SEW MOVITRAC LTP series Operating Instructions Manual

Drive Technology \ Drive Automation \ System Integration \ Services

MOVITRAC

Edition 12/2008

16766016 / EN

®

LTP

Operating Instructions

SEW-EURODRIVE – Driving the world

1 Important Notes................................................................................................. 4

1.1 Structure of the safety notes ..................................................................... 4

1.2 Application environment............................................................................ 5

1.3 Waste disposal.......................................................................................... 5

2 Safety Notes ......................................................................................................6

2.1 Installation and startup .............................................................................. 6

2.2 Operation and servicing ............................................................................ 7

3 General specifications ...................................................................................... 8

3.1 Input voltage ranges ................................................................................. 8

3.2 Product designation .................................................................................. 9

3.3 Overload capability ................................................................................... 9

3.4 Protection features .................................................................................. 10

4 Mechanical Installation ................................................................................... 11

4.1 Dimensions ............................................................................................. 12

4.2 IP20 / NEMA 1 housing: mounting and dimensions................................ 14

5 Electrical Installation ...................................................................................... 16

5.1 Prior to installation .................................................................................. 16

5.2 Installation............................................................................................... 18

5.3 Optical interface ...................................................................................... 24

5.4 UL-compliant installation ......................................................................... 24

5.5 Electromagnetic compatibility.................................................................. 26

6 Startup.............................................................................................................. 27

6.1 Operating the keypad.............................................................................. 27

6.2 Easy startup ............................................................................................ 28

7 Operation and Service .................................................................................... 30

7.1 Drive status ............................................................................................. 30

7.2 Fault codes and history ........................................................................... 31

7.3 SEW electronics service ......................................................................... 33

8 Parameters....................................................................................................... 34

8.1 Parameter access and reset ................................................................... 34

8.2 Parameter specifications: ....................................................................... 36

8.3 Selection of Parameter P2-01, Digital Input Function............................. 43

9 Software ........................................................................................................... 49

9.1 MODBUS Control.................................................................................... 49

10 Technical data ................................................................................................. 55

10.1 Conformance .......................................................................................... 55

10.2 Environmental ......................................................................................... 55

10.3 Output power and current ratings............................................................ 56

11 Index ................................................................................................................. 65

Operating Instructions– MOVITRAC® LTP

3

1

Important Notes

Structure of the safety notes

1 Important Notes

erschöpftOperating Instructions

1.1 Structure of the safety notes

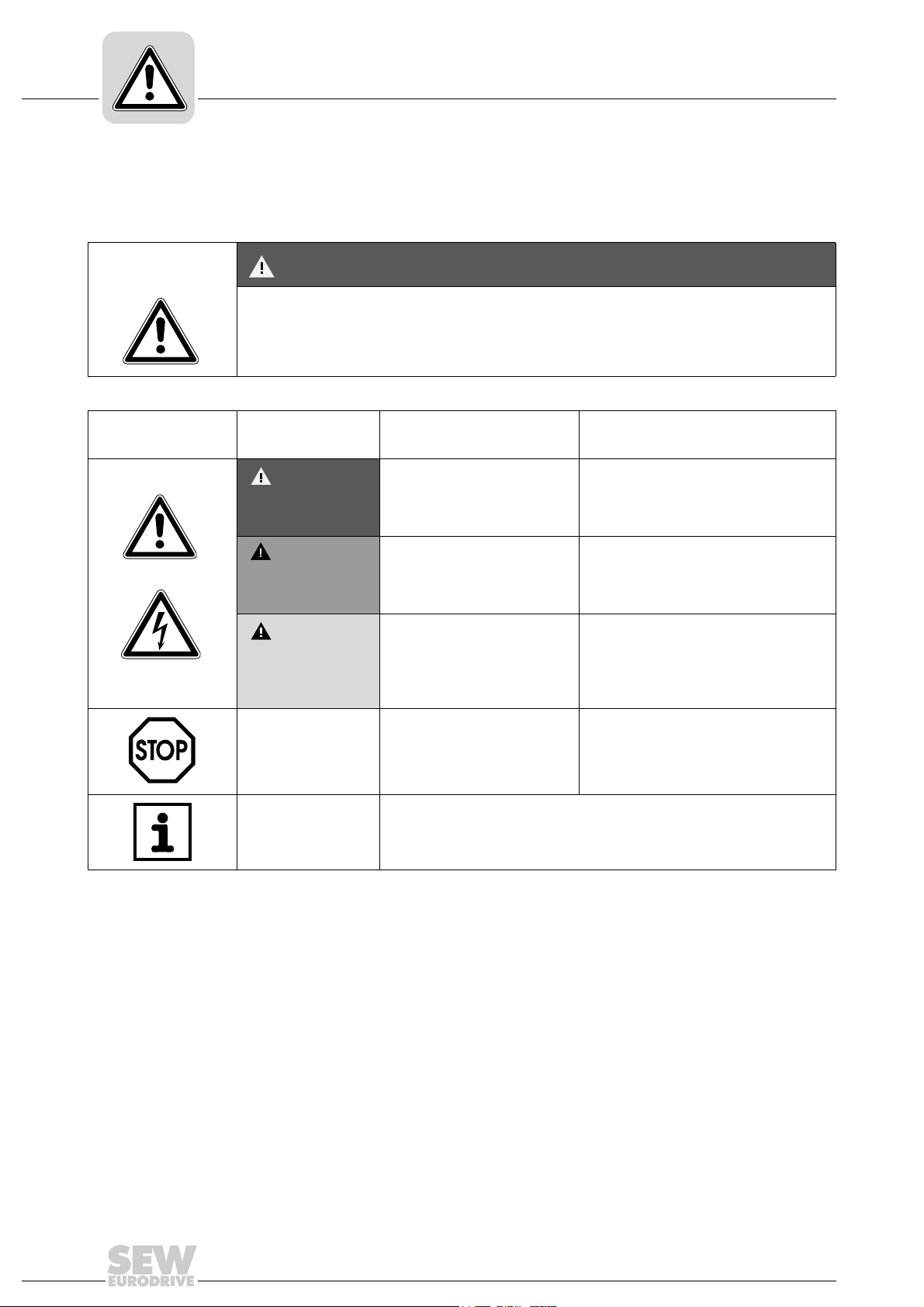

The safety notes in these operating instructions are structured as follows:

Symbol SIGNAL WORD

Nature and source of hazard.

Possible consequence(s) if disregarded.

• Measure(s) to avoid the hazard.

Symbol Signal Word Meaning Consequences if

disregarded

Example:

General hazard

HAZARD Imminent hazard Severe or fatal injuries

WARNING Possible hazardous situation Severe or fatal injuries

Specific hazard,

e.g. electric shock

CAUTION Possible hazardous situation Minor injuries

STOP Possible damage to property Damage to the drive system or its environ-

ment

NOTE Useful information or tip

Simplifies drive system handling

Unless the information in the operating instructions is adhered to, it will be impossible to

ensure:

• Trouble-free operation

• Fulfillment of any rights to claim under guarantee

Consequently, read the operating instructions before you start working with the

unit!

The operating instructions contain important information about servicing. Therefore,

keep the operating instructions close to the unit.

4

Operating Instructions – MOVITRAC® LTP

1.2 Application environment

The following applications are forbidden unless measures are expressly taken to make

them possible:

• Use in explosion-proof areas.

• Use in environments with harmful substances:

– Oils

–Acids

– Gases

– Vapors

–Dust

– Radiated interference

– Other harmful environments

• Use subject to mechanical vibration and shock loads in excess of the requirements

in EN 50178.

• If the inverter performs safety functions which have to guarantee the protection of

machinery and people.

Important Notes

Application environment

1

1.3 Waste disposal

Please follow the current instructions: dispose in accordance with the regulations in

force:

• Electronics scrap (printed-circuit boards)

• Plastic (housing)

• Sheet metal

• Copper

Operating Instructions – MOVITRAC® LTP

5

2

Safety Notes

Installation and startup

2 Safety Notes

MOVITRAC® LTP drive inverters may not perform safety functions without higher-level

safety systems.

Use higher-level safety systems to guarantee the protection of machinery and people.

Do not use MOVITRAC

hoist applications.

Use monitoring systems or mechanical protection devices as safety features to avoid

possible injury or damage to property.

2.1 Installation and startup

• Never install or operate damaged products. Please submit a complaint to the

• Installation, startup and service work on the unit only by trained personnel.

• Follow the specific instructions during installation and startup of the motor and

• Make sure that preventive measures and protection devices correspond to the

• The unit meets all requirements for reliable isolation of power and electronics

• Take suitable measures to ensure that the connected motor does not start up

• Integral solid state short circuit protection does not provide branch circuit pro-

®

LTP drive inverters for any safety functions in conjunction with

transport company immediately in the event of damage.

The personnel must be trained in the relevant aspects of accident prevention andmust comply with the regulations in force (e.g. EN 60204, VBG 4,

DIN-VDE 0100/0113/0160).

the brake!

applicable regulations (e.g. EN 60204 or EN 50178).

Grounding the unit is a necessary protective measure.

Overcurrent protection devices are a necessary protective measure.

connections in accordance with UL508. All connected circuits must also satisfy

the requirements for reliable isolation so as to guarantee reliable isolation.

automatically when the inverter is switched on. To do this, you can connect binary

inputs DI01 through DI03 to GND.

tection. Branch circuit protection must be provided in accordance with the National

Electrical Code and any additional local codes.

6

Operating Instructions – MOVITRAC® LTP

2.2 Operation and servicing

WARNING

Danger of electrical shock. High voltages are present in the terminals and in within the

drive for up to 10 minutes after the electrical supply has been disconnected.

Severe or fatal injuries.

• Disconnect and isolate the MOVITRAC

minutes before commencing any work on it.

• Dangerous voltages are present in the output terminals and the cables and

motor terminals connected to them when the unit is switched on. Dangerous

voltages may also be present when the unit is inhibited and the motor at a standstill.

• The unit is not necessarily deenergized when the LEDs and the 7-segment

display are off.

• Safety functions inside the unit or a mechanical blockage may cause the motor

to stop. The removal of the source of the malfunction or a reset can result in an

automatic restart of the drive. If, for safety reasons, this is not permissible for the

driven machine, disconnect the unit from the supply system before correcting the

fault.

Safety Notes

Operation and servicing

®

LTP from the electrical supply at least 10

2

Operating Instructions – MOVITRAC® LTP

7

kVA

3

i

n

f

General specifications

Input voltage ranges

Hz

P

3 General specifications

3.1 Input voltage ranges

Depending upon model and power rating, the drives are designed for direct connection

to the following supplies:

MOVITRAC

200 ... 240 V ± 10 %, 1-phase* / 3-phase, 50 … 60 Hz ± 5 %

NOTE

*It is also possible to connect 1-phase MOVITRAC® LTP units to 2-phases of a

200 ... 240 V, 3-phase mains.

®

LTP 240 V units:

MOVITRAC

380 ... 480 V ± 10 %, 3-phase, 50 … 60 Hz ± 5 %

MOVITRAC

480 ... 525 V ± 10 %, 3-phase, 50 … 60 Hz ± 5 % (Sizes 5 & 6 only)

MOVITRAC

500 ... 600 V ± 10 %, 3-phase, 50 … 60 Hz ± 5 %

Products used with a 3-phase supply are designed for a maximum supply imbalance of

3 % between phases. For input supplies which have a supply imbalance greater than

3 % (typically the Indian subcontinent and parts of Asia Pacific including China) we

recommend that input chokes are used.

®

LTP 400 V units:

®

LTP 525 V units:

®

LTP 575 V units:

8

Operating Instructions – MOVITRAC® LTP

3.2 Product designation

MC LTP A 0015 2 0 1 1 00 (60 Hz)

General specifications

Product designation

60 Hz American version only

00 = Standard IP20 / NEMA 1 housing

10 = IP55 / NEMA 12 housing

Type

Quadrants

20 = IP55 / NEMA 12 housing with switch

50 = 525 V, standard IP20 / NEMA 1 housing

0M = Optional Modbus Firmware

1 = 1Q (without brake chopper)

4 = 4Q (with brake chopper)

kVA

i

n

f

Hz

P

3

3.3 Overload capability

All MOVITRAC® LTP units have a possible overload of:

• 150 % for 60 seconds

• 175 % for 2 seconds

Connection type

Interference

suppression on the

supply side

Mains voltage

Recommended motor

power

Version A

Product type MC LTP

1 = 1-phase

3 = 3-phase

0 = class 0

A = class A

B = class B

1 = 115 V

2 = 200 ... 240 V

5 = 380 ... 480 V

6 = 500 ... 600 V

0015 = 1.5 kW

Operating Instructions – MOVITRAC® LTP

9

kVA

3

i

n

f

General specifications

Protection features

Hz

P

3.4 Protection features

• Output short-circuit, phase-to-phase, phase-to-ground

• Output over-current

– Trip set at 175 % of rated drive current.

• Overload protection

– Drive delivers 150 % of rated motor current for 60 seconds.

• Braking transistor protected against short-circuit.

• Braking resistor overload (when enabled)

• Over-voltage trip

– Set at 123 % of drive maximum rated supply voltage.

• Under-voltage trip

• Over temperature trip

• Under temperature trip

– Drive will trip if enabled below –10 °C

• Supply phase imbalance

– A running drive will trip if there is a supply imbalance of >3 % persisting for

more than 30 seconds.

• Supply phase loss

– A running drive will trip if one phase of a 3-phase supply is lost for more than

15 seconds.

10

Operating Instructions – MOVITRAC® LTP

4 Mechanical Installation

• Carefully inspect the MOVITRAC® LTP prior to installation to ensure it is undamaged.

• Store the MOVITRAC

and within the ambient temperature range –40 °C to +60 °C.

• Install the MOVITRAC

within suitable housing. This should be according to EN 60529 if specific Ingress

Protection ratings are required.

• Do not place flammable material close to the drive.

• The entry of conductive or flammable foreign bodies should be prevented.

• The maximum operational ambient temperature is 50 °C and the minimum is 0 °C.

• Relative humidity must be less than 95 % (non-condensing).

•MOVITRAC

touching. This gives adequate ventilation space between them. If the

MOVITRAC

device, the minimum vertical spacing is 150 mm. The enclosure should either be

force-ventilated or large enough to allow natural cooling (see chapter "IP20 / NEMA

1 housing: mounting and dimensions" on page 14).

®

LTP units can be installed side by side with their heatsink flanges

®

LTP is to be installed above another drive or any other heat-producing

Mechanical Installation

Protection features

®

LTP in its box until required. Storage should be clean and dry

®

LTP on a flat, vertical, flame-resistant, vibration-free surface,

4

Operating Instructions – MOVITRAC® LTP

11

4

A

Mechanical Installation

Dimensions

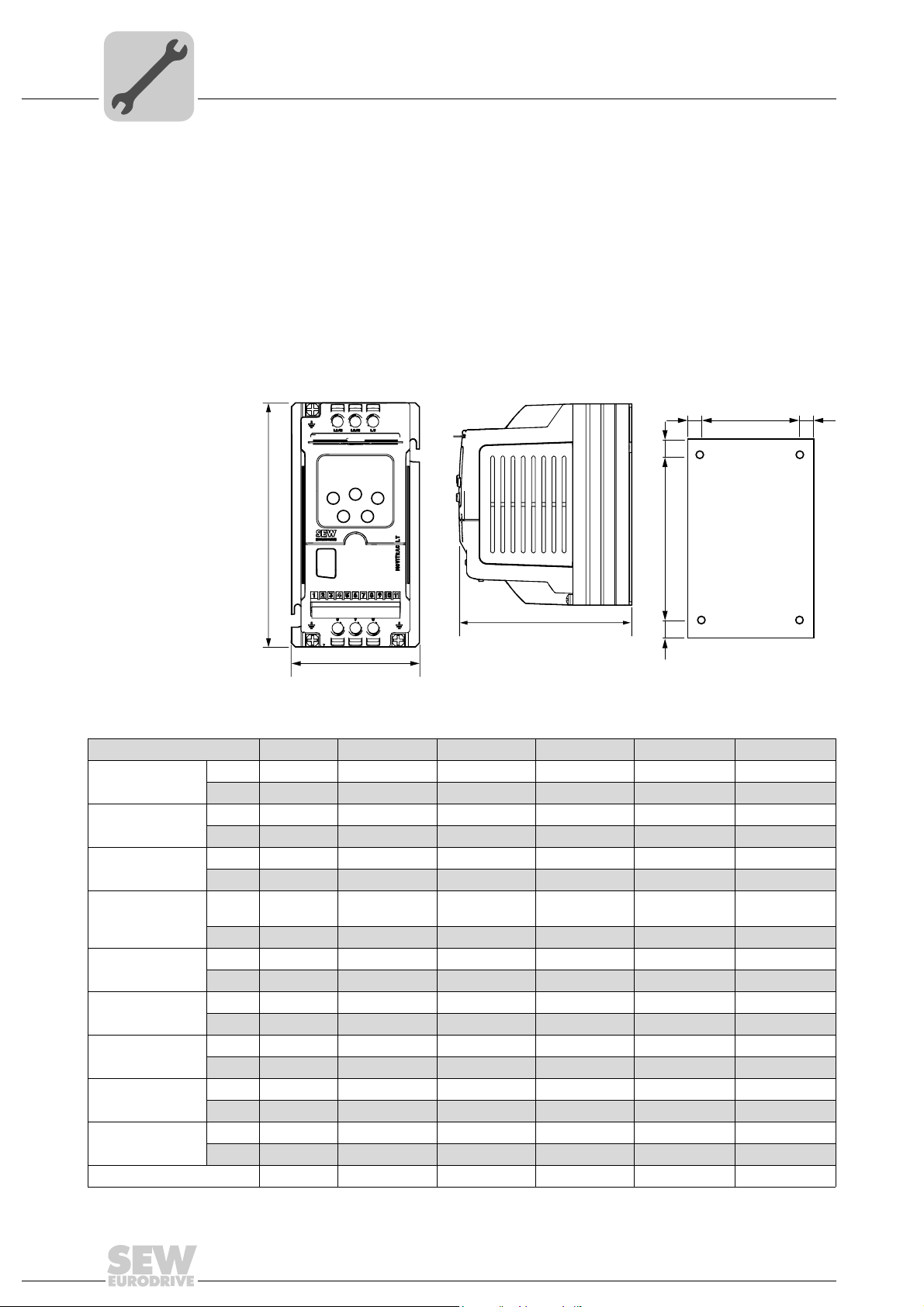

4.1 Dimensions

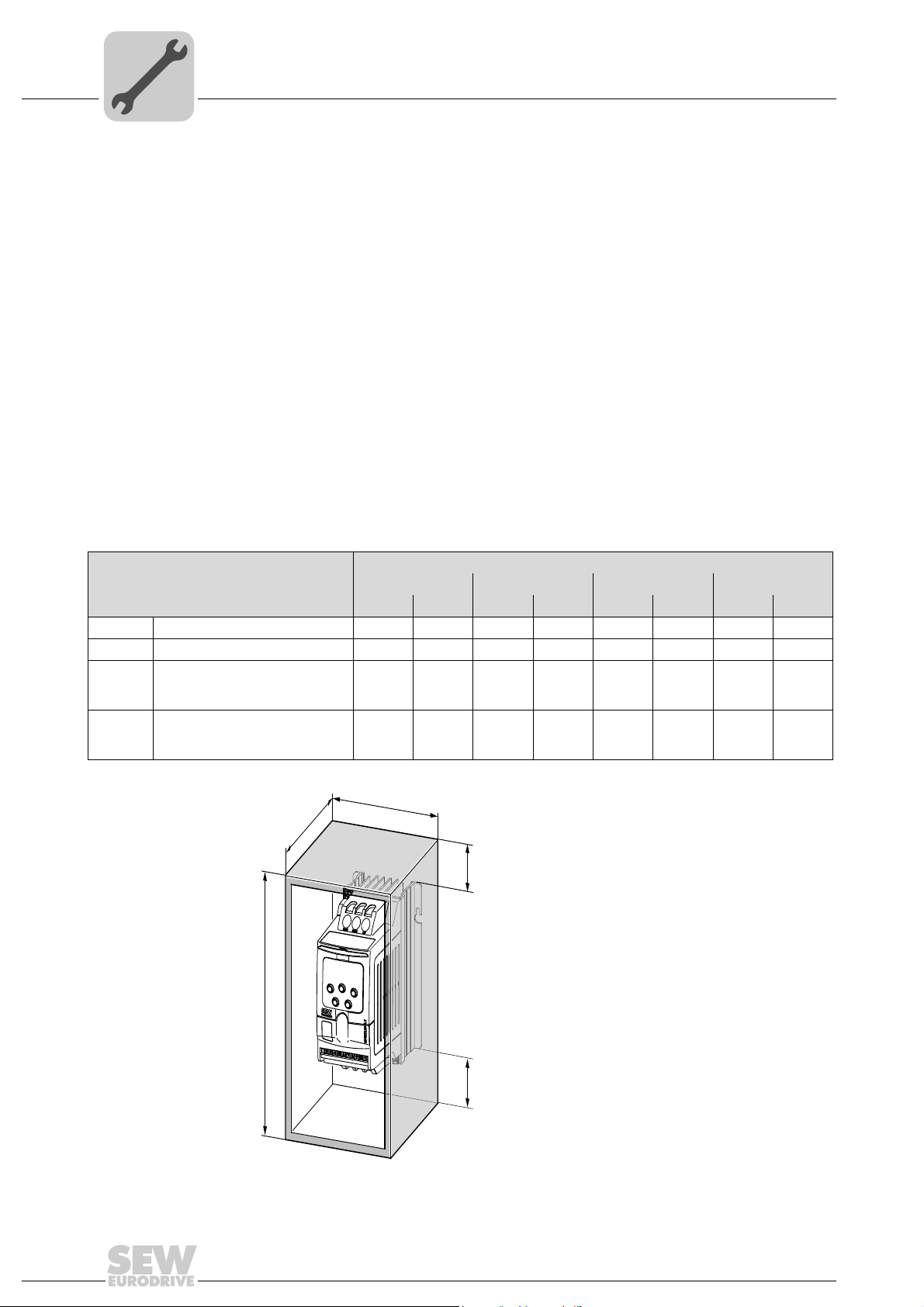

MOVITRAC® LTP is available in 2 housing versions:

• Standard IP20 / NEMA 1 housing for use in switch cabinets

• IP55 / NEMA 12 K version for size 1 and size 2 drives

The IP55 / NEMA 12 K housing is protected against moisture and dust. Therefore, the

drives can be operated indoors under harsh conditions. Electronically, the drives are

identical and the only differences are the dimensions of the housing and the weight.

4.1.1 Dimensions of the IP20 / NEMA 1 housing

bb

c

d

C

B

54769AXX 54781AXX 54770AXX

Dimension Size 1 Size 2 Size 3 Size 4 Size 5 Size 6

Height (A) [mm] 155 260 260 520 1045 1100

[in] 6.10 10.20 10.20 20.47 41.14 43.31

Width (B) [mm] 80 100 171 340 340 340

[in] 3.15 3.94 6.73 13.39 13.39 13.39

Depth (C) [mm] 130 175 175 220 220 330

[in] 5.12 6.89 6.89 8.66 8.66 12.99

Weight

a [mm] 72 92 163 320 320 320

b [mm] 4 4 4 9.5 9.5 9.5

c [mm] 25 25 25 50 50 50

d [mm] 105 210 210 420 945 945

Power terminal

torque settings

Fixings 2 × M4 2 × M4 4 × M4 4 × M8 4 × M8 4 × M8

1) Size 6 comes with an external line choke

[kg] 1.1 2.6 5.3 28 68

[lb] 2.43 5.73 11.68 61.73 149.91 149.91

[in] 2.84 3.62 6.42 12.6 12.6 12.6

[in] 0.16 0.16 0.16 0.37 0.37 0.37

[in] 0.98 0.98 0.98 1.97 1.97 1.97

[in] 4.13 8.27 8.27 16.54 37.21 37.21

[Nm] 1 1 1 4 8 8

[lb.in] 8.85 8.85 8.85 35.4 70.8 70.8

c

a

1)

Unit = 55

Choke = 27

12

Operating Instructions – MOVITRAC® LTP

Mechanical Installation

A

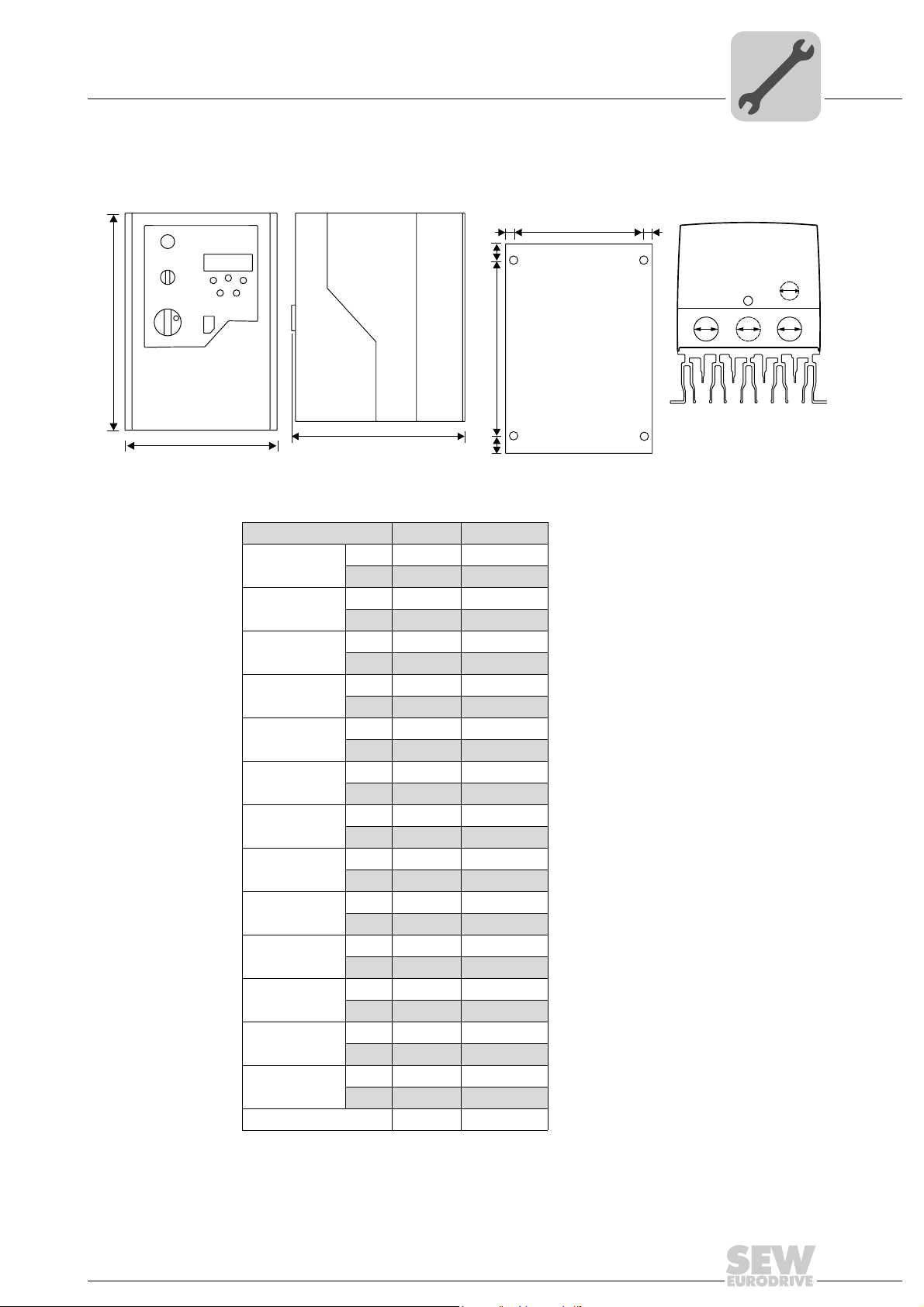

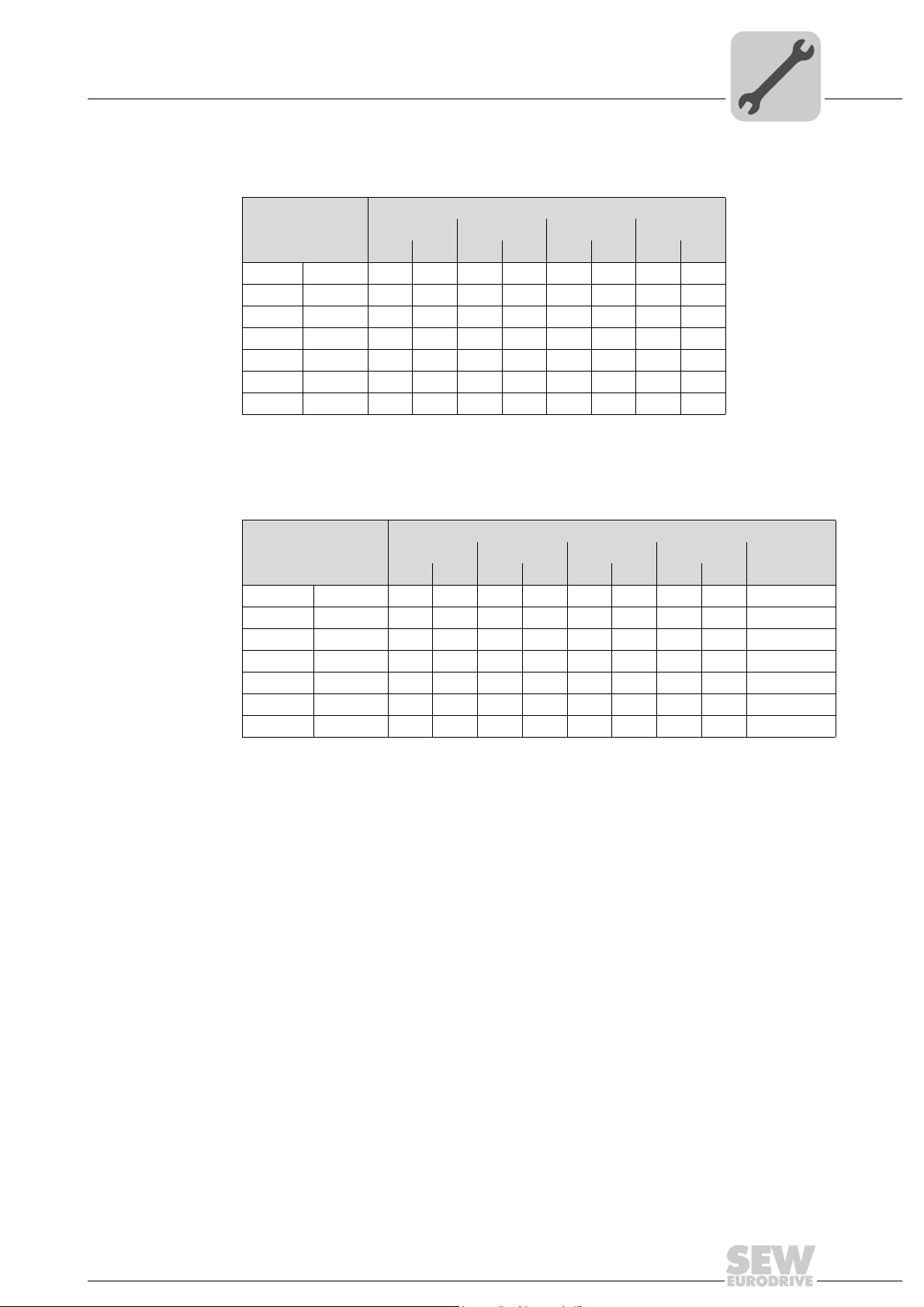

4.1.2 Dimensions of the IP55 / NEMA 12 housing (LTP xxx –10 and –20)

Dimensions

4

b

c

d

B

60198AXX 60200AXX 60199AXX 60497AXX

Dimension Size 1 Size 2

Height (A) [mm] 200 310

Width (B) [mm] 140 165

Depth (C) [mm] 165 176

Weight [kg] 2.3 4.5

a [mm] 128 153

b [mm] 6 6

c [mm] 25 25

d [mm] 142 252

X [mm] 22 25

1)

Y

1)

Z

Power terminal

torque settings

Control terminal

torque settings

Fixings 2 × M4 4 × M4

1) Glands Y and Z are flip out glands.

C

[in] 7.9 12.2

[in] 5.5 6.5

[in] 6.5 6.9

[lb] 5.1 9.9

[in] 5 6

[in] 0.23 0.23

[in] 0.98 0.98

[in] 5.6 9.9

[in] 0.87 0.98

[mm] 22 22

[in] 0.87 0.87

[mm] 17 17

[in] 0.67 0.67

[Nm] 1 1

[lb.in] 8.85 8.85

[Nm] 0.5 0.5

[lb.in] 4.43 4.43

c

a

b

Z

XX

Y

Operating Instructions – MOVITRAC® LTP

13

4

A

Mechanical Installation

IP20 / NEMA 1 housing: mounting and dimensions

4.2 IP20 / NEMA 1 housing: mounting and dimensions

For applications that require a higher IP rating than the IP20 offered by the standard

drive, the drive must be mounted in housing. The following guidelines should be

observed for these applications:

• Housing should be made from a thermally conductive material, unless forced ventilation is used.

• When vented housing is used, there should be venting above and below the drive to

ensure good air circulation. Air should be drawn in below the drive and expelled

above the drive.

• If the external environment contains contamination particles (e.g. dust), a suitable

particle filter should be fitted to the vents and forced ventilation implemented. The

filter must be serviced and cleaned appropriately.

• High moisture, salt or chemical content environments should use a suitably sealed

(non-vented) housing.

4.2.1 Dimensions of non-vented metal housing

Sealed housing

Drive power rating

Size 1 0.75 kW 230 V 300 11.81 250 9.84 200 7.87 50 1.97

Size 1 1.5 kW 230 V 400 15.75 300 11.81 250 9.84 75 2.95

Size 2 1.5 kW 230 V

0.75 kW, 1.5 kW, 2.2 kW 400 V

2.2 kW 400 V

Size 2 2.2 kW 230 V

4.0 kW 400 V

5.5 kW 575 V

C

A B C D

[mm] [in] [mm] [in] [mm] [in] [mm] [in]

400 15.75 300 11.81 300 11.81 60 2.36

600 23.62 450 17.72 300 11.81 100 3.94

B

D

D

Figure 1: Housing

14

54784AXX

Operating Instructions – MOVITRAC® LTP

IP20 / NEMA 1 housing: mounting and dimensions

4.2.2 Dimensions of vented housing

Drive power rating

[mm] [in] [mm] [in] [mm] [in] [mm] [in]

Size 1 1.5 kW 400 15.75 300 11.81 150 5.91 75 2.95

Size 2 5.5 kW 600 23.62 400 15.75 250 9.84 100 3.94

Size 3 15 kW 800 31.50 600 23.62 300 11.81 150 5.91

Size 4 22 kW 1000 39.37 600 23.62 300 11.81 200 7.87

Size 437 kW ––––––––

Size 590 kW ––––––––

Size 6160 kW––––––––

4.2.3 Dimensions of force vented housing

Mechanical Installation

Vented housing

A B C D

4

Force vented housing (with fan)

Drive power rating

Size 1 1.5 kW 275 10.83 150 5.91 150 5.91 50 1.97 > 15 m

Size 2 5.5 kW 320 12.60 200 7.87 250 9.84 75 2.95 > 45 m

Size 3 15 kW 400 15.75 250 9.84 250 9.84 100 3.94 > 80 m

Size 4 22 kW 800 31.50 500 19.69 300 11.81 130 5.12 > 300 m

Size 4 37 kW 800 31.50 500 19.69 300 11.81 130 5.12 > 300 m

Size 5 90 kW 1500 59.06 600 23.62 400 15.75 200 7.87 > 900 m

Size 6 160 kW 1600 62.99 600 23.62 400 15.75 250 9.84 > 1000 m

A B C D

Air Flow[mm] [in] [mm] [in] [mm] [in] [mm] [in]

3

/ h

3

/ h

3

/ h

3

/ h

3

/ h

3

/ h

3

/ h

Operating Instructions – MOVITRAC® LTP

15

5

Electrical Installation

Prior to installation

5 Electrical Installation

It is essential to comply with the safety instructions in chapter 2 during installation.

Danger of electrical shock. High voltages are present in the terminals and in within the

drive for up to 10 minutes after the electrical supply has been disconnected.

Severe or fatal injuries.

• Disconnect and isolate the MOVITRAC

10 minutes before commencing any work on it.

•MOVITRAC

accordance with local and national regulations and codes of practice.

• The MOVITRAC

use a suitable enclosure or the IP55 version.

• Where the electrical supply to the drive is through a plug and socket connector, do

not disconnect until 10 minutes have elapsed after turning off the supply.

• Ensure correct earthing connections. See diagram in chapter "Drive and motor

connection" on page 20.

• The earth cable must be sufficient to carry the maximum supply fault current which

normally will be limited by the fuses or motor circuit breaker.

WARNING

®

LTP units should only be installed by qualified electricians and in

®

LTP from the electrical supply at least

®

LTP has an Ingress Protection rating of IP20. For higher IP ratings,

HAZARD

Risk of fatal injury if the hoist falls.

Severe or fatal injuries.

•MOVITRAC

Use monitoring systems or mechanical protection devices to ensure safety.

5.1 Prior to installation

• Ensure that the supply voltage, frequency and number of phases (single or 3-phase)

correspond to the rating of the MOVITRAC

• An isolator or similar should be installed between the power supply and the drive.

• Never connect the mains power supply to the MOVITRAC

U, V or W.

• When installing 575 V inverters ensure the motor is always in STAR connection.

• The cables are only protected when slow blow HRC fuses or a motor circuit breaker

(MCB) are used.

• Do not install any type of automatic switchgear between the drive and the motor.

Wherever control cabling is close to power cabling, maintain a minimum separation

of 100 mm and arrange crossings at 90 °.

• Ensure that screening or armoring of power cables is effected in accordance with the

connections diagram in chapter "Drive and motor connection" on page 20.

• Ensure that all terminals are tightened to the appropriate torque.

®

LTP is not designed for use as a safety device in hoist applications.

®

LTP as delivered.

®

LTP output terminals

16

Operating Instructions – MOVITRAC® LTP

Electrical Installation

Prior to installation

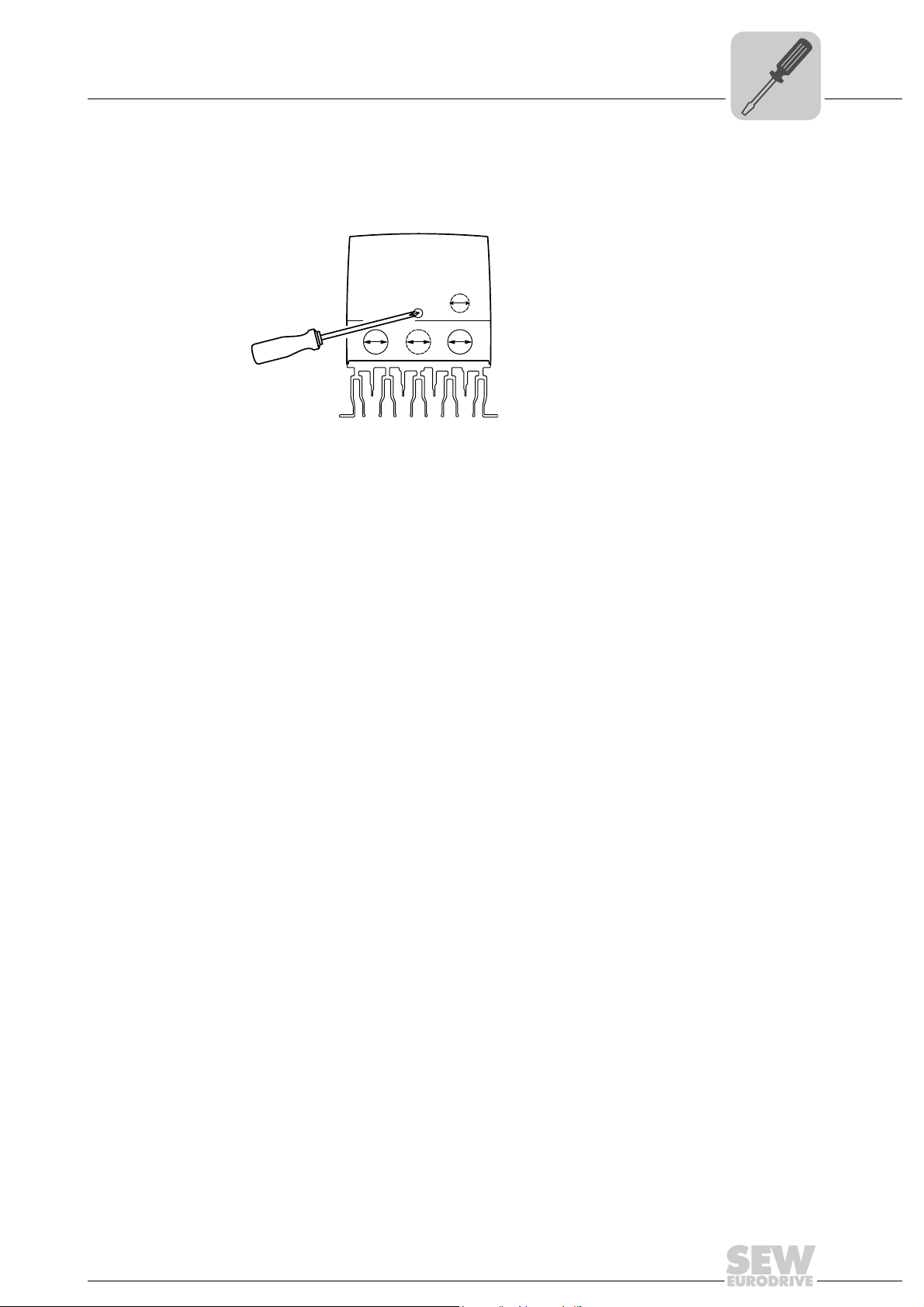

5.1.1 Opening the front cover

IP55 size 1 & 2 Insert a screwdriver into the opening as illustrated below to release the front cover.

Z

XX

Y

64506AXX

5.1.2 Helpcard

In the IP20 housing the helpcard is located in a separate slot above the display. In the

IP55 housing the helpcard is attached to the inside of the front cover.

5

Operating Instructions – MOVITRAC® LTP

17

5

Electrical Installation

Installation

5.2 Installation

Connect the drive according to the following diagram. Ensure that the motor terminal box

connections are correct. There are two standards in general: Star and Delta. It is essential to ensure that the motor is connected in accordance with the voltage at which it will

be operated. For more information, refer to the diagram below.

Please refer to chapter 10 for the recommended cabling and wiring sizing.

It is recommended that the power cabling should be 4-core PVC-insulated screened

cable, laid in accordance with local industrial regulations and codes of practice.

The ground terminal of each MOVITRAC

directly to the site earth (ground) busbar (through the filter if installed) as shown.

MOVITRAC

should also not loop to or from any other equipment. Ground loop impedance must

conform to local industrial safety regulations. To meet UL regulations, UL approved ring

crimp terminals should be used for all earth wiring connections.

5.2.1 Motor terminal box connections

®

LTP should be individually connected

®

LTP ground connections should not loop from one drive to another. They

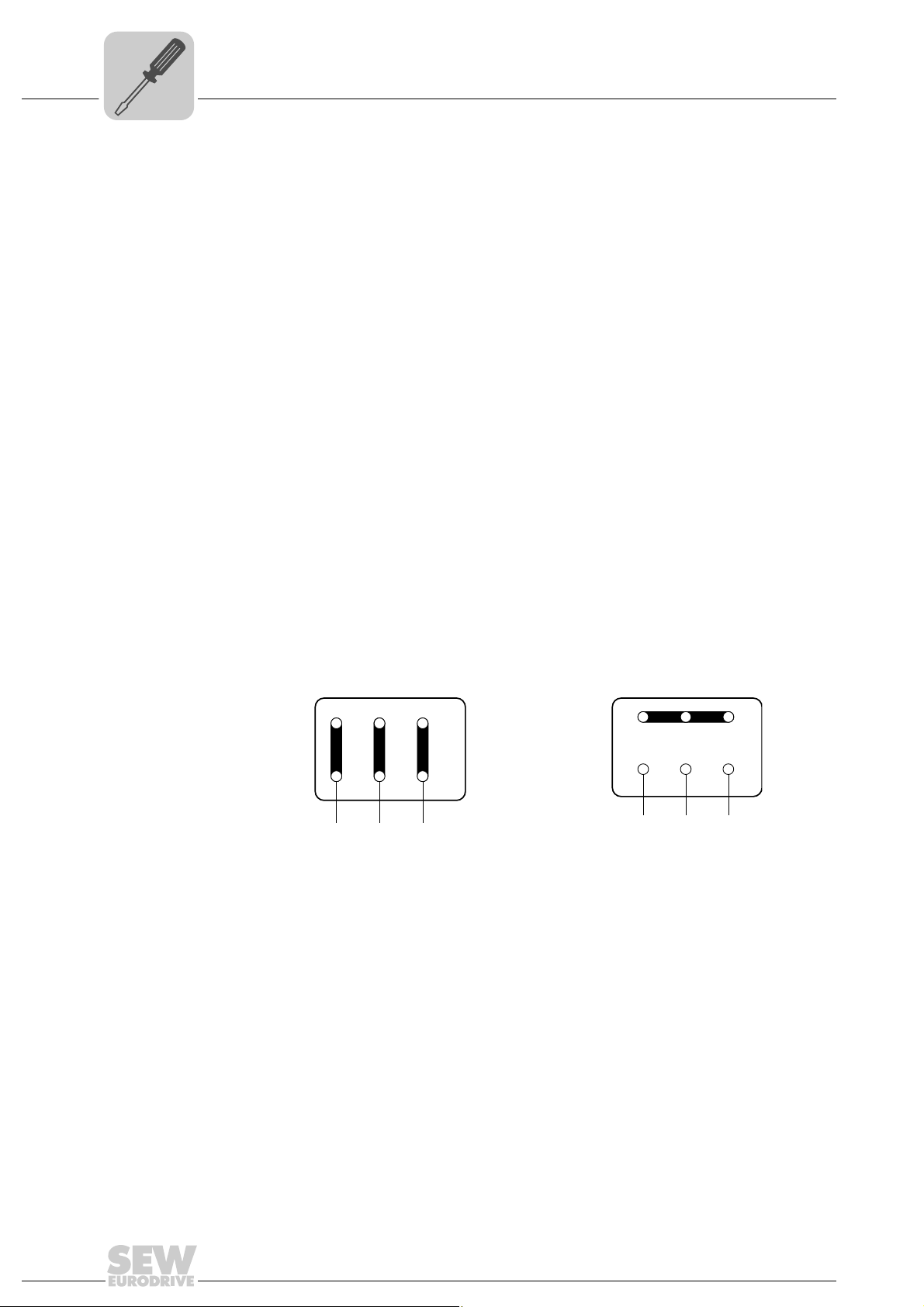

Motors are connected in either Star, Delta, Double Star or Star Nema motors. The motor

rating plate indicates the voltage rating for the method of connection, which must match

the operating voltage of the MOVITRAC

R13

U2

W2

V2

®

LTP unit.

W2 U2

V2

U1UV1 W1

U1UV1

V W

Low voltage Δ High voltage 댴

W1

V W

18

Operating Instructions – MOVITRAC® LTP

R76

Electrical Installation

Installation

5

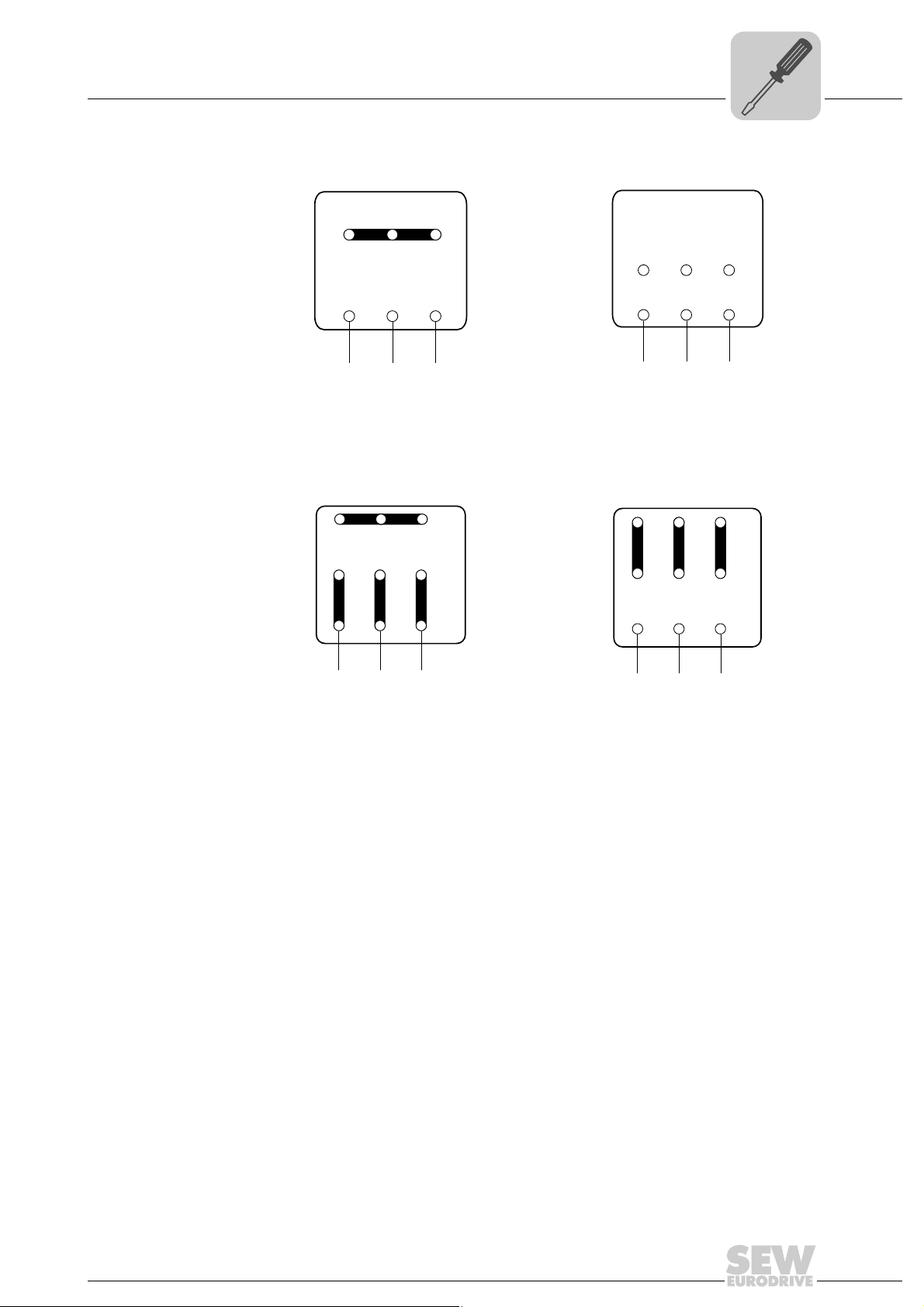

DT / DV

T6 T4 T5

W2 U2 V2

T6 T4 T5

W2 U2 V2

T9 T7

T9 T7 T8

U3 V3

W3

T1 T2 T3

V1 W1

U1

L1

L2 L1

Low voltage 댴댴 High voltage 댴

W3 U3 V3

T1 T2 T3

U1L1V1 W1

L2 L1

T4 T5 T6

T4 T5 T6

U2 V2 W2

T7 T8

V3

U3

T1 T2

U1

V1

T9

W3

T3

W1

U2 V2 W2

T7 T8 T9

V3

U3

T1 T2 T3

V1

U1

T8

W3

W1

U

V W

Low voltage 댴댴 High voltage 댴

U

V W

Operating Instructions – MOVITRAC® LTP

19

5

Electrical Installation

Installation

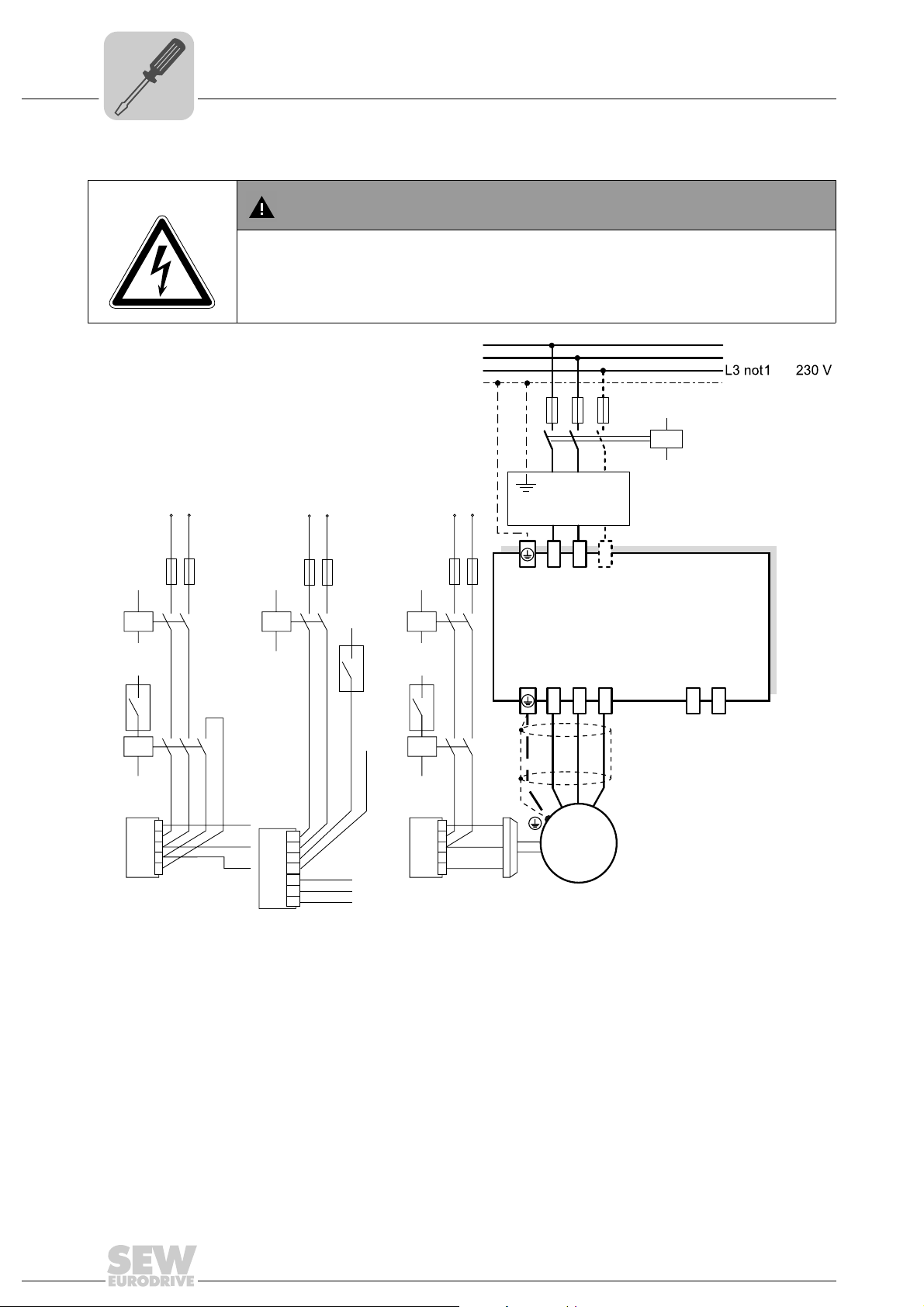

5.2.2 Drive and motor connection

Danger of electrical shock. Risk of exposure to high voltage may occur if the unit is

wired incorrectly.

Severe or fatal injuries.

• It is essential to observe the connection sequence illustrated below.

WARNING

L1

L2/N

-ph.

PE

F11/F12/F13

F14/F15

V

AC

V

AC

[2]

red

white

blue

+V

10

11

GND

K11

(AC-3)

K11

(AC-3)

[V+] +V

10

11

[4]

K12

(AC-3)

*

[3]

1

2

BG

3

BGE

4

5

DT/DV/D: DT/DV/D:

Cut-off in the DC

and AC circuits

white

red

blue

BMK

1

2

3

4

13

14

15

Figure 2: Wiring diagram for power section

K11

(AC-3)

K12

(AC-3)

GNDGND

V

AC

F14/F15F14/F15

10

11

white

1

2

BG

3

BGE

4

5

Cut-off in the AC

circuit

L1 L2

Option ND.. input choke

L1' L2'

L1 L2 L3

UVW

red

blue

3-phase

L3

L3'

Power section

M

BW

K10

[1]

(AC-3)

BR

+

BW.. / BW..-T

braking resistor

connection*

64606AEN

20

[1] Mains supply contactor to drive

[2] Mains supply to brake rectifier, switched simultaneously by K10

[3] Control contactor / relay, energized via the internal relay contact [4] in the drive and supplies the brake rectifier

[4] Potential free relay contact inside the drive

[V+] External power supply for energizing the control contactor / relay

* Size 2 an

d above

Operating Instructions – MOVITRAC® LTP

Electrical Installation

Installation

NOTE

• Connect the brake rectifier using a separate supply system lead.

• Supply via the motor voltage is not permitted!

The 230 V and 400 V drives do not require a line choke on the supply unless the specified supply voltages cannot be guaranteed.

Drives from 0.37 kW (0.5 HP) to 5.5 kW (7.5 HP) must be fitted with external line chokes

if the quality of the supply cannot be guaranteed.

An external line choke is always required for 575 V drives from 0.75 kW (1 HP) to 5.5 kW

(7.5 HP).

All drives with 7.5 kW (10 HP) or greater have a built-in choke and therefore do not need

external chokes fitted to ensure transient protection.

An external choke is required if 230 V or 400 V drives up to 5.5 kW (7.5 HP) are installed

under the following conditions:

• Local generator

• Large loads on the same supply

• High dV / dt voltage fluctuations e.g. when welders are being used

• Outdoor pumping stations with exposed supply lines, which may be hit by lightening

strikes.

Always switch off the brake on the DC and AC sides with:

• All hoist applications

• Drives that require a rapid brake response time

5

It is essential to adhere to the connection sequence of the brake connector. Incorrect

connection will lead to irreparable damage to the brake. The connection to the brake

rectifier requires a separate supply system cable. Supply from the motor voltage is not

permitted.

If the brake rectifier is installed in the switch cabinet the connecting cable between the

brake rectifier and the brake must be routed separately to other power cables. Routing

together with other cables is only permitted if the other cables are shielded. Set P2-13

to 3 to use the relay output to control the brake rectifier (BGx).

5.2.3 Motor thermal protection (TF / TH)

Motors with an internal PTC over-temperature sensor (TF, TH or similar) can be connected directly to the MOVITRAC

The sensor is connected to terminal 1 (+24 V) and Digital Input 3. Parameter P2-01 must

be set to external trip input to receive over-temperature trips. The trip level should be set

to 2.5 k

Ω.

®

LTP. A trip will then be displayed on the drive.

Operating Instructions – MOVITRAC® LTP

21

5

Electrical Installation

Installation

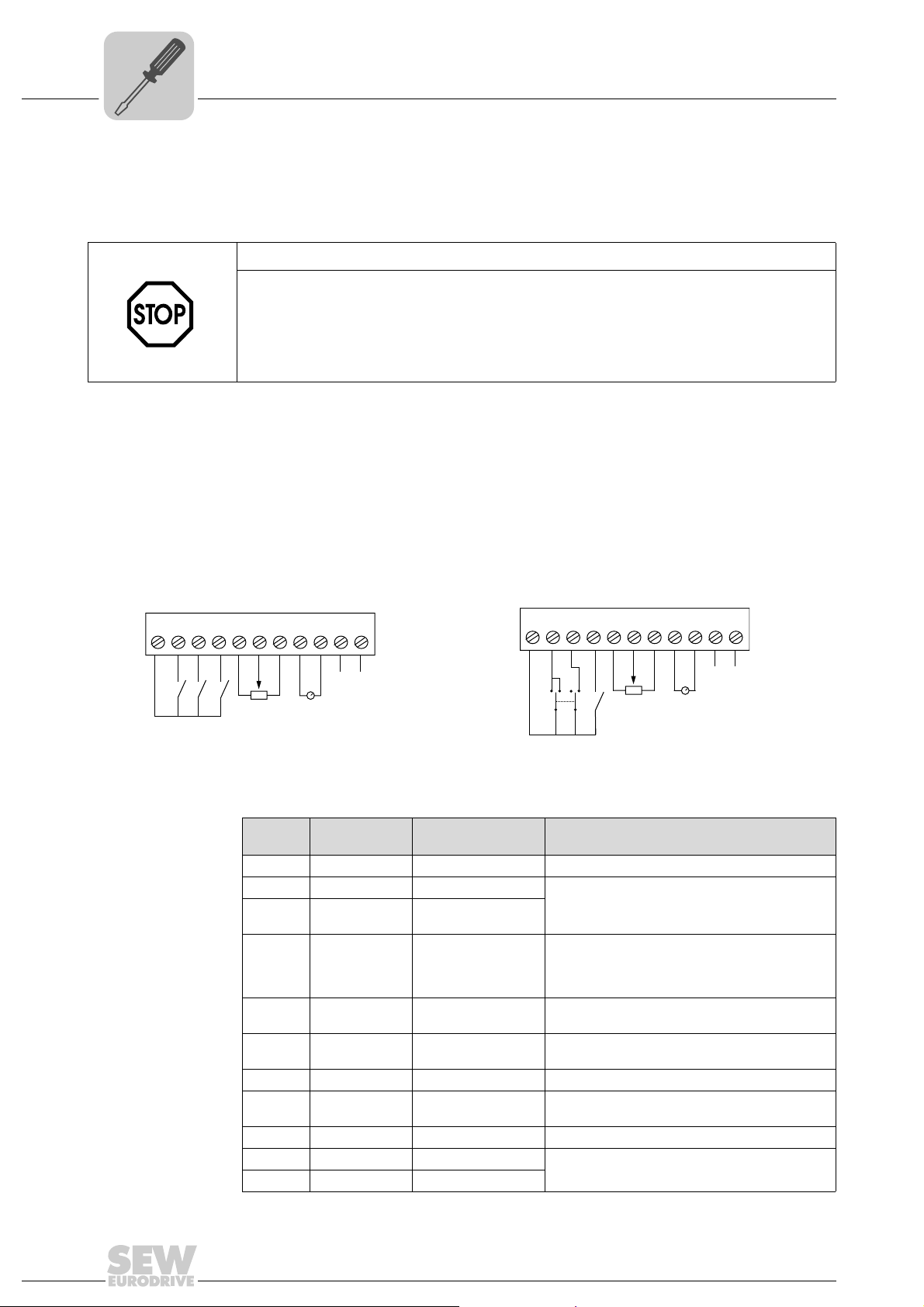

5.2.4 Signal terminal overview

IP20 and IP55 IP55 with switch option

The User Control terminals are available via an 11-way pluggable connector. All terminals are galvanically isolated, allowing direct connection to other equipment.

STOP!

Danger of damage to the MOVITRAC® LTP unit.

Do not connect mains supply voltages to any terminals other than the user relay output.

Doing so will result in permanent damage to the unit.

The user relay output can handle up to AC 250 V. All other inputs only withstand

DC 30 V without damage.

The functionality of the inputs and outputs is user configurable. All operating modes are

set up via the parameter set.

Up to 100 mA can be sourced from the User +24 V output and up to 20 mA from the

analog output.

+24 V

DI 1

DI 2

DI 3

+10 V

AI/DI

0 V

AO/DO

0 V

Relay contact

Relay common

1 234567891011

64485AEN 64608AEN

The signal terminal block has the following signal connections:

Ter minal

no.

10 Relay contact Relay contact N.O. relay contact (AC 250 V / DC 30 V @ 5 A)

11 Relay common Relay common

Signal Connection Description

1 +24 V +24 V ref out Ref. to activate DI1 ... DI3 (100 mA max.)

2 DI1 Digital input 1 Positive logic

3 DI2 / DO2 Digital input 2 /

4 DI3 / AI2 Digital input 3 /

5 +10 V +10 V ref out 24 V ref for analog input

6 AI / DI Analog input (12 bit)

7 0 V 0 V common 0 V ref for analog input (pot supply –)

8 AO / DO Analog output (8 bit)

9 0 V 0 V common 0 V ref for analog output

Digital output 2

Analog input 2

Digital input 4

Digital output

+24 V

DI 1

DI 2

DI 3

+10 V

AI/DI

0 V

AO/DO

0 V

Relay contact

Relay common

1 234567891011

FWD

REV

"Logic 1" in

"Logic 0" in

Positive logic (P2-33)

"Logic 1" in

"Logic 0" input voltage range: DC 0... 8 V

0 ... 10 V, 0 ... 20 mA, 4 ... 20 mA

(pot supply +, 100 mA max., 1 k Ω min.)

0 ... 10 V, –10 ... 10 V, 0 ... 24 V, –24 ... 24 V

"Logic 1" input voltage range: DC 8 ... 30 V (P2-30)

0 ... 10 V, 4 ... 20 mA analog

24 V, 20 mA digital (P2-36)

put voltage range: DC 8... 30 V

put voltage range: DC 0... 8 V

put voltage range: DC 8... 30 V

22

Operating Instructions – MOVITRAC® LTP

Key information on the control terminal

• Maximum input voltage on any terminal: DC 30 V

• All outputs are short circuit proof

• Recommended potentiometer resistance: 1 k

• Digital input response time < 8 ms

• Bipolar analog input response time < 16 ms. Resolution ±12-bit (0.025 %)

• Second analog input response time < 16ms. Resolution +11-bit (0.05 %)

• Analog / digital output response time < 16ms. Resolution 8-bit (0.25 %)

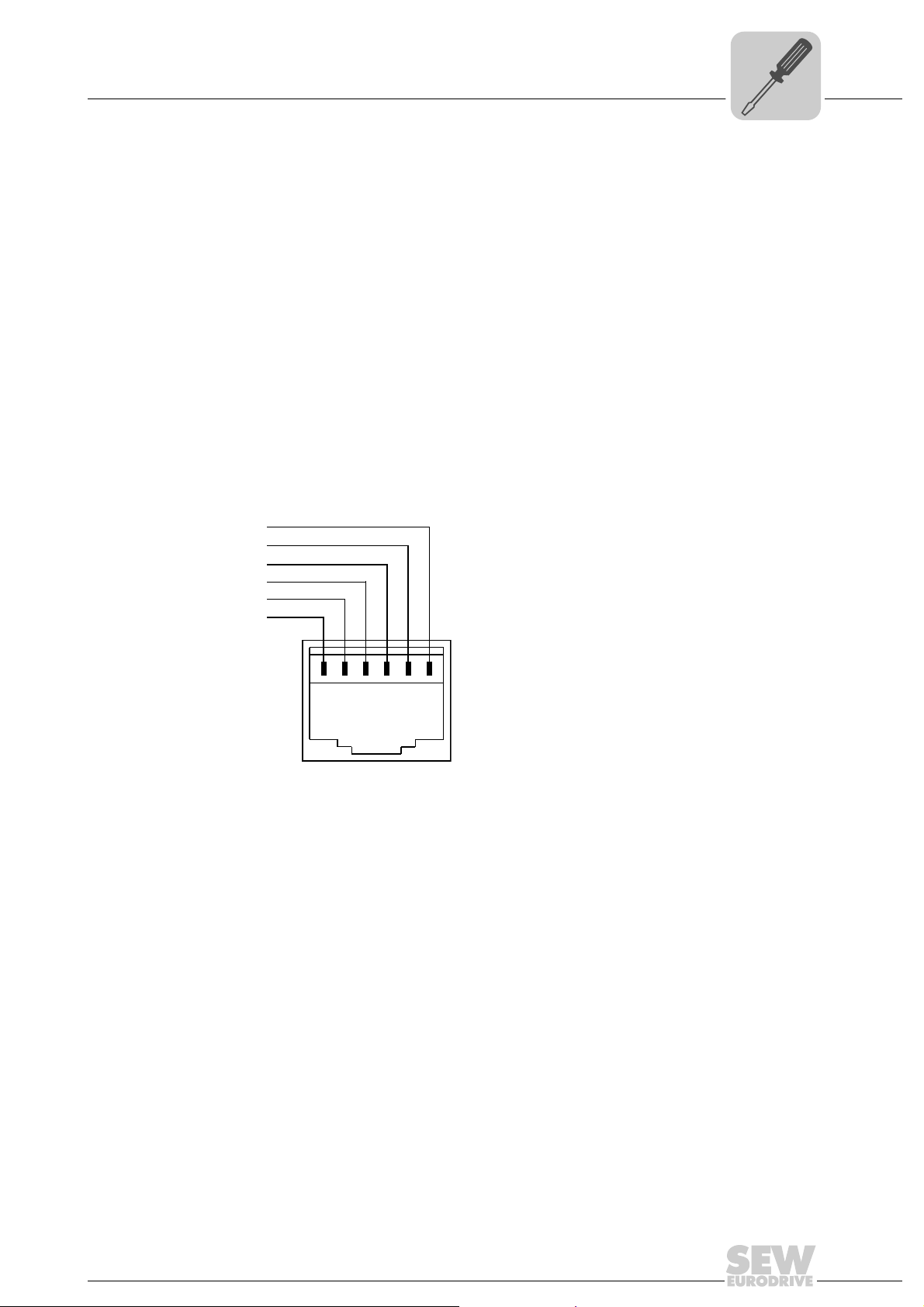

5.2.5 RJ11 Communication socket

The RJ11 communication socket can be used to set up a RS-485 communication to the

PC via UWS11A.

With MOVITRAC

MODBUS communication network.

Electrical Installation

Installation

Ω

®

LTP units it is possible to use this RJ11 connector to set up a

5

[1]

[2]

[3]

[4]

[5]

[6]

57406AXX

[1] RS-485– / MODBUS 1)

[2] RS-485+ / internal bus

[3] RS-485– / internal bus

[4] +24 V

[5] 0 V

[6] RS-485+ / MODBUS

1) The bit format is fixed as: 1 start bit, 8 data bits, 1 stop bit, no parity

1)

1)

1)

The internal bus works with 115 k Baud (bps). It can be used for drive-to-drive communication. In this case, up to 63 drives can communicate.

The MODBUS RTU works between 9,6 and 115 k Baud (bps). It can be used to communicate directly with an external PLC or with a fieldbus gateway. In this case, up to 63

drives can be controlled via bus communication.

Operating Instructions – MOVITRAC® LTP

23

5

Electrical Installation

Optical interface

5.3 Optical interface

The optical interface, which is located next to the RJ11 connector, is mainly used for

commissioning and monitoring the drive with a pocket PC. When LTP shell CE is

installed, the pocket PC can be used to commission the drive and monitor the current

status of the drive.

5.4 UL-compliant installation

Note the following for UL-compliant installation:

• The drives can be operated within an ambient temperature of 0 ... 50 °C.

• Only use copper connection cables which can withstand ambient temperatures of up

to 75 °C.

• Permitted tightening torques for MOVITRAC

– Sizes 1, 2 & 3 = 1 Nm / 8.9 lb.in

– Size 4 = 4 Nm / 35.4 lb.in

– Sizes 5 & 6 = 8 Nm / 70 lb.in

®

LTP power terminals are:

®

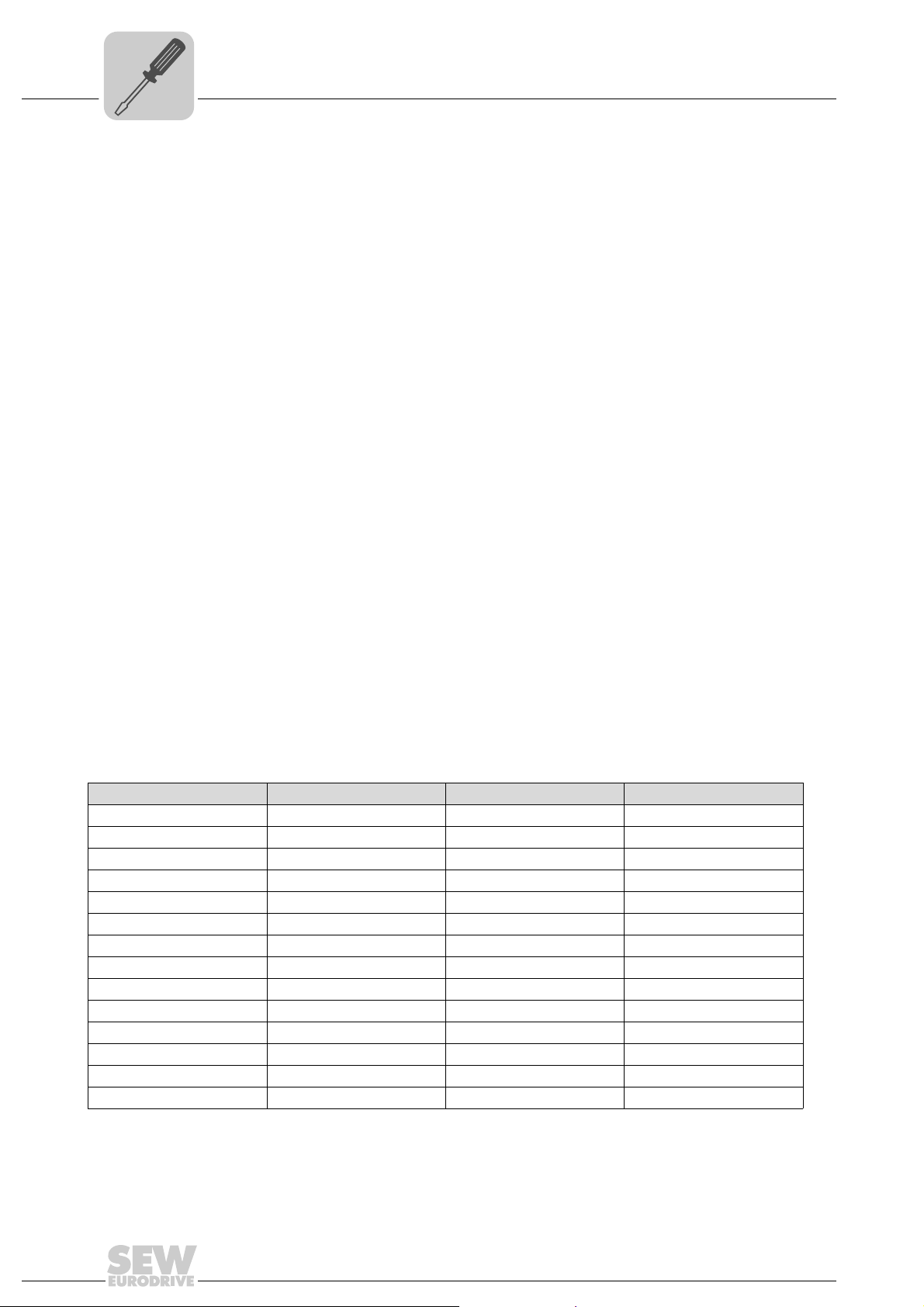

MOVITRAC

LTP drive inverters are suitable for operation in voltage power systems

with an earthed star point (TN and TT systems), which can supply a maximum supply

current and a maximum supply voltage in accordance with the following table. The fuses

listed in the following tables are the maximum permitted fuses for each inverter. Only

use melting fuses.

Only use tested units with a limited output voltage (V

= DC 30 V) and limited output

max

current (I = < 8 A) as an external DC 24 V source.

UL certification does not apply to operation in voltage supply systems with a non-earthed

star point (IT systems).

5.4.1 200 ... 240 V Units

MOVITRAC® LTP... Short circuit rating Max. supply voltage Fuses

0004 AC 5000 A AC 240 V AC 6 A / 250 V

0008 AC 5000 A AC 240 V AC 10A / 250 V

0015 AC 5000 A AC 240 V AC 20A / 250 V

0030, 0040, 022 AC 5000 A AC 240 V AC 32 A / 250 V

0055 AC 5000 A AC 240 V AC 50 A / 250 V

0075 AC 5000 A AC 240 V AC 80 A / 250 V

0110, 0150 AC 5000 A AC 240 V AC 100 A / 250 V

0185 AC 5000 A AC 240 V AC 125 A / 250 V

0220 AC 10000 A AC 240 V AC 160 A / 250 V

0300 AC 10000 A AC 240 V AC 200 A / 250 V

0370, 0450 AC 10000 A AC 240 V AC 300 A / 250 V

0550 AC 10000 A AC 240 V AC 350 A / 250 V

0750 AC 10000 A AC 240 V AC 400 A / 250 V

0900 AC 10000 A AC 240 V AC 500 A / 250 V

24

Operating Instructions – MOVITRAC® LTP

Loading...

Loading...