Page 1

Operating

Instructions

(with Display)

90

®

FERROTEC

FERROTEC

300

350

®

70

50

30

10

4

5

3

2

1

FERROTEC® 350

6

7

Page 2

Measurable success by Sewerin equipment

Congratulations. You have chosen a quality instrument manufactured

by Hermann Sewerin GmbH.

Our equipment will provide you with the highest standards of perfor-

mance, safety and efciency. They correspond with the national and

international guide-lines.

Please read and understand the following operating instructions before

using the equipment; they will help you to use the instrument quickly and

competently. If you have any queries we are available to offer advice

and assistance at any time.

Yours

Hermann Sewerin GmbH

Robert-Bosch-Straße 3

33334 Gütersloh, Germany

Tel.: +49 5241 934-0

Fax: +49 5241 934-444

www.sewerin.com

info@sewerin.com

SEWERIN SARL

17, rue Ampère – BP 211

67727 HOERDT CEDEX, France

Tél. : +33 3 88 68 15 15

Fax : +33 3 88 68 11 77

www.sewerin.fr

sewerin@sewerin.fr

SEWERIN IBERIA S.L.

Centro de Negocios Eisenhower

Avenida Sur del Aeropuerto

de Barajas 24, Ed. 5 Of. 2C

28042 Madrid, España

Tel.: +34 91 74807-57

Fax: +34 91 74807-58

www.sewerin.es

info@sewerin.es

Sewerin USA LLC

2835 Haddoneld Road

Pennsauken, NJ 08110-1108

Phone: +1 215-852-8355

Fax: +1 856-662-7070

www.sewerin.net

sewerin-usa@sewerin.net

Sewerin Ltd

Hertfordshire

UK

Phone: +44 1462-634363

www.sewerin.co.uk

info@sewerin.co.uk

Sewerin Sp.z o.o.

ul. Annopol 3

03-236 Warszawa, Polska

Tel.: +48 22 519 01 50

Fax: +48 22 519 01 51

Tel. kom.+48 501 879 444

+48 608 01 37 39

www.sewerin.com

info@sewerin.pl

Page 3

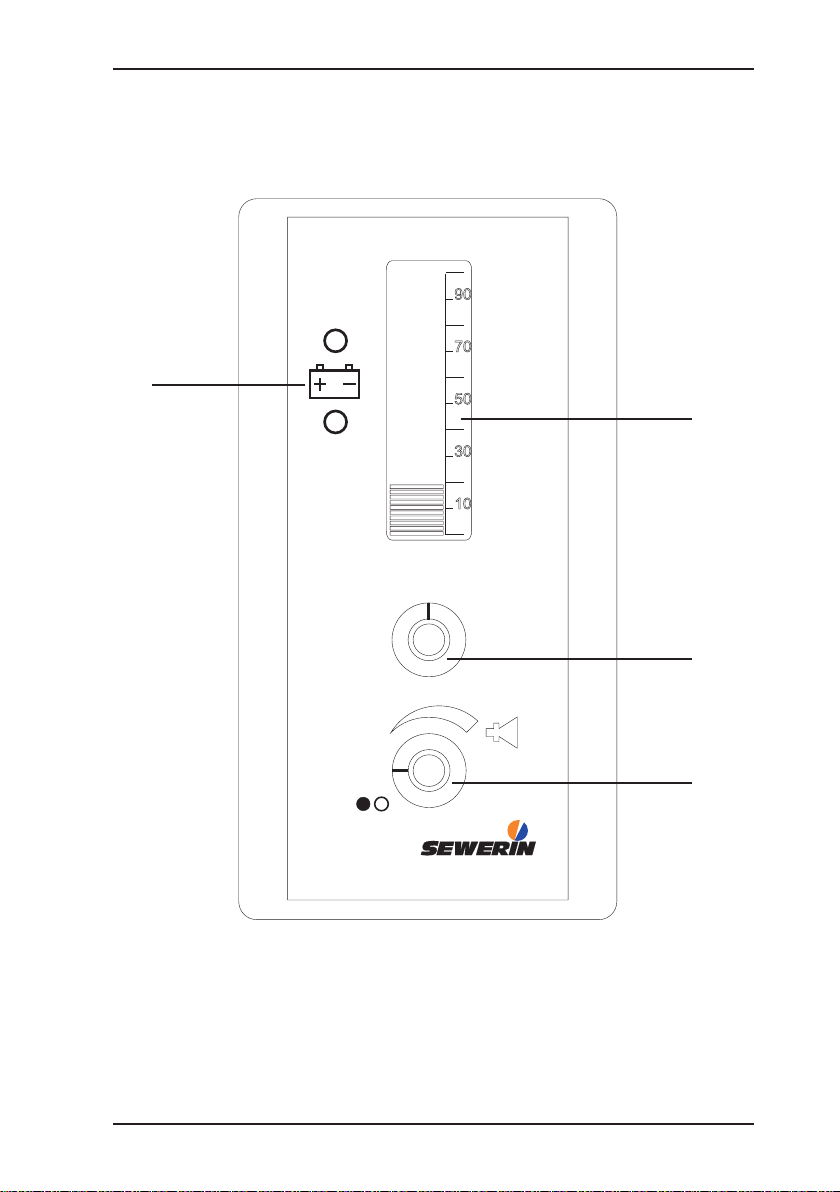

Design of the FERROTEC® 300 and FERROTEC® 350 (with Display)

90

70

4

50

3

30

10

4

3

2

5

6

2

1

7

1

FERROTEC® 350

Page 4

Operating Instructions

23.10.2008 – V2.XXX – 102661 – en

FERROTEC ® 300

FERROTEC ® 350

Page 5

Warranty & Used symbols

To ensure reliable operation and safety, it is required to pay attention to

the following notes.

Hermann Sewerin GmbH is not liable for damage caused by failure to

comply with these notes. The guarantee and liability conditions of the

sales and delivery conditions of Hermann Sewerin GmbH are not extended by the following notes.

This product may only be taken into operation after reading thoroughly

the accompanying operating instructions.

This product may only be used for intended applications.

This product is destined for industrial and commercial applications.

Repairs may only be performed by the manufacturer or appropriately

trained staff.

The manufacturer is not liable for damage resulting from arbitrary mo-

difi cations of the product.

Only spare parts may be used which are approved by Hermann Sewerin

GmbH.

Only approved battery types may be used.

Technical changes within the scope of further development reserved.

Note:

This symbol refers to information and useful tips which

are exceeding the basic operating procedures.

Page 6

Contents Page

1 Designated purpose and function .........................................1

2 Operation .................................................................................2

3 Carrying ....................................................................................3

4 Notes on operation .................................................................4

4.1 Sensitivity ..................................................................................4

4.2 Location and shape of an object ..............................................4

4.3 Distinguishing between large and small objects .......................5

4.4 Highly magnetised objects ........................................................6

4.5 Searching in the vicinity of interference sources ......................6

4.6 Cast-iron pipes ..........................................................................7

4.7 Snow and water ........................................................................7

5 Battery display/Changing the battery ...................................8

6 Maintenance, malfunctions .................................................... 9

6.1 Function testing ........................................................................9

7 Accessories ...........................................................................10

8 Specifi cations ........................................................................11

9 Appendix ................................................................................12

9.1 Declarations of Conformity .....................................................12

Page 7

1

Designated purpose and function1

Designated purpose and function1

The FERROTEC is designed to locate concealed ferromagnetic

objects (steel, iron, cast iron). It is particularly suitable for the

location of valve rods, cap sills, metal shaft and tank covers,

marking nails and marking magnets.

There are 2 sensors in the sensor rod which react to changes

in the earth‘s magnetic eld caused by ferromagnetic materials.

The change in the earth‘s magnetic eld does not reach maxi-

mum strength until the object has been motionless for several

days or even weeks, so objects placed on the ground for testing

purposes are often difcult to locate.

The FERROTEC design excludes interference and mislocation

due to non-ferrous metals.

Fig. 1

Object in the ground, representation of magnetic-eld lines. The magnetic eld

at the end of the sensor rod, sensor A, is not the same as at sensor B.

Differences in the earth‘s magnetic eld increase with proximity

to the object. This causes an indication in the form of a rise in the

loudspeaker frequency. With the FERROTEC 350 this increase is

also shown in the bar-graph display. When the pitch is highest or

the bar largest, the sensor rod is pointing at an object.

Page 8

2

Operation2

Operation2

Note:

Please avoid wearing shoes with steel insoles or

steel toe-caps when using the FERROTEC as these

will disturb the location results.

The device is switched on with the on/off switch (item 1). This z

also sets the required volume.

Sensitivity is then set with the knob (item 2). The default setting z

is approximtely “4”.

Check function by placing the z FERROTEC close to a suitable

object (e.g a car, an iron post or a hydrant cap which is not

concealed). This must cause a rise in the pitch of the sound,

plus (on the FERROTEC 350) a clear increase in the size of

the bar-graph display (item 3). See „Battery display/Changing

the battery“ and „Function testing“.

After use the z FERROTEC is switched off with the on/off switch

(item 1).

Page 9

3

Carrying3

Carrying3

This illustration shows how the device should be carried:

The sensor rod should be kept as close as possible to the

ground.

Once the presence of an object has been detected the FERROTEC

should be held vertically. The exact location of the object is now

determined by passing the device over the ground in the form of

a cross.

Page 10

4

Notes on operation4

Notes on operation4

Sensitivity4.1

If the object to be located is small or at a great depth, select a

higher sensitivity (5 – 7 on the scale). If you wish to avoid interference from small objects, a low sensitivity (1 – 3 on the scale)

should be selected.

Valve rods and street caps show up well at a depth of 30 cm

when the sensitivity is set to “4”.

Practical tip: when attempting to locate a concealed manhole

cover, rst set the sensitivity by checking it against a similar visible cover.

Location and shape of an object4.2

Fig. 2

Differing signals:

a) a maximum for a vertical object (e.g a marking pipe)

b) two maxima for horizontal objects (e.g a pipe or cover) at the edges or

ends.

Page 11

5

Notes on operation4

Distinguishing between large and small objects4.3

This is important, because small objects like nails, screws and

the like are displayed.

There are two ways of distinguishing between them.

With small objects the display decreases more markedly as the z

distance increases than it does with larger objects.

Fig. 3

Example: a screw and a boundary-mark pipe are displayed when the sensor

rod is passed over the ground at a distance of 5 cm (a). At a distance of 30 cm

- with the same sensitivity - only the boundarymark pipe is displayed (b).

Larger objects appear broader in the display than smaller z

ones.

You should therefore vary the sensitivity setting and the distance

of the sensor rod from the ground depending on the size of the

object you are looking for.

Page 12

6

Notes on operation4

Highly magnetised objects4.4

With highly magnetised objects (for example marking pipes or

permanent magnets) the FERROTEC may give apparently misleading readings. The following illustration shows the signal curve

(C) of a highly magnetised object.

Fig. 4

The superimposition of the magnetic eld of the object on that

of the earth produces zones in which the effects cancel each

other out. As a result the signal curve shows a minimum next to

the object at A and B.

In practical use care should therefore be taken that the rst

change in pitch is not taken as an indication of the precise loca-

tion. It is advisable to subject areas which have given the rst

indication to an extensive and critical search.

Searching in the vicinity of interference sources4.5

In the vicinity of steel fences, grilles, vehicles and the like, in-

terference naturally makes location difcult - if not impossible.

Care should be taken to hold the device vertical and to set a

low sensitivity.

Page 13

7

Notes on operation4

Cast-iron pipes4.6

It may be possible to locate cast-iron pipes if there is no interference and if they run more or less from north to south. They

generate the strongest signal at the joints (sleeves).

Proceed as follows:

Select maximum sensitivity. z

Hold the sensor rod vertically at a distance of 30 – 40 cm z

above the ground. Slowly walk the terrain, moving the sensor

rod slowly.

Approximately mark the display maxima. z

Search again directly above the ground with the sensor rod z

vertical.

The more the orientation of the pipe diverges from the northsouth line, the more the location result may differ from there

actual position.

Snow and water4.7

The sensor rod is waterproof, so it can be used in snow or water.

Page 14

8

Battery display/Changing the battery5

Battery display/Changing the battery5

The battery display (pos. 4) next to the battery symbol shows

the battery capacity with two LED:

Green LED (above) ashes: battery is in good order

Red LED (below) glows permanently: battery is discharched,

the battery has to be

changed

A heavily discharged battery may reduce the sensitivity and dynamics of the acoustic signal. The battery should therefore be

changed regularly.

The slotted-head screws on the side of the device are released

by rotating them half a turn. The battery compartment under the

cover is extracted for the battery to be removed. Make sure the

cover is properly replaced to protect the battery from water.

Page 15

9

Maintenance, malfunctions6

Maintenance, malfunctions6

No maintenance is necessary apart from changing the battery. In

the event of malfunctions (no display, interrupted display), check

the battery condition and make sure the battery is making proper

contact with its holder.

Function testing6.1

A function test may be carried out under the following conditions:

An iron rod 10 mm in diameter and 300 mm long, which has been

in the ground in a vertical position for at least a week, must be

detectable at a distance of about 50 cm at the maximum sensitivity setting.

Page 16

10

Accessories7

Accessories7

Carrying bag FERROTEC

300/350

Part-No.: 3204-0028

with polyethylene insert z

Headphones K3

Part-No.: EZ13-11000

Robust and spray-protected z

headphones with changeable

cushion.

Page 17

11

Specications8

Specications8

Operating-/storage

temperature:

-20 °C – +70 °C

Total Length: approx. 130 cm

Detection: up to 1,5 m depth

Power supply: Block battery

(9V, 1200 mAh), operating time up

to 18 hours

Protection type: according to IP54, Sensor rod

IP68

Visual display: LCD bar-display with the

FERROTEC 350)

Acoustic display: integrated loudspeaker or

headphones

Page 18

12

Appendix9

Appendix9

Declaration of Conformity9.1

Konformitätserklärung / Declaration of Conformity

Gerätebezeichnung:

Type of Product:

Batteriebetriebenes Magnetometer

battery operated magnetometric instrument

Geräte-Typ:

Product Name:

Ferrotec 300

Fabrikations-Nr.:

Fabr. No.:

051 11 xxxx

Hiermit erklären wir, dass oben genanntes Produkt mit der/den folgenden Norm(en) oder

normativen Dokument(en) übereinstimmt. Bei einer mit uns nicht abgestimmten

Änderung des Produkts verliert diese Erklärung ihre Gültigkeit.

We hereby declare that the above product complies with the following norms or

standardized directives. In the event of any modification of this product which has not

been authorized by us, this declaration becomes invalid.

Norm(en)/Norm(s):

DIN EN 61000-6 Teil 1 und 2

EMV – Fachgrundnorm Störfestigkeit

Generic Immunity Standard

DIN EN 61000-6 Teil 3 und 4

EMV – Fachgrundnorm Störaussendung

Generic Emission Standard

Gemäß den Bestimmungen der Richtlinie(n)/The unit complies with:

89/336/EWG

EG-Richtlinie: Elektromagnetische Verträglichkeit

EG-Directive: Electromagnetic Compatibility

92/31/EWG

Änderung dazu/amendment to above

93/68/EWG

Änderung dazu/amendment to above

Gütersloh, den 24.10.2006

HERMANN SEWERIN GMBH

(Geschäftsführer/Managing Director)

Page 19

13

Appendix9

Konformitätserklärung / Declaration of Conformity

Gerätebezeichnung:

Type of Product:

Batteriebetriebenes Magnetometer

Battery operated magnetometric instrument

Geräte-Typ:

Product Name:

Ferrotec 350

Fabrikations-Nr.:

Fabr. No.:

051 12 xxxx

Hiermit erklären wir, dass oben genanntes Produkt mit der/den folgenden Norm(en) oder

normativen Dokument(en) übereinstimmt. Bei einer mit uns nicht abgestimmten

Änderung des Produkts verliert diese Erklärung ihre Gültigkeit.

We hereby declare that the above product complies with the following norms or

standardized directives. In the event of any modification of this product which has not

been authorized by us, this declaration becomes invalid.

Norm(en)/Norm(s):

DIN EN 61000-6 Teil 1 und 2

EMV – Fachgrundnorm Störfestigkeit

Generic Immunity Standard

DIN EN 61000-6 Teil 3 und 4

EMV – Fachgrundnorm Störaussendung

Generic Emission Standard

Gemäß den Bestimmungen der Richtlinie(n)/The unit complies with:

89/336/EWG

EG-Richtlinie: Elektromagnetische Verträglichkeit

EG-Directive: Electromagnetic Compatibility

92/31/EWG

Änderung dazu/amendment to above

93/68/EWG

Änderung dazu/amendment to above

Gütersloh, den 24.10.2006

HERMANN SEWERIN GMBH

(Geschäftsführer/Managing Director)

Page 20

Hermann Sewerin GmbH

Robert-Bosch-Straße 3 · 33334 Gütersloh · Germany

Telefon +49 5241 934-0 · Telefax +49 5241 934-444

www.sewerin.com · info@sewerin.com

23.10.2008 b – 102661 – en

Loading...

Loading...