Page 1

RMLD-IS

Operating

Instructions

Page 2

Measurable success by Sewerin equipment

Congratulations. You have chosen a quality instrument manufactured

by Hermann Sewerin GmbH.

Our equipment will provide you with the highest standards of perfor-

mance, safety and efciency. They correspond with the national and

international guidelines.

Please read and understand the following operating instructions before

using the equipment; they will help you to use the instrument quickly and

competently. If you have any queries we are available to offer advice

and assistance at any time.

Yours

Hermann Sewerin GmbH

Robert-Bosch-Straße 3

33334 Gütersloh, Germany

Tel.: +49 5241 934-0

Fax: +49 5241 934-444

www.sewerin.com

info@sewerin.com

SEWERIN SARL

17, rue Ampère - BP 211

67727 Hoerdt Cedex, France

Tél. : +33 3 88 68 15 15

Fax : +33 3 88 68 11 77

www.sewerin.fr

sewerin@sewerin.fr

SEWERIN IBERIA S.L.

Centro de Negocios Eisenhower

Avenida Sur del Aeropuerto

de Barajas 24, Ed. 5 Of. 2C

28042 Madrid, España

Tel.: +34 91 74807-57

Fax: +34 91 74807-58

www.sewerin.es

info@sewerin.es

Sewerin Ltd

Hertfordshire

UK

Phone: +44 1462-634363

www.sewerin.co.uk

info@sewerin.co.uk

Sewerin Sp.z o.o.

ul. Twórcza 79L/1

03-289 Warszawa, Polska

Tel.: +48 22 675 09 69

Faks: +48 22 486 93 44

Tel. kom. +48 501 879 444

www.sewerin.pl

info@sewerin.pl

Page 3

Operating Instructions

RMLD-IS

Remote Methane Leak Detector

01.10.2015 – 107216 – en

Page 4

Contents Page

Overview ..................................................................................1

Warranty ...................................................................................4

Warning notices ......................................................................5

Section I (System description) ............................................... 6

1.1 Technical data for the RMLD-IS system .................................... 6

1.2 RMLD-IS system components ..................................................8

1.2.1 Controller ................................................................................8

1.2.2 Transceiver.............................................................................8

1.2.3 Carrying strap .........................................................................9

1.2.4 AC/DC adapter ....................................................................... 9

1.2.5 Carrying case ......................................................................... 9

1.2.6 Headphones ........................................................................... 9

1.3 Accessories ............................................................................. 10

1.3.1 Dual shoulder strap harness ................................................10

Section II (Battery charging) ................................................ 11

2.1 Rechargeable battery .............................................................. 11

2.2 AC/DC adapter ........................................................................ 13

2.3 Charging procedure ................................................................13

Section III (Operating the RMLD-IS) ....................................14

3.1 Switching on the RMLD-IS ......................................................16

3.2 Switching on the spotter laser .................................................17

3.3 Switching off the RMLD-IS ......................................................18

3.4 Using the menus .....................................................................18

3.5 Using DMD mode .................................................................... 20

3.6 Using the Pure Tone mode ......................................................21

3.7 Self-test and calibration ........................................................... 22

3.7.1 Calibration override .............................................................. 25

I

Page 5

Contents Page

Section IV (Monitoring with the RMLD-IS) ..........................27

4.1 Monitoring with the RMLD-IS ..................................................27

4.2 Long range scanning ............................................................... 30

4.3 Dealing with false detections ................................................... 31

4.4 How does the RMLD-IS measure gas concentrations? ..........32

Section V (Maintenance and troubleshooting) ................... 36

5.1 Troubleshooting the device .....................................................36

5.2 Maintenance ............................................................................ 40

Appendix ................................................................................41

Glossary ..................................................................................41

Daily log of RMLD-IS self-test and calibration ......................... 43

II

Page 6

Overview

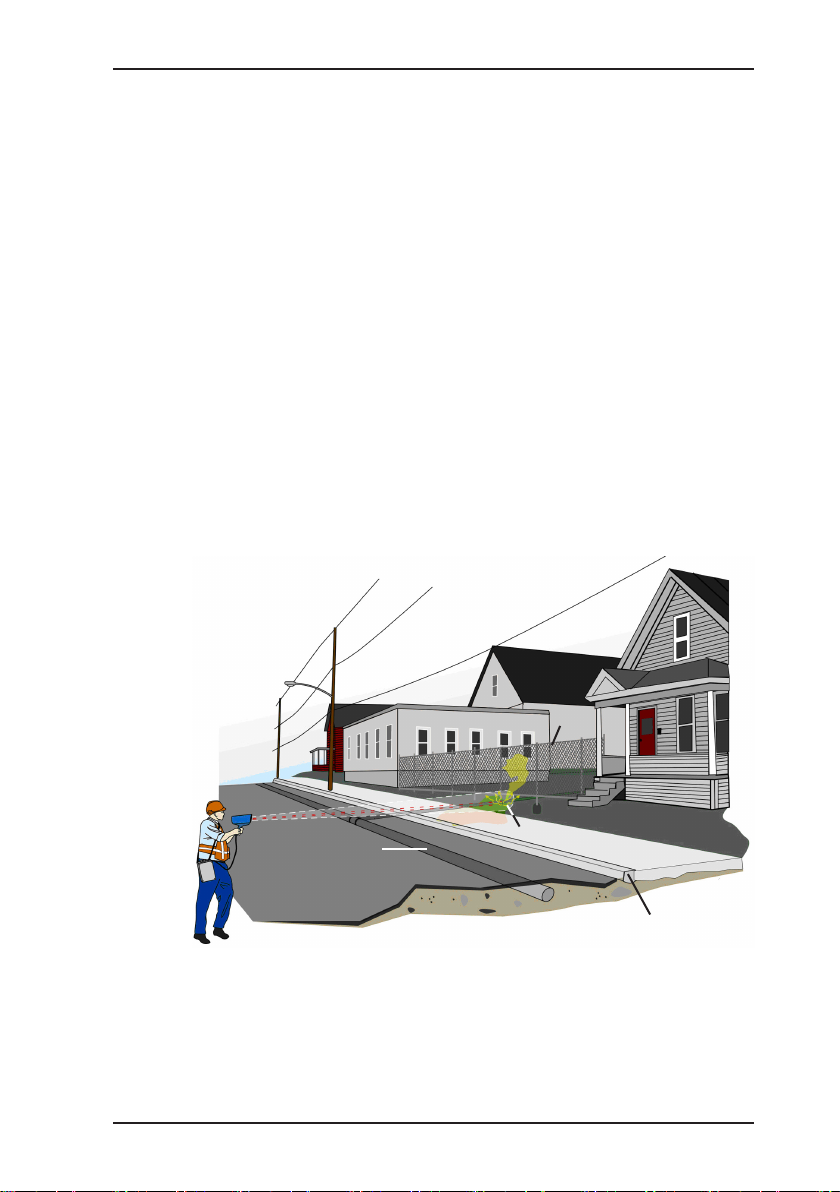

The Methane Leak Detector (RMLD-IS™) uses state-of-the-art

technology to identify methane leaks from a considerable dis-

tance. The RMLD-IS the rst of a new generation of leak monitoring devices that signicantly improve the productivity and safety

of mobile monitoring activities.

Using the RMLD-IS, it is now possible to monitor areas that are

hard to reach or are not easy to access. The use of TDLAS (Tunable Diode Laser Absorption Spectroscopy) laser technology

means that the RMLD-IS does not need to be located directly

in the gas plume. As the laser passes through a gas plume, the

methane absorbs a portion of the light, which is then detected by

the RMLD-IS. This technology makes it possible to detect leaks

along the line of sight without always having to walk the full length

of the gas pipe.

Fence

Gas pipe

Road (asphalt)

Figure 1-2

Leak

Kerb

Remote detection using laser technology, allows areas to be safely

monitored that may otherwise be difcult to reach, such as busy

roads, properties with guard dogs, fenced off areas, and other

hard to access places.

1

Page 7

The device is designed to selectively detect methane only, and

will not give a false alarm should other hydrocarbon gases be

present. Gas concentration is calculated according to the amount

of infrared light absorbed by the gas. Because the gas is detected

along the line of sight of the laser, the concentration is given in

ppm•m (parts-per-million•meter). In other words, the RMLD-IS

measures the concentration of the gas cloud multiplied by its

width. Depending on the local meteorological conditions, a given

amount of gas escaping from the ground will produce a plume

that varies in size and uniformity of concentration levels. Gas

plumes are variable in nature and depend on the soil conditions,

temperature, wind, and leak rate.

The RMLD-IS consists of two main components that interact with

each other:

z Transceiver

z Controller

Figure 1-3: The RMLD-IS system consists of a laser transmitter/receiver

and a controller

2

Page 8

The transceiver has two lasers. The infrared laser is invisible

and is continuously active when the device is switched on. The

visible green spotter laser must be activated by the operator by

pressing the trigger button.

The RMLD-IS can be operated in a wide variety of environmental

conditions, including cold and hot weather and light rain. Its rugged design will withstand normal eld use and operating conditions. Sensitivity and range are not negatively affected by normal

amounts of dust on the optics window.

The RMLD-IS includes integrated self-test and calibration functions that guarantee correct functioning of the device. The calibra-

tion cell built into the carrying case allows the operator to carry

out the self-test and calibration as part of a daily start up routine.

While in use, the RMLD-IS continuously monitors several parameters to ensure that the instrument is functioning correctly. Should

any of these parameters exceed the specied operating limits,

an audible alarm will sound and a fault/warning error message

will be shown on the display.

The device is supplied with a training video. It is strongly recommend that all operators view the video in order to learn the basic

techniques required to carry out monitoring using the RMLD-IS.

3

Page 9

Warranty

To ensure reliable operation and safety, it is essential to pay attention to

the following notes.

Hermann Sewerin GmbH is not liable for damage caused by failure to

comply with these notes. The guarantee and liability conditions of the sales

and delivery conditions of Hermann Sewerin GmbH are not extended by

the following notes.

z This product may only be taken operated after reading thoroughly the

accompanying operating instructions.

z This product may only be used for intended applications.

z This product is destined for industrial and commercial applications.

z Repairs may only be performed by the manufacturer or appropriately

trained staff.

z The manufacturer is not liable for damage resulting from arbitrary modi-

cations of the product.

z Only spare parts may be used which are approved by Hermann Sewerin

GmbH.

Technical changes within the scope of further development reserved.

4

Page 10

Warning notices

z The visible green Spotter laser is a Class IIIa laser product. Do not look

into the beam or view directly using optical instruments.

z Do not attempt to repair this device. Please refer to Section V in this man-

ual if the device does not work correctly or indicates a fault or warning.

z Do not switch on or use the RMLD-IS indoors if there is any indication,

possibility or suspicion that an explosive level of gas may be present.

z Do not charge in a danger zone.

z Replacing components can have an effect on the intrinsic safety of the

device.

z To avoid sparks in dangerous environments, rechargeable batteries must

only be exchanged in areas known to be safe.

5

Page 11

Section I (System description)

1.1 Technical data for the RMLD-IS system

Detection method: TDLAS (Tunable Diode Laser

Absorption Spectroscopy)

Measurement range: 0 to 99.999 ppm•m

Sensitivity: 5 ppm•m at a distance of 0 to 15 m

Min. 10 ppm•m at a distance of 15 to

30 m

Detection range: 30 m (nominal). Actual distances

may vary depending on the type of

background and other conditions.

Beam size: Conical beam, width 56 cm at 30 m

Alarm modes for

detection:

System fault

warning:

Self-test and

calibration:

Standards complied

with:

DMD (Digital Methane Detection)

z Audible signal, variable pitch accord-

ing to concentration when the alarm

activation threshold is exceeded.

z Alarm activation threshold adjustable

from 0 to 255 ppm•m.

Pure Tone

z Continuous audible signal, variable

pitch according to concentration.

Audible signal and symbol on display

Integrated self-test and calibration

function for checking correct operation

and adjusting laser wavelength for best

sensitivity. Gas test cell integrated into

carrying case

EMC (EN 61000-6-2, EN 6100-6-4)

(pending)

6

Page 12

Laser safety (eye

protection):

CDRH, ANSI and IEC

z IR detection laser

– Class I

z Green spotter laser

– Class IIIa: Do not look into the beam

or view directly using optical instruments.

Display: Large, easy to read display with

backlight (0.75", numeric)

Operating

-17 °C to 50 °C

temperature:

Humidity: 5 to 95% (non-condensing)

Housing: IP54 (protected against water spray

and dust)

Weight of device: 4 kg (transceiver 1.3 kg, controller 2.7 kg)

Carrying case: 6.4 kg; 86 cm x 24 cm x 36 cm

Power supply: Internal lithium-ion rechargeable

battery

Battery operating

life:

8 hours at 0 °C with backlight switched

off (internal battery)

AC/DC adapter: External adapter, 100 – 240 V~, 1.6 A,

50 – 60 Hz with charge indicator

(max. 8 hours for full charge)

Shoulder strap: Single shoulder strap with pad

Ergonomic dual shoulder strap harness

with belt (optional)

Intrinsic safety: Class 1 Division 1 Group D, T4

UL 913 MetLab listing #E112840

7

Page 13

1.2 RMLD-IS system components

This section describes the features of the RMLD-IS. Please refer

to Figure 1-4 for illustrations of individual parts.

Figure 1-4: System components

1.2.1 Controller

The controller provides the user interface, menu selection keys,

and external connections including: RS-232 port, AC/DC adapter

port, external power supply port, headphone port, and power

switch.

1.2.2 Transceiver

The transceiver houses the infrared detection laser and the visible green spotter laser, and has a trigger for the spotter laser.

The unit also has hooks for the carrying strap.

8

Page 14

1.2.3 Carrying strap

The RMLD-IS comes complete with a single carrying strap, including shoulder pad. An optional dual shoulder strap harness

is also available.

1.2.4 AC/DC adapter

An AC/DC adapter is supplied with the device for recharging the

battery.

The AC/DC adapter is a universal adaptor operating at

110 – 240 V~, 1.6 A and 50 – 60 Hz.

2 LEDs on the front of the controller display the current battery

charge level.

1.2.5 Carrying case

The carrying case provides protection for the device during

transportation and storage. The device must always be stored

in this case when not in use. A gas calibration cell is integrated

into the case.

1.2.6 Headphones

Allow audible signals to be heard through headphones instead

of the external loudspeaker.

9

Page 15

1.3 Accessories

1.3.1 Dual shoulder strap harness

The dual shoulder strap harness provides additional comfort and

support when carrying the device for extended periods. The inte-

grated lanyard is used to carry the weight of the transceiver and

provides additional stability and control over the unit during moni-

toring activities. SEWERIN recommends the use of this harness

by all personnel who operate this equipment for extended periods

of time in order to limit fatigue when holding the transceiver and

to improve monitoring technique.

10

Page 16

Section II (Battery charging)

2.1 Rechargeable battery

The RMLD-IS is tted with an internal lithium-ion battery that

provides the main source of power for the device. This battery

is designed to provide 8 hours of device operation when fully

charged. The battery must be recharged every time the device is

not in use in order to guarantee uninterrupted use of the device.

A battery charge indicator is provided on the display. This indicator is accurate to within 20% of actual capacity. The indicator

should only be used as a guideline value. Always start the day

with a fully charged battery to ensure that the device can be used

for the whole day.

Battery charge indicator

Figure 2-1

Note

To ensure the battery stores its full capacity,

charge when the ambient temperature is between

10 °C – 30 °C.

The device should have a battery level of at least

40 % (3 – 4 bars) if it is to be stored for a period of

longer than a week. Store at approx. 20 °C room

temperature and 70 % relative humidity.

11

Page 17

CAUTION!

Prolonged periods of not using the rechargeable

battery either inside or outside the device may result

in irreparable damage.

It is advisable to check once a month that the bat-

tery level remains at at least 40% during storage.

Never fully discharge the rechargeable battery or

leave it stored for prolonged periods of time as this

will reduce the useful life and capacity of the battery.

CAUTION!

To prevent damage to the battery or electrical circuits, always plug the AC/DC adapter into a surge-

protected socket.

12

Page 18

2.2 AC/DC adapter

The RMLD-IS is supplied with a universal AC adapter. The adapter

plug can be changed according to the sockets which are available.

2.3 Charging procedure

DANGER! Risk of explosion due to sparks

High charging current occurs when batteries are

being charged.

Only charge the device outside of explosive areas.

Carry out the following procedure to recharge the internal battery.

1. Switch off the device.

2. Insert the AC plug into a surge-protected socket.

3. Plug the AC/DC adapter into the external power supply.

4. A red LED will ash on the front of the control unit to indicate

that the charging process is underway.

5. Allow the device to charge until the green LED indicator is

continuously lit or off.

6. Unplug the adapter.

Warning!

Only charge the battery using the dedicated RMLD-IS

adapter supplied by SEWERIN. Use of any other type

of adapter may cause severe damage to both the battery and electrical circuits.

13

Page 19

Section III (Operating the RMLD-IS)

The section provides information on operating the RMLD-IS. This

includes an explanation of how to use the menu, how to set operational parameters, and the procedures for activating various

features of the device.

5 6 7 8

1 2 3 4 13 14 15

Figure 3-1 RMLD-IS front panel with display.

(Note: the illustration shows all icons displayed

simultaneously. During actual operation, only those symbols

related to an active function will be displayed.)

1 DMD key Press this key to activate/deactivate

DMD mode

2 Up key Press this key to increase a value or to

acknowledge an on-screen prompt.

9

10

11

12

14

3 Down key Press this key to decrease a value.

4 SELECT key Press this key to scroll through the

menu options.

Display

5 Battery charge

Shows remaining charge in the battery.

indicator

6 DMD symbol This symbol indicates when DMD

detection mode is active.

7 Gas concentration Shows the amount of gas detected in

ppm•m. The display “1-------” indicates

a value is out of range.

Page 20

8 Volume Shows the volume level for the loud

speaker and headphones.

9 WARNING symbol This symbol indicates that the device

is operating outside functional limits.

10 ERROR symbol This symbol indicates a fault, i.e. the

device is not functioning correctly.

11 Backlight symbol This symbol indicates that the

backlight is switched on.

12 Spotter symbol This symbol indicates that the spotter

laser is active.

13 RE-TRY This symbol indicates that the self-test

has not completed successfully and

needs to be carried out again.

14 SELF-TEST This symbol indicates that self-test

mode is active.

15 OK This symbol indicates that the self test

completed successfully.

15

Page 21

Figure 3-2: RMLD-IS rear panel

HEADPHONE port Socket for the headphone jack.

POWER SWitch Pressing this switch turns the device

on/off.

External power

Socket for the external adapter.

supply connector,

EXT. POWER

RS-232 port Female sub-D connector for PC

interface (only used for factory

calibration).

3.1 Switching on the RMLD-IS

Press the power switch located on the rear panel. When the device is switched on, the green spotter laser will ash briey and

the display will show all symbols together for a short period. The

display will then switch to the main operating mode showing the

ppm•m measurement value. The warning symbol will also be

displayed briey during the warm up period for the laser. This

warning should disappear after a few seconds. The device will

start up using the same settings that were active when it was

switched off (e.g. alarm activation threshold, spotter active, etc.).

16

Page 22

Note:

The infrared detection laser is always active and the

device continuously monitors methane concentration whenever it is switched on.

3.2 Switching on the spotter laser

CAUTION!

The green spotter laser is controlled by the operator

and is only switched on when the spotter trigger is

pressed. When using the green spotter laser, never

point the beam at another person’s eyes and take

care not to distract drivers of vehicles. This laser is of

the same type used in commercially available laser

pointers, as commonly used for presentations. This

laser is safe provided it is used correctly.

Danger!

The visible green spotter laser is a Class IIIa laser

product. Do not look into the beam or view directly

using optical instruments.

Spotter laser

IR detection laser

Spotter trigger

Figure 3-3

17

Page 23

3.3 Switching off the RMLD-IS

Press the power switch located on the rear panel. The device

will switch off. All settings will be saved automatically (e.g. alarm

activation threshold, spotter active, etc.).

3.4 Using the menus

The RMLD-IS allows the operator to set certain operational parameters and to activate/deactivate functions. The following operational parameters can be changed by the operator:

1. Volume

2. Alarm activation threshold

The following functions can be activated and deactivated:

1. Self-test

2. Spotter

3. Backlight

Pressing the menu key will scroll through the menu options in the

following sequence:

Self-test

z Press the up key to start the self-test and calibration.

– Press the up key to acknowledge on-screen prompts (OK

or RE-TRY)

18

Ready to start self-test

VOL

z Press the up key to increase the volume

z Press the down key to decrease the volume

Page 24

SPO

z Press the up key to activate or deactivate the spotter laser

AL

z Press the up key to increase the alarm activation threshold

z Press the down key to decrease the alarm activation threshold

Figure 3-4

BACLI

z Press the up key to activate or deactivate the backlight for the

display

Figure 3-5

The ppm•m measurement value will not be updated while menu

options other than the main screen are displayed, however the

device will continue to function normally.

19

Page 25

3.5 Using DMD mode

DMD (Digital Methane Detection) mode is a highly sophisticated

detection algorithm that greatly enhances the use of the RMLD-IS.

In most situations, the operator should carry out monitoring with

DMD mode activated. Press the DMD key to activate DMD mode

(the DMD symbol will be shown on the display). This mode can

only be activated when the display is showing the main monitoring screen.

Figure 3-6: The DMD symbol is displayed while DMD mode is active.

When DMD mode is active, no sound is produced until methane

is detected. The pitch of the sound is dependent on the concentration of methane. The higher the pitch, the higher the methane

concentration.

A low-pitched pulsating or continuous sound indicates a warning

of low infrared laser intensity or a problem with the device. A warn-

ing symbol is also displayed in cases where the light intensity is

too low (see Section 4.2). The operator must move closer to the

gas plume in order to be in detection range.

If the warning continues to be displayed, then this may indicate

that there is a fault in the device. Check the error code and follow

the instruction in Section V.

When in DMD mode, the device will indicate that methane has

been detected when the ppm•m measurement value exceeds the

average background level plus the alarm activation threshold, or

when the reading is excessively high. Even when the low light

intensity warning signal is audible, the RMLD-IS may still be able

to detect very high gas concentrations; this situation is indicated

by a higher pitched sound.

The alarm activation threshold controls the sensitivity in DMD

mode. The alarm activation threshold value can be adjusted by

the operator. The monitoring procedures used by some organisations may require that a specic value is used or a that a certain

adjustment procedure is followed. Set the alarm threshold value

to a level that gives a low number of false alarms, while at the

same time not being so high that gas leaks are not detected.

DMD symbol is displayed

20

Page 26

To change the alarm activation threshold, scroll through the menu

options until the “AL” option is displayed. Press the up/down key

to increase/decrease the threshold. Setting a higher threshold

value will decrease the sensitivity of the device.

3.6 Using the Pure Tone mode

In “Pure Tone” mode, the RMLD-IS will produce a continuous

tone that is related to the instantaneous concentration level. The

higher the pitch of the tone, the higher the methane concentration. If no sound is heard then this indicates low light intensity

or a fault in the device. Note that the pitch will increase with in-

creasing distance scanned. This is due to the background level

of methane in the air.

Figure 3-7

“Pure Tone” mode is most effective when used over short dis-

tances and can be helpful in detecting low concentrations or in

identifying the location of the highest gas concentration.

Pitch is proportional to

ppm•m measurement value

DMD symbol is not displayed

21

Page 27

Follow the procedure below to identify a leak producing a low

concentration of gas:

1. Stand about 3 m from the leak, ideally upwind.

2. Sweep the laser back and forth across the leak, maintaining

a constant distance.

3. Listen for a persistent increase in pitch as the beam passes

through the leak. The pitch will only increase slightly if the

leak is very small.

Follow the procedure below to identify the location of the highest

concentration of gas:

1. Stand about 3 m from the leak, ideally upwind.

2. Sweep the laser in and around the area of the leak, starting

from the upwind side.

3. Listen for the highest pitched tone.

4. Change the angle of the sweep slightly and rescan the area

around the leak.

5. If the location that produces the highest pitched tone is consistent, then this indicates the location of the leak.

6. Continue scanning if the pitch of the tone produced is not the

same. It is possible that the gas plume may be drifting around,

which will produce inconsistent readings. In some cases, the

gas plume may be so large that precise pinpointing of the

source is not possible.

3.7 Self-test and calibration

The RMLD-IS features an integrated function for carrying out a

self-test and calibrating the laser wavelength. The self-test func-

tion should be run on a daily basis to ensure trouble-free operation of the device. Each self-test and each calibration should be

recorded in a daily log. An example of a daily log can be found

at the end of this manual.

22

Page 28

Proceed as described below to carry out the self-test and calibration.

1. Remove the controller from the carrying case.

2. Switch on the device and allow it to warm up for 2 to 3 minutes.

3. Place the transceiver in the carrying case in the position de-

signed for this purpose, ensuring that it is level and properly

seated. The space between the transceiver, receiver and

calibration cell must be free of obstacles.

4. Press the SELECT key until the SELF-TEST symbol appears

on the display (note: the RE-TRY and OK symbols will also

be displayed).

Figure 3-7

5. Press the up key to start the test. The number 255 will be

displayed.

6. The OK symbol will be displayed if the device completes the

self-test satisfactorily.

– If the RE-TRY symbol is displayed, then the self-test was

not completed successfully. Press the up key to restart the

self-test, referring to the instructions in the following section,

“Calibration override”.

7. Press the up key. This will initiate the procedure for calibrating

the laser wavelength. The procedure takes about 45 seconds

to complete, during which time the measured gas concentration value can be seen to vary up and down.

8. The OK symbol will be displayed when the device has suc-

cessfully completed calibration of the laser.

– The RE-TRY symbol will be displayed if the device is un-

able to successfully calibrate the laser. Press the up key to

restart the self-test.

9. Press the up key to acknowledge.

10. Press the SELECT key to scroll back through the display

modes until the main screen is seen.

23

Page 29

What if the device failed to successfully complete the selftest or calibration?

This is usually caused either by the transceiver being positioned

incorrectly in the carrying case or by a drift in the laser wavelength.

Ensure that the device is in the correct position, level and prop-

erly seated. Observe the gas concentration. This is usually around

1,100 ppm•m, however values between 500 and 2,000 ppm•m

are acceptable. Restart the self-test and calibration after the above

points have been checked.

24

Page 30

3.7.1 Calibration override

Proceed as described below if the device calibration fails at Step

6 due to low initial measurement values.

1. Ensure that the device is still in the self-test menu (see Step

6 above).

2. Override the normal self-test function by pressing the DMD key.

This will cause the laser calibration procedure to be carried out.

3. “OK” will be displayed at the end of the rst sweep. Press the

up key again to restart the sweep.

4. “Self-Test OK” will be displayed at the end of this sweep.

Press the up key followed by the SELECT key to leave the

self-test menu.

– “RE-TRY” will be displayed if the procedure fails. This means

that the device will not function correctly. Please contact

SEWERIN directly for assistance.

Note:

Laser wavelength drift is a normal characteristic of

the RMLD-IS. Normally, the magnitude of the drift is

small and does not have any negative effect on the

self-test, provided this is carried out regularly. Monitoring work that is carried out using an uncalibrated

device may have to be repeated. Please contact

SEWERIN service if the initial measured concentration values are regularly so low that the calibration

override feature must be used repeatedly.

25

Page 31

The following table may help identify the cause of the problem if

the self-test fails:

Cause Corrective action

Low signal strength

or noise

Initial ppm•m

measurement value

too low or too high

Laser adjustment

failed

CAUTION!

If the device does not successfully complete a selftest after several attempts, do not use the device

for monitoring work before the problem has been

rectied. Please contact SEWERIN directly for assistance.

z Make sure that the battery is fully

charged.

z Ensure that the device is in the correct

position, level and properly seated.

z Make sure that the battery is fully

charged.

z Ensure that the device is in the correct

position, level and properly seated.

z Check the calibration cell for signs of

damage.

z Use the calibration override function.

z Make sure that the battery is fully

charged.

z Ensure that the device is in the correct

position, level and properly seated.

z Check the calibration cell for signs of

damage.

26

Page 32

Section IV (Monitoring with the RMLD-IS)

4.1 Monitoring with the RMLD-IS

The RMLD-IS is supplied with a training video, which is the best

way to get an overview of the techniques used. It is important to

learn these techniques in order to be able to effectively detect

and monitor methane gas leaks. The purpose of the video is to

familiarise personnel responsible for monitoring gas leaks with

how to use the RMLD-IS. The video does not provide any training

in basic leak monitoring techniques.Please refer to your organisa-

tion’s own training and procedural requirements for the specic

qualications necessary for leak monitoring.

Three conditions must be met before the RMLD-IS is able to

detect a gas leak:

1. The size and concentration of the gas plume must be greater

than the minimum permitted by the sensitivity of the device.

2. The infrared beam must pass through the gas plume.

3. The target background (i.e. ground, building, etc.) must reect

the infrared beam.

The concentration and size of the gas plume are inuenced by

various factors. Leaks where a low volume of gas is escaping will

only produce small or undetectable gas plumes. Additionally, some

types of surface (e.g. concrete) spread the gas through cracks

and holes in the surface, thereby creating leaks at several points.

Weather conditions such as strong wind and high temperatures

result in the gas plume being dispersed more quickly.The opera-

tor must take these factors and their corresponding effects into

account whilst carrying out monitoring.

The most important factors when using the RMLD-IS are correctly aiming and controlling the infrared beam.

The rst things to learn in order to effectively use the RMLD-IS

for monitoring are to gain control over the direction of the laser

and to use the correct speed of sweep. Sudden or jerky motions

may lead to false detections due to rapid changes in distance or

changes in the background reecting the laser. This type of

rapid motion can result in the area not being thoroughly scanned

by the laser.

27

Page 33

Below are some tips for patrolling the gas pipe on foot:

z Use a smooth sweeping motion.

z Maintain a target distance for the beam of 5 m to 7 m. This

means that the footprint of the beam on the ground is large

enough to provide good coverage, while still giving good control

over the path of the beam.

z Scan the areas around connections and valves as you ap-

proach them.

z Direct the beam at likely leak locations (e.g. cracks, poor veg-

etation, etc.).

Consider the following points when scanning a gas pipe or gas

meter in familiar locations:

z Make full use of the advantages of the beam by sweeping more

widely around the pipe.

z Trace out an “S” pattern with the beam while moving along

the pipe.

z Scan the area around the gas meter.

z Rescan the pipe in the opposite direction, again following an

“S” pattern.

z Move closer to the pipe if the area to be scanned is too far

away or raised ground means that the beam does not hit the

surface (dark zones).

28

Proceed as follows when scanning a gas pipe at an unfamiliar

location:

z Use an “X” pattern or similar to ensure that the area is thor-

oughly scanned.

z Target areas where gas typically escapes e.g. along streets

and pavements.

z Target areas where valves might be located.

z Scan along the foundations of buildings.

z Move closer to the pipe if the area to be scanned is too far

away or raised ground means that the beam does not hit the

surface, thereby causing dark zones (shadows).

Page 34

Proceed as follows when scanning a gas meter:

z Maintain a distance of at least 3 m from the gas meter to ensure

that the beam width is not too narrow.

z Thoroughly scan the ground in the area around the meter.

z Aim the device at the gas meter from the angle that provides

the best background behind the meter.

z If the meter is in the open, or a limited choice of angles means

there is no background available directly behind the meter,

scan the meter using a horizontal “Z” pattern, making sure to

maintain a constant sweep distance.

If a leak is found near or on a gas meter, the following tips will

be of assistance in determining whether the leak is underground

or on the meter.

z Stand upwind whenever possible.

z Stand about 1.5 m to 3 m from the leak.

z Use the “Pure Tone” mode to pin point the highest concentra-

tion.

z Start by pointing the beam downwards towards the ground.

z Scan by moving the beam upwards and around the pipe. (Note:

the spotter laser beam is approximately 7 cm higher than the

infrared beam).

z In the case of underground leaks or if in doubt, clear the area

around the leak.

29

Page 35

4.2 Long range scanning

The RMLD-IS can detect leaks at a distance of up to 30 m. The

actual maximum distance may depend on the characteristics of

the target surface and variations in environmental conditions. As

the scanning distance is increased, the intensity of the reected

laser light will become lower. An audible signal indicating low light

intensity will be heard when the maximum scanning distance is

reached. In such cases it will be necessary to move closer to

the target.

For best results when scanning at distances greater than 15 m, it

is important to slow down the scanning speed and to take extra

care when aiming the laser. Make use of the spotter laser or the

sighting marks on the side of the transceiver to ensure that the

target area is scanned properly.

Be aware of any raised ground. Scanning across the peak of a

mound or the corner of a building can cause the beam to skip (a

sudden change in distance), which may lead to false measurements.

30

Dark zone

Beam skipping

The beam moves quickly from a close

object to a far object.

Figure 4-1: Sudden changes in distance may lead to false measurements

Page 36

Obstructions or changes in the landscape can create dark zones

where it is not possible to scan with the laser. Look for the best

angle from which to aim the laser in order to scan these areas

thoroughly. Scanning upwards along a slope may lead to beam

skipping or dark zones around the foundations of a structure.

Stone or

other obstruction

Dark zone

This area will not be scanned.

Figure 4-2: Raised ground or obstructions in the line of sight create dark

zones (shadows).

4.3 Dealing with false detections

There are several conditions that may occur when using DMD

mode that can lead to the algorithm giving a false detection indication. In most cases these are caused by one of the following

situations:

z Sudden or jerky motions that lead to a sudden change in scan-

ning distance.

z Excessively high measurement values due to strong reectors.

The majority of false detections occur when scanning at a in the

15 m-range. This is due to the beam footprint becoming very

large. In DMD mode, abrupt motions, changes in terrain or

changes in distance to a target object may cause the device to

indicate briey that a low gas concentration has been detected. In

order to ensure that the detection is due to an actual gas leak, the

same area in the 15 m-range should be scanned a second time.

Moving from long range to short range whilst scanning will also

help minimise false detections.

31

Page 37

Strong reections from certain surfaces (e.g. black rubbish bags,

water droplets, glass, polished surfaces, stones, vehicle number

plates, reectors, etc.) can also lead to false detections. Rescan

the area from a slightly different angle.

4.4 How does the RMLD-IS measure gas concentrations?

The RMLD-IS can be used to monitor areas that are hard to access. The use of TDLAS (Tunable Diode Laser Absorption Spectroscopy) laser technology means that the RMLD-IS does not

need to be located directly in the gas plume. As the laser passes

through a gas plume, the methane absorbs a portion of the light,

which is then detected by the RMLD-IS. This technology makes

it possible to detect leaks along the sight line without always having to walk the full length of the gas pipe.

Infrared detection laser

32

Figure 4-3

The invisible infrared detector laser beam is emitted through the

emission aperture. With a normal background, e.g. brick, concrete

or grass, this has a maximum range of up to 30 m (actual distance

may vary depending on the characteristics of the surface).

Page 38

Direct sunlight and

ambient light contribute

an additional level of

background photons

Topographic backscatter

of laser light and background

light collected at the receiver

Detector

Light is converted to

electrical signals

Figure 4-4

Laser

Methane leak

The diagram above shows how the device uses reected light

to detect leaks. After passing through a gas plume, the infrared

laser beam is reected and received at the detector, where it is

collected and converted to an electrical signal that transmits the

information needed to determine the methane concentration.

The laser is designed to selectively detect methane and will not

give a false alarm should other hydrocarbon gases be present.

The signal is processed to allow methane concentrations to be

reported in ppm•m (parts-per-million•meter).

The ppm•m value is the product of methane concentration mul-

tiplied by gas plume width. For example, if a leak generates a

gas cloud of 1,000 ppm that is approximately 0.5 m wide (the

distance travelled by the infrared beam through the plume), then

the RMLD-IS will measure a value of 500 ppm•m.

By way of another example, consider a medium-concentration gas

cloud of 20 ppm that is approximately 2 m wide; the RMLD-IS will

measure a value of 40 ppm•m plus, in this case, a background

level of 15 ppm•m, meaning that a total value of 55 ppm•m is

displayed.

33

Page 39

IR beam footprint

15 m

Figure 4-5: The ppm•m measurement value is the product of gas plume

concentration multiplied by the distance that the beam passes

through the gas (width of the gas plume) plus any background

gas concentration level. The footprint of the laser beam

increases with the scanning distance.

Example

Scanning distance = 15 m

IR beam footprint = 4.9 m x 0.3 m

Background methane level = 1 ppm

Average gas plume concentration = 20 ppm

Width of the gas plume (distance

that the IR beam travels through

the plume) = 2 m

RMLD-IS measurement value = background level + leak concentration

= (15 m x 1 ppm) + (2 m x 20 ppm)

= 55 ppm•m

At a distance of 30 m, the width of the infrared beam is approximately 55 cm. It is important to note that the length and width of

the laser footprint increase as the distance to the target increases

(see Figure 4-5). For this reason, it is considerably easier to detect

leaks from a distance of 5 m of more.

34

Note:

Atmospheric air always contains a low level of methane. This natural background methane level is also

measured by the RMLD-IS. The ppm•m measure-

ment value therefore increases as the scanning

distance is increased.

Page 40

Note:

The nature of gas plumes varies considerably.

The illustrations above are only intended to give

an illustrate the basic theory. With some leaks it is

possible that there is a high surface methane concentration, with little or no detectable gas plume

above the ground.

35

Page 41

Section V (Maintenance and troubleshooting)

5.1 Troubleshooting the device

The advanced design of the RMLD-IS makes it one of the most

reliable leak monitoring devices available today. However, should

problems occur with the device, or if it is suspected that the device

is not functioning correctly, then it should not be used for monitor-

ing until the problem is rectied.

Repairs and adjustments to the device must only be carried out

by qualied RMLD-IS repair technicians. The RMLD-IS does not

contain any components that can be repaired or replaced by the

user.

In most cases there is a simple explanation for problems with the

device. The following table contains a list of the most common

faults, causes and solutions. Pleased contact SEWERIN for fur-

ther assistance if a fault is encountered that is not listed here, or

the suggested solution does not rectify the problem.

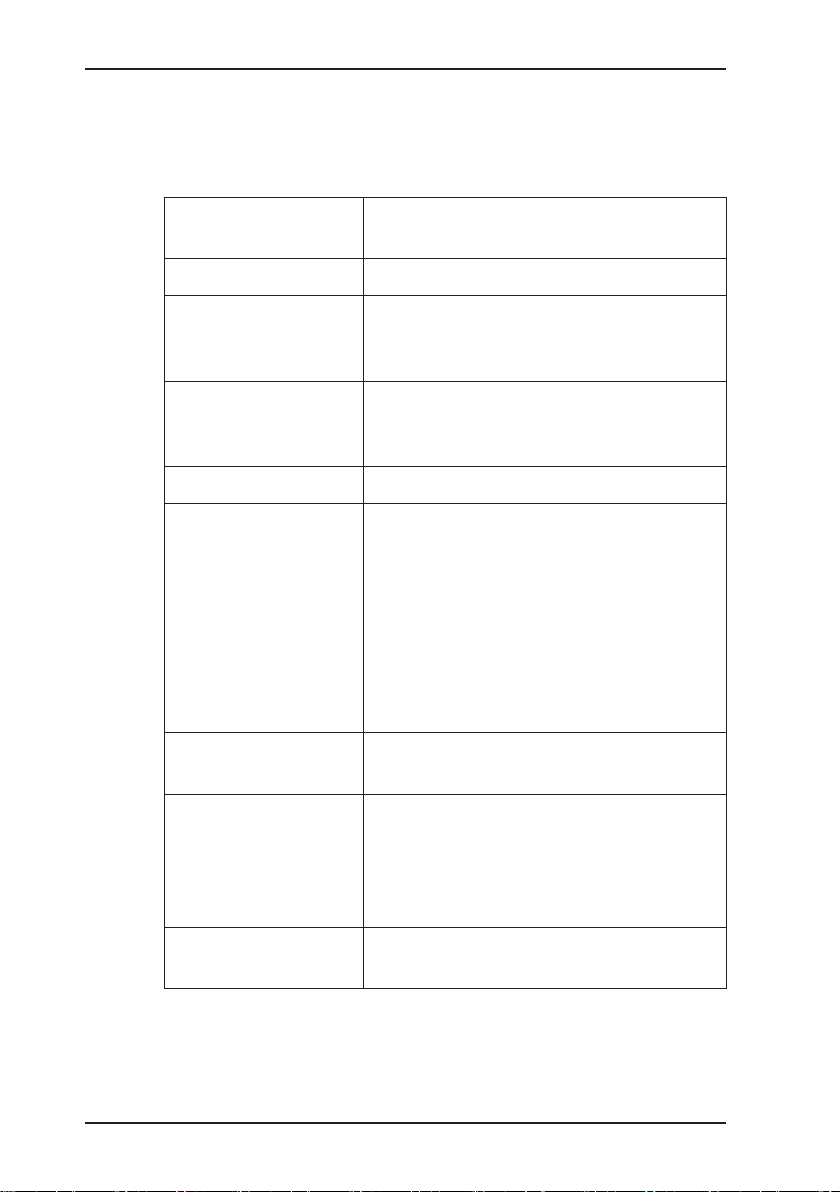

Symptom Possible cause(s) Solution

36

Higher

measurement

values than usual

are obtained

when measuring

at short range

and measurement

values are lower

than usual at

longer range.

Measurement

value for the gas

concentration is

low and self-test

did not complete

successfully

z Laser calibration

drift

z Laser calibration

drift

z Run self-test

z Run the self-test

and use the override function

Page 42

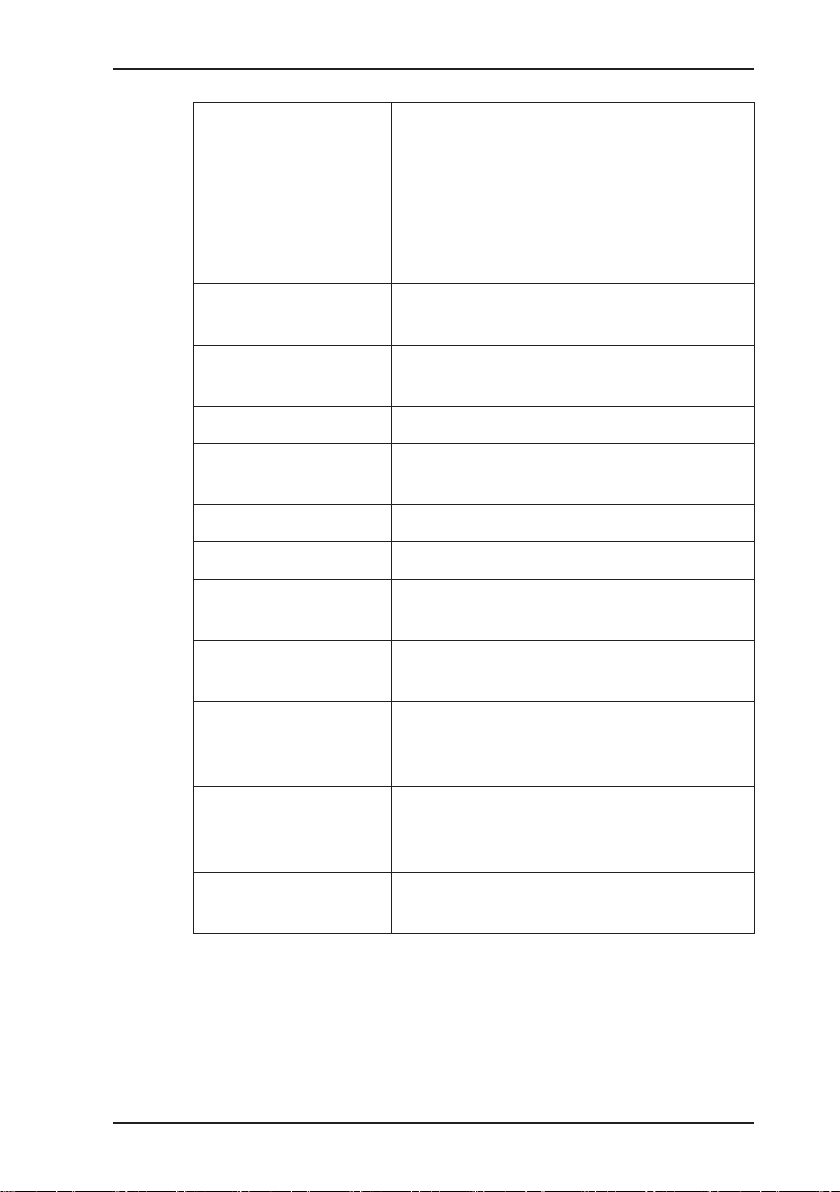

Symptom Possible cause(s) Solution

The override

function has to be

used every time

the self-test is run

The device will

not switch on

An audible

warning signal is

repeatedly heard

during scanning/a

warning symbol is

displayed

z Laser calibration

drift

z Run self-test daily

z Contact SEWERIN

z Laser calibration

drift is too high

z Battery not charged z Charge the inter-

nal battery

or

z use the external

power source

z Scanning is being

carried out beyond

the range of the

RMLD-IS

z The background

surface is absorbing or reflecting

the light

z Battery not charged

z Move closer to the

target

or

z Change the angle

of the laser to the

target to take advantage of a better reecting background

z Check the charge

level of the battery

and recharge if required

An excessive

number of false

detections occur

when scanning at

long range

z Scanning is be-

ing carried out to

quickly

z Alarm threshold

value is set too low

z Scanning is being

carried out beyond

the range of the

device

z Scan more slow-

ly. Pause at long

range and sweep

the beam closer

z Increase alarm acti-

vation threshold

z Move closer to the

target

37

Page 43

Symptom Possible cause(s) Solution

An excessive

number of false

detections occur

when scanning at

short range

An excessive

number of false

detections

occur or a loss

in sensitivity is

experienced

Error symbol

or warning

symbol shown

permanently

z Scanning is be-

ing carried out to

quickly

z Alarm threshold

value is set too low

z Laser output not

optimised

z The alarm activa-

tion threshold is set

too high or to low

for the prevailing

conditions.

z Battery not charged

z Condensation on

the mirror due to

rapid temperature

change

z Failure of an inter-

nal component

z Avoid sudden move-

ments whilst scanning

z Increase alarm ac-

tivation threshold

z Run self-test

z Check alarm acti-

vation threshold

z Check the charge

level of the battery

and recharge if required

z Wait until the tem-

perature has stabilised

z Make a note of the

error code and con-

tact SEWERIN

38

Battery indicator

shows that the

battery is not fully

charged after

charging

z Battery not fully

charged

z Battery charge in-

dicator calibration

error

z Charge the device

until the green LED

is permanently lit

z Run the device un-

til it switches off

automatically, then

charge the battery

fully without interruption

Page 44

Symptom Possible cause(s) Solution

Bars on the

battery indicator

are ashing

z Battery charge in-

dicator calibration

error

z Run the device un-

til is switches off

automatically, then

charge the battery

fully without interruption

39

Page 45

5.2 Maintenance

In order to maintain the RMLD-IS in proper working order, the

following maintenance tasks must be carried out at the specied

intervals.

Maintenance task Interval

Clean outer surfaces with a

As required

damp cloth

Clean the transceiver window

with a non-abrasive lens cloth

As required to remove built-up

dust or water marks

Self-test and calibration Daily to ensure that the device

continues to function correctly

Charging internal battery Recharge fully after every use

40

Page 46

Glossary

Beam skipping This term refers to the effect that occurs

Controller The part of the RMLD-IS carried on the

Dark zone An area that is not scanned because it lies

DMD mode Digital Methane Detection

Footprint The surface area covered by the IR beam.

when the distance to the target for the IR

beam suddenly changes. This may lead to

a false detection.

body that includes the keypad and display

behind an obstruction. This can be caused,

for example, by raised ground, the side of a

building, the area behind a kerb, etc.

An advance detection mode that, when

activated, means the operator is only

alerted when there is a good probability that

methane gas has been detected.

This increases with distance. At a range of

30 m, this area has a diameter of approximately 55 cm when the beam is aimed horizontally at vertical target.

Infrared (IR) A wavelength of light just beyond the visible

spectrum.

Laser

calibration drift

A normal characteristic of tunable laser

diodes that means the calibrated

wavelength can gradually change over time.

The RMLD-IS includes an integrated self-

test and calibration function that

automatically maintains correct calibration.

ppm•m The product of methane concentration

multiplied by gas plume width

Pure Tone

mode

An operating mode that causes a

continuous tone to be produced, the pitch of

which is relative to the gas concentration.

41

Page 47

Spotter laser The green ashing laser located at the top

of the transceiver, used by the operator to

indicate the direction of the IR beam. This

laser is activated using the trigger button on

the handle of the transceiver.

TDLAS Tunable Diode Laser Absorption

Spectroscopy

A method of detecting gas that makes use

of a laser. The laser light is partially

absorbed when shone through a cloud of

methane, thereby allowing the gas

concentration to be measured.

Transceiver The hand-held part of the RMLD-IS that

contains the invisible IR laser transmitter/

receiver and the green spotter laser

42

Page 48

Daily log of RMLD-IS self-test and calibration

RMLD-IS serial no.: ..............

Date Operator Self test

success-

ful?

Self test

ppm•m

measurement

value

Alarm

activation

threshold

Notes

43

Page 49

Hermann Sewerin GmbH

Robert-Bosch-Straße 3 · 33334 Gütersloh · Germany

Telefon +49 5241 934-0 · Telefax +49 5241 934-444

www.sewerin.com · info@sewerin.com

01.10.2015 – 107216 – en

Loading...

Loading...