Page 1

Operating

Instructions

Page 2

Measurable success by Sewerin equipment

Congratulations. You have chosen a quality instrument manufactured

by Hermann Sewerin GmbH.

Our equipment will provide you with the highest standards of perfor-

mance, safety and efciency. They correspond with the national and

international guide-lines.

Please read and understand the following operating instructions before

using the equipment; they will help you to use the instrument quickly and

competently. If you have any queries we are available to offer advice

and assistance at any time.

Yours

Hermann Sewerin GmbH

Robert-Bosch-Straße 3

33334 Gütersloh, Germany

Tel.: +49 5241 934-0

Fax: +49 5241 934-444

www.sewerin.com

info@sewerin.com

SEWERIN SARL

17, rue Ampère – BP 211

67727 Hoerdt Cedex, France

Tél. : +33 3 88 68 15 15

Fax : +33 3 88 68 11 77

www.sewerin.fr

sewerin@sewerin.fr

SEWERIN IBERIA S.L.

Centro de Negocios “Eisenhower”

Avenida Sur del Aeropuerto

de Barajas 28, Of. 2.1 y 2.2

28042 Madrid, España

Tel.: +34 91 74807-57

Fax: +34 91 74807-58

www.sewerin.es

info@sewerin.es

Sewerin Ltd

Hertfordshire

UK

Phone: +44 1462-634363

www.sewerin.co.uk

info@sewerin.co.uk

Sewerin Sp.z o.o.

ul. Twórcza 79L/1

03-289 Warszawa, Polska

Tel.: +48 22 675 09 69

Tel. kom.: +48 501 879 444

www.sewerin.pl

info@sewerin.pl

Page 3

Illustration EX-TEC PM 4

Overview of device

Sensor head Suspension tting

Buzzer

Keypad

Battery charge

contacts

Alarm light

LCD matrix

Liquid Crystal Display

Case / operating

mode

Battery status

Alarm threshold

activation

Trend bar

Gas type

Gas concentration

Unit of measure

Page 4

Overview

Control keys

Symbols on LCD

Device On/Off

(press and hold for approx. 3 seconds)

Used to enter / conrm selection

(press briey)

Used to switch between applications /

menu item selections

Press and hold one key for 2 seconds:

accesses user menu

Press and hold both keys for 2 seconds:

accesses advanced settings

Display of available operating hours

(5 bars = 5 hours)

Alarm thresholds are activated

Device is in House application

Device is in Enclosed spaces application

Device is in Warning %LEL application

Device is in Measuring VOL% application

Device is in Automatic measuring range

changeover mode

Page 5

Operating Instructions

EX-TEC® PM 4

20.04.2016 – V2.XXX – 105806 – en

Page 6

Symbols used

CAUTION! Danger of damages!

This symbol refers to important safety instructions.

Adhere strictly to these instructions to avoid material damages!

Note:

This symbol refers to information and useful tips which

are exceeding the basic operating procedures.

CAUTION! Danger of injuries!

This symbol refers to important safety instructions.

Adhere strictly to these instructions to avoid injuries!

Symbols for the applications:

House

Enclosed spaces

Warning %LEL

Measuring vol%

Page 7

Contents Page

1 General .....................................................................................1

1.1 Warranty ....................................................................................1

1.2 Purpose .....................................................................................2

1.3 Intended use .............................................................................2

1.4 General safety information ........................................................3

2 Features ...................................................................................5

2.1 Visual signals and audible signals ............................................5

2.2 Measurement principles ............................................................6

2.3 Explosion protection .................................................................. 7

3 Operation .................................................................................9

3.1 General information on operation .............................................. 9

3.1.1 Operator guidance .................................................................9

3.1.2 Operating modes ..................................................................10

3.2 Measuring mode ..................................................................... 11

3.2.1 User menu ............................................................................14

3.2.2 Setting the zero point ...........................................................15

3.2.3 House application .................................................................16

3.2.4 Enclosed spaces application ................................................ 18

3.2.5 Warning %LEL application ...................................................20

3.2.6 Measuring VOL% application ............................................... 23

3.2.7 Function control ....................................................................25

3.2.8 Changing gas types .............................................................26

3.3 Advanced settings ................................................................... 27

3.3.1 Access ..................................................................................27

3.3.2 Menu structure .....................................................................29

3.3.3 Procedure ............................................................................. 30

3.3.4 Info menu .............................................................................32

3.3.4.1 Adjustment menu .............................................................. 32

3.3.4.2 System menu .................................................................... 33

3.3.4.3 Hardware menu.................................................................38

3.3.4.4 Memory menu ................................................................... 41

3.4 Connecting accessory devices ................................................ 42

I

Page 8

Contents Page

4 Charging and battery operation ........................................... 43

4.1 General information on charging and battery operation .......... 43

4.1.1 Suitable types of rechargeable and disposable batteries .....43

4.1.1.1 Devices with serial numbers 060 0X and 061 0X..............43

4.1.1.2 Devices with serial numbers 060 1X and 061 1X..............44

4.1.2 Setting the rechargeable / disposable battery type .............. 45

4.2 Battery alarm ........................................................................... 45

4.3 Operation with nickel metal hydride rechargeable batteries

(NiMH) .....................................................................................46

4.4 Operation with alkaline non-rechargeable batteries ................ 48

5 Maintenance ..........................................................................49

5.1 Function control ....................................................................... 49

5.2 Testing indication accuracy with test gas ................................50

5.3 Adjustment ..............................................................................52

5.3.1 ppm range ............................................................................ 53

5.3.2 LEL range and % vol. range .................................................54

5.3.3 Conrming adjustment .........................................................55

5.4 Servicing .................................................................................55

5.5 Pump .......................................................................................56

5.5.1 Function control of pump ......................................................56

5.5.2 Changing the pump lter ...................................................... 57

5.5.3 Changing the sensor lter ....................................................57

6 Faults ......................................................................................58

7 Technical data........................................................................59

7.1 Features ..................................................................................59

7.2 Alarm thresholds .....................................................................60

7.2.1 Alarm thresholds for gas type methane CH4 ....................... 60

7.2.2 Setting ranges of alarm thresholds for different gas types ... 62

7.3 Response times ......................................................................63

7.4 Sensors ...................................................................................64

7.5 Ranges of use .........................................................................65

7.6 Pump capacity ......................................................................... 65

7.7 Power supply ........................................................................... 65

7.8 Dimensions and weight ...........................................................65

7.9 Technical information ..............................................................66

7.10 Advice on disposal ..................................................................68

II

Page 9

Contents Page

8 Available models and accessories ......................................69

8.1 Available models .....................................................................69

8.2 Accessories ............................................................................. 70

Appendix

Gas types

Setting ranges for test gases

Test certicates

..............................................................................................75

..............................................................................................75

................................................................. 79

......................................................................................80

EU declaration of Conformity.................................................................81

Entering a user name

............................................................................84

List of abbreviations...............................................................................86

......................................................................................................87

Index

III

Page 10

1 General

1.1 Warranty

The following instructions must be complied with in order for any

warranty to be applicable regarding functionality and safe operation of this equipment.

Hermann Sewerin GmbH cannot be held responsible for any dam-

ages resulting from non-compliance with these instructions. The

warranty and liability provisions of the terms of sale and delivery

of Hermann Sewerin GmbH are not affected by the information

given below.

z This product must only be operated after the relevant operating

instructions have been read and understood.

z This product may only be operated by qualied profession-

als who are familiar with the legal requirements (Germany:

DVGW).

z This product must only be used for its intended purpose.

z This product is only suitable for use in industrial and commer-

cial applications.

z Repairs must only be carried out by a specialist technician or

by other suitably trained personnel.

z Changes or modications to this product must not be carried

out without approval from Hermann Sewerin GmbH. The manufacturer cannot be held responsible for damages if unapproved

modications have been made.

z Only accessories supplied by Hermann Sewerin GmbH may

be used with this product.

z All repairs must be carried out using replacement parts that

have been approved by Hermann Sewerin GmbH.

z Only approved battery types may be used, otherwise the device

will not be explosion-proof.

z The manufacturer reserves the right to make technical modi-

cations in the course of further development.

1 General

Generally applicable safety and accident-prevention regulations

must be complied with, in addition to the information provided in

this manual.

1

Page 11

1 General

1.2 Purpose

The EX-TEC

tection and measurement of gas concentrations. Equipped with

three sensors, it can be used for the ppm range, the % vol. range

and the LEL range.

The EX-TEC PM 4 is available as a diffusion device (without a

pump) or pump device (with an integrated pump).

Note:

These operating instructions describe the functions of rmware version 2.XXX. The manufac-

turer reserves the right to make technical changes.

The information provided here refers to a fully

equipped EX-TEC PM 4, including pump (pump

device). It also applies for diffusion devices.

1.3 Intended use

According to DVGW Note G 465-4 the device can be used for

the following purposes:

z Testing in houses/buildings ,

e.g. measuring minute gas concentrations in buildings and

locating the origin of the gas

z Testing in enclosed spaces ,

e.g. measuring the gas concentration in enclosed spaces or

shafts with an increased potential of gas dispersal

z Warning against explosive gas concentrations ,

e.g. for monitoring work areas whilst carrying out work to gas

pipes or gas systems

z Measurement of gas concentrations ,

e.g. when decommissioning gas systems

PM 4 is an electronic handheld device for the de-

WARNING!

The EX-TEC

PM 4 is not suitable for the location or

analysis of leaks in underground pressure lines.

2

Page 12

1.4 General safety information

z The EX-TEC PM 4 has been tested to ensure that it is explosion-

proof in accordance with European standards (CENELEC).

z The functional safety of the EX-TEC PM 4 has been tested

in the LEL range, Warning (%LEL) application, for gas types

methane (CH4) and propane (C3H8).

z Use only original SEWERIN accessories with the EX-TEC PM 4.

For Flex handheld probe HG4 and Flex probe HG4, use

only SEWERIN-approved lters with activated carbon.

Otherwise, the functional safety of the EX-TEC PM 4 is not

guaranteed.

z Always open the battery compartment of the EX-TEC PM 4 and

recharge the batteries outside the potentially explosive area.

z Always use the test gases in well ventilated areas.

z Always operate the pump device model of the EX-TEC PM 4

with the pump switched on.

z Always carry out a function control (see Section 5.1) after the

EX-TEC PM 4 has suffered an impact (for example, if dropped

accidentally). Readjust the zero point if necessary (see Section 5.3).

z The EX-TEC PM 4 complies with the limits of the EMC Direc-

tive. Always observe the information in the manuals of (mobile)

radio equipment when using the device close to (mobile) radio

equipment.

z Use the EX-TEC PM 4 with the following gases only:

– Methane (CH4)

– Propane (C3H8)

– Butane (C4H10)

– Hexane (C6H14)

– Nonane (C9H20)

– Kerosene (JFUEL)

– Hydrogen (H2)

– Acetylene (C2H2)

1 General

3

Page 13

1 General

WARNING!

Follow the advice regarding explosion protection

(see Section 2.3).

z When the Warning %LEL application is in use, a brief audi-

ble signal emitted every 5 seconds indicates that the device

is working properly. If no operating signal sounds, there is no

guarantee that the gas concentration is being monitored. You

must leave the danger zone immediately.

4

Page 14

2 Features

The EX-TEC PM 4 is available in two models (see Section 8.1):

z Diffusion device: basic device without a pump

z Pump device: basic device with an integrated pump

(designation on back of device: P)

The

EX-TEC PM 4 is suitable for the following applications:

– House

– Enclosed spaces

– Warning %LEL

– Measuring vol%

2.1 Visual signals and audible signals

The device features two signalling mechanisms:

z Red alarm light on top of the device

z Buzzer on the front of the device

2 Features

Note:

These signalling mechanisms cannot be switched

off.

An audible signal is emitted each time a key is pressed:

z Very long signal On error message

z Long signal When switching device off,

When changing menus

z Short signal When switching device on,

When conrming a selection,

When navigating within a menu

5

Page 15

2 Features

2.2 Measurement principles

The device features three sensors:

Semiconductor sensor

Measuring range

Application House

Catalytic combustion sensor

Measuring range 0 to 100 % LEL

Application

Thermal conductivity sensor

Measuring range 0 to 100 % vol.

Application

0 to 10,000 ppm

Enclosed spaces

Warning %LEL

Measuring vol%

House

Enclosed spaces

6

Page 16

2.3 Explosion protection

The

EX-TEC PM 4 features the following explosion-protection

classications:

II2G Ex d e ib IIB T4 Gb

Basic device without leather bag for:

II2G Ex d e ib IIC T4 Gb

Basic device with leather bag for:

2 Features

– Methane CH

– Propane C3H

– Butane C4H

– Hexane C6H

– Nonane C9H

4

8

10

14

20

– Kerosene (JFUEL)

– Hydrogen

– Acetylene (C2H2)

– Methane CH

– Propane C3H

– Butane C4H

– Hexane C6H

– Nonane C9H

4

8

10

14

20

– Kerosene (JFUEL)

The respective test certicates are provided in the appendix.

7

Page 17

2 Features

WARNING!

It is essential to observe the following points to en-

sure that the device is explosion-proof:

– Always open the battery compartment outside the

potentially explosive area.

– Always recharge the batteries outside the poten-

tially explosive area.

– Use only approved battery types.

– Use of the leather bag is mandatory to achieve

class IIC for gas types hydrogen (H2) und acetylene (C2H2).

8

Page 18

3 Operation

3.1 General information on operation

3.1.1 Operator guidance

There are two ways to operate the

– Operator guidance by application

– Operator guidance by sensor

These operating instructions are based on operator guidance by

application in accordance with DVGW Note G 465-4:

– Testing in houses/buildings (House application)

– Testing in enclosed spaces (Enclosed spaces application)

– Warning against explosive gas concentrations

(Warning %LEL application)

– Measurement of gas concentrations

(Measuring VOL% application)

3 Operation

EX-TEC PM 4:

Note:

The factory default operator guidance setting for the

device is Application. This can be changed to Sen-

sor in the advanced settings (see Section 3.3.4.2).

9

Page 19

3 Operation

3.1.2 Operating modes

The device is operated in two modes:

z Measuring mode (Section 3.2)

Measurements are taken in measuring mode. The zero point

can be set, the application can be changed and the gas type

can be selected via the user menu.

z Advanced settings (Section 3.3)

The advanced settings allow you to change specications for

the measurements as well as other device settings (e.g. adjustment, system, hardware, etc.). You cannot perform measurements in the advanced settings.

10

Page 20

3.2 Measuring mode

The device is switched off.

Note:

Always switch the device on in fresh air.

z Press the key for approximately 3 seconds.

The device switches on. At this point, the two signalling mechanisms are always tested.

WARNING!

Do not use the device if you do not see the visual

signal and hear the audible signal briey when

switching on the device.

The LCD switches on. The pump runs with constant output

power.

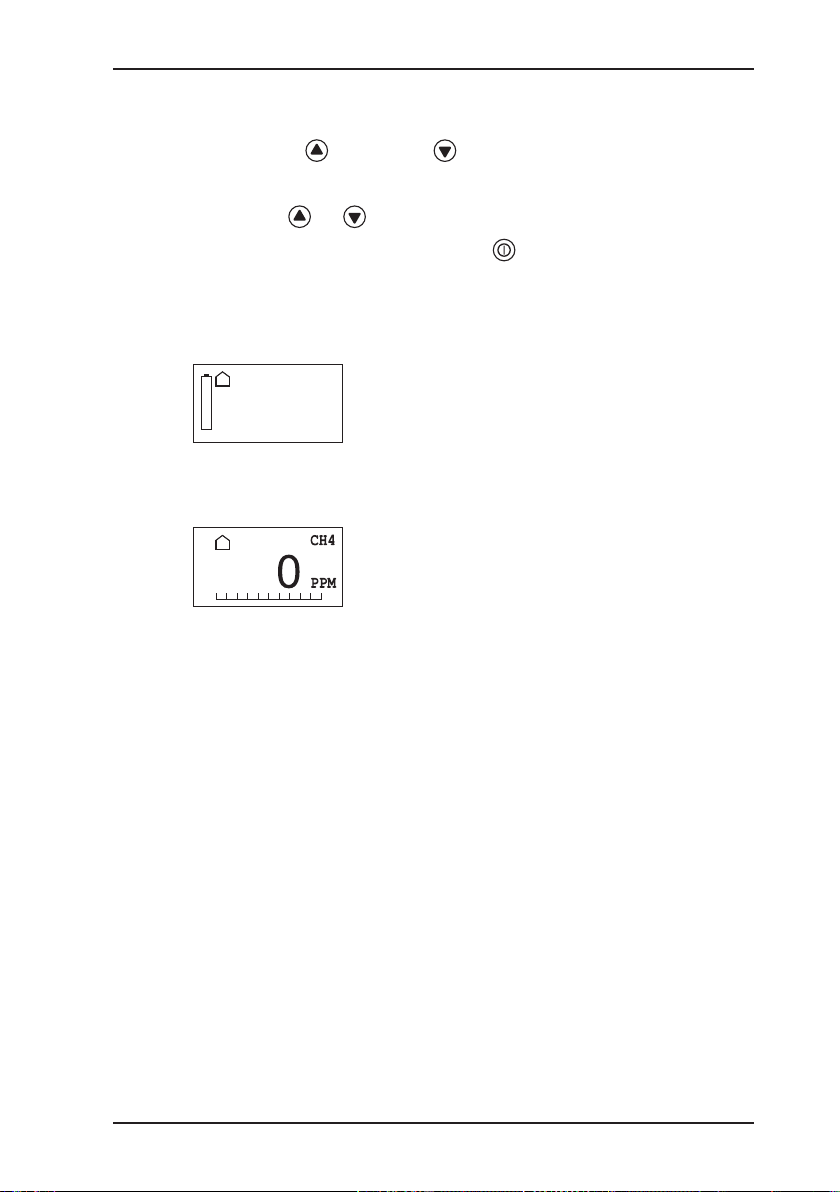

The two start screens shown below are displayed:

3 Operation

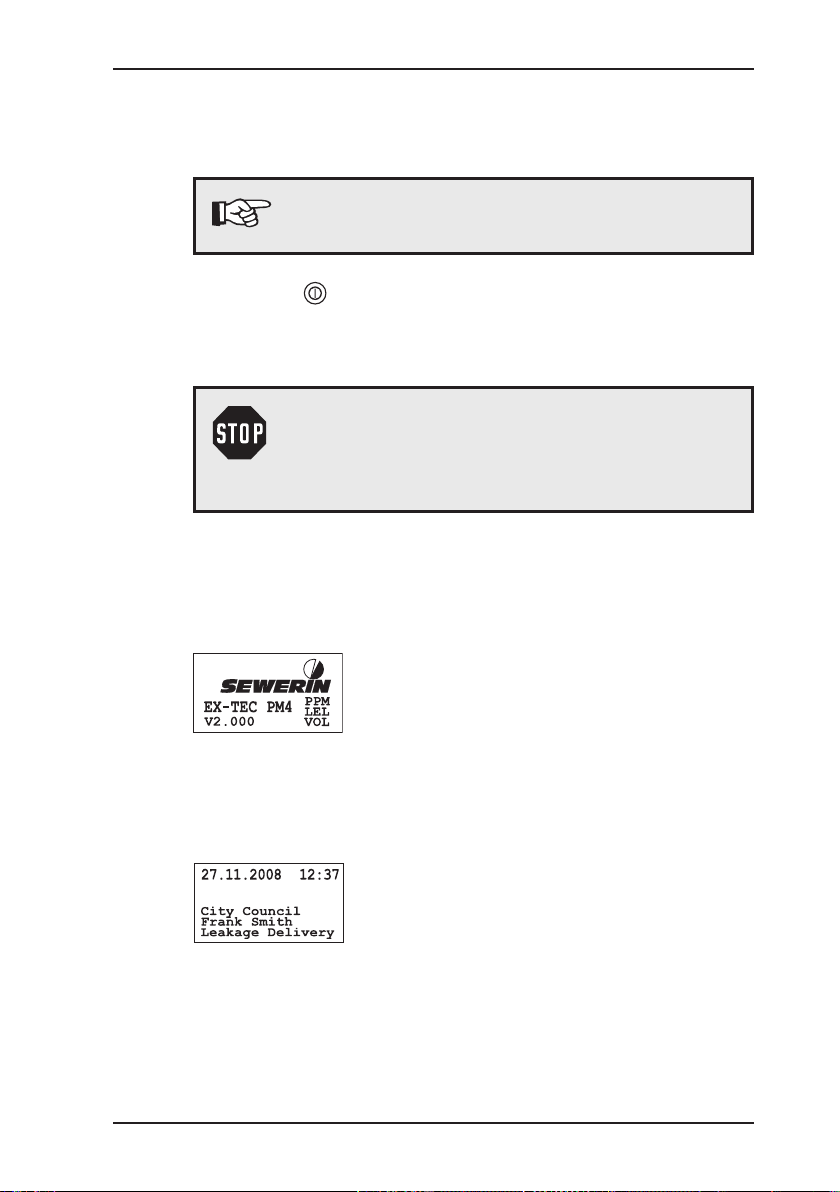

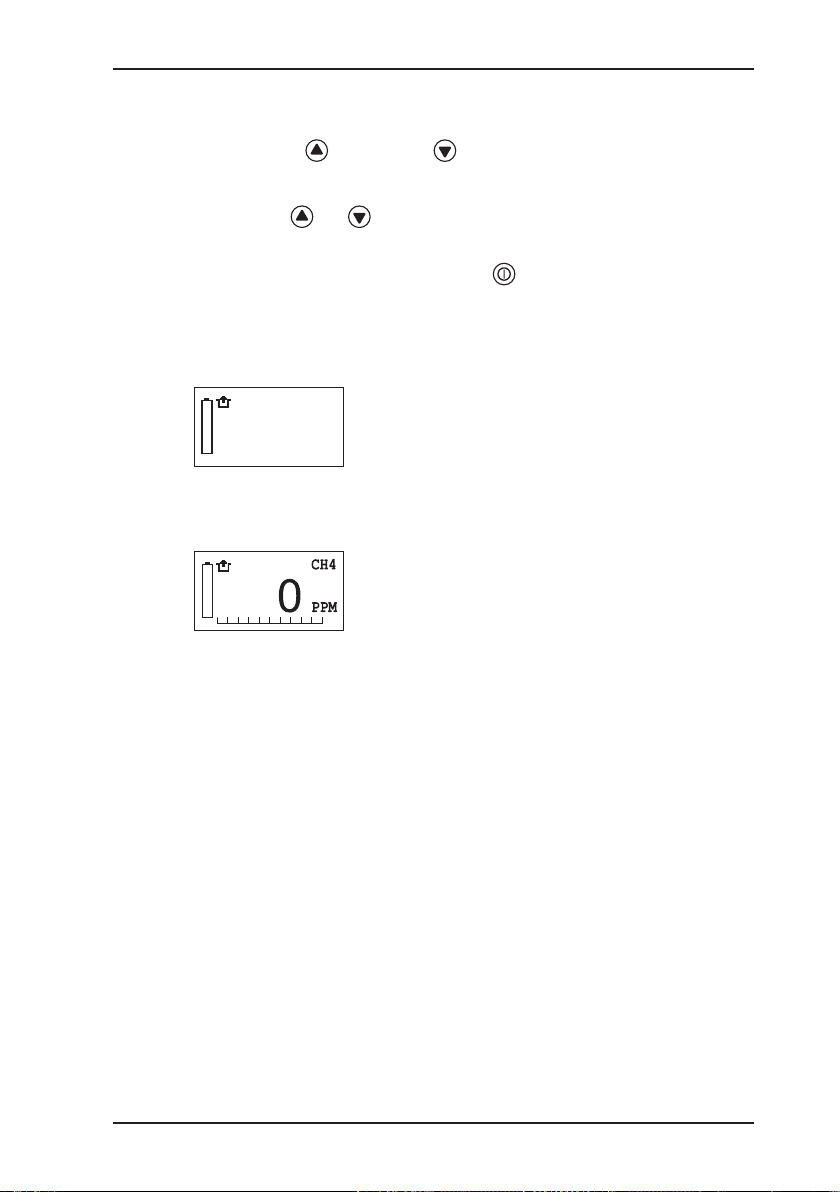

Start screen

Display:

– Device type (EX TEC PM4)

– Firmware version (V2.000)

– Integrated sensors

(PPM LEL VOL)

Date/time

Display:

– Date (27/11/2008)

– Time (12:37)

– User data

11

Page 21

3 Operation

Enclosed spaces

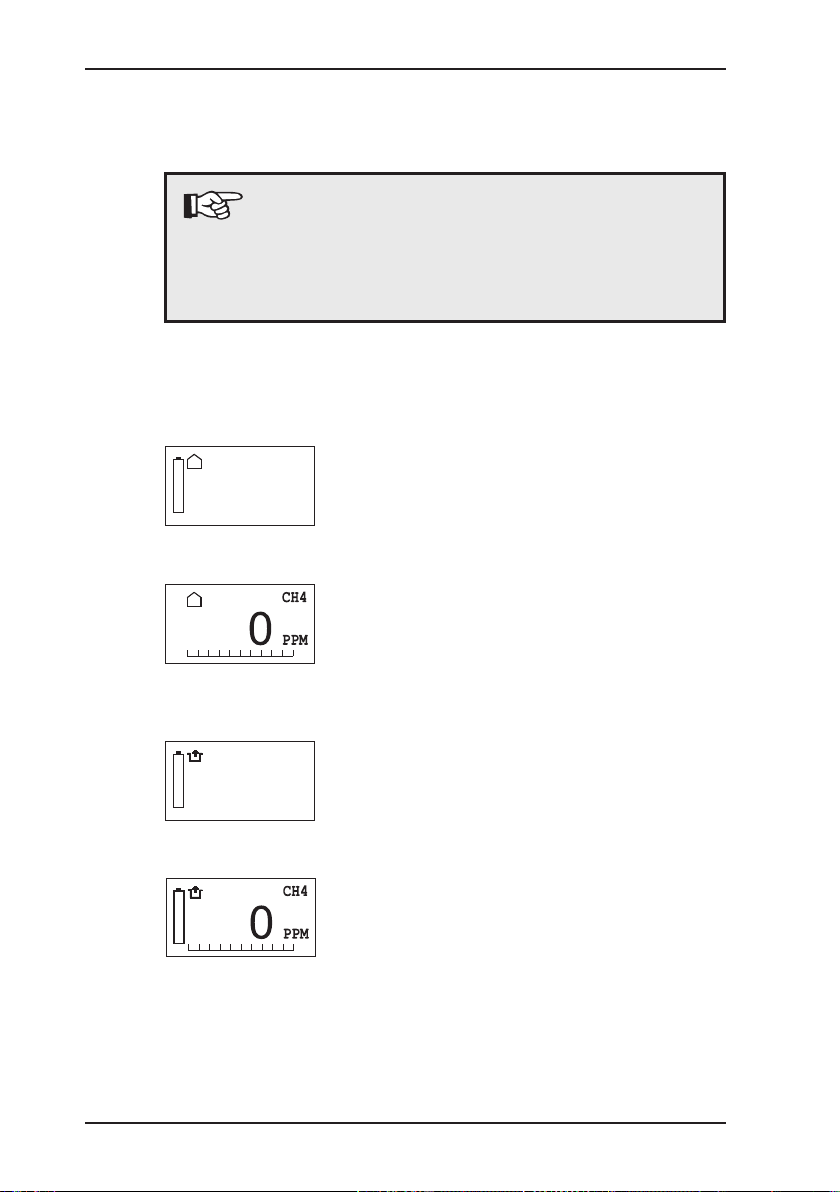

The device accesses the preset application. Two additional

screens are displayed automatically.

Display screens for the different applications:

Note:

The start-up application can be changed in the advanced settings (see Section 3.3.4.3). The factory

default setting for the device is the

application.

z House

House

acoustic/LED

1 PPM

CH4

Warning %LEL

Measuring range

Name of application with specication of associated signals and

measurement unit

Measurement data

Measurement data display

12

z Enclosed spaces

CH4

LED

1 PPM

Measuring range

Name of application with specication of associated signals and

measurement unit

Measurement data

Measurement data display

Page 22

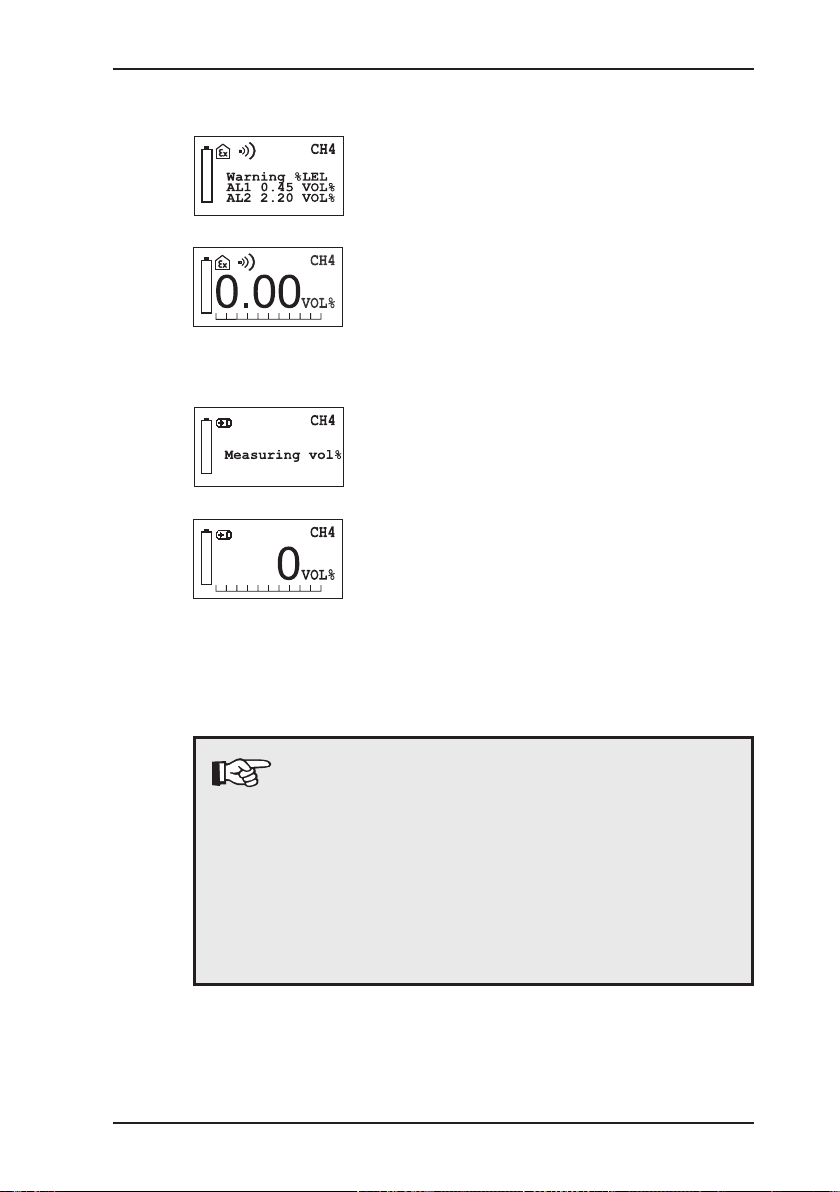

z Warning %LEL

z Measuring VOL%

3 Operation

Measuring range

Name of application with specication of measurement unit

Measurement data

Measurement data display

Measuring range

Name of application with specication of measurement unit

Measurement data

Measurement data display

You cannot input any information until the device has stopped

cycling through the displays. The device is not in measuring mode

until the Measurement data screen is displayed.

Note:

When the device is switched on, the sensors must

warm up. The duration of the warm-up time depends

on the sensor type.

After switching on the device, changing the measuring range or setting the zero point, you may notice

the reading ashing on the display. The device is

only ready for use when the displayed reading stops

ashing.

13

Page 23

3 Operation

zero point

type of gas

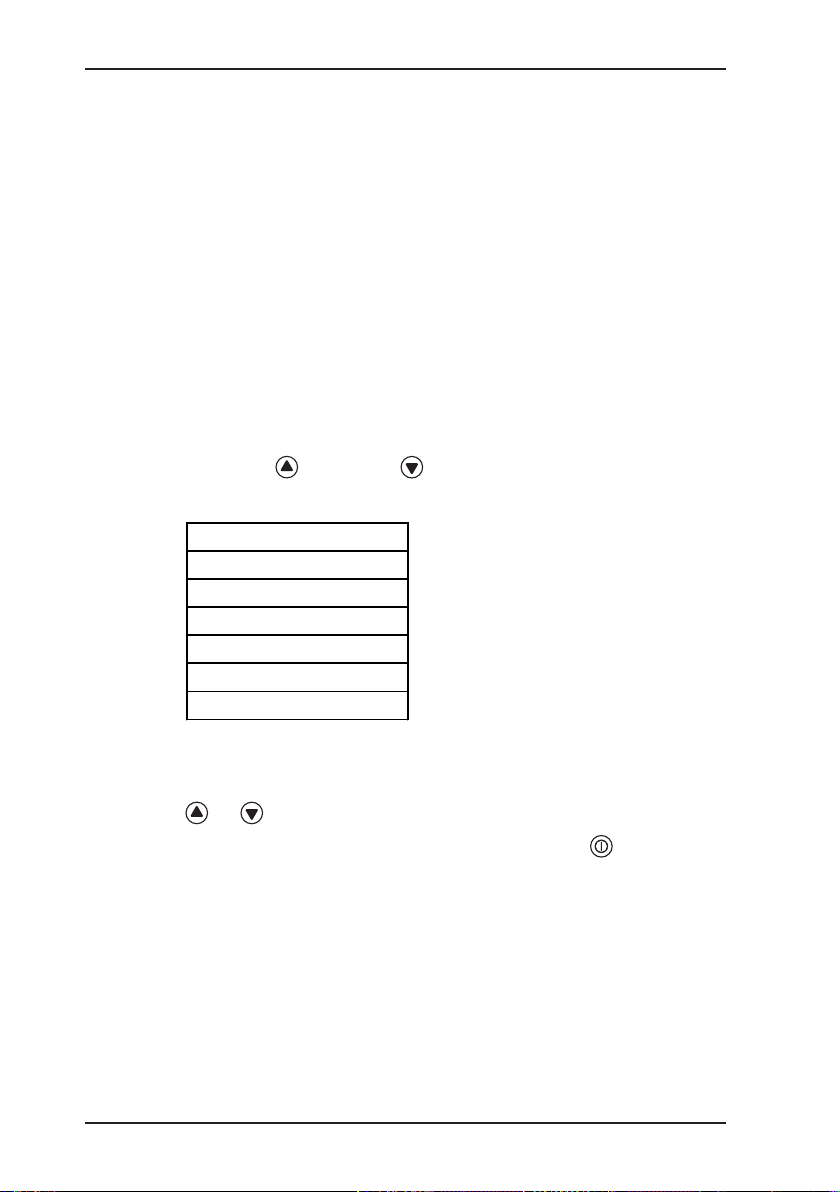

3.2.1 User menu

Measuring mode comprises the following functional scope:

– Zero point correction

– Application selection

– Conrmation of function control

– Gas type (optional)

The functions in the user menu are described in Sections 3.2.2

to 3.2.8.

To select functions, you must rst access the user menu:

z Press the key or the key for approximately 2 seconds.

The user menu is displayed:

House

Enclosed spaces

Warning %LEL

Measuring vol%

inspection ok

14

To move between menu items:

z Navigate up and down in the menu by briey pressing the

or key.

z Conrm your selection by briey pressing the key.

If the selection is not conrmed, the display reverts back to measuring mode after approximately 10 seconds.

Page 24

3.2.2 Setting the zero point

In general, the device sets the zero point automatically. However,

in certain cases, values other than zero may be displayed when

the device is switched on. This indicates a deviating zero point,

meaning that the device must be adjusted manually to environmental conditions.

Note:

The zero point must be set separately for each application. The zero point setting must be carried out

with fresh air.

To set the device to zero:

z Press the key or the key for approximately 2 seconds.

z Use the or key to select the Zero point menu item.

z Conrm your selection with the key.

The device returns to measuring mode.

The displayed value is zero (0).

3 Operation

Note:

If the displayed value is not zero (0), this means that

the zero point of the device could not be set because

the measured value was outside the specied limits

(see appendix).

15

Page 25

3 Operation

3.2.3 House application

The House application is used to measure minute gas concentra-

tions in buildings and to locate the origin of the gas.

Measurement unit:

Measuring range:

Semiconductor 0 to 10,000 ppm

Thermal conductivity 1 to 100 % vol.

ppm (parts per million)

% vol.

Signals (methane CH

):

4

Audible Intermittent tone

increasing from

0 to 22,000 ppm (AL2)

Continuous tone

2.2 % vol. and greater (AL2)

Visual Flashing

increasing from 4,400 ppm

(AL1) to 22,000 ppm (AL2)

Continuously On

2.2 % vol. and greater (AL2)

16

Page 26

3 Operation

Procedure:

z Press the key or the key for approximately 2 seconds

to access the user menu.

z Use the or key to select the House menu item.

z Conrm your selection with the key.

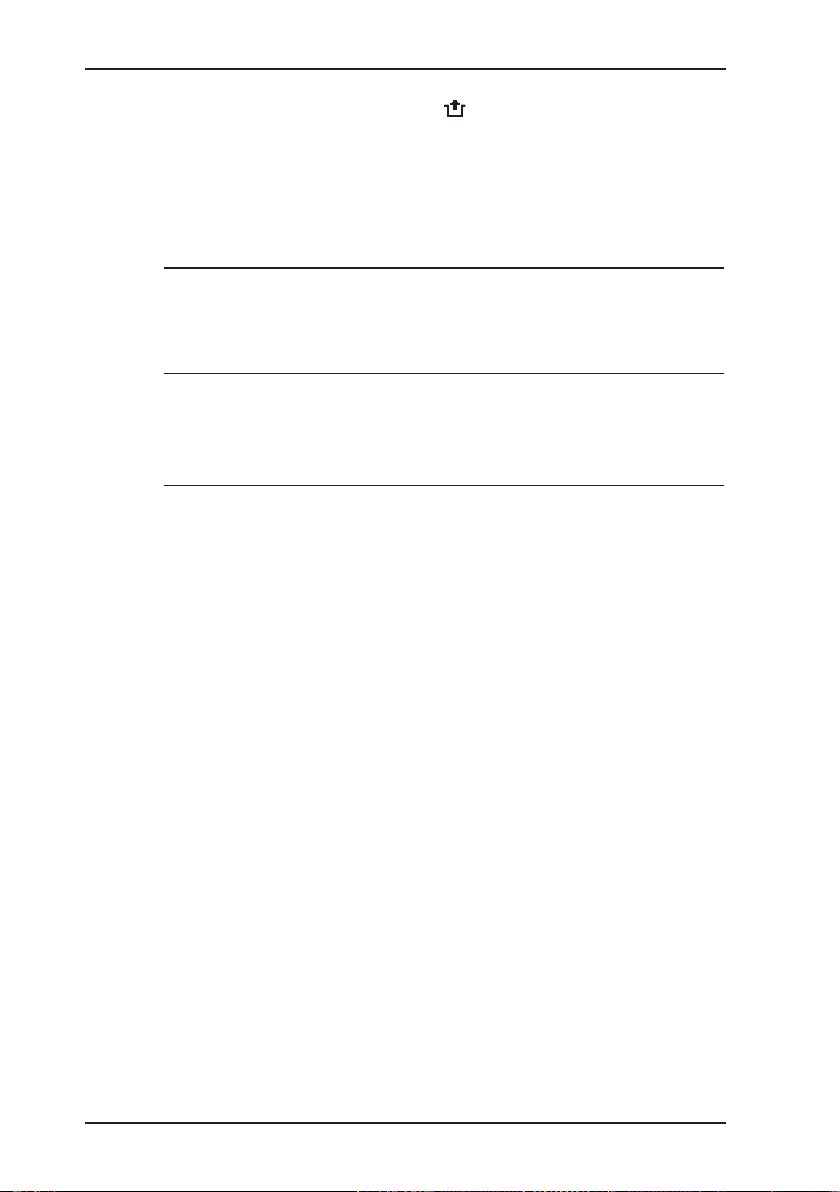

Following conrmation, the start screen for the House application

is displayed initially.

House

acoustic/LED

CH4

1 PPM

Measuring range

Then the device returns to measuring mode. The measured values are displayed.

Measurement data

In number format: e.g. 0 ppm

As a trend bar divided into

4 parts ranging from

0 ppm to 10,000 ppm: 0 ppm – 10 ppm

10 ppm – 100 ppm

100 ppm – 1,000 ppm

1,000 ppm – 10,000 ppm

A specic signal is emitted based on the reading, gas type and

preset value.

17

Page 27

3 Operation

3.2.4 Enclosed spaces application

The Enclosed spaces application is used to measure gas con-

centrations in enclosed spaces where there is increased potential

of gas dispersal.

Measurement unit:

Measuring range:

Semiconductor 0 to 10,000 ppm

Thermal conductivity 0.1 to 100 % vol.

ppm (parts per million)

% vol.

Signals (methane CH

):

4

Audible No signal

Visual Flashing

increasing from 4,400 ppm

(AL1) to 22,000 ppm (AL2)

Continuously On

2.2 % vol. and greater (AL2)

18

Page 28

3 Operation

Enclosed spaces

Procedure:

z Press the key or the key for approximately 2 seconds

to access the user menu.

z Use the or key to select the Enclosed spaces menu

item.

z Conrm your selection with the key.

Following conrmation, the start screen for the Enclosed spaces

application is displayed initially.

CH4

LED

1 PPM

Measuring range

Then the device returns to measuring mode. The measured values are displayed.

Measurement data

In number format: e.g. 0 ppm

As a trend bar divided into

6 parts ranging from

0 ppm to 100 % vol.: 0 ppm – 10 ppm

10 ppm – 100 ppm

100 ppm – 1,000 ppm (0.1 % vol.)

0.1 % vol. - 1 % vol.

1 % vol. - 10 % vol.

10 % vol. - 100 % vol.

19

Page 29

3 Operation

3.2.5 Warning %LEL application

The Warning %LEL application is used to test working environ-

ments where explosion is possible, e.g. working on gas pipes or

gas systems.

Measurement unit:

Measuring range:

Catalytic combustion 1 % LEL to 100 % LEL

In the

Warning %LEL application, a brief audible signal emitted

every 5 seconds indicates that the device is working properly.

WARNING!

If no operating signal sounds, there is no guarantee

that the gas concentration is being monitored. You

must leave the danger zone immediately.

% LEL

20

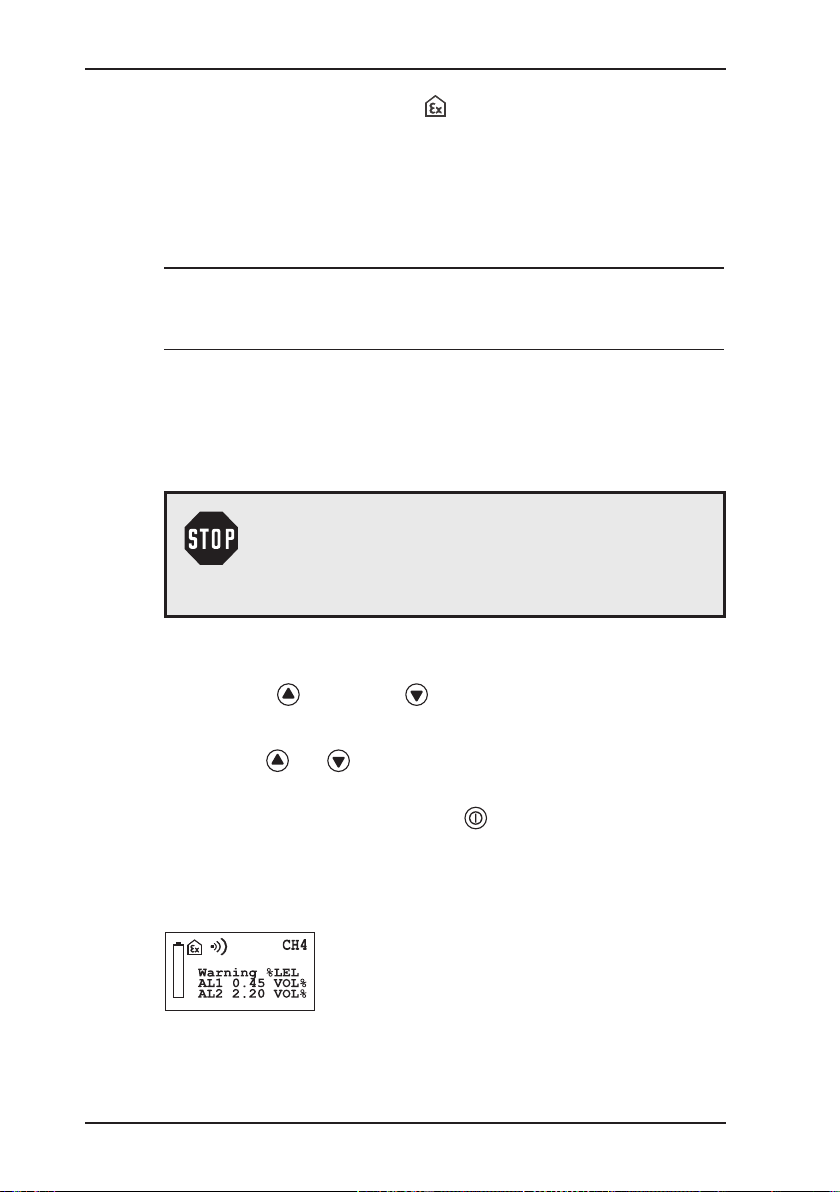

Procedure:

z Press the key or the key for approximately 2 seconds

to access the user menu.

z Use the or key to select the Warning %LEL menu

item.

z Conrm your selection with the key.

Following conrmation, the start screen for the Warning %LEL

application is displayed initially.

Measuring range

Page 30

3 Operation

Then the device returns to measuring mode. The measured values are displayed.

Measurement data

In number format: e.g. 0.00 % vol.

As a trend bar divided into 10 parts ranging from 0 % LEL to

100 % LEL in increments of 10 %.

For the Warning %LEL application, the EX-TEC PM 4 features

three alarm thresholds.

Alarm thresholds

z Alarm threshold 1 (AL1 – pre-alarm):

– When this alarm threshold is exceeded, an audible alarm and

a visual alarm are triggered and AL1 appears on the display.

– The audible alarm (2-Hz intermittent tone) is distinctly differ-

ent from the operating signal.

– The audible alarm can be acknowledged by pressing the

key. The visual alarm remains active.

– When the level drops below this alarm threshold concentra-

tion, the alarms switch off.

z Alarm threshold 2 (AL2 – main alarm):

– When this alarm threshold is exceeded, an audible alarm

and a visual alarm are triggered and AL2 appears on the

display.

– The audible alarm (5-Hz rapid intermittent tone) is distinctly

different from the operating signal.

– The AL2 alarm cannot be acknowledged.

– When the level drops below this alarm threshold concentra-

tion, the alarm can be acknowledged.

21

Page 31

3 Operation

z Alarm threshold 3 (AL3 – continuous alarm and end of meas-

uring range):

– When this alarm threshold is exceeded, a continuous audible

alarm and a continuous visual alarm are triggered and AL3

ashes on the display.

– The continuous tone is distinctly different from the operat-

ing signal.

– The AL3 alarm cannot be acknowledged.

– There are two ways to terminate the AL3 alarm:

– By switching to the Measuring VOL% application

– By switching off the device

The alarm thresholds can be adjusted in the System menu

(see Section 3.3.4.2).

The setting ranges of the alarm thresholds are specied under

Technical data (see Section 7.2).

22

Page 32

3.2.6 Measuring VOL% application

The Measuring VOL% application is used to demonstrate gas

purity or the absence of gas in gas pipes.

WARNING!

The

Measuring VOL% application is not suitable

for use in hazardous areas. It does not comprise

an alarm mechanism.

Measurement unit:

Measuring range:

Thermal conductivity

Signals (methane CH4):

Audible Intermittent tone

3 Operation

% vol.

1 % vol. to 100 % vol.

At 100 % vol. (AL5)

Visual Flashing

At 100 % vol. (AL5)

Procedure:

z Press the key or the key for approximately 2 seconds

to access the user menu.

z Use the or key to select the Measuring VOL% menu

item.

z Conrm your selection with the key.

23

Page 33

3 Operation

Following conrmation, the start screen for the Measuring VOL%

application is displayed initially.

Then the device returns to measuring mode. The measured values are displayed.

In number format: e.g. 0 % vol.

As a trend bar divided into 10 parts from 0 % vol. to 100 % vol.

in increments of 10 %.

Measuring range

Measurement data

24

Page 34

3.2.7 Function control

Before starting work and when resuming work after an interruption,

you must carry out a function control. The scope of the function

control is described in Section 5.1.

Conrm the successful completion of the control on the device

as follows:

z Press the key or the key for approximately 2 seconds.

z Use the or key to select the Inspection OK menu

item.

z Conrm your selection with the key.

The function control is saved. The device returns to the application.

3 Operation

25

Page 35

3 Operation

3.2.8 Changing gas types

Note:

Always change the gas type in fresh air.

Only calibrated gas types can be selected in the

user menu.

The factory default setting for the device is

methane CH4 (or a special gas you have ordered).

z Press the key or the key for approximately 2 seconds.

z Use the or key to select the Gas type menu item.

z Conrm your selection with the key.

z Use the or key to select the required gas type.

z Conrm your selection with the key.

After you have selected the gas type, the device returns to the

Warning %LEL application.

To perform measurements for another application, follow the instructions provided to select this application.

26

Note:

Gas type changes made in the user menu are only

temporary. The preset gas will be selected again the

next time the device is switched off and back on. To

permanently change the gas type, use the advanced

settings (see Section 3.3.4.3).

Page 36

3.3 Advanced settings

PIN 0001

Settings for the following areas of the device can be made in the

advanced settings:

z Adjustment

z System

z Hardware

z Memory

You cannot perform measurements in the advanced settings.

3.3.1 Access

There are two ways to access the Advanced settings area:

The device is switched off:

z Simultaneously press the , and keys for approximately

2 seconds.

The device is in measuring mode:

z Simultaneously press the and keys for approximately

2 seconds.

The following display appears:

3 Operation

Access is protected by a PIN code. The default setting is always

PIN code 0001.

The device can be set so that only authorised users have access

to the Info menu.

It is advisable to reset the PIN code after starting the device for

the rst time.

27

Page 37

3 Operation

Enter the PIN code from left to right. The active digit is always

displayed with a black background:

If the PIN code has been entered correctly, the Info menu will

appear once the last digit has been conrmed:

Note:

If the PIN code is set to 0000, you will not be

asked to enter the PIN code. The advanced

settings can then be accessed by anyone.

If you cannot access the Advanced settings area,

for example, if you have lost the PIN code, you must

contact SEWERIN Service.

z Use the or key to select the rst digit.

z Conrm your selection with the key. The device jumps to

the second digit.

z Enter all digits of your code in sequence, conrming each entry.

adjustment

system

hardware

memory

exit

28

Otherwise the device will return to measuring mode.

Page 38

3.3.2 Menu structure

Menu level 1 Menu level 2

Measuring mode Info V2.000

PIN code adjustment 0 PPM

Measuring mode

3 Operation

10000 PPM

0 %LEL

50 %LEL

100 VOL%

inspection ok

exit

system date / time

date format

INS interval

INS block

PPM signal

PIN code

AL1 alarm

AL2 alarm

AL4 alarm

AL5 alarm

test gas PPM

test gas %LEL

unit %LEL

unit VOL%

user name

Operator guid.

language

exit

hardware battery

Accu capacity

back light

contrast

sensors

type of gas

autostart

level PPM

pump

LCD test

reset

exit

memory clear

interval

exit

exit

29

Page 39

3 Operation

3.3.3 Procedure

The advanced settings are divided into three menu levels.

z The rst two menu levels are used to organise and subdivide

the settings options.

z A concrete selection or entry is made in the third menu level.

The name of the current menu

(e.g. Info) is always shown at

the top left of the display.

The items available for selection

are displayed in the frame below

(e.g. Adjustment, System).

The Info menu (menu level 1)

also includes the rmware ver-

sion (e.g. V2.000).

30

Use the

and keys to navigate within a menu.

Press the key to conrm the selected menu item.

Menu level 1 and 2

The Exit menu item always appears at the end of a menu.

When you select this item, the display reverts back to the previ-

ous menu.

Exception: In menu level 1 the device returns to measuring mode.

Page 40

3 Operation

Menu level 3

Menu level 3 is used to select settings or enter values:

z Selecting settings

Use the

and keys to navigate within a selection.

Press the key to conrm the selected setting.

When you have conrmed your selection, the display reverts

to the previous menu.

z Entering values

The congurable position is always displayed with a black

background.

Use the

or key to increase or decrease the value.

Press the key to conrm the selected value.

Note:

Always conrm each value. Values can only be

specied going forward. Once you have started

entering values, it is not possible to interrupt this

process.

When you have conrmed the last value, the display reverts to

the previous menu.

31

Page 41

3 Operation

3.3.4 Info menu

The Info menu is located at the top of the Advanced settings:

adjustment

system

hardware

memory

exit

Note:

When you select Exit from the Info menu, the de-

vice returns to measuring mode.

3.3.4.1 Adjustment menu

The Adjustment menu is used to set the sensors.

adjustment 0 PPM

10000 PPM

0 %LEL

50 %LEL

100 VOL%

inspection ok

exit

32

Note:

Refer to Section 5.3 for detailed information on carrying out an adjustment.

Page 42

3.3.4.2 System menu

27.11.2008 12:37

DD.MM.YYYY

YYYY-MM-DD

Weeks 00

General information and specications for operation, inspection

and alarms are set on the System menu.

system date/time

3 Operation

date format

INS interval

INS block

PPM signal

PIN code

AL1 alarm

AL2 alarm

AL4 alarm

AL5 alarm

test gas PPM

test gas %LEL

unit %LEL

unit VOL%

user name

Operator guid.

language

exit

Date/time

Used to enter the date and time.

This is important for documenting the measurements.

Date format

There are two formats available

for the date.

INS interval

The inspection interval setting

reminds you to inspect/adjust the

device regularly.

33

Page 43

3 Operation

Yes

No

acoustic /LED

No

%LEL 10

%LEL 20

A 0.50 Vol%

acoustic

LED

INS block

When the inspection block is

enabled, an inspection must be

performed on the next due date.

The device cannot be used in

measuring mode until the inspection has been carried out and

conrmed.

PPM signal

Used to switch visual/audible

signals on and off in the ppm

range.

PIN 0000

PIN code

Used to enter your PIN code

enabling access to the advanced

settings.

AL1 alarm

First modifiable alarm thresh-

old: e.g. 10 % LEL for Warning %LEL application

AL2 alarm

Second modiable alarm threshold: e.g. 20 % LEL for Warn-

ing %LEL application

AL4 alarm

No function assigned for operator guidance by application

For operator guidance by sen-

sor, this is the permanently

assigned alarm threshold for

automatic mode.

.

34

Page 44

3 Operation

VOL% 100

1.00 Vol%

2.20 Vol%

%LEL 50

%UEG

tf.%

AL5 alarm

Permanently assigned alarm

threshold for the Measur-

ing VOL% application.

Indicates the end of the measuring range.

Test gas PPM

Used to set the test gas concentration for the ppm range

based on the gas type.

The setting range is provided in

the appendix.

Test gas %LEL

Used to set the test gas con-

centration for the LEL range

based on the gas type.

The setting range is provided in

the appendix.

%LEL

%LIE

%DMV

%DGW

%SEM

%DGE

ARH%

VOL%

%VOL

%GAZ

%OBJ

Unit %LEL

Used to set individual measured

variables for the LEL range

(

Warning %LEL application).

35

Page 45

VOL%

tf.%

City Council

Leakage Delivery

Intended use

sensors

3 Operation

%VOL

%GAZ

%OBJ

Frank Smith

Unit VOL%

Used to set individual measured

variables for the VOL range

(

Measuring VOL% application).

User name

Used to enter the user name.

This is important for documenting the measurements.

The procedure and characters

that can be displayed are provided in the appendix.

Operator guidance

Used to select operator guidance

by application (House, Enclosed

spaces, Warning %LEL, Measuring VOL%) or by sensor (PPM,

LEL, VOL).

When using operator guidance

by sensor, the four applications

for measuring mode are replaced

by the following operating modes:

z GAS DETECTION

(0..10000 PPM)

z GAS WARNING

(0....100%LEL)

z GAS MEASURING

(0....100 VOL%)

z AUTOMATIC

Automatic measuring range

changeover from 0 ppm to 100 %

vol. according to gas concentration present.

36

Page 46

zero point

type of gas

Deutsch

English

Hungarian

Français

Italiano

Dansk

Cesky

Polski

Chinese

Slovenia

Kroatian

Dutch

Español

3 Operation

For operator guidance by sensor,

the user menu looks like this:

0..10000 PPM

0....100 %LEL

0....100 VOL%

automatic

inspection ok

Language

The device can be operated in

13 different languages.

37

Page 47

3 Operation

hardware battery

exit

Accu Ni-MH

Alcaline

mAh 1850

Sec 010

3.3.4.3 Hardware menu

The Hardware menu comprises settings pertaining to device

management.

Accu capacity

back light

contrast

sensors

type of gas

autostart

level PPM

pump

LCD test

reset

Battery

Used to set the battery type in

use. This is important for calculating the operating time.

38

Accu capacity

Used to enter the rechargeable

battery capacity. This is important for calculating the operating

time.

Light

Used to specify how long the

LCD will remain lit after a key is

pressed.

Page 48

0 – 100%

CH4

C2H2

PPM LEL VOL

PPM LEL

VOL

PPM VOL

PPM

LEL VOL

LEL

CAUTION!

Settings in the Sensors menu item may only be

congured by SEWERIN Service!

3 Operation

Contrast

Contrast settings to facilitate

reading of the LCD (in approximately 30 increments).

Sensors

C3H8

C4H10

C6H14

C9H20

JFUEL

H2

TGAS

Gas type

Used to permanently change the

measuring medium.

Note:

The new gas type is not activated until the device

has been adjusted (and the adjustment has been

conrmed) (see Section 5.3).

39

Page 49

3 Operation

0..10000 PPM

automatic

House

Measuring vol%

PPM 001

Yes

No

LCD test

Yes

No

Enclosed spaces

Warning %LEL

Autostart

Use to set the test type that is

activated when the device is

switched on.

For operator guidance by sensor, the autostart menu looks

like this:

0....100 %LEL

0....100 VOL%

Level PPM

Used to set the response threshold for the House and Enclosed

spaces applications, for example, to decrease the measuring

sensitivity.

40

Pump

Used to switch the pump on

and off.

WARNING!

When using a pump device, never switch the pump

off for any reason other than maintenance.

LCD test

Used to test the working condi-

tion of the LCD.

Reset

Used to reset all settings to the

factory settings.

Page 50

3.3.4.4 Memory menu

memory clear

exit

Yes

No

30 Sec

The Memory menu enables you to delete the recorded measurements, function controls and alarms. All other settings remain

unchanged.

Capacity of data memory:

3 Operation

interval

Clear

Used to clear the contents of the

memory.

Interval

The frequency with which readings are to be saved can be set

according to the table below.

Interval [s] Typ. capacity [h]

1 7

2 15

5 39

10 78

20 156

30 234

60 470

Note:

Data stored in memory can be retrieved by means

of a docking station with an interface.

41

Page 51

3 Operation

3.4 Connecting accessory devices

The following accessory devices can be tted to the sensor head:

z Probes

For detection and measurement in hard-to-reach places.

Probes are tted using two knurled thumb screws.

z Test head

For adjusting the device using a test set.

Note:

Certain probe types can only be used with devices

having an integrated pump.

42

Page 52

4 Charging and battery operation

4 Charging and battery operation

4.1 General information on charging and battery operation

WARNING!

The device must not be used with leaking disposable / rechargeable batteries. Replace disposable / re-

chargeable batteries in a timely manner. Clean the battery compartment (and, if necessary, the device) before

inserting the new disposable / rechargeable batteries.

4.1.1 Suitable types of rechargeable and disposable batteries

WARNING!

Use only approved rechargeable or disposable

battery types; otherwise, the device will not be

explosion-proof!

Compliance with indications based on the serial

number of your device is strictly mandatory!

4.1.1.1 Devices with serial numbers 060 0X and 061 0X

Only the following rechargeable batteries and disposable batteries

approved by the Physikalisch-Technische Bundesanstalt (German national metrology institute) or the TÜV (German technical

inspection association) are permitted for use in these devices

(

II 2 G EEx ib d IIB T3):

Manufacturer Designation

NiMH rechargeable cell batteries

Panasonic: HHR-150-AA Flat Top

Sanyo: AA HR3U

Varta: VH 1600AA, 55117 201 052

Alkaline disposable batteries

Varta: No. 4006, LR6-AA-AM3

Varta / Electric Power: No. 8006, LR6-AA-AM3

Duracell: MN 1500, size AA

43

Page 53

4 Charging and battery operation

4.1.1.2 Devices with serial numbers 060 1X and 061 1X

WARNING!

To ensure that the device remains explosion-proof

as per Directive 94/9/EC, only the following disposable / rechargeable batteries may be used:

– Batteries supplied by SEWERIN

– Batteries other than those supplied by

SEWERIN, provided they comply with standard

EN 60079-7:2003 (in particular Section 5.7.2.1.17;

explanation below)

The battery types used in a battery compartment

must always be identical in terms of sort (dispos-

able / rechargeable), capacity and manufacturer.

Disposable battery requirements

z Type: size AA

z The creepage distance and air gap between the poles must not

be less than 0.5 mm (EN 60079-7:2003; Section 5.7.2.1.17).

z Alkaline disposable batteries must comply with EN 60086-1

type LR6.

44

Rechargeable battery requirements

z Type: size AA

z The creepage distance and air gap between the poles must not

be less than 0.5 mm (EN 60079-7:2003; Section 5.7.2.1.17).

z Rechargeable batteries must meet the requirements of

IEC 61951-2 type HR6 and comply with the temperature

range.

CAUTION!

A device operated with disposable alkaline batteries

cannot be charged. A note will appear in the display

accordingly.

The device comes supplied with nickel metal hydride rechargeable batteries. The corresponding settings are stored.

Page 54

4 Charging and battery operation

4.1.2 Setting the rechargeable / disposable battery type

To ensure that the charging time and remaining battery life are

properly displayed, you must specify the following in the advanced

settings:

z Rechargeable battery type (Info menu – Hardware – Battery)

z Capacity of rechargeable types in use (Info menu – Hardware –

Accu capacity)

The device comes supplied with nickel metal hydride rechargeable batteries. The corresponding settings are stored.

This device can be operated using:

z Nickel metal hydride rechargeable batteries (see Section 4.3)

z Alkaline non-rechargeable batteries (see Section 4.4)

4.2 Battery alarm

When the power supply becomes

low, a battery alarm is emitted:

– The battery symbol appears

on the LCD.

– The operating signal sounds at

double the normal frequency.

When the battery alarm is triggered, an operating time of at least

15 minutes remains. After this, the device must be recharged.

45

Page 55

4 Charging and battery operation

4.3 Operation with nickel metal hydride rechargeable batteries (NiMH)

The docking station HG4 is

required for charging.

The docking station can be used

in the workshop or in the service

vehicle.

CAUTION!

Compliance with the following guidelines is essential

to ensure trouble-free operation:

z The docking station must not be directly connected

to a 24-V on-board power supply in the vehicle.

The voltage is too high for the charging process.

z The rechargeable battery should be charged at

approximately room temperature.

z Short operating times and long periods out of use

can reduce the available capacity of the rechargeable battery (memory effect).

46

Ways to connect the docking station to the power supply:

z AC/DC adapter for 100 – 240 V~

z Vehicle cable mounting for 12 V=

z Vehicle cable mobile for 12 V=

z Vehicle cable mounting for 24 V=

Note:

Up to three docking stations can be operated on an

AC/DC adapter for 100 – 240 V~. For four or more

docking stations, the charging voltage is too low. In

this case, an error message is displayed.

Page 56

4 Charging and battery operation

Charging:

z Place the device (switched off) into the docking station.

The time required for complete charging is displayed.

Once the rechargeable batteries have been fully charged, the

device automatically switches to charge maintenance mode.

It can remain in the docking station until the next time it is used.

After at least 12 hours of charging time (depending on the capacity of the rechargeable battery), the device has an available

operating time of at least 8 hours.

Note:

If the device is switched off and stored outside the docking station, the nickel metal hydride rechargeable battery will begin to self-

discharge. The rechargeable batteries will

lose their charge after 30 days at the latest.

To preserve the capacity of the rechargeable batter-

ies, discharge the device completely and recharge it

again fully on a regular basis (e.g. once a month).

Discharging:

z Place the device (switched on) into the docking station.

z The rechargeable batteries will be fully discharged. Once the

device has been discharged, it will automatically switch to

charging mode.

A full discharging and recharging cycle takes approximately

20 hours (8 hours discharging + 12 hours recharging). The

duration depends on the capacity of the accumulator used.

Note:

When you switch from alkaline disposable batteries to nickel metal hydride rechargeable batteries,

the operating hours indication on the display is incorrect. Switch the device on and place it into the

docking station to allow it to discharge and recharge

automatically. The operating hours will then be displayed correctly.

47

Page 57

4 Charging and battery operation

4.4 Operation with alkaline non-rechargeable batteries

CAUTION!

A device operated with alkaline disposable batteries

cannot be charged in the docking station. A message

to this effect appears on the display if the device is

placed into the docking station.

When equipped with new disposable alkaline batteries, the

EX-TEC PM 4 has an available operating time of at least 12 hours

(depending on the capacity of the accumulator used).

Follow the steps below to change the batteries:

z Using the supplied screwdriver, unscrew the bottom two screws

on the back of the device.

z Open the battery compartment.

z Insert the new battery cells in the direction indicated.

z Close the battery compartment.

z Re-tighten the bottom two screws on the back of the device.

48

Note:

If it takes longer than 120 seconds to change the

batteries, the date and time will have to be reset

the next time you switch the device on. All the other

data will be saved.

Page 58

5 Maintenance

In accordance with legal regulations, device maintenance com-

prises the following elements:

z Function control

z Indication accuracy test

z Adjustment

z Servicing

Note:

As specied in EN 60079-29-2 / BGI T 023, portable gas warning devices must be tested by the

user immediately prior to each use. The test scope

comprises the function control and the indication

accuracy test using test gas.

5.1 Function control

The function control must be carried out by the user before commencing work.

The following elements must be tested:

z External condition of device incl. probe systems

z Function of controls

z Battery charge status

z Airow passages

z Pump function (Section 5.5)

z Zero point when switching device on (fresh air)

z Accessories

When switching the device on, if the zero point deviation is greater

than is permissible for the respective gas type (see appendix: Gas

types), you must readjust the zero point (see Section 5.3).

The following must also be tested:

z Indication accuracy with test gas (Section 5.2)

5 Maintenance

49

Page 59

5 Maintenance

The frequency of the test depends on the application. For the

Warning %LEL application, it must be carried out before commencing each work session!

When the function control is complete, it can be stored in the user

menu (see Section 3.2.7).

5.2 Testing indication accuracy with test gas

The frequency of the test depends on the application.

Application When to test Legal basis

Warning %LEL Daily when com-

mencing work

House Weekly to every six

Enclosed spaces

months

EN 60079-292 / BGI T 023

DVGW G 465-4

Measuring VOL%

The indication accuracy must be tested separately for each

calibrated gas type.

All tests must be documented. The documentation must be kept

for at least one year.

50

Connections and controls on the

(shown here: SPE HG)

C

D

A Device connection

B Test gas connection

C Pressure gauge

D Release button

A

E Connecting hose

B

E

tester

Page 60

5 Maintenance

Carry out the indication accuracy test as follows:

z Insert connecting hose (E) into connection (A) and attach it to

the EX-TEC PM 4.

z Screw the test gas canister onto connection (B). Pressure

gauge (C) indicates the pressure inside the test gas canister.

z Switch on the EX-TEC PM 4.

z Wait until the EX-TEC PM 4 has nished warming up.

z Press release button (D) to release the test gas. Keep the but-

ton depressed.

z Continue to keep release button (D) depressed until the value

displayed on the EX-TEC PM 4 has stabilized. Then release

the button.

The value displayed on the

EX-TEC PM 4 must correspond

to the specified concentration of the test gas or fall with-

in the permissible tolerances (see appendix: Gas types).

If the display values fall outside the specied tolerances, the

EX-TEC PM 4 must be readjusted (see Section 5.3).

Enter the test results in the test protocol (see appendix).

51

Page 61

5 Maintenance

5.3 Adjustment

Both the zero point and the indication accuracy must be adjusted

for each of the three sensors.

The Adjustment menu is shown in Section 3.3.4.1. The overview

below shows the menu items and corresponding sensors. These

these items in menu level 2 can be accessed via the advanced

settings of the Info menu, under Adjustment.

WARNING!

The device be adjusted by specialist technicians

only. Incorrect adjustment can result in incorrect

analysis of the measurement results.

Menu item Sensor Measuring

Adjusts:

range

0 PPM Semiconductor ppm Zero point

10000 PPM Semiconductor ppm Indication

accuracy

0%LEL Catalytic

LEL Zero point

combustion

Thermal

% vol.

conductivity

50%LEL Catalytic

combustion

100 VOL% Thermal

conductivity

LEL Indication

accuracy

% vol. Indication

accuracy

Note:

Each time you select Reset from the Hardware

menu, you must subsequently carry out an adjustment.

52

Page 62

5.3.1 ppm range

5 Maintenance

CAUTION!

Atmospheric humidity can cause interference in the

semiconductor sensor. Therefore, never adjust the

device without using conditioner tted between the

device and the test set!

Tools:

z Test head HG 4

z Test set with integrated conditioner

(e.g. SPE ppm, SPE 2, SPE DUO)

OR

Test set without integrated conditioner

(e.g. SPE HG, SPE VOL, SPE Y) and

additionally a conditioner, which must

be tted between the device and the

test set

Zero point test gas: Fresh air

Indication accuracy

1.00 % vol. CH

4

test gas:

Setting the zero point

z Connect the device to the test set.

To do so, follow the steps indicated in the operating instructions

for the tester. Be sure to remember the conditioner if it is not

already included in the test set.

z Add fresh air as the test gas.

z Wait until the value on the LCD no longer ashes.

z Press the On/Off key to conrm.

Setting the indication accuracy

z Connect the device to the test set.

To do so, follow the steps indicated in the operating instructions

for the tester. Be sure to remember the conditioner if it is not

already included in the test set.

z Place the test head on the device.

53

Page 63

5 Maintenance

z Press and hold the release button on the test set until the con-

centration displayed on the device has reached a stable value.

z Press the On/Off key to conrm.

5.3.2 LEL range and % vol. range

Tools:

z Test head HG 4

z Test set (see Accessories)

Zero point test gas: Fresh air

Indication accuracy

test gas:

2.20 % vol. CH4 for 50 % LEL adjustment

100 % vol. CH4 for 100 % LEL adjustment

Setting the zero point

Tools are not required to set the zero point.

The zero points for the LEL range and the % vol. range are always

set together in one step.

z Switch on the device.

z Add fresh air as the test gas.

z Wait until the value on the LCD no longer ashes.

z Press the On/Off key to conrm.

Setting the indication accuracy

z Connect the device to the test set.

To do so, follow the steps indicated in the operating instructions for the tester.

z Place the test head on the device.

z Press and hold the release button on the test set for at least

1 minute. Do not let go of the release button until the concen-

tration displayed on the device has reached a stable value.

z Press the On/Off key to conrm.

z Remove the test head and wait until the zero point has reset

itself.

54

Page 64

5.3.3 Conrming adjustment

As part of the adjustment process, each completed test must

be stored in memory. This is done via the Inspection OK menu

item. As a result:

z The test date is saved.

z The next adjustment date is calculated based on the specied

inspection interval.

z An inspection block (if set) is triggered.

Conrm the completed adjustment on the device as follows:

z Using the or key, select the Inspection OK menu item.

z Conrm your selection with the key.

5.4 Servicing

The device must only be serviced and repaired by SEWERIN

Service or a qualied service technician/company authorised by

SEWERIN.

z Send the device to SEWERIN for repairs and for annual main-

tenance.

5 Maintenance

Note:

If there is a service agreement in place, the device can

be serviced by the mobile maintenance service.

The inspection plate on the device shows

conrmation of the last maintenance and the

next scheduled maintenance.

55

Page 65

5 Maintenance

5.5 Pump

Note:

The descriptions in this section refer only to pump

devices.

The integrated pump in pump devices accelerates the purging

of the device with fresh air. The device pump has a capacity of

approximately 10 l/h.

5.5.1 Function control of pump

The pump function in pump devices is tested by a simple leak

tightness check:

z Switch on the device in fresh air.

z Make sure the pump is switched on.

z Seal off the sensor head for approximately 10 seconds, by

holding the test cap closed, for example.

If the pump is functioning properly, a corresponding error

message will be displayed.

56

Press any key to acknowledge the error message.

If the error message does not appear, the pump may be faulty.

Have the device tested by SEWERIN Service.

Page 66

5.5.2 Changing the pump lter

CAUTION!

Always switch off the device before changing the

lter.

z Unscrew and remove the sensor cap.

z Take the sensor out of its holder.

z Remove the pump lter (white disk, 4 mm in diameter).

z Insert a new pump lter.

z Place the sensor with rubber seal back into the holder.

z Attach the sensor cap, making sure the screws are not too

tight.

5.5.3 Changing the sensor lter

CAUTION!

Always switch off the device before changing the

lter.

5 Maintenance

z Unscrew and remove the sensor cap.

z Remove the sensor lter from the sensor cap.

z Insert a new sensor lter.

z Attach the sensor cap, making sure the screws are not too

tight.

57

Page 67

6 Faults

6 Faults

If a fault occurs during operation, an error message will appear on

the screen. The error number and error name will be shown.

If more than one error occurs, only the error that occurred rst

will be displayed. Each additional error message will be displayed

only after the previous error has been corrected.

Overview of possible error messages

Error

no.

9 NO

10 ADJUSTMENT

11 ADJUSTMENT

12 ADJUSTMENT

13 ADJUSTMENT

14 ADJUSTMENT

15 ADJUSTMENT

40 END OF

51-54 ERROR

59 VOLTAGE

60 ERROR

61 ERROR

62 ERROR

100 PUMP

Appearance

on LCD (error

name)

ADJUSTMENT

ERROR

ERROR

ERROR

ERROR

ERROR

ERROR

RANGE

UNKNOWN

SUPPLY

UNKNOWN

UNKNOWN

UNKNOWN

CAPACITY

Cause Error correction

No adjustment data

available

Zero point in ppm range

(SC)

Zero point in LEL range

(CC)

Zero point in vol. range

(TC)

Sensitivity in ppm range

(SC)

Sensitivity in LEL range

(CC)

Sensitivity in vol. range

(TC)

Measuring range

violation in LEL range

Component error Switch device off and back

Voltage outside

permissible range

Semiconductor sensor

break (SC)

Catalytic combustion

sensor break (CC)

Thermal conductivity

sensor break (TC)

Insufcient pump

capacity

Carry out adjustment

Check test gas or repeat

adjustment

Check test gas or repeat

adjustment

Check test gas or repeat

adjustment

Check test gas or repeat

adjustment

Check test gas or repeat

adjustment

Check test gas or repeat

adjustment

Adjust LEL range

on or consult SEWERIN-

Service

Error can only be corrected

by SEWERIN Service

Error can only be corrected

by SEWERIN Service

Error can only be corrected

by SEWERIN Service

Error can only be corrected

by SEWERIN Service

Check lter in device and

in probes

58

Page 68

7 Technical data

7.1 Features

z Gas types

– Standard: Methane (CH4)

– Optional: Propane (C3H8)

z Liquid Crystal Display Graphic display, 65 × 132 pixels

z Membrane keypad 3 keys

z Buzzer Frequency 2.4 kHz

7 Technical data

Butane (C

Hexane (C

Nonane (C

4H10

6H14

9H20

)

)

)

Kerosene (JFUEL)

Hydrogen (H

Acetylene (C

)

2

2H2

)

Volume = 75 dB (A) / 1m

z Alarm light Red

z PC interface via docking station HG4 with in-

terface

z Memory Capacity: see Section 3.3.4.4

z Type of protection IP54

59

Page 69

7 Technical data

7.2 Alarm thresholds

7.2.1 Alarm thresholds for gas type methane CH4

CAUTION!

AL1 must always be set to a lower value than AL2.

z House application

Alarm Gas concentration Signal

AL1

AL2

Setting range Factory

setting

10 – 4,400 ppm 10 Concentration-

0.44 – 2.2 % vol. 0.44 % vol. Concentration-

0.48 – 4.18 % vol. 2.2 % vol. Continuously OnContinuously

Audible Visual

dependent

dependent

z Conned spaces application

Alarm Gas concentration Signal

AL1

AL2

Setting range Factory

setting

1 – 4,400 ppm 1 – –

0.44 – 2.2 % vol. 0.44 % vol. – Concentration-

0.48 – 4.18 % vol. 2.2 % vol. – Continuously

Audible Visual

Concentrationdependent

Concentrationdependent

On

dependent

On

60

Page 70

z Warning application (Warning %LEL)

Alarm Gas concentration Signal

7 Technical data

Setting range Factory

0 – 10 % LEL – –

AL1

AL2

AL3 Invariable

10 – 50 % LEL 10 % LEL Pre-alarm 2 Hz Pre-alarm 2 Hz

10 – 60 % LEL 50 % LEL Main alarm

setting

100 % LEL Continuous

Audible Visual

5 Hz

alarm

Main alarm

5 Hz

Continuous

alarm

When the LEL unit in the system settings is set to % vol., the

alarm thresholds are also set to % vol.

z Measuring application (Measuring VOL%)

Alarm Gas concentration Signal

Setting range Factory

setting

AL5 1 – 100 % vol. 100 %

vol.

Audible Visual

2 Hz ashing 2 Hz ashing

61

Page 71

7 Technical data

7.2.2 Setting ranges of alarm thresholds for different gas types

The factory settings are shown in bold.

Gas type AL1 AL2

All (%LEL) Threshold 10 % LEL 50 % LEL

Threshold 0.45 % vol. 2.20 % vol.

Methane (CH4)

Propane

(C3H8)

Butane (C4H10)

Hexane

(C6H14)

Nonane

(C9H20)

Kerosene

(JFUEL)

Hydrogen (H2)

Acetylene

(C2H2)

Setting range 0.45 – 2.20 % vol. 0.50 – 2.64 % vol.

Increment 0.05 % vol. 0.05 % vol.

Threshold 0.18 % vol. 0.86 % vol.

Setting range 0.18 – 0.85 % vol. 0.18 – 1.02 % vol.

Increment 0.02 % vol. 0.02 % vol.

Threshold 0.14 % vol. 0.70 % vol.

Setting range 0.14 – 0.70 % vol. 0.16 – 0.84 % vol.

Increment 0.02 % vol. 0.02 % vol.

Threshold 0.10 % vol. 0.50 % vol.

Setting range 0.10 – 0.50 % vol. 0.11 – 0.60 % vol.

Increment 0.01 % vol. 0.01 % vol.

Threshold 0.08 % vol. 0.36 % vol.

Setting range 0.08 – 0.35 % vol. 0.08 – 0.42 % vol.

Increment 0.02 % vol. 0.02 % vol.

Threshold 0.07 % vol. 0.35 % vol.

Setting range 0.07 – 0.35 % vol. 0.07 – 0.42 % vol.

Increment 0.01 % vol. 0.01 % vol.

Threshold 0.40 % vol. 2.00 % vol.

Setting range 0.40 – 2.00 % vol. 0.44 – 2.40 % vol.

Increment 0.04 % vol. 0.04 % vol.

Threshold 0.25 % vol. 1.15 % vol.

Setting range 0.23 – 1.10 % vol. 0.25 – 1.38 % vol.

Increment 0.01 % vol. 0.01 % vol.

62

Page 72

7 Technical data

z Alarm thresholds (as delivered, depending on tted sensors)

Alarm Gas concentration,

AL1

AL2

AL3 100 % LEL (end of

AL4

AL5 100 % vol. Measuring Gas measuring

factory setting

10 % LEL House, Enclosed

50 % LEL House, Enclosed

measuring range)

0.5 % vol. Automatic

7.3 Response times

z Response times of EX-TEC PM 4 (pump devices)

– ppm range: t

– LEL range: t

Operator guidance by

Application Sensor (operating

spaces, Warning

spaces, Warning

Warning Gas warning

< 7 s for methane (CH4)

90

t

< 7 s for propane (C3H8)

90

t

< 7 s for butane (C4H10)

90

t

< 7 s for hydrogen (H2)

90

< 5 s for methane (CH4)

50

t

< 6 s for propane (C3H8)

50

t

< 12 s for methane (CH4)

90

t

< 16 s for propane (C3H8)

90

t

< 3 min for hexane (C6H14)

90

t

< 3 min for nonane (C9H20)

90

t

< 3 min for kerosene (JFUEL)

90

t

< 12 s for acetylene (C2H2)

90

mode)

Gas detection,

Gas warning

Gas detection,

Gas warning

– % vol. range: < 10 s

Probes increase the stated response times.

63

Page 73

7 Technical data

z Response times of EX-TEC PM 4

(diffusion device without probe)

– LEL range: t50 < 8 s for methane (CH4)

z Warm-up time

– ppm range: Approx. 1 min

– LEL range: ≤ 22 s

– % vol. range: ≤ 22 s

7.4 Sensors

z Lifetime

Catalytic combustion sensor (CC)

– Warranted: 1 year

– Expected: 5 years

Semiconductor sensor (SC)

– Warranted: 1 year

– Expected: 5 years

Thermal conductivity sensor (TC)

– Warranted: 1 year

– Expected: 5 years

z Interference

– ppm / % LEL range: All ammable gases

– % vol. range: All gases with a different thermal

z Measuring error

– ppm range ±30 %

– % LEL range ±2 % LEL (short-term stability)

– % vol. range ±5 % vol.

t

< 17 s for propane (C3H8)

50

t

< 36 s for methane (CH4)

90

t

< 74 s for propane (C3H8)

90

t

< 3 min for nonane (C9H20)

90

conductivity than air

±4 % LEL (long-term stability)

acc. to EN 60079-29-1

acc. to EN 60079-29-1

64

Page 74

7.5 Ranges of use

z Operating temperature: -20 °C to +40 °C

z Storage temperature: -25 °C to +55 °C

z Humidity: 5 % r.h. to 90 % r.h.

z Pressure: 800 hPa to 1,200 hPa

7.6 Pump capacity

z Vacuum: > 150 mbar

z Volume ow: 5 to 15 l/h, typical

7.7 Power supply

z Operated with: NiMH rechargeable batteries or

z Operating time 8 h, minimum

z NiMH rechargeable

batteries charged:

z Charging time: Approx. 12 h (fully charged) depend-

7 Technical data

(non-condensing)

alkaline disposable batteries

Via docking station HG4 and plug-in

adapter with 12-V interface

ing on capacity of accumulator

7.8 Dimensions and weight

z Dimensions (W × H × D) Approx. 60 × 144 × 35 mm

z Weight Approx. 300 g

(without swan neck)

(depending on equipment)

65

Page 75

7 Technical data

7.9 Technical information

Identication sticker

The pictogramme on the identication sticker (back of device)

signies that the battery must only be opened outside the potentially explosive area!

Gas application

Gas application (increasing concentration to 100

/ inerting

% vol.) and in-

erting (decreasing concentration to 0 % vol.) must be carried out

in the Measuring VOL% application.

Unambiguous monitoring of the measurement is possible only

in this application.

Sensitivity of the catalytic combustion sensor

The sensitivity of the catalytic combustion sensor can be distorted

under the following conditions:

– Oxygen-decient atmospheres lead to indication of lower values

(sensor suffocation).

– Operation of the device in oxygen-enriched atmospheres is

impermissible to ensure explosion protection.

Gaseous components of silicones, oils and phosphate esters, for

example, are harmful to the sensor. They cause an irreversible

decrease in sensitivity.

Impurities in the measuring environment, for example, due to

halogens, burned neoprene, PVC or trichlorethylene, also decrease the sensitivity of the sensors; in this case, however, the

sensitivity can be restored.

66

Page 76

7 Technical data

Cleaning

The device must only be cleaned with a damp cloth.

CAUTION!

Do not use solvents, petrol or cockpit spray containing silicone or similar substances to clean the

device!

Static charging

Electrostatic charging must generally be avoided. Electrostatically unearthed objects (e.g. including metallic housing without

an earth connection) are not protected against applied charges

(e.g. through dust or dispersed ows).

CAUTION!

When working with the gas types hydrogen (H

)

2

and acetylene (C2H2), the leather bag is mandatory

because it is a component of the explosion protec-

tion of the device!

67

Page 77

7 Technical data

7.10 Advice on disposal

The European Waste Catalogue (EWC) governs the disposal of

appliances and accessories.

Description of waste Assigned to EWC waste code

Device 16 02 13

Test gas can 16 05 05

Disposable battery,

rechargeable battery

End-of-life equipment

End-of-life equipment can be returned to Hermann Sewerin

GmbH. We will arrange for the equipment to be disposed of appropriately by certied specialist contractors free of charge.

16 06 05

68

Page 78

8 Available models and accessories

8 Available models and accessories

8.1 Available models

EX-TEC

Art. no.: PM04-20001

z Diffusion device for Warning

application

z Includes catalytic combustion

sensor

EX-TEC

Art. no.: PM04-20201

z Pump device for Warning,

Enclosed spaces, House and

Measuring applications

z Includes semiconductor, cata-

lytic combustion and thermal