equipment........................................................................... 33

5.3 Test gases.................................................................................. 35

5. 4 Function testing .......................................................................... 36

6 Settings menu

6. 1 Setting the ppm sensor .............................................................. 38

6. 2 Setting the LEL sensor............................................................... 40

6. 3 Setting the VOL sensor.............................................................. 41

6. 4 Setting the measurement unit (%LEL range language).............. 43

6. 5 Setting 10 ppm sensitivity .......................................................... 45

6. 6 Activating the ETHANE box........................................................ 46

6.7 Interface mode ........................................................................... 46

6. 8 Checking the LC display ............................................................. 47

6. 9 Leaving the settings menu ......................................................... 47

7 Technical aspects

7.1 Technical notes ........................................................................... 48

7. 2 Technical data............................................................................. 49

7.3 Error messages.......................................................................... 52

7.4 Wearing parts ............................................................................. 54

Appendix

EC-type-examination certificates ......................................................... 55

Declarations of conformity................................................................... 60

Test report ............................................................................................ 62

6

Page 9

1 EX-TEC SR 6, VARIOTEC 9-EX system

1 EX-TEC SR 6, VARIOTEC 9-EX system

1.1 Models

EX-TEC SR 6 (explosion-proof)

Gas detection

above-ground gas detection for

pipeline monitoring (ppm range)

Interior installations

leak detection for pipelines in

buildings (ppm range)

Gas warning

monitoring proximity to the lower

explosion limit (%LEL range)

Location

concentration measurement in

probe holes (vol.% range)

Gas injection and blanketing

concentration measurement in

pipelines (vol.% range)

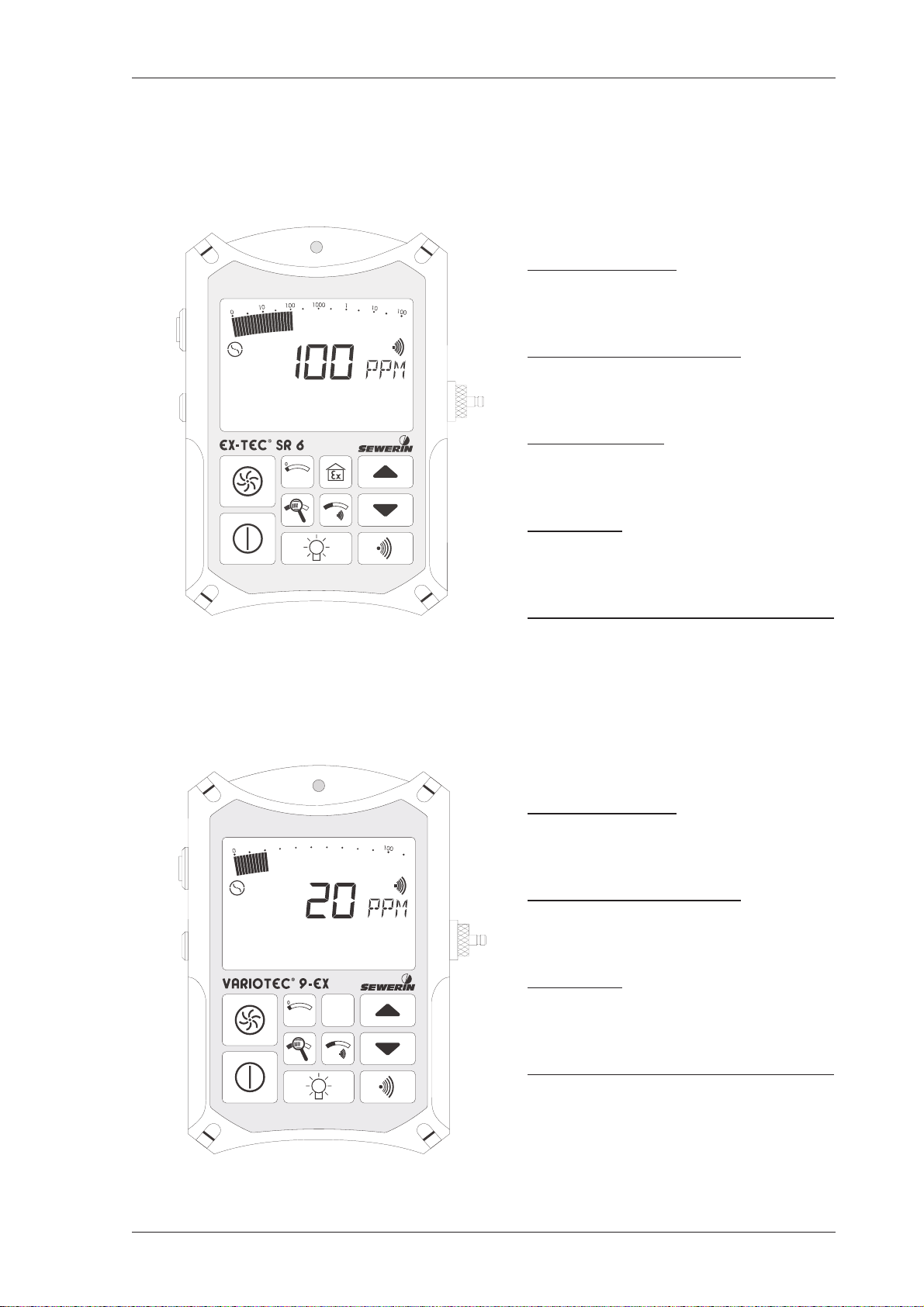

VARIOTEC 9-EX (explosion-proof)

Gas detection

above-ground gas detection for

pipeline monitoring (ppm range)

Interior installations

leak detection for pipelines in

buildings (ppm range)

Location

concentration measurement in

probe holes (vol.% range)

Gas injection and blanketing

concentration measurement in

pipelines (vol.% range)

7

Page 10

1 EX-TEC SR 6, VARIOTEC 9-EX system

1.2 Test certificates

Passive explosion protection

The EX-TEC SR 6 and VARIOTEC 9-EX models are explosion-proof

in accordance with European norms (CENELEC):

EC prototype test certificate: PTB 96 ATEX 2166

Identification mark: II 2 G EEx ib d IIB T3

Testing institution: Physikalische-Technische

Bundesanstalt, Brunswick

Active explosion protection

The EX-TEC SR 6 has also been tested for functional safety in the gas-

warning field:

Test report: PFG no. 41300897

Testing institution: DMT - Gesellschaft for Forschung

und Prüfung mbH, Essen

The test certificates can be found on and after page 55.

8

Page 11

1 EX-TEC SR 6, VARIOTEC 9-EX system

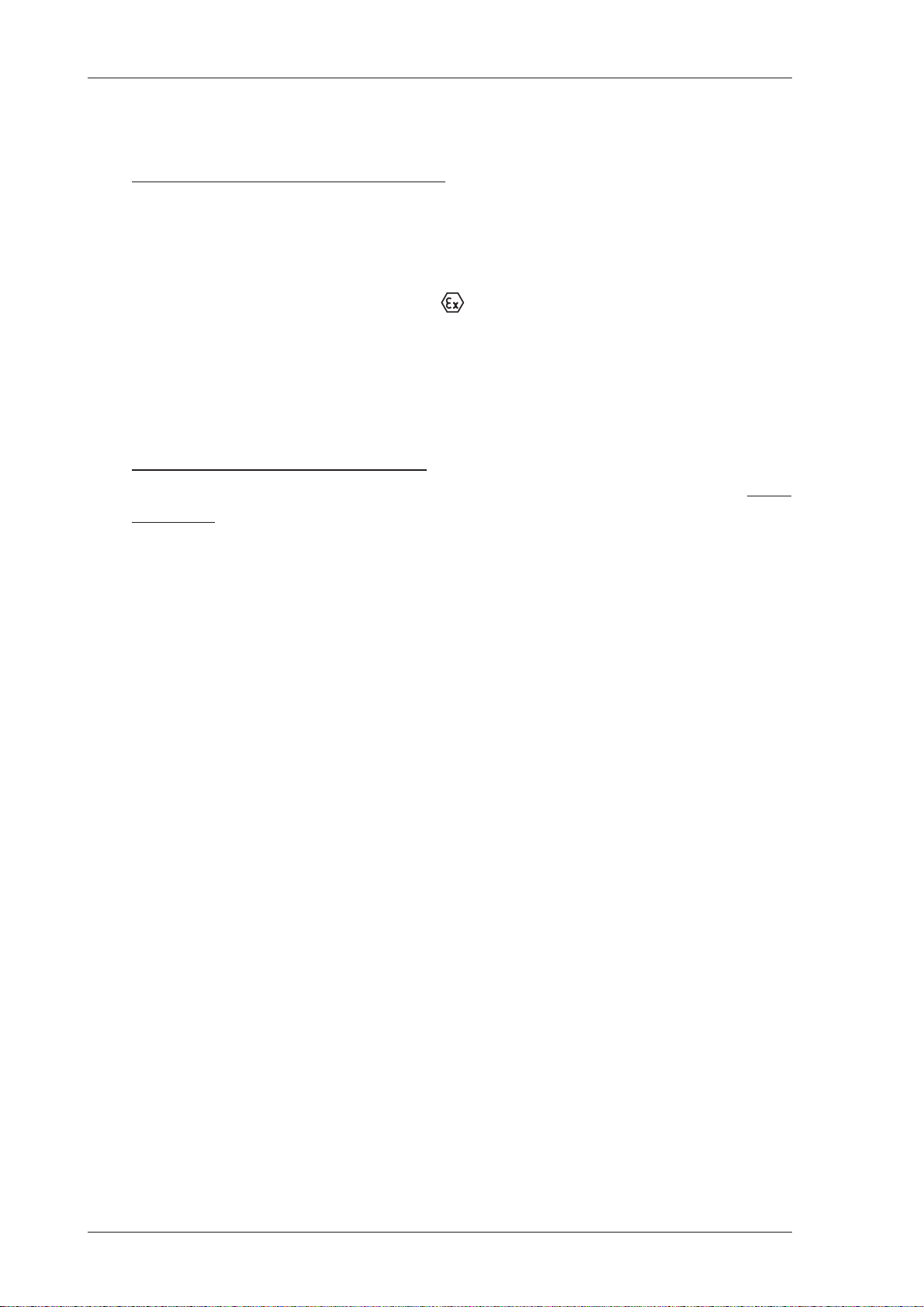

1.3 Charging equipment

The EX-TEC SR 6 and the VARIOTEC 9-EX can be charged either in

the workshop or in the standby vehicle:

HS charging adapter

to hold the detector, with a

connection socket for the plug-in

power pack or a vehicle adapter

(not shown)

230V plug-in power pack

to connect the HS HS charging

adapter to a 230-volt mains supply

12V vehicle adapter

to connect the HS charging adapter

to a 12-volt vehicle battery

24V vehicle adapter

to connect the HS charging adapter

to a 24-volt vehicle battery

9

Page 12

1 EX-TEC SR 6, VARIOTEC 9-EX system

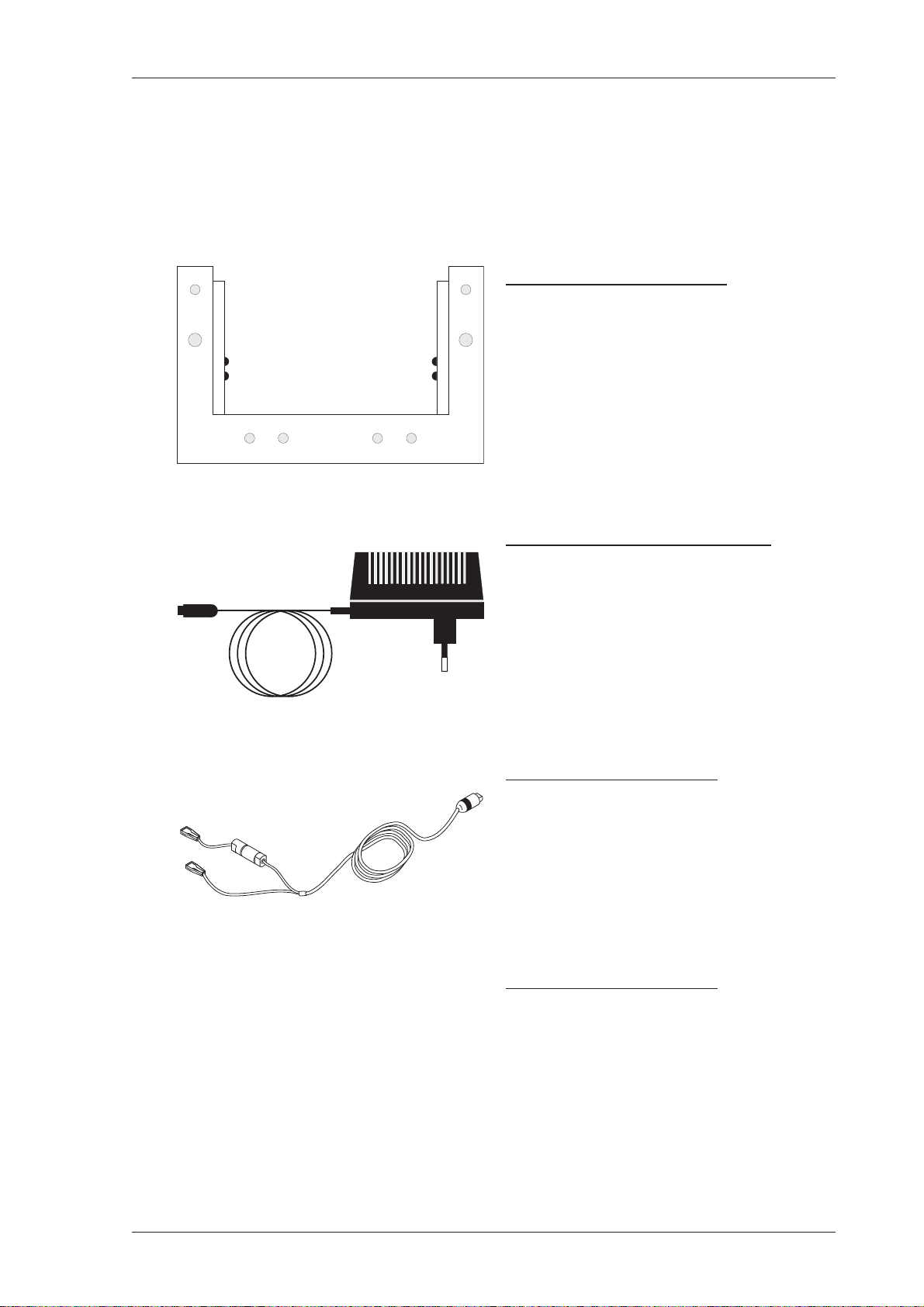

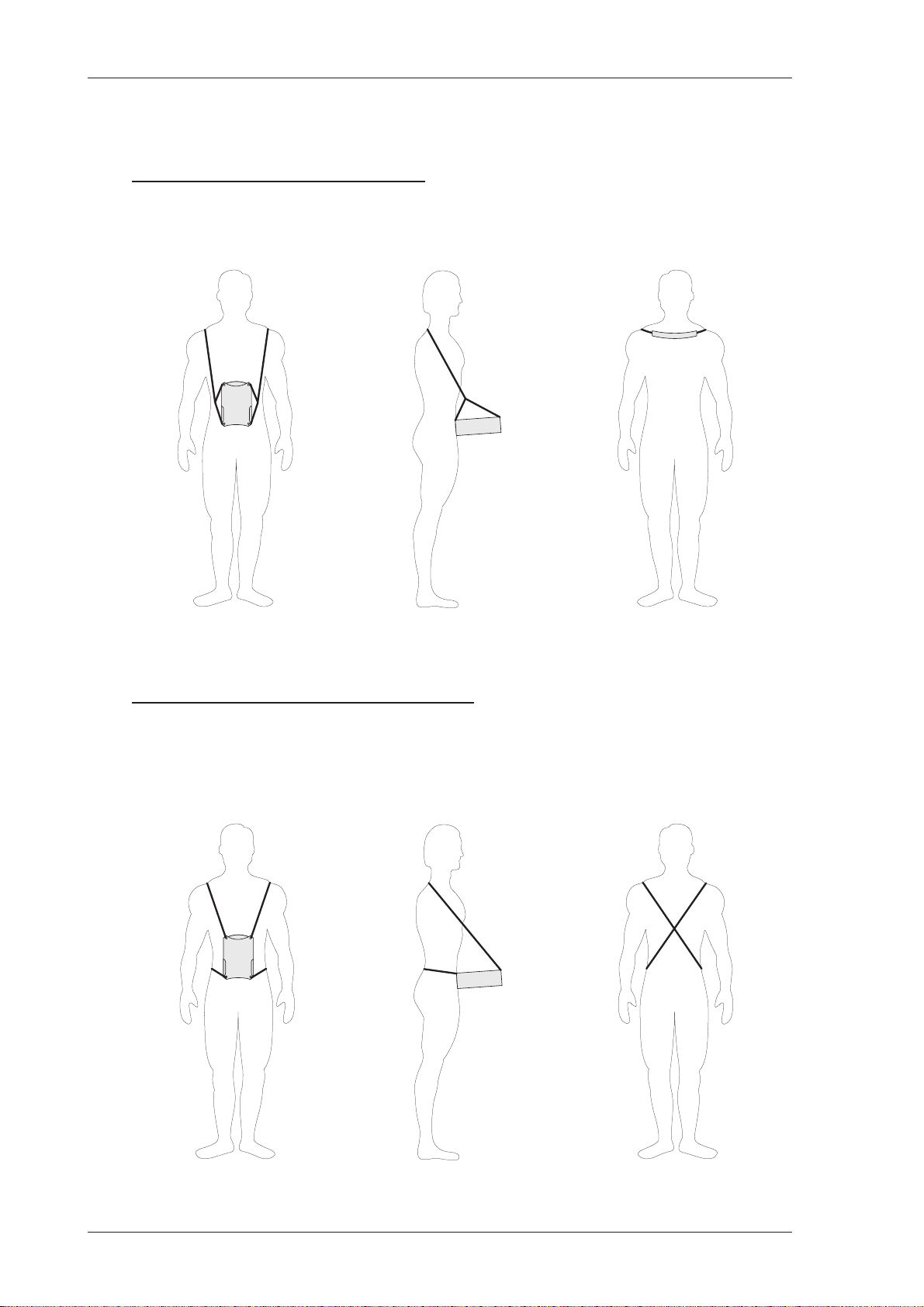

1.4 Carrying equipment

TRIANGEL carrying system

a quick and easy way of carrying the detector , consisting of a carrying

strap and neck-pad

front view side view rear view

CROSS-STRAP carrying system

a comfortable way to carry the detector for longer periods, consisting

of 2 carrying straps crossed at the back

10

front view side view rear view

Page 13

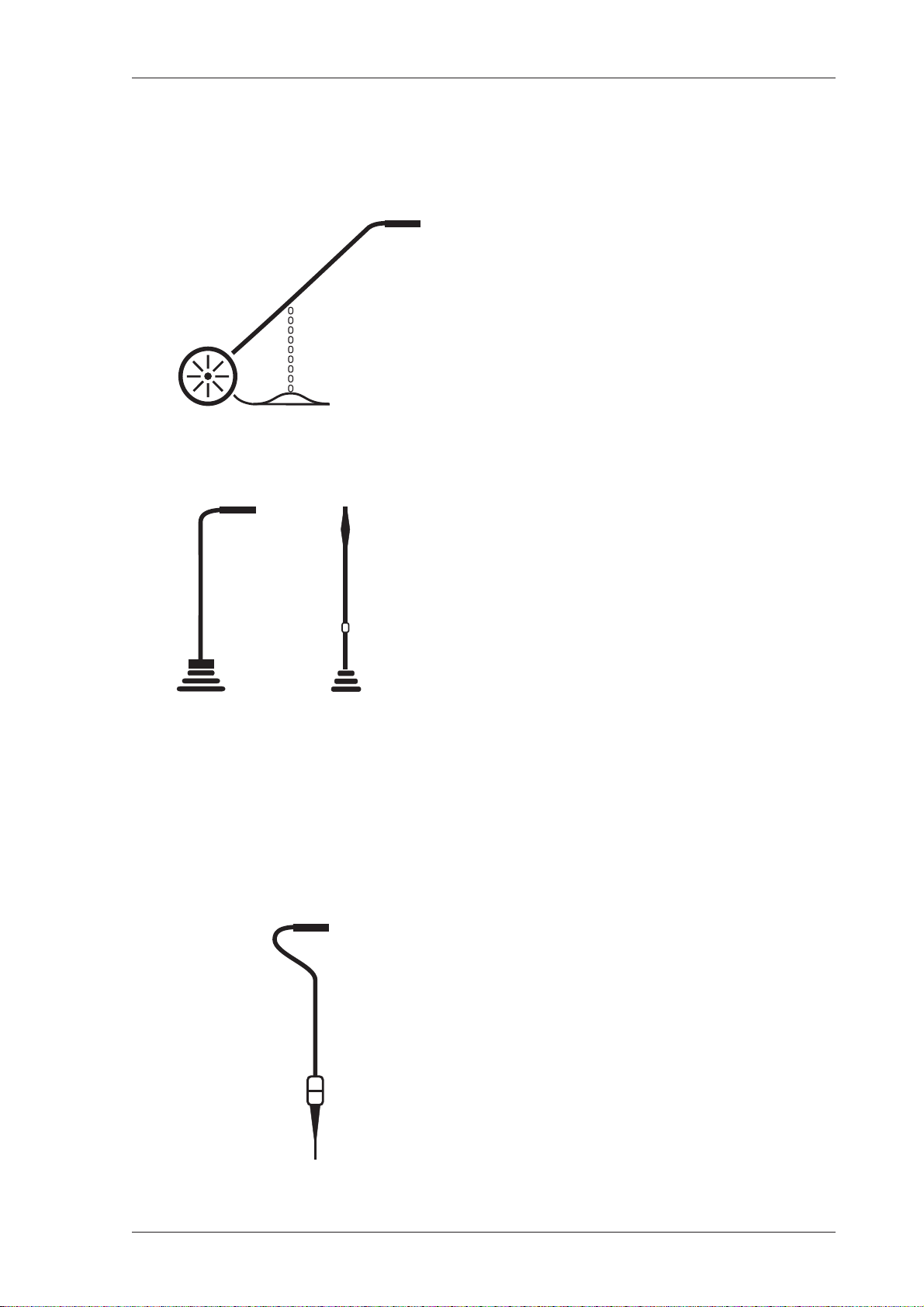

1.5 Probe systems

- Pipe-monitoring probes -

1 EX-TEC SR 6, VARIOTEC 9-EX system

Carpet probe

for checking stable surfaces.

The sample is drawn into an

excrescence in a neoprene mat in

contact with the surface with no

extraneous emissions

- Location probes-

Bell probe,

telescopic bell probe

for checking unstable and

overgrown surfaces.

It can be used in confined spaces,

e.g. between parked cars or in front

gardens

Location probe

for measuring concentrations in

probe holes,

with a rigid rubber cone to seal off

the probe hole and

2 different probe tips (length 245

mm or 345 mm)

11

Page 14

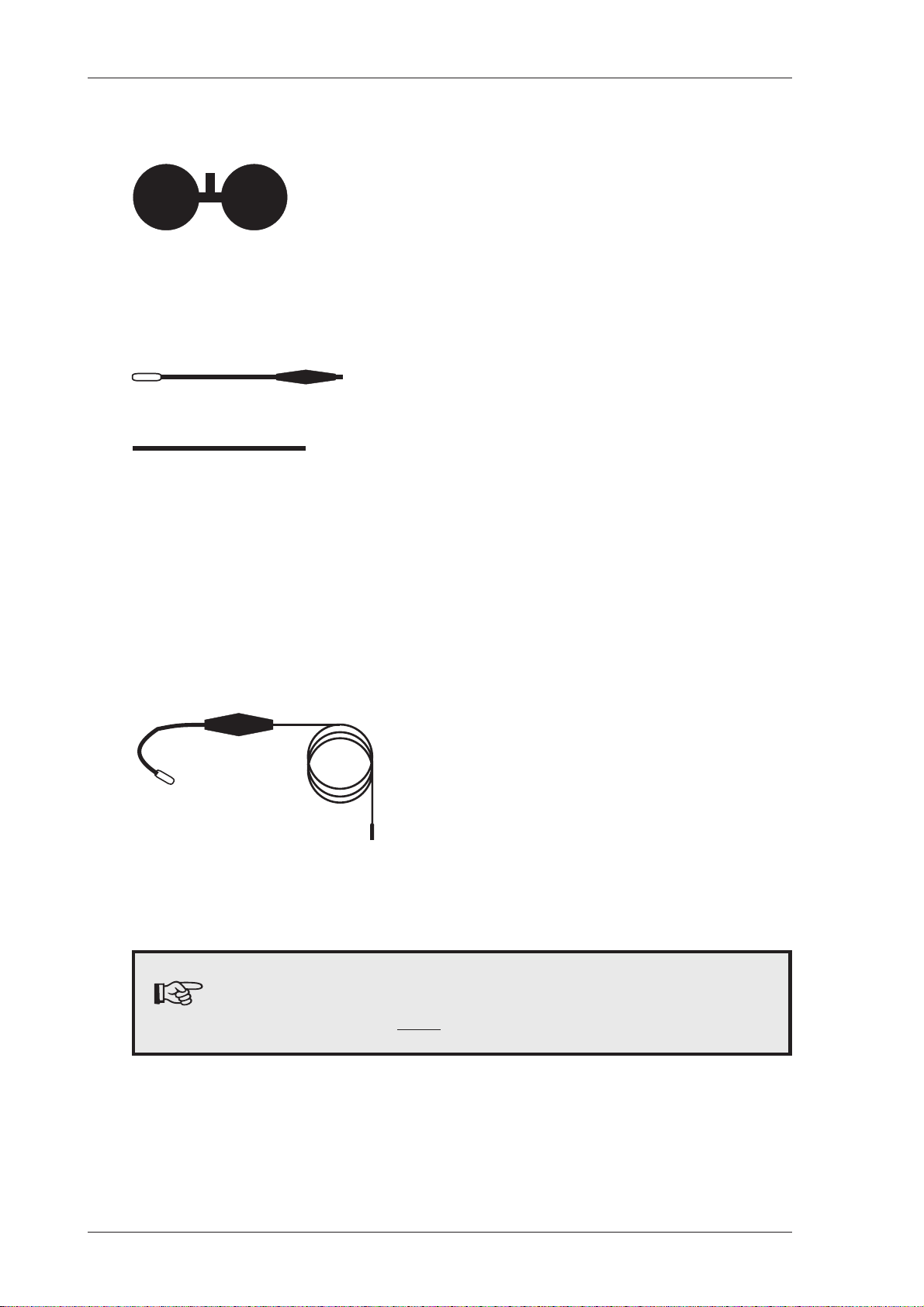

1 EX-TEC SR 6, VARIOTEC 9-EX system

- Probes for use in enclosed spaces -

Floater probe

for measuring concentrations in

shafts,

floater with intake orifice and hose

connection

Divisible manual probe

for use with unenclosed pipes or

at inaccessible locations,

measuring concentrations in

containers, overall length 900 mm

- Probes for interior installations -

Flexible manual probes

for use with interior pipework,

grip with flexible swan-neck and

probe hose, overall lengths 360 mm

or 660 mm

Except with the carpet probe, a probe hose should

always be used

with a hydrophobic filter.

12

Page 15

1 EX-TEC SR 6, VARIOTEC 9-EX system

1.6 Test equipment

The following equipment is available for monitoring and testing the

pump power and sensitivity of the EX-TEC SR 6 and VARIOTEC 9-EX:

SPE1 and SPE3 testers

for mobile use including in-vehicle

use,

with connections for SEWERIN

test-gas bottles, flow meter,

release button and connection

hose

Test-gas bottles

for testing and adjusting display

sensitivity,

various test-gas concentrations in

1-litre bottles at pressures of about

12 bar

SPE2 tester

for non-mobile use in the

workshop, with connections for

several SEWERIN pressure

cylinders, pressure and flow meter ,

release button and connection

hoses

(not shown)

Pressure cylinders

for testing and adjusting display

sensitivity, various test-gas

concentrations in 0.4 / 2.0 / 10.0

litre steel cylinders at pressures of

100-150 bar

13

Page 16

2 Safety

2 Safety

2.1 Safety instructions

Always use original SEWERIN accessories with the

EX-TEC SR 6 and VARIOTEC 9-EX

Always use a probe hose with a hydrophobic filter

Observe the permissible operating temperature

range of minus 10 °C to plus 40 °C

The EX-TEC SR 6 and VARIOTEC 9-EX must not be

recharged in areas exposed to the danger of

explosion

Test gases may only be used in well-ventilated

spaces

14

The EX-TEC SR 6 and VARIOTEC 9-EX satisfy the

limits of the EMV regulation. When using it near

(mobile) radio equipment please also follow the

instructions in the manuals for that equipment

Page 17

3 Measuring operation

3.1 Model overview

Fold out the illustration inside the front cover

Item description function

1 alarm lamp optical warning on:

breaching alarm thresholds

display of error messages

2 LC display display of:

gas concentrations

menu items

operating conditions

error messages

3 Measuring operation

3 probe connection connection for:

probe hose

tester

4 keypad detector operation

5 attachment for carrying systems:

Triangel

cross-strap

6 outlet for the gas sample

7 buzzer acoustic warning on:

reaching alarm thresholds

display of error messageses

15

Page 18

3 Measuring operation

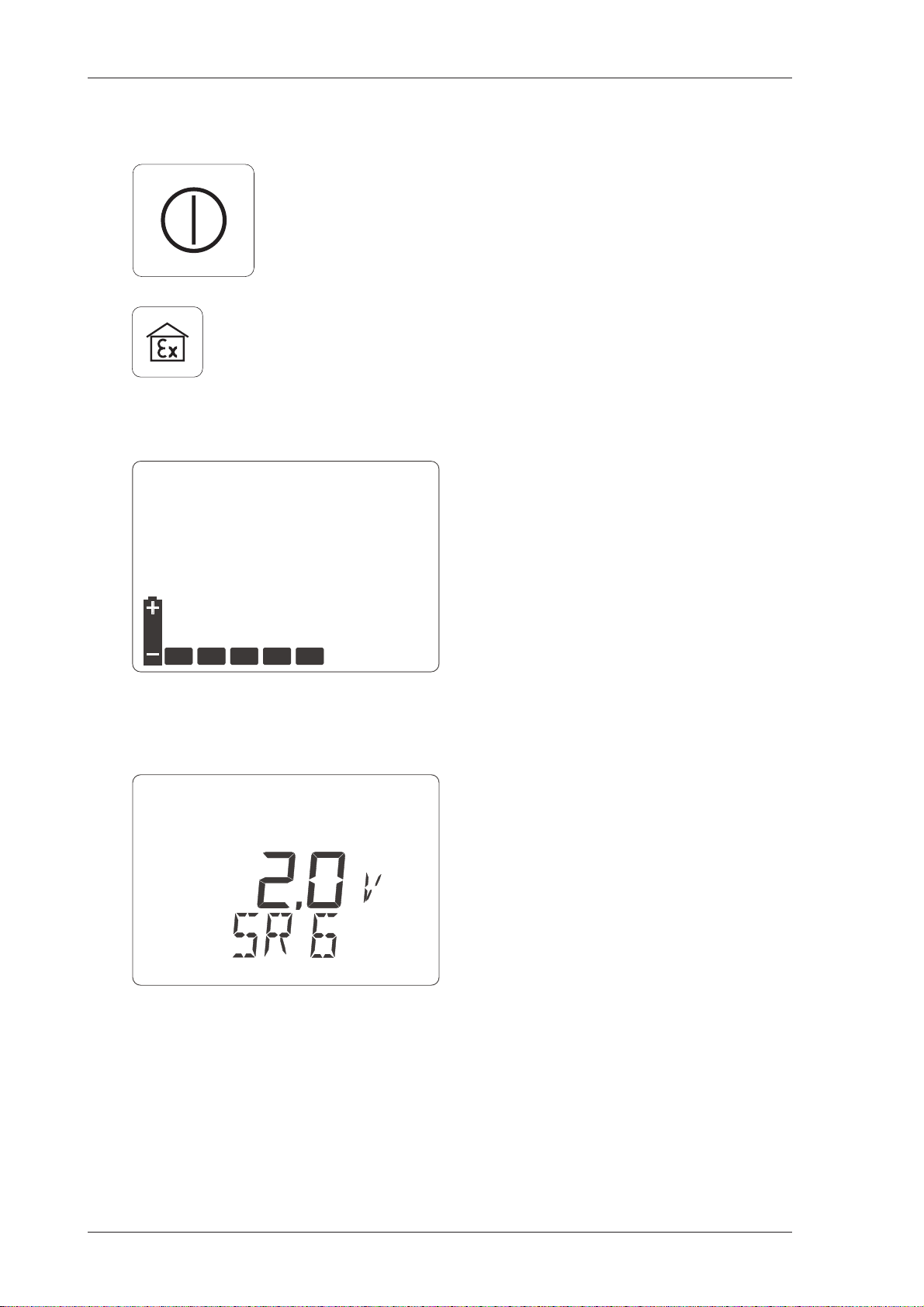

3.2 Switching on

hold the on/off button down for

about 2 seconds

or, on the SR 6 only, hold the gas-

warning button down for about

2 seconds to start the detector in

gas-warning mode (see p. 25 ff.)

the optical and acoustic control

signals (items 1 and 7) operate

for about 2 seconds

available operating hours are

displayed in the form of bars (e.g.

5 hours)

the integral pump runs at full power

the software version number

(e.g. 2.0) and detector type

(SR 6) are displayed

16

Page 19

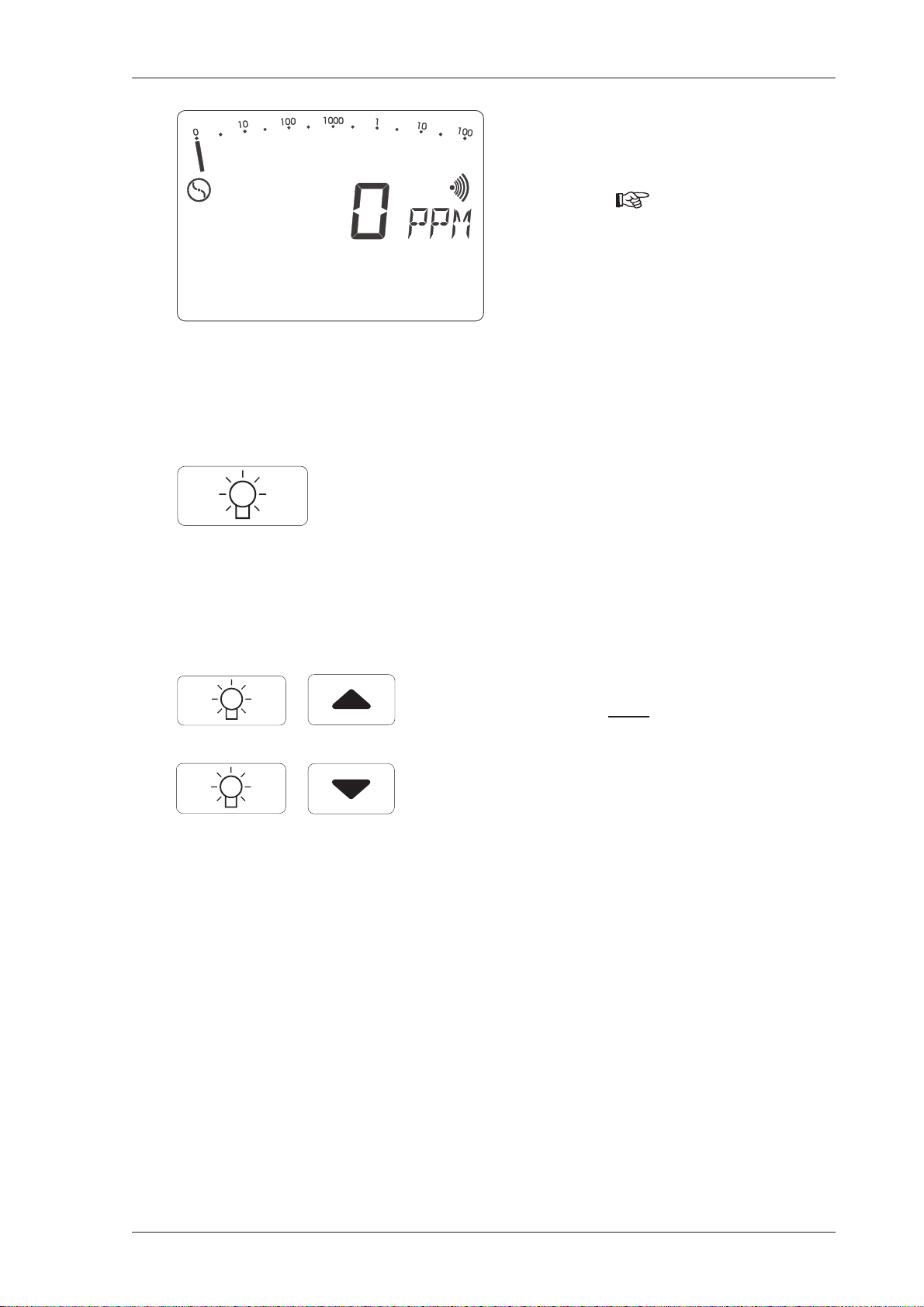

3.3 Illumination and contrast

3 Measuring operation

wait for the zero point to establish

itself in fresh air (approx. 1 minute):

display: 0 PPM

(after flashing stops)

pressing the light button

switches the LC DISPLAY

illumination on and off

the illumination automatically

switches off approx. 4 minutes

after being switched on

simultaneously pressing the light

button

and a cursor button

increases or reduces the contrast

of the LC display

17

Page 20

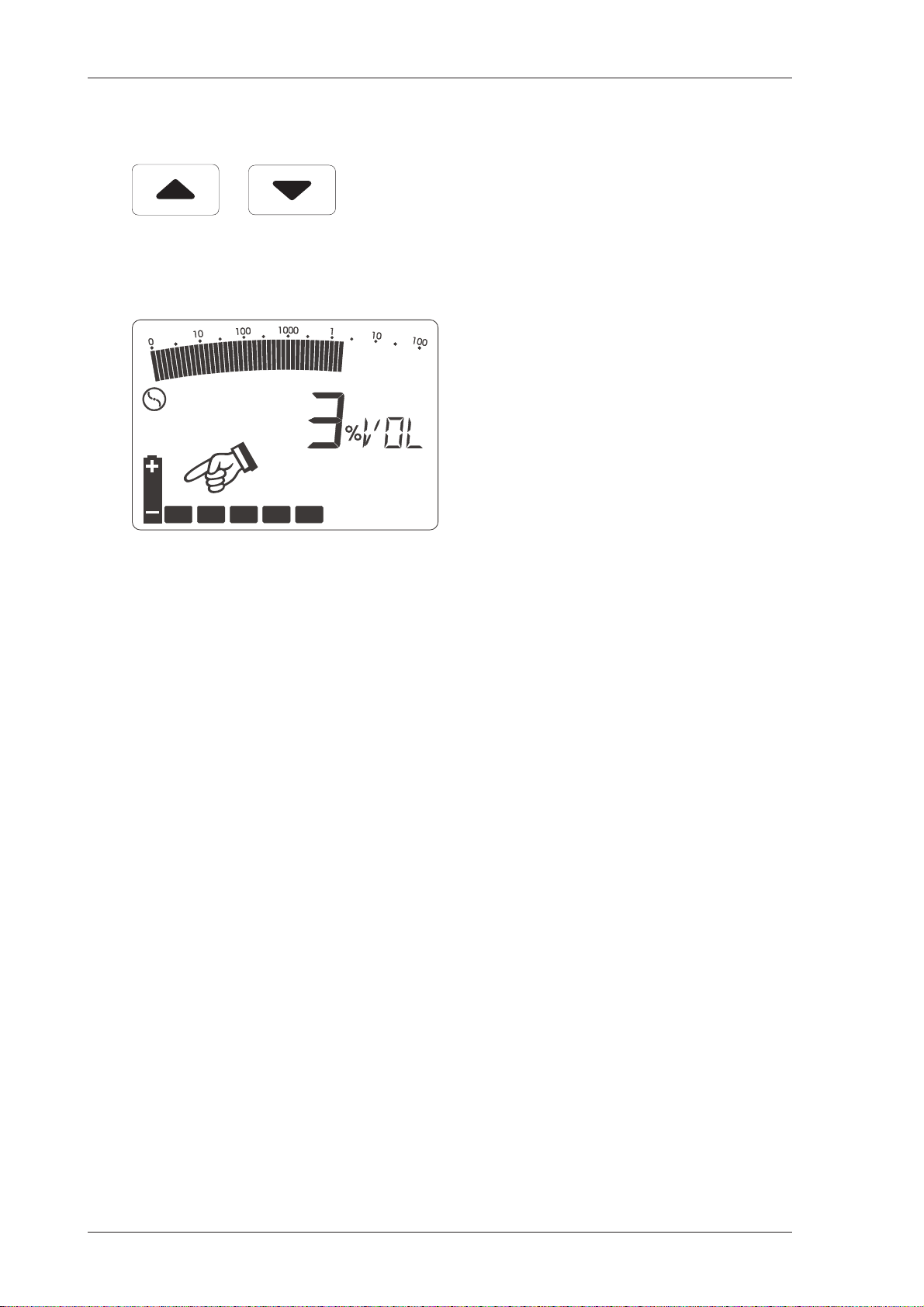

3 Measuring operation

3.3.1

Operating hours in measuring operation

simultaneously pressing both

this display (battery symbol and

cursor buttons in measuring

operation displays the operating

hours still available (e.g. 5 hours)

bars) disappears automatically

after about 10 seconds

18

Page 21

3.4 Pump operation

3 Measuring operation

pressing the pump button

switches the pump on and off

this turns the corresponding

symbol on or off in the LC display

(item 2)

this enables you to monitor the

pump function

Changing the pump power

simultaneously pressing the

pump button

increases or reduces the pump

power

always use maximum pump

power for above-ground gas

detection in pipelines

and a cursor button

Gas detection

Interior installations

always use minimum pump

power for leak detection in

pipelines in buildings

19

Page 22

3 Measuring operation

3.5 Alarm signal and volume

pressing the signal button

switches the alarm signal on and

off

this turns the corresponding

symbol on or off in the LC display

(item 2)

this enables you to check the

alarm signal

3.5.1Automatic alarm reactivation

simultaneously pressing the

signal button and a cursor button

increases or reduces the volume

of the buzzer (item 7)

if you turn off an alarm with the

signal button, the alarm signal is

automatically reactivated after

about 60 seconds

the corresponding symbol then

reappears in the LC display (item

2)

20

this avoids the problem of the

operator forgetting to reactivate

the alarm signal

Page 23

3.6 Alarm threshold value

3 Measuring operation

hold down the threshold value

button

and the alarm threshold value

flashes on the scale (here 10 PPM)

holding down the the detector's

value button while pressing a

cursor button increases or

reduces the alarm threshold value

this value is preserved even when

the detector is switched off

21

Page 24

3 Measuring operation

3.7 Switching measuring ranges

the detectors have both an

analogue scale (above - here

showing the full measurement

range) and a digital display

(below); both displays show the

same concentration (here 70 PPM)

the scale is logarithmic, ranging

from:

0 PPM ... 100 %VOL

the scale can display low

concentrations in magnified form;

the reading is also shown in the

digital display

pressing the zoom button

toggles between the full and the

optimum measuring ranges

depending on the concentration,

switching between the following

measuring ranges is automatic:

0 ... 10 ppm

0 ... 100 ppm

0 ... 1000 ppm

0 ... 1 %VOL

0 ... 100 %VOL

in this example the optimum

measuring range is 0 ... 100 ppm

22

you can switch manually to your

preferred display range by

holding down the zoom button

and pressing a cursor button

Page 25

3 Measuring operation

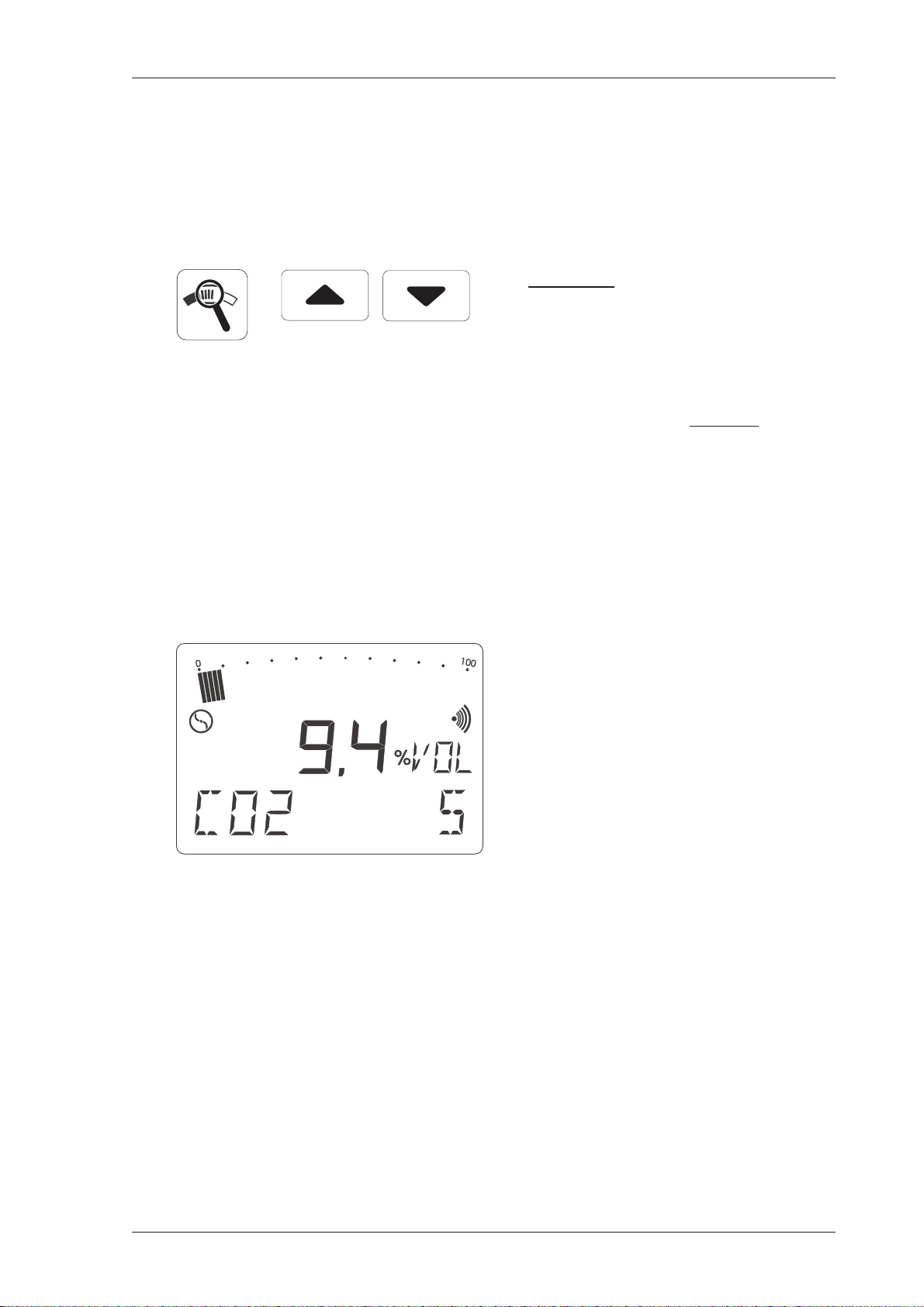

3.8 Location / gas injection / blanketing

To carry out a location, gas injection (concentration increase to

100 vol.%) or blanketing (concentration reduction to 0 vol.%), proceed as

follows:

manually select the measuring

range 0.0 ... 100 %VOL with the

zoom button and the cursor

buttons

this is the only measuring range

in which you can

reliably monitor

location, gas injection and

blanketing

manually switching to the

measuring range 0.0 ... 100 %VOL

is the only way to make sure that

the CO

component is also shown

2

in the display

in this example the readings are:

9.4 %VOL CH

and 5 %VOL CO

4

2

23

Page 26

3 Measuring operation

3.9 Delayed-action indicator

To make it easier to compare concentrations - for location purposes,

for example - the maximum value is displayed in the form of a flashing

delayed-action indicator.

this remains in the LC display

(item 2) for about 4 minutes, or if

the concentration rises it is

updated

the delayed-action indicator

disappears when the zoom button

is pressed

24

Page 27

3.10Zero-point correction

3 Measuring operation

if the detector fails to reach its

zero point even after being

thoroughly flushed with fresh air ,

you can manually correct the zero

point by pressing the zero point

button

the reading display flashes while

the correction is under way

measurement may not continue

until after the flashing stops

3.11 Gas-warning mode

This function is only available on the EX-TEC SR 6

this function is switched on by

pressing the gas-warning

button

this button can also be used to

switch the detector on direct

25

Page 28

3 Measuring operation

this measuring range is used to

monitor proximity to the LEL

(lower explosion limit)

a stable zero point is reached

after about 8 seconds' warm-up

time

the pump runs at minimum power,

and the acoustic operating signal

(item 7) sounds every 5 seconds

when the pre-set threshold of

10% LEL = 0.45 vol.% (CH4) is

reached, the advance alarm is

triggered both optically (item 1)

and acoustically (item 7)

the advance alarm is an

intermittent tone quite distinct

from the operating signal;

it ceases after a certain period

and cannot be cleared

if the concentration exceeds

100 % LEL of methane (100

% LEL = 4.40 vol.%) the main

alarm is triggered both optically

(item 1) and acoustically (item 7)

26

Page 29

3.12Battery alarm

3 Measuring operation

the main alarm is a continuous

tone quite distinct from the

operating signal;

it continues indefinitely and

cannot be cleared

Leaving gas-warning mode:

hold down the pump button for

about 2 seconds or switch the

detector off

3.13 Switching off

if the battery symbol appears in

the LC display, at least 15 minutes'

operating time remains;

after that the detector must be

recharged

in gas-warning mode the battery

alarm sounds as a double beep

to distinguish it from the operating

signal

Press the on/off button for about

2 seconds

the optical and acoustic

monitoring signals (items 1 and

7) operate for about 2 seconds

remaining operating hours are

displayed in the form of bars

27

Page 30

4 Charging operation

4 Charging operation

4.1 Charging and charge maintenance

Charging

When fully charged the detector has a

maximum of 8 hours' operating

time with the pump running.

To charge the detector you will need the HS charging adapter (see

illustration), which can be used either in the workshop or the emergency

vehicle.

The following connection sockets

can be found on the side of the

charging adapter:

230-V plug-in power pack

12-V vehicle adapter

24-V vehicle adapter.

Switch off the EX-TEC SR 6 or VARIOTEC 9-EX and place it in the

charger. A display on the following lines appears:

the detector still has 5 operating

hours left (= 5 bars) and will take

another 3 hours to be fully

recharged

if it is fully charged, all the bars

appear and the numerical display

is blank

Charge maintenance

As soon as the detector is fully charged it automatically switches to

charge maintenance. It can be left in the charging adapter until the next

time it is needed.

28

Page 31

4 Charging operation

4.2 Spontaneous discharge

If the detector is not placed in the charger when it is switched off, the

nickel-cadmium battery spontaneously discharges, thus reducing the

available operating hours.

After a maximum of 30 days the indicator shows that there are no

operating hours left, and it must be recharged.

Short periods of operation and prolonged disuse

may lead in the long term to the so-called "memory

effect", in which the display indicates a higher battery

capacity than is actually available.

This can be avoided by fully discharging the EX-TEC

SR 6 or V ARIOTEC 9-EX regularly (e.g. once a month),

i.e. leaving it switched on until it automatically switches

off, then recharging it.

29

Page 32

5 Testing and maintenance

5 Testing and maintenance

Gas-warning instruments must always be tested by

the operator before the gas-warning facility is used

and before every working shift. Topics covered by

this test include:

checking the battery charge

display with neutral gas and test gas

(leaflet T 023/BG chemicals: "Gas-warning instruments

for explosion protection - operation and maintenance")

DIN EN 50073 provides that portable gas-warning

instruments (such as the EX-TEC SR 6) must be

tested immediately before use in accordance with

the operating manual. This must include testing the

zero point and display sensitivity with a fieldcalibration device and test gas.

5.1 Function testing, testing display accuracy

The test must also cover ancillary equipment. The tests listed above

and other activities must be documented, and the documentation

preserved for at least 1 year. The required and prescribed instrument

tests in accordance with DVGW G 465-4 (Technical reports, note) are

divided into the following sections:

30

Page 33

5 Testing and maintenance

What? Who? When?

function test user before the utility company

commences work

display-accuracy expert or daily to half-yearly

test (adjustment) specialist firm

upkeep SEWERIN, annually or whenever a

(maintenance, utility-company defect occurs

repair if necessary) expert

Function test

This is the simplest form of instrument test. Carried out by the user

before use, it comprises the following points:

external condition including probe systems

function of the operating controls

battery-charge check

pump and intake-channel inspection

pump function

mechanical/electrical zero point

display-sensitivity test by gas admission

Function control and sensitivity test ("10 ppm test")

In addition, DVGW worksheet G 465-1 provides that gas-detection

instruments used for systematic pipeline inspection must undergo a

sensitivity test with 10 ppm conditioned (i.e. humidified) test gas.

Using the SPE 3 tester ensures that the test gas is conditioned.

Depending on the circumstances, this test may have to be carried out

(and documented) several times per working day.

31

Page 34

5 Testing and maintenance

Checking display sensitivity (adjustment)

The testing frequency must be specified as a function of the sensors

fitted and the use of the detector . It can be anywhere between daily and

half-yearly.

Testing must be carried out by an expert on the operator's own staff,

by a specialist firm or by Sewerin itself.

The test gas described in section 5.3 must be used. The explosionprotection rules (BGR 104 EX-RL) must be complied with, as must the

principles for testing the functionability of non-fixed gas-warning

instruments for explosion protection (ZH 1/108.1) and the guidelines

for the selection, installation, use and maintenance of instruments for

the detection and measurement of combustible gases or oxygen (DIN

EN 50073/VDE 0400, part 6).

The function test should be carried out at the same time.

Upkeep - maintenance and repair

The detector must be maintained at least once a year by SEWERIN

Service, a specialist firm authorised by SEWERIN or an authorised

specialist of the gas-supply company.

Certificates must be issued accordingly.

The test disc on the detector

confirms when maintenance was

last carried out and indicates the

next scheduled date (e.g. 5/02 =

May 2002).

Annual maintenance and repair must cover at least the specialist care

and adjustment of the detector and the replacement of components

with a limited useful life.

32

Where detectors are explosion-proof the applicable

regulations must be observed

Maintenance specialists must have been trained and

instructed by Sewerin

Page 35

5 Testing and maintenance

5.2 Test equipment

The pump power, zero point and sensitivity should be tested with the

SPE 1 or SPE 3 testers and a suitable test gas:

Fig. 1

The SPE 1 is used to test:

pump power

the zero point in the %LEL and %VOL ranges

sensitivity in the %LEL and %VOL ranges.

It is used with the following test gases:

methane CH

: 1.00 vol.%

4

2.20 vol.% (50% LEL)

100 vol.%

carbon dioxide CO2: 100 vol.%

33

Page 36

5 Testing and maintenance

Fig. 2

The SPE 3 tester is used to test:

pump power

the zero point in the PPM range

sensitivity in the PPM range.

It is used with the following test gases:

methane CH4: 10 ppm

100 ppm

1000 ppm

34

Page 37

5 Testing and maintenance

5.3 Test gases

The following test gases are used to function-test the detectors:

CH

EX-TEC SR 6 ppm range 10 ppm

(gas detection, 100 ppm

interior 1000 ppm

installations) 1.00 vol.%

%LEL range 2.20 vol.%

(gas warning) (50% LEL)

vol.% range 100 vol.% 100 vol.%

(location,

gas injection,

blanketing)

VARIOTEC 9-EX ppm range 10 ppm

(gas detection, 100 ppm

interior 1000 ppm

installations) 1.00 vol.%

4

CO

2

vol.% range 100 vol.% 100 vol.%

(location,

gas injection,

blanketing)

35

Page 38

5 Testing and maintenance

5.4 Function testing

Proceed as follows:

screw the selected test-gas bottle onto the tester as far as it will

go (fig. 1/2 - item 2)

connect the probe nipple of the detector (item 3) to the tester

hose (fig. 1/2 - item 1)

switch the detector on: the pump draws in fresh air through the

tester (fig. 1/2 - item 4)

maximise the flow rate with the needle valve (fig. 1/2 - item 5) -

it must be greater than 50 l/h (fig. 1/2 - item 6)

wait for the detector to warm up and reach a stable zero point

press the tester's release button (fig. 1/2 - item 3) and correct

the flow rate to the value with fresh air (fig. 1/2 - item 6)

hold it down until the displayed concentration has reached a

stable value

Admissible display values with methane CH4 test gas:

test gas 10 ppm : > 10 ppm

test gas 100 ppm : 70 ... 140 ppm

test gas 1000 ppm : 800 ... 1.200 ppm

test gas 1.00 vol.% : 0.80 ... 1.20 vol.%,

test gas 2.20 vol.% : 2.00 ... 2.40 vol.% (45 ... 55% LEL)

test gas 100 vol.% : 98 ... 102 vol.%

Admissible display values with carbon dioxide CO2 test gas :

test gas 100 vol.% : 98 ... 102 vol.%

If display values are outside these tolerances the detector must be

readjusted (cf. section 6.0: Settings menu).

36

Page 39

6 Settings menu

6 Settings menu

The EX-TEC SR 6 and VARIOTEC 9-EX detectors are factory-set for

all measuring ranges.

You can adjust each of the ranges using appropriate test gases (one

for each range).

All the following adjustment steps are shown on an

EX-TEC SR 6, the more comprehensive version.

They also apply to the VARIOTEC 9-EX.

Testing procedure

Connect your detector (switched off) to the SPE 1 or SPE 3 tester and

a test gas.

now press these 3 buttons

simultaneously

Once the number of available operating hours has been displayed the

detector is in adjustment mode:

the software version number (e.g.

V1.7) is displayed and the pump

runs at maximum power

the reading display flashes until

the zero point of the sensor has

been automatically established

37

Page 40

6 Settings menu

once the zero point has been set,

press the cursor-up button to

move to the next step

6.1 Setting the ppm sensor

10 ppm setting

Now release the 10 ppm methane CH4 test gas from the SPE 3 tester.

wait for the display to stabilise

confirm the setting with the on/off

button (OK appears in the LC

display)

turn off the test-gas feed

press the cursor-up button to

move to the next step

100 ppm setting (not absolutely essential)

Now release the 100 ppm methane CH

test gas from the SPE 3

4

tester.

wait for the display to stabilise

confirm the setting with the on/off

button (OK appears in the LC

display)

38

turn off the test-gas feed

press the cursor-up button to

move to the next step

Page 41

6 Settings menu

1000 ppm setting (not absolutely essential)

Now release the 1000 ppm methane CH4 test gas from the SPE 3

tester.

wait for the display to stabilise

confirm the setting with the on/off

button (OK appears in the LC

display)

turn off the test-gas feed

press the cursor-up button to

move to the next step

NB: change the tester

1.00 vol.% setting

Now release the 1.00 vol.% methane CH4 test gas from the SPE 1

tester.

wait for the display to stabilise

confirm the setting with the on/off

button (OK appears in the LC

display)

turn off the test-gas feed

press the cursor-up button to

move to the next step

39

Page 42

6 Settings menu

6.2 Setting the LEL sensor

0 %LEL setting

Now set the zero point of the % LEL range with fresh air using the

SPE 1 tester.

wait for the display to stabilise

confirm the setting with the on/off

button (OK appears in the LC

display)

50 %LEL setting

Now release:

2.20 vol.% methane CH

via the SPE 1 tester.

press the cursor-up button to

move to the next step

test gas = 50 %LEL

4

wait for the display to stabilise

confirm the setting with the on/off

button (OK appears in the LC

display)

40

turn off the test-gas feed

press the cursor-up button to

move to the next step

Page 43

6.3 Setting the VOL sensor

6 Settings menu

0 vol.% setting

Now set the zero point of the vol.% range with fresh air using the

SPE 1 tester.

wait for the display to stabilise

confirm the setting with the on/off

button (OK appears in the LC

display)

press the cursor-up button to

move to the next step

100 vol.% methane (CH4) setting

Now release the:

100 vol.% methane (CH

) test gas

4

via the SPE 1 tester.

wait for the display to stabilise

confirm the setting with the on/off

button (OK appears in the LC

display)

turn off the test-gas feed

press the cursor-up button to

move to the next step

41

Page 44

6 Settings menu

100 vol.% carbon dioxide (CO 2) setting

Now release the:

100 vol.% carbon dioxide (CO

via the SPE 1 tester.

) test gas

2

wait for the display to stabilise

confirm the setting with the on/off

button (OK appears in the LC

display)

turn off the test-gas feed

press the cursor-up button to

move to the next step

42

Page 45

6 Settings menu

6.4 Setting the measurement unit (%LEL range language)

Repeatedly pressing the on/off button enables you to select among the

following displays in the %LEL range:

%UEG -

Untere Explosionsgrenze (German)

%LEL - Lower Explosive Limit (English)

%LIE - Limite Inférieure d´Explosion (French)

%VOL - concentration display in vol.% (German/English)

%GAZ - concentration display in vol.% (French)

confirm the display, e.g. %UEG,

with the on/off button (OK appears

in the LC display)

this display is retained even when

the detector is switched off

press the cursor-up button to

move to the next step

43

Page 46

6 Settings menu

%VOL range language

By repeatedly pressing the on/off button you can choose between the

following displays in the vol.% range:

%VOL - concentration display in vol.% (German/English)

%GAZ - concentration display in vol.% (French)

confirm the display, e.g. %VOL,

with the on/off button (OK appears

in the LCD display)

this setting is retained even when

the detector is switched off

press the cursor-up button to

move to the next step

44

Page 47

6 Settings menu

6.5 Setting 10 ppm sensitivity

Depending on whether synthetic or fresh air is used for the zero-point

adjustment, you must always achieve sensitivity of > 5 ppm when using

10 ppm methane CH

test gas.

4

To this end you can select from the following amplification ratios in the

10 ppm range by repeatedly pressing the on/off switch:

1.0 x 10 ppm - 100% amplification

1.2 x 10 ppm - 120% amplification

1.5 x 10 ppm - 150% amplification (factory setting)

confirm the selected amplification

(e.g. 1.5 x 10 PPM) with the on/

off button

press the cursor-up button to

move to the next step

45

Page 48

6 Settings menu

6. 6 Activating the ETHANE BOX

If you are using an EX-TEC SR 6 or VARIOTEC 9-EX in conjunction

with the ETHANE BOX, this function must be enabled:

pressing the on/off button

switches the function on and off:

ETHANE 1 = (on)

ETHANE 0 = (off)

press the cursor-up button to

move to the next step

For further details see the ETHANE BOX operating manual.

6.7 Interface mode

if your detector has an external

RS 232 interface, you can enable

it:

RS 232 1 = (on)

RS 232 0 = (off)

if your detector lacks this interface,

the interface function must be

deactivated

46

press the cursor-up button to

move to the next step

Page 49

6 Settings menu

6.8 Checking the LC display

With this function you can check whether all elements of the LC display

are operating normally.

confirm the LCD check with the

on/off button

6.9 Leaving the settings menu

press the cursor-up button to

return to the first step

press the pump button for about

2 seconds

hold down the gas-warning button

for about 2 seconds to return to

gas-warning mode or

press the on/off button to switch

the detector off

47

Page 50

7 Technical aspects

7 Technical aspects

7.1 Technical notes

Oxygen concentration

In order to guarantee electrical safety the detectors may not be used

in an oxygen concentration exceeding 21 vol.%.

An oxygen deficiency may lead to deviations from the correct reading.

Cleaning

Clean the detectors only with a damp cloth. No solvents, benzenes or

similar substances may be used.

Static charging

Generally speaking electrostatic charging should be avoided. Objects

with no electrostatic earth (including, for example, metallic housings

with no earth connection) are not protected from charges resulting from

dust, vapour flows and the like.

Fine dust filters

There are fine dust filters in the screw-on probe connector (item 3) and

in most probes.

The filters can be cleaned by tapping or blowing them to remove the

dust.

After the filters have been cleaned, they must be

replaced in exactly the same position as before

Heavily-soiled filters should be replaced by new

ones (accessories)

Sensor sensitivity

The sensors are deleteriously affected by gaseous components of

silicones, oils and phosphate esters, which irreversibly reduce their

sensitivity.

Pollution of the measuring environment by halogens, burnt neoprene,

PVC, trichloroethylene and the like also weakens the sensitivity of the

sensors, but in this case it can be regenerated.

48

Page 51

7 Technical aspects

7.2 Technical data

Models : EX-TEC SR 6

VARIOTEC 9-EX

Setting : methane CH4 /carbon dioxide CO

Measuring systems

- ppm range : semiconductor sensor

- %LEL range : heat-tinting sensor

- vol.% range : 2 thermal-conductivity sensors

CH4 measuring range : 10 ppm - 1 ppm steps

100 ppm - 2 ppm steps

1000 ppm - 20 ppm steps

1 vol.% - 0.02 vol.% steps

10 vol.% - 0.1 vol.% steps

100 vol.% - 1 vol.% steps

CO2 measuring range : 100 vol.% - 1 vol.% steps

gas warning : 100% LEL - 1% LEL steps

or : 4.40 vol.% - 0.05 vol.% steps

t90 times

- ppm range : ≤ 4 seconds

- LEL range : ≤ 4 seconds

- VOL range : ≤ 8 seconds

Lifetime

Heat-tinting sensor

- guaranteed : 1 year

- expected : 5 years

Semiconductor sensor

- guaranteed : 1 year

- expected : 5 years

Thermal-conductivity sensor

- guaranteed : 1 year

- expected : 5 years

2

Cross-sensitivity

- ppm/LEL range: all combustible gases

- vol range: all gases with thermal conductivity different from that of

air

Measurement error

- ppm range ± 30 %

- LEL range ± 5 % in accordance with norm EN 50054/57

- vol range ± 5% in accordance with norm EN 50054/58

49

Page 52

7 Technical aspects

Pump power

- gas detection / location : > 50 l/h and >150 mbar

- gas-measuring mode : > 35 l/h

Explosion protection (CENELEC)

- Testing institution : Physikalisch-Technische

Bundesanstalt, Brunswick

- Test number : Ex-96.ATEX.2166

- Identification mark : II 2 G EEx ib d IIB T3

Test report : PFG no. 41300897

Testing institution : DMT - Gesellschaft für Forschung

und Prüfung mbH, Essen

50

Page 53

7 Technical aspects

Alarm thresholds : 4 ppm to 2 vol.% (variable)

10% LEL

(fixed, in gas-warning mode only)

100% LEL

(fixed, in gas-warning mode only)

Dimensions (WxHxD) : 129 x 192 x 65 mm

Weight : 1500 g

Type of protection : IP 54

Operating time : up to 8 hours

Power supply : NiCd rechargeable batteries

Operating temperature : - 10 °C ... + 40 °C

Storage temperature : - 25 °C ... + 70 °C

Humidity range : 5 ... 90 % r.h., non-condensing

Pressure range : 900 h Pa ... 1100 h Pa

51

Page 54

7 Technical aspects

7.3 Error messages

Error code Cause and remedy

the detectors self-diagnose

faults and display an error code in

the LC display (item 2)

F10 - F14...................adjustment error in the ppm range

check test gas or repeat adjustment

F15, F16, F19, F20 ...adjustment error in the %VOL range

check test gas or repeat adjustment

F17, F18 .................... adjustment error in the %LEL range

check test gas or repeat adjustment

F21 ............................component error

contact SEWERIN service

F31 ............................ synchronisation alarm (not clearable) in

gas-warning mode

error due to nitrogen or carbon dioxide

in the gas sample

switch off detector and switch on again in

fresh air

F50 - F56...................component errors

contact SEWERIN service

52

Page 55

7 Technical aspects

F61 ............................breakage in the heat-tinting sensor:

contact SEWERIN service

F62, F63 .................... breakage in the thermal-conductivity sensor

contact SEWERIN service

F64 ............................breakage in the flow sensor:

contact SEWERIN service

F6 5 ............................breakage in the semiconductor sensor

contact SEWERIN service

F66 ............................defective humidity sensor

contact SEWERIN service

F100 .......................... pump power too low:

switch detector off and on again, inspect filters

in detector and probes

Should any other error codes occur, please contact

SEWERIN service

53

Page 56

7 Technical aspects

7.4 Wearing parts

Fine dust filters in the probe connection of the

detectors (item 3) and in most probes

Hose filter in the carpet probe

Probe filter inserts in the bell probe and the gas-detection

probe

Hydrophobic filters in the 1m, 2m and 6m probe hoses

Neoprene mat for the carpet probe

Test-gas bottle various concentrations in synthetic air

or nitrogen

Test-gas bottles are under pressure, do not store

above 50 °C

54

Page 57

Appendix

55

Page 58

Appendix

56

Page 59

Appendix

57

Page 60

Appendix

58

Page 61

Appendix

59

Page 62

Appendix

Gerätebezeichnung:

Type of Product:

Geräte-Typ:

Product Name:

Fabrikations-Nr.:

Fabr.No.:

Hiermit erklären wir, dass oben genanntes Produkt mit der / den folgenden Norm(en) oder

dem / den folgenden normativen Dokument(en) übereinstimmt. Bei einer mit uns nicht

abgestimmten Änderung des Produkts verliert diese Erklärung ihre Gültigkeit.

Konformitätserklärung / Declaration of Conformity

tragbares,batteriebetriebenes Gasmeßgerät

portable battery-operated gas measuring device

EX-TEC SR 6 Methan

041 11 5xxx

We hereby declare that the above product complies with the following norms or standardized

directives. In the event of any modification of this product which has not been authorized by

us, this declaration becomes invalid.

Norm(en) / Norm(s):

DIN EN 50 081-1

DIN EN 50 082-1

DIN EN 50 014/18/20

DIN EN 50054/57

Fundstellen bez. EN 50 081/82 sind Amtsblätter der EG Nr. C 44/12 bzw. Nr.C 90/2

The Norms EN 50 081/82 are recorded in the Gazette of the EG no. C 44/12 and no. C90/2

respectively.

Gemäß den Bestimmungen der Richtlinie(n) / The unit complies with:

89/336/EWG

92/31/EWG

93/68/EWG

94/9/EG

Gütersloh, 3.12.2001

HERMANN SEWERIN GMBH

EMV – Fachgrundnorm Störaussendung

Generic Emission Standard

EMV – Fachgrundnorm Störfestigkeit

Generic Immunity Standard

Ex – Allgemeine Bestimm. /Druckf. Kapselung/ Eigensicherheit

General Requirements /Flameproof Encl./ Intrinsic Safety -iEl. Geräte für das Aufspüren brennbarer Gas

El. devices to detect and measure combustible gases

EG-Richtlinie : Elektromagnetische Verträglichkeit

EG-Directive: Electromagnetic Compatibility

Änderung dazu /amendment to above

Änderung dazu /amendment to above

ATEX 100a

( Geschäftsführer / Managing Director )

60

Page 63

Konformitätserklärung / Declaration of Conformity

Gerätebezeichnung:

Type of Product:

Geräte-Typ:

Product Name:

Fabrikations-Nr.:

Fabr.No.:

Hiermit erklären wir, dass oben genanntes Produkt mit der / den folgenden Norm(en) oder

dem / den folgenden normativen Dokument(en) übereinstimmt. Bei einer mit uns nicht

abgestimmten Änderung des Produkts verliert diese Erklärung ihre Gültigkeit.

tragbares,batteriebetriebenes Gasmeßgerät

portable battery-operated gas measuring device

Variotec 9 Ex Methan

044 05 xxxx

Appendix

We hereby declare that the above product complies with the following norms or standardized

directives. In the event of any modification of this product which has not been authorized by

us, this declaration becomes invalid.

Norm(en) / Norm(s):

DIN EN 50 081-1

DIN EN 50 082-1

DIN EN 50 014/18/20

Fundstellen bez. EN 50 081/82 sind Amtsblätter der EG Nr. C 44/12 bzw. Nr.C 90/2

The Norms EN 50 081/82 are recorded in the Gazette of the EG no. C 44/12 and no. C90/2

respectively.

Gemäß den Bestimmungen der Richtlinie(n) / The unit complies with:

89/336/EWG

92/31/EWG

93/68/EWG

94/9/EG

Gütersloh, 3.12.2001

HERMANN SEWERIN GMBH

EMV – Fachgrundnorm Störaussendung

Generic Emission Standard

EMV – Fachgrundnorm Störfestigkeit

Generic Immunity Standard

Ex - Allgemeine Bestimm. /Druckf. Kapselung/ Eigensicherheit

General Requirements /Flameproof Encl./ Intrinsic Safety -i-

EG-Richtlinie : Elektromagnetische Verträglichkeit

EG-Directive: Electromagnetic Compatibility

Änderung dazu /amendment to above

Änderung dazu /amendment to above

ATEX 100a

( Geschäftsführer / Managing Director )

61

Page 64

Appendix

Test Report

Calibration:

Serial Number (e.g.: 041 11 5001)

1.0 Device status

1.1 - status correct (e.g.: Y / N)

1.2 - fine-dust filters correct (e.g.: Y/ N)

1.3 - remaining operating hours (e.g.: 5 h)

2.0 Pump test

2.1 - low pressure > 150 mbar

2.2 - volume flow > 50 l/h

3.0 PPM measuring range (gas detection)

3.1 zero point

- fresh air reading

test gas 10 PPM CH

3.2

- display > 10 PPM

test gas 100 PPM CH

3.3

- display 70 ... 140 PPM

test gas 1.000 PPM CH

3.4

- display 800 ... 1.200 PPM

test gas 1,00 VOL.% CH

3.5

- display 0,80 ... 1,20 VOL.%

4

4

4

4

EX-TEC® SR 6, VARIOTEC® 9-EX

methane CH

/carbon dioxide CO

4

2

04.12.2002

4.0 %LEL measuring range (gas warning)

4.1 zero point

- display -3 ... +3 %LEL or

- display -0,15 ... +0,15 VOL.%

test gas 50 %LEL = 2,20 VOL.% CH

4.2

4

- display 45 ... 55 %LEL or

- display 2,00 ... 2,40 VOL.%

4.3 optical alarm (e.g.: Y/ N)

4.4 audible alarm (e.g.: Y / N)

5.0 VOL.% measuring range (location, gas injection, blanketing)

5.1 zero point

- display -1 ... +1 VOL.%

Testgas 100 VOL.% CH

5.2

4

- display 98 ... 102 VOL.%

Testgas 100 VOL.% CO

5.3

2

- display 98 ... 102 VOL.%

6.0 Observations

- housing broken

- adjustment, repair

- factory inspection

- or the like

7.0 Test

- day

- month

- year

- signature

62

Page 65

Hermann Sewerin GmbH

Robert-Bosch-Strasse 3 · 33334 Gütersloh · Germany

Telephone +49 (0) 52 41 93 40 · Fax +49 (0) 52 41 93 44 44

www.sewerin.com · info@sewerin.com

Loading...

Loading...