Page 1

Operating

Instructions

Page 2

Measurable success by Sewerin equipment

Congratulations. You have chosen a quality instrument manufactured

by Hermann Sewerin GmbH.

Our equipment will provide you with the highest standards of perfor-

mance, safety and efciency. They correspond with the national and

international guide-lines.

Please read and understand the following operating instructions before

using the equipment; they will help you to use the instrument quickly and

competently. If you have any queries we are available to offer advice

and assistance at any time.

Yours

Hermann Sewerin GmbH

Robert-Bosch-Straße 3

33334 Gütersloh, Germany

Tel.: +49 5241 934-0

Fax: +49 5241 934-444

www.sewerin.com

info@sewerin.com

Sewerin Ltd

Hertfordshire

UK

Phone: +44 1462-634363

www.sewerin.co.uk

info@sewerin.co.uk

Sewerin USA, LLC

13551 W. 43rd Drive, Unit R

Golden, CO 80403-7272

Phone: +1 303-424-3611

Fax: +1 303-420-0033

www.sewerin.net

jerry.palmer@sewerin.net

SEWERIN Sarl

17, rue Ampère - BP 211

67727 HOERDT CEDEX, France

Tél. : +33 3 88 68 15 15

Fax : +33 3 88 68 11 77

www.sewerin.fr

sewerin@sewerin.fr

SEWERIN IBERIA S.L.

c/ Cañada Real de Merinas, 17

Centro de Negocios „Eisenhower“

Edicio 5; Planta 2 - C

28042 Madrid, España

Tel.: +34 91 74807-57

Fax: +34 91 74807-58

www.sewerin.es

info@sewerin.es

Page 3

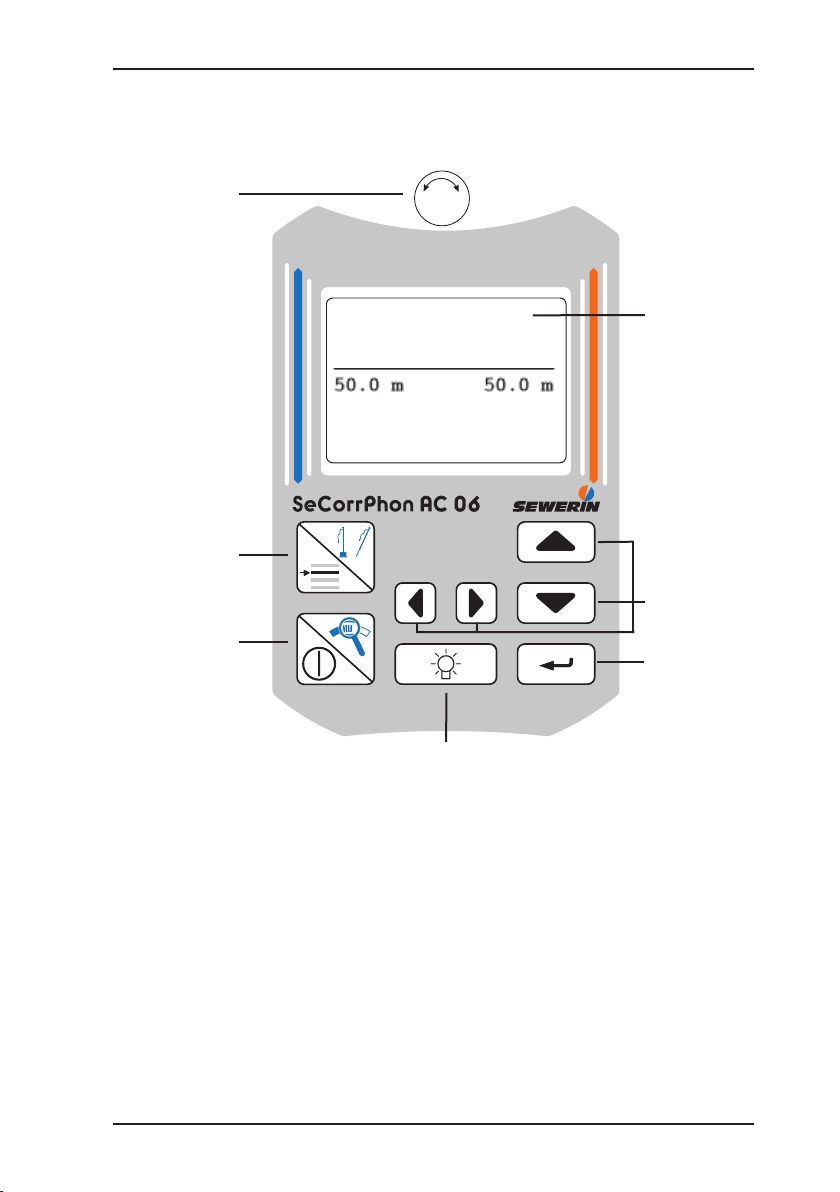

Illustration SeCorrPhon AC 06

Mikrophone

key/

Menu key

Magnifying-

glass key/

ON/OFF key

Light key

Central

screen

Arrow keys

Enter key

Rotary

regulator

pipe data

start

continue

Page 4

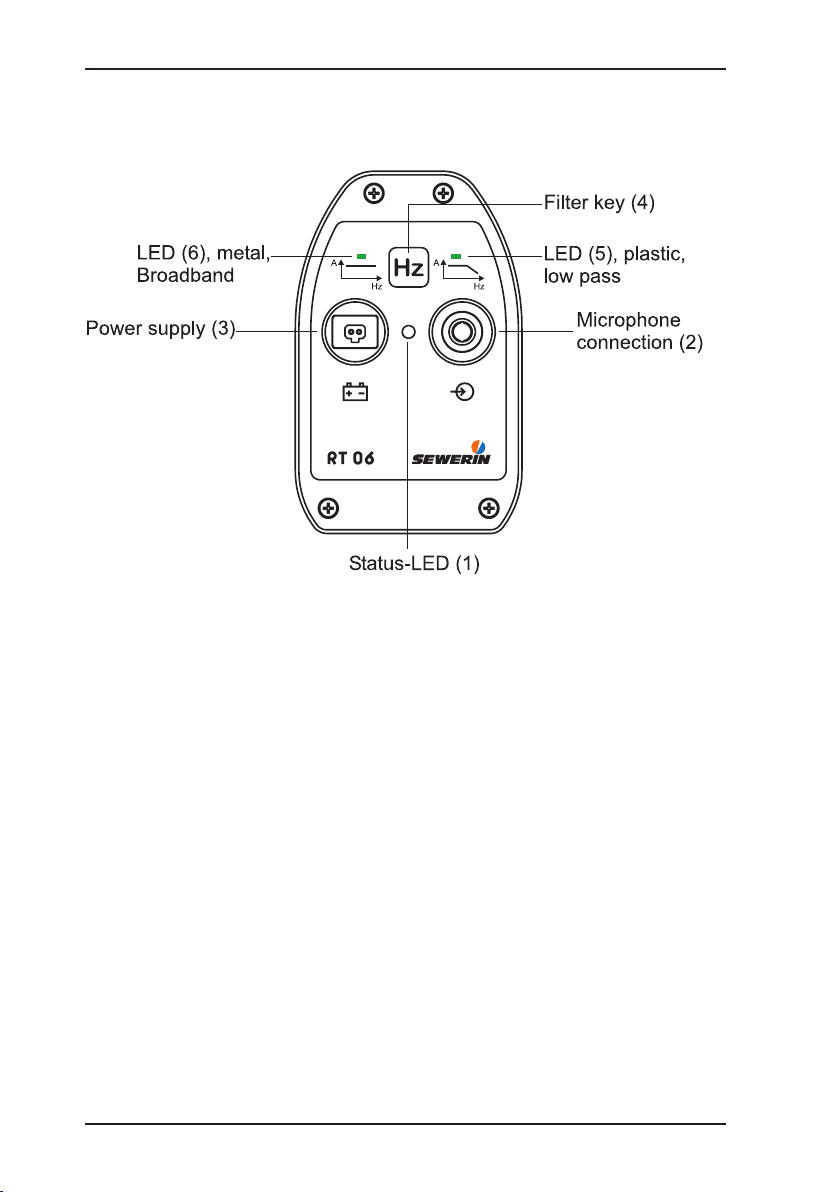

Illustration RT 06

Page 5

Operating Instructions

01.06.2007 – V 1.X – 105723 – en-us

SeCorrPhon AC 06

Page 6

Warranty & Used symbols

To ensure reliable operation and safety, it is required to pay attention to

the following notes.

Hermann Sewerin GmbH is not liable for damage caused by failure to

comply with these notes. The guarantee and liability conditions of the sales

and delivery conditions of Hermann Sewerin GmbH are not extended by

the following notes.

This product may only be taken into operation after reading thoroughly

the accompanying operating instructions.

This product may only be used for intended applications.

This product is destined for industrial and commercial applications.

Repairs may only be performed by the manufacturer or appropriately

trained staff.

The manufacturer is not liable for damage resulting from arbitrary modications of the product.

Only spare parts may be used which are approved by Hermann Sewerin

GmbH.

Only approved battery types may be used.

Technical changes within the scope of further development reserved.

Used symbols:

CAUTION!

This symbol is used to indicate dangers which may

either result in hazards for the operators or in severe

damage – or even destruction – of the product.

Note:

This symbol is used to call attention to information

and tips which may be helpful and which are exceeding the basic operating procedures.

Page 7

I

Contents Page

1 Functional description ............................................................1

1.1 Use ............................................................................................1

1.2 How electroacoustic water leak detection works .......................1

1.3 How acoustic pipeline detection works .....................................1

1.4 How correlation works ...............................................................2

2 Starting up ............................................................................... 3

2.1 Starting up for the rst time .......................................................3

2.2 Switching on and off for electroacoustic water leak detection ........4

2.3 Switching on for correlation .......................................................5

2.3.1 Channel allocation ..................................................................6

2.3.2 Radio transmitter RT 06 .........................................................7

3 Controls ...................................................................................8

3.1 ON/OFF key/Magnifying-glass key ...........................................8

3.2 Rotary regulator ........................................................................9

3.3 Enter key .................................................................................10

3.4 Microphone key/Menu key ...................................................... 10

3.5 Left/right arrow keys ................................................................10

3.6 Up/down arrow keys ................................................................ 11

3.7 Light key ..................................................................................11

3.8 Adjusting the contrast ............................................................. 11

4 Electroacoustic water leak detection ..................................12

4.1 Display ....................................................................................12

4.1.1 Analog display ......................................................................12

4.1.2 Digital display .......................................................................12

4.1.3 Small digital display ..............................................................12

4.1.4 Loudspeaker symbol ............................................................12

4.2 Menu ....................................................................................... 13

4.2.1 Filter ..................................................................................... 13

4.2.2 Hearing protection ................................................................14

4.2.3 “MAX” mode ........................................................................15

4.2.4 Default values ......................................................................15

4.2.5 Measuring mode ..................................................................15

4.3 Probe overview .......................................................................16

4.3.1 Ground microphone BO-4 ....................................................16

4.3.2 Ground microphone 3P-4 .....................................................16

Page 8

II

Contents Page

4.3.3 Carrying rod H-4 ...................................................................16

4.3.4 Test rod T-4 ..........................................................................17

4.3.5 Piezo microphone EM 30 .....................................................17

4.4 Preliminary detection ...............................................................18

4.5 Locating leaks ......................................................................... 21

5 Performing a correlation measurement ..............................23

5.1 Entering pipe data ..................................................................23

5.2 Starting a measurement ..........................................................24

5.3 Analyzing results .....................................................................25

5.3.1 Filtering ................................................................................26

5.3.2 Cursor ..................................................................................26

5.3.3 Zoom ....................................................................................27

5.4 Continuing a measurement .....................................................28

6 Measuring the sound velocity .............................................29

6.1 General ...................................................................................29

6.2 Performing a measurement .....................................................29

7 Charging equipment ............................................................. 31

7.1 Battery condition .....................................................................32

7.2 Charging / battery maintenance ................................................33

8 Menu (in correlator mode) ....................................................34

8.1 Menu structure ........................................................................ 34

8.2 Listening ..................................................................................35

8.3 File ..........................................................................................35

8.3.1 Saving .................................................................................. 35

8.3.2 Opening ................................................................................36

8.3.3 Deleting ................................................................................37

8.4 Filtering ...................................................................................37

8.4.1 Automatic ltering .................................................................37

8.4.2 Manual ltering .....................................................................37

8.4.3 Setup ....................................................................................40

8.4.3.1 Frequency analysis ........................................................... 40

8.4.3.2 Filter limits .........................................................................40

8.4.3.3 Filter basis .........................................................................41

8.4.3.4 Filtering method ................................................................41

Page 9

III

Contents Page

8.5 Measuring method ..................................................................41

8.6 Measuring parameters ............................................................ 41

8.6.1 Noise suppression ................................................................41

8.6.2 Measuring time .....................................................................43

8.6.3 Summation / Averaging ..........................................................43

8.6.4 Mode of curve ......................................................................43

8.6.5 Type of correlation ................................................................ 44

8.6.6 Sampling frequency .............................................................44

8.6.7 Table ..................................................................................... 45

8.6.8 Default values ......................................................................46

8.7 Components ............................................................................46

8.8 Setup .......................................................................................47

8.8.1 Date, time .............................................................................47

8.8.2 Language ............................................................................. 47

8.8.3 Radio / cable .......................................................................... 48

8.8.4 System ................................................................................. 48

8.8.5 Name ....................................................................................48

8.8.6 Service ................................................................................. 48

9 Options for optimizing measurement results .....................49

9.1 Changing the number of averaging procedures ......................49

9.2 Using lters .............................................................................49

9.3 Automatic ltering ....................................................................50

9.4 Checking the microphone connection .....................................50

9.5 Using accessories ...................................................................50

9.6 Changing location ...................................................................50

9.7 Saving time .............................................................................50

10 Communication with the PC ................................................51

10.1 Requirements ..........................................................................51

10.2 Installing the software and establishing a connection .............51

11 Technical information ...........................................................53

12 Accessories ...........................................................................54

12.1 Accessories for electroacoustic water leak detection .............. 55

13 Error messages .....................................................................56

Page 10

IV

Contents Page

14 Hints on Disposal ..................................................................58

Appendix ..............................................................................................59

EC Declaration of Conformity ................................................................59

Index ......................................................................................................60

Page 11

1

1 Functional descriptionFunctional description

1 Functional description

1.1 Use

The SeCorrPhon AC 06 is used for electroacoustic water leak

detection and acoustic pipeline location. It can also detect leaks

in underground pressure line systems by correlation.

CAUTION!

To comply with FCC RF exposure compliance requirements, a separation distance of at least 20 cm

must be maintained between the antenna of the

transmitter RT 06 and all persons.

The antenna used for this transmitter must not be

co-located or operating in conjunction with any other

antenna or transmitter.

1.2 How electroacoustic water leak detection works

The SeCorrPhon AC 06 is used to detect water leaks by

electroacoustic means. The device is used in conjunction with

various microphones which are listed in section “Accessories”.

When pressure pipelines leak, water gushes out of the crack into

the ground.

The consequences:

The pipe material begins to vibrate at the leakage point. These

vibrations are transmitted by the pipe and can even be felt at

distant contact points, e.g. ttings. The SeCorrPhon AC 06 makes

this structure-borne sound audible.

The water jet and the pipe in the vicinity of the leak also cause

the ground to vibrate. These vibrations are transmitted through

the ground to the earth’s surface where they manifest themselves

as ground noise.

The human ear continues to play a crucial role in electroacoustic

leak detection. With the right training, it can compare the type and

sound of different noises and distinguish between the noise of a

leak and background noise.

Page 12

2

1 Functional descriptionFunctional description

1.3 How acoustic pipeline detection works

Plastic pipes cannot be located by conventional electromagnetic

means because they are not electroconductive.

The acoustic method of locating pipes applies a different principle:

Pipes transmit mechanical vibrations better than the surrounding

ground. When the pipe is caused to vibrate appropriately, these

vibrations are transmitted along the pipe and then through the

ground to the earth’s surface. Here they can be picked up using

a ground microphone and the corresponding receiver with

headphones according to the water leak detection principle.

Just like with water leak detection, the pipeline is usually wherever

the greatest intensity is detected. Fiber cement pipes and metal

pipes can also be located in this way.

If you want to locate pipes by acoustic means, follow the operating

instructions for the vibration detector (e.g. COMBIPHON). To

locate the pipe, proceed as you would when detecting a water

leak. The SeCorrPhon AC 06 offers an extra mode to help you

locate the pipeline (see section 3.4).

1.4 How correlation works

Sensitive microphones record the noise from leaks at accessible

ttings and transmit them by radio to the correlator.

The SeCorrPhon AC 06 then calculates the position of the

leak using Fast Fourier Transformation (FFT = mathematical

calculation rule).

Additional functions allow you to, for example, improve the leak display,

enter several sections of pipe or measure the sound velocity.

Radio transmitter RT 06 can automatically measure the input level

of the microphone and optimally adjust its amplier modulation

accordingly. Features such as the microphone used, the battery

condition and the amplier setting are transmitted to the correlator

by radio data where they are analyzed. This ensures optimal results

in all situations with maximum ease of use (switch on by plugging in

the microphone).

Note:

These operating instructions refer to the SeCorrPhon

AC 06. They explain the functions of software

version 1.X. The manufacturer reserves the right

to make technical changes..

Page 13

3

2 Starting upStarting up

2 Starting up

2.1 Starting up for the rst time

CAUTION!

The batteries of the AC 06 and RT 06 must be fully

charged once before starting up for the rst time.

If the batteries are only partially charged, their capacity and consequently their operating time may

be reduced.

CAUTION!

Safety measures

Do not use the headphones at a high volume.

Hearing specialists warn against using headphones at a high volume constantly or for a prolonged period.

Set the volume so that you only hear the sounds

at a moderate level.

Disable the headphones as soon as you realize

that interference noise may occur (footsteps,

vehicles etc.).

Disable the headphones when the microphone

is in motion.

Please note that it is more difcult to pick up

sounds in trafc.

Page 14

4

2 Starting upStarting up

2.2 Switching on and off for electroacoustic water leak detectionSwitching on and off for electroacoustic water leak detection

If you switch the device on as follows, you will be in what is known

as AQUAPHON mode. Certain functions are only possible in this

mode.

Place a probe in the appropriate input

The software version will appear in the display

The condition of the batteries

will appear in the display

Th e type of probe that is

plugged in is recognized automatically

Remove the probe to switch

off the systemstem

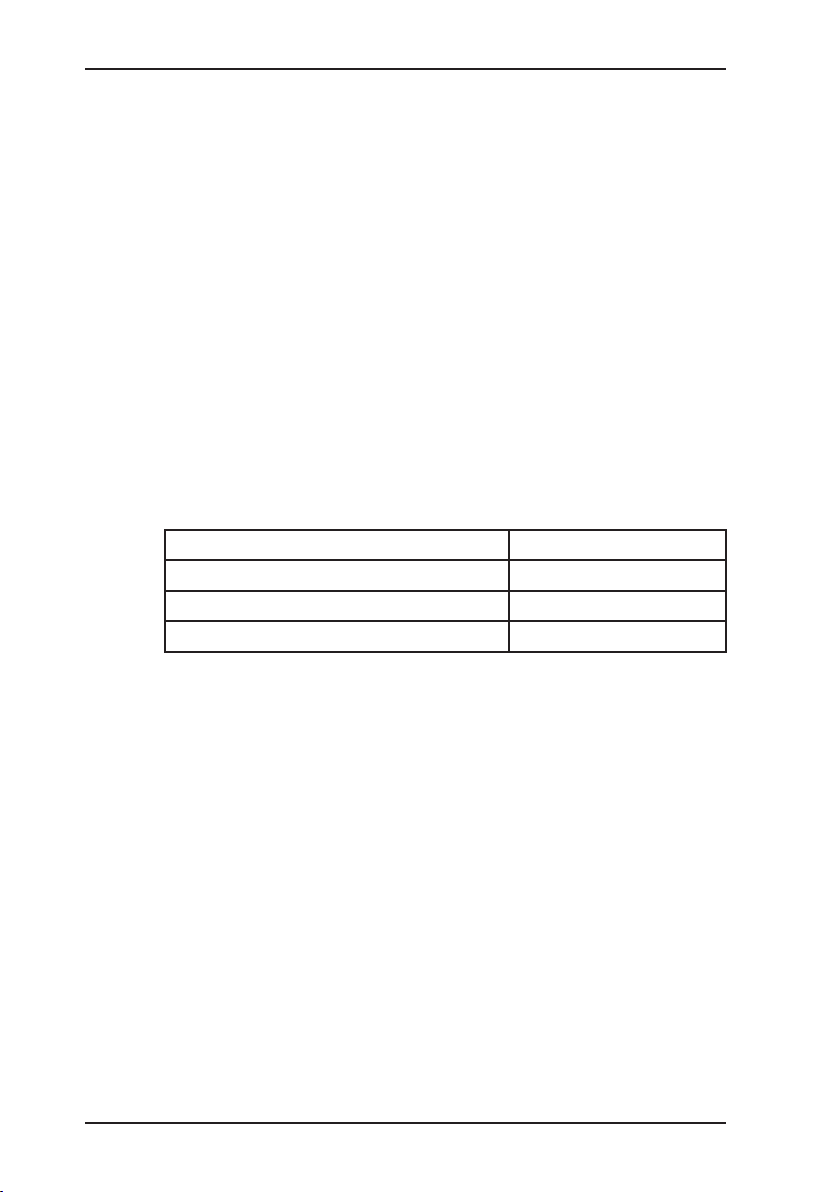

Type of microphone Display

Ground microphone BO-4 and 3P-4 BO-4 / 3P-4

Test rod T-4 T-4

Piezo microphone EM 30 M 01

Page 15

5

2 Starting upStarting up

2.3 Switching on for correlation

If you switch the device on as follows, you will be in what is known

as correlator mode. Certain functions are only possible in this

mode, others are not available.

Attach the two piezo microphones to accessible ttings.

When the round magnet is

screwed onto the piezo microphone, remove the very securely attached round magnet

protector if necessary.

Insert the two microphone connection cables into the sockets

of the RT 06 radio transmitters

(1). If you are only using one

RT 06, you must connect one

microphone directly to the

input (2) of the AC 06.

LED 1 on the RT 06 should

light up green.

Connect the headphones to

the input (3) of the AC 06.

Switch on the AC 06 by holding down the ON key.

The main screen displaying

the software version number

and the battery capacity will

briey appear.

Next the main screen (see

inside cover). From here you

can go to the menu (menu

key) or perform one of the

functions.

To switch the appliance off,

hold down the ON key until it

responds.

1

3

2

Page 16

6

2 Starting upStarting up

2.3.1 Channel allocation

Channel 1 Channel 2

Denotes „Battery

empty“ message

RT 06-1 RT 06-2

Display Left Right

Model with one

radio channel

Direct microphone

connection to the

AC 06

Orange radio

transmitter 22

Model with two radio channels

Blue radio

transmitter 1

Orange radio

transmitter 2

Only one radio

transmitter in use

(e.g. if faulty):

Version 1

(blue radio

transmitter in use)

Blue radio

transmitter 1

Direct microphone

connection to the

AC 06

Version 2

(orange radio

transmitter in use)

Direct microphone

connection to the

AC 06

Orange radio

transmitter 2

The noise intensity of the two

microphone channels is displayed to the left and right of

the correlation function during

the correlation measurement.

Note:

Note!

A microphone can also be connected directly to

an AC 06 model with two radio transmitters, e.g. if

one of the radio transmitters is faulty (see section

8.8.3).

started

Page 17

7

2 Starting upStarting up

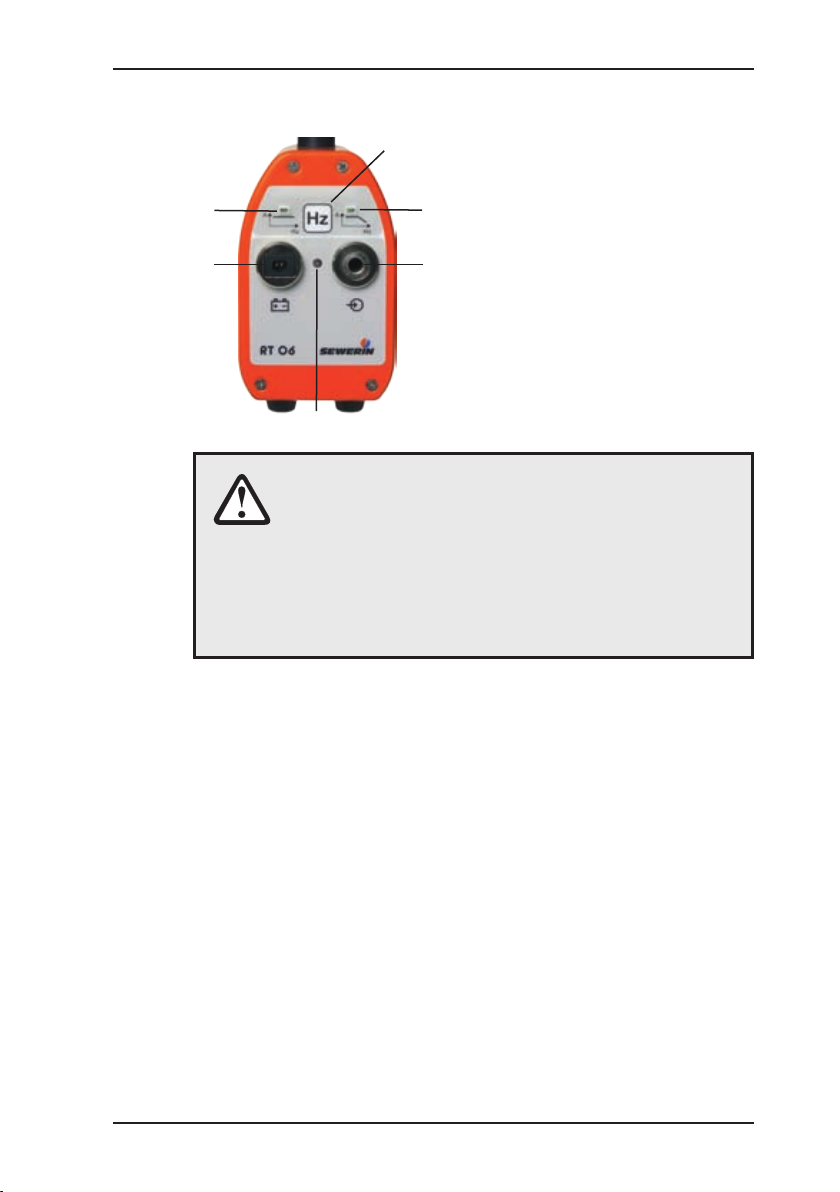

2.3.2 Radio transmitter RT 06

Radio transmitter RT 06 can

be operated with various sen-

sors, EM30 microphones and

the HA hydrophone. It is recommended to use active lter

ZF01 if you want to lter out

interference noise or if you

only want to transmit a certain

acoustic frequency range to

correlator AC 06.

CAUTION!

Always connect the sensor to the measuring point

rst (connect microphone to slide gate, hydrants

etc.) before switching on the RT 06 by plugging the

sensor into the socket (2).

This ensures that the automatic amplication in the

RT 06 is set quickly and correctly.

The RT 06 is switched on by plugging the sensor into the socket

(2).

Always press the lter key (4) for plastic piping. The right LED

(5) lights up to indicate the switch. At this setting only the lower

frequencies (low pass) are transmitted to the correlator by radio.

This often increases the quality of the correlation measurement.

Every time the RT 06 is switched on all frequencies are transmitted and the left LED (6) lights up.

The carrying knob attached to the top of the aerial is ideal for

transportation.

The LED (1) indicates the status of the RT 06:

Operation: green

Undervoltage: ashing red

Charging: 1 x ashing green

Buffering: 2 x ashing green

Not charging: red (because temperature below 0 °C)

1

2

3

6

5

4

Page 18

8

3 Controls

3 Controls

3.1 ON / OFF key / Magnifying-glass key

In correlator mode this key is

the ON/OFF key.

To switch on and off, hold

the key down until the AC 06

responds.

Pressing the key briey stops

the current function (e.g. ongoing correlation). If you are in

the menu, you can move up

a level by briey pressing the

ON key.

If you stop a correlation, you

can enlarge the image (correlation function). Press any key

to return to the normal view.

In AQUAPHON mode this key is

the magnifying-glass key.

The magnifying-glass key

sets the basic amplication.

10 = high noise amplication

100 = average noise ampli-

cation

1000 = low noise amplication

Basic amplication is useful for

adapting to extreme situations.

The higher the basic amplication, the louder the noise in the

headphones.

Page 19

9

3 Controls

The scale for the analog display

is also set. Change the basic

amplication when the analog

display is constantly in the bottom/top range.

If the basic amplication is too

high, the analog display scale

will ash.

3.2 Rotary regulator

The rotary regulator serves the

following functions in correlator

mode:

Turning the regulator moves

the selection or the cursor to

the left/right or up/down.

In input fields with numeric

values (e.g. for entering the

pipe length), you can change

the value directly by turning

the knob.

Pressing the rotary regulator switches the direction of

movement between up/down

and left/right. Pressing the

rotary regulator has the same

effect as the Enter key.

In AQUAPHON mode the enter

key is only used to set the volume

and for activation/deactivation.

Page 20

10

3 Controls

3.3 Enter key

Pressing the Enter key performs the function that is currently selected. Selecting the

“cancel” function in the menu

takes you back to the main

screen.

3.4 Microphone key / Menu key

In correlator mode this key is

the menu key.

Pressing the menu key brings

up the menu.

In AQUAPHON mode this key

is the microphone key.

Pressing the microphone key

activates the AC 06. Pressing it again deactivates the

AC 06.

3.5 Left / right arrow keys

Pressing the ar row keys

takes you through the functions to the left and right. You

can also make a selection in

some menus.

When you are in a menu, you

can move up a level with the

“left” arrow key, albeit only

when no left or right cursor

movement is possible at the

respective position.

Page 21

11

3 Controls

3.6 Up / down arrow keys

Pressing the ar row keys

takes you up and down within

the menus. You can also make

a selection in some menus.

3.7 Light key

Pressing the light key illumi-

nates the display. The light

remains on for a short time

before going off automatically.

(see section 8.8.4).

3.8 Adjusting the contrast

The display contrast is automatically controlled according

to the temperature.

You can adjust the contrast

manually by holding down the

light key and then pressing

the arrow key up or down.

Page 22

12

4 Electroacoustic water leak detectionElectroacoustic water leak detection

4 Electroacoustic water leak detection

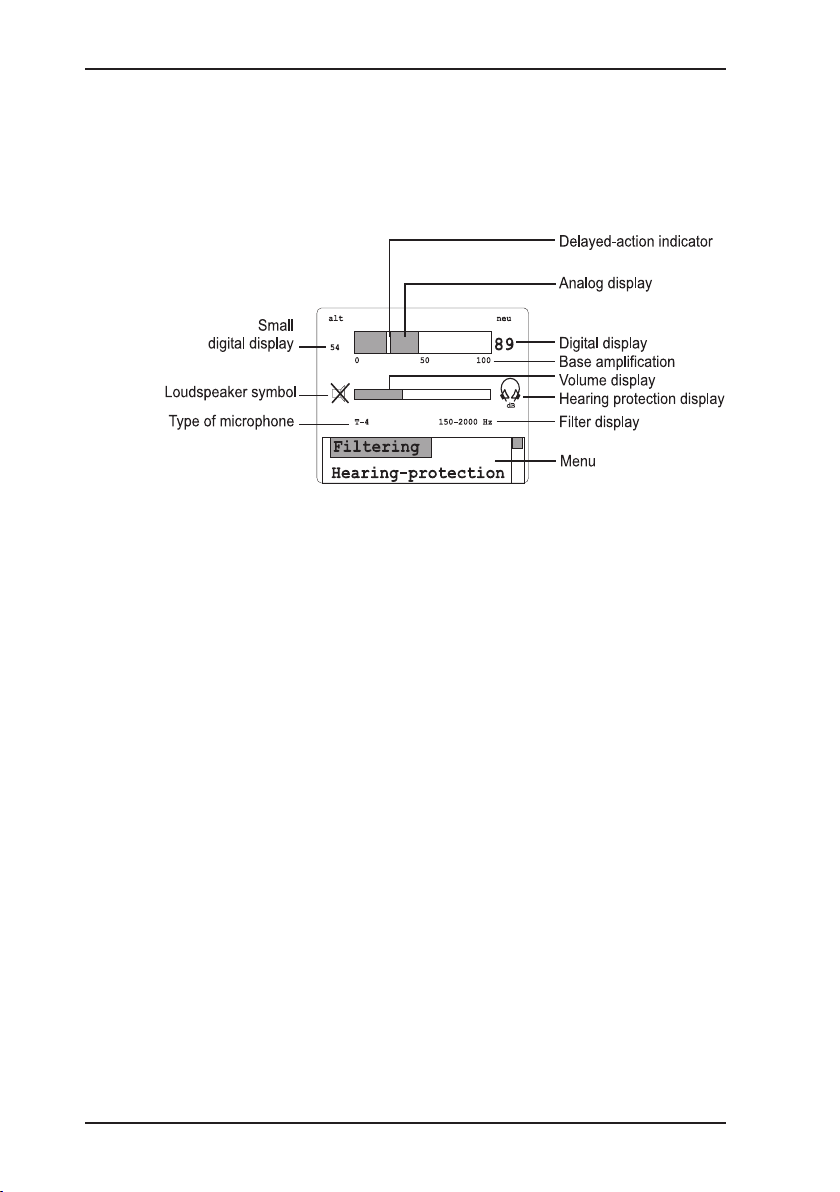

4.1 Display

The display contains the following display elements:

4.1.1 Analog display

The analog display shows the current measurement value.

(See also section 3.1).

4.1.2 Digital display

The digital display (new) - depending on the rmware language -

displays the smallest measured value during a single measurement.

In “MAX“ mode, the digital display always shows the highest

measured value.

4.1.3 Small digital display

The small digital display (old) always shows the previously measured value for comparison purposes.

4.1.4 Loudspeaker symbol

The loudspeaker symbol shows that the headphones of the AC 06

are activated.

Page 23

13

4 Electroacoustic water leak detectionElectroacoustic water leak detection

4.2 Menu

4.2.1 Filter

The frequency lter setting can be changed in the lter menu.

The band pass of the lter can be adjusted from 1 Hz to 9950

Hz; it is at least 300 Hz wide.

Leak noises have different ranges in which they can be heard

particularly well. Even the same sound is perceived differently by

different people. A band pass can be set to optimize the acoustic

perception. This means that only one particular frequency range

will be relayed to the headphones. You can either nd the best

setting yourself by trial and error or the AC 06 can search for it

automatically.

Automatic search for the best frequency range

With the lter optimization function the AC 06 can automatically

search for the best frequency range provided this is done when

there is little background noise interference. Furthermore, the

noise from the leak, in particular the ground noise, should already

be discernible.

Automatic

The AC 06 records and analyzes a “noise sample”.

The display will show various frequency ranges during the

analysis process. You will also hear on the headphones the

noise produced from the displayed lter values.

The AC 06 sets the frequency range which distinguishes the

leak particularly vividly.

Default

Here you can reset the default band pass setting (factory set-

ting) for the probe that is currently plugged in. The band pass

setting for other probes will not be reset.

Page 24

14

4 Electroacoustic water leak detectionElectroacoustic water leak detection

4.2.2 Hearing protection

The AC 06 features a hearing protection function which reduces

the volume of the headphones in case of sudden, loud noises. If

the noise gets even louder, the headphones will be switched off.

Once the source of the noise goes quiet, the AC 06 recommences

its work. The hearing protection function prevents the ears from

being exposed to excessive acoustic pressure.

This headphones symbol appears when the hearing protection function is activated.

Sensitive

The hearing protection function activates at a low (quiet) threshold.

Average

The hearing protection function activates at a moderate threshold

(default setting).

Insensitive

The hearing protection function activates at a high (loud) threshold.

CAUTION!

Only use SEWERIN headphones, as these are

specially designed for the AC 06.

Note:

The hearing protection function should only be set

to “sensitive” for quiet ambient sounds so that it

activates with moderate noise. In situations where

loud ambient noise is common, the threshold should

be set to “average”. In exceptional circumstances

the threshold can be set to “insensitive”. The hear-

ing protection function is only activated at very loud

noise values. To prevent the hearing protection

function from activating very frequently and thus

making leak detection more difcult, the headphone

volume and the basic amplication should not be

set too high!

Page 25

15

4 Electroacoustic water leak detectionElectroacoustic water leak detection

4.2.3 “MAX” mode

This mode helps detect pipelines by acoustic means. Instead

of showing the minimum values, this mode always shows the

maximum values.

“MAX” appears in the display when this mode is activated. The

mode is not saved.

4.2.4 Default values

This function restores (resets) all the default settings (factory settings) of AQUAPHON mode.

4.2.5 Measuring mode

This setting determines how the rotary regulator activates/deactivates a measurement or the headphones.

1 x press

The measurement is activated by briey pressing the rotary regulator and will remain active for as long as the rotary regulator is

pressed down. The measurement is deactivated when the rotary

regulator is released. This key principle is the default setting.

2 x press

The measurement is activated by briey pressing the rotary regulator. The measurement is only deactivated when you press the

rotary regulator again (switch principle).

Page 26

16

4 Electroacoustic water leak detectionElectroacoustic water leak detection

4.3 Probe overview

4.3.1 Ground microphone BO-4

Ground microphone BO-4 is

used to locate leaks under xed

surfaces.

4.3.2 Ground microphone 3P-4

Ground microphone 3P-4 is used

to locate leaks under non-xed

earth surfaces. A spike can be

screwed on for soft ground. The

three feet provide stable contact

at all times.

4.3.3 Carrying rod H-4

The carrying rod can be used

with both ground microphones.

Microphone BO-4 or 3P-4 is

screwed onto the bottom end of

the carrying rod.

Page 27

17

4 Electroacoustic water leak detectionElectroacoustic water leak detection

4.3.4 Test rod T-4

The test rod is used in the preliminary detection of leaks. The

test rod is attached to ttings on

the pipe that is under examination.

4.3.5 Piezo microphone EM 30

The piezo microphone is used

for preliminary detection and for

detection mainly in buildings.

Thanks to the screw-on M 10 tripod, it can be used for oors and

for ttings and sections of piping

with the straight probe.

Page 28

18

4 Electroacoustic water leak detectionElectroacoustic water leak detection

4.4 Preliminary detection

Metal pipe materials transmit

structure-borne sound over a

particularly wide area. The test

rod can therefore be used very

effectively for pre-detection.

Connect the headphones to

the AC 06.

Connect the test rod to the

AC 06.

Place the test rod at the rst

measurement location.

Activate the AC 06 with the

rotary regulator or the micro-

phone key.

During the measurement the

loudspeaker symbol is not

crossed out in the display.

The analog display shows

the current volume measurement.

The n oise can be hea r d

through the headphones.

During this measurement, the

large digital display shows the

smallest value measured.

During this measurement, the

small digital display shows

the smallest value measured

during the last measurement.

(This value is 0 during the rst

measurement.)

During this meas ure men t

th e an alog disp lay shows

the smallest measured value

inverted.

Page 29

19

4 Electroacoustic water leak detectionElectroacoustic water leak detection

To deactivate the AC 06 re-

lease the rotary regulator or

press the microphone key

again.

If the AC 06 does not go off

when you release the rotary

regulator, the function of the

ro tary regulato r h as been

changed. In this case press

the rotary regulator again.

Place the test rod at the next

measurement location and

proceed as above.

The pre vio usly measu red

value will now appear in the

small digital display for comparison purposes.

Page 30

20

4 Electroacoustic water leak detectionElectroacoustic water leak detection

The illustration above is an example of what might be displayed

in the course of detecting a water leak.

The sound is loudest close to the leak, the further away you get,

the quieter it is.

Left: The analog display shows approx. 30% scale division, this

is the current noise value.

The analog display, however, often uctuates heavily due to the

changing ambient noise. It is even hard to discern a trend. For

this reason the large digital display (number 16) shows the smallest noise value measured at this measurement location over the

measuring time (current slider value). Even if the noise gets

louder (ambient), the display will freeze, if the noise gets quieter,

the display will continue to fall.

In the analog display the numeric value 16 will also be displayed

as an inverse segment.

The small digital display shows “0”: there is no value in the

memory yet.

Centre: The analog display shows approx. 60% scale division.

The large digital display (number 38) shows a greater value than

at the measurement location on the left. This indicates that the

location of the leak is closer.

The small digital display now shows “16”: it is a reminder of the

result from the last measurement location (last slider value).

This helps you determine whether or not you have reached the

leak, or if you have already gone past it.

Right: The current slider value has dropped because the leak is further away. The last slider value shows “38” again for comparison.

Page 31

21

4 Electroacoustic water leak detectionElectroacoustic water leak detection

4.5 Locating leaks

Non-metallic pipe materials transmit the structure-borne sound

less effectively. It is therefore not enough to examine the ttings.

A ground microphone is used to perform an additional check on

the length of piping between the ttings.

Using the ground microphone at regular intervals enables the leak

to be located without excavation. Once again, the AC 06 shows

an accurate optical comparison of the noise intensities.

The illustration above is an example of how the display changes

when a leak occurs.

Connect the ground microphone to the AC 06.

Place the ground microphone

on the ground.

Activate the AC 06 with the

rotary regulator or the micro-

phone key.

A loudspeaker symbol appears in the display during the

measurement.

The analog display shows

the current volume measurement.

Page 32

22

4 Electroacoustic water leak detectionElectroacoustic water leak detection

Th e c urrent n oise can be

heard on the headphones.

The digital display shows the

smallest value measured.

The small digital display shows

the value measured previous-

ly. This value is 0 for the rst

measurement.

The smallest value measured

is shown inverted in the analog

display.

To deactivate the AC 06 re-

lease the rotary regulator or

press the microphone key

again.

If the AC 06 does not go off

when you release the rotary

regulator, the function of the

ro tary regulato r h as been

changed. In this case press

the rotary regulator again.

Place the ground microphone

at the next measurement location and proceed as above.

The pre vio usly measu red

value will now appear in the

small digital display for comparison purposes.

Using the ground microphone,

listen to the section of pipe

where you suspect the leak is

situated.

The illustration on the previous

page is an example of what

the display shows when you

cross a leak.

Page 33

23

5 Performing a correlation measurementPerforming a correlation measurement

5 Performing a correlation measurement

5.1 Entering pipe data

The pipe data must be entered in preparation for each measurement.

Using the arrow keys select

“Pipe data” from the menu

and conrm by pressing the

Enter key. You will be asked

how many pipe sections there

are.

Select “one”, “two”, or “three”

pipe sections accordingly with

the arrow keys and then press

Enter.

Next you will be asked to enter

the pipe length. The left/right

arrow keys allow you to move

between the digits.

The up/down arrow keys

increases or reduces the respective digit by one.

Conrm the length by pressing

Enter.

Select the material of the pipe

section from the list using the

arrow keys or select “manual“

to enter the sound velocity

directly.

Please note: the values in

the list are approximate and

can cause inaccuracies (see

section 6).

Select the pipe diameter from

the list using the arrow keys.

Repeat these entries for the

second and third sections of

pipe as necessary.

Page 34

24

5 Performing a correlation measurementPerforming a correlation measurement

Note:

As well as the standard “cross correlation”, the

AC 06 can also perform “auto correlation”, see section 8.6.5.

5.2 Starting a measurement

This function must be selected to measure a section for the rst

time, or after the rst measurement if errors have occurred (trans-

mitter not switched on, badly connected microphone etc.).

Using the arrow keys select

“Start” and conrm by pressing the Enter key. Use the

headphones to check the progression of the measurement

acoustically (safety measures:

see section 2.1).

pipe data

start

continue

Start

cancel

100.0 m

steel

125 mm

1280 m/s

A summary of the pipe data

entered will be shown.

Mark “start” using the arrow

keys. Press the Enter key.

The correlation measurement

will begin.

Page 35

25

5 Performing a correlation measurementPerforming a correlation measurement

De pending on the setting

(see section 8.6.2) 16, 32, 64

or 128 averaging procedures

(measuring processes) will be

performed.

The display will show which

averaging procedure is currently being performed.

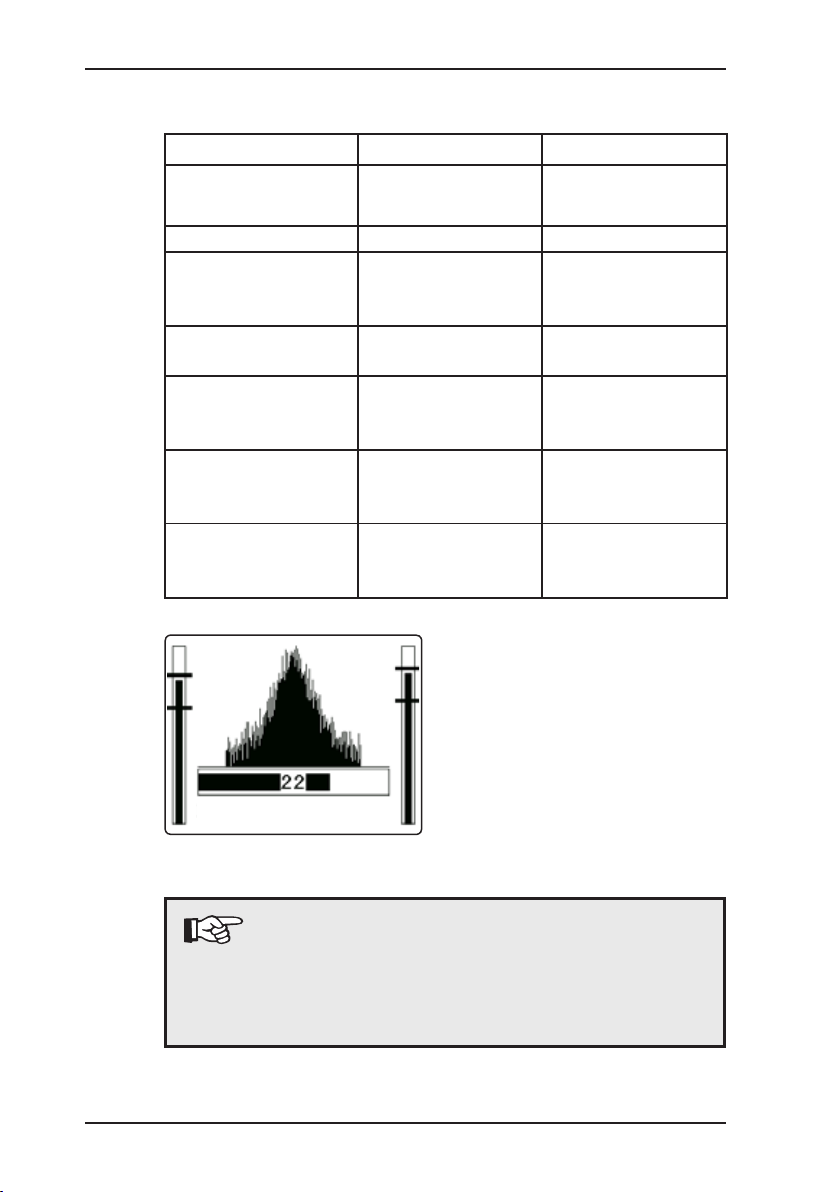

The correlation function is

updated continually during the

measurement.

You can pause the correlation

measurement at any time by

briey pressing the ON key.

You can continue the paused

measurement at any time.

The result will be shown after

the measurement. The illustra-

tion on the left is an example

of the progression of the correlation function. The mode of

curve depends on the setting

in the Filters/Setup menu.

5.3 Analyzing results

The correlation function indicates in the form of peaks

where a leak may be located.

The “x-axis” shows the time

difference in ms (milliseconds).

The marking is automatically

set at the highest peak.

pipe data

start

continue

pipe data

start

continue

Page 36

26

5 Performing a correlation measurementPerforming a correlation measurement

CAUTION!

If you see a peak right in the middle of the screen,

this may indicate that radio transmitter RT 06 is too

close to the AC 06 (receiver). Increase the distance

between the two appliances to several (5 – 10)

meters.

5.3.1 Filtering

Please read section 8.4 on the basic principles of ltering.

The ltering option here from the function in the main screen offers

faster access to manual functioning than via Menu / Filter / Manual.

The range of functions here is, however, limited.

Select “Filter“ in the main screen.

The left lter limit ashes and can be set.

Enter key: calculates the result function; the other lter limit can

be set (can be repeated as often as you wish).

ON key: returns to the main screen, the result is displayed.

5.3.2 Cursor

If you select the “cursor” function with the arrow keys, you

can place the cursor in any

position you desire with the

arro w keys or the rotary

regulator.

The measurement will be recalculated immediately in accordance with the marked position.

The time indicated beside the

cursor indicates the time difference setting.

The distances stated under the

correlation function indicate the

distance of the cursor position

from the two microphones.

Page 37

27

5 Performing a correlation measurementPerforming a correlation measurement

5.3.3 Zoom

The “zoom” function allows you

to enlarge areas of the correlation function.

Select “zoom” with the arrow

keys.

The “right” arrow key en-

larges the mode of curve.

Position bar 1 below the correlation function shows which

part of the entire pipe length is

displayed.

The “left” arrow key displays

the entire correlation function

again.

Note:

Subjective evaluation of the form of the cross correlation function (CCF) is particularly important when

applying the correlation procedure. The knowledge

required for this cannot be taught as a theory; practical experience is essential.

The measurement is based on the value marked in

the CCF and on the pipe data you have entered. The

CCF represents, in simple terms, the time relationship in terms of quality of the two sounds recorded

by the two microphones to each other.

It is impossible to distinguish between the (sought)

leak sounds and the background noise. The measurement may not always, therefore, indicate a

leak; sources of background noise can also be

detected!

If there is “no“ noise present, a random measurement will be calculated. In such cases you should

look for other connection points for the microphones

where the leak noise can be picked up much more

clearly.

Page 38

28

5 Performing a correlation measurementPerforming a correlation measurement

5.4 Continuing a measurement

This function starts the correlation measurement with the old

pipe data. All the previous results from any prior correlation will

be retained.

Any pipe data which has changed since the last correlation will

not be taken into account.

You should continue the measurement if the result of the rst

correlation measurement (number of averaging procedures e.g.

32) is not yet reliable enough.

Using the arrow keys select

“conti nue” and confirm b y

pressing the Enter key.

The measuring procedure is

the same as if you were starting a new measurement.

pipe data

start

continue

Page 39

29

6 Measuring the sound velocity

6 Measuring the sound velocity

6.1 General

Sound velocity measurements are necessary because it is important to enter the correct sound velocity for an exact measurement.

The sound velocity values are contained in an internal table (see

section 8.6.7). The sound velocity data in “pipe data” is, however,

approximate. Furthermore, you may not know the pipe dimension

or the material.

This function requires a source of noise,

for example, an open hydrant,

which produces a clear symbol in the CCF, in other words is

“correlatable”,

which must have a known position,

which must not be positioned in the “middle area” of the measuring section in order to increase accuracy.

If the measuring section is comprised of several pipe sections

(material or dimension intersections), the sound velocity measurement will produce erroneous results.

6.2 Performing a measurement

The measuring procedure is very similar to a correlation measurement.

First connect the microphones and radio transmitter as de-

scribed (see sections 2.3).

Activate “Measuring method” “Sound velocity” in the menu

(see section 8.5).

Select “Pipe data” from the menu and enter the data accord-

ingly.

When asked about a “man-made leak” you must enter the distance of the man-made leak from microphone 1:

If it is outside of the measuring section and beyond

microphone 1, enter 0 m for the distance.

microphone 2, enter the total length of the measuring section

for the distance, i.e. the „pipe length“.

–

–

Page 40

30

6 Measuring the sound velocityMeasuring the sound velocity

To create a source of noise, either generate a man-made leak

(e.g. open hydrant) or bang on the tting in quick succession

using a hammer.

Select „start“ using the arrow keys.

The measuring procedure will begin.

After the measurement, the correlation function will appear in

the display.

The cursor will automatically be placed at the position with the

greatest value. Check whether this position is your man-made

leak. If necessary, move the cursor to the man-made leak using the arrow keys or the rotary regulator.

If you select “accept“ in the menu:

The calculated sound velocity will be applied in the internal

memory.

You will exit the “measure sound velocity” measuring method

(and return to the “standard” measuring method).

Return to the main screen.

You can now perform a correlation measurement to detect the

real leak. When entering any modications to the pipe data,

also enter the calculated sound velocity by selecting “manual”

under pipe material.

If you select “cancel“ in the menu:

the calculated sound velocity will not be applied.

you will exit the “measure sound velocity” measuring method

(and return to the “standard” measuring method).

Return to the main screen.

–

–

–

–

–

–

Page 41

31

7 Charging equipmentCharging equipment

7 Charging equipment

Power is supplied to the AC 06

and the RT 06 by the integrated

NiMH batteries.

The AC 06 can be operated for

approx. 10 hours. The operating

time may be reduced considerably when using the display light

or in low outside temperatures

(display heating).

The RT 06 radio transmitter

can be operated for at least 8

hours.

Alternatively, (if the battery is

empty) the AC 06 and the RT

06 transmitter can be operated

using an external 12 V = power

source (e.g. vehicle cable).

Docking station HS 1.2 A and

the AC/DC adapter or the vehicle

cable are required for charging

or for external operation. The

AC 06 charges in 4 hours maximum, radio transmitter RT 06 in

5 hours maximum.

The vehic le cab le mus t be

plugged into socket 1 of the

docking station or socket 3 of the

RT 06 transmitter.

1

3

Page 42

32

7 Charging equipmentCharging equipment

The AC 06 and RT 06 transmit-

ters can also be charged directly

in the case.

To do this, connect vehicle cable

L or AC/DC adapter L to socket

1 in the case.

Cables 2 and 4 must be connected to each of the RT 06

transmitters and cable 3 must

be connected to docking station

HS 1.2 A.

7.1 Battery condition

The battery condition is shown in the AC 06 display in the form

of a battery symbol with the text

RT 06-1 or RT 06-1 or AC 06

if the respective component has less than approx. 15 minutes

operating time remaining.

The status LEDs provide further information on the RT 06 (see

section 2.3.2).

1

32 4

Page 43

33

7 Charging equipmentCharging equipment

7.2 Charging / battery maintenance

While charging, the AC 06 displays the remaining charging time

in hours. When in this mode the “battery maintenance” function

can be selected using the menu key. This discharges the battery

and recharges it again, thereby eliminating chemical deposits in

the battery and improving its storage capacity. The process takes

approx. 10 hours and should be carried out approx. every 60 days,

especially with appliances which are not used often.

Symbols and what they mean during the charging process:

“Battery maintenance” is acti-

vated

The temperature is below 0 °C,

the battery cannot be charged.

The temperature is above 45 °C,

the battery cannot be charged.

Page 44

34

8 Menu

8 Menu (in correlator mode)

8.1 Menu structure

(*) Settings which remain in effect even

after the device has been switched

off. All others are reset to the default

values. (See section 8.6.8)

Listen

Channel 1

Channel 2

Channel 1 and 2

File

Open

Low resolution

High resolution

Noise

Store

... see „Open“

Delete / All

... see „Open“

Filtering

Automatic

Manuel

Setup (*)

Subs. treatment

Automatic

Manuel

Off / On

Filter limit

Filter basis

Coherence

Cross spectrum

Spectrum KA 1

Spectrum KA 2

Filtering method

Rectangle

Hanning

Measuring method

Standard

Sound velocity

Parameter

Noise suppression

Automatic

Manuel

Off

Measuring time

Standard =32

Summation / Average

Summation

Averaging

Mode of curve (*)

CCF positive

CCF pos. + neg.

TOP pos. + neg.

Type of correlation

Cross correlation

Auto Corr. CH 1

Auto Corr. CH 2

Sampling frequency

Automatic

Manuel

Table (*)

Standard values

Components

Setup (*)

Date, Time

Language

Radio / Cable

System

Name

Service

Page 45

35

8 Menu

8.2 Listening

The “listen” function allows you to adjust the volume of the two

channels.

Using the arrow keys select the channel to be adjusted.

You can adjust the volume of the selected channel using the

arrow keys or the rotary regulator.

If “channel 1” is selected, you will hear channel 1 through both

ears (mono mode). The same applies for “channel 2”. If “channel 1 and 2” is set, you will hear both channels at the same

time (stereo mode).

8.3 File

In this menu you can open, save and delete individual measurements and noises. The data is led in the internal memory of the

AC 06 and can be accessed even after the appliance has been

switched off.

8.3.1 Saving

The following number of memory slots are available:

a) 50 memory slots (low resolution)

b) 25 (1 – 25) memory slots (high resolution)

c) 5 (1 – 5) memory slots (noises)

Note:

b) and c) share one memory area

Measurements saved at a low resolution cannot be processed

later, e.g. ltered.

Only the main screen can be viewed.

Functions: view main screen,

move cursor,

start, continue.

There are 50 memory slots of low resolution available.

Measurements saved at a high resolution can be processed later.

In other words, all functions that are possible after the end of a

Page 46

36

8 Menu

measurement (after a measurement has been stopped), are also

possible here.

Exception: it is not possible to “continue” the measurement.

There are up to 25 memory slots available, they are used together

with the memory slots for “noises”.

If you select “noises” approx. 7 seconds of the current noise is

saved.

Please note that the saving process takes approx. 35 seconds due

to the high storage volume. The process cannot be cancelled.

Use the arrow keys to select what you want to save: low reso-

lution, high resolution or noises.

Once you press the Enter key, the measurement or the noise

will be saved.

8.3.2 Opening

The “open” function allows you to reload measurements/noises.

Use the arrow keys to select what you want to open: low

resolution, high resolution or noises. Please note that it takes

approx. 25 seconds to load a noise. Conrm your selection by

pressing the Enter key.

A list containing the les stored in the AC 06 memory will ap-

pear.

Using the arrow keys select a le and then conrm by pressing the Enter key.

This le will appear when you open a measurement.

If you open a noise, the 7 second noise clip will be played on

repeat. You can cancel the playback by briey pressing the

ON key.

Page 47

37

8 Menu

8.3.3 Deleting

Using the arrow keys select what you want to delete: “low

resolution”, “high resolution” or “noises”. Conrm your selection

by pressing the Enter key. A list containing the les stored in

the AC 06 memory will appear.

Using the arrow keys select the le you want to delete and

then conrm by pressing the Enter key.

The le will be deleted.

8.4 Filtering

The lter function allows you to hide certain frequencies from the

correlation function to improve the result.

You can choose between manual and automatic ltering.

8.4.1 Automatic ltering

The AC 06 performs automatic ltering (processing control) after

a measurement. The lters are automatically optimized.

8.4.2 Manual ltering

An image will appear which will display a frequency response below (lter basis, see section 8.4.3.3) and the result above (mode

of curve, see section 8.6.4) from the set lters.

Page 48

38

8 Menu

Pressing the Enter key takes

you into processing mode.

Using the arrow keys select

which lter limit is to be adjusted:

- Filter left

- Filter right

- Hide left

- Hide right

Use the arrow keys to move

the relevant limit.

The corresponding frequency

will be shown in the display.

Light grey frequency ranges

will be hidden.

Black areas will be included in

the correlation.

If you want to enlarge the

frequency range, you must

rst change the lter limit settings in the Setup (see section

8.4.3.2).

Page 49

39

8 Menu

Using the arrow keys select

“OK”.

The set lters will be applied

and the frequency response

with the result w il l be updated.

Pressing the Enter key takes

you back to the “manual lter-

ing” mode of curve where you

can change the filter limits

again if necessary.

Selecting “back” takes you

back to the main screen, the

lter settings will remain effective.

left

ltering limit

right

cut off limit

left

cut off limit

right

ltering limit

zoom

filter right

cut off left

filter left

Page 50

40

8 Menu

8.4.3 Setup

Settings are saved in the setup so that you do not have to call up

the required individual functions again and again. Place the cursor

on the desired option and then press the Enter key.

8.4.3.1 Frequency analysis

The frequency analysis optimizes the coherence function lters

using statistical methods to achieve an optimal correlation result.

An automatic frequency analysis can be performed on ongoing

measurements and saved measurements.

Automatic

After each correlation procedure, automatic ltering is performed (see section 8.4.1).

Manual

After each correlation procedure the manual ltering menu will

appear (see section 8.4.2). The lter settings under “lter limits”

in the menu (see section 8.4.3.2) are used as the default.

Off

This switches off both of the processing options above.

8.4.3.2 Filter limits

Setting option for the lter settings to be used for manual ltering

(see section 8.4.3.1).

Factory setting: if you enter a sound velocity above or below

700 m/s for a measurement, the correlator will adjust itself to:

lower limit / Hz upper limit / Hz

< 700 m/s 5 500 Plastic

> 700 m/s 0 3000 Metal

It does not matter whether the sound velocity is entered by manually selecting the numeric value or by selecting the corresponding

pipe parameters.

Page 51

41

8 Menu

8.4.3.3 Filter basis

Here you can change the mode of curve of the frequency curve

for the lter settings.

Coherence

The similarity of the frequencies is displayed.

Cross spectrum

The cross spectrum from the two channels is displayed.

Spectrum, Ka 1

The frequency spectrum of channel 1 is displayed.

Spectrum, Ka 2

The frequency spectrum of channel 2 is displayed.

8.4.3.4 Filtering method

Under “square” the signal is ltered exactly at the marked position.

Under “Hanning” a “soft transition” is created around the marked

position.

8.5 Measuring method

The “measuring method” function allows you to switch between

the standard measurement (= correlation measurement) and the

sound velocity measurement (see section 6).

8.6 Measuring parameters

The “measuring parameters” submenus allow you to set various

parameters which affect the measurement.

8.6.1 Noise suppression

“Noise suppression” is a function to reduce the negative impact

of temporary interference noise (vehicles, pedestrians).

With “noise suppression” it is assumed that optimal results can

be achieved at moments when the noise (signal) measured is

relatively small. This is when the permanent leak noise is by and

large free from interference.

Page 52

42

8 Menu

When the signal is relatively high, the additional noises must stem

from a source of interference which has a negative effect on the

measuring result.

Noise suppression ensures that correlation (averaging) only takes

place when the signals are in a certain level range (volume). If

the signals are outside of the level range, the measurement will

be discontinued.

The level range is limited by the lower threshold and the upper

threshold. These thresholds are shown for signals 1 and 2 as

horizontal lines on the far left / far right of the display when the

measurement is taking place. The level range is always reset

when starting the measurement. The correlator uses the level

values measured at the start as a point of reference.

a) automatic

This setting is suitable for achieving good results in all standard

cases.

After a certain time, the level range is automatically raised slowly

if the current level values are permanently over the level range.

In the same way, the level range is lowered if the current level

values are permanently below the level range.

b) manual (default setting)

This setting is recommended if you want to work with maximum

noise suppression and have maximum individual inuence on

the measurement.

If the measurement is interrupted for too long because the noise

is too loud, the level range can be manually raised by pressing

“continue” and thus made less sensitive. The measurement will

continue as the user ignores a certain amount of interference

noise.

Once the current level values fall below the level range an automatic adjustment takes place and the correlator becomes more

sensitive to interference noise.

c) off

This setting should only be selected if the constantly heavily uctuating signals mean that the measurement is often interrupted

and correlation would not be possible otherwise.

Noise suppression is disabled. It is accepted that interference

noise occasionally masks the leak noise.

Page 53

43

8 Menu

8.6.2 Measuring time

The “measuring time” function allows you to specify how many

single measurements are to be performed before measurement

stops.

8.6.3 Summation / Averaging

The “summation” function uses all the individual results for the

mode of curve of the CCF and analyzes them equally.

The “averaging” function evaluates the individual results differently: the most recently performed measurement has the greatest

inuence on the CCF; the previous ones much less etc.

The “averaging” setting of the CCF thus tends to reect the cur-

rent noise.

8.6.4 Mode of curve

You can change the mode of curve of the correlation function:

CCF positive

The CCF only has positive values.

CCF pos. + neg.

The CCF contains positive and negative values.

TOP positive

The mode of curve is like the “CCF positive” one, but the top

values are usually more prominent.

TOP pos. + neg.

The mode of curve is like the “CCF pos. + neg.” one, but the

top values are usually more prominent.

Page 54

44

8 Menu

8.6.5 Type of correlation

The cross correlation uses channel 1 and channel 2 to measure;

the source of noise to be located must be within the measuring

section.

Auto correlation uses either channel 1 or channel 2. The sec-

ond signal required for correlation is produced by reecting the

noise to be located at a reection point. It must be received by

the channel in use.

As the energy from the reected noise is usually very low, this

procedure is rarely feasible. The chances are usually better if

there are gaseous media in the pipe.

The position of the reection point must be known for auto correlation.

The auto correlation function (ACF) always has a symmetrical

progression. Only the negative area of the ACF (delta t <0) is of

interest.

8.6.6 Sampling frequency

The continuous time signal of the channels used is scanned and

digitized at a certain frequency, the sampling frequency.

The lower the sampling frequency, the less calculating time is

required for averaging. However, the sampling theorem requires

a sampling frequency which is at least twice as high as the highest frequency contained in the signal! If the sampling frequency

setting is too low, measuring errors may occur. For this reason,

the sampling frequency should only be reduced in exceptional

circumstances, for noises of very low frequency.

The sampling frequency is at the maximum with “automatic”.

Select “manual” for a manual setting. You can change the sam-

pling frequency using the arrow keys.

All subsequent measurements will be performed at this sampling

frequency.

Page 55

45

8 Menu

8.6.7 Table

This menu offers a choice of 3 tables for the sound velocity measurement. You can choose between two set and one individually

editable table.

Table 1: Particularly good experience in France

Table 2: Internationally applicable

Table 3: Individually editable

Selecting a table

Select the respective row and press the Enter key. If you choose

individual table 3, another window will open which you should

conrm accordingly.

Creating and editing the table

When creating a table for the rst time, think about the basis (table

1 or 2) on which your table should be created. The values present

in the preset table are (in the background) copied into individual

table 3 (still blank) where they can be changed. Tables 1 and 2

will remain unchanged.

Select the desired table (table 1 or 2).

In the menu select Table – Individual – Edit.

You can now edit table 3.

Select the material from the list followed by the diameter to be

changed.

Press the Enter key to enter edit mode and set the desired

value.

If you select Individual (1 ... 3) under material, a window will

appear in which you can edit the name of the material and the

respective values.

This data will not be overwritten when you update the appliance.

However, as a precautionary measure you are advised to make

a note of the values.

Deleting the table

In the menu select Table – Individual – Delete. After a warn-

ing prompt (Yes / No) table 3 will be deleted.

You will now have the option of creating a new table 3 based

on table 1 or 2.

Page 56

46

8 Menu

8.6.8 Default values

All parameters in the measuring parameters menu of the AC 06

are reset to the default values. This also includes those that are

preserved after the device is switched off. The language setting

and the individual sound velocity table will remain unchanged.

8.7 Components

The screen shows an overview of the main information about the

3 (maximum) main system components (2 x RT 06, 1 x AC 06

correlator).

Page 57

47

8 Menu

Explanation of symbols

Accu empty

Accu full

Low volume High volume

Poor radio reception Good radio reception

8.8 Setup

8.8.1 Date, time

This menu item allows you to set the current date and time. You

can also select the date format.

8.8.2 Language

This menu item allows you to change the language.

Note:

When American English is set, the product-related

use of some units will change accordingly.

For example:

Distance feet (ft),

Diameter inches (in)

Speed feet per second (ft/s)

Page 58

48

8 Menu

8.8.3 Radio / cable

This menu item determines which channel is radio-operated and

which one is directly connected to the AC 06.

Using the arrow keys select

the channel you would like to

change.

Conrm by pressing the Enter

key.

Using the arrow keys you

can switch between “RT 06-X”

and “AC 06”, where “RT 06”

represents radio operation

and “AC 06” stands for cable

operation.

Conrm by pressing the Enter

key.

8.8.4 System

This menu item allows you to make the following settings:

The time when the light goes out automatically.

The time when the device switches off automatically.

8.8.5 Name

This menu item allows you to enter the name, company and the

address.

8.8.6 Service

This menu item is reserved for the Sewerin Service team.

Page 59

49

9 Options forOptions for optimising measurement results

9 Options for optimizing measurement results

The ability to detect a leak depends on the correct calculation of

the time difference. In cases where the leak noises are strong

enough and there are no external sources of noise, the time dif-

ference displayed after just a few averaging procedures (4 to 16)

should sufce.

But what can you do when a “nice” incisive peak just will not

form? The following advice cannot of course replace the practice

and experience required for difcult cases, but it can provide an

insight. Regardless of this, however, you must always remember:

when the leak noises do not reach the microphones with enough

intensity, correlation is not possible.

9.1 Changing the number of averaging procedures

If the result is still unsatisfactory after the initial averagings, you

can increase the number of averagings as often as you wish. The

result will improve because the calculation can be based on additional information over the progression of the leak noise. From

experience, however, the result does not improve any further after

64 to 128 averagings.

9.2 Using lters

Use the possibilities offered by mathematical lters. Unfortunately

universal “formulae” can rarely be given. Only your own experi-

ence and trial and error will result in success.

Usually it is only recommended to select frequency ranges for

the CCF in which the coherence function has a signicant excessive increase compared to the surrounding area, in other words,

features a “hump”.

Single frequencies from various sources of interference produce

a continuously sinusoidal CCF. They can be identied in the

spectra as a sharp line.

Page 60

50

9 Options forOptions for optimising measurement results

9.3 Automatic ltering

The AC 06 can perform automatic ltering (processing control)

after a measurement (see section 8.4.1). This involves optimizing

the coherence function lters using statistical methods to achieve

an optimal correlation result.

A frequency analysis can be performed on ongoing measurements

and saved measurements.

9.4 Checking the microphone connection

Ensure that the microphone contact to the ttings is as secure

and undamped as possible; remove any dirt and rust.

9.5 Using accessories

Use Sewerin accessories and tools. Use a hydrophone for plastic

piping. The active lter creates new possibilities. The “teach-your-

self tape” allows you to check the system and with a minimum of

effort you can practice and keep yourself “in training”.

9.6 Changing location

Change the location of the microphones. Even ttings further away

can achieve a better result if they transmit the sound better.

9.7 Saving time

If it transpires during a measurement that no peak can be measured, any painstaking calculation of the exact pipe data prior

to the measurement may have been a waste of time. Practical

experience has shown that it is therefore advisable to start the

measurement initially with estimated pipe data. If the length of

the pipe is greater and/or the sound velocity less than assumed,

a potential peak will appear in any case within the CCF and will

therefore never be “overlooked”.

If you use this practical approach, you must of course calculate

the exact pipe data at the end.

Page 61

51

10 Communication with the PCCommunication with the PC

10 Communication with the PC

It is possible to transfer the “high resolution measurements” saved

in the AC 06 to a PC. These les can be archived and processed

on the PC (e.g. create log). If you have a printer you can also print

out the data and images. The saved “noises” and “low resolution

measurements” cannot be transferred.

10.1 Requirements

PC (operating systems Windows 95 / 98 / 2000 or XP)

“SeCorr 05” program (PC correlator program) Version 10.16 and

up from 15/1/2003

10.2 Installing the software and establishing a connection

Install the SeCorr 05 software (demo version on CD) on the

PC.

Connect the communication cable (accessory) from any serial

interface on the PC to the AC 06 (socket with cover cap on

the left side of the appliance). The PC interface must not be

congured higher than COM 4.

Place the AC 06 in the 12 V= powered HS docking station. It

does not matter whether the AC 06 is switched on or off.

Transferring data from the AC 06:

Start the SeCorr 05 program and in the “File” menu select the

“SeCorr 08” function.

The data will be transferred, converted and saved in the

SeCorr 08 target directory. The duration of this process depends

on the size and number of measurements and is displayed on

the PC in the form of an animation for each measurement. The

SeCorr 08 target directory is created under the working directory

from which the SeCorr 05 program was started, e.g. C:\Programs\

SEWERIN\SeCorr 05.

–

–

–

Page 62

52

10 Communication with the PCCommunication with the PC

The le names are allocated automatically from the measurement

date and the exact (to-the-minute) measuring time in the AC 06.

They take the following form:

HA_DD-MM-YYYY_HH-MM.COR

The abbreviations stand for the following:

DD-MM-YYYY = Date (day, month, year)

HH-MM = Time (hour, minute)

You can manage the les in the usual way (rename, move).

Opening measurements

Open the measurements in the SeCorr 05 program via File/Open

le. All further instructions on how to use the SeCorr 05 program

can be found in its help function.

–

Page 63

53

11 Technical informationTechnical information

11 Technical information

SeCorrPhon AC 06 correlator

Operating time: 10 hours

Operating temperature: -10 °C – +40 °C

Storage temperature: -20 °C – +60 °C

Charging time: 4 hours

Weight: 1.3 kg

Type of protection: IP54

Dimensions (W × H × D): 125 × 180 × 65 mm

SeCorrPhon AC 06 correlator in AQUAPHON mode

Transmission bandwidth 1 – 9950 Hz

Adjustable lter 50, 500 and 1000 Hz increments

Filter, minimum bandwidth 300 Hz

Radio transmitter RT 06

Transmitting power: 500 mW

Charging time: 5 hours

Operating time: 10 hours

Broadband lter setting: 0 – 3000 Hz

Low pass lter setting: 0 – 300 Hz

Weight: 1.3 kg

Dimensions (W × H × D): 73 × 190 × 150 mm

(with aerial = 510 mm)

Type of protection: IP67

Page 64

54

12 Accessories

12 Accessories

Case with foam insert, for two hydro-

phones and two airborne noise

microphones

Hydrophone type HA e.g. for connecting to PE house

service connections following

removal of water meter.

Hydrophone adapter UFH

DN 80 on 1“ female threads

between underground hydrant

and hydrophone type HA

Main pipe adapter M10 to permanently connect a micro-

phone to slide gate or hydrant

House connection adapter

M10

to permanently connect a microphone to a house shut-off

valve

Airborne sound microphone to detect leaks in pipes with

gaseous medium

Active lter to lter out interference frequen-

cies

Test-and-teach-yourself tape with set of cables

Test-and-teach-yourself CD with set of cables

Page 65