Page 1

SNOOPER mini

SNOOPER mini H

Page 2

Operating Instructions SNOOPER mini / SNOOPER mini H

1 Intended use ...........................................29

2 Device variants .......................................30

3 Safety instructions .................................31

4 Useful information about the device ....32

4.1 Structure – device and display .................32

4.2 Operating modes ......................................34

4.3 Measuring range ......................................34

4.4 Automatic power-off..................................35

4.5 Display illumination ...................................35

5 Measurement mode ................................36

5.1 How to start the measurement mode .......36

5.2 Increased gas concentration ....................38

5.3 Setting the zero point – when and how? ..38

5.4 Verifying the indication accuracy – when

and how? ..................................................39

English

6 Adjustment ..............................................40

6.1 Tools and requirements ............................40

6.2 How to perform the adjustment ................41

6.3 Adjustment error – what to do? ................44

7 Maintenance and cleaning .....................45

7.1 Overview ..................................................45

7.2 Sensor cap ...............................................46

7.3 Replacing the lter ....................................47

7.4 Changing the battery ................................48

8 Technical data .........................................49

9 Disposal and recycling instructions .....50

Appendix .................................................51

Used Symbols ..........................................51

Declaration of Conformity .........................52

27

Page 3

English

Warranty

To ensure reliable operation and safety, it is required to pay attention to the following notes.

Hermann Sewerin GmbH is not liable for damage caused by failure to comply with these notes. The guarantee

and liability conditions of the sales and delivery conditions of Hermann Sewerin GmbH are not extended

by the following notes.

z

The product may only be taken into operation after reading thoroughly the accompanying operating

instructions.

The product may only be used for intended applications. z

z

The product is destined for industrial and commercial applications.

z

Repairs may only be performed by the manufacturer or appropriately trained staff.

z

The manufacturer is not liable for damage resulting from arbitrary modications of the product.

z

Only spare parts may be used which are approved by Hermann Sewerin GmbH.

z

Only approved battery types may be used.

Technical changes within the scope of further development reserved.

28

Page 4

1 Intended use

SNOOPER mini is a gas detector for plumbers and service technicians for detecting leaks at free

laid gas pipes.

Fields of application (for example):

z

Detection of gas leaks by directly inspecting joints of: pipes, ttings, anges, threaded connections,

pressure reducers, etc.

z

Leak detection at openly routed natural gas pipelines in buildings

z

Inspection of covered gas pipelines at the gas discharge locations

z

Inspection at the house service tting

CAUTION! Danger of life!

SNOOPER mini must not be used as a gas warning instrument.

It is not suitable for checking whether the ambient air or the air inside pits and sewers

is approaching the lower explosion level (LEL).

English

29

Page 5

English

2 Device variants

The device is available in two different versions:

SNOOPER mini z > with exible swan neck

SNOOPER mini H z > with hand sensor (spiral cable, handle, exible swan neck)

Both device variants are operated the same way.

The device is available for the following types of gas: Methane CH

z

Propane C z

Hydrogen H z

4

3H8

2

Note:

The type of gas is indicated on the rear of the device. It is not possible to change it.

About these operating instructions: Texts and illustrations usually refer to the

SNOOPER mini

calibrated to methane. Generally, they also apply to the SNOOPER mini H and to the other gas types, propane and hydrogen.

30

Page 6

3 Safety instructions

Never open the housing (only exception: the battery compartment). Otherwise, all warranty claims z

expire.

z

The swan neck cannot be disassembled. It must not be bent in a sharp angle. The maximum

permissible angle is 90 degrees.

Never carry the device at the swan neck and/or the hand sensor! z

z

Prevent that the swan neck comes into contact with water. Water destroys the sensor!

English

31

Page 7

English

4 Useful information about the device

4.1 Structure – device and display SNOOPER mini SNOOPER mini H

Sensorcapwithlter

for protecting the gas-sensitive z

sensor

Swan neck

Display

Loudspeaker key

z

for switching on/off the audible signal

ON/OFF key

z

for switching on/off the device

z Hand sensor

for setting the zero point

Bar

z

for attaching the carrying loop

(alike SNOOPER mini)

32

Page 8

Display

Measured value or type of gas

Time bar

indicates the remaining time, e. g. of the z

heating period

Unit or status message

Loudspeaker icon (crossed out)

z

audible signal is switched off

Battery icon

z

currently available capacity of the

batteries (disposable or rechargeable);

the number of bars indicates the capacity

level

English

Abbreviations:

ADJ Adjust

APF Automatic power-off

BAT Battery

CAL Calibrate

CWT Calibration waiting time

ERR Error

HT Heating-up

PPM Unit of measurement (ppm)

VOL Unit of measurement

(vol. %)

ZRO Setting the zero point

33

Page 9

English

4.2 Operating modes

The device can be used in two different modes:

z > see chapter 5

Measurement

Adjustment z > see chapter 6

4.3 Measuring range

The device operates with a single measuring range, but two different units of measurement (parts per

million [ppm], percent by volume [vol.%]). The device automatically switches between the different

units of measurement.

Conversion: 10,000 ppm = 1 vol.%

Indication of

Limits Resolution

measurement values in

ppm 0 – 100 ppm 5 ppm

ppm > 100 – 2,000 ppm 50 ppm

percent by volume CH

, C3H8: > 2,000 – 22,000 ppm (0.2 – 2.2 vol.%) 0.2 vol.%

4

: > 2,000 – 10,000 ppm (0.2 – 1.0 vol.%)

H

2

34

Page 10

4.4 Automatic power-off SNOOPER mini switches itself off automatically,

assoonasthebatterychargeisnolongersufcient z . (BAT will be indicated briey on the display.)

The automatic power-off may also occur immediately after switching on the device! Exchange or

recharge batteries (see chapter 7.4).

z 20 minutes (i. e. no key is pressed) or if the display is not changing.

if the device is not operated for

(APF will be indicated briey on the display.)

4.5 Display illumination

The device automatically switches on the display illumination:

z key is pressed (duration of illumination 20 s),

if a

if the z gas concentration is higher than 25 ppm.

English

35

Page 11

English

5 Measurement mode

5.1 How to start the measurement mode

Note:

The device must always be switched on in an unpolluted environment (e. g. in the

fresh air).

36

What to do? What happens? Why?

1.

press for approx. 2 s

2. wait Display ashes,

Device is switched on,

audible signal sounds

time bar runs out

Heating period,

approx. 20 s

Indication on

the display

Page 12

3. Device ready for

measuring

Note:

After switching on, the device needs one minute to recognise whether it is operated with

disposable or rechargeable batteries. After this check, the battery icon is indicated.

English

37

Page 13

English

5.2 Increased gas concentration

An automatic audio signal makes the user always aware of an increased gas concentration.

Audible signal of the device (loudspeaker key)

switched on:

z the interval signal gradually changes to a steady tone

z steady tone sounds as soon as the device measures a value higher than 1 vol.%

switched off:

5.3 Setting the zero point – when and how?

When working with the SNOOPER mini, the zero point may start to drift (e. g. if the device is ready

for measuring and put aside for some time). In this case, the display indicates a value deviating from

zero.

z brieyon the ON/OFF key. ZRO is indicated on the display. The device is ready to reset

Press

the zero point.

z brieyon the ON/OFF key within 5 seconds. The zero point is reset.

Re-press

38

Page 14

5.4 Verifying the indication accuracy – when and how?

According to DVGW regulations (DVGW: German technical and scientic association for gas and

water), it is required to check the indication accuracy in intervals ranging from every week to every

six months – depending on the frequency of usage and experience.

Gas type of the device Test gas Permissible range

Methane 1 vol.% CH

Propane 1 vol.% C

4

0.8 – 1.4 vol.%

3H8

Hydrogen 1,000 ppm H2800 – 1,400 ppm

The device must be ready for measuring (see chapter 5.1). z

Apply test gas with the help of a suitable test set (e. g. SPE-Y). z

z

Compare the deviations indicated by the device with the permissible values in the table. If the values

are outside the permissible range, you need to perform an adjustment (see chapter 6).

English

39

Page 15

English

6 Adjustment

The device must be adjusted if the deviation of the indication accuracy is outside the permissible

range (see chapter 5.4).

6.1 Tools and requirements

Required tools:

Suitable test set (e. g. SPE HG, SPE-Y) z

z

Test head

z

Test gas, depending on the type of gas of the relevant device (see table in chapter 5.4)

You can nd all information on how to connect the test set to the device in the operating instructions

of the test set.

Requirements for a proper adjustment:

z

Device is switched off

z

Test head is not yet attached

Atmosphere of the environment is not polluted (e. g. fresh air) z

40

Page 16

6.2 How to perform the adjustment What to do? What happens? Why? Indication on

Prepare adjustment

1.

keep pressed and press

at the same time

2. wait Time bar runs out Heating period,

3. Device is ready for

…

English

Device is switched on,

audible signal sounds

approx. 60 s

adjustment

the display

41

Page 17

English

What to do? What happens? Why? Indication on

4. apply test gas

Start adjustment

5.

press briey

6. wait Time bar runs out Calibration waiting

time

7. Adjustment starts au-

tomatically

8. Brief audible signal

sounds

Adjustment completed

the display

42

Page 18

What to do? What happens? Why? Indication on

Adjustment error

Briey: audible signal

(amplitude variation)

and error indicated on

the display

Quit adjustment mode (two options)

A)

press for approx. 2 s

B)

press briey

English

Device is switched off

Device in

measurement mode

the display

followed by:

ADJ

43

Page 19

English

6.3 Adjustment error – what to do?

If error 001 ERR occurs (refer to description in chapter 6.2), the device was not able to perform a

proper adjustment.

z

Repeat the adjustment.

z

If the error is indicated again, get in touch with the manufacturer.

44

Page 20

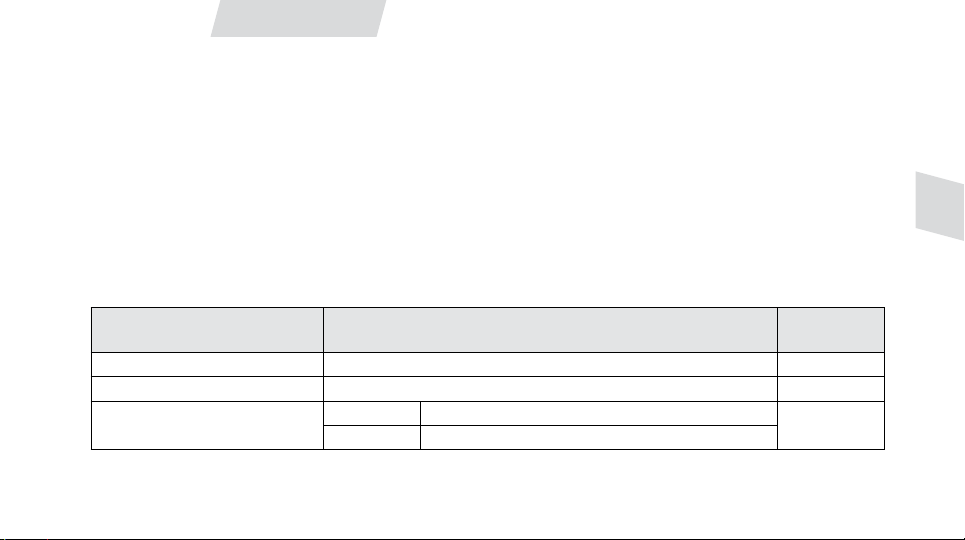

7 Maintenance and cleaning

7.1 Overview

Maintenance and cleaning of the SNOOPER mini should cover the following points:

What? How? Who is reMaintenance --- authorized

Checking the indication

accuracy

Adjustment

Cleaning wipe with damp cloth user when required

Sensor cap

Filter replacement

Changing the battery/accu

English

see chapter 5.4 user every week to every six

see chapter 6 user if the deviation of the indication

see chapter 7.2 user when required

see chapter 7.3 user when required

see chapter 7.4 user when required

sponsible?

company

How often?

Once a year

months (acc. to DVGW)

accuracy is no longer within

the permissible range

45

Page 21

English

7.2 Sensor cap

The sensor cap is detachable. The sensor housing can be seen after removing the cap.

CAUTION! Sensitive sensor!

Avoid touching the sensor. Never try to remove the sensor. The sensor must never

come into contact with water!

If the sensor cap is soiled, you must replace or clean the cap.

Cleaning

Unscrew the sensor cap and remove the lter (see chapter 7.3).

z

z

Clean the sensor cap thoroughly with a commercially available detergent.

z

Dry the cap until any residual moisture is removed.

z

Place a new lter loosely into the sensor cap.

z

Screw the sensor cap on the swan neck. The lter will be pressed into the correct position.

46

Page 22

7.3 Replacingthelter

The sensor cap contains a lter. The lter must be exchanged, if you detect any soil.

z

Unscrew the sensor cap.

Push the soiled lter from above out of the sensor cap, using a suitable tool (e. g. a small z

screwdriver).

Place a new lter loosely into the sensor cap. z

z

Screw the sensor cap on the swan neck. The lter will be pressed into the correct position.

English

47

Page 23

English

7.4 Changing the battery

The battery compartment is locked by a quick-release lock (1/4 of a turn). It can be opened with the

help of a suitable tool (e. g. a coin or screwdriver).

CAUTION!

Pay attention to the correct polarity when inserting the two batteries.

48

Page 24

8 Technical data

Operating time: min. 8 h

Power supply: 2 rechargeable NiMH accumulators (each with min. 1600 mAh)

or

2 alkaline AA batteries

Protection: IP54

Operating temperature: -10 °C … +60 °C

Storage temperature: -25 °C … +70 °C

Air pressure: 950 hPa … 1100 hPa

Humidity:

Dimensions: 50 × 150 × 30 mm (W × H × D)

Weight: approx. 130 g

English

15 % RH … 90 % RH (non-condensing)

49

Page 25

English

9 Disposal and recycling instructions

The disposal of instruments and accessories is governed by the European Waste Catalogue

(EWC).

Type of Waste Corresponding EWC Code

Instrument 16 02 13

Test gas can 16 05 05

Battery, Accu 16 06 05

Old Instruments

Old instruments can be returned to Hermann Sewerin GmbH. We will arrange the qualied disposal

free of charge through certied specialists.

50

Page 26

Used symbols:

CAUTION!

This symbol is used to indicate dangers which may either result in hazards for the operators or in severe damage – or even destruction – of the product.

Note:

This symbol is used to call attention to information and tips which may be helpful and

which are exceeding the basic operating procedures.

51

English

Page 27

English

EC Declaration of Conformity

Product:

SNOOPER mini

Intended use: Handheld battery-powered gas measuring device

Manufacturer: Hermann Sewerin GmbH

Address: Robert-Bosch-Str. 3

33334 Gütersloh - Germany

The product complies with the following directives:

2004/108/EC

Electromagnetic compatibility

For evaluation of conformity the following harmonised standards apply:

EN 61000-6-1

EN 61000-6-2

EN 61000-6-3

EN 61000-6-4

Gütersloh, 2008-08-15

Dr. S. Sewerin

(General Manager)

ke_snooper_mini_08-08-15_en.doc

52

Page 28

Hermann Sewerin GmbH

Robert-Bosch-Straße 3 · 33334 Gütersloh · Germany

Telefon +49 5241 934-0 · Telefax +49 5241 934-444

www.sewerin.com · info@sewerin.com

15.08.2008 – 104171 – de, en, fr, es, it

Loading...

Loading...