Page 1

Multitec® 560

20.04.2016 a – 106810 – en

Operating instructions

Page 2

Multitec® 560

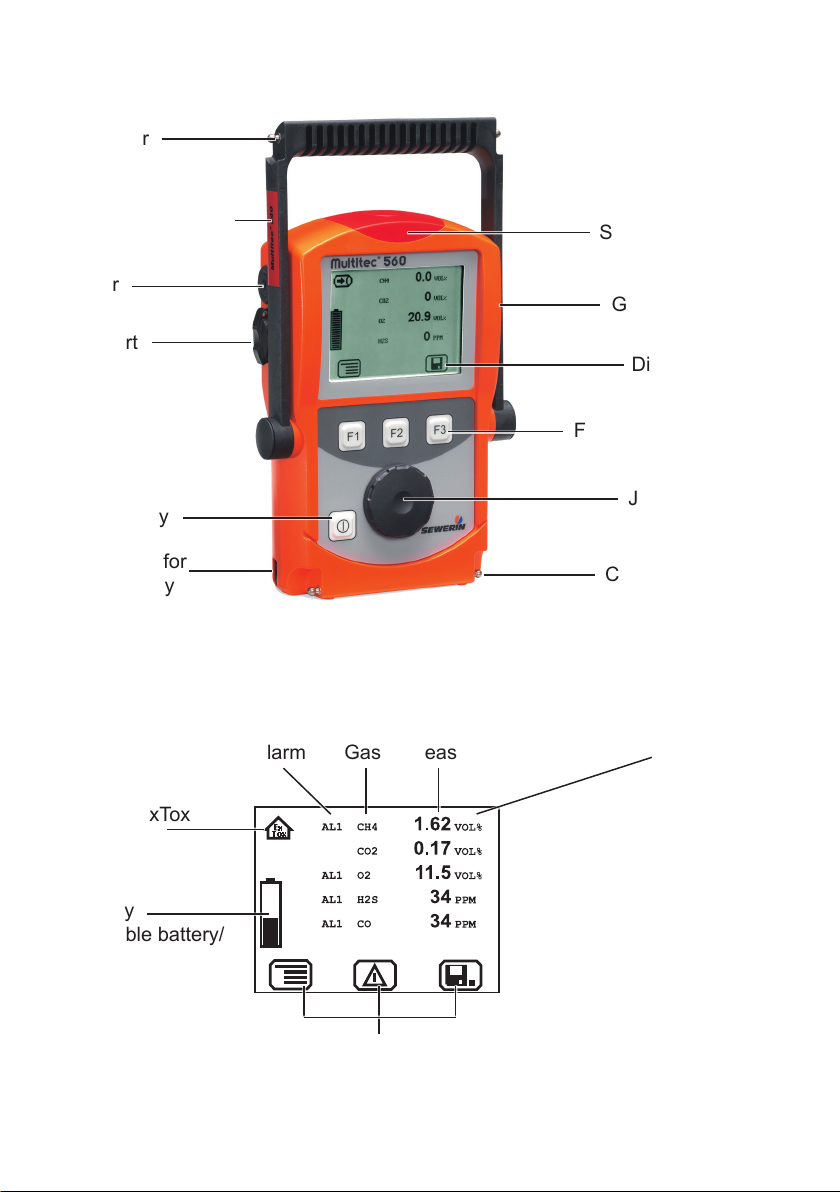

Connector

Supporting bracket

Buzzer

USB port

ON/OFF key

Connection for

power supply

Fig. 1: Multitec 560 device overview

Alarm

Gas

Signal light

Gas input

Display

Function keys

Jog dial

Connector

Measured value Unit

Warning ExTox

symbol

Capacity

disposable battery/

rechargeable

battery

Fig. 2: Multitec 560 display

Current assignment of

function keys F1 – F3

Page 3

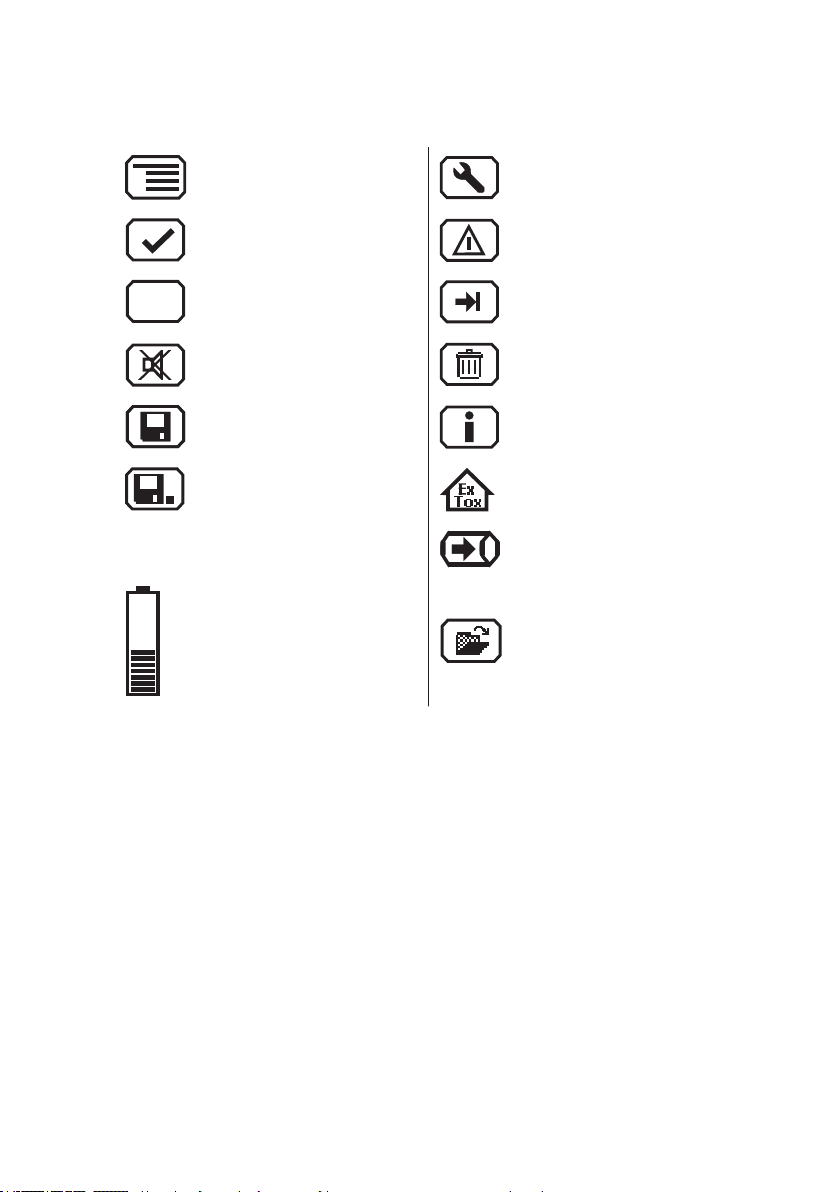

Display symbols

Menu Fault

OK Carry out device inspection

Esc

Cancel

Buzzer off Clear

Save Information

Stop measurement Warning ExTox

Capacity

disposable battery/

rechargeable capacity

Tab

(jump to next input eld)

Gas measuring

Open stored comment

Open stored inspector

Page 4

Information about this document

The warnings and notes in the document mean the following:

DANGER!

A

A

A

Risk of personal injury. Results include serious injury or

death.

WARNING!

Risk of personal injury. Can result in serious injury or

death.

CAUTION!

Risk of personal injury. Can result in injury or a risk to

health.

CAUTION!

Risk of damage to property.

Note:

Tips and important information.

Enumerated lists (numbers, letters) are used for:

● Instructions that must be followed in a specic sequence

Bulleted lists (bullet points, dashes) are used for:

● Lists

● Instructions comprising only one action

Numbers enclosed by forward slashes /.../ refer to referenced documents.

Page 5

Contents Page

1 General .....................................................................................1

1.1 Warranty ....................................................................................1

1.2 Purpose .....................................................................................2

1.3 Intended use .............................................................................3

1.4 General safety information ........................................................4

2 Features ...................................................................................5

2.1 Visual and audible signals .........................................................5

2.2 Sensors .....................................................................................6

2.3 Explosion protection .................................................................. 7

2.3.1 Passive explosion protection ..................................................7

2.3.2 Active explosion protection ....................................................8

3 Operation .................................................................................9

3.1 General information on operation .............................................. 9

3.1.1 Keys and jog dial .................................................................... 9

3.1.2 Selecting/exiting menus and menu items .............................10

3.1.3 Switching the device on ....................................................... 11

3.1.4 Selecting/switching application ............................................13

3.1.5 Differences between measuring mode and settings mode ..13

3.2 Measuring mode .....................................................................14

3.2.1 Accessing the menu (measuring mode menu structure) ......15

3.2.2 Zero point ............................................................................. 15

3.2.3 Gas measuring ..................................................................... 16

3.2.4 Warning ExTox .....................................................................16

3.2.5 Settings ................................................................................16

3.2.6 Starting/stopping a measurement ........................................17

3.2.7 Protocols ..............................................................................18

3.2.8 Device inspection ................................................................. 19

3.2.9 Device information ...............................................................19

3.3 Settings ...................................................................................20

3.3.1 Opening Settings ..................................................................20

3.3.2 Settings menu structure .......................................................22

3.3.3 Adjustment ...........................................................................23

3.3.4 System .................................................................................24

3.3.5 Alarms ..................................................................................26

3.3.6 Date/time .............................................................................. 26

3.3.7 Memory ................................................................................26

I

Page 6

Contents Page

4 Power supply .........................................................................27

4.1 Suitable disposable/rechargeable battery types .....................27

4.2 Operation with rechargeable batteries ....................................28

4.2.1 Charging ............................................................................... 28

4.2.2 Rechargeable battery maintenance .....................................29

4.3 Battery alarm ........................................................................... 30

4.4 Replacing disposable/rechargeable batteries .........................30

5 Maintenance ..........................................................................32

5.1 Device inspection ....................................................................32

5.1.1 General information on the device inspection ...................... 32

5.1.1.1 Scope ................................................................................ 32

5.1.1.2 Frequency .........................................................................33

5.1.1.3 Documentation .................................................................. 33

5.1.1.4 Integrated device inspection .............................................33

5.1.1.5 Order .................................................................................34

5.1.1.6 Test gases for the device inspection .................................34

5.1.2 Carrying out the device inspection ....................................... 35

5.1.2.1 Accessing the device inspection ....................................... 35

5.1.2.2 Concluding the device inspection......................................36

5.1.3 Testing the general status .................................................... 37

5.1.3.1 Housing ............................................................................. 38

5.1.3.2 Signals ..............................................................................38

5.1.3.3 Probe.................................................................................38

5.1.3.4 Filter ..................................................................................39

5.1.3.5 Pump .................................................................................39

5.1.4 Testing indication accuracy with supply of fresh air ............. 39

5.1.5 Testing indication accuracy with supply of test gas .............. 40

5.2 Adjustment ..............................................................................41

5.2.1 Scope ...................................................................................42

5.2.2 Test gases for the adjustment .............................................. 42

5.2.3 Special features of adjustment with gas mixture .................. 43

5.2.4 Preparation ........................................................................... 44

5.2.5 Performing the adjustment ................................................... 44

5.2.5.1 Adjusting the zero point.....................................................44

5.2.5.2 Adjusting the sensitivity ..................................................... 45

5.2.6 Carrying out an oxygen adjustment .....................................46

5.2.6.1 Adjusting the zero point for oxygen ................................... 46

5.2.6.2 Adjusting the sensitivity for oxygen ................................... 47

5.3 Servicing .................................................................................48

II

Page 7

Contents Page

6 Faults ......................................................................................49

7 Appendix ................................................................................50

7.1 Specications and permitted operating conditions .................. 50

7.2 Alarms .....................................................................................51

7.2.1 Features ...............................................................................51

7.2.2 Occupational exposure limits (OELs) and

excess factors (STEL and LTEL) ..........................................54

7.2.3 Alarm thresholds (factory settings) .......................................54

7.2.4 Setting ranges for gas types ................................................55

7.3 Limit values for the device inspection .....................................56

7.4 Memory capacity .....................................................................57

7.5 Sensors ...................................................................................58

7.5.1 Infrared sensors (IR) ............................................................58

7.5.1.1 Methane CH4 for warning ExTox ....................................... 58

7.5.1.2 Methane CH4 for gas measuring ....................................... 58

7.5.1.3 Carbon dioxide CO2 for warning ExTox ............................. 59

7.5.1.4 Carbon dioxide CO2 for gas measuring .............................59

7.5.2 Electrochemical sensors (EC) .............................................. 60

7.5.2.1 Oxygen O2 ........................................................................ 60

7.5.2.2 Carbon monoxide CO .......................................................60

7.5.2.3 Hydrogen sulphide H2S for warning ExTox .......................61

7.5.2.4 Hydrogen sulphide H2S for gas measuring .......................62

7.6 Technical information ..............................................................63

7.6.1 Identication sticker (back of device) ...................................63

7.6.2 Cleaning ............................................................................... 63

7.6.3 Electrostatic charge ..............................................................63

7.7 Accessories and consumables ............................................... 64

7.8 EU declaration of conformity ...................................................65

7.9 Inspection protocol ..................................................................66

7.10 Advice on disposal ..................................................................68

7.11 Terminology and abbreviations ...............................................69

7.12 Referenced documents ...........................................................70

8 Index .......................................................................................71

III

Page 8

1 General

1.1 Warranty

The following instructions must be complied with in order for any

warranty to be applicable regarding functionality and safe operation of this equipment. This product must only be commissioned

by qualied professionals who are familiar with the legal requirements (Germany: DVGW).

● Read these operating instructions prior to operating the product.

● Use the product only as intended.

● Repairs and maintenance must only be carried out by special-

ist technicians or other suitably trained personnel. Only spare

parts approved by Hermann Sewerin GmbH may be used when

performing repairs.

● Use only suitable battery types, otherwise the device will not

be explosion-proof.

● Changes or modications to this product may only be carried

out with the approval of Hermann Sewerin GmbH.

● Use only Hermann Sewerin GmbH accessories for the product.

Hermann Sewerin GmbH shall not be liable for damages resulting

from the non-observance of this information. The warranty con-

ditions of the General Terms and Conditions (AGB) of Hermann

Sewerin GmbH are not affected by this information.

In addition to the warnings and other information in these Operating Instructions, always observe the generally applicable safety

and accident prevention regulations.

The manufacturer reserves the right to make technical changes.

1 General

1

Page 9

1 General

1.2 Purpose

The Multitec 560 can be used as a gas measuring and gas

warning device.

The device is tted with infrared sensors for measuring hydrocarbons CXHY and carbon dioxide CO2 as standard. It can also

be equipped with electrochemical sensors for measuring O2, H2S

and CO.

The infrared sensors operate on the principle of absorption via

infrared-active gases, and the electrochemical sensors operate

on the electrochemical cell principle.

Multitec 560 as a gas warning device

As a warning device it is used to monitor the ambient air at the

workplace. The device can measure up to ve gases simultaneously, thus offering comprehensive protection against dangerous

gas concentrations. It provides warnings including:

● explosive gas concentrations

● lack of oxygen/excessive oxygen

● toxic gases

Multitec 560 as a gas measuring device

As a gas measuring device it determines the composition of gas

mixtures that are formed in biological processes (biogas, landll

gas). It measures the concentration of several gases in the gas

mixture simultaneously. The device is ideal for use in waste disposal sites, sewage plants and biogas plants.

Note:

These operating instructions describe the Multitec 560 with all

additional equipment (rmware version 1.XXX). All descriptions

refer to the device as delivered (factory settings). The manufac-

turer reserves the right to make changes.

2

Page 10

1.3 Intended use

This device is intended for professional residential and commer-

cial use including small rms and commercial operations. The

appropriate specialist knowledge is required to operate the device.

The device may only be used to measure the following gases

(depending on additional equipment):

● Methane CH

● Carbon dioxide CO

● Oxygen O

● Hydrogen sulphide H2S

● Carbon monoxide CO

The device must not be used for:

● Gas analysis of technical processes

● Monitoring liquids

The device can be used up to a temperature of 40 ºC. However,

high temperatures reduce the lifetime of the sensors and rechargeable batteries.

If a device with an electrochemical sensor is exposed to gas

concentrations above the measuring range limit, this can reduce

the lifetime of the sensor.

1 General

4

2

2

3

Page 11

1 General

1.4 General safety information

● The device has been tested to ensure that it is explosion-proof

in accordance with European standards (CENELEC).

● The work area must be well ventilated.

● The device must only be switched on with fresh air.

● In measuring mode, only change applications with fresh air.

● When switching from the Gas measuring application (using

the device as a gas measuring device) to the Warning ExTox

application (using as a gas warning device), the device should

only be used as a gas warning device once the zero points

have appeared.

● Do not use this device in oxygen-enriched atmospheres, oth-

erwise it will not be explosion-proof.

● Observe the relevant safety regulations when working at agri-

cultural biogas plants.

● Only probe hoses with a hydrophobic lter may be used.

Exception:

If the probe has a built-in hydrophobic lter, the hose does not

require any other lters.

● The device must only be tested and adjusted with test gases

in well ventilated rooms or in the open air. Test gases must be

handled in a professional manner.

● Always carry out a device inspection after the device has suf-

fered an impact (for example, if dropped accidentally).

● The device complies with the limits of the EMC directive. Always

observe the information in the manuals of (mobile) radio equipment when using the device close to (mobile) radio equipment.

Note:

Follow the advice regarding explosion protection (see Section. 2.3

on page 7).

4

Page 12

2 Features

2.1 Visual and audible signals

The device features two alarms:

● Signal light on top of device (visual signal)

● Buzzer on side of device (audible signal)

The signals indicate alarms and faults (see Section. 6 on

page 49). The device also emits signals when it is switched

on and off.

If this symbol appears on the display, the audible signal

can be switched off.

When an audible signal has been switched off it cannot

be switched back on.

This symbol appears at the top left of the display as soon

as the audible signal has been switched off. It disappears

automatically if the level falls below the alarm threshold.

2 Features

Operating signal

Only applies to Warning ExTox application.

The device emits a visual signal and an audible signal at regular

intervals. This indicates that the device is working properly.

Alarm

Only applies to Warning ExTox application.

The device can monitor several gases at the same time. If the

measured gas concentration of one or more gases exceeds spec-

ied limit values (alarm thresholds) the device gives a warning. It

emits both audible and visual signals, which are distinctly different

from the operating signal.

5

Page 13

2 Features

WARNING! Danger of death due to hazardous gas

A

concentrations

An alarm always indicates danger.

There is detailed information on alarms in Section. 7.2 on

page 51.

2.2 Sensors

The device features two types of sensor:

● Infrared sensor (IR)

● Electrochemical sensor (EC)

● Take all necessary measures for your own safety and

the safety of others immediately.

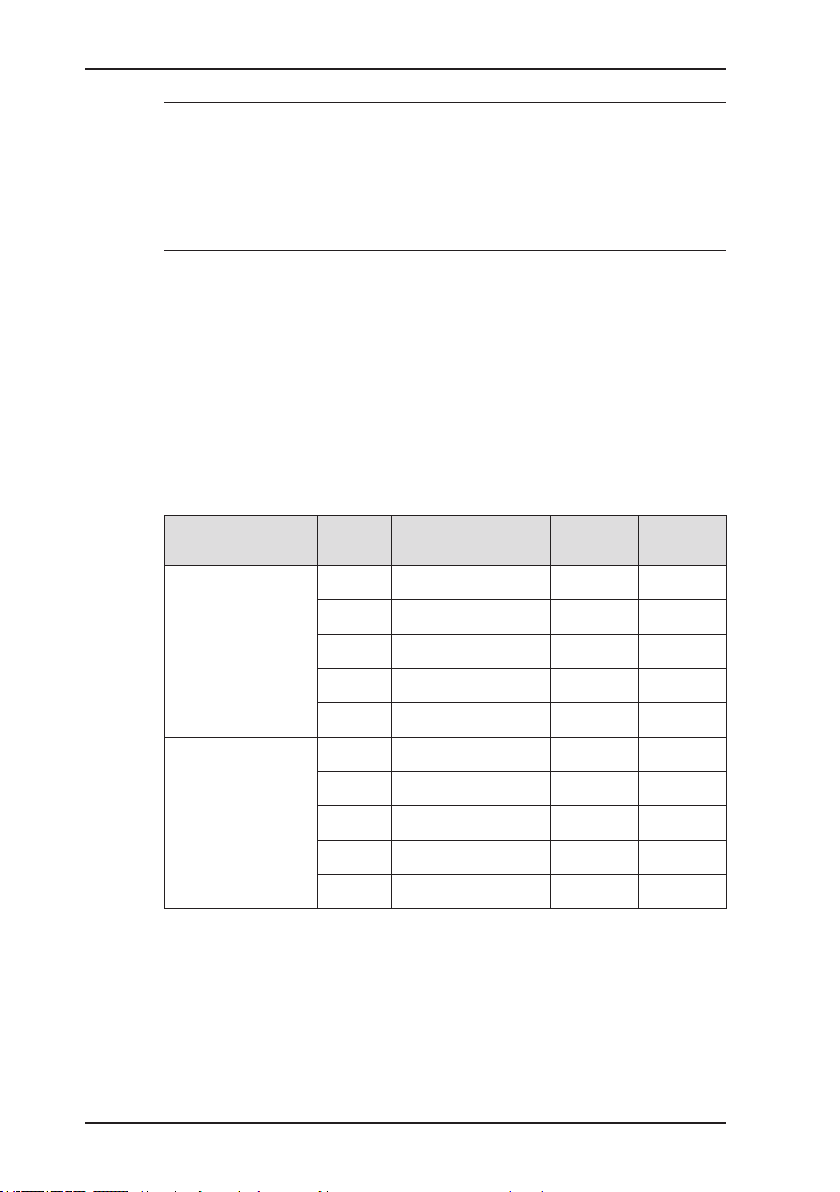

Application Gas Measuring

range

Warning ExTox CH

0 – 100 % LEL IR ×

4

CO 0 – 500 ppm EC ○

CO

0 – 5 % vol. IR ×

2

H2S 0 – 100 ppm EC ○

O

Gas measuring CH

0 – 25 % vol. EC ○

2

0.0 – 100 % vol. IR ×

4

CO 0 – 500 ppm EC ○

CO

0 – 100 % vol. IR ×

2

H2S 0 – 2000 ppm EC ○

O

0 – 25.0 % vol. EC ○

2

Sensor Fea-

tures

× standard

○ optional

6

Page 14

2.3 Explosion protection

2.3.1 Passive explosion protection

The device is assigned to the following explosion-proof groups:

2 Features

Explosion-proof

group

II2G Ex d e ib IIB T4 Gb – Methane CH

For the following atmospheres

– Propane C3H

– Butane C4H

– Nonane C9H

4

8

10

20

When using

Device without carrying

bag TG8

– Hydrogen sulphide H2S

– Carbon monoxide CO

II2G Ex d e ib IIC T4 Gb – Methane CH

– Propane C3H

– Butane C4H

– Nonane C9H

4

8

10

20

Device with

carrying bag

TG8

– Hydrogen sulphide H2S

– Carbon monoxide CO

– Hydrogen H

2

EC type-examination certicate: TÜV 07 ATEX 553353 X

DANGER! Risk of explosion due to sparks

A

● Only open the battery compartment outside of explo-

sive areas.

● Only charge the device outside of explosive areas.

● Only use the USB port outside of explosive areas.

● Use only suitable battery types.

● When working with hydrogen, always use the carrying

bag TG8 for the device.

7

Page 15

2 Features

2.3.2 Active explosion protection

The functional safety test applies to:

Application: Warning ExTox

Gas types: Measuring range: As per:

– Methane CH

4

Gases: Measuring range: As per:

– Oxygen O

– Carbon dioxide CO

2

2

– Carbon monoxide CO 0 – 500 ppm CO /4/, /5/

– Hydrogen sulphide H2S 0 – 100 ppm /4/, /5/

Tested accessories: – Test set SPE VOL

Type examination

Testing institute: DEKRA EXAM GmbH

0 – 100 % LEL /9/

0 – 25 % O

0 – 5 % CO

2

2

/7/

/4/, /5/

– Flexible hand probe, 1 m

– Floating probe 2 m, 6 m

Certicates: PFG 08 G 002 X

BVS 09 ATEX G 001 X

The following points were not part of the type examination:

● Saving measurement data (see Section. 3.2.6 on page 17)

● Saving protocols from the integrated device inspection (see

Section. 5.1.1.4 on page 33)

● Disposable alkaline batteries for the power supply (see Sec-

tion. 4.1 on page 27)

8

Page 16

3 Operation

3.1 General information on operation

3.1.1 Keys and jog dial

The ON/OFF key is the only control on the device that does not

change its function.

When switched on, the device is operated using the jog dial and

function keys to navigate the display.

Control Action Function

ON/OFF key Press ● Switches the device on

● Switches the device off

Function keys

F1, F2, F3

Jog dial Turn ● Selects functions, settings,

Press ● Variable

● As indicated on the display at

the bottom of the screen

● Function keys may also have

no function assigned in some

cases

measurement data, etc.

● Modies values

Press ● Opens the next program lev-

el (e.g. menu item, function,

measurement data, selectable

values)

● Accepts values

3 Operation

9

Page 17

3 Operation

3.1.2 Selecting/exiting menus and menu items

Functions, applications and settings etc. are selected via the main

menu (for short: Menu). This menu has submenus and menu

items. Refer to Section. 3.2.1 on page 15 for information on

accessing the menu.

Selecting submenus/menu items

Submenus and menu items are selected and opened using the

jog dial and/or function keys.

In measuring mode the selected application is indicated by the

symbol at the top left of the display.

Exiting menus/menu items

There are generally two ways to exit open menus/menu items

and go back up a level:

● Press Esc

● Select Exit menu item

10

Page 18

3.1.3 Switching the device on

Note:

Always switch the device on with fresh air.

● Press the ON/OFF key. The device switches on.

The switching on process involves an internal check.

Process Test purpose

Buzzer emits audible signal.

Signal light gives visual

signal.

Display is inverted. Are there pixels missing from the

The start screen appears on the display.

®

Multitec 560

Frank Smith

City Council

Leakage Delivery

V1.000

Fig. 3: Start screen

22.04.2013

13:02

3 Operation

Is the audible signal working?

Is the visual signal working?

display?

Display:

– Device type: Multitec 560

– User:

Frank Smith

City Council

Leakage Delivery

– Firmware version: V1.000

– Date and time

– Capacity disposable battery/

rechargeable battery

The start screen for the application set under Autostart then

appears (see Section. 3.3.4 on page 24).

11

Page 19

3 Operation

Fig. 4: Start screen for gas measuring

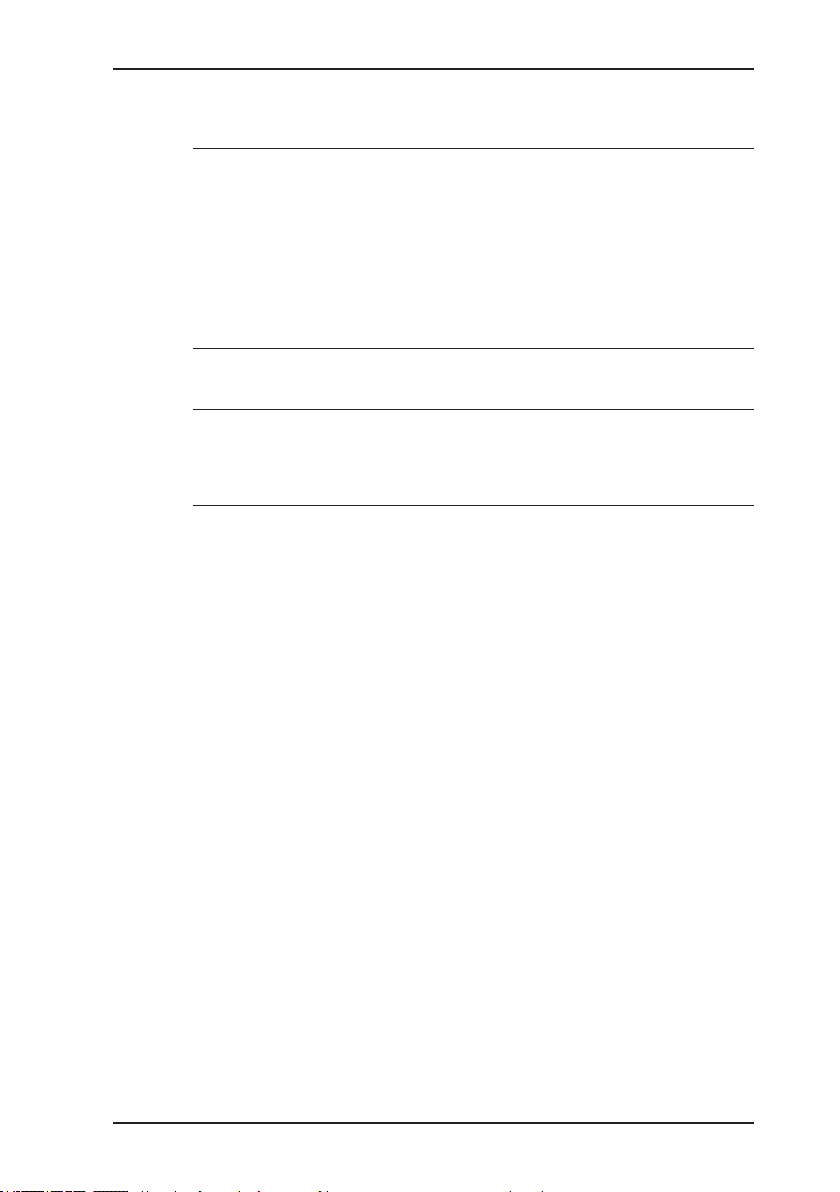

Fig. 5: Measuring mode – display of current readings

Display:

– Symbol: Warning ExTox

Warning ExTox

Range

CH4 4.40 VOL%

CO2 5.00 VOL%

O2 25.0 VOL%

H2S 100 PPM

CO 500 PPM

AL1 AL2 STEL LTEL

0.45 2.20 - -

0.50 1.00 1.00 0.50

18.0 23.0 - 10 20 10 10

30 60 30 30

– Detectable gases

– Measuring range

– Alarm thresholds

– Capacity disposable battery/

rechargeable battery

The device switches to measuring mode.

Display:

– Current readings: zero when

device is switched on with fresh

air

The device is ready for use.

12

A

WARNING! Danger of death due to incorrectly adjusted or faulty devices

Gas warning instruments must be inspected before use

at regular intervals.

● Carry out a device inspection every day before starting

work.

Page 20

3.1.4 Selecting/switching application

WARNING! Danger of death due to incorrectly ad-

A

Note:

You may only switch applications when the device is drawing in

fresh air.

The current application is indicated by the symbol at the top left

of the display. The symbol at the bottom right shows the next application that can be selected via function key F3. The Settings

under System (see Section 3.3.4) are used to specify which ap-

plication is rst activated when you switch the device on.

justed or faulty devices

If the device is used as a gas warning instrument (Warning ExTox application), it must be regularly inspected

before use.

● Carry out a device inspection every day before starting

work.

● Press Menu. Select the menu item for the application you

want to use.

OR

a) Press function key F3. The device switches to the next ap-

plication.

b) Repeat until the symbol for the application you want to use

appears at the top left.

3 Operation

3.1.5 Differences between measuring mode and settings mode

The device is operated in two modes:

● Measuring mode (see Section. 3.2 on page 14)

Measurements are taken in measuring mode. All functions

needed to take readings can be accessed from one menu.

13

Page 21

3 Operation

● Settings (see Section. 3.1 on page 9)

The device settings can be changed in settings mode. Information about the device can also be retrieved. Measurements

cannot be taken in settings mode.

Settings are accessed via the menu in measuring mode. The

settings are access-protected by a PIN code.

WARNING!

A

3.2 Measuring mode

When switched on, the device is in measuring mode. In measuring mode, the current measurements are always displayed

(Fig. 5). However, to save the data from a measurement, you

must always start the measurement manually (see Section. 3.2.6

on page 17).

Danger of death due to lack of alarm signal

The device only issues alarms in measuring mode. As

soon you access the menu, alarms are no longer triggered.

● Only change the settings outside of explosive areas and

away from toxic or low-oxygen atmospheres.

14

A

WARNING!

Danger of death due to operating signal failure

If the operating signal fails in the Warning ExTox appli-

cation, the device is not safe to use.

● Stop using the device immediately.

● Move away from explosive areas or toxic or low-oxygen

atmospheres immediately.

Page 22

3 Operation

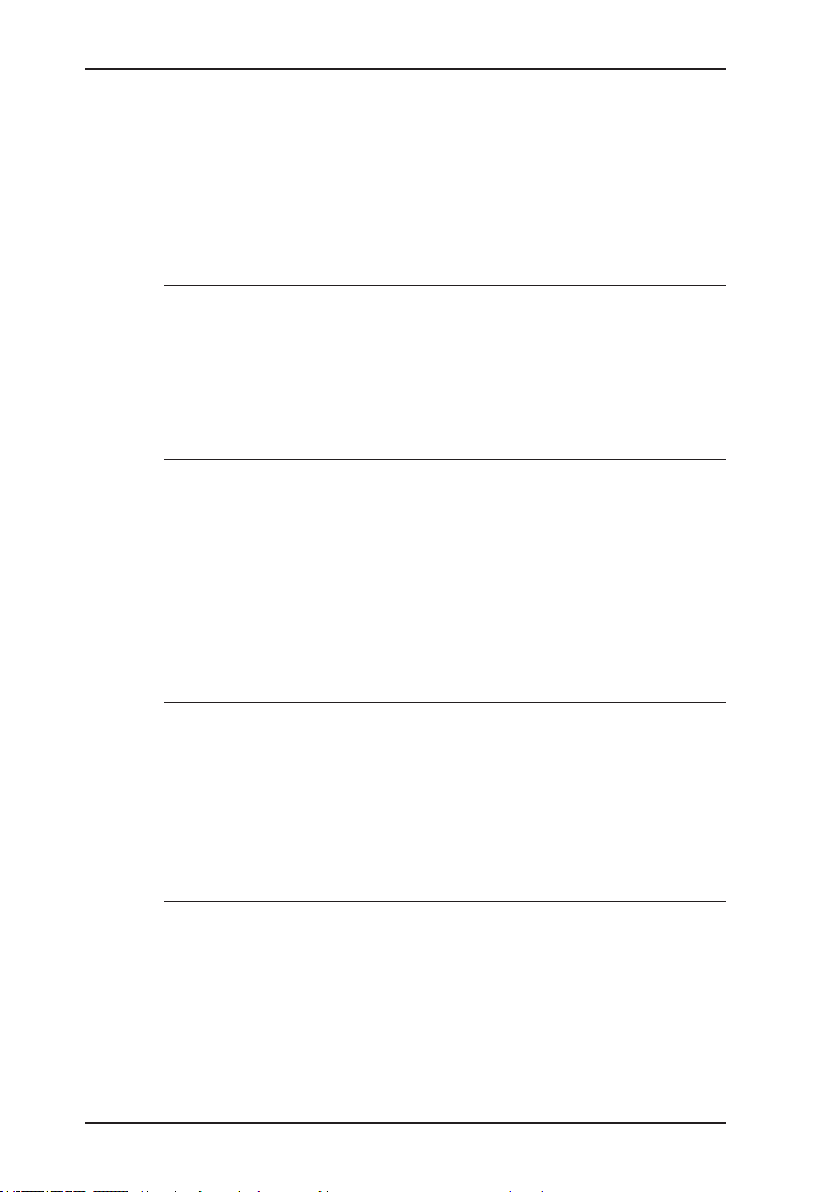

3.2.1 Accessing the menu (measuring mode menu structure)

In measuring mode F1 can be used to access the menu.

Zero point

Gas measuring

Warning ExTox

Settings

Start measurement

Protocol

Device inspection

Device information

Exit

Fig. 6: Menu with submenus/menu items

Once you have started a measurement, Start measurement in

the menu becomes Stop measurement. You can nd detailed

information on starting and stopping measurements in Section. 3.2.6 on page 17.

Protocol does not appear in the menu until you save a protocol

for the rst time.

3.2.2 Zero point

The zero point can be set manually in the Zero point menu item.

This is only necessary if the displayed fresh air measurement is

not zero after the end of the warm-up period.

Gas Content in fresh air Correct zero point on device

CH40 % vol. 0.0 % vol.

CO 0 ppm 0 ppm

CO20.04 % vol. 0.04 % vol.

H2S 0 ppm 0 ppm

O

20.9 % vol. 20.9 % vol.

2

The manual zero point setting is not saved. The zero point can be

corrected by adjustment as often as zero point deviations occur.

15

Page 23

3 Operation

Requirements for correct setting of the zero point

● Device has been switched on with fresh air.

● Device continues to draw in fresh air.

Setting zero point (manual zero point setting)

1. Press Menu.

2. Select Zero point menu item. The values are automatically

adjusted. The device returns to measuring mode.

3.2.3 Gas measuring

You can nd an overview of detectable gases under Gas measuring in the menu. The device automatically returns to measuring

mode.

3.2.4 Warning ExTox

You can access the overview of detectable gases and corresponding alarm thresholds under Warning ExTox in the menu.

The device automatically returns to measuring mode.

CAUTION! Health risk due to late alarm

A

3.2.5 Settings

You can change the device settings and access information

about the device under Settings in the menu (see Section. 3.3

on page 20).

16

If you switch from Warning ExTox to Gas measuring, data

that could initiate a STEL or LTEL alarm is reset to zero.

● Only switch from Warning ExTox to Gas measuring

once you have left the work area being monitored.

Page 24

3.2.6 Starting/stopping a measurement

Measurements must always be started and then stopped. When

the measurement is stopped, the measurement data is stored

in a le.

Note:

Measurements cannot be cancelled. The only way to cancel a

measurement is to stop it.

Up to 80 measurements can be saved.

The measured values can be saved with or without a comment.

Comment entries are saved automatically (ring memory with

max. 10 entries).

Once the rst comment has been entered, the Open

stored comments function will become available.

The stored measurement les can be displayed on a computer

using a readout program. The program is available at www.

sewerin.com.

3 Operation

Starting a measurement

1. Press Menu.

2. Select Start measurement from the menu. This starts meas-

urement plot recording.

Measurement plot recording must always be concluded with Stop

measurement.

17

Page 25

3 Operation

Stopping a measurement

1. Press Stop measurement.

2. Answer Yes to the warning prompt.

3. Enter a comment for the measurement.

OR

a) Press Menu.

b) Select Stop measurement from the menu.

a) Select the characters required using the jog dial. Conrm

each character using the jog dial.

OR

− Press Open stored comments. A list of the stored com-

ments will appear.

− Select the desired comment. Open the comment with OK.

b) Then conrm your entry/selection with OK.

OR

Press Esc if you do not wish to enter a comment for the

measurement.

The measurement is saved as a protocol. The protocol name

is formed from the date, time and comment.

3.2.7 Protocols

You can retrieve or clear protocols of saved data under Protocol

in the menu. When saved, the protocols are assigned to different

protocol types.

The following protocol types are available:

● Device inspection

● Measurements

Protocols can only be cleared individually.

You can nd information on how to clear all protocols of one pro-

tocol type in Section. 3.3.7 on page 26.

18

Page 26

3.2.8 Device inspection

The device inspection can be used to check the general status

and the indication accuracies. Device inspection only appears

in the menu when the integrated device inspection is switched on.

Note:

The integrated device inspection is switched off in the factory

settings. More detailed information about the device inspection

can be found in Section. 5.1 on page 32.

If the integrated device inspection is switched on, the device will

remind you to carry out a device inspection.

The Carry out device inspection symbol will appear

when the inspection is due. It is visible in the display

until the complete integrated device inspection has been

carried out successfully.

3.2.9 Device information

The following device information is shown under Device information in the menu:

● Installed electrochemical sensors: gas, installation date, war-

ranted/expected lifetime

● Firmware: version, date

● Service: date of the last service, date of the next service

3 Operation

19

Page 27

3 Operation

3.3 Settings

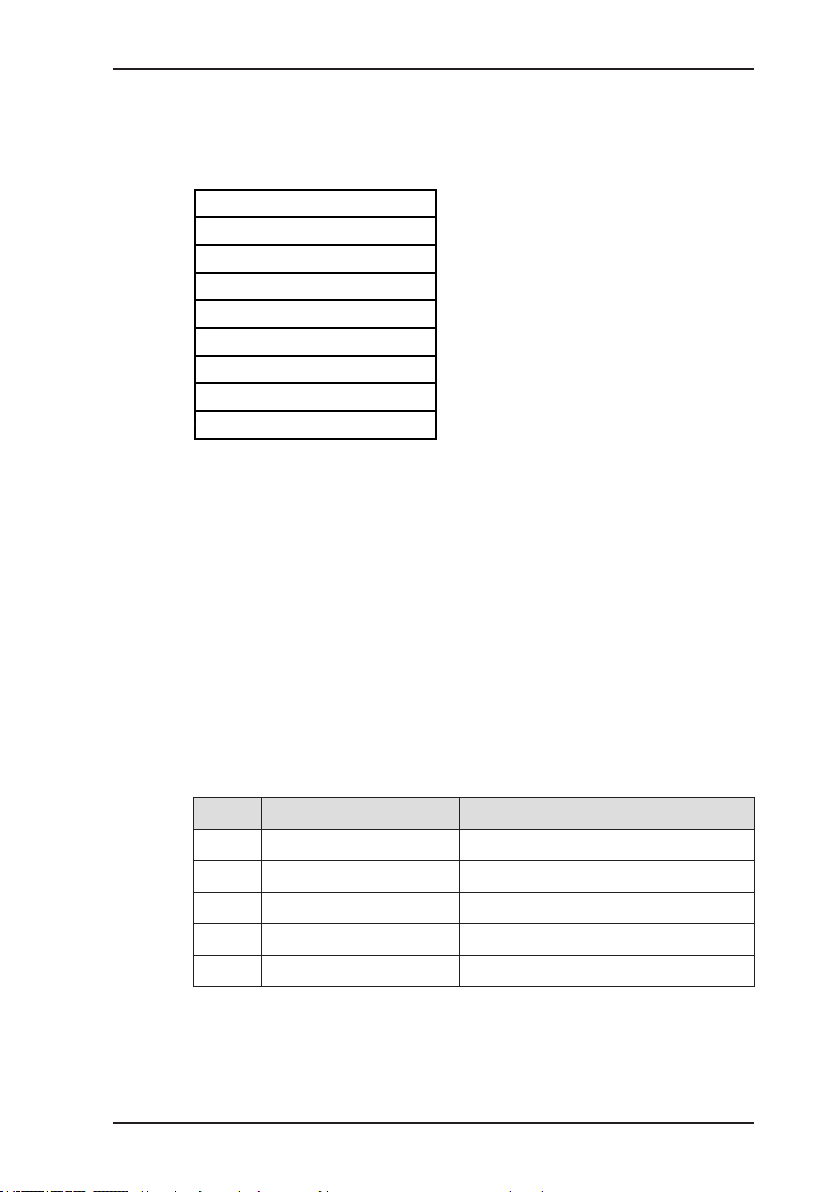

The following menus and menu items are included under Settings :

● Adjustment

● System

● Alarms

● Date/time

● Memory

You can nd information on selecting and exiting menus and menu

items in Section. 3.1.2 on page 10.

3.3.1 Opening Settings

1. Press Menu.

WARNING!

A

Danger of death due to lack of alarm signal

The device only issues alarms in measuring mode. As

soon you access the menu, alarms are no longer triggered.

● Only change the settings outside of explosive areas and

away from toxic or low-oxygen atmospheres.

20

2. Select the Settings menu item.

Access is protected by a PIN code. The default setting is

always PIN code 0001.

Note:

You can change the PIN code at any time.

SEWERIN recommends setting a different PIN code after initial

start-up, so only authorised personnel have access to the settings.

3. Enter the PIN code from left to right. The active digit is always

displayed with a black background.

Page 28

3 Operation

Exit

Digit To change To conrm

1st digit

Press the jog dial

2nd digit Press the jog dial

3rd digit Press the jog dial

Turn the jog dial

4th digit

If the PIN code has been entered correctly, the Settings menu

will appear once the last digit has been conrmed (Fig. 7).

Otherwise the device will revert to measuring mode.

Adjustment

System

Alarms

Date/time

Memory

Fig. 7: Settings menu

21

Page 29

3 Operation

3.3.2 Settings menu structure

Settings Adjustment Adjustment gas mixture warning

Measuring mode

PIN Code

Adjustment gas mixture measuring

Test gas

Adjustment CH4

Adjustment CO2

Adjustment O2

Adjustment CO

Adjustment H2S

Inspection OK

Exit

System PIN Code

Alarms

Date/time

Memory Clear

Exit

Service interval

Display

Battery

Autostart

Unit %LEL

Device inspection

Language

Exit

Interval

Memory mode

Exit

Fig. 8: Settings menu structure for Multitec 560 (gas type: methane)

22

Note:

The number of available menu items depends on the optional

additional equipment.

Page 30

3.3.3 Adjustment

The Adjustment menu is used to set the sensors.

WARNING! Danger of death due to incorrect adjust-

A

A detailed description of adjustment along with important information is provided in Section. 5.2 on page 41.

Adjustment gas mixture warning

Used to adjust the infrared and electrochemical sensors for all

components of the test gas (gas mixture).

ment

Incorrect adjustment can lead to incorrect measurement

results. This means that the user may not be warned about

dangerous gas concentrations in time.

● Only specialist technicians may perform adjustments

● Adjustments must be made in well ventilated rooms or

in the open air.

3 Operation

Application: – Warning ExTox

Adjustment gas mixture measuring

Used to adjust the infrared sensors for methane CH4 and carbon

dioxide CO2.

Application: – Gas measuring

Test gas

Used to adjust the concentration of the test gases used.

Adjustment CO2

Used to adjust the infrared sensor for carbon dioxide CO2 in the

% vol. range.

23

Page 31

3 Operation

Adjustment O2

Used to adjust the electrochemical sensor for oxygen O2 in the

% vol. range.

Adjustment CO

Used to adjust the electrochemical sensor for carbon monoxide CO in the ppm range.

Adjustment H2S

Used to adjust the electrochemical sensor for hydrogen sulphide

H2S in the ppm range.

Inspection OK

Conrms the device is in proper working order. This extends the

service interval.

3.3.4 System

General information and specications for operation are set in

the System menu.

24

PIN code

Used to change or reset the PIN code.

Note:

If you lose the PIN code, you must contact SEWERIN Service.

If the PIN code is set to 0000, you will not be asked to enter it.

The settings can then be accessed by anyone.

Service interval

Species the regular inspections/maintenance required for the

device. You can also activate the automatic switch-off function

once the set interval has passed.

Page 32

3 Operation

Display

Used to set how long the display remains illuminated after any

key is pressed as well as the display contrast.

Battery

Used to set the type of disposable/rechargeable battery used.

CAUTION! Damage possible due to device overheating

If the battery type is not correctly set, the device can overheat.

● Always enter the correct battery type.

Autostart

Sets the application that is automatically activated when the device is switched on.

Unit %LEL

Used to set the unit of measurement.

Device inspection

Used to switch the integrated device inspection on or off.

Language

Sets the language.

25

Page 33

3 Operation

3.3.5 Alarms

Sets the alarm thresholds for methane CH

There is detailed information on alarms in Section. 7.2 on

page 51.

AL1 alarm

Used to set the pre-alarm.

AL2 alarm

Used to set the main alarm.

3.3.6 Date/time

Used to set the time, day, month and year. There are two formats

available for the date.

3.3.7 Memory

The Memory menu is used to specify how measurement data

and protocols are handled.

4.

26

Clear

Used to clear protocols.

The different protocol types must each be cleared separately. All

protocols in one protocol type are cleared at once.

You can nd information on clearing individual protocols in Section. 3.2.7 on page 18.

Interval

Sets the interval at which measurement data is automatically

saved.

Memory mode

Switches between ring memory and stack memory.

Page 34

4 Power supply

4 Power supply

This device can be operated using:

● Disposable (non-rechargeable) alkaline batteries

● Rechargeable NiMH batteries

The device comes with nickel metal hydride rechargeable batteries. The corresponding settings are stored.

WARNING! Risk of explosion due to leaking batteries

A

4.1 Suitable disposable/rechargeable battery types

Leaking electrolytes can shorten the creepage distance

and air gap between the poles. As a result, the requirements for the batteries may no longer be met.

● Replace leaking batteries immediately.

● Clean the battery compartment (and, if necessary, the

device) before inserting the new disposable/rechargeable batteries.

A

WARNING! Risk of explosion due to unsuitable batteries

To ensure that the device remains explosion-proof as per

/16/, only certain disposable/rechargeable batteries may

be used:

● Only use batteries supplied by SEWERIN. Other dis-

posable/rechargeable batteries, which have not been

supplied by SEWERIN, may only be used if they meet

the specications in accordance with /8/.

● In each battery compartment use only batteries that are

identical with respect to type (disposable or recharge-

able), capacity and manufacturer.

27

Page 35

4 Power supply

Disposable battery requirements

● Alkaline disposable batteries

● Size: AA, type: LR6 as per /11/

● The creepage distance and air gap between the poles must

not be less than 0.5 mm in accordance with /8/.

Rechargeable battery requirements

● NiMH rechargeable batteries

● Size: AA, type: HR6 as per /13/

● The creepage distance and air gap between the poles must

not be less than 0.5 mm in accordance with /8/.

● The rechargeable batteries must be fast charging (I > 1.25 A)

and remain within the temperature range.

Note:

A device operated with disposable alkaline batteries cannot be

charged. A note to this effect is shown on the display.

4.2 Operation with rechargeable batteries

The operating time of the device depends on the battery capacity.

If the device is not used or not kept in the docking station, the

batteries will lose their charge due to self-discharge. The self-discharge intensity depends on the battery type.

4.2.1 Charging

The device can be charged via:

● Connection for power supply

● Docking station TG8

28

Page 36

DANGER! Risk of explosion due to sparks

A

For charging you will need either:

Please note the following points:

4.2.2 Rechargeable battery maintenance

If the device is not used for a long period of time, it is advisable

to fully discharge the battery before recharging it again.

A full discharging and recharging process takes approx. 11 hours

(8 hours to discharge + 3 hours to recharge). The duration depends on the capacity of the rechargeable batteries used.

High charging current occurs when batteries are being

charged.

The power supply is not explosion-proof.

● Only charge the device outside of explosive areas.

● AC/DC adapter M4

● Vehicle cable M4

● The device or docking station must not be directly connected

to a 24-V on-board power supply in the vehicle. The voltage is

too high for the charging process.

● The battery should be charged at approximately room tem-

perature.

4 Power supply

DANGER! Risk of explosion due to sparks

A

High charging current occurs when batteries are being

charged.

The power supply is not explosion-proof.

● Only charge the device outside of explosive areas.

● Connect the device (switched on) to the power supply via the

side connection.

OR

Place the device (switched on) into the docking station.

The rechargeable batteries will be fully discharged. Once the

device has been discharged, it will automatically switch to

charging mode.

29

Page 37

4 Power supply

4.3 Battery alarm

As soon as the remaining capacity of the batteries gets low, a

battery alarm will go off:

Level 1: Battery almost empty

– Capacity disposable battery/rechargeable

battery symbol ashes

– Audible signal (one-off)

– Operating signal doubles

– Remaining operating time: approx. 15 min

Level 2: Battery empty

– Blank display apart from Capacity disposable

battery/rechargeable battery symbol

– Continuous audible signal

– Measuring mode unavailable

– Device shuts off

4.4 Replacing disposable/rechargeable batteries

DANGER! Risk of explosion due to sparks

A

When the housing is open, the device is not explosion-proof.

● Only open the battery compartment outside of explo-

sive areas.

30

A 2.5 mm Allen key (supplied) is required to open the battery

compartment on the back of the device.

1. Loosen the two screws securing the battery compartment. Remove the screws by repeatedly turning them alternately a short

way; this ensures that the battery compartment does not twist.

2. Lift out the battery compartment.

3. Remove the disposable/rechargeable batteries and insert new

ones. Ensure that the batteries are inserted with the correct

polarity.

4. Replace the battery compartment so it ts neatly into place

and secure rmly with the screws.

5. When you switch the device back on again, you will be asked

which battery type is in use. Enter the correct battery type.

Page 38

4 Power supply

If it takes longer than 120 seconds to replace the batteries, the

date and time will have to be reset the next time you switch the

device on. All the other data will be saved.

31

Page 39

5 Maintenance

5 Maintenance

In accordance with the legal regulations, device maintenance

comprises the following elements:

● Device inspection including test of indication accuracy

● Adjustment

● Maintenance

All inspections must be documented. The documentation must

be retained for at least one year.

WARNING! Danger of death due to incorrectly ad-

A

5.1 Device inspection

justed or faulty devices

Gas warning instruments must be inspected before use

at regular intervals.

● Carry out a device inspection every day before starting

work (as per /1/, /2/, /6//10/).

5.1.1 General information on the device inspection

5.1.1.1 Scope

The device inspection includes the following tests:

● Analysis of the general status

● Test of the indication accuracy with supply of fresh air

● Test of the indication accuracy with supply of test gas

32

Page 40

5.1.1.2 Frequency

The frequency of the device inspection depends on the application.

Application When to test Legal basis

Warning ExTox Each work day /1/, /2/, /4/, /6/, /10/

Gas measuring Weekly to every six

If the integrated device inspection is switched on, the device will

remind you to carry out a device inspection.

5.1.1.3 Documentation

The device inspection procedure must be documented. There

are two ways of doing this:

● On paper

● Saved electronically supported by the device (integrated de-

vice inspection)

Only the integrated device inspection is described in these operating instructions.

5 Maintenance

/3/

months

Note:

If the integrated device inspection is switched off, the device inspection must be documented on paper.

5.1.1.4 Integrated device inspection

The integrated device inspection is accessed via the menu

(Fig. 6).

The results of the device inspection are stored in the device as

a protocol.

The device inspection protocols can be opened at any time. They

can also be displayed on a computer using a readout program.

The program is available at www.sewerin.com.

33

Page 41

5 Maintenance

The integrated device inspection is switched off in the factory

settings. The integrated device inspection has to be switched on

(once only) before it can be performed.

Switching on the integrated device inspection

1. Press Menu.

2. Select Settings.

3. Enter your PIN code.

4. Select System.

5. Select Device inspection.

6. Select Yes.

7. Accept the setting with OK.

8. Exit the settings with Exit.

The Carry out device inspection symbol appears when

a device inspection is due. It is visible in the display until the complete integrated device inspection has been

carried out successfully.

If the device inspection was completed but the device

failed on some points, the symbol will remain visible.

5.1.1.5 Order

You can carry out the tests that make up the device inspection

in any order you wish. You can repeat the tests as often as you

wish provided you have not yet concluded the device inspection.

5.1.1.6 Test gases for the device inspection

The following test gases can be used to check the indication accuracy when supplying test gas:

Test Recommended test gases

Gas measuring Gas mixture Bio IR

Warning Gas mixture ExTox IR

34

Page 42

Note:

Gas measuring

Warning

General status

Fresh air

Gas mixture Gas measuring

General status

Fresh air

Gas mixture Warning

Use of test gases not provided by SEWERIN can cause interference.

The concentration of the test gas used must match the specied

test gas concentration.

Changing the test gas concentration

If there is no test gas with the specied concentrations available

for the inspection, the values can be adjusted to the test gas

used in the adjustment menu under Test gas (see Section 3.3.3).

5.1.2 Carrying out the device inspection

5.1.2.1 Accessing the device inspection

The device is in measuring mode.

1. Press Device inspection.

OR

a) Press Menu.

b) Select Device inspection menu item.

The Device inspection menu appears.

5 Maintenance

Fig. 9: Device inspection menu

2. Select the application for which you wish to perform the de-

vice inspection (Gas measuring or Warning). A submenu

will appear.

Fig. 10: Submenus for the device inspection:

Dev. test Gas measuring (left) / Dev. Test Warning (right)

35

Page 43

5 Maintenance

3. Select a test from the menu (Device inspection, Fresh air,

Gas mixture…).

4. Carry out the test.

For detailed information, refer to the following sections:

− General status Section. 5.1.3 on page 37

− Fresh air Section. 5.1.4 on page 39

− Test gas … Section. 5.1.5 on page 40

5.1.2.2 Concluding the device inspection

After all the tests have been carried out as described in Section 5.1.3 to Section 5.1.5, the Save symbol will appear in the

display.

An integrated device inspection is concluded by saving it. Up to

40 device inspections can be saved. The following information

can be stored along with the device inspection:

● Inspector (e.g. inspector's name or initials)

● Password to protect the protocol from being accessed by un-

authorised people

Inspector entries are saved automatically (ring memory with max.

10 entries).

Once the rst inspector has been entered, the Open

stored inspectors function will become available.

36

1. Press Save.

2. If necessary enter the name of the inspector.

a) Select the characters required using the jog dial. Conrm

each character using the jog dial.

OR

− Press Open stored inspectors. A list of the stored in-

spectors will appear.

− Select the desired inspector. Open the inspector with OK.

Page 44

b) Then conrm your entry/selection with OK.

OR

Press Esc if you do not wish to enter an inspector for the

device inspection.

3. Enter a password.

a) Select the characters required using the jog dial. Conrm

each character using the jog dial.

b) Then conrm your entry with OK.

OR

Press Esc if you do not wish to enter a password for the

device inspection.

The device inspection is saved as a protocol. An overview with

the device inspection results is displayed.

4. Conrm the overview by pressing OK. The device returns to

measuring mode.

5.1.3 Testing the general status

The general status test is part of the device inspection. The general status test is based on estimations by the user. The following

must be tested:

● Housing

● Signals

● Probe

● Filter

● Pump

The battery charge status and the working condition of the controls

are automatically tested during the integrated device inspection.

5 Maintenance

37

Page 45

5 Maintenance

The device inspection has been opened.

1. Select the General status menu item from the Dev. Test …

submenu.

2. Test all associated subitems as described in Section 5.1.3.1

to Section 5.1.3.5.

3. Conrm the prompt General status OK? by pressing Yes if

all subitems show no faults during testing. General status

OK appears on the display.

This concludes the General status test.

5.1.3.1 Housing

● Is the housing free from external damage?

5.1.3.2 Signals

During the integrated device inspection the signals are emitted

at short intervals.

● Can the audible signal be heard?

● Is the visual signal visible?

5.1.3.3 Probe

Probes are accessories. They only need to be tested if they are

likely to be used in the course of the working day.

● Are the probes free from external damage?

Probe hoses are tested with a simple leak check.

1. Connect the probe hose to the gas input.

2. Seal the free end of the probe hose.

An error message should appear after approx. 10 seconds.

This indicates that the probe hose is in good condition.

38

Page 46

5.1.3.4 Filter

The ne dust lter is located behind the gas input. It is tested by

means of a visual inspection.

1. Unscrew the gas input.

2. Remove the ne dust lter.

3. Check that there is no dirt in the ne dust lter.

As soon as there are any signs of deposits, the lter must be

replaced. If you do not replace the lter, you must reinsert it

exactly as you found it.

5.1.3.5 Pump

The pump function is tested with a simple leak check.

1. Seal the gas input.

After a maximum of 10 seconds an error message should appear. This indicates that the pump is working correctly.

If the error message does not appear, the pump may be faulty.

The device must be tested by SEWERIN Service.

2. Release the gas input again.

After approximately 5 seconds, the error message should

disappear again. Otherwise there is a fault.

5 Maintenance

5.1.4 Testing indication accuracy with supply of fresh air

The indication accuracy with supply of fresh air test is part of the

device inspection.

The device inspection has been opened.

1. Make sure that only fresh air is being drawn in.

2. Select the Fresh air menu item from the Dev. Test … sub-

menu.

3. Wait until the displayed readings are stable. A Status: OK

message will appear.

4. Press OK to conrm. Fresh air OK will appear on the display.

This concludes the Fresh air test.

If the Status: OK message does not appear within a reasonable

amount of time, the air inow does not correspond to the limit val-

39

Page 47

5 Maintenance

ues stored in the device (see Section. 7.3 on page 56). Move

the device to another location and repeat the test.

If the Status: OK message still does not appear when the test

is repeated, the device must be re-adjusted (see Section. 5.2 on

page 41).

5.1.5 Testing indication accuracy with supply of test gas

The indication accuracy with supply of test gas test is part of the

device inspection.

All test gases specied in the device must be tested. The number

of specied test gases is dependent on the optional additional

equipment.

The following resources are needed for the test:

● Test gas (e.g. gas mixture ExTox IR)

Information on test gases for the device inspection can be found

in Section. 5.1.1.6 on page 34.

● Test set for the supply of test gas (e.g. SPE VOL)

Note:

Details of how to use the test set can be found in the accompanying operating instructions.

40

The device inspection has been opened.

1. Select the menu item Gas mixture measuring/ Gas mixture

warning menu item from the Dev. Test… submenu.

2. Check whether the test gas concentration specied by the

device matches the test gas you intend to use. To do this

press Information.

3. Add the test gas

4. Wait until the displayed readings are stable. A Status: OK

message will appear.

5. Press OK to conrm.

6. Stop the test gas supply.

The device switches back to the Dev. test... menu. A Test gas

OK message will appear.

Page 48

Once all tests have been successfully completed, the full test of

the indication accuracy with supply of test gas is also complete.

Test gas test unsuccessful

If a Gas mixture… test was not carried out successfully, the

message Test gas not OK appears.

A test may be unsuccessful for the following reasons:

Cause Corrective action

Connections leaking Repeat check, checking the

Measurement values outside

the specied limit values (see

Section. 7.3 on page 56)

5.2 Adjustment

WARNING! Danger of death due to incorrect adjust-

A

ment

Incorrect adjustment can lead to incorrect measurement

results. This means that the user may not be warned about

dangerous gas concentrations in time.

● Only specialist technicians may perform adjustments

● Adjustments must be made in well ventilated rooms or

in the open air.

5 Maintenance

seal on the connections

Adjustment required

41

Page 49

5 Maintenance

5.2.1 Scope

Adjustments must be made separately for each measuring range.

● Zero point

● Sensitivity

Note:

For each measuring range always adjust the zero point rst, followed by the sensitivity.

Only gases for which the readings are outside the predened

limits need to be adjusted during the adjustment process (see

Section. 7.3 on page 56).

5.2.2 Test gases for the adjustment

The following test gases can be used for adjustment:

Gas Suitable test gases for

Zero point Sensitivity

CO ● Fresh air ● Gas mixture ExTox IR

CO

CH

2

4

● Fresh air ● Gas mixture ExTox IR

● Fresh air ● Gas mixture ExTox IR

H2S ● Fresh air ● Gas mixture ExTox IR

O

2

● Gas mixture ExTox IR

● Gas mixture Bio IR

and gas mixture Bio

IR

and gas mixture Bio

IR

and gas mixture Bio

IR

● Fresh air

42

If more than one test gas can be used to adjust a gas, it does

not have to be adjusted with all test gases. However, adjusting

with more than one test gas increases the measurement quality.

Fresh air contains 20.9 % vol. O2 and is therefore used with oxygen to adjust the sensitivity.

Page 50

Note:

Use of test gases not provided by SEWERIN can cause interference.

The concentration of the test gas used must match the specied

test gas concentration.

5.2.3 Special features of adjustment with gas mixture

If a SEWERIN gas mixture is used as a test gas, several gases

can be adjusted in a single step:

Gases which can be adjusted simultaneously with a

SEWERIN gas mixture

5 Maintenance

Test gas: ExTox IR

Menu item:

Adjustment

gas mixture warning

● Methane CH

4

● Carbon dioxide CO

● Hydrogen sulphide H2S

● Oxygen O

2

2

Test gas: Bio IR

Menu item:

Adjustment

gas mixture measuring

● Methane CH

● Carbon dioxide CO

4

2

● Hydrogen sulphide H2S

● Oxygen O

2

● Carbon monoxide CO

Zero point

The zero point is adjusted under Fresh air in the menu. The

following parameters are adjusted in a single step:

● Zero points of CH4, CO2, H2S and CO

● Sensitivity of O2

Sensitivity

The sensitivity is adjusted under Gas mixture in the menu. The

following parameters are adjusted in a single step:

● Sensitivities of CH4, CO2, H2S and CO

● Zero point of O2

43

Page 51

5 Maintenance

5.2.4 Preparation

An adjustment always requires time. Leave yourself plenty of time

to prepare the necessary steps of the procedure.

● Have all necessary tools available.

● Let the device run for several minutes to guarantee that the

temperature is correct, for example.

5.2.5 Performing the adjustment

The zero point and sensitivity are adjusted following the same

procedure for all gases. The adjustment of oxygen is an excep-

tion. It is therefore described separately.

You can nd detailed information on the adjustment

of various gases (for example, test gas concentration,

installation date of the sensor, date of last adjustment)

under Information.

The symbol appears after the corresponding Adjust-

ment… menu item has been selected.

5.2.5.1 Adjusting the zero point

For all gases except oxygen O2, the zero point is adjusted following the same procedure.

44

Note:

When adjusting the zero point of carbon dioxide CO2, a carbon

dioxide lter must be used.

This applies to both the zero point adjustment for Adjustment

CO2 in the menu and Adjustment gas mixture warning.

1. Make sure that only fresh air is being drawn in.

2. Open Settings.

3. Select the Adjustment menu item.

4. Select the desired adjustment (e.g. Adjustment CH4, Adjust-

ment gas mixture warning).

5. Wait at least 1 minute. The displayed reading must be stable.

Page 52

Note:

For Adjustment gas mixture warning and Adjustment gas

mixture measuring, all values must be stable. The time required

for this can vary depending on the specic gas.

6. From the menu select the method you wish to use to adjust

the zero point.

− e.g. for Adjustment CH4: Zero point

− for Adjustment gas mixture warning: Fresh air

7. Press OK to conrm.

This adjusts the zero point. The reading shows zero (0.00 %

vol. / 0 ppm). (Except for Adjustment gas mixture: the value

for oxygen O2 is 20.9 % vol.)

5.2.5.2 Adjusting the sensitivity

For all gases except oxygen O2, the sensitivity is adjusted following the same procedure.

The following resources are needed for adjusting the sensitivity:

● Test gas

Information on test gases for adjustment can be found in Section. 5.2.2 on page 42.

● Test set for the supply of test gas (e.g. SPE VOL)

5 Maintenance

Note:

Details of how to use the test set can be found in the accompanying operating instructions.

Note:

When adjusting the sensitivity, never use a carbon dioxide lter.

45

Page 53

5 Maintenance

1. Connect the device to the test set.

2. Open Settings.

3. Select the Adjustment menu item.

4. Select the desired adjustment (e.g. Adjustment CH4, Adjust-

5. Select the menu item that species the sensitivity to be tested.

6. Press and hold the release button on the test set. The test gas

7. Wait at least 1 minute. The displayed reading must be stable.

Note:

For Adjustment gas mixture warning and Adjustment gas

mixture measuring, all values must be stable. The time required

for this can vary depending on the specic gas.

ment gas mixture warning).

− e.g. for Adjustment CH4: 2.20 %VOL. CH4

− for Adjustment gas mixture warning: Gas mixture

Do not conrm with OK yet.

is added. Do not let go of the release button.

8. Press OK to conrm. The device is adjusted. The reading

shows the specied value (e.g. 2.20 % vol. CH4).

9. Let go of the release button on the test set.

5.2.6 Carrying out an oxygen adjustment

As oxygen is a component of fresh air, the procedure for adjusting

oxygen is different from the procedure for all other gases.

5.2.6.1 Adjusting the zero point for oxygen

The zero point of oxygen must be adjusted using a gas that does

not contain any oxygen and which will not damage the sensor.

The following resources are needed for adjusting the zero point

of oxygen:

46

Page 54

5 Maintenance

● Test gas

Information on test gases for adjustment can be found in Section. 5.2.2 on page 42.

● Test set for the supply of test gas (e.g. SPE VOL)

Note:

Details of how to use the test set can be found in the accompanying operating instructions.

1. Connect the device to the test set.

2. Open Settings.

3. Select the Adjustment menu item.

4. Select the Adjustment O2 menu item.

5. Select Zero point menu item. Do not conrm with OK yet.

6. Press and hold the release button on the test set. The test gas

is added. Do not let go of the release button.

7. Wait at least 1 minute. The displayed reading must be stable.

8. Press OK to conrm. The device is adjusted. The reading

shows zero (0.0 % vol.).

9. Let go of the release button on the test set.

5.2.6.2 Adjusting the sensitivity for oxygen

The sensitivity for oxygen is adjusted with fresh air.

1. Make sure that only fresh air is being drawn in.

2. Open Settings.

3. Select the Adjustment menu item.

4. Select the Adjustment O2 menu item.

5. Wait until the displayed reading is stable. (The reading may

still ash.)

6. Select 20.9 % VOL. (fresh air) from the menu (select and

conrm with OK ).

This adjusts the sensitivity. The reading shows 20.9 % vol.

47

Page 55

5 Maintenance

5.3 Servicing

The device must only be serviced and repaired by SEWERIN

Service.

● Send the device to SEWERIN for repairs and for annual main-

tenance.

Note:

If there is a service agreement in place, the device can be serviced by the mobile maintenance service.

Fig. 11: Inspection plate

The inspection plate on the device shows con-

rmation of the last maintenance and the next

scheduled maintenance.

48

Page 56

6 Faults

If a fault occurs during operation, an error message will appear

on the screen.

Error messages are displayed in the order in which they occur.

Up to ve errors can be displayed.

Error messages continue to be displayed until the error is corrected.

Overview of possible error messages

6 Faults

Error

code

9 No calibration

10 Adjustment failed

11 Zero point

52 XFLASH

59 Error unknown

62 IR sensor Error can only be corrected by

80 Error unknown

100 Pump error

105 Pump error

200 I2C HOST – IR

201 I2C HOST – EC

202 I2C HOST – EX

Error message on the

display

IR sensor adjustment

Test gas

Adjustment required

SEWERIN Service

SEWERIN Service

SEWERIN Service

Probe/lter

Gas outlet

SEWERIN Service

SEWERIN Service

SEWERIN Service

Error correction

Adjustment required (Adjustment

CH4, Adjustment CO2 or Adjustment gas mixture ...)

Check test gas

Adjustment required

Error can only be corrected by

SEWERIN Service

Error can only be corrected by

SEWERIN Service

SEWERIN Service

Error can only be corrected by

SEWERIN Service

Check all lters, probes and hose

connections for porosity and dirt

Check pressure at gas input/gas

outlet

Error can only be corrected by

SEWERIN Service

Error can only be corrected by

SEWERIN Service

Error can only be corrected by

SEWERIN Service

49

Page 57

7 Appendix

7 Appendix

7.1 Specications and permitted operating conditions

Dimensions (W×D×H): Approx. 148 × 57 × 205 mm

Approx. 148 × 57 × 253 mm with supporting

bracket

Weight: Approx. 1000 g, depending on equipment

Operating position: Any

Protection rating: IP54

Power supply: 4 cells, either:

– Rechargeable batteries: NiMH

– Disposable batteries: Alkaline

Operating time: Minimum 8 h

Charging time for re-

chargeable batteries:

Charging voltage: 12 V DC (max. 1 A)

Operating temperature: -20 ºC – +40 ºC

Storage temperature: -25 ºC – +60 ºC

Pressure: 800 – 1100 hPa

Permissible relative

humidity:

Sensors: – IR for CO2, CH

Warm-up time: – < 30 s

PC connection: USB

Memory: 8 MB

Display: 320 × 240 pixels

Buzzer: Frequency: 2.4 kHz

Signal light: Red

Pump: Vacuum: > 250 mbar

Pressure at gas input: max. 100 mbar

Operation: – ON/OFF key

Approx. 3 h (full charge),

depending on capacity

5 – 90 % r.h., non-condensing

Optional:

– EC for O2, H2S, CO

– Up to 90 s for EC

Volume: 80 dB (A) / 1 m

Volume ow: Typically 50 l/h ±20 l/h

Pump error (F100) dependent on volume ow:

– ≤ 20 l/h F100 certain

– > 20 l/h – ≤ 35 l/h F100 possible

– Jog dial

– 3 function keys

4

50

Page 58

7.2 Alarms

Only applies to Warning ExTox application.

WARNING! Danger of death due to hazardous gas

A

concentrations

An alarm always indicates danger.

The type of action depends on the situation. In the event of a

pre-alarm, it may be sufcient to ventilate thoroughly. In the event

of a main alarm, it may be necessary to leave the danger zone

immediately.

7.2.1 Features

AL1

Type: Pre-alarm

Adjustable: Yes

Latching: No

Trigger: Alarm threshold AL1 exceeded

Indicator: – Audible signal

Acknowledgement:

Reset: – Automatic when level falls below alarm threshold

7 Appendix

● Take all necessary measures for your own safety and

the safety of others immediately.

– Visual signal

– AL1 message on display

– Possible for audible signal when alarm threshold

AL1 is exceeded

AL1

Exception for oxygen: alarm AL1 is triggered when the level falls

below alarm threshold AL1.

51

Page 59

7 Appendix

AL2

Exception for oxygen: alarm AL2 is not latching.

AL3

Type: Main alarm

Adjustable: Yes

Latching: Yes

Trigger: Alarm threshold AL2 exceeded

Indicator: – Audible signal

– Visual signal

– AL2 message on display

Acknowledgement:

Reset: – By acknowledgement after level falls below alarm

Type: End of measuring range

Adjustable: No

Latching: Yes

Trigger: Alarm threshold AL3 exceeded

Indicator: – Audible signal

Acknowledgement:

Reset: – By acknowledgement after level falls below alarm

– Possible for audible signal when alarm threshold

AL2 is exceeded

– Possible overall after level falls below alarm thresh-

old AL2

threshold AL2

– By switching device off

– Visual signal

– AL3 message on display

– Reading ashes

– Possible after level falls below alarm threshold AL2

threshold AL2

– By switching device off

52

Page 60

7 Appendix

STEL

Type: Main alarm (short-time exposure limit)

Adjustable: No

Latching: Yes

Trigger: Sum of the concentrations of a gas is greater than

the product of the OEL and the excess factor over the

averaging time

Indicator: – Audible signal

– Visual signal

– STEL message on display

Acknowledgement:

Reset: – By switching device off

– Not possible

LTEL

Type: Main alarm (long-time exposure limit)

Adjustable: No

Latching: Yes

Trigger: Sum of the concentrations of a gas is greater than the

OEL over the averaging time

Indicator: – Audible signal

– Visual signal

– LTEL message on display

Acknowledgement:

Reset: – By switching device off

– Not possible

53

Page 61

7 Appendix

7.2.2 Occupational exposure limits (OELs) and excess factors (STEL and LTEL)

The short-time exposure limit (STEL) is calculated by multiplying

the OEL value by the excess factor over an averaging time of

15 minutes, as per /15/.

The long-time exposure limit (LTEL) is obtained from the OEL

value over an averaging period of 8 hours, as per /15/.

Gas OEL Excess factor

CO 30 ppm 1

CO

2

H2S 5 ppm 1

0.50 % vol. 2

7.2.3 Alarm thresholds (factory settings)

Gas AL1 AL2 AL3 STEL LTEL

CH410 % LEL 50 % LEL 100 % LEL — —

CO 30 ppm 60 ppm 500 ppm 30 ppm 30 ppm

CO20.50 % vol. 1.00 % vol. 5 % vol. 1.00 % vol. 0.50 % vol.

O

18.0 % vol. 23.0 % vol. 25 % vol. — —

2

H2S 5 ppm 20 ppm 100 ppm 5 ppm 5 ppm

54

Page 62

7.2.4 Setting ranges for gas types

LEL values are specied as per /14/.

The setting for AL1 must not exceed the setting for AL2.

Gas type AL1 AL2

All CxHy in

% LEL

CH

CO

CO

H2S

O

2

Threshold 10 % LEL 50 % LEL

Threshold 0.45 % vol. 2.20 % vol.

Setting range 0.20 – 2.60 % vol. 0.25 – 2.65 % vol.

4

Increment 0.05 % vol. 0.05 % vol.

Threshold 30 ppm 60 ppm

Setting range 5 – 499 ppm 6 – 500 ppm

Increment 1 ppm 1 ppm

Threshold 0.5 % vol. 1.0 % vol.

Setting range 0.1 – 4.99 % vol. 0.11 – 5.0 % vol.

2

Increment 0.01 % vol. 0.01 % vol.

Threshold 5 ppm 20 ppm

Setting range 5 – 99 ppm 6 – 100 ppm

Increment 1 ppm 1 ppm

Threshold 18.0 % vol. 23.0 % vol.

Setting range 0.5 – 20.5 % vol. 21.2 – 25.0 % vol.

Increment 0.1 % vol. 0.1 % vol.

7 Appendix

Factory settings in bold

55

Page 63

7 Appendix

7.3 Limit values for the device inspection

Warning ExTox

Gas Zero point Sensitivity

Specication Deviation Specication Deviation

CH40.00 % vol. ±0.15 % vol. 2.20 % vol. ±0.20 % vol.

CO 0 ppm ±3 ppm 40 ppm ±3 ppm

CO20.04 % vol. ±0.06 % vol. 2.00 % vol. ±0.20 % vol.

O

0 % vol. ±0.5 % vol. 20.9 % vol. ±0.5 % vol.

2

H2S 0 ppm ±3 ppm 40 ppm ±3 ppm

Gas measuring

Gas Zero point Sensitivity

Specication Deviation Specication Deviation

CH40.00 % vol. ±2 % vol. 100 % vol. ±5 % vol.

CO20 % vol. ±2 % vol. 100 % vol. ±5 % vol.

56

Page 64

7.4 Memory capacity

The total memory capacity of the device is divided up as follows:

Protocol type Maximum number of storable protocols

Device inspection 40

Measurement 80

There is a choice of two memory modes (see Section. 3.3.7 on

page 26). The selected memory mode applies for all protocol

types.

Measurements

Note:

A le is saved after each Start measurement – Stop meas-

urement cycle, regardless of whether the memory capacity is

exhausted.

Each le has a maximum memory capacity of 1800 data records.

This means that a le can record data for 30 mins (0.5 h) at a

save interval of 1 second. After this, data recording continues

automatically in the next le.

7 Appendix

Save

interval

1 s 0.5 h 40 h

2 s 1 h 80 h

5 s 2.5 h 200 h

10 s 5 h 400 h

20 s 10 h 800 h

Factory settings in bold

Save time for 1 le

(1800 data records)

Save time for 80 les

(max. memory capacity)

57

Page 65

7 Appendix

7.5 Sensors

Note:

Probes increase the stated response times.

7.5.1 Infrared sensors (IR)

7.5.1.1 Methane CH4 for warning ExTox

Type: Infrared sensor

Measuring range: 0 – 100 % LEL

Measuring error:

– Linearity

– Short-term stability

– Long-term stability

Response times: t50 < 8 s t90 < 14 s

Temperature range: -20 ºC – +40 ºC

Interference: All hydrocarbons CxH

Lifetime, expected: 5 years

Test gases:

– Zero point

– Sensitivity

As per /9/

≤ 3 % LEL

≤ 2 % LEL