Page 1

Operating-

Instructions

102424

Page 2

Measurable success by Sewerin equipment

You settled on a precision instrument.

A good choice!

Our equipment stands out for guaranteed safety, optimal output and efficiency .

They correspond with the national and international guide-lines.

These operating instructions will help you to handle the instrument quickly and

competently.

Please pay close attention to our operating instructions before usage.

In case of further queries our staff is at your disposal at any time.

Yours

Hermann Sewerin GmbH

Robert-Bosch-Straße 3

D-33334 Gütersloh

: +49 - (0) - 52 41/9 34-0

FAX : +49 - (0) - 9 34-4 44

http:// www.sewerin.com

Page 3

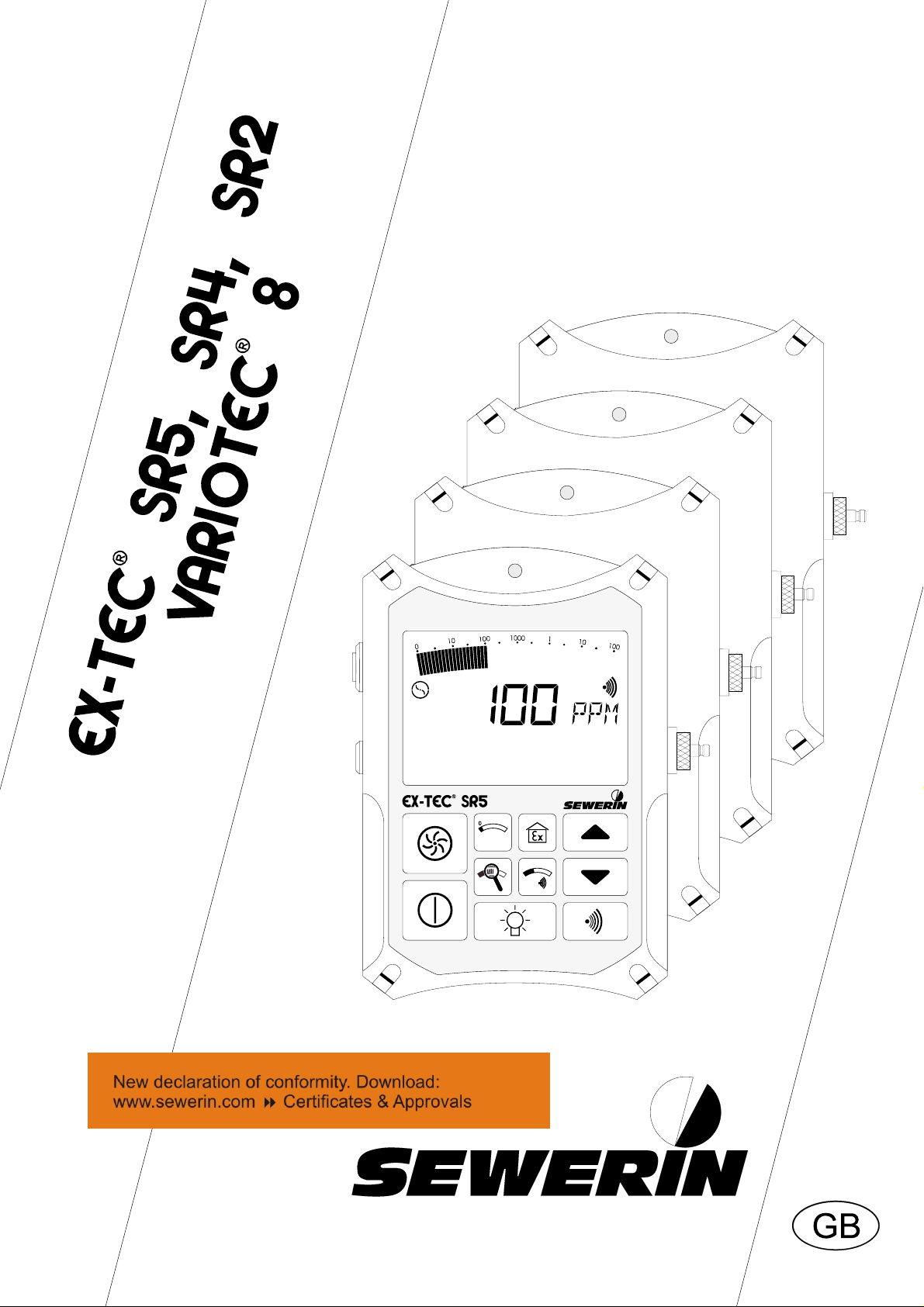

Design of the: EX-TEC® SR5

7

1

2

6

3

4

5

1

Page 4

Notes

2

Page 5

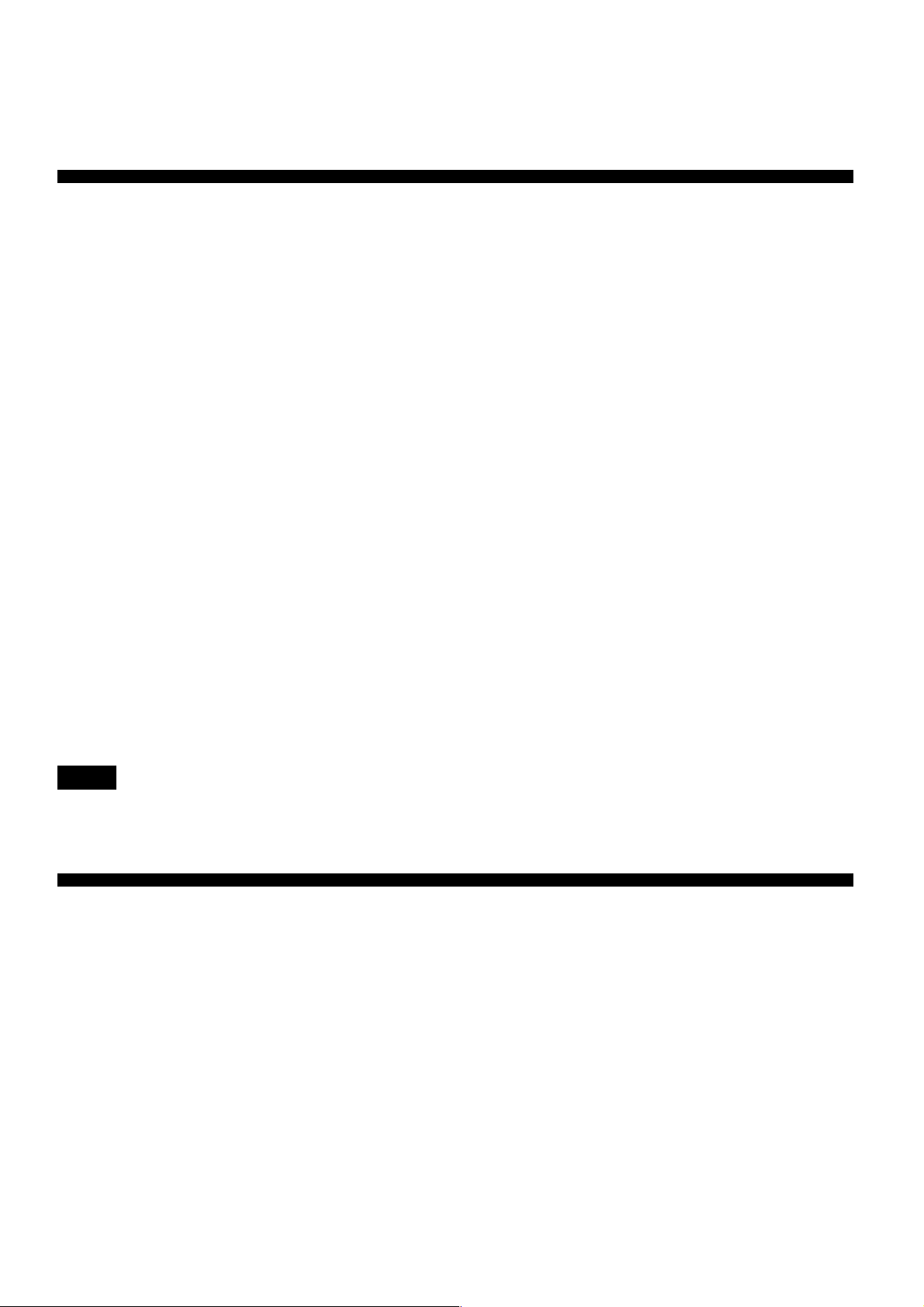

EX-TEC® SR 5, SR4, SR2

VARIOTEC® 8

Operating InstructionsOperating Instructions

Operating Instructions

Operating InstructionsOperating Instructions

102424 - 04/20.08.1999

................

........

................

pages 3 - 52pages 3 - 52

pages 3 - 52

pages 3 - 52pages 3 - 52

3

Page 6

For your safety *For your safety *

For your safety *

For your safety *For your safety *

The law governing technical equipment (the Law on the Safety of Appliances)

of 24.06.1968 (BGBl.I, page 717) as amended by the Amendment Law of

13.08.1979 (BGBl.I, page 1432) requires the following matters to be drawn

to your attention:

Comply with the Operating InstructionsComply with the Operating Instructions

Comply with the Operating Instructions.

Comply with the Operating InstructionsComply with the Operating Instructions

Before operating or adjusting the appliance you must be thoroughly familiar

with this operating manual. You must comply with it in every respect.

The appliance is designed only for the application described and for

industrial (commercial) use.

Liability for Function and/or DamageLiability for Function and/or Damage

Liability for Function and/or Damage

Liability for Function and/or DamageLiability for Function and/or Damage

Liability for the functioning of the appliance passes to the owner or operator

in all cases in which the appliance has been improperly maintained or

repaired by persons not associated with SEWERIN Service or if it has been

used for a purpose not in accordance with its designated application.

You should therefore always use original SEWERIN accessories with the

EX-TEC® SR 5, SR4, SR2 and VARIOTEC® 8.

Hermann Sewerin GmbH accepts no responsibility for damage due to a

failure to comply with the foregoing instructions. The guarantee and liability

terms of the Hermann Sewerin GmbH terms of sale and supply are not

extended by the foregoing.

We reserve the right to make technical changes in the course of continued

development.

HERMANN SEWERIN GMBH

* All references to laws, statutes and norms relate to the legislation of the Federal Republic of

Germany.

4

Page 7

ContentsContents

Contents

ContentsContents

pagepage

page

pagepage

For your safetyFor your safety

For your safety

For your safetyFor your safety

1.01.0

1.0 The EX-TEC® SR5, SR4, SR2 and VARIOTEC® 8

1.01.0

........................................................................................................................................................................

....................................................................................

........................................................................................................................................................................

models .............

4 4

4

4 4

6 6

6

6 6

1.1 Tests ............................................................................................. 8

1.2 Probe systems ............................................................................. 9

2.02.0

2.0

2.02.0

Measuring operationMeasuring operation

Measuring operation

Measuring operationMeasuring operation

................................................................................................................................

................................................................

................................................................................................................................

1 1

1

1 1

2.1 Switching on ................................................................................ 11

2.2 Illumination and contrast ............................................................. 12

2.3 Pump operation .......................................................................... 13

2.4 Alarm signal and volume ............................................................ 14

2.5 Alarm threshold value ................................................................. 14

2.6 Switching measuring ranges ...................................................... 15

2.7 Zero-point adjustment ................................................................ 16

2.8 Workplace monitoring ................................................................ 16

2.9 Battery alarm............................................................................... 18

2.10 Switching off ............................................................................... 18

3.03.0

3.0

3.03.0

Charging techniqueCharging technique

Charging technique

Charging techniqueCharging technique

..................................................................................................................................

.................................................................

..................................................................................................................................

19 19

19

19 19

11

1

11

4.04.0

4.0

4.04.0

Inspection, testing and maintenanceInspection, testing and maintenance

Inspection, testing and maintenance

Inspection, testing and maintenanceInspection, testing and maintenance

........................................................................

....................................

........................................................................

21 21

21

21 21

4.1 Test sets ..................................................................................... 22

4.2 Test gases .................................................................................. 24

4.3 Function testing .......................................................................... 25

5.05.0

5.0

5.05.0

6.06.0

6.0

6.06.0

7.07.0

7.0

7.07.0

8.08.0

8.0

8.08.0

9.09.0

9.0

9.09.0

10.010.0

10.0

10.010.0

EC-TEC-T

EC-T

EC-TEC-T

Declarations of conformityDeclarations of conformity

Declarations of conformity

Declarations of conformityDeclarations of conformity

AdjustmentAdjustment

Adjustment

AdjustmentAdjustment

TT

echnical specificationsechnical specifications

T

echnical specifications

TT

echnical specificationsechnical specifications

TT

echnical dataechnical data

T

echnical data

TT

echnical dataechnical data

AccessoriesAccessories

Accessories

AccessoriesAccessories

Error messagesError messages

Error messages

Error messagesError messages

Parts subject to wearParts subject to wear

Parts subject to wear

Parts subject to wearParts subject to wear

ype Examinations Certificateype Examinations Certificate

ype Examinations Certificate

ype Examinations Certificateype Examinations Certificate

................................................................................................................................................................

................................................................................

................................................................................................................................................................

..................................................................................................................

.........................................................

..................................................................................................................

....................................................................................................................................................

..........................................................................

....................................................................................................................................................

............................................................................................................................................................

..............................................................................

............................................................................................................................................................

..............................................................................................................................................

.......................................................................

..............................................................................................................................................

............................................................................................................................

..............................................................

............................................................................................................................

............................................................................................................................

..............................................................

............................................................................................................................

....................................................................................................

..................................................

....................................................................................................

26 26

26

26 26

34 34

34

34 34

37 37

37

37 37

39 39

39

39 39

40 40

40

40 40

42 42

42

42 42

43 43

43

43 43

47 47

47

47 47

TT

est reportsest reports

T

est reports

TT

est reportsest reports

................................................................................................................................................................................

........................................................................................

................................................................................................................................................................................

51 51

51

51 51

5

Page 8

1.01.0

The The

1.0

The EX-TEC® SR5, SR4, SR2 and VARIOTEC® 8

1.01.0

The The

modelsmodels

models

modelsmodels

This family of detectors consists of a total of four combined detectors

for the following uses:

EX-TEC® SR5 (Ex-protected)

Gas detectionGas detection

Gas detection

•

Gas detectionGas detection

above-ground gas detection for

pipeline monitoring (ppm range)

Interior installationsInterior installations

Interior installations

•

Interior installationsInterior installations

leak detection for pipelines in

buildings (ppm range)

Workplace monitoringWorkplace monitoring

•

Workplace monitoring

Workplace monitoringWorkplace monitoring

monitoring proximity to the

Lower Explosive Limit (%LEL

range)

LocationLocation

Location

•

LocationLocation

concentration measurement in

probe holes (vol.% range)

Gasing and inertisationGasing and inertisation

Gasing and inertisation

•

Gasing and inertisationGasing and inertisation

concentration measurement in

pipelines (vol.% range)

EX-TEC® SR4 (Ex-protected)

Workplace monitoringWorkplace monitoring

•

Workplace monitoring

Workplace monitoringWorkplace monitoring

monitoring proximity to the

Lower Explosive Limit (%LEL

range)

LocationLocation

Location

•

LocationLocation

concentration measurement in

probe holes (vol.% range)

Gasing and inertisationGasing and inertisation

Gasing and inertisation

•

Gasing and inertisationGasing and inertisation

concentration measurement in

pipelines (vol.% range)

6

Page 9

EX-TEC® SR2 (Ex-protected)

LocationLocation

Location

•

LocationLocation

concentration measurement in

probe holes (vol.% range)

Gasing and inertisationGasing and inertisation

Gasing and inertisation

•

Gasing and inertisationGasing and inertisation

concentration measurement in

pipelines (vol.% range)

VARIOTEC® 8

Gas detectionGas detection

•

Gas detection

Gas detectionGas detection

above-ground gas detection for

pipeline monitoring (ppm range)

LocationLocation

Location

•

LocationLocation

concentration measurement in

probe holes (vol.% range)

7

Page 10

1.11.1

TT

1.1

1.11.1

estsests

T

ests

TT

estsests

Passive explosion protectionPassive explosion protection

Passive explosion protection

Passive explosion protectionPassive explosion protection

The EX-TEC® SR5, EX-TEC® SR4 and EX-TEC® SR2 models are explosion-

proof in accordance with European norms (CENELEC):

EC prototype test certificate: PTB 96 ATEX 2166

Classification: II 2 G EEx ib d IIB T4

Test institute: Physikalische-Technische

Bundesanstalt, Braunschweig

Active explosion protectionActive explosion protection

Active explosion protection

Active explosion protectionActive explosion protection

The EX-TEC® SR5 and EX-TEC® SR4 have also been tested for

functional safety in the Workplace Monitoring (WPM) field:

Test report: PFG no. 41300897

Test institute: DMT-Gesellschaft für Forschung

und Prüfung mbH, Essen

The test certificates can be found on and after page 43.

8

Page 11

1.21.2

Probe systemsProbe systems

1.2

Probe systems

1.21.2

Probe systemsProbe systems

- Probes for the survey of gas distributions networks -- Probes for the survey of gas distributions networks -

- Probes for the survey of gas distributions networks -

- Probes for the survey of gas distributions networks -- Probes for the survey of gas distributions networks -

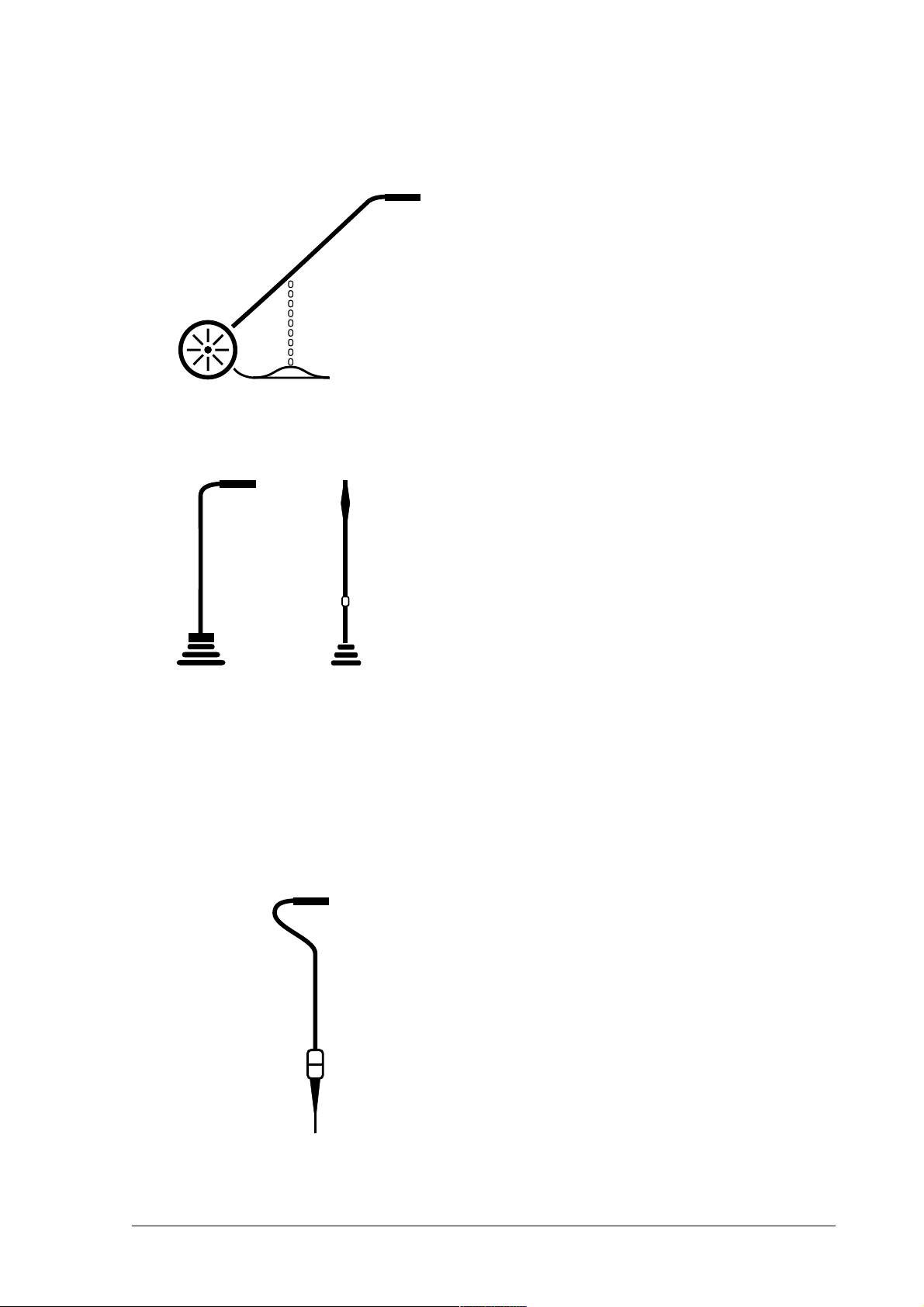

Carpet probeCarpet probe

Carpet probe

Carpet probeCarpet probe

for checking stable surfaces.

The sample is drawn into an

excrescence in a neoprene mat

in contact with the surface with no

extraneous emissions.

Bell probe,Bell probe,

Bell probe,

Bell probe,Bell probe,

telescopic bell probetelescopic bell probe

telescopic bell probe

telescopic bell probetelescopic bell probe

for checking unstable and

overgrown surfaces.

It can be used in confined

spaces, e.g. between parked

cars or in front gardens.

- Probes for localisation -- Probes for localisation -

- Probes for localisation -

- Probes for localisation -- Probes for localisation -

Search probeSearch probe

Search probe

Search probeSearch probe

for measuring concentrations in

probe holes,

with a rigid rubber cone to seal

off the probe hole,

2 different probe tips (length 245

mm or 345 mm),

carbon-dioxide filter to filter out

traces of CO

2

9

Page 12

- Probes for hollow spaces -- Probes for hollow spaces -

- Probes for hollow spaces -

- Probes for hollow spaces -- Probes for hollow spaces -

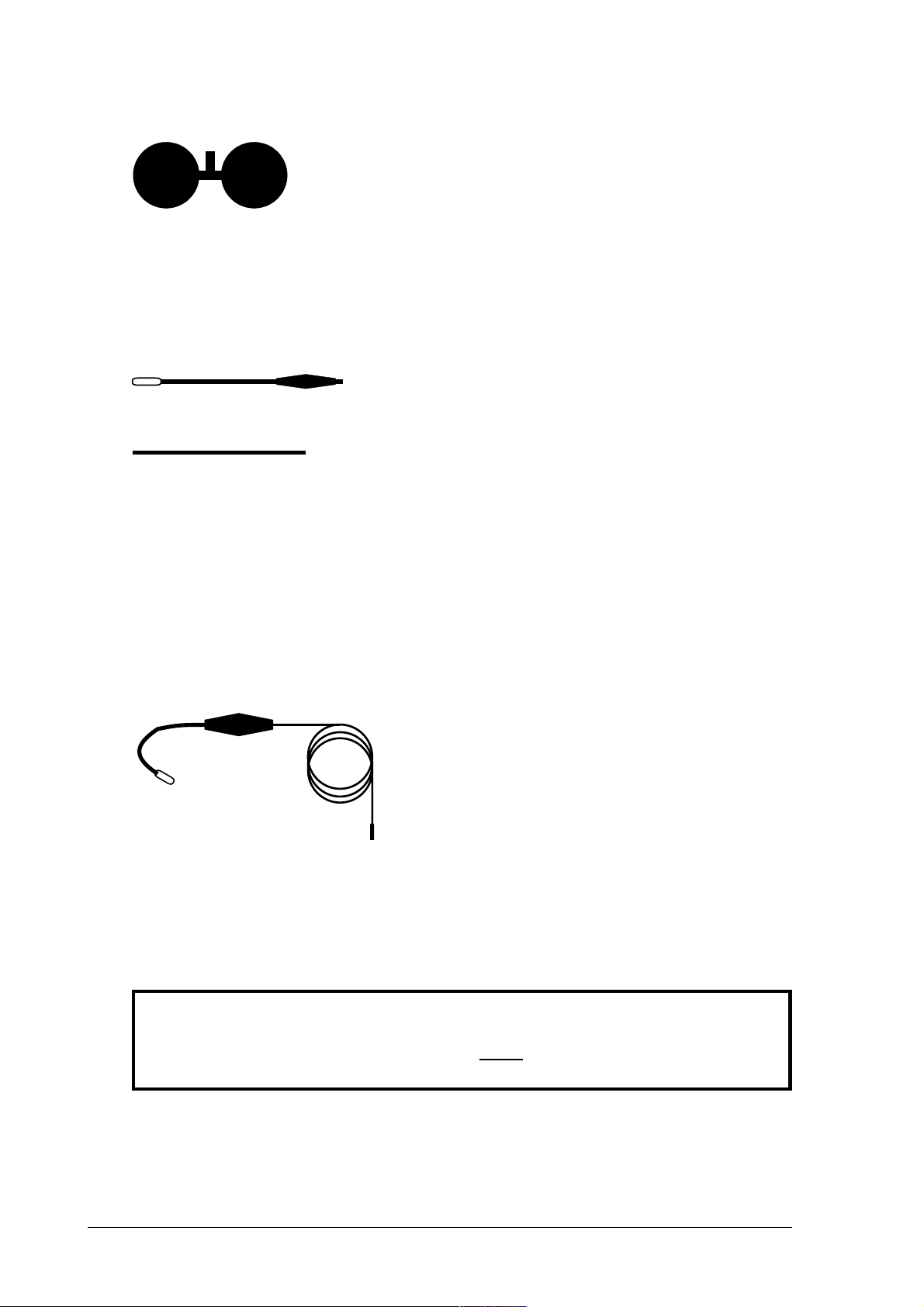

Floating probeFloating probe

Floating probe

Floating probeFloating probe

for measuring concentrations in

pits,

with suction vent and hose

connection

Divisible handprobeDivisible handprobe

Divisible handprobe

Divisible handprobeDivisible handprobe

for the detection of leaks in pipes

installed in poorly accessible places,

measuring of concentration in containers, overall length 900 mm

- Probes for house service lines -- Probes for house service lines -

- Probes for house service lines -

- Probes for house service lines -- Probes for house service lines -

Flexible hand probesFlexible hand probes

Flexible hand probes

Flexible hand probesFlexible hand probes

for the detection of leaks in

house service lines, handle with

flexible swan neck and probe

hose, overall lengths 360 mm or

660 mm

☞

Except with the carpet probe , a probe hoseExcept with the carpet probe , a probe hose

Except with the carpet probe , a probe hose

Except with the carpet probe , a probe hoseExcept with the carpet probe , a probe hose

should always be used should always be used

should always be used

should always be used should always be used

withwith

a hydrophobic filter ! a hydrophobic filter !

with

a hydrophobic filter !

withwith

a hydrophobic filter ! a hydrophobic filter !

10

Page 13

2.02.0

Measuring operationMeasuring operation

2.0

Measuring operation

2.02.0

Measuring operationMeasuring operation

☞

ItemItem

Item

ItemItem

1 alarm lamp optical warning

2 LCD display display of gas

3 probe connection connection to the probes

4 buttonboard operating the detector

Please fold out the illustration inside thePlease fold out the illustration inside the

Please fold out the illustration inside the

Please fold out the illustration inside thePlease fold out the illustration inside the

front cover !front cover !

front cover !

front cover !front cover !

DescriptionDescription

Description

DescriptionDescription

FunctionFunction

Function

FunctionFunction

when alarm thresholds are

exceeded

concentrations and

operating conditions

described

5 harness for portable systems

6 outlet for gas sample

7 buzzer acoustic warning

when alarm thresholds are

exceeded

2.12.1

Switching onSwitching on

2.1

Switching on

2.12.1

Switching onSwitching on

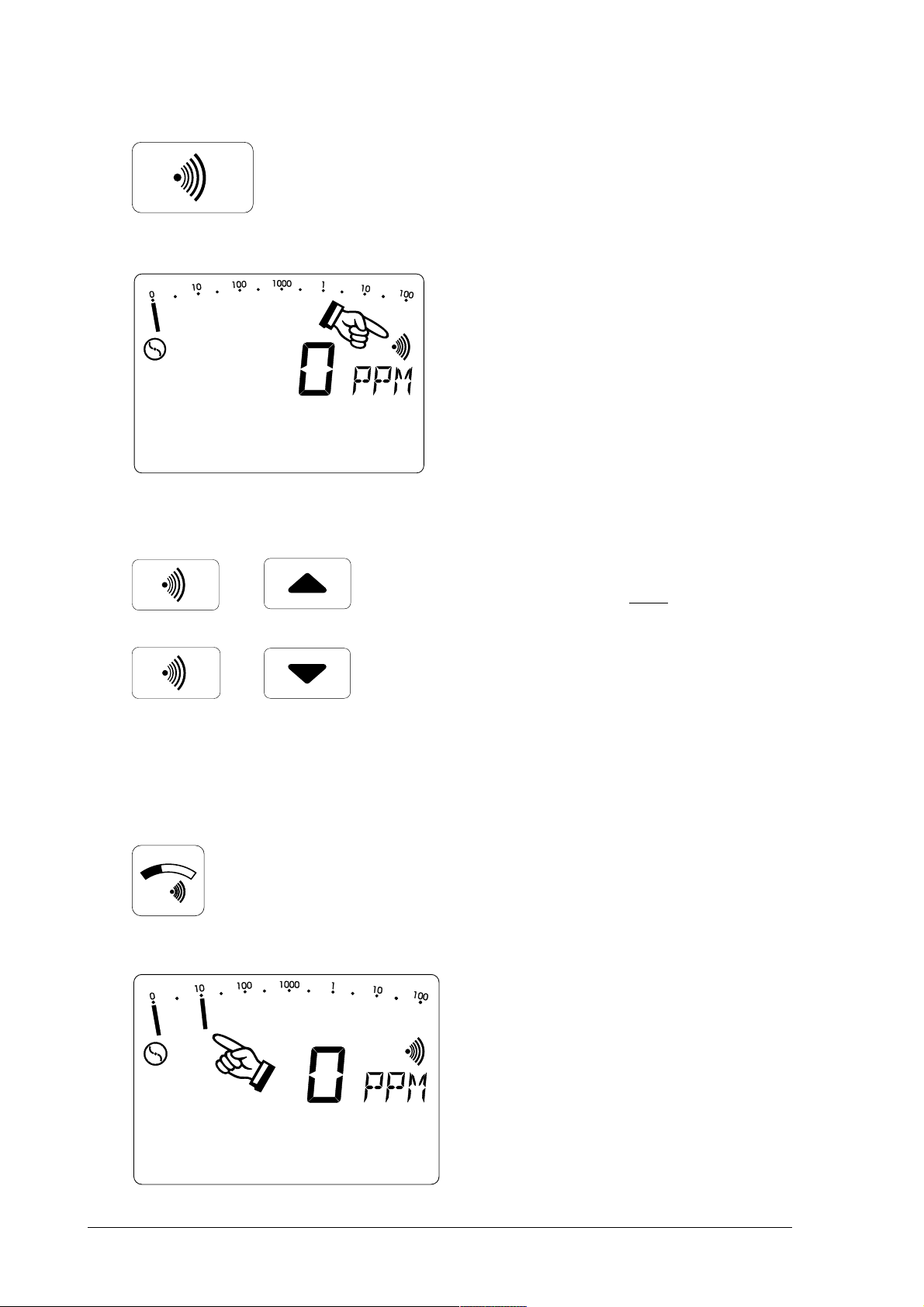

• press the

detection mode) or

(workplace-monitoring mode, p.

16 ff.) for approx. 2 seconds

• optical and acoustic control signal

(items 1 and 7) operate for approx.

2 seconds

on/off buttonon/off button

on/off button (gas-

on/off buttonon/off button

WPM button WPM button

WPM button

WPM button WPM button

11

Page 14

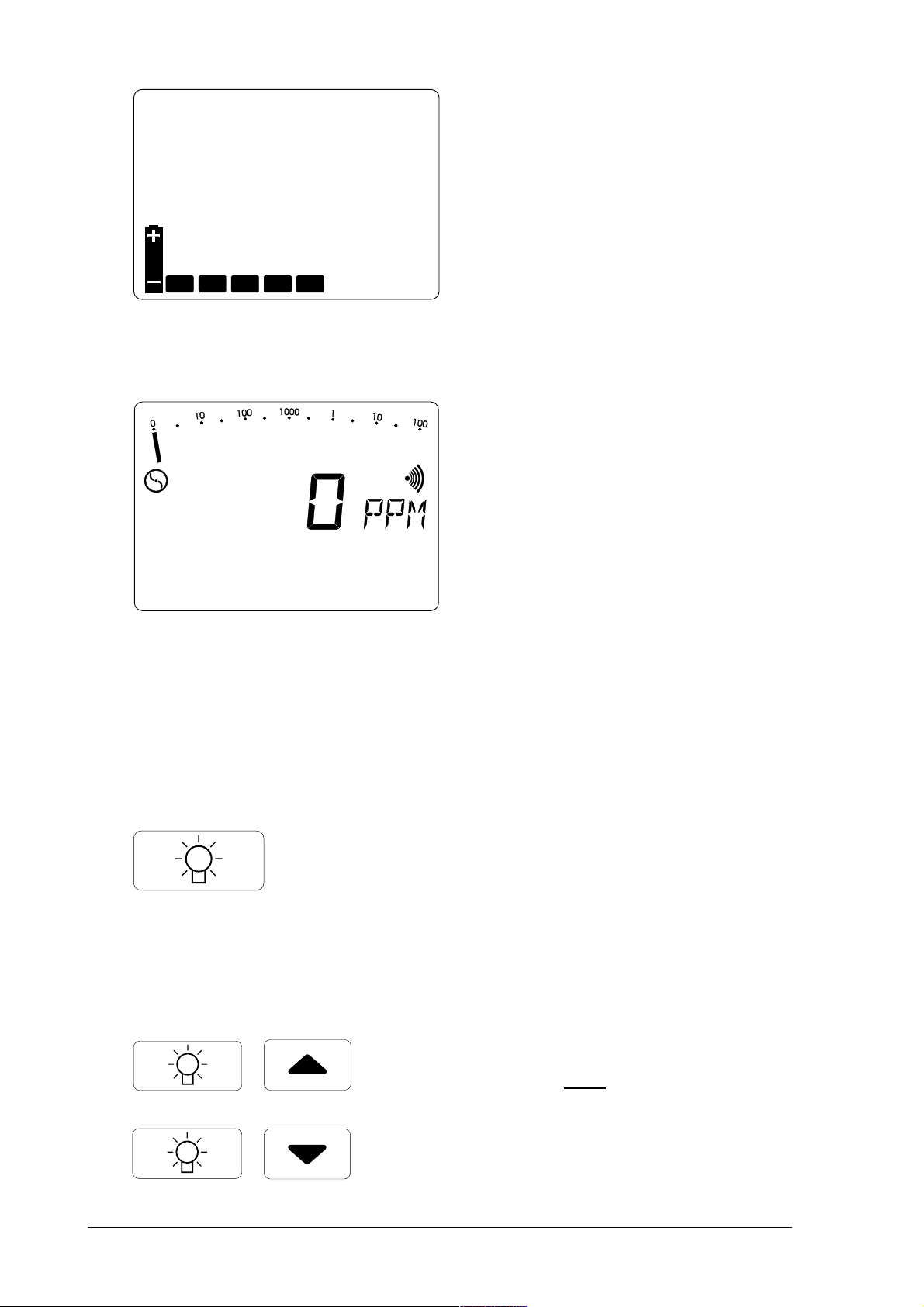

• display of available operating

hours in the form of bars (e.g. 5

hours)

• the integral pump operates at

maximum power

• wait until the zero point has

established itself in fresh air

(approx. 2-3 minutes):

EX-TEC® SR5 and VARIOTEC® 8:

0 PPM0 PPM

☞

0 PPM

0 PPM0 PPM

2.22.2

Illumination and contrastIllumination and contrast

2.2

Illumination and contrast

2.22.2

Illumination and contrastIllumination and contrast

(after flashing stops)

EX-TEC® SR4 and EX-TEC® SR2:

0,0 %VOL0,0 %VOL

☞

0,0 %VOL

0,0 %VOL0,0 %VOL

• pressing the

switches the LCD illumination on

and off

• the illumination automatically

switches off approx. 4 minutes

after being switched on

light buttonlight button

light button

light buttonlight button

12

• simultaneously pressing the light

andand

button

increases or reduces the contrast

of the LCD display

and a cursor button

andand

Page 15

2.32.3

Pump operationPump operation

2.3

Pump operation

2.32.3

Pump operationPump operation

• pressing the

switches the pump on and off

• the corresponding symbol

appears in or disappears from

the LCD display (item 2)

• this enables the pump function to

be checked

pump buttonpump button

pump button

pump buttonpump button

☞

Altering the pump powerAltering the pump power

Altering the pump power

Altering the pump powerAltering the pump power

(available only on the (available only on the

(available only on the EX-TEC® SR5

(available only on the (available only on the

• simultaneously pressing the

pump button

button increases or reduces the

pump power

gas detectiongas detection

☞

gas detection

gas detectiongas detection

for above-ground gas detection

(pipeline monitoring) always use

maximum pump powermaximum pump power

maximum pump power

maximum pump powermaximum pump power

house service lineshouse service lines

☞

house service lines

house service lineshouse service lines

) !) !

) !

) !) !

andand

and one cursor

andand

for detecting leaks in pipelines

inside buildings always use

minimum pump powerminimum pump power

minimum pump power

minimum pump powerminimum pump power

13

Page 16

2.42.4

Alarm signal and volumeAlarm signal and volume

2.4

Alarm signal and volume

2.42.4

Alarm signal and volumeAlarm signal and volume

• pressing the

signal buttonsignal button

signal button

signal buttonsignal button

switches the alarm signal on and

off

• the corresponding symbol

appears in or disappears from

the LCD display (item 2)

• this enables the alarm signal to

be checked

• simultaneously pressing the

signal button

andand

and one cursor

andand

button increases or reduces the

buzzer volume (item 7)

2.52.5

Alarm threshold valueAlarm threshold value

2.5

Alarm threshold value

2.52.5

Alarm threshold valueAlarm threshold value

14

• when the

buttonbutton

button is held down

buttonbutton

threshold valuethreshold value

threshold value

threshold valuethreshold value

• the alarm threshold value (e.g. 10

PPM) flashes in the full-range

display

Page 17

2.62.6

Switching measuring rangesSwitching measuring ranges

2.6

Switching measuring ranges

2.62.6

Switching measuring rangesSwitching measuring ranges

• holding down the threshold value

button

andand

and repeatedly pressing

andand

one cursor button increases or

reduces the alarm threshold value

• this value is preserved even when

the detector is switched off

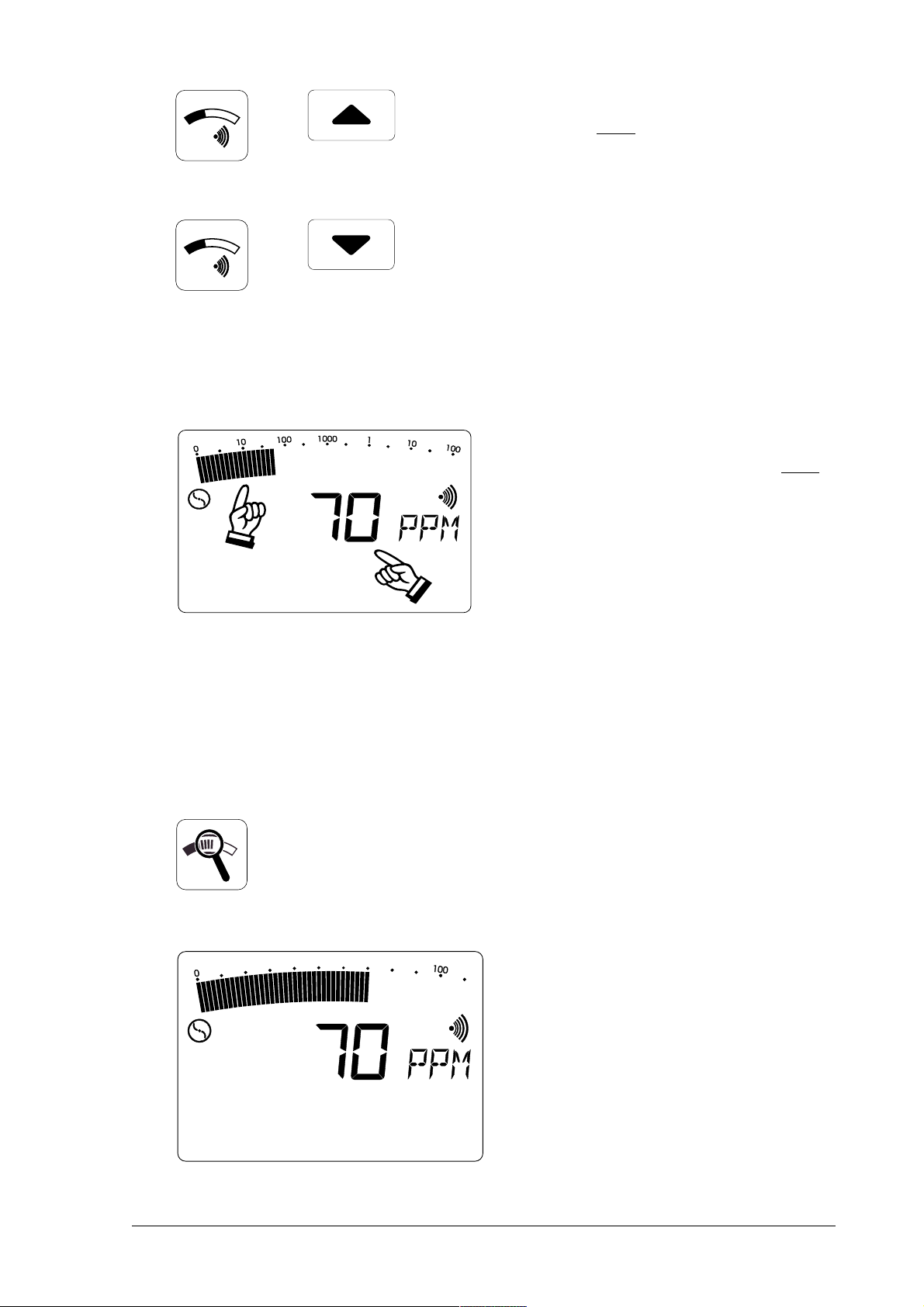

• all detectors have an

displaydisplay

display (above, full range)

displaydisplay

digital displaydigital display

digital display (below);

digital displaydigital display

analogueanalogue

analogue

analogueanalogue

andand

and a

andand

both scales indicate the same

concentration (e.g. 70 PPM)

• the

full rangefull range

full range is a logarithmic

full rangefull range

scale covering the range:

0 PPM ... 100 %VOL

• here the display of low

concentrations is intensified;

the measurement result can be

read off from the digital display

• repeatedly pressing the

buttonbutton

button switches between the

buttonbutton

optimum rangesoptimum ranges

and

optimum ranges

optimum rangesoptimum ranges

zoomzoom

zoom

zoomzoom

fullfull

full

fullfull

• depending on the concentration,

switching between the following

measurement ranges is

automatic:automatic:

automatic:

automatic:automatic:

0 ... 10 PPM 0 ... 1 %VOL

0 ... 100 PPM 0 ... 10 %VOL

0 ... 1,000 PPM 0 ... 100 %VOL

• the optimum measurement range

in this example is 0 ... 100 PPM

15

Page 18

2.72.7

Zero-point adjustmentZero-point adjustment

2.7

Zero-point adjustment

2.72.7

Zero-point adjustmentZero-point adjustment

• repeatedly pressing one of the

cursor buttons while holding down

the zoom button switches

manually to the required display

range

• if the detector fails to reach its

zero point of

0 PPM0 PPM

0 PPM or

0 PPM0 PPM

after flushing with copious fresh

air, pressing the

buttonbutton

button enables you to adjust it

buttonbutton

manually

0,00,0

%VOL%VOL

0,0

%VOL

0,00,0

%VOL%VOL

zero pointzero point

zero point

zero pointzero point

2.82.8

Workplace monitoringWorkplace monitoring

2.8

Workplace monitoring

2.82.8

Workplace monitoringWorkplace monitoring

☞

This function is available only with the This function is available only with the

This function is available only with the EX-TEC® SR5

This function is available only with the This function is available only with the

and and

and EX-TEC® SR4

and and

• the reading display flashes while

the adjustment is being carried

out

• measurement cannot be

resumed until

stops

detectors ! detectors !

detectors !

detectors ! detectors !

• this function is switched on by

pressing the

mm

monitoring)

mm

afteafte

after the flashing

afteafte

WPM WPM

WPM (

WPM WPM

buttonbutton

button

buttonbutton

ww

work

ww

pp

place

pp

16

• the detector can also be switched

on by pressing this button

Page 19

• this measuring range is used to

monitor proximity to the

ll

lower

(

ll

ee

explosion

ee

ll

limit)

ll

LELLEL

LEL

LELLEL

• after approx. 8 seconds' warm-

up time a stable zero point is

reached

• the pump runs at minimum power

and the acoustic operating signal

(item 7) sounds every 5 seconds

• when the pre-set threshold of

20 %LEL is exceeded

methane:methane:

methane: 20 %LEL = 0,88 %VOL

methane:methane:

(display = 0,90 %VOL)

propane:propane:

propane: 20 %LEL = 0,34 %VOL

propane:propane:

advance alarmadvance alarm

the

advance alarm is triggered

advance alarmadvance alarm

both optically (item 1) and

acoustically (item 7)

• the advance alarm is an

intermittent tone quite distinct

from the operating signal;

ceases after a certain periodceases after a certain period

it

ceases after a certain period

ceases after a certain periodceases after a certain period

and cannot be cleared

• if the concentration exceeds

100 %LEL

methane:methane:

methane:100 %LEL = 4,40 %VOL

methane:methane:

propane:propane:

propane:100 %LEL = 1,70 %VOL

propane:propane:

main alarmmain alarm

the

main alarm is triggered

main alarmmain alarm

optically (item 1) and acoustically

(item 7)

17

Page 20

2.92.9

Battery alarmBattery alarm

2.9

Battery alarm

2.92.9

Battery alarmBattery alarm

• the main alarm is a continuous

tone quite distinct from the

operating signal;

continues indefinitelycontinues indefinitely

it

continues indefinitely and

continues indefinitelycontinues indefinitely

cannot be cleared

Cancelling the main alarm:Cancelling the main alarm:

•

Cancelling the main alarm:

Cancelling the main alarm:Cancelling the main alarm:

switch to location operation (press

the pump button for approx. 2

seconds ) or switch the detector

off

• if the battery symbol appears in

the LCD display, at least 15

minutes' operating time remains;

after that the detector must be

recharged

2.10Switching off2.10Switching off

2.10Switching off

2.10Switching off2.10Switching off

• in workplace-monitoring mode

the battery alarm is accompanied

by a "double beep" to distinguish

it from the operating signal

• Press the

on/off buttonon/off button

on/off button for

on/off buttonon/off button

approx. 2 seconds

• the optical and acoustic

monitoring signals (items 1 and

7) operate for approx. 2 seconds

18

• remaining operating hours are

displayed in the form of bars

Page 21

3.03.0

Charging techniqueCharging technique

3.0

Charging technique

3.03.0

Charging techniqueCharging technique

☞

When fully charged the detectors have a

operating time with the pump running.

For charging you need the

which can be used either in the workshop or in the standby vehicle.

The The

The EX-TEC® SR5,

The The

must not be recharged in an explosive gasmust not be recharged in an explosive gas

must not be recharged in an explosive gas

must not be recharged in an explosive gasmust not be recharged in an explosive gas

atmosphere !atmosphere !

atmosphere !

atmosphere !atmosphere !

SR4, SR2

HS charging adapterHS charging adapter

HS charging adapter (see illustration),

HS charging adapterHS charging adapter

and and

and VARIOTEC® 8

and and

maximummaximum

maximum of 8 hours'

maximummaximum

The following items can be

connected to the side of the

charging adapter:

• 230 V mains power pack ≈,

detectors detectors

detectors

detectors detectors

• 12 V= vehicle adapter,

• 24 V= vehicle adapter.

ChargingCharging

Charging

ChargingCharging

Switch the detector off and plug it into the charger. A display of the

following type appears:

• the detector has 5 operating hours

left (= 5 bars) and will take 3 hours

to become fully charged

• if it is fully charged all the bars are

visible and the number display

disappears

• the detector can be left in the

charger until it is next needed

19

Page 22

Spontaneous dischargeSpontaneous discharge

Spontaneous discharge

Spontaneous dischargeSpontaneous discharge

If the detector is

nickel-cadmium battery spontaneously discharges, thus reducing the

available operating hours.

After a maximum of 30 days the detector indicator shows that there are

no operating hours left, and it must be recharged.

not connected to the charger when switched off, the

☞

Short periods of operation and prolonged disuseShort periods of operation and prolonged disuse

Short periods of operation and prolonged disuse

Short periods of operation and prolonged disuseShort periods of operation and prolonged disuse

may lead in the long term to the so-called "memorymay lead in the long term to the so-called "memory

may lead in the long term to the so-called "memory

may lead in the long term to the so-called "memorymay lead in the long term to the so-called "memory

effect", in which the display indicates a highereffect", in which the display indicates a higher

effect", in which the display indicates a higher

effect", in which the display indicates a highereffect", in which the display indicates a higher

battery capacity than is actually available. This canbattery capacity than is actually available. This can

battery capacity than is actually available. This can

battery capacity than is actually available. This canbattery capacity than is actually available. This can

be avoided by fully discharging -the detectorbe avoided by fully discharging -the detector

be avoided by fully discharging -the detector

be avoided by fully discharging -the detectorbe avoided by fully discharging -the detector

regularly (e.g. once a month), leaving it switched onregularly (e.g. once a month), leaving it switched on

regularly (e.g. once a month), leaving it switched on

regularly (e.g. once a month), leaving it switched onregularly (e.g. once a month), leaving it switched on

until it automatically switches off, then recharginguntil it automatically switches off, then recharging

until it automatically switches off, then recharging

until it automatically switches off, then recharginguntil it automatically switches off, then recharging

it !it !

it !

it !it !

20

Page 23

4.04.0

Inspection, testing and maintenanceInspection, testing and maintenance

4.0

Inspection, testing and maintenance

4.04.0

Inspection, testing and maintenanceInspection, testing and maintenance

DVGW work sheet G 465/IV requires detectors to be inspected,

tested and maintained.

Sensitivity testingSensitivity testing

Sensitivity testing

Sensitivity testingSensitivity testing

may be necessary several times a day, according to G 465/I, depending

on the circumstances - particularly with gas detectors used to monitor

mains pipes.

InspectionInspection

Inspection

InspectionInspection

must be carried out up to six times a year, depending on frequency of

use - and at any rate at least once a year. The following items must be

tested:

• detector condition • pump power

• battery condition • zero point

• intake channel • sensitivity (with test gas)

☞

TT

est reportest report

T

est report

TT

est reportest report

Test results must be recorded. A specimen form will be found on the

last page of this manual.

Servicing and maintenanceServicing and maintenance

Servicing and maintenance

Servicing and maintenanceServicing and maintenance

DVGW work sheet G 465/IV specifies that servicing and maintenance

of the detectors may be carried out only by the following persons:

• the SEWERIN Service Department or

• an expert authorised by SEWERIN.

Workplace monitoring mode:Workplace monitoring mode:

Workplace monitoring mode:

Workplace monitoring mode:Workplace monitoring mode:

For your own safety you are recommended alwaysFor your own safety you are recommended always

For your own safety you are recommended always

For your own safety you are recommended alwaysFor your own safety you are recommended always

to check the %LEL range with test gas before useto check the %LEL range with test gas before use

to check the %LEL range with test gas before use

to check the %LEL range with test gas before useto check the %LEL range with test gas before use

and recalibrate if necessaryand recalibrate if necessary

and recalibrate if necessary

and recalibrate if necessaryand recalibrate if necessary

(instruction sheet T 031 / BG Chemie) !(instruction sheet T 031 / BG Chemie) !

(instruction sheet T 031 / BG Chemie) !

(instruction sheet T 031 / BG Chemie) !(instruction sheet T 031 / BG Chemie) !

Servicing must be carried out at least once a year. The next scheduled

date must be entered on the inspection sticker attached to the detector

(month/year).

After servicing a certificate must be completed.

21

Page 24

4.14.1

TT

4.1

4.14.1

est setsest sets

T

est sets

TT

est setsest sets

Pump power, zero point and sensitivity should be tested with an

SPE 1SPE 1

SPE 1 or

SPE 1SPE 1

SPE 3SPE 3

SPE 3 test set and a suitable test gas:

SPE 3SPE 3

Pos. 1

SPE 1 SPE 1

SPE 1 test set, used to test:

SPE 1 SPE 1

• pump power

• zero point in the

• sensitivity in the

%LEL and %VOL range%LEL and %VOL range

%LEL and %VOL range

%LEL and %VOL range%LEL and %VOL range

%LEL and %VOL range%LEL and %VOL range

%LEL and %VOL range

%LEL and %VOL range%LEL and %VOL range

and for use with the following test gases:

methane CH4: • 1.00 vol.%

• 2.20 vol.% (50 %LEL)

• 100 vol.%

propane C3H8: • 1.00 vol.% (59 %LEL)

• 100 vol.%

22

Page 25

Pos. 2

SPE 3 SPE 3

SPE 3 test set, used to test:

SPE 3 SPE 3

• pump power

• zero point in the

• sensitivity in the

PPM rangePPM range

PPM range

PPM rangePPM range

PPM rangePPM range

PPM range

PPM rangePPM range

and for use with the following test gases:

methane CH4: • 10 ppm

• 100 ppm

• 1,000 ppm

23

Page 26

4.24.2

TT

4.2

4.24.2

est gasesest gases

T

est gases

TT

est gasesest gases

The following test gases were used to function-test the detectors:

methane CH

EX-TEC® SR5 ppm range 10 ppm CH

100 ppm CH

1,000 ppm CH

1.00 vol.% CH

propane C3H

4

4

4

4

4

%LEL range 2.20 vol.% 1.00 vol.%

(50 %LEL) (59 %LEL)

vol.% range 100 vol.% 100 vol.%

or location

natural gas

EX-TEC® SR4 %LEL range 2.20 vol.% 1.00 vol.%

(50 %LEL) (59 %LEL)

vol.% range 100 vol.% 100 vol.%

or location

natural gas

8

EX-TEC® SR2 vol.% range 100 vol.% 100 vol.%

or location

natural gas

VARIOTEC® 8 ppm range 10 ppm CH

100 ppm CH

1,000 ppm CH

1.00 vol.% CH

4

4

4

4

vol.% range 100 vol.% 100 vol.%

or location

natural gas

For detector settings other than methane or propane the correct values

can be found inside the cover on page 2.

24

Page 27

4.34.3

Function testingFunction testing

4.3

Function testing

4.34.3

Function testingFunction testing

Proceed as follows:

• screw the selected test-gas bottle onto the test set as far as it

will go (illustration 1/2 - item 2)

• connect the detector's probe nipple (item 3) to the test set hose

(illustration 1/2 - item 1)

• switch the detector on; the pump draws in

fresh airfresh air

fresh air through the

fresh airfresh air

test set (illustration 1/2 - item 4)

• use the needle valve (illustration 1/2 - item 5) to set the maximum

flow; it must be > 50 l/h (illustration 1/2 - item 6)

• wait until a stable zero point has been established (warm-up

time)

• press the release button (illustration 1/2 - item 3) on the test set

and adjust the flow to the fresh-air value (illustration 1/2 - item 6)

• hold it down until the indicated concentration has reached a

stable value

Admissible display values for methane CH4 test gas:

• test gas 10 ppm : > 5 ppm

• test gas 100 ppm : 70 ... 140 ppm

• test gas 1,000 ppm : 800 ... 1,200 ppm

• test gas 1.00 vol.% : 0.80 ... 1.20 vol.%,

• test gas 2.20 vol.% : 2.00 ... 2.40 vol.% (45 - 55 %LEL)

• test gas 100 vol.% : 98 ... 102 vol.%

Admissible display values for propane C3H8 test gas:

• test gas 1.00 vol.% : 0.90 ... 1.10 vol.% (55 - 64 %LEL)

• test gas 100 vol.% : 98 ... 102 vol.%

If display values are outside these tolerances the detector must be

recalibrated (section 5.0 Adjustment).

25

Page 28

5.05.0

AdjustmentAdjustment

5.0

Adjustment

5.05.0

AdjustmentAdjustment

EX-TEC® SR5, SR4, SR2 and VARIOTEC® 8 detectors are factory-set

for all measuring ranges.

You can adjust each of the ranges using appropriate test gases (one

for each range).

☞

TT

esting procedureesting procedure

T

esting procedure

TT

esting procedureesting procedure

Connect your detector (switched off) to the

and a test gas .

All the following adjustment steps are shown on anAll the following adjustment steps are shown on an

All the following adjustment steps are shown on an

All the following adjustment steps are shown on anAll the following adjustment steps are shown on an

EX-TEC® SR5

models !models !

models !

models !models !

detector; they are identical for all other detector; they are identical for all other

detector; they are identical for all other

detector; they are identical for all other detector; they are identical for all other

• now press these 3 buttons

simultaneously

SPE 1SPE 1

SPE 1 or

SPE 1SPE 1

SPE 3SPE 3

SPE 3 test set

SPE 3SPE 3

Display 1 - version number / zero pointDisplay 1 - version number / zero point

Display 1 - version number / zero point

Display 1 - version number / zero pointDisplay 1 - version number / zero point

Once the number of available operating hours has been displayed the

detector is in

26

adjustment mode:adjustment mode:

adjustment mode:

adjustment mode:adjustment mode:

• the software version number (e.g.

V1.0) is displayed and the pump

runs at maximum power

• the reading display flashes until

the zero point of the sensor has

been automatically established

Page 29

Display 2 - 10 ppm adjustmentDisplay 2 - 10 ppm adjustment

Display 2 - 10 ppm adjustment

Display 2 - 10 ppm adjustmentDisplay 2 - 10 ppm adjustment

Now release the

10 ppm methane CH10 ppm methane CH

10 ppm methane CH

10 ppm methane CH10 ppm methane CH

set.

• once the zero point has been set,

press the cursor-up button to

move to the next display

test gas test gas

test gas from the

test gas test gas

44

4

44

SPE 3SPE 3

SPE 3 test

SPE 3SPE 3

• wait until the display has stabilised

• confirm the adjustment with the

on/off button (

OKOK

OK appears in the

OKOK

LCD display)

• turn off the test-gas feed

Display 3 - 100 ppm adjustmentDisplay 3 - 100 ppm adjustment

Display 3 - 100 ppm adjustment

Display 3 - 100 ppm adjustmentDisplay 3 - 100 ppm adjustment

Now release the

100 ppm methane CH100 ppm methane CH

100 ppm methane CH

100 ppm methane CH100 ppm methane CH

set.

• press the cursor-up button to

move to the next display

test gas test gas

test gas from the

test gas test gas

44

4

44

SPE 3SPE 3

SPE 3 test

SPE 3SPE 3

• wait until the display has stabilised

• confirm the adjustment with the

on/off button (

OKOK

OK appears in the

OKOK

LCD display)

• turn off the test-gas feed

• press the cursor-up button to

move to the next display

27

Page 30

Display 4 - 1,000 ppm adjustmentDisplay 4 - 1,000 ppm adjustment

Display 4 - 1,000 ppm adjustment

Display 4 - 1,000 ppm adjustmentDisplay 4 - 1,000 ppm adjustment

Now release the

1,000 ppm methane CH1,000 ppm methane CH

1,000 ppm methane CH

1,000 ppm methane CH1,000 ppm methane CH

test set.

• wait until the display has stabilised

• confirm the adjustment with the

• turn off the test-gas feed

• press the cursor-up button to

test gas test gas

test gas from the

test gas test gas

44

4

44

on/off button (

OKOK

OK appears in the

OKOK

LCD display)

move to the next display

SPE 3SPE 3

SPE 3

SPE 3SPE 3

☞

Display 5 - 1.00 vol.% adjustmentDisplay 5 - 1.00 vol.% adjustment

Display 5 - 1.00 vol.% adjustment

Display 5 - 1.00 vol.% adjustmentDisplay 5 - 1.00 vol.% adjustment

Now release the

NB: change the test set !NB: change the test set !

NB: change the test set !

NB: change the test set !NB: change the test set !

1.00 vol.% methane CH1.00 vol.% methane CH

1.00 vol.% methane CH

1.00 vol.% methane CH1.00 vol.% methane CH

test set.

• wait until the display has stabilised

• confirm the adjustment with the

• turn off the test-gas feed

test gas test gas

test gas from the

test gas test gas

44

4

44

on/off button (

LCD display)

SPE 1SPE 1

SPE 1

SPE 1SPE 1

OKOK

OK appears in the

OKOK

28

• press the cursor-up button to

move to the next display

Page 31

Display 6 - 0 %LEL adjustmentDisplay 6 - 0 %LEL adjustment

Display 6 - 0 %LEL adjustment

Display 6 - 0 %LEL adjustmentDisplay 6 - 0 %LEL adjustment

Now set the zero point of the %LEL range with

SPE 1SPE 1

SPE 1 test set.

SPE 1SPE 1

• wait until the display has stabilised

• confirm the adjustment with the

on/off button (

LCD display)

• press the cursor-up button to

move to the next display

fresh airfresh air

fresh air using the

fresh airfresh air

OKOK

OK appears in the

OKOK

Display 7 - 50 %LEL or 59 %LEL adjustmentDisplay 7 - 50 %LEL or 59 %LEL adjustment

Display 7 - 50 %LEL or 59 %LEL adjustment

Display 7 - 50 %LEL or 59 %LEL adjustmentDisplay 7 - 50 %LEL or 59 %LEL adjustment

Now release:

2.20 vol.% methane CH2.20 vol.% methane CH

2.20 vol.% methane CH

2.20 vol.% methane CH2.20 vol.% methane CH

1.00 vol.% propane C1.00 vol.% propane C

1.00 vol.% propane C

1.00 vol.% propane C1.00 vol.% propane C

via the

SPE 1SPE 1

SPE 1 test set.

SPE 1SPE 1

test gas =test gas =

test gas =

test gas =test gas =

44

4

44

HH

test gas = test gas =

H

test gas =

HH

test gas = test gas =

33

88

3

8

33

88

50 %LEL50 %LEL

50 %LEL or

50 %LEL50 %LEL

59 %LEL59 %LEL

59 %LEL

59 %LEL59 %LEL

• wait until the display has stabilised

• confirm the adjustment with the

on/off button (

LCD display)

• turn off the test-gas feed

OKOK

OK appears in the

OKOK

• press the cursor-up button to

move to the next display

29

Page 32

Display 8 - 0 vol.% adjustmentDisplay 8 - 0 vol.% adjustment

Display 8 - 0 vol.% adjustment

Display 8 - 0 vol.% adjustmentDisplay 8 - 0 vol.% adjustment

Now set the zero point of the vol.% range with

SPE 1SPE 1

SPE 1 test set.

SPE 1SPE 1

• wait until the display has stabilised

• confirm the adjustment with the

on/off button (

LCD display)

• press the cursor-up button to

move to the next display

fresh airfresh air

fresh air using the

fresh airfresh air

OKOK

OK appears in the

OKOK

Display 9 - 100 vol.% adjustmentDisplay 9 - 100 vol.% adjustment

Display 9 - 100 vol.% adjustment

Display 9 - 100 vol.% adjustmentDisplay 9 - 100 vol.% adjustment

Now release the

100 vol.% methane CH100 vol.% methane CH

100 vol.% methane CH

100 vol.% methane CH100 vol.% methane CH

100 vol.% propane C100 vol.% propane C

100 vol.% propane C

100 vol.% propane C100 vol.% propane C

via the

SPE 1SPE 1

SPE 1 test set. This requires a steel test-gas bottle with pressure

SPE 1SPE 1

44

4

44

HH

H

HH

33

3

33

or

test gas

8 8

8

8 8

reducer and connecting hose.

• wait until the display has stabilised

• confirm the adjustment with the

• turn off the test-gas feed

on/off button (

LCD display)

OKOK

OK appears in the

OKOK

30

• press the cursor-up button to

move to the next display

Page 33

You can also set the detector to your local natural gas:

• switch the pump off

• admit the natural gas directly to

the detector (not via the test set)

and wait for the display to reach a

stable value

• confirm the adjustment with the

on/off button (

OKOK

OK appears in the

OKOK

LCD display) and switch the pump

on again

• press the cursor-up button to

move to the next display

Display 10 - %LEL range languageDisplay 10 - %LEL range language

Display 10 - %LEL range language

Display 10 - %LEL range languageDisplay 10 - %LEL range language

Repeatedly pressing the on/off button enables you to select among the

following displays in the %LEL range:

%UEG%UEG

%UEG -

%UEG%UEG

%LEL%LEL

%LEL -

%LEL%LEL

%LIE%LIE

%LIE -

%LIE%LIE

%VOL%VOL

%VOL - concentration display in vol.% (German/English)

%VOL%VOL

%GAZ%GAZ

%GAZ - concentration display in vol.% (French)

%GAZ%GAZ

UU

Untere

UU

LL

Lower

LL

LL

Limite

LL

EE

Explosions

EE

EE

Explosive

EE

II

Inférieure d´

II

LL

Limit (English)

LL

• confirm the display e.g.

gg

grenze (German)

gg

EE

Explosion (French)

EE

with the on/off button (

%UEG%UEG

%UEG

%UEG%UEG

OKOK

OK appears

OKOK

in the LCD display)

• this display is retained even when

the detector is switched off

• press the cursor-up button to

move to the next display

31

çç

ç

çç

Page 34

Display 1Display 1

Display 1

Display 1Display 1

1 - %VOL1 - %VOL

1 - %VOL

1 - %VOL1 - %VOL

range language range language

range language

range language range language

By repeatedly pressing the on/off button you can choose between the

following displays in the vol.% range:

%VOL%VOL

%VOL - concentration display in vol.% (German/English)

%VOL%VOL

%GAZ%GAZ

%GAZ - concentration display in vol.% (French)

%GAZ%GAZ

• confirm the display, e.g.

with the on/off button (

%VOL%VOL

%VOL,

%VOL%VOL

OKOK

OK appears

OKOK

in the LCD display)

• this setting is retained even when

the detector is switched off

• press the cursor-up button to

move to the next display

Display 12 - 10 PPM sensitivityDisplay 12 - 10 PPM sensitivity

Display 12 - 10 PPM sensitivity

Display 12 - 10 PPM sensitivityDisplay 12 - 10 PPM sensitivity

Synthetic or fresh air is used for the zero-point adjustment, you must

always achieve sensitivity of > 5 ppm when using 10 ppm methane CH

test gas.

To this end you can select from the following amplification ratios in the

10 ppm range by repeatedly pressing the on/off switch:

4

32

1,0 x 10 PPM1,0 x 10 PPM

1,0 x 10 PPM - 100% amplification

1,0 x 10 PPM1,0 x 10 PPM

1,2 x 10 PPM1,2 x 10 PPM

1,2 x 10 PPM - 120% amplification

1,2 x 10 PPM1,2 x 10 PPM

1,5 x 10 PPM1,5 x 10 PPM

1,5 x 10 PPM - 150% amplification (factory setting)

1,5 x 10 PPM1,5 x 10 PPM

• confirm the selected amplification

(e.g.

1,5 x 10 PPM1,5 x 10 PPM

1,5 x 10 PPM) with the on/

1,5 x 10 PPM1,5 x 10 PPM

off button

Page 35

Display 13 - LCD checkDisplay 13 - LCD check

Display 13 - LCD check

Display 13 - LCD checkDisplay 13 - LCD check

With this function you can check whether all elements of the LCD

display are operating normally.

• confirm the LCD check with the

on/off button

• press the cursor-up button to

return to the first display

Leaving adjustment modeLeaving adjustment mode

Leaving adjustment mode

Leaving adjustment modeLeaving adjustment mode

• press the pump button to return

gas-detection modegas-detection mode

to

gas-detection mode or

gas-detection modegas-detection mode

• press the WPM button to return

workplace-monitoring workplace-monitoring

to

workplace-monitoring

workplace-monitoring workplace-monitoring

mode mode

mode

mode mode

or

• press the on/off button to switch

the detector off.

33

Page 36

6.06.0

TT

6.0

6.06.0

echnical specificationsechnical specifications

T

echnical specifications

TT

echnical specificationsechnical specifications

Maximum pointerMaximum pointer

Maximum pointer

Maximum pointerMaximum pointer

To facilitate the comparison of different gas concentrations, the

maximum value is displayed by a flashing

maximum pointermaximum pointer

maximum pointer.

maximum pointermaximum pointer

• this remains in the LCD display

(item 2) for about 4 minutes unless

updated by a higher concentration

• pressing the zoom button makes

the maximum pointer disappear

Heavy gasHeavy gas

Heavy gas

Heavy gasHeavy gas

• a negative sign in the measuring-

value display indicates a mixture

of light and heavy gas in which the

heavy gas (e.g. propane C3H8 or

carbon dioxide CO2)

predominates.

• if it is carbon dioxide, we

recommend the use of a CO

filter (accessories) to suppress

this heavy-gas component

Oxygen concentrationOxygen concentration

Oxygen concentration

Oxygen concentrationOxygen concentration

In order to guarantee electrical safety the detectors may not be used

in an oxygen concentration exceeding 21 vol.%.

An oxygen deficiency may lead to deviations from the correct reading.

At oxygen concentrations beteween 20.9 vol.% and 5 vol.% this

deviation is less than 5 %.

2

34

Page 37

Gasing and InertisationGasing and Inertisation

Gasing and Inertisation

Gasing and InertisationGasing and Inertisation

To carry out gasing (concentration increase to 100 vol.%) or inertisation

(concentration reduction to 0 vol.%) proceed as follows:

• manually select the

0...100 %VOL measuring0...100 %VOL measuring

0...100 %VOL measuring

0...100 %VOL measuring0...100 %VOL measuring

range range

range with the zoom button and

range range

the cursor buttons

• this is the only measuring range

in which gasing and inertisation

can be unambiguously monitored

Automatic alarm resetAutomatic alarm reset

Automatic alarm reset

Automatic alarm resetAutomatic alarm reset

• if the signal button has been

pressed to deactivate an alarm,

the alarm signal is automatically

reset after approx. 60 seconds

• the corresponding symbol

reappears in the LCD display

(item 2)

• this is intended to stop you

forgetting that the alarm signal

has gone off

CleaningCleaning

Cleaning

CleaningCleaning

Clean the detectors only with a damp cloth. No solvents, benzenes or

similar substances may be used !

35

Page 38

Static chargingStatic charging

Static charging

Static chargingStatic charging

Generally speaking electrostatic charging should be avoided. Objects

with no electrostatic earth (including, for example, metallic housings

with no earth connection) are not protected from charges resulting from

dust, vapour flows and the like.

Fine dust filtersFine dust filters

Fine dust filters

Fine dust filtersFine dust filters

There are fine dust filters in the screw-on probe connector (item 3) and

in most probes.

The filters can be cleaned by tapping or blowing to remove the dust.

☞

Sensor sensitivitySensor sensitivity

Sensor sensitivity

Sensor sensitivitySensor sensitivity

The sensors are deleteriously affected by gaseous components of

silicones, oils and phosphate esters, which irreversibly reduce their

sensitivity.

Pollution of the measuring environment by halogens, burnt neoprene,

PVC, trichloroethylene and the like also weakens the sensitivity of the

sensors, but in this case it can be regenerated.

After cleaning the filters must be replaced in theAfter cleaning the filters must be replaced in the

After cleaning the filters must be replaced in the

After cleaning the filters must be replaced in theAfter cleaning the filters must be replaced in the

same position as before !same position as before !

same position as before !

same position as before !same position as before !

Heavily-soiled filters should be replaced by newHeavily-soiled filters should be replaced by new

Heavily-soiled filters should be replaced by new

Heavily-soiled filters should be replaced by newHeavily-soiled filters should be replaced by new

ones (accessories) !ones (accessories) !

ones (accessories) !

ones (accessories) !ones (accessories) !

Operation hours during measuring timeOperation hours during measuring time

Operation hours during measuring time

Operation hours during measuring timeOperation hours during measuring time

36

• simultaneously pressing both

cursor buttons in the detection

mode displays the remaining

operating time (e.g. 5 hours)

• display disappears (battery

symbol and bars) automatically

after approx. 10 seconds.

Page 39

7.07.0

TT

7.0

7.07.0

echnical dataechnical data

T

echnical data

TT

echnical dataechnical data

ModelsModels

Models : EX-TEC® SR5,

ModelsModels

EX-TEC® SR4,

EX-TEC® SR2,

VARIOTEC® 8

CalibrationCalibration

Calibration : methane CH4 / natural gas,

CalibrationCalibration

Measuring systemsMeasuring systems

Measuring systems

Measuring systemsMeasuring systems

propane C3H

8

- PPM range : semiconductor sensor

- %LEL range : thermal combustion sensor

- %VOL range : thermal conductivity sensor

Measuring rangesMeasuring ranges

Measuring ranges : 10 ppm - 1 ppm steps

Measuring rangesMeasuring ranges

100 ppm - 2 ppm steps

1,000 ppm - 20 ppm steps

1 vol.% - 0.02 vol.% steps

10 vol.% - 0.1 vol.% steps

100 vol.% - 1 vol.% steps

100 %LEL - 1 %LEL steps

Workplace monitoringWorkplace monitoring

Workplace monitoring

Workplace monitoringWorkplace monitoring

- measuring system : thermal combustion sensor

-t

Pump powerPump power

Pump power

Pump powerPump power

time : ≤ 4 seconds

90

- gas detection / location : > 50 l/h and >150 mbar

- workplace monitoring : > 35 l/h

Ex-protection (CENELEC)Ex-protection (CENELEC)

Ex-protection (CENELEC)

Ex-protection (CENELEC)Ex-protection (CENELEC)

- test institute : Physikalisch-Technische

Bundesanstalt, Braunschweig

- Certificate No. : Ex-96.ATEX.2166

- Classification : II 2 G EEx ib d IIB T4

37

Page 40

Alarm thresholdsAlarm thresholds

Alarm thresholds : 4 ppm or 2 vol.% (variable),

Alarm thresholdsAlarm thresholds

20 %LEL (fixed)

DimensionsDimensions

Dimensions

DimensionsDimensions

WeightWeight

Weight : 1500 g

WeightWeight

TT

ype of protectionype of protection

T

ype of protection : IP 54

TT

ype of protectionype of protection

Operating timeOperating time

Operating time : max. 8 hours

Operating timeOperating time

Power supplyPower supply

Power supply : NiCd battery, rechargeable

Power supplyPower supply

Operating temperatureOperating temperature

Operating temperature : -10° to +40° Celsius

Operating temperatureOperating temperature

(W x H x D)(W x H x D)

(W x H x D) : 129 x 192 x 65 mm

(W x H x D)(W x H x D)

Storage temperatureStorage temperature

Storage temperature : -25° to +70° Celsius

Storage temperatureStorage temperature

Humidity rangeHumidity range

Humidity range : 5 - 90 % relative humidity

Humidity rangeHumidity range

(non-condensing)

Pressure rangePressure range

Pressure range : 900 h Pa to 1100 h Pa

Pressure rangePressure range

38

Page 41

8.08.0

AccessoriesAccessories

8.0

Accessories

8.08.0

AccessoriesAccessories

CHARGING TECHNIQUE

PROBE SYSTEMS

PROBE HOSE

CO2 FILTER

PLUNGER BAR

HS charging adapter,

230 V mains power pack,

12 V or 24 V vehicle adapter

for pipeline monitoring,

location,

space monitoring and

interior installations

(see section 1.2)

with hydrophobic filter and quickrelease fastenings,

in lengths of 1 m, 2 m and 6 m

to filter out carbon-dioxide traces

in the sample gas

for making probe holes manually

handle insulated to 10 kV

working lengths 625 mm, 1025 mm

and 1325 mm

TEST SETS

TEST GASES

CARRYING CASE

CARRYING SYSTEMS

SPE 1SPE 1

SPE 1 and

SPE 1SPE 1

SPE 3SPE 3

SPE 3 for mobile

SPE 3SPE 3

use (e.g. in a vehicle) with testgas bottles,

SPE 2SPE 2

SPE 2 for stationary use in the

SPE 2SPE 2

workshop with test-gas flasks

Test gases in various concentrations,

in pressurised gas bottles or flasks

with foam lining and compartments

for accessories, detector can be

charged in the case

TT

riangle carrying system:riangle carrying system:

T

riangle carrying system:

TT

riangle carrying system:riangle carrying system:

neck-strap and pad,

Cross-strap carrying system:Cross-strap carrying system:

Cross-strap carrying system:

Cross-strap carrying system:Cross-strap carrying system:

2 cross-straps

39

Page 42

9.09.0

Error messagesError messages

9.0

Error messages

9.09.0

Error messagesError messages

• the detectors automatically

identify errors and show the error

code in the LCD display (item 2)

Error codeError code

Error code

Error codeError code

cause and remedycause and remedy

cause and remedy

cause and remedycause and remedy

F10 - F14 ................... adjustment errors in the PPM range

check test gas or repeat adjustment

F15, F16, F19, F20 ... adjustment error in %VOL range,

check test gas or repeat adjustment

F17, F18 ................... adjustment error in %LEL range,

check test gas or repeat adjustment

F21 ............................ component error

can only be rectified by SEWERIN Service

F31 ............................ synchronisation alarm (not clearable) in

WPM mode,

error due to nitrogen or carbon dioxide

in the gas sample;

switch off detector and switch on again in

fresh air

F50 - F56 ................... component errors

can only be rectified by SEWERIN Service

40

Page 43

F61 ............................ sensor breakage in the thermal combustion

sensor:

contact SEWERIN service

F62, F63 ....................sensor breakage in the thermal conductivity

sensor: contact SEWERIN service

F64 ............................ sensor breakage in the flow sensor:

contact SEWERIN service

F65 ............................ sensor breakage in the semiconductor sensor:

contact SEWERIN service

F66 ............................ defective humidity sensor:

contact SEWERIN service

F100 .......................... pump power too low:

switch detector off and on again, inspect filters

in detector and probes

☞

Should any other error codes occurShould any other error codes occur

Should any other error codes occur

Should any other error codes occurShould any other error codes occur

SEWERIN service !SEWERIN service !

SEWERIN service !

SEWERIN service !SEWERIN service !

, please contact, please contact

, please contact

, please contact, please contact

41

Page 44

10.0Wearing parts10.0Wearing parts

10.0Wearing parts

10.0Wearing parts10.0Wearing parts

FINE DUST FILTER

HOSE FILTER

PROBE FILTER INSERT

HYDROPHOBIC FILTERS

NEOPRENE MAT

SODA LIME FLASK

TEST GAS CAN

in the probe connection of the

detectors (item 3) and in most probes

in the carpet probe

in the bell probe and the gas-detection

probe

in the 1m, 2m and 6m probe hoses

for the carpet probe

to refill the CO2 filter

various concentrations in synthetic air

or nitrogen

Caution!

The can is pressurized: do not store

at temperatures above 50° C.

42

Page 45

EC-TEC-T

EC-T

EC-TEC-T

ype Examination Certificateype Examination Certificate

ype Examination Certificate

ype Examination Certificateype Examination Certificate

43

Page 46

EC-TEC-T

EC-T

EC-TEC-T

ype Examination Certificateype Examination Certificate

ype Examination Certificate

ype Examination Certificateype Examination Certificate

44

Page 47

EC-TEC-T

EC-T

EC-TEC-T

ype Examination Certificateype Examination Certificate

ype Examination Certificate

ype Examination Certificateype Examination Certificate

45

Page 48

EC-TEC-T

EC-T

EC-TEC-T

ype Examination Certificateype Examination Certificate

ype Examination Certificate

ype Examination Certificateype Examination Certificate

46

Page 49

Declaration of Conformity EX-TEC® SR5

47

Page 50

Declaration of Conformity EX-TEC® SR4

48

Page 51

Declaration of Conformity EX-TEC® SR2

49

Page 52

Declaration of Conformity VARIOTEC® 8

50

Page 53

Sample of Inspection Sheet (Methane-Devices)Sample of Inspection Sheet (Methane-Devices)

Sample of Inspection Sheet (Methane-Devices)

Sample of Inspection Sheet (Methane-Devices)Sample of Inspection Sheet (Methane-Devices)

TEST REPORT

Calibration: methane CH4

Serial Number (e.g.: 041 11 0001)

1.0 Device status

1.1 - status correct (e.g.: Y / N)

1.2 - fine-dust filters correct (e.g.: Y/ N)

1.3 - remaining operating hours (e.g.: 5 h)

2.0 Pump test

2.1 - low pressure > 150 mbar

2.2 - volume flow > 50 l/h

3.0 PPM measuring range

3.1 zero point

- fresh air reading

3.2 test gas 10 PPM CH4

- display > 5 PPM

3.3 test gas 100 PPM CH4

- display 70 ... 140 PPM

3.4 test gas 1.000 PPM CH4

- display 800 ... 1.200 PPM

3.5 test gas 1,00 VOL.% CH4

- display 0,80 ... 1,20 VOL.%

EX-TEC® SR5, SR4, SR2, VARIOTEC® 8

23.10.1998

4.0 %LEL measuring range

4.1 zero point

- display -3 ... +3 %LEL or

- display -0,15 ... +0,15 VOL.%

4.2 test gas 50 %LEL = 2,20 VOL.% CH4

- display 45 ... 55 %LEL or

- display 2,00 ... 2,40 VOL.%

4.3 optical alarm (e.g.: Y/ N)

4.4 audible alarm (e.g.: Y / N)

5.0 VOL.% measuring range

5.1 zero point

- display -2 ... +2 VOL.%

5.2 test gas 100 VOL.% CH4 and/or Erdgas

- display 98 ... 102 VOL.%

6.0 Observations

- housing broken

- adjustment, repair

- factory inspection

- or the like

7.0 Test

- day

- month

- year

- signature

51

Page 54

Sample of Inspection Sheet (Propane-Devices)Sample of Inspection Sheet (Propane-Devices)

Sample of Inspection Sheet (Propane-Devices)

Sample of Inspection Sheet (Propane-Devices)Sample of Inspection Sheet (Propane-Devices)

TEST REPORT

Calibration: propane C3H8

Serial Number (e.g.: 041 12 0001)

1.0 Device status

1.1 - status correct (e.g.: Y / N)

1.2 - fine-dust filters correct (e.g.: Y/ N)

1.3 - remaining operating hours (e.g.: 5 h)

2.0 Pump test

2.1 - low pressure > 150 mbar

2.2 - volume flow > 50 l/h

3.0 PPM measuring range

3.1 zero point

- fresh air reading

3.2 test gas 10 PPM CH4

- display > 5 PPM

3.3 test gas 100 PPM CH4

- display 70 ... 140 PPM

3.4 test gas 1.000 PPM CH4

- display 800 ... 1.200 PPM

3.5 test gas 1,00 VOL.% CH4

- display 0,80 ... 1,20 VOL.%

EX-TEC® SR5, SR4, SR2, VARIOTEC® 8

23.10.1998

4.0 Meßbereich %LEL

4.1 zero point

- display -3 ... +3 %LEL or

- display -0,06 ... +0,06 VOL.%

4.2 test gas 59 %UEG = 1,00 VOL.% C3H8

- display 55 ... 64 %LEL or

- display 0,90 ... 1,10 VOL.%

4.3 optical alarm (e.g.: Y/ N)

4.4 audible alarm (e.g.: Y / N)

5.0 VOL.% measuring range

5.1 zero point

- display -2 ... +2 VOL.%

5.2 test gas 100 VOL.% C3H8

- display 98 ... 102 VOL.%

6.0 Observations

- housing broken

- adjustment, repair

- factory inspection

- or the like

7.0 Test

- day

- month

- year

- signature

52

Page 55

Hermann Sewerin GmbH

Robert-Bosch-Straße 3 · D-33334 Gütersloh

Telefon +49 - (0) - 52 41/9 34-0 · Telefax +49 - (0) - 52 41/9 34-4 44

http://www.sewerin.com

Loading...

Loading...