Page 1

Operating

SeCorr® 08

Instructions

Page 2

Measurable success by Sewerin equipment

Congratulations.

You have chosen a quality instrument manufactured by Hermann

Sewerin GmbH.

Our equipment will provide you with the highest standards of perfor-

mance, safety and efciency. They correspond with the national and

international guide-lines.

Please read and understand the following operating instructions before

using the equipment; they will help you to use the instrument quickly and

competently. If you have any queries we are available to offer advice

and assistance at any time.

Yours

Hermann Sewerin GmbH

Robert-Bosch-Straße 3

33334 Gütersloh, Germany

Tel.: +49 5241 934-0

Fax: +49 5241 934-444

www.sewerin.com

info@sewerin.com

SEWERIN SARL

17, rue Ampère – BP 211

67727 Hoerdt Cedex, France

Tél. : +33 3 88 68 15 15

Fax : +33 3 88 68 11 77

www.sewerin.fr

sewerin@sewerin.fr

SEWERIN IBERIA S.L.

Centro de Negocios Eisenhower

Avenida Sur del Aeropuerto

de Barajas 24, Ed. 5 Of. 2C

28042 Madrid, España

Tel.: +34 91 74807-57

Fax: +34 91 74807-58

www.sewerin.es

info@sewerin.es

Sewerin USA LLC

2835 Haddoneld Road

Pennsauken, NJ 08110-1108

Phone: +1 215-852-8355

Fax: +1 856-662-7070

www.sewerin.net

sewerin-usa@sewerin.net

Sewerin Ltd

Hertfordshire

UK

Phone: +44 1462-634363

www.sewerin.co.uk

info

@sewerin.co.uk

Sewerin Sp.z o.o.

ul. Annopol 3

03-236 Warszawa, Polska

Tel.: +48 22 519 01 50

Fax: +48 22 519 01 51

Tel. kom.+48 501 879 444

+48 608 01 37 39

www.sewerin.com

info@sewerin.pl

Page 3

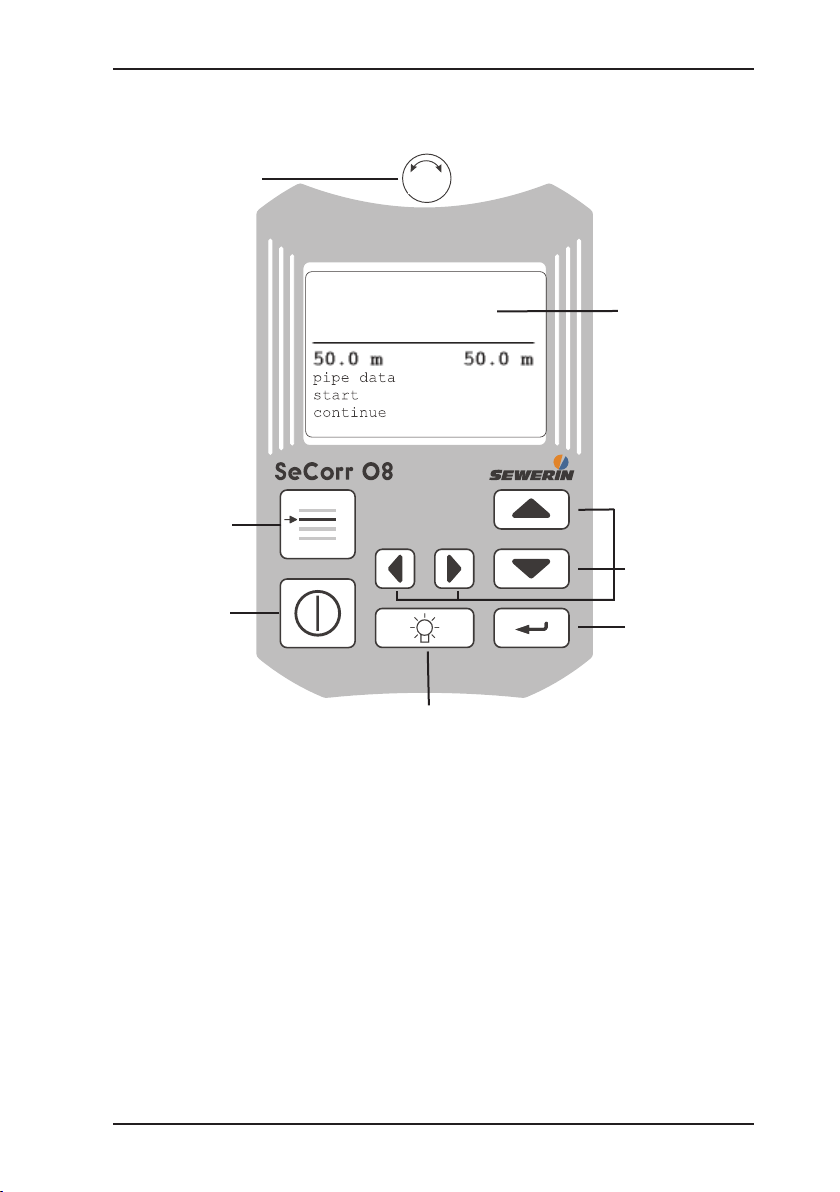

Illustration SeCorr 08

Rotary regulator

Menu key

Central screen

Arrow keys

ON/OFF key

Enter key

Light key

Page 4

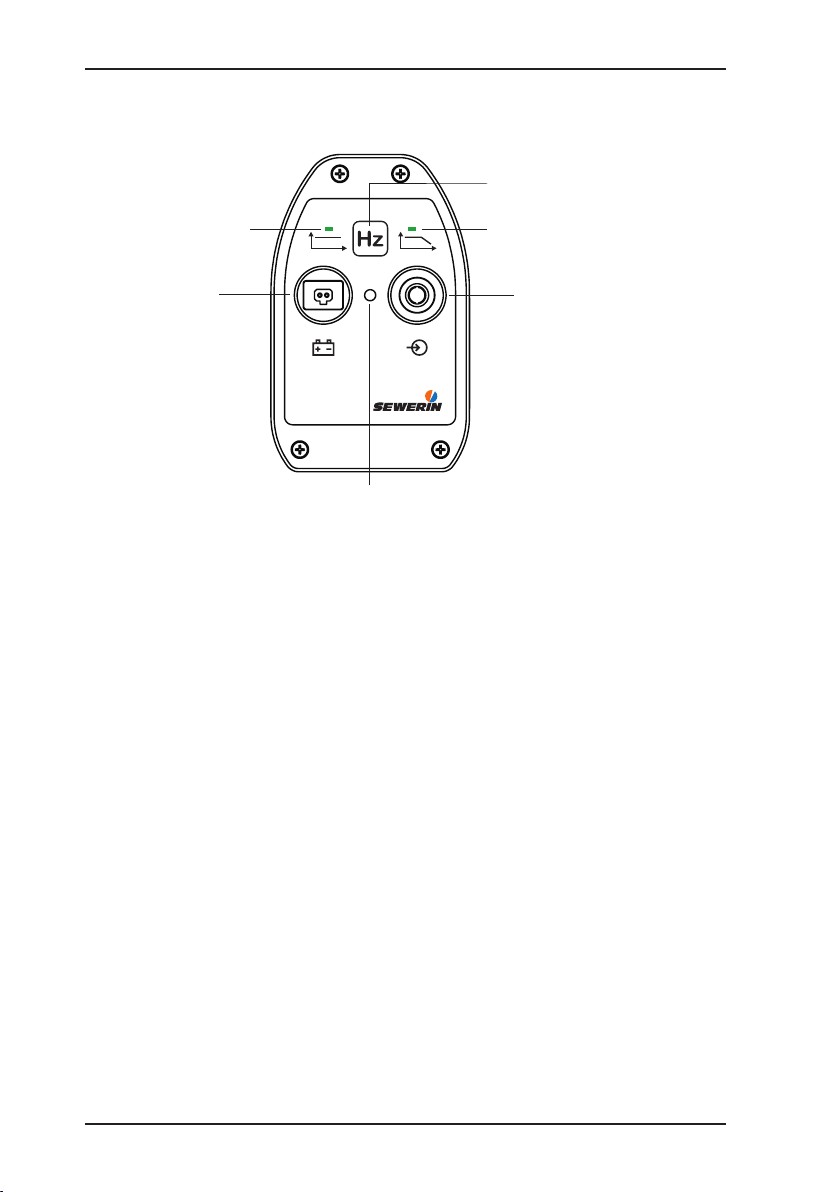

RT 06

A

Hz

A

Hz

Filter key (4)

LED (5), plastic,

low pass

LED (6), metal,

Wideband

Status-LED (1)

Power supply (3)

Microphone connection (2)

Illustration RT 06

Page 5

Operating Instructions

SeCorr® 08

26.04.2010 – V 4.X – 103923 – en

Page 6

Warranty & Used symbols

The following instructions must be complied with in order for any warranty

to be applicable in respect of the functionality and safe operation of this

equipment.

Hermann Sewerin GmbH accepts no liability for any damages resulting

from failure to observe these instructions. The warranty and liability provisions of the terms of sale and delivery of Hermann Sewerin GmbH are not

affected by the information given below.

The product must only be operated after the relevant operating instruc- z

tions have been read and understood.

The product must only be used for its intended purpose. z

The product is only suitable for use in industrial and commercial ap- z

plications.

Repairs must only be carried out by a specialist technician or by other z

suitably trained personnel.

Changes or modications to this product must not be carried out with- z

out approval from Hermann Sewerin GmbH. The manufacturer cannot

be held responsible for damages if non-approved modications have

been made.

All repairs must be carried out using replacement parts that have been z

approved by Hermann Sewerin GmbH.

The manufacturer reserves the right to make technical modications in z

the course of further development.

Generally applicable safety and accident-prevention regulations must be

complied with, in addition to the information provided in this manual.

Used symbols:

CAUTION!

This symbol is used to indicate dangers which may

either result in hazards for the operators or in severe

damage – or even destruction – of the product.

Note:

This symbol is used to call attention to information

and tips which may be helpful and which are exceeding the basic operating procedures.

Page 7

Contents Page

1 Function description ...............................................................1

1.1 Usage ........................................................................................ 1

2 Use ............................................................................................2

2.1 First use ....................................................................................2

2.2 Switching ON/OFF ....................................................................2

2.3 Channel assignment .................................................................3

2.4 Radio transmitter RT 06 ............................................................5

3 Operating elements .................................................................6

3.1 ON/OFF key ..............................................................................6

3.2 Rotary regulator ........................................................................6

3.3 Enter key ...................................................................................7

3.4 Menu key ...................................................................................7

3.5 Left/right arrow keys .................................................................. 7

3.6 Up/down arrow keys ..................................................................7

3.7 Light key .................................................................................... 8

3.8 Adjusting the contrast ................................................................8

4 Performing a correlation measurement ................................9

4.1 Entering pipe data .....................................................................9

4.2 Starting a measurement .......................................................... 10

4.3 Evaluating the result ................................................................ 11

4.3.1 Filtering ................................................................................12

4.3.2 Cursor ..................................................................................12

4.3.3 Zoom ....................................................................................13

4.4 Continuing a measurement .....................................................14

5 Measuring the sound velocity ..............................................15

5.1 General information .................................................................15

5.2 Performing a measurement .....................................................15

6 Charging equipment .............................................................17

6.1 Battery state ............................................................................18

6.2 Charging process/battery maintenance ..................................19

I

Page 8

Contents Page

7 Menu ....................................................................................... 20

7.1 Menu structure ........................................................................20

7.2 Listen .......................................................................................21

7.2.1 AQUAPHON .........................................................................21

7.2.1.1 Display ..............................................................................22

7.2.1.2 Assignment of keys ...........................................................23

7.2.1.3 Sensitivity ..........................................................................23

7.3 File ..........................................................................................23

7.3.1 Store .....................................................................................23

7.3.2 Open ....................................................................................24

7.3.3 Delete ................................................................................... 25

7.4 Filtering ...................................................................................25

7.4.1 Automatic ltering .................................................................25

7.4.2 Manual ltering ..................................................................... 25

7.4.3 Setup .................................................................................... 28

7.4.3.1 Filter limits .........................................................................28

7.4.3.2 Filter basis ......................................................................... 28

7.4.3.3 Filtering method ................................................................29

7.5 Measurement method .............................................................29

7.6 Parameter ...............................................................................29

7.6.1 Noise suppression ................................................................29

7.6.2 Measuring time .....................................................................31

7.6.3 Summation/average .............................................................31

7.6.4 Mode of curve ......................................................................31

7.6.5 Correlation ............................................................................31

7.6.6 Sampling frequency .............................................................32

7.6.7 Table .....................................................................................32

7.6.8 Standard values ...................................................................32

7.7 Components ............................................................................ 33

7.8 Setup ....................................................................................... 34

7.8.1 Date, time ............................................................................. 34

7.8.2 Language .............................................................................34

7.8.3 Radio/cable ..........................................................................34

7.8.4 System .................................................................................34

7.8.5 Name ....................................................................................35

7.8.6 Service .................................................................................35

8 Methods of optimising measuring results .......................... 36

8.1 Changing the number of averaging processes .......................36

8.2 Using lters .............................................................................36

II

Page 9

Contents Page

8.3 Automatic ltering ....................................................................37

8.4 Checking the microphone connections ...................................37

8.5 Using accessories ...................................................................37

8.6 Changing the location .............................................................37

8.7 Saving time .............................................................................37

9 Communication with PC ....................................................... 38

9.1 Requirements .......................................................................... 38

9.2 Software installation ................................................................38

10 Technical data........................................................................40

11 Accessories ...........................................................................41

12 Error messages .....................................................................42

13 Annexe ...................................................................................44

13.1 EC Declarations of Conformity ................................................ 44

Advice on disposal ..................................................................44

13.2

13.3 History of changes ..................................................................45

14 Index ....................................................................................... 46

III

Page 10

1 Function description

1.1 Usage

The correlator SeCorr 08 permits to detect leakage points an

directly buried pressure line systems according to the correlation principle. Sensitive microphones are used to record leakage

noise on accessible installations and ttings. These recordings

are wireless transmitted to the correlator.

SeCorr 08 calculates then the exact leakage position using the

Fast Fourier Transformation (FFT = mathematic algorithm).

Supplementary functions are available to improve e.g., the indication of leaks, to enter several pipe sections or to measure the

sound velocity.

The RT 06 radio transmitter can be used to measure fully auto-

matically the input level of the microphone and to set the level

control of the amplier to the optimum value. Characteristics and

parameters – such as the used microphone type, the charge state

of batteries and the amplier setting – are wireless transmitted to

the correlator for further evaluation.

1 Function description

Note:

These operating instructions are based on software release 4.X, with „X“ standing for any number.

The currently installed software version of your

SeCorr 08 is displayed after switching on the device.

Future releases are subject to change!

1

Page 11

2

2 Use

2 Use

2.1 First use

CAUTION!

Before placing SeCorr 08 and RT 06 for the rst

time into service, make sure that all used batteries

are completely charged. If the batteries are only

partially charged, the capacity of the batteries may

be reduced thus leading to shorter operation.

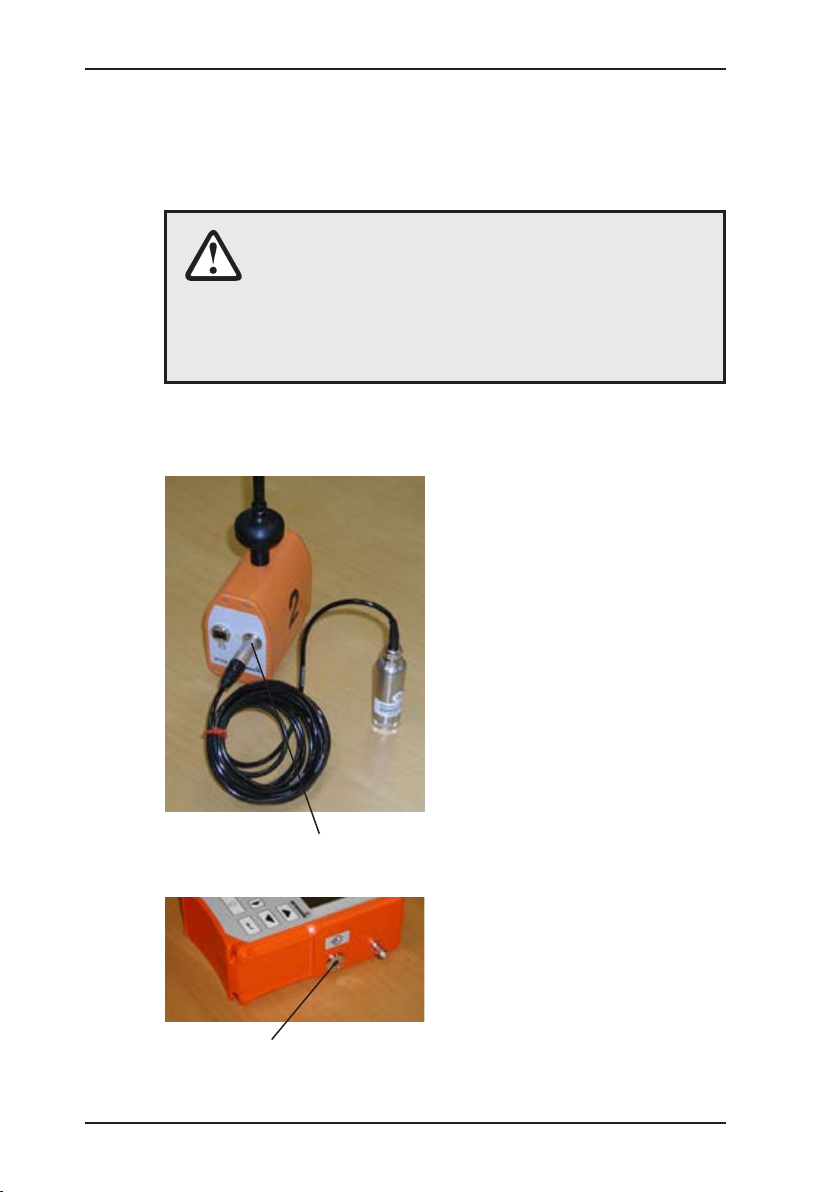

2.2 Switching ON/OFF

1

Position both piezo micro- z

phones at accessible fitting

parts. If the circular magnet

is screwed on the piezo microphone, it may be required

to remove the circular, rmly

adhering protective disk from

the magnet.

Plug both microphone con- z

nectors into the sockets of the

radio transmitter RT 06. If you

want to use only one RT 06, it

is required to connect a micro-

phone directly to input 2 of the

SeCorr 08.

On the RT 06, LED 1 must

be lit.

Connect the headphones to z

socket 3 of the SeCorr 08.

Switch on the SeCorr 08 by z

pressing the ON/OFF key for

a couple of seconds.

2

Page 12

3

3

2.3 Channel assignment

Is indicated together

with message

„battery empty“

Indication Left Right

Type with one signal

channel

Type with two sig-

nal channels

Only one radio

transmitter is used

(e. g. in case of a

defect):

Variant 1 z

(blue radio transmitter in use)

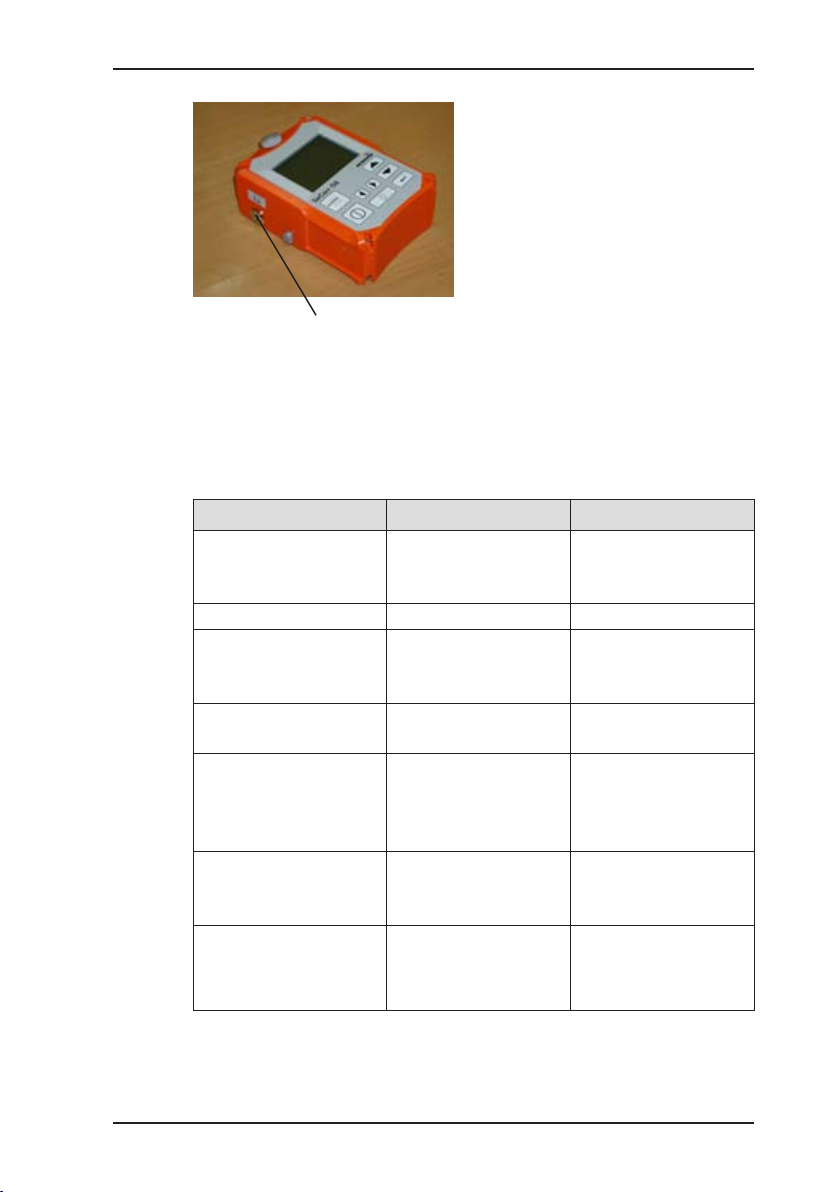

The initial screen is briefly

displayed, containing information on the release number of

the software and the battery

capacity.

Then the central screen appears (see back of cover

page). From this screen, you

ca n acc ess the individual

menus (menu key) or start the

desired functions.

Keep the z ON/OFF key pressed

until the device switches off.

Channel 1 Channel 2

RT 06-1 RT 06-2

Director connection

of microphone to

Radio transmitter 2

(orange)

SeCorr 08

Radio transmitter

1 (blue)

Radio transmitter 1

(blue)

Radio transmitter

2 (orange)

Direct connection

of microphone to

SeCorr 08

2 Use

Variant 2 z

(orange radio

transmitter in use)

Direct connection

of microphone to

SeCorr 08

Radio transmitter 2

(orange)

Page 13

4

2 Use

During correlation measure- z

ments the noise intensity of

both microphone channels is

indicated to the left- and righthand side of the correlation

function.

started

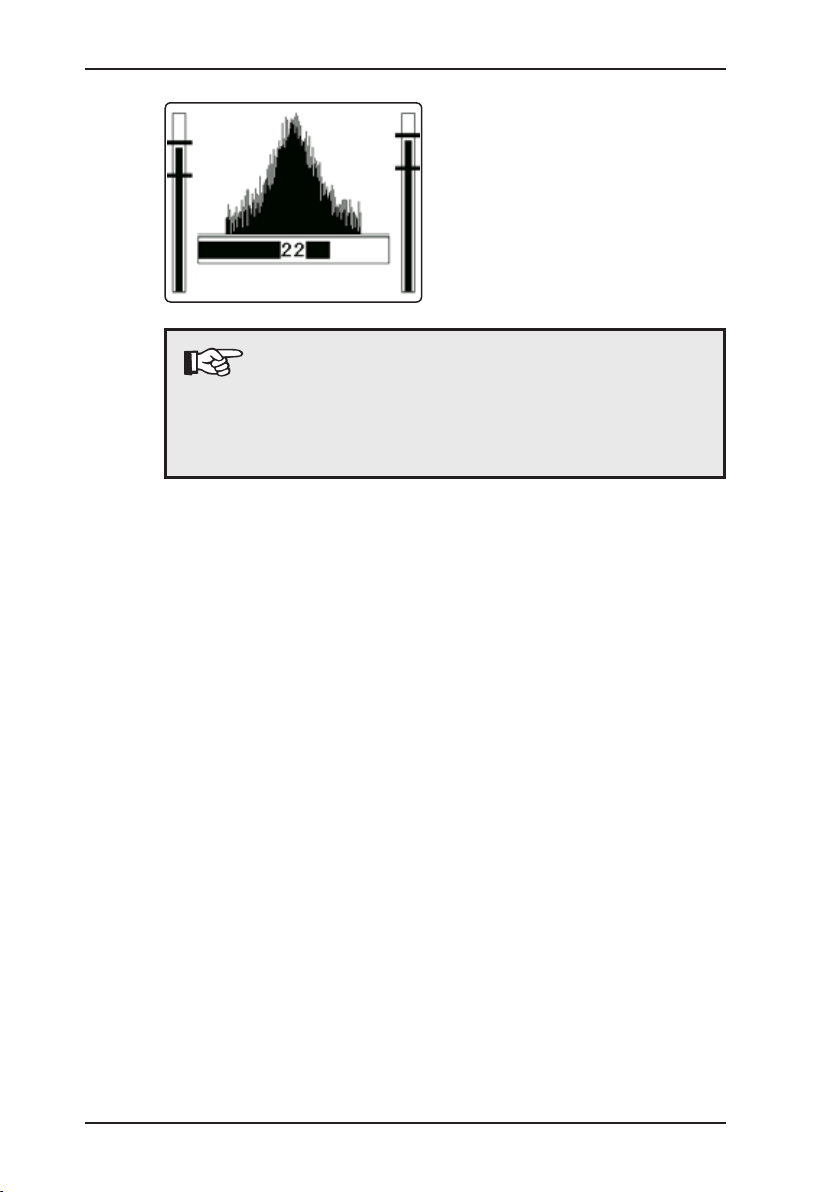

Note:

The SeCorr 08 version with two transmitters permits

to connect a microphone directly two the SeCorr 08,

e.g., if a radio transmitter is defective (see also section 7.8.3).

Page 14

5

2.4 Radio transmitter RT 06

4

6

3

1

CAUTION!

Connect always rst the sensor to the measurement

location (by coupling the microphone to the slide

valve, hydrant, etc.). Then, switch on the RT 06 by

plugging the sensor into socket 2.

This sequence of steps ensures that the automatic

amplication in the RT 06 is quickly and properly

set.

2 Use

The radio transmitter RT 06

can be operated with different

5

2

sensors, EM30 microphones

and the HA hydrophone.

It is recommended to use the

active lter ZF01, if interfering

noise is to ltered out or if only

a specic acoustic frequency

range is to be transmitted to

the correlator SeCorr 08.

The RT 06 is enabled when the sensor is plugged into socket 2.

Press the lter key 4 generally if plastic pipes are used. The right

LED 5 is lit to indicate the changeover. If this setting is selected,

only the low-pass frequencies are transmitted to the correlator.

This may help to increase the quality of the correlation measurement. If the RT 06 is switched on, all frequencies are always

transmitted; the left LED 6 is lit.

The transport handle on top of the antenna can be used for car-

rying the device.

LED 1 shows the state of the RT 06:

Operation: green

Undervoltage: ashed red

Charging: 1 x ashing green

Buffering: 2 x ashing green

No charging: red (because temperature below 0 °C)

Page 15

6

3 Operating elements

3 Operating elements

3.1 ON/OFF key

Press this key to switch the device on or off. Hold it pressed until the SeCorr 08 is activated.

If the key is pressed only shortly,

the currently running function is

stopped (e.g., a correlation in

progress). If you have opened

the menu, you can use the ON/

OFF key to return to the next

higher menu level. Press the key

only shortly.

If a correlation is stopped, the

diagram (correlation function)

can be zoomed in. If any key is

pressed, the display returns to

normal representation.

3.2 Rotary regulator

Turn the Rotary regulator to

move the selection or the cursor

to the left/right or up/down.

You can use the Rotary regulator

to change values in numerical

entry elds (e.g., pipe length).

Press the Rotary regulator once

to change the direction of movement from up/down to left/right or

vice versa.Pressing the Rotary

regulator has the same effect as

pressing the Enter key.

Page 16

7

3.3 Enter key

3.4 Menu key

3.5 Left/right arrow keys

3 Operating elements

Press this key to enable the currently selected function.If you

select „Cancel“ in the menu, the

display returns to the central

screen.

Press this key to open the menu

(see section 7).

Press these keys to move to the

left or right within the selected

function. In some menus the

arrow keys can also be used for

selecting options.

You can access the next higher

menu level by pressing the left

arrow key. You can use this function only if the cursor is set to its

left or right end position.

3.6 Up/down arrow keys

Press these keys to move the

cursor up or down in a menu.

In some menus the Arrow keys

can also be used for selecting

options.

Page 17

8

3 Operating elements

3.7 Light key

3.8 Adjusting the contrast

Use this key to switch the illumination on or off. The illumination automatically switches off after a pre-set period

(see section 7.8.4).

The contrast of the display is au-

tomatically controlled in relation

to the temperature.

You can ad just the contrast

manually by holding the Light

key pressed while operating the

Up or Down Arrow key at the

same time.

Page 18

9

4 Performing a correlation measurement

4 Performing a correlation measurement

4.1 Entering pipe data

Before starting a measurement, it is required to enter the pipe

data.

Select option pipe data using z

the Arrow keys and conrm

your selection with the Enter

key.Then, enter the number of

pipe sections.

Depending on the type of ap- z

plication, select One, Two or

Three pipe sections with the

arrow keys. Conrm your selection with the Enter key.

Enter the pipe length. Use z

the left or right arrow key to

change between the displayed

digits.

You can use the Up/Down z

arrow keys to increase or

reduce the displayed value in

increments.

Confirm the length with the z

Enter key.

In the list, select the material z

of the pipe section using the

Arrow keys. You can also use

the direct option to enter the

sound velocity manually.

Pay attention to the following: z

The values in the list are ap-

proximate values and may be

subject to inaccuracies (see

section 5.)

In the displayed list, select the z

pipe diameter using Arrow keys.

Page 19

10

4 Performing a correlation measurement

Start

cancel

100.0 m

steel

125 mm

1280 m/s

Note:

Apart from the default application, „Cross cor-

relation“, SeCorr 08 can also be used to perform

automatic correlations („Auto correlation“); refer to

chapter 7.6.5!

4.2 Starting a measurement

Select this function, if a measurement section is measured for

the rst time or if an error occurred during the rst measurement

(transmitter is not switched on, problems during connecting the

microphone, etc.).

pipe data

start

continue

If necessary, repeat these en- z

tries for the second and third

pipe section.

Select start with the Arrow z

keys and conrm your selection with the Enter key.

Use the headphones to check

the measurement trend acous-

tically (safety instructions: see

section 7.2.1).

A summary of the entered z pipe

data appears on the screen.

Select Start with the Arrow

keys. Press the Enter key.

The correlation measurement

starts.

Page 20

11

pipe data

start

continue

4 Performing a correlation measurement

Press Cancel to return to the z

main menu.

Depending on the selected

settings (see section 7.6.2)

either 16, 32, 64 or 128 averaging processes (i.e., measurements) are performed.

The display shows the current-

ly performed measurement.

During the measurement, the

correlation function is continuously updated.

The correlation measurement z

can be interrupted any time

by pressing the ON/OFF key

shortly.

An interrupted measurement

can always be resumed.

After the z measurement the re-

sult is displayed. The adjacent

illustration shows a correlation

example. The method of display depends on the setting

selected in the „Filter / Setup“

menu.

4.3 Evaluating the result

pipe data

start

continue

The correlation function uses

peaks to indicate where a leak

may be located. The time-delay

difference is displayed on the x

axis in ms (i.e., milliseconds).

The highest peak is automati-

cally highlighted.

Page 21

12

4 Performing a correlation measurement

CAUTION!

If a peak is displayed right in the centre of the screen,

this may indicate that the RT 06 radio transmitter is

placed too close to the SeCorr 08 (receiver). In this

case, increase the distance (5 – 10 m).

4.3.1 Filtering

Please read section 7.4 and 7.4.2 on the basic principles of ltering.

The ltering option here from the function in the main screen offers faster access to manual functioning than via Menu / Filter /

Manual. The range of functions here is, however, limited.

Select “Filter“ in the main screen. z

The left lter limit ashes and can be set. z

Enter key: calculates the result function; the other lter limit can z

be set (can be repeated as often as you wish).

ON key: returns to the main screen, the result is displayed. z

4.3.2 Cursor

After selecting the Cursor function with the Arrow keys, you

can move the cursor to any

position using the Arrow keys

or Rotary regulator.

Depending on the highlighted

position, the measurement result

is immediately recalculated. The

time indicated next to the cursor

represents the set time-delay

difference.

Below the correlation function,

the distance between the current cursor position and the two

microphones is displayed.

Page 22

13

4.3.3 Zoom

cursor

zoom

zoom

menue

4 Performing a correlation measurement

Use the Zoom function to zoom

in any area of the correlation

function.

Select zoom with the z Arrow

keys.

Zoom in the display by press- z

ing the right Arrow key. The

position bar 1 below the corre-

lation function indicates which

part of the total pipe length is

zoomed in.

Press the left Arrow key to re- z

turn to the display of the complete correlation function.

Note:

If the correlation procedure is used, subjectively

assessing the form of the correlation function may

be signicant. The experience required for this

cannot be taken from books – only practice makes

perfect.

The result of the measurement is based on the value

marked in the CCF and on the entered pipe data.

In simple terms, the correlation function represents

– qualitatively and chronologically – the relation

between the two noise signals that were recorded

by both microphones.

It is generally not possible to distinguish between

leakage noise (that is the noise that we are looking

for) and other background noise. For this reason,

the measurement result does not always represent

a leakage point; background noise can also be the

cause!

If no specic noise signal is present, the measurement result may be arbitrary. In this case, you should

use positions with more distinct leakage noises for

connecting the microphones.

Page 23

14

4 Performing a correlation measurement

4.4 Continuing a measurement

This function starts the correlation measurement using the available pipe data. The results obtained remain stored (e.g., from a

previously performed correlation).

Pipe data changed after the last correlation is not used.

It is recommended to continue the measurement, if the result of

the rst measurement (e.g., number of averaging processes: 32)

is not completely reliable.

pipe data

start

continue

Select continue with the Ar- z

row keys and conrm with the

Enter key.

Perform the measurement as

described in section „Starting

a measurement“.

Page 24

15

5 Measuring the sound velocity

5 Measuring the sound velocity

5.1 General information

It is required to measure the sound velocity since only correctly

entered sound velocity values ensure precise measurements.

The sound velocity values are taken from an internal table, see

section 7.6.7. However, the sound velocity values entered under

Pipe data are only approximate values. Apart from that, it may

also be possible that you do not know the pipe dimensions or

material.

This function requires a noise source:

You can use an opened hydrant, for example, z

which generates a clear display in the correlation-function eld, z

thus being „correlatable“,

whose location must be known, z

whose location should not lie in the central range of the mea- z

surement section, in order to increase the measuring precision.

If the measurement section consists of varying pipe sections (different materials or dimensions), the sound velocity measurement

will lead to incorrect results.

5.2 Performing a measurement

The measurement procedure is very similar to that of correlation

measurements.

First, connect microphones and z radio transmitter as described

in section 2.2).

Enable option Sound velocity in z menu Measurement method

(see section 7.5).

Select Pipe data and enter the corresponding data. z

Under Articial leak, enter the distance between the articial z

leak and microphone 1: if it lies outside and beyond the mea-

surement section

of microphone 1, enter 0 m as distance, –

of microphone 2, enter the entire length of the measurement –

section under distance (i.e., the „pipe length“).

Page 25

16

5 Measuring the sound velocity

Create an articial leak to generate a noise source (e.g., opened z

hydrant) or take a hammer and beat rapidly on the tting.

Select Start with the Arrow keys. z

The measurement procedure begins.

After the z measurement the correlation function is displayed

on screen.

The cursor is automatically set to the position with the largest z

value. Check whether this position corresponds to your articial

leak. If require, move the cursor with the arrow keys or Rotary

regulator to the articial leak.

If you select Input in the menu: z

The determined sound velocity is loaded into the internal –

memory.

The measurement method „Measure sound velocity“ is exited –

(reset to „standard“ method).

The central screen is called up. –

You can now perform a correlation measurement for determining the real leak. When entering pipe data which may require

modifying, it is recommended that you also enter the determined

sound velocity. Select the item „Direct“ under ”Pipe material”

for this.

If you select ”Cancel” in the z menu:

the determined – sound velocity will not be accepted.

the – measurement method “Measure sound velocity” is exited

(reset to “Standard” method).

The central screen is called up. –

Page 26

17

6 Charging equipment

1

6 Charging equipment

Built-in NiMH cells are used for

supplying the SeCorr 08 and

RT 06.

The ope r a t i o n time of the

SeCorr 08 is approx. 8 hours. If

the display illumination is used

or if the outside temperature is

low (so that the display heater is

switched on), the operation time

can be signicantly shorter.

The operation time of the ra-

dio transmitter RT 06 is min.

8 hours.

Optionally (if the battery is empty) the SeCorr 08 and the radio

transmitter RT 06 can be operat-

ed with an external 12 V = power

source (e.g. vehicle cable).

If the devices are to be charged

or operated externally, either the

docking station HS 1,2 A with

the AC/DC adapter or the vehicle

cable is required. Charging the

SeCorr 08 takes max. 4 hours.

Charging the radio transmitter

RT 06 takes max. 5 hours.

Connect the vehicle cable to

socket 1 on the docking station

or to socket 3 on the transmitter

RT 06.

3

Page 27

18

6 Charging equipment

The SeCorr 08 and the RT 06

transmitters can also be charged

when put into transport case.

To do this, connect vehicle cable

or AC/DC adapter to socket 1 in

the case.

1

Inside the transport case, connect

cables 2 and 4 to the two RT 06

transmitters and cable 3 to the

docking station HS 1,2 A.

2 3 4

6.1 Battery state

The battery state is indicated on the SeCorr 08 display by a bat-

tery icon together with the following messages:

RT 06-1 z or RT 06-2 or SeCorr 08

Battery icon and message appear when the operation time of the

corresponding component is less than 15 minutes.

More details are indicated by the status LED on the RT 06, see

also section 2.4.

Page 28

19

6.2 Charging process/battery maintenance

During charging, the SeCorr 08 displays a number indicating the

remaining charging time in hours. In this mode, you can select

the function Battery maintenance using the menu key. With this

function, the battery is rst discharged and then recharged. This

ensures that chemical deposits inside the battery are removed

and that the memory capacity of the battery is improved. The

process takes approx. 10 hours. It is recommended to use this

function regularly (in cycles of 60 days) for devices which are

only rarely used.

Symbols and their meaning during the charging process:

Battery maintenance is enabled.

The temperature has dropped

below 0 °C, the battery cannot

be charged.

6 Charging equipment

The temperature has exceeded

45 °C, the battery cannot be

charged.

Page 29

20

7 Menu

Listen

Channel 1

Channel 2

Channel 1 and 2

AQUAPHON

File

Open

Low resolution

High resolution

Noise

Store

... see „Open“

Delete/All

... see „Open“

Filtering

Automatic

Manuel (**)

Setup (*), (**)

Filter limit

Filter basis

Coherence

Cross spectrum

Spectrum KA 1

Spectrum KA 2

Filtering method

Rectangle

Hanning

Measuring method

Standard

Sound velocity

Parameter

Noise suppression

Automatic

Manuel

Off

Measuring time

Standard =32

Summation/Average

Summation

Averaging

Mode of curve (*)

CCF positive

CCF pos. + neg

TOP pos. + neg.

Type of correlation

Cross correlation

Auto Corr. CH 1

Auto Corr. CH 2

Sampling frequency

Automatic

Manuel

Table (*)

Standard values

Components

Setup (*)

Date, Time

Language

Radio/Cable

System

Name

Service

7 Menu

7.1 Menu structure

(*) Settings which remain stored

after switching off the device.

All other settings are reset to

the respective standard val-

ues (see section 7.6.8).

(**) This menu and the corre-

sponding functionality is only

available in the professional

version.

Page 30

21

Note:

Certain menu items are not available in the standard

version. If you select an item which is not available,

an appropriate message is indicated. If you want to

upgrade from the standard version to the professional version, a registration code is needed.

7.2 Listen

Use the Listen function to set the sound level of both channels.

Select the channel which you want to change with the arrow z

keys.

You can then change the sound level of he selected channel z

using the arrow keys or Rotary regulator.

If you select z „Channel 1“, you will hear channel 1 on both ears

(mono mode). The same applies to „Channel 2“. If you select

„Channel 1 and 2“, you will hear both channels at the same

time (stereo mode).

7.2.1 AQUAPHON

Use the “Aquaphon” function to enable the integrated feature

for searching leaks. This feature can be compared to that of the

Sewerin AQUAPHON A 100 / AF 100 device. These devices, how-

ever, are provided with a considerably wider range of functions.

You can use the microphones of this system.

The maximum measured value can be measured in the vicinity

of the leak.

Select the menu option Correlator to return to the correlator

mode.

To switch off the device:

pull the microphone connector from the socket (otherwise the –

device is switched on again and again)

enable the Correlator menu item (this permits to save the modi- –

ed settings for sensitivity and sound volume)

press the ON/OFF button. –

7 Menu

Page 31

22

7 Menu

Note:

You can access the Aquaphon mode directly by

connecting a suitable microphone to the disabled

device (power OFF).

CAUTION!

Do not use the headphones with high volume. Audiologists warn that the exposure to persistent or

sustained noise may result in hearing defects.

Set the volume to an appropriate level. z

Switch off the headphones when you suspect that z

interfering noise may occur (pedestrians, cars,

etc.).

Switch off the headphones before moving the z

microphone.

Bear in mind that your perception capability is z

reduced.

7.2.1.1 Display

The display contains the following components:

sensitivity

correlator

Measured value (sound level at microphone)

Set sensitivity

Headphones volume

Filter settings

Detected microphone type

Page 32

23

7.2.1.2 Assignment of keys

In the Aquaphon mode, the key assignment of the SeCorr 08

differs from the standard mode.

7.2.1.3 Sensitivity

Use the Sensitivity option to set the basic amplication of the

leakage noise.

You can select the following levels

sensitive z (display range 10)

medium z (display range 100)

insensitive z (display range 1000)

7 Menu

Switch ON/OFF the headphones.

Turn the Rotary regulator to set

the volume of the headphones.

The headphones are switched

on as long as you press on the

Rotary regulator.

Use the ON/OFF key to change

the sensitivity level (see section

below).

7.3 File

In this menu, you can open, save and delete individual measure-

ments. The professional version also permits to open, save and

delete sound samples. The data is led in the internal storage

of the SeCorr 08 and can be called up even after switching off

the device.

7.3.1 Store

The following number of storage locations is available:

a) 50 storage locations (low resolution)

b) 25 (1 – 25) storage locations (high resolution)

c) 5 (1 – 5) storage locations (sound)

Page 33

24

7 Menu

Note:

b) and c) share a common storage area.

Measurements which were stored with a low resolution cannot

be post-post-processed (e.g., ltered) at a later date. Only the

central screen can be called up for viewing.

Functions: View of the central screen,

cursor navigation,

starting, continuing.

50 storage locations with low resolution are available.

Measurements which were stored with a high resolution can be

post-processed at a later date. This means that all functions which

are usually possible after closing (i.e., stopping) a measurement,

are also possible in this situation. Exception: It is not possible to

„continue“ the measurement.

Up to 25 storage locations are available. These locations are

shared with the „sound“ storage.

If you select Noise, the currently measured noise is stored for

approx. 7 seconds.

Pay attention to the following: Saving takes approx. 35 seconds

due to the high memory capacity. The process cannot be inter-

rupted.

Use the arrow keys to select the item which you want to save: z

Low resolution, High resolution or Noise.

After conrming with Enter, the measurement or noise signal z

is saved.

7.3.2 Open

Use the arrow keys to select the item which you want to

open:

Low resolution, High resolution or Noise. Please note that it z

takes approx. 25 seconds to load a sound.

Conrm your selection with the Enter key.

A list is displayed including all les of the SeCorr 08 memory.

Page 34

25

Select a le with the Arrow keys and conrm your selection z

with the Enter key.

If you have opened a measurement, it will then be displayed. z

If you have opened a noise signal, the noise will be played back

with a phasic duration of 7 seconds. You can cancel the playback

by shortly pressing on the ON/OFF key.

7.3.3 Delete

Use the Arrow keys to select the item which you want to z delete:

low resolution, high resolution or noise. Conrm your selection

with the Enter key. A list is displayed including all les of the

SeCorr 08 memory.

Select the le which you want to delete with the Arrow keys z

and conrm your selection with the Enter key. The le is then

deleted.

7.4 Filtering

You can use the ltering function to cut off certain frequencies from

the correlation function, thus leading to improved results.

You can select between manual or automatic ltering.

7 Menu

7.4.1 Automaticltering

After a measurement, SeCorr 08 performs an automatic lter run

(post-processing). During this procedure the lters are automati-

cally optimised.

7.4.2 Manualltering

An image is generated in which you can see a frequency trend

(lter base at the bottom of the image, see chapter 7.4.3.3), as

well as the result based on the set lters (representation, see

chapter 7.6.4).

Page 35

26

7 Menu

Press the Enter key to change to

the editing mode.

Use the Arrow keys to select z

the filtering limit which you

want to change:

- Filter left

- Filter right

- Cut off left

- Cut off right

Use the arrow keys to shift the z

corresponding limit.

The appropriate frequency is

displayed on screen.

Light grey frequency ranges

are cut off.

Ranges which are indicated

in black are used for correlation.

If you want to zoom in the

frequency range, you need

to change the set filter lim-

its beforehand (see chapter

7.4.3.1).

Page 36

27

zoom

filter left

filter right

cut off left

7 Menu

left

ltering limit

cut off limit

left

right

ltering limit

right

cut off limit

Select “OK” with the Arrow z

keys.

The set lters are applied and

the indicated frequency trend

is updated together with the

result.

Press the z Enter key to return

to the direct ltering screen to

redene other lter limits, if

necessary.

Select “Return” to return to the z

central screen and to store the

changed settings.

Page 37

28

7 Menu

7.4.3 Setup

Customized settings are saved in the setup, sparing users the task

of calling up the desired functions every time they are required.

Place the cursor on the desired item and press the Enter key.

7.4.3.1 Filter limits

Use this setting to dene the lter settings to be used for manual

ltering (see chapter 7.4.3.1).

Default setting: If you enter a sound velocity for a measurement

which is lower or higher than 700 m/s, the correlator uses the

following values:

Lower limit / Hz Upper limit / Hz

< 700 m/s 5 500 Synthetic material / plastic

> 700 m/s 0 3000 Metal

It plays no role whether the sound velocity is manually entered or

whether appropriate pipe parameters are selected.

7.4.3.2 Filter basis

You can use this menu option to change how the frequency curve

of the lter setting is represented.

Coherence z

This function is used to indicate similar frequencies.

Cross spectrum z

This function is used to indicate the cross spectrum of both

channels.

Spectrum, CH 1 z

Used to indicate the frequency spectrum of channel 1.

Spectrum, CH 2 z

Used to indicate the frequency spectrum of channel 2.

Page 38

29

7.4.3.3 Filtering method

If rectangle is selected, signal ltering is performed precisely at

the marked point.

With Hanning, the range of the marked point is faded in with soft

transitions.

7.5 Measurement method

You can use the measurement method function to change be-

tween standard measurement (= correlation measurement) and

sound velocity measurement (see section 5).

7.6 Parameter

Use the parameter sub-menus to set parameters which are having effect on the measurement.

7.6.1 Noise suppression

The noise suppression function can be used for reducing the negative effect of temporary interferences (vehicles, pedestrians).

If the noise suppression function is enabled, it is assumed that

optimum results can be achieved in those moments in which the

measured noise (signal) is relatively low. This means that the permanently present leakage noise is preponderantly undisturbed.

In moments in which the signal is relatively loud, the additional

noise must come from a interference source in all probability,

leading to much less reliable measurement results.

The level range is limited by the upper threshold and the lower

threshold. During a running measurement, these thresholds for

signal 1 and 2 are indicated as horizontal lines on the left or right

edge of the display.

After a dened interval, the level range is automatically and slowly

increased, if the current level values lie permanently above the

level range. In the same way the level range is reduced, if the

current level values lie permanently below the level range.

7 Menu

Page 39

30

7 Menu

a) Automatic mode (Default setting)

This setting is recommended for standard situations and ensures

reliable results.

After a dened interval, the level range is automatically and slowly

increased, if the current level values lie permanently above the

level range. In the same way the level range is reduced, if the

current level values lie permanently below the level range.

b) Manual mode

This setting is recommended, if you want to work with maximum

interference suppression and if you desire greatest possible in-

uencing control for measurements.

If the interruption is too long due to excess noise, it is possible

to manually increase the level range with Continue, so that the

sensitivity level is reduced. The measurement is continued with

the operator ignoring a certain level of interfering noise.

If the current level values fall below the level range, an adjustment is automatically performed, i.e., the correlator is set to a

more sensitive level.

c) Off

It is recommended to select this setting only in situations which are

marked by frequently returning, strongly varying signals resulting

in the measurement being frequently interrupted, thus preventing

a correlation completely.

Noise suppression is disabled. With this setting, it is accepted

that interfering noise is jamming the leakage noise from time to

time.

Page 40

31

7.6.2 Measuring time

You can use the Measuring time function to dene how many indi-

vidual measurements are to be performed until the measurement

sequence is stopped.

7.6.3 Summation/average

With the „Summation“ function all individual results are used for

representing the CCF. This representation is immediately used.

If you select „Average“, the individual results are evaluated using

a different procedure: The last performed measurement has the

largest inuence on the CCF. The preceding measurement has

less inuence, etc.

This procedure ensures that the CCF, with selected Average,

represents the current noise situation.

7.6.4 Mode of curve

You can change the mode how the correlation function is repre-

sented as follows:

CCF positive z

The CCF has only positive values.

CCF pos. + neg. z

The CCF contains positive and negative values.

TOP positive z

The representation is similar to that of CCF positive. Peaks,

however, are represented more signicantly in most cases.

TOP pos. + neg. z

The representation is similar to that of CCF pos. + neg. Peaks,

however, are represented more signicantly in most cases.

7 Menu

7.6.5 Correlation

If Cross correlation is selected, the noise source to be located

must lie within the measurement section. The measurement is

carried out with both channels (1 and 2).

With Auto correlation, either channel 1 or channel 2 is used. The

second signal required for the correlation is created by the noise

reection which is detected at the reection point. It is required

that the signal is received by the channel which is to be used.

Page 41

32

7 Menu

Since the energy of the reected noise signals is generally extremely low, it is recommended to use this procedure only in special

cases. If the pipe contains gases, the chances may be better.

If Auto correlation is used, the location of the reection point must

be known.

The auto correlation function (ACF) always runs symmetrically. Only

the negative range of the auto correlation (delta t < 0) is signicant.

7.6.6 Sampling frequency

The continuous time signal of the used channels is sampled and

digitised with a particular frequency, the sampling frequency.

The lower the sampling frequency, the less time is required for calculating the averaging processes. However, the used sampling theorem

demands a sampling frequency which is at least twice as high as the

highest frequency contained in the signal! Setting the sampling frequency too low may lead to faulty measurements. For this reason, it

is recommended to decrease the sampling frequency only in special

cases, e.g., if extreme low-frequency noise is to be measured.

If Automatic is selected, the sampling frequency is set to its maximum height.

If you want to dene the setting manually, select Direct. You can

then change the sampling frequency with the arrow keys.

All following measurements are performed with this sampling

frequency.

7.6.7 Table

In this menu, you can select two different sound velocity tables.

They differ in subranges.

Sound velocity 1: Particularly good experiences in France

Sound velocity 2: International validity

Sound velocity 3: This function is not available

7.6.8 Standard values

All parameters in the Parameter menu of the SeCorr 08 are re-

set to the respective standard values. This also includes those

parameters which remain stored after switching off the device.

The set language is not changed.

Page 42

33

7.7 Components

The screen shows an overview of the most important information

on the max. 3 main components of the system (2 RT 06 devices,

1 SeCorr 08 correlator).

7 Menu

Symbol explanation

Battery empty

Low volume High volume

Bad signal

reception

Battery fully

charged

Good signal

reception

Page 43

34

7 Menu

7.8 Setup

7.8.1 Date, time

Use this option to set the current date and time. You can also

select the date format.

7.8.2 Language

Use this option to select the desired language.

7.8.3 Radio/cable

Use this option to dene which channel is to be operated with

radio transmission and which channel is to be directly connected

to the SeCorr 08.

Use the Arrow keys to select the channel which you want to z

change. Conrm your selection with the Enter key.

Use the Arrow keys to toggle between RT 06-X and SeCorr 08, z

with RT 06 standing for radio transmission and SeCorr 08 for

cable operation. Conrm your selection with the Enter key.

Note:

If „American English“ is selected, several productspecic units of measurement will change.

For example:

Distance feet (ft), z

Diameter inch (in) z

Velocity feet per second (ft/s) z

7.8.4 System

You can use this option for:

Setting the time at which the light is to be z switched off auto-

matically.

Setting the time at which the device is to be switched off au- z

tomatically.

Page 44

35

7.8.5 Name

This option is used for entering name, company and address.

7.8.6 Service

This menu option is reserved for the Sewerin service.

7 Menu

Page 45

36

8 Methods of optimising measuring results

8 Methods of optimising measuring results

The location is based on the correct determination of the timedelay difference. If the leakage noise is sufciently loud and if

there are no background noise sources, the time-delay difference is adequately well-displayed after only a few averaging

processes (4 to 16).

But what can be done if no sufciently clear peak can be generated? The following instructions cannot substitute practice and

experience still required in difcult situations. However, they will

help you to learn the basic operations.

Be that as it may, you must always remember one thing: If the

leakage noise does not reach the microphones with sufcient

intensity, no correlation is possible!

8.1 Changing the number of averaging processes

If a result is unsatisfactory after the initial series of averaging proc-

esses, you can improve it by increasing the number of cycles. The

result is improved because the calculation is based on a greater

body of information on the chronological behaviour of the leakage

noise. However, experience has shown that the result can only

rarely be additionally improved if more than 64 to 128 averaging

processes are selected.

8.2 Usinglters

Use the features made available by the mathematical lters.

Unfortunately it is hardly possible to give any generally valid

„formula“. Only your own experience, i.e., learning by doing, will

lead to success.

In most cases, it is only practical to select frequency ranges for

the correlation function in which the coherence function does

clearly stand out from its environment, i.e., where there is peak.

Individual frequencies from various interference sources generate

a uniformly sinusoidal correlation function. They can be recognised in the spectra as sharp lines.

Page 46

37

8 Methods of optimising measuring results

8.3 Automaticltering

The SeCorr 08 can perform an automatic lter run (post-process-

ing) after a measurement (see chapter 7.4.1). This procedure is

used to optimise the lters of the coherence function with the

help of statistical methods. This permits to obtain optimum cor-

relation results.

You may perform an automatic frequency analysis for both, running measurements or already stored measurements.

8.4 Checking the microphone connections

Make sure that the microphones are rmly and securely plugged

into their sockets. Remove any dirt or rust.

8.5 Using accessories

Use Sewerin accessories and auxiliary equipment. Use a hydrophone for plastic pipes. The active lter makes additional features available. You can use the „teach yourself“ tape to check

the system and to keep your level of knowledge up-to-date with

a minimum of effort.

8.6 Changing the location

Use a different location for positioning the microphones. Even

remote locations can generate better results if the sound transmission is improved.

8.7 Saving time

If it turns out during a measurement that it is not possible to record

a peak, all run-up efforts to collect precise data on the pipe were

in vain. Practice has shown that it might be better to start the

measurement with estimated pipe data. If it turns out that the

assumed pipe length is greater and/or the sound velocity lower

than expected, a possible peak will appear in any case within the

correlation function – which simply cannot be „overlooked“.

Also with this more practice-oriented approach, it is still required

to determine the pipe data precisely.

Page 47

38

9 Communication with PC

9 Communication with PC

It is possible to transmit measurements to a PC which are stored

with high resolution in SeCorr 08. These les can be archived and

post-processed on computer (e.g., to set up a protocol). In addition, it is possible to print out data and graphics, provided that a

printer is available. The stored „sound“ as well as measurements

with low resolution cannot be transmitted.

9.1 Requirements

PC (operating system: Windows 95 / 98 / 2000 or XP)

Program “SeCorr 05” (PC correlator software), from version 10.16

onwards (15.1.2003)

SeCorr 08 Professional version

9.2 Software installation

Install the SeCorr 05 software (demo version on CD) on the

PC.

Connection of all cables and connectors: –

Connect any serial interface of the PC to the SeCorr 08 (socket

with cap at the left-hand side of the device). Use the communication cable (accessory) for this. The PC must not be congured

to an interface higher than COM 4.

Put the – SeCorr 08 into the HSM docking station which is sup-

plied with 12 V=. It plays no role whether the SeCorr 08 is

switched on or off.

Transmitting data from – SeCorr 08:

Start the SeCorr 05 program and select function SeCorr 08 in

the File menu.

The data is transmitted, converted and stored in the „SeCorr 08“

target directory. Depending on the extent and number of measurements this process may take some time. The progress of

transmission is indicated on the computer. The SeCorr 08 target

directory is generated in the working directory from which the

SeCorr 05 program was started, e.g., C:\CORWI.

Page 48

39

9 Communication with PC

The le names are automatically generated using the measuring

date and the measurement time in SeCorr 08 (which is precise

to the minute). They have the following format:

HA_DD-MM-YYYY_HH-MM.COR

with:

DD-MM-YYYY = Date (day, month, year)

HH-MM = Time (hour, minute)

The les can be managed (e.g., renamed, moved) just as any

other le.

Opening measurements –

In the SeCorr 05 program, you can open measurements with File

Open le. You can nd more detailed information on how to use

SeCorr 05 in the program’s help menu.

Page 49

40

10 Technical data

10 Technical data

Correlator SeCorr 08

Operation time: approx. 8 hours

Operating temperature: -10 °C – +40 °C

Storage temperature: -20 °C – +60 °C

Charging time: 4 hours

Weight: 1.3 kg

Protection class: IP65

Dimensions

(W × H × D):

Radio transmitter RT 06

Signal transmission: 500 mW

Charging time: 5 hours

Operating time: 10 hours

Filter setting – wideband: 0 – 3000 Hz

Filter setting – low-pass: 0 – 300 Hz

Weight: 1.3 kg

Dimensions

(W × H × D):

Protection class: IP67

125 × 180 × 65 mm

73 × 190 × 125 mm

(with antenna = 510 mm )

Page 50

41

11 Accessories

Communication cable between PC (COM interface)

Carrying case with foam inset for the correct

Hydrophone type HA e.g., for connection to inhouse

Hydrophone adapter UFH

DN 80 for 1“ female threads

Adapter for main pipes M10 for the permanent coupling of a

Adapter for in-house

connection M10

Piezo microphone EM30 non-corrosive version

Activelter for suppressing interferences

Test-and-teach-yourself tape cables incl.

Test-and-teach-yourself CD cables incl.

11 Accessories

and SeCorr 08 correlator.

arrangement of correlator, radio

transmitter, microphones and

head phones.

PE pipes after dismounting the

water meter.

between ground hydrant and

hydrophone type HA.

microphone to a slide valve or

hydrant.

for the permanent coupling of a

microphone to an in-house cutoff valve.

Page 51

42

12 Error messages

12 Error messages

Error code Cause

Radio! RT 06-1 This message may appear if a correlation

measurement is to be started. It is used to

warn the operator. It is nevertheless possible to perform a correlation measurement.

However, the quality of the radio transmission may be worse.

This error message appears when:

the z radio transmitter is not operated,

the transmission is impaired by buildings, z

etc. between SeCorr 08 and RT 06,

the distance between z SeCorr 08 and

RT 06 is too large.

Remedy:

Check the corresponding radio transmit- z

ters. Are they really switched on?

Position the radio transmitter in such a z

way that the signal route between transmitter and correlator is as good as pos-

sible (line-of-sight between transmitter

and receiver).

Check the radio transmission with the z

headphones. Can you hear any distinct

(leakage) signals or only noise?

Radio! RT 06-2 see „Radio! RT 06-1“

Microphone!

no microphone connected z

Channel 1

Channel 1

(resp. 2)

automatic amplier is being readjusted z

(simultaneous display of a bar graph

showing the progress)

Page 52

43

Error code Cause

F200 Communication error

Error F200 can be ignored if they appear

only occasionally. If they appear frequently,

contact the SEWERIN service..

F201 Communication error

Error F201 can be ignored if they appear

only occasionally. If they appear frequently,

contact the SEWERIN service..

Note:

If further error codes are indicated, please contact

the SEWERIN service!

12 Error messages

Page 53

44

13 Annexe

13 Annexe

13.1 EC Declarations of Conformity

Hermann Sewerin GmbH hereby declares that the SeCorr 08

fulls the requirements of the following guidelines:

2004/108/EC

z

The transmitter RT 06 fulls the requirements of the following

guidelines:

1999/5/EC

z

The complete declarations of conformity can be found online

(www.sewerin.com > Downloads).

Advice on disposal

13.2

The European Waste Catalogue (EWC) governs the disposal of

appliances and accessories.

Description of waste Allocated EWC waste code

Device 16 02 13

Disposable battery, rechargea-

ble battery

16 06 05

End-of-life equipment

Used equipment can be returned to Hermann Sewerin GmbH. We

will arrange for the equipment to be disposed of appropriately by

certied specialist contractors free of charge.

Page 54

45

13.3 History of changes

Version Description Date

13 Annexe

4.0 Additional function available in central z

screen: ltering. It performs a faster and

simplied access to manual ltering

3.0 Extended functionality of z RT 06 (ad-

ditional lters). Improvement of radio

transmission characteristics. Not (!)

compatible with RT 06 without lter.

Additional z listening feature (mono) in

the correlator mode

Structural modication of the “Filter” z

menu

2.1 Upgrade of PC correlator program z

SeCorr 05, version 11.xx. By that

means data read-out to PC has been

improved, the same sound velocity

tables are used.

new error codes, which refer to micro- z

phones not attached.

2.0 Modications in the z Aquaphon Mode

Storage of sounds z

March

2006

December

2004

January

2004

January

2003

Storage of measurements with high z

resolution

Transmission of measurements to PC z

Post-processing of measurements on z

the PC

2 different sound-velocity tables z

Modications in the operating sequence z

of sound-velocity measurements

Page 55

14 Index

14 Index

A

Accessories 37, 38, 41

Active lter 37, 41

AQUAPHON 21

Aquaphon mode 22, 23, 45

Arrow key 7, 8, 13

Auto correlation 10, 31

Average 11, 31, 32

B

Battery state 18

C

Cable 18, 34

Channel 1 3, 21, 28, 31, 42

Channel 2 3, 21, 28, 31

Channel assignment 3

Charging 5, 17

Components 33

Correlation 6, 14, 26, 31, 36

Correlation result 37

Cross correlation 10, 31

D

Date 34, 39

Delete 23, 25

Dimensions 15

Display 11, 22, 42

E

Enter key 6, 7, 10, 14, 24, 25, 26, 27,

28, 34

F

File 23, 24, 39

Filter 25, 27, 28, 37, 45

Filter settings 22

Frequency analysis 37

Function description 1

H

Hydrophone 37, 41

I

Individual results 31

Interfering noise 5, 22, 30

L

Language 32, 34

Leakage point 13

Light key 8

Listen 21, 45

M

Measurement 9, 10, 11, 14, 15, 16, 24,

25, 28, 29, 37, 39

Measurement method 15, 16, 29

Measurement result 12, 13, 29, 36

Measuring time 31

Menu 3, 7, 11, 15, 16, 20, 23, 32, 38

Menu key 3, 7, 19

Menu structure 20

Microphone! Channel 1 42

N

Name 35

Noise suppression 29, 30

O

ON/OFF key 2, 3, 6, 11, 23, 25

Optimising 36

P

Parameter 29, 32

Peaks 11

Pipe data 9, 10, 13, 14, 15, 16

Plastic pipes 5, 37

Power supply 17

R

Radio 34

Radio! RT 06-1 42

Radio! RT 06-2 42

Radio transmitter 1, 2, 3, 5, 12, 15, 17,

40, 42

46

Page 56

14 Index

Reection 31

Reection point 31

Result 11, 14, 25, 30, 36, 37

Rotary regulator 6, 12, 16, 21, 23

RT 06 1, 2, 5, 12, 17, 18, 34, 42, 45

S

Sampling frequency 32

Sampling theorem 32

Sensor 5

Service 35, 43

Setup 11, 28

Signal reception 33

Software 3, 38

Sound velocity 1, 9, 15, 16, 28, 29,

32, 37

Standard values 20, 32

Store 23

Summation 31

Switching off 2, 3, 6, 20, 32, 34

Switching on 1, 2, 5, 6

System 34, 37

T

Table 15, 32

Tape „teach yourself“ 37, 41

Time 34, 39

U

Units 34

Use 2

47

Page 57

Hermann Sewerin GmbH

Robert-Bosch-Straße 3 · 33334 Gütersloh · Germany

Telefon +49 5241 934-0 · Telefax +49 5241 934-444

www.sewerin.com · info@sewerin.com

26.04.2010 b – 103923 – en

Loading...

Loading...