SEW movigear sni-b Operating Instructions Manual

Drive Technology \ Drive Automation \ System Integration \ Services

Operating Instructions

Mechatronic Drive System

MOVIGEAR

®

SNI-B

Single Line Network Installation

Edition 12/2013 20254547 / EN

SEW-EURODRIVE—Driving the world

Contents

Contents

1 General information ............................................................................................ 6

1.1 How to use this documentation................................................................... 6

1.2 Structure of the safety notes ....................................................................... 6

1.3 Rights to claim under warranty ................................................................... 7

1.4 Exclusion of liability..................................................................................... 7

1.5 Copyright..................................................................................................... 7

1.6 Product names and trademarks.................................................................. 7

2 Safety notes......................................................................................................... 8

2.1 General information .................................................................................... 8

2.2 Target group ............................................................................................... 8

2.3 Designated use ........................................................................................... 9

2.4 Transportation, storage ............................................................................ 9

2.5 Installation................................................................................................. 10

2.6 Electrical connection ................................................................................. 10

2.7 Safe disconnection.................................................................................... 10

2.8 Operation .............................................................................................. 11

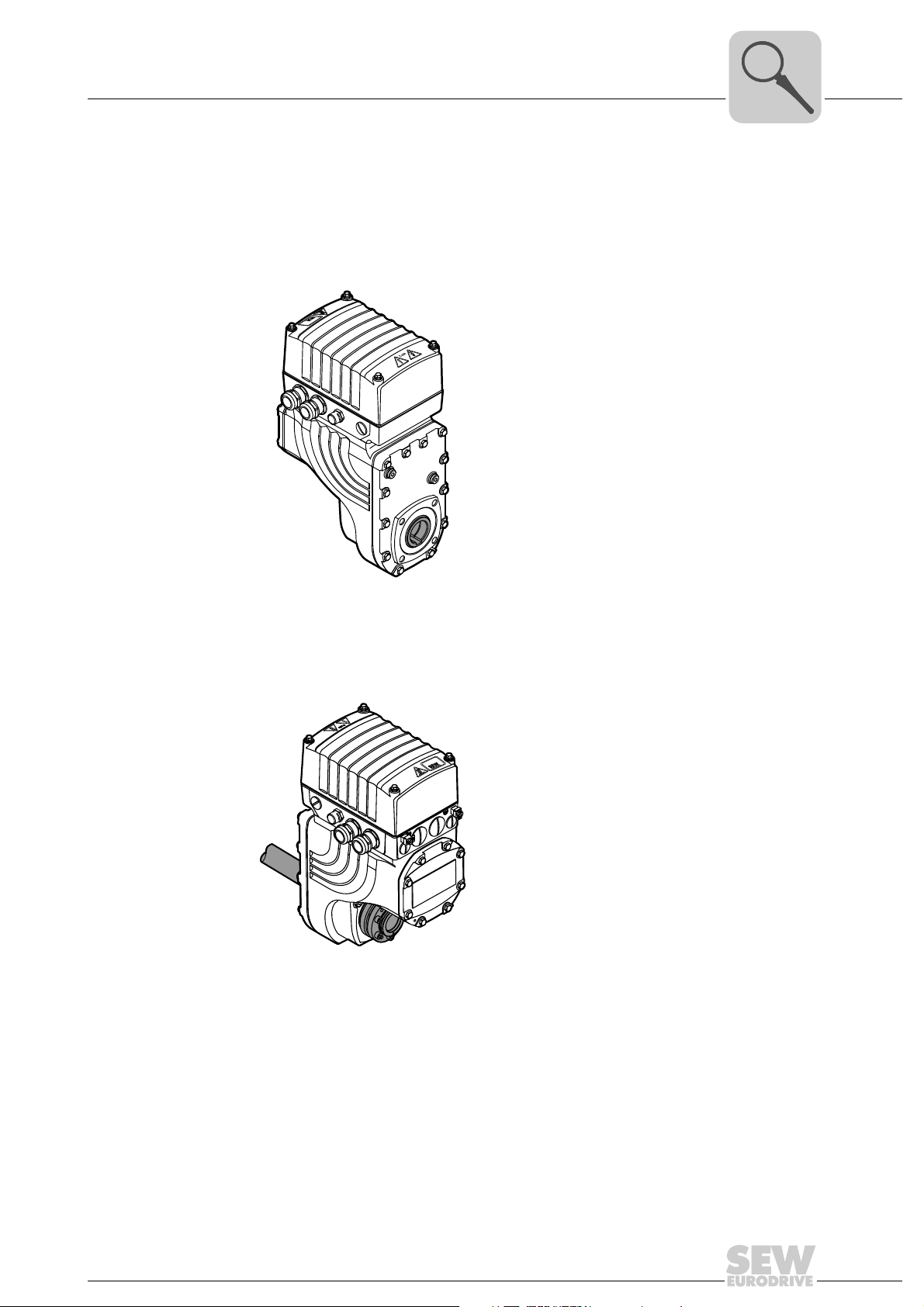

3 Unit structure..................................................................................................... 12

3.1 MOVIGEAR

3.2 Shaft types .............................................................................................. 13

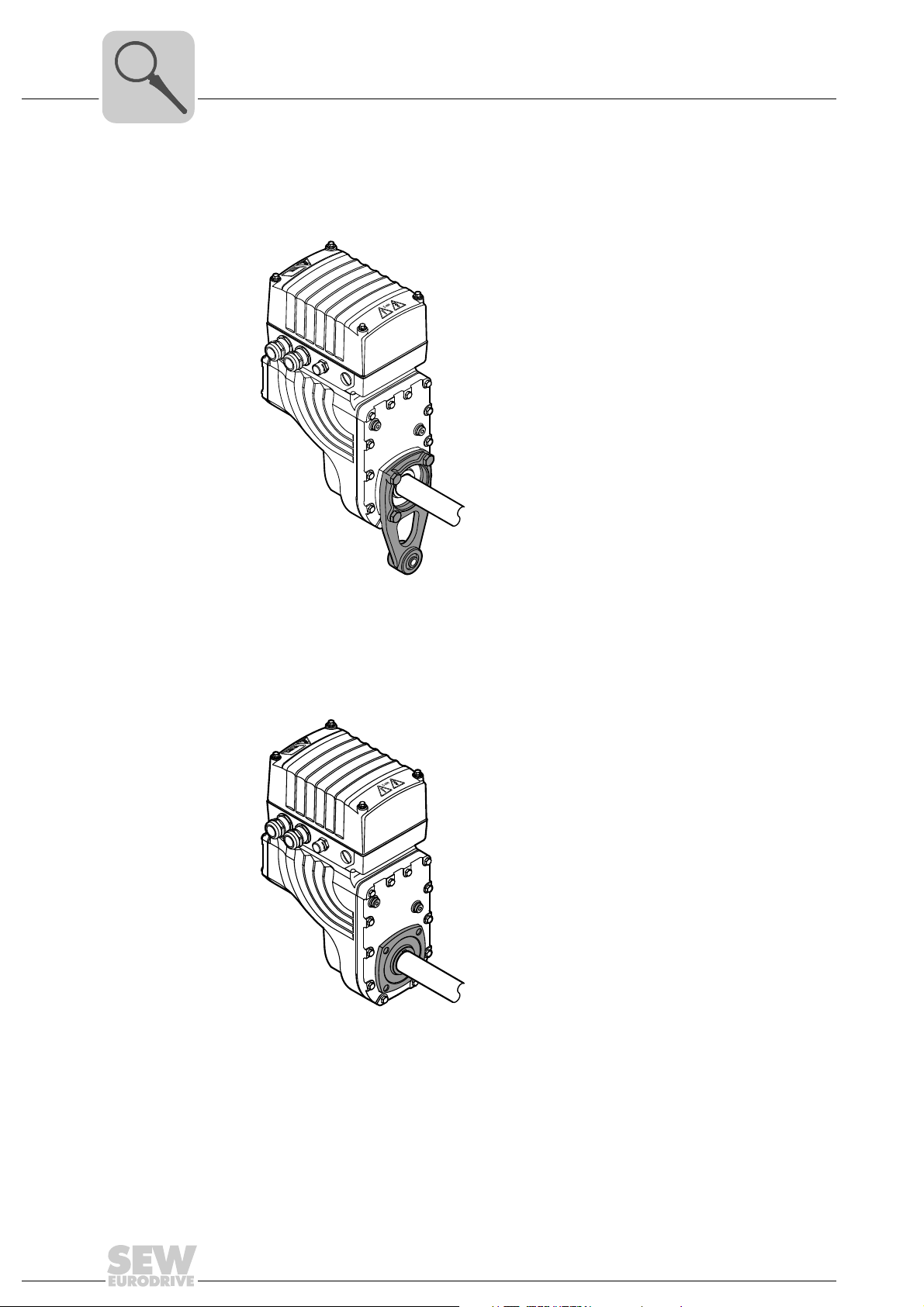

3.3 Housing mounting ................................................................................... 14

3.4 Cable entry positions ............................................................................. 15

3.5 Example nameplate and type designation of the drive unit ................... 16

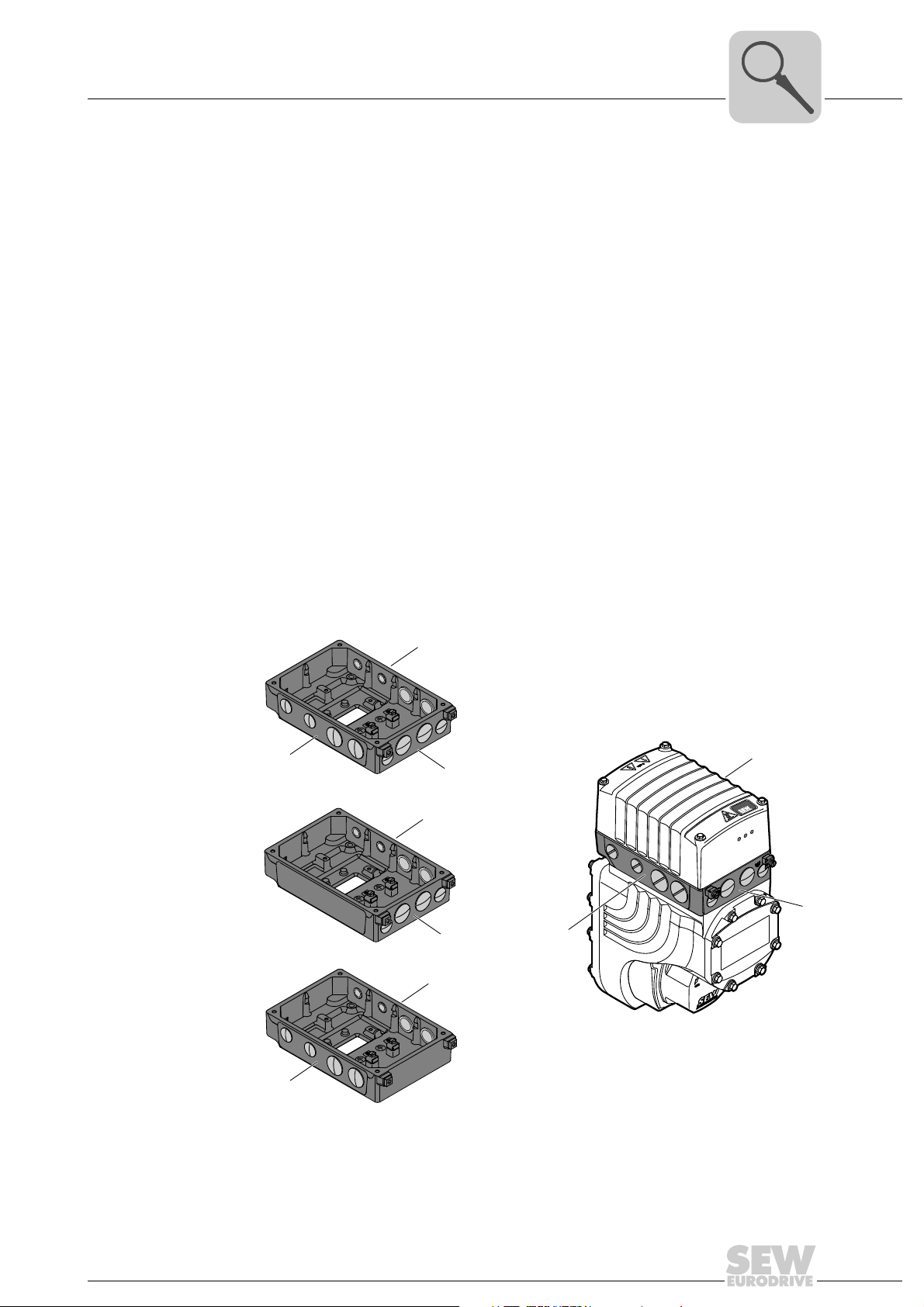

3.6 Electronics ............................................................................................ 17

3.7 Application options .............................................................................. 19

3.8 Example nameplate and type designation of electronics ...................... 21

3.9 MOVIGEAR

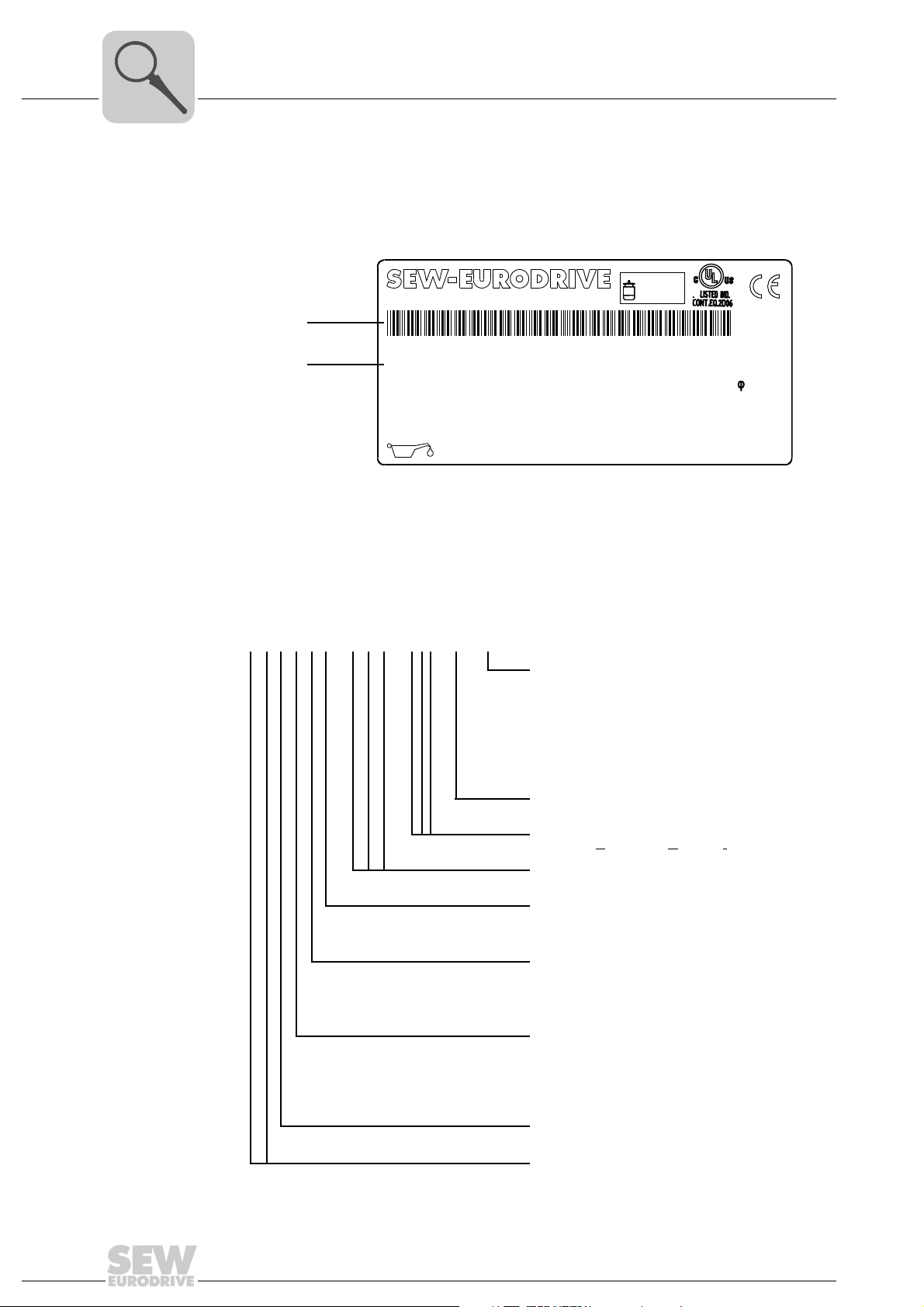

4 Mechanical installation..................................................................................... 25

4.1 Installation notes ................................................................................... 25

4.2 Required tools and resources ................................................................... 25

4.3 Installation requirements........................................................................... 26

4.4 Setting up the drive unit ............................................................................ 27

4.5 Application options .............................................................................. 31

4.6 Shaft-mounted gear unit with keyway .................................................... 34

4.7 Shaft mounted gear unit with TorqLOC

(customer shaft without contact shoulder) ............................................. 39

4.8 Shaft mounted gear unit with TorqLOC

(customer shaft with contact shoulder) .................................................. 45

4.9 Shaft-mounted gear unit with TorqLOC

Removal, cleaning, lubrication ............................................................... 51

4.10 Installing the protective cover ................................................................ 53

4.11 Torque arm ........................................................................................... 55

4.12 Tightening torques ............................................................................... 56

4.13 Drive units with optional version for use in wet areas ............................ 59

®

drive unit ........................................................................ 12

®

with optional design for wet areas (/WA option) ............. 23

®

®

®

–

Operating Instructions – MOVIGEAR® SNI-B

3

Contents

5 Electrical installation ........................................................................................ 66

5.1 Installation planning considering EMC aspects .................................... 66

5.2 Installation instructions.............................................................................. 68

5.3 Installation topology (example) ............................................................. 73

5.4 Terminal assignment .............................................................................. 74

5.5 Connecting MOVIGEAR

5.6 Cable routing and shielding .................................................................... 77

5.7 EMC cable glands ................................................................................. 82

5.8 Required power leads .......................................................................... 83

5.9 Plug connectors .................................................................................... 85

5.10 Assignment of optional plug connectors ............................................... 90

5.11 Application options .............................................................................. 99

6 Startup.............................................................................................................. 101

6.1 Startup notes ....................................................................................... 101

6.2 Prerequisties for startup ...................................................................... 102

6.3 Description of DIP switches ................................................................ 103

6.4 Startup procedure .............................................................................. 105

6.5 Starting up the GIO13B application option ........................................ 107

6.6 Disabling DynaStop

7 Operation of MOVITOOLS

7.1 About MOVITOOLS

7.2 First steps .............................................................................................. 111

7.3 Connection mode.................................................................................... 114

7.4 Executing functions of the units .............................................................. 116

8 Parameters ................................................................................................... 118

8.1 Overview of parameters of the command PCB ..................................... 118

8.2 Overview of parameters for application options ................................... 120

8.3 Overview of power section parameters ................................................. 122

8.4 Description of command PCB parameters.............................................. 135

8.5 Description of application option parameters ........................................ 138

8.6 Description of power section parameters................................................ 141

®

drive units ..................................................... 76

®

for startup purposes ........................................... 110

®

MotionStudio ................................................ 111

®

MotionStudio ........................................................ 111

9 Operation ..................................................................................................... 171

9.1 Local mode (only in conjunction with optional plug connector) ............. 171

9.2 DynaStop

9.3 Deactivating DynaStop

®

............................................................................................ 173

®

..................................................................... 173

10 Service ............................................................................................................. 176

10.1 Malfunctions of the mechanical MOVIGEAR

®

drive ............................. 176

10.2 Evaluating error messages ................................................................. 177

10.3 Switch-off responses ............................................................................ 178

10.4 Reset of error messages .................................................................. 178

10.5 Description of status and operating displays ...................................... 179

10.6 Error table ........................................................................................... 182

10.7 Unit replacement ................................................................................. 184

10.8 SEW-EURODRIVE Service ................................................................... 186

4

Operating Instructions – MOVIGEAR® SNI-B

Contents

10.9 Shutdown ............................................................................................ 187

10.10 Storage ................................................................................................... 187

10.11 Extended storage .................................................................................... 188

10.12 Disposal ............................................................................................... 190

11 Inspection and maintenance.......................................................................... 191

11.1 Determining the operating hours ......................................................... 191

11.2 Inspection and maintenance intervals .................................................. 192

11.3 Lubrication change intervals ................................................................ 193

11.4 Inspection and maintenance work .......................................................... 194

12 Technical data and dimension sheets .......................................................... 202

12.1 Technical data ..................................................................................... 202

12.2 Technical data of application options ................................................ 205

12.3 Integrated BW1 braking resistor ........................................................... 207

12.4 DynaStop

12.5 Torque characteristics ........................................................................... 209

12.6 Surface protection ................................................................................ 217

12.7 Variant for use in wet areas ................................................................. 219

12.8 Screw fittings........................................................................................... 223

12.9 Connection cables .......................................................................... 224

12.10 Mounting positions ............................................................................... 226

12.11 Lubricants ............................................................................................ 228

12.12 Design notes for gear units with hollow shaft and key ......................... 231

12.13 Dimension drawings ........................................................................... 233

®

deceleration torque ............................................................ 208

13 EC declaration of conformity ....................................................................... 242

14 Address list...................................................................................................... 243

Index................................................................................................................. 255

Operating Instructions – MOVIGEAR® SNI-B

5

1

General information

How to use this documentation

1 General information

1.1 How to use this documentation

The documentation is an integral part of the product and contains important information

on operation and service. The documentation is written for all employees who assemble,

install, start up, and service this product.

The documentation must be accessible and legible. Make sure that persons responsible

for the system and its operation, as well as persons who work independently on the unit,

have read through the documentation carefully and understood it. If you are unclear

about any of the information in this documentation, or if you require further information,

contact SEW-EURODRIVE.

1.2 Structure of the safety notes

1.2.1 Meaning of signal words

The following table shows the graduation and meaning of the signal words for safety

notes, warnings regarding potential risks of damage to property, and other notes.

Signal word Meaning Consequences if disregarded

DANGER! Imminent hazard Severe or fatal injuries

WARNING! Possible dangerous situation Severe or fatal injuries

CAUTION! Possible dangerous situation Minor injuries

NOTICE Possible damage to property Damage to the drive system or its envi-

INFORMATION Useful information or tip: Simpli-

fies handling of the drive system.

1.2.2 Design of the section-related safety notes

Section-related safety notes do not apply to a specific action, but to several actions pertaining to one subject. The symbols used either indicate a general hazard or a specific

hazard.

This is the formal structure of a safety note for a specific section:

SIGNAL WORD!

Type and source of danger.

Possible consequence(s) if disregarded.

• Measure(s) to prevent the danger.

ronment

1.2.3 Design of the embedded safety notes

Embedded safety notes are directly integrated into the instructions just before the description of the dangerous action.

This is the formal structure of an embedded safety note:

• SIGNAL WORD! Type and source of hazard.

Possible consequence(s) if disregarded.

– Measure(s) to prevent the hazard.

6

Operating Instructions – MOVIGEAR® SNI-B

1.3 Rights to claim under warranty

A requirement of fault-free operation and fulfillment of any rights to claim under limited

warranty is that you adhere to the information in the documentation. Therefore read the

documentation before you start working with the unit.

1.4 Exclusion of liability

You must comply with the information contained in this documentation to ensure safe

operation and to achieve the specified product characteristics and performance features. SEW-EURODRIVE assumes no liability for injury to persons or damage to equipment or property resulting from non-observance of these operating instructions. In such

cases, any liability for defects is excluded.

1.5 Copyright

© 2013 SEW-EURODRIVE. All rights reserved.

Unauthorized duplication, modification, distribution or any other use of the whole or any

part of this documentation is strictly prohibited.

General information

Rights to claim under warranty

1

1.6 Product names and trademarks

All product names in this documentation are trademarks or registered trademarks of

their respective titleholders.

Operating Instructions – MOVIGEAR® SNI-B

7

2

Safety notes

General information

2 Safety notes

2.1 General information

The following basic safety notes must be read carefully to prevent injury to persons and

damage to property. The operator must ensure that the basic safety notes are read and

adhered to. Ensure that persons responsible for the system and its operation, as well as

persons who work independently on the unit, have read through the operating

instructions carefully and understood them. If you are unclear about any of the information in this documentation, or if you require further information, please contact SEWEURODRIVE.

Never install damaged products or take them into operation. Submit a complaint to the

shipping company immediately in the event of damage.

During operation, MOVIGEAR

parts as well as hot surfaces, depending on their degree of protection.

Removing covers without authorization, improper use as well as incorrect installation or

operation may result in severe injuries to persons or damage to property.

®

drive units can have live, bare and movable or rotating

Refer to the documentation for additional information.

2.2 Target group

Only qualified electricians are authorized to install, start up or service the units or

correct unit faults (observing IEC 60364 or CENELEC HD 384 or DIN VDE 0100 and

IEC 60664 or DIN VDE 0110 as well as national accident prevention guidelines).

Qualified electricians in the context of these basic safety notes are all persons familiar

with installation, assembly, startup and operation of the product who possess the

necessary qualifications.

All persons involved in any other work, such as transportation, storage, operation and

disposal, must be trained appropriately.

8

Operating Instructions – MOVIGEAR® SNI-B

2.3 Designated use

MOVIGEAR® drive units are components intended for installation in electrical systems

or machines.

In case of installation in machines, taking the MOVIGEAR

(i.e. start of designated operation) is prohibited until it is determined that the machine

meets the requirements stipulated in EC Directive 2006/42/EC (Machinery Directive).

Startup (i.e. the start of designated use) is only permitted under observance of EMC

directive 2004/108/EC (EMC Directive).

MOVIGEAR

2006/95/EC. The standards given in the declaration of conformity are applied to the

MOVIGEAR

You must observe the technical data and information on the connection requirements

as provided on the nameplate and in the documentation.

2.3.1 Safety functions

MOVIGEAR

described and expressly permitted.

Safety notes

Designated use

®

drive units into operation

®

drive units comply with the regulations of the Low Voltage Directive

®

drive units.

®

drive units may not perform safety functions unless these functions are

2

2.3.2 Lifting applications

MOVIGEAR

MOVIGEAR

performed a risk assessment. Refer to the relevant information in the documentation.

®

drive units must not be used for lifting applications.

®

drive units may only be used for inclining tracks after the operator has

2.4 Transportation, storage

You must observe the notes in the documentation regarding transportation, storage and

proper handling. Use suitable, sufficiently rated handling equipment (e.g. rope guides)

if required. Do not attach any additional loads. Observe climatic conditions in accordance with the documentation.

The following figure shows the eyebolt of MOVIGEAR

®

drive units:

Operating Instructions – MOVIGEAR® SNI-B

9007202025361803

9

2

Safety notes

Installation

2.5 Installation

2.6 Electrical connection

The units must be installed and cooled according to the regulations and specifications

in the corresponding documentation.

®

Protect the MOVIGEAR

The following applications are prohibited unless explicitly permitted:

• Use in potentially explosive atmospheres.

• Use in areas exposed to harmful oils, acids, gases, vapors, dust, radiation, etc.

• Use in non-stationary applications that are subject to mechanical vibration and shock

loads as stated in the documentation for MOVIGEAR

Important: MOVIGEAR

trude into footways.

Working on live parts of MOVIGEAR® drive units is not permitted.

The drive is operated as a generator due to the kinetic energy of the system/machine.

Secure the output shaft against rotation before opening the wiring compartment.

Electrical installation must be carried out in compliance with pertinent regulations (e.g.

cable cross sections, fusing, protective conductor connection). For any additional information, refer to the applicable documentation.

drive units from improper strain.

®

drive units.

®

drive units and corresponding mount-on parts must not pro-

You find notes on EMC-compliant installation, such as shielding, grounding, arrangement of filters and routing of lines, in the documentation of the MOVIGEAR

The manufacturer of the system or machine is responsible for maintaining the limits established by EMC legislation.

Protective measures and protection devices must comply with the regulations in force

(e.g. EN 60204-1 or EN 61800-5-1).

2.7 Safe disconnection

MOVIGEAR® drive units meet all requirements for safe disconnection of power and

electronics connections in accordance with EN 61800-5-1. All connected circuits must

also satisfy the requirements for safe disconnection to ensure reliable isolation.

®

drive units.

10

Operating Instructions – MOVIGEAR® SNI-B

2.8 Operation

5 minutes

Safety notes

Operation

Systems with integrated MOVIGEAR® drive units must be equipped with additional

monitoring and protection devices according to the applicable safety guidelines, such as

the law governing technical equipment, accident prevention regulations, etc. Additional

protective measures may be necessary for applications with increased potential risk.

Changes to MOVIGEAR

®

drive units using the operating software are permitted.

WARNING

Do not touch live components and power connections immediately after separation of

the MOVIGEAR

still be charged.

Severe or fatal injuries.

• Wait at least for 5 minutes after the supply voltage has been switched off.

®

drive units from the supply voltage because some capacitors might

2

The connection boxes must be closed and screwed on before the supply voltages are

connected to MOVIGEAR

The unit may still be live and connected to the power supply even if the operation LEDs

and other display elements are no longer illuminated.

Mechanical blocking or internal safety functions of the unit can cause a motor standstill.

Eliminating the cause of the problem or performing a reset may result in the drive restarting automatically. If this is not permitted for the driven machine for safety reasons,

disconnect the unit from the supply system before correcting the fault.

Caution: Danger of burns: The surface temperatures of MOVIGEAR

more than 60 °C during operation.

®

drive units.

®

drive units can be

Operating Instructions – MOVIGEAR® SNI-B

11

3

MGF..4/XT

[1]

[2]

[3]

[3]

MGF..4

MOVIGEAR

®

B

MOVIGEAR

®

B

M

O

V

I

G

E

A

R

®

®

B

MGF..2

[4]

[5]

[5]

[5]

[1]

[2]

[4]

[3]

[4]

[1]

[2]

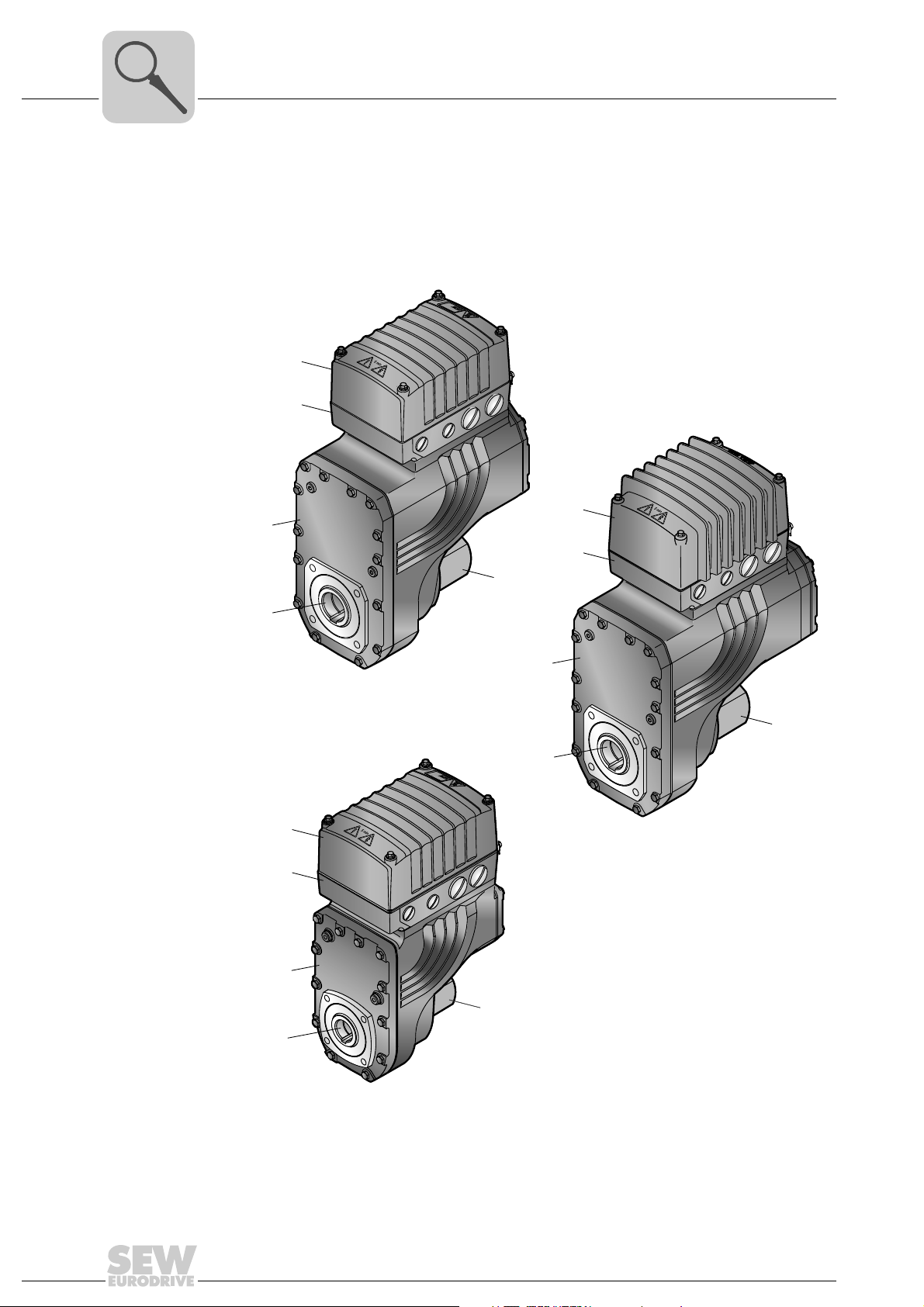

Unit structure

MOVIGEAR® drive unit

3 Unit structure

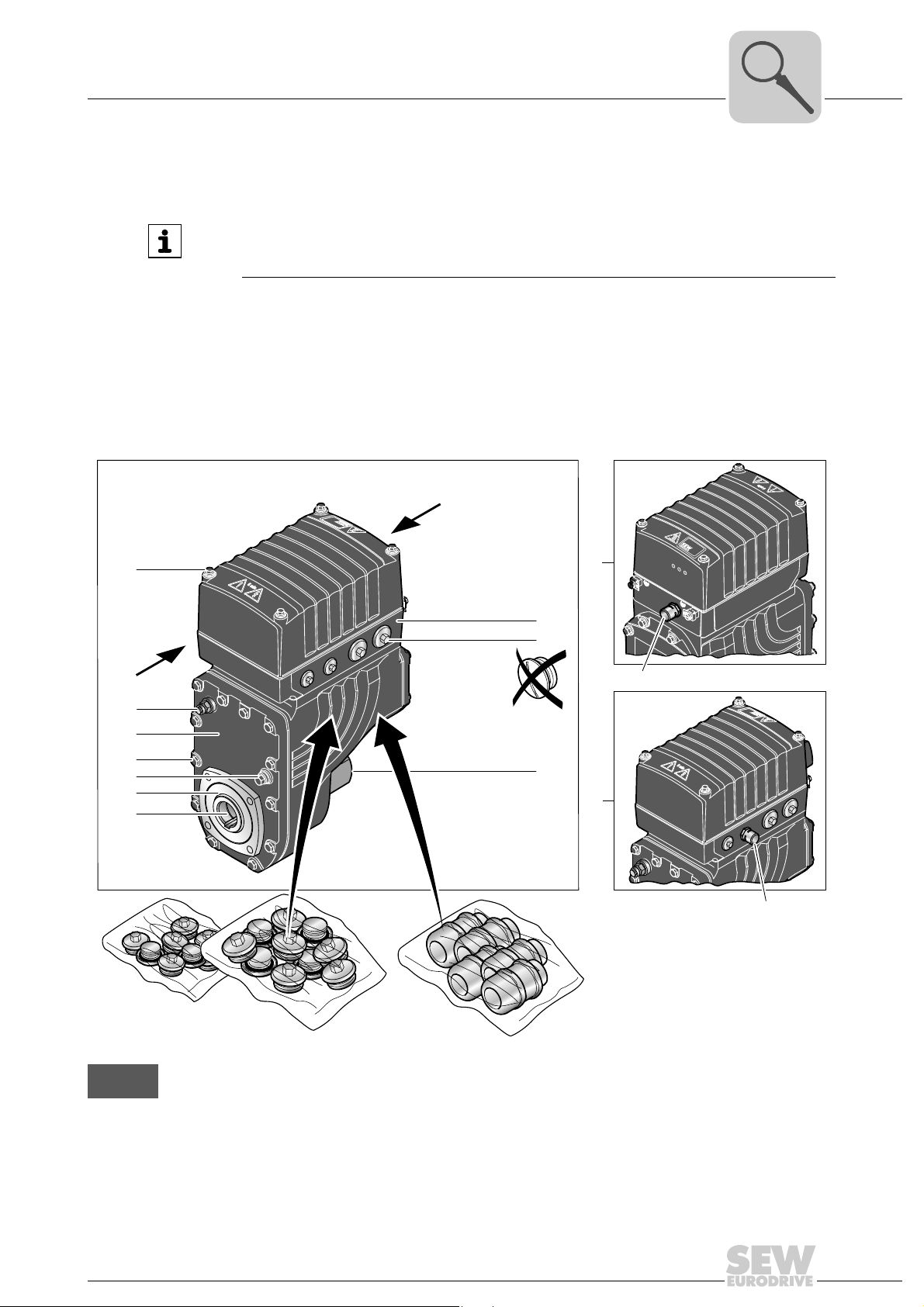

3.1 MOVIGEAR® drive unit

MOVIGEAR® drive units are made up of 3 core components: gear unit, motor and drive

electronics. These 3 core components are included in one die-cast aluminum housing

(see following figure).

36028799382850955

[1] MOVIGEAR® electronics cover

[2] Connection ring for cable glands

[3] Inspection cover

[4] Output shaft variant (pictured here: hollow shaft with keyway)

12

[5] Optional cover

Operating Instructions – MOVIGEAR® SNI-B

3.2 Shaft types

3.2.1 MOVIGEAR

®

Unit structure

MOVIGEAR® is available with the following shaft types:

with hollow shaft and keyway (MGFA..)

The following figure shows a MOVIGEAR

®

unit with hollow shaft and keyway:

Shaft types

3

3.2.2 MOVIGEAR

18014401200302603

®

with TorqLOC® hollow shaft mounting system (MGFT..)

The following figure shows a MOVIGEAR

system

18014401200304523

®

unit with TorqLOC® hollow shaft mounting

Operating Instructions – MOVIGEAR® SNI-B

13

3

Unit structure

Housing mounting

3.3 Housing mounting

3.3.1 Torque arm (MGF.T)

The following figure shows the torque arm for MGF.T:

3.3.2 Housing with threads (MGF.S)

The following figure shows the housing type with threads for mounting a torque arm.

This type does not include a centering shoulder, which means it is not suitable for direct

installation to the machine:

18014401200308363

18014401200306443

14

Operating Instructions – MOVIGEAR® SNI-B

3.4 Cable entry positions

The following cable entries are possible for MOVIGEAR® drive units:

• Position X + 2

– X: 2 x M25 x 1.5 + 2 x M16 x 1.5

– 2: 2 x M25 x 1.5 + 2 x M16 x 1.5

• Position X + 2 + 3

– X: 2 x M25 x 1.5 + 2 x M16 x 1.5

– 2: 2 x M25 x 1.5 + 2 x M16 x 1.5

– 3: 2 x M25 x 1.5 + 2 x M16 x 1.5

• Position X + 3

– X: 2 x M25 x 1.5 + 2 x M16 x 1.5

– 3: 2 x M25 x 1.5 + 2 x M16 x 1.5

• Position 2 + 3

– 2: 2 x M25 x 1.5 + 2 x M16 x 1.5

Unit structure

Cable entry positions

3

3.4.1 Overview

– 3: 2 x M25 x 1.5 + 2 x M16 x 1.5

The following figure shows the possible cable entries:

2

X

3

2

3

X

2

MOVIGEAR

NET

2

®

B

DRIVE

RUN

3

X

Operating Instructions – MOVIGEAR® SNI-B

18014401200378763

15

3

76646 Bruchsal/Germany

Nm

°C

n

R

U

N

f

N

Nm

n

A

A

M

A

M

a pk

i

Made in Germany

IM

kg

cos

IP

r/min

Hz

V

13356887

MGFAT2-DSM-SNI-B/DSP

01.1233697403.0001.08

5,4...53,7

37,24

M1,M2,M4,M5,M6 50...60

380...500

65

0,99

1,52

1/10

16.000

CLP HC 220 Synth.Öl/0,55l

0 ... +40

[1]

[2]

3~ EN61800

TENV

M.L.

149

220

eff%

86,3

IE4

Unit structure

Example nameplate and type designation of the drive unit

3.5 Example nameplate and type designation of the drive unit

3.5.1 Nameplate

The following figure gives an example of a MOVIGEAR

of the type designation, refer to chapter "Type designation".

[1] Unique serial number

[2] The bar code on the nameplate (code 39) according to ISO/IEC 16388 represents the unique

serial number (with a period as separator).

®

nameplate. For the structure

18014400877661323

3.5.2 Type designation

16

The following table shows the type designation of MOVIGEAR

MGFAS2–DSM–SNI–B / DSP

MOVIGEAR® option

Electrodynamic

=

DSP

deceleration function DynaStop

=

Extended control range

=

Increased torque

=

Plug connectors

=

Version for use in wet areas

®

version

®

installation technology

ingle Line Network Installation

==Torque class 200 Nm

Torque class 400 Nm

Drive with torque arm

Housing with threads for

mounting a torque arm

(hollow shaft with key)

To rq L OC

tem

Operating Instructions – MOVIGEAR® SNI-B

ECR

XT

IV

WA

MOVIGEAR

MOVIGEAR

SNI = S

Motor type

Frame size

2

4

Housing mounting

T

S ==

Shaft type

A T= =Shaft-mounted gear unit

Gear unit type

F = Parallel-shaft helical gear units

Product line

MG = MOVIGEAR

®

:

®

®

hollow shaft mounting sys-

®

3.6 Electronics

[1]

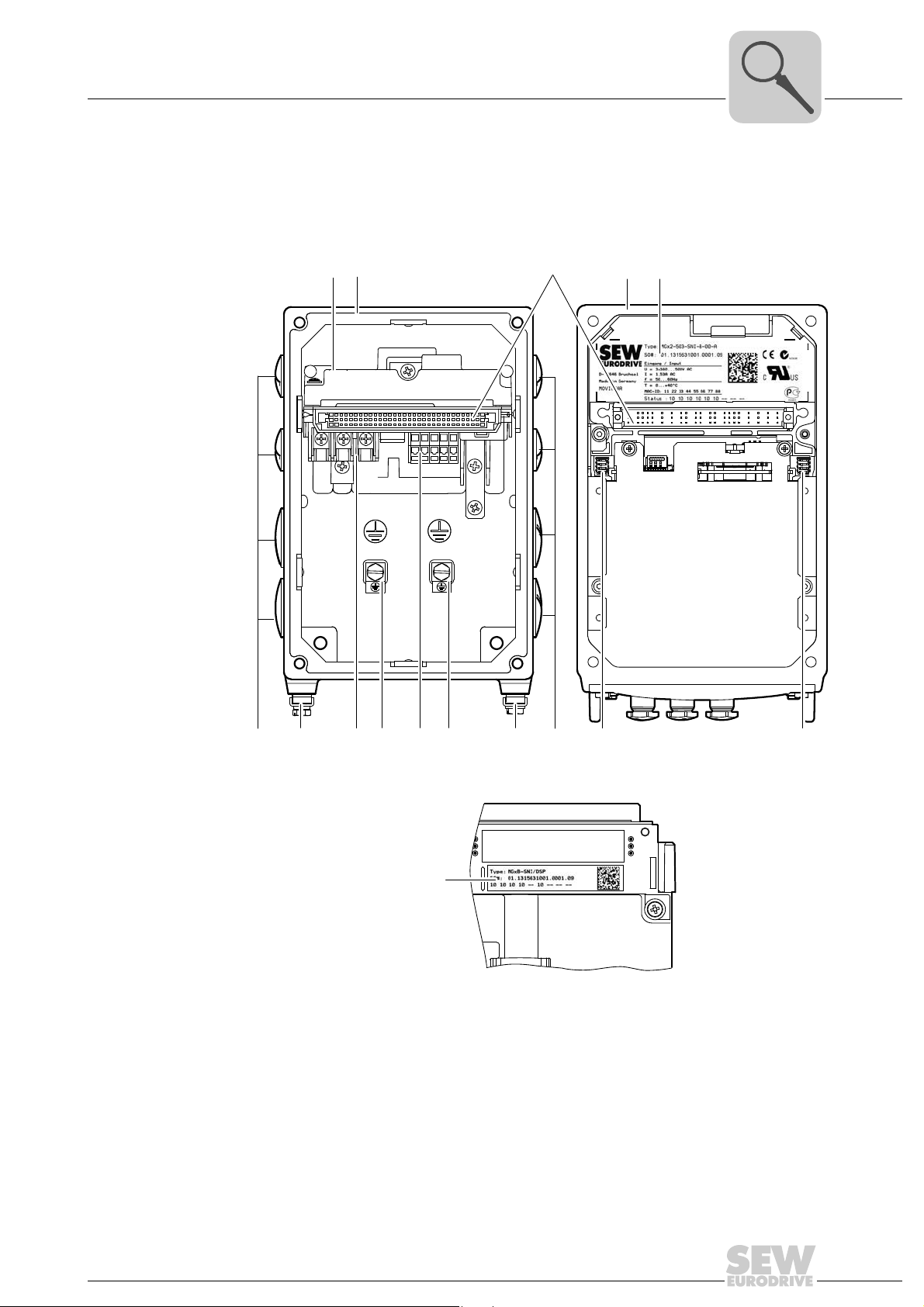

3.6.1 MOVIGEAR® electronics cover (inside) and connection box

The following figure shows the connection box and the bottom side of the MOVIGEAR

electronics cover:

Unit structure

Electronics

3

®

[1]

[2]

[3]

[4] [5]

[7] [7][7]

[6]

[1] Nameplate of drive unit, see following detailed view

[2] Connection ring

[3] Plug connector connection unit for MOVIGEAR

[4] MOVIGEAR

[5] Electronics cover nameplate

[6] Cable glands

[7] Screws for PE connection

[8] Line connection L1, L2, L3

[9] Electronics terminal strips

[10] DIP switches S2/1 – S2/4

[11] DIP switches S1/1 – S1/4

[7]

[8] [10] [11]

®

electronics cover

[9]

[6]

®

electronics cover

2389525515

2584370315

Operating Instructions – MOVIGEAR® SNI-B

17

3

NET

RUN

DRIVE

NET

RUN

DRIVE

[1]

[1] [2] [3] [4]

AB

Unit structure

Electronics

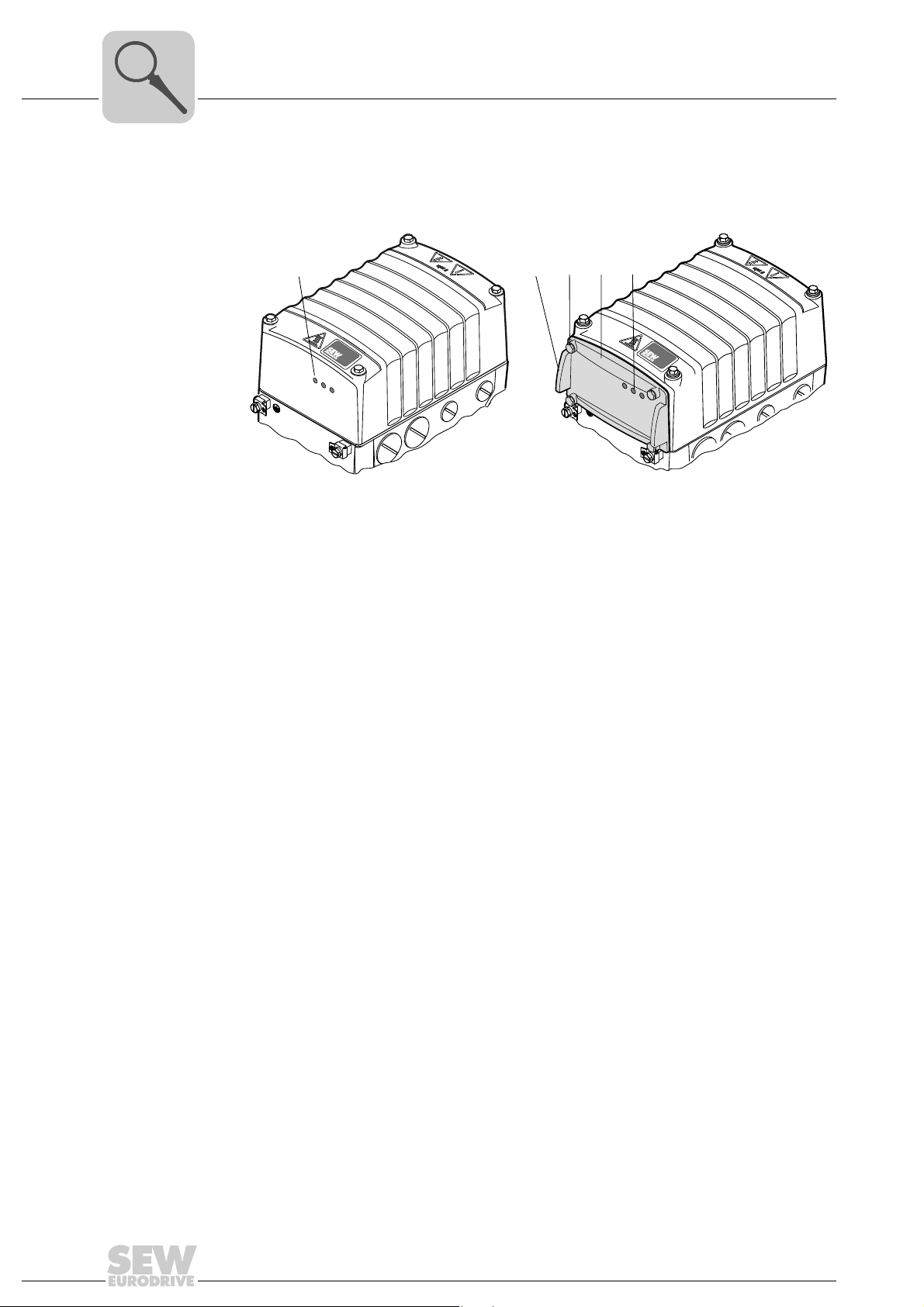

3.6.2 Electronics cover (outside)

The following figure shows the possible variants of the electronic cover using one frame

size as an example:

A Electronics cover without application slot B Electronics cover with application slot

[1] LED displays [1] Assembly/disassembly handle

18014400877430923

[2] Retaining screws (4x)

[3] Application cover

[4] LED displays

18

Operating Instructions – MOVIGEAR® SNI-B

3.7 Application options

[1] [2] [3]

NET

RUN

DRIVE

X4

X3

X2

X1

[1]

3.7.1 GIO12B application option

The following figure shows the GIO12B application option:

Unit structure

Application options

3

[1] Assembly/disassembly handle

[2] Retaining screws (4x)

[3] M12 plug connector for digital I/Os

The following figure shows the position of the GIO12B nameplate:

[1] Nameplate

9007201622841227

18014401210968331

Operating Instructions – MOVIGEAR® SNI-B

19

3

NE

T

RUN

DRIVE

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

S1

S2

S3

ON

1234

[1]

Unit structure

Application options

3.7.2 GIO13B application option

The following figure shows the GIO13B application option:

[1] [2] [3]

X4

X3

X2

X1

9007201839769867

[1] Assembly/disassembly handle

[2] Retaining screws (4x)

[3] M12 plug connector for digital/analog I/Os

The following figure shows the DIP switches S1 to S3 of the GIO13B application option:

18014401245670283

[1] Nameplate

20

Operating Instructions – MOVIGEAR® SNI-B

Unit structure

[1]

[3]

[2]

Example nameplate and type designation of electronics

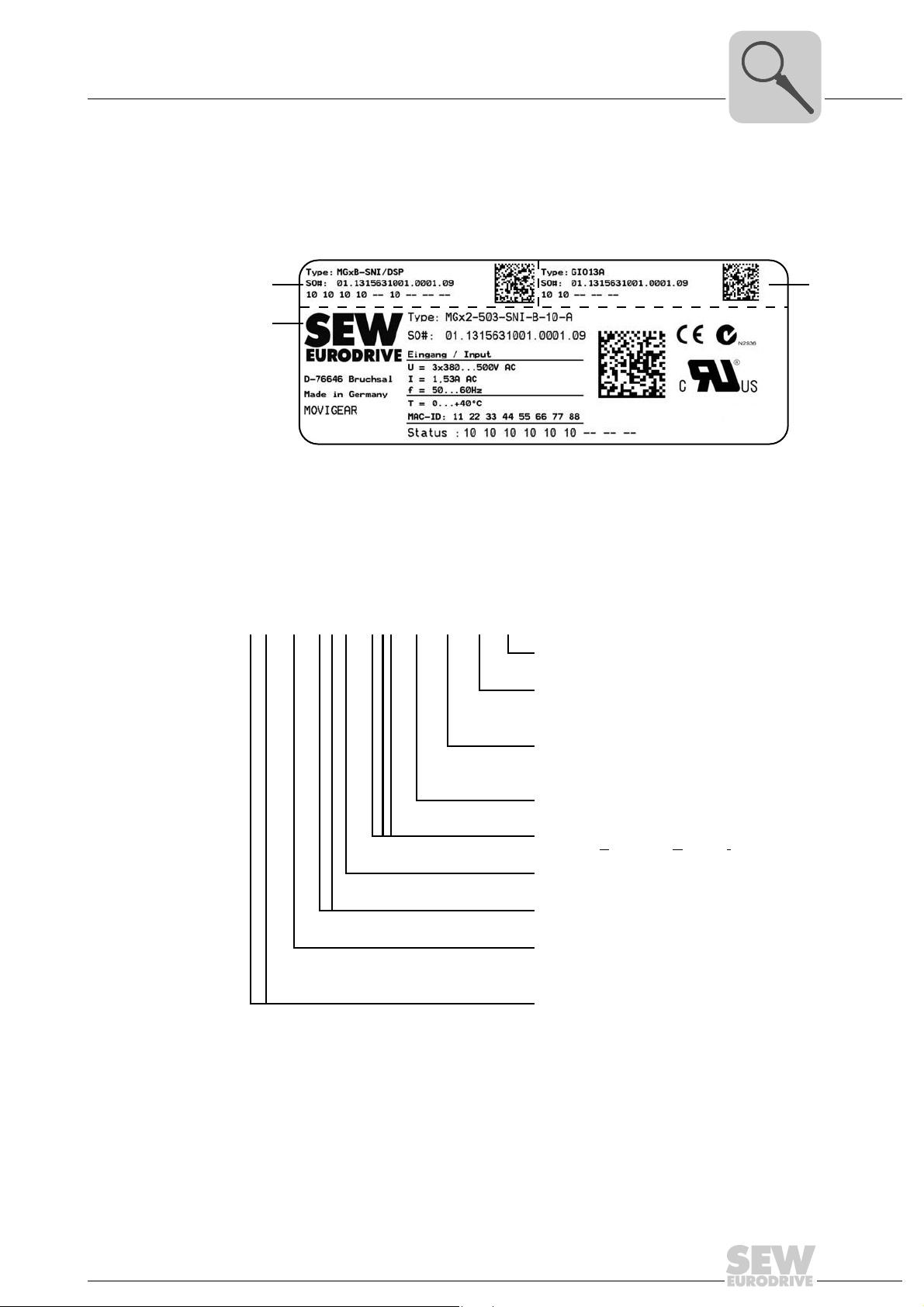

3.8 Example nameplate and type designation of electronics

3.8.1 Nameplate

®

The following figure gives an example of a MOVIGEAR

of the type designation, refer to chapter "Type designation".

[1] Nameplate of connection unit

[2] Nameplate of application option

[3] Electronics cover nameplate

nameplate. For the structure

3

9007201839835019

3.8.2 Type designation of electronic cover

The following table shows the type designation of the electronics cover:

M Gx 4–5 0 3–SNI–B – 10 – A / XT

1)

MGF..4/XT has a different connection voltage range, see chapter "Technical data"

Electronics cover option

XT = Increased torque

Electronics cover variant

A = With application slot

0 = Without application

Design

1011==Die-cast design (standard)

Die-cast design (wet areas)

MOVIGEAR

MOVIGEAR

SNI = S

Connection type

3 = 3-phase

Connection voltage

50 = AC 380 – 500 V

Size

2 4==Torque class 200 Nm

Product line

MG = MOVIGEAR

®

version

®

installation technology

ingle Line Network Installation

1)

Torque class 400 Nm

®

Operating Instructions – MOVIGEAR® SNI-B

21

3

Unit structure

Example nameplate and type designation of electronics

3.8.3 Type designation of connection unit

The following table shows the type designation of the connection unit:

M G x B – SNI / DSP

Connection unit option

DSP = Electrodynamic

deceleration function DynaStop

MOVIGEAR

SNI = S

MOVIGEAR

®

installation technology

ingle Line Network Installation

®

version

®

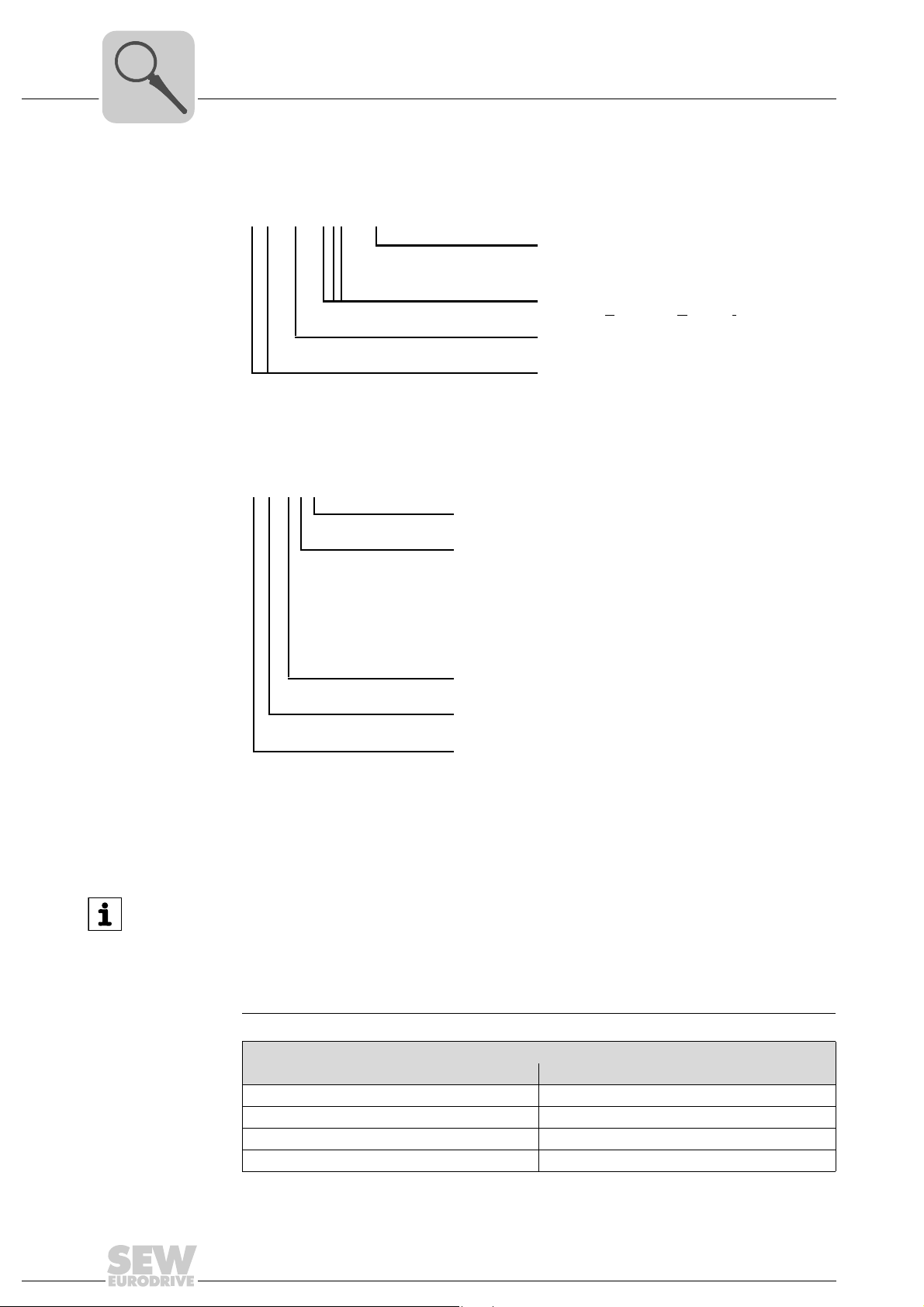

3.8.4 Type designation of application options

The following table shows the type designation of application options:

G IO 1 2 B

Note on the version of the application option

Product line

MG = MOVIGEAR

Version

Design

2 = 4 digital inputs + 2 digital outputs

3 = 4 digital inputs

(2 inputs can be used as primary frequency input)

+ 1 digital output

+ 1 analog input

+ 1 analog output

Version

Functionality

IO = Digital inputs/outputs

Product line

G = Option for MOVIGEAR

®

/ DRC

®

22

INFORMATION

For electronics covers in die-cast design, you can only use application options

GIO12B and GIO13B. For electronics covers in sand-cast design, you can only use

application options GIO12A and GIO13A .

You can identify units with die-cast housing by means of the type designation of the

electronics cover.

Application options

Design Part number

GIO12A application option On request

GIO13A application option On request

GIO12B application option Part number 1 823 801 7

GIO13B application option Part number 1 822 652 3

Operating Instructions – MOVIGEAR® SNI-B

Unit structure

M

O

V

I

G

E

A

R

®

B

NET

RUN

DRIVE

MOVIGEAR

®

B

M

O

V

I

G

E

A

R

®

B

MOVIGEAR® with optional design for wet areas (/WA option)

3.9 MOVIGEAR® with optional design for wet areas (/WA option)

INFORMATION

Slight color differences are possible in the HP200 surface finish due to the treatment

process (individual treatment of the components).

®

The following figure shows the additional features of ® drive units with the optional ver-

sion for applications in wet areas (/WA option):

• The variant for use in wet areas is delivered as standard with screw plugs made of

stainless steel.

• Plastic screw plugs can be chosen instead. To achieve degree of protection IP66 and

compatibility with cleaning agents, you have to replace the plastic screw plugs by

suitable screw fittings made of stainless steel.

3

A

[A1]

[A2]

[A3]

[A4]

[A5]

[A6]

[A7]

X

[A 2]

Y

Y

[A8]

[A9]

[A12]

[A10]

X

[A13]

B

[B 1]

In this publication, all illustrations depicting the version for use in wet areas are displayed with a shading

(= HP200 surface protection).

Operating Instructions – MOVIGEAR® SNI-B

[B 2]

8796664203

23

3

A Scope of delivery

[A1] Mounting screws for cover made of stainless steel

[A2] Breather valve mounted and activated according to mounting position, see chapter "Technical data

[A3] HP200 surface protection, see chapter "Technical data and dimension sheets"

[A4] Mounting screws for gear unit housing made of stainless steel

[A5] Oil screw plug made of stainless steel (hexagon)

[A6] Fluorocarbon rubber oil seal

[A7] Output shaft made of stainless steel

[A8] Connection ring only possible with cable outlet pointing "downward" or "on the side":

[A9] Standard:

[A10] Additional cover opposite the output side

[A12] Factory-installed pressure compensation fitting (M16) with mounting positions M5, M6

[A13] Factory-installed pressure compensation fitting (M16) with mounting position M1, M2, M3*, M4

Unit structure

MOVIGEAR® with optional design for wet areas (/WA option)

and dimension sheets"

– In connection with mounting positions M1, M2, M3*: 2 + 3, 2 + X, X + 3, 2 + X + 3

– In connection with mounting position M4: 2 + X

– In connection with mounting position M5: X + 3

– In connection with mounting position M6: 2 + 3

Optional:

Screw plugs made of stainless steel Plastic screw plugs. To achieve degree of pro-

tection IP66 and compatibility with cleaning

agents, you have to replace the plastic screw

plugs by suitable screw fittings made of stainless

steel.

Optional plug connectors (see chapter "Electrical installation") are available in connection with the

design for wet areas.

B Required screw fittings

[B1] Screw plugs made of stainless steel, if required

[B2] Cable glands made of stainless steel

* = Mounting position M3 only possible after consultation with SEW-EURODRIVE

The required screw fittings can be ordered from SEW-EURODRIVE. For an overview, refer to chapter "Optional metal screw fittings".

1)

Make sure to select plug seals that are compatible with the used cleaning agents

1)

1)

24

Operating Instructions – MOVIGEAR® SNI-B

4 Mechanical installation

4.1 Installation notes

INFORMATION

Adhere to the safety notes during installation.

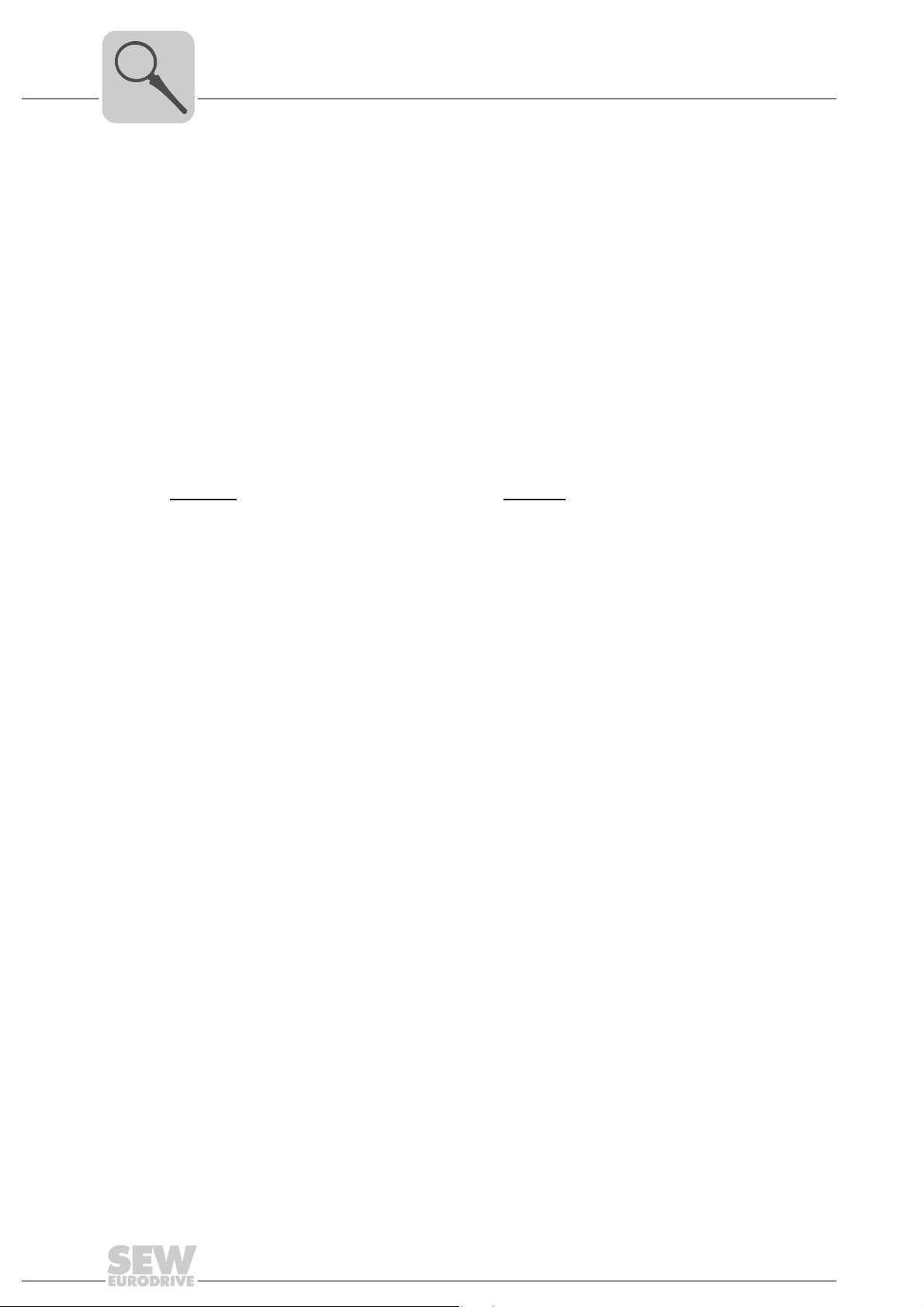

WARNING

Improper installation/disassembly of MOVIGEAR® drive units and mount-on components.

Risk of injury.

• Adhere to the notes about installation and disassembly.

• Before releasing shaft connections, make sure that there are no active torsional

moments present (tensions within the system).

Mechanical installation

Installation notes

4

WARNING

Risk of injury if the drive starts up unintentionally and danger of electrical voltage.

Dangerous voltages may still be present for up to 5 minutes after disconnection from

the power supply.

Severe or fatal injuries.

5 minutes

• Disconnect the MOVIGEAR

working on the unit and secure it against unintentional reconnection to the power

supply.

• Secure the output shaft against rotation.

• Wait for at least 5 minutes before removing the electronics cover.

4.2 Required tools and resources

• Set of wrenches

• Torque wrench

• Mounting device

• Compensation elements (shims and spacing rings), if necessary

• Mounting materials for output components

• Lubricant (e.g. NOCO

• Standard parts are not included in the delivery

®

Fluid)

®

drive unit from the power supply before you start

4.2.1 Installation tolerances for shaft ends

Diameter tolerance in accordance with DIN 748:

• ISO H7 for hollow shafts

4.2.2 Tolerances for torque ratings

The specified torques must be adhered to with a tolerance of +/− 10% .

Operating Instructions – MOVIGEAR® SNI-B

25

4

Mechanical installation

Installation requirements

4.3 Installation requirements

Check that the following conditions have been met:

• The entries on the nameplate of the MOVIGEAR

tem.

• The drive is undamaged (no damage caused by transportation or storage)

• Ambient temperature according to the operating instructions, nameplate and lubricant table in chapter "Technical data/lubricants".

• The drive must not be assembled in the following ambient conditions:

– Potentially-explosive atmosphere

– Oils

–Acids

– Gases

– Vapors

– Radiation

• For special designs: The drive is designed in accordance with the actual ambient

conditions.

• Clean the output shafts and flange surfaces thoroughly to ensure they are free of

anti-corrosion agents, contamination or similar. Use a commercially available solvent. Do not expose the sealing lips of the oil seals to the solvent – damage to the

material.

®

unit match the voltage supply sys-

• When the drive is installed in abrasive ambient conditions, protect the output end oil

seals against wear.

26

Operating Instructions – MOVIGEAR® SNI-B

4.4 Setting up the drive unit

4.4.1 Information

• Clean the output shafts thoroughly to ensure they are free of anti-corrosion agents

(use a commercially available solvent). Do not expose the bearings and sealing rings

to the solvent – damage to the material!

• Carefully align the MOVIGEAR

any unacceptable strain on the motor shafts (observe permissible overhung loads).

• Do not butt or hammer the shaft end.

• Ensure that cooling air supply is unobstructed and that air discharged by other units

does not influence cooling.

• Use suitable cable glands for the supply leads (use reducing adapters if necessary).

• Seal the cable entry well.

• Clean the sealing faces of the MOVIGEAR

• Restore the corrosion protection if necessary.

• Check the validity of the degree of protection using the information in the operating

instructions and the data on the nameplate.

Mechanical installation

Setting up the drive unit

®

drive unit and the driven machine to avoid placing

®

cover well before reassembling the unit.

4

Change in mounting position

Make sure to read the following information when you operate the drive unit in a mounting position other than the one indicated in the order:

• Adjust the position of the breather valve and, if necessary, the position of the

pressure compensation fitting.

Operating Instructions – MOVIGEAR® SNI-B

27

4

NET RUN DRIVE

MOVIGEAR

®

B

SNI

NET RUN DRIVE

MOVIGEAR

®

B

SNI

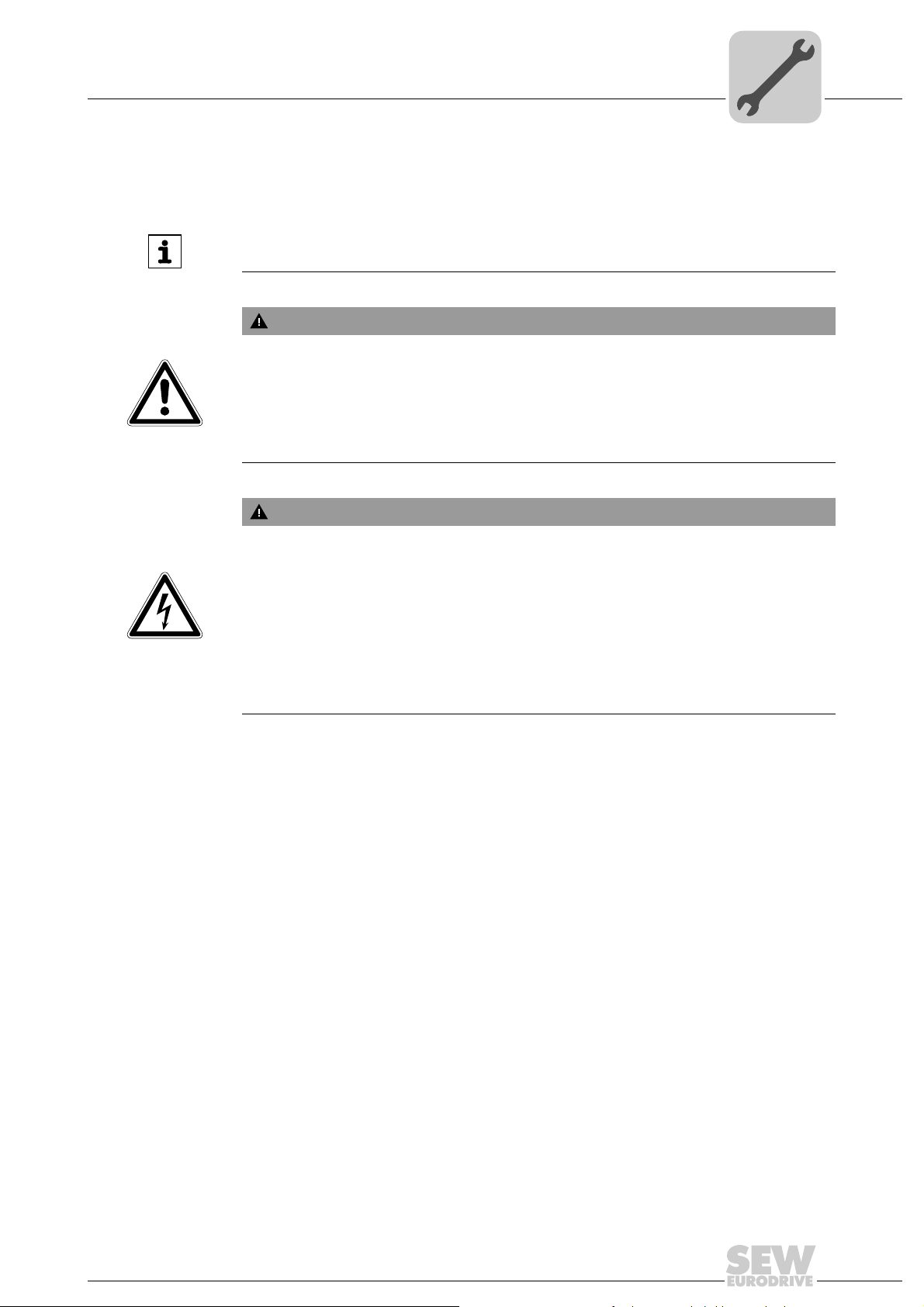

4.4.2 Electronics cover

Mechanical installation

Setting up the drive unit

WARNING

Burns caused by hot surfaces.

Severe injuries.

• Let the units cool down before touching them.

NOTICE

Loss of the guaranteed degree of protection.

Possible damage to property.

• When the MOVIGEAR

have to protect it from humidity, dust or foreign particles.

• Check to see that the MOVIGEAR

®

electronics cover is removed from the connection box, you

®

electronics cover was mounted properly.

Installing the

electronics cover

Minimum installation clearance

• Use only electronics covers that match the size.

• Be careful not to tilt the electronics cover when placing it on the connection box.

4813126155

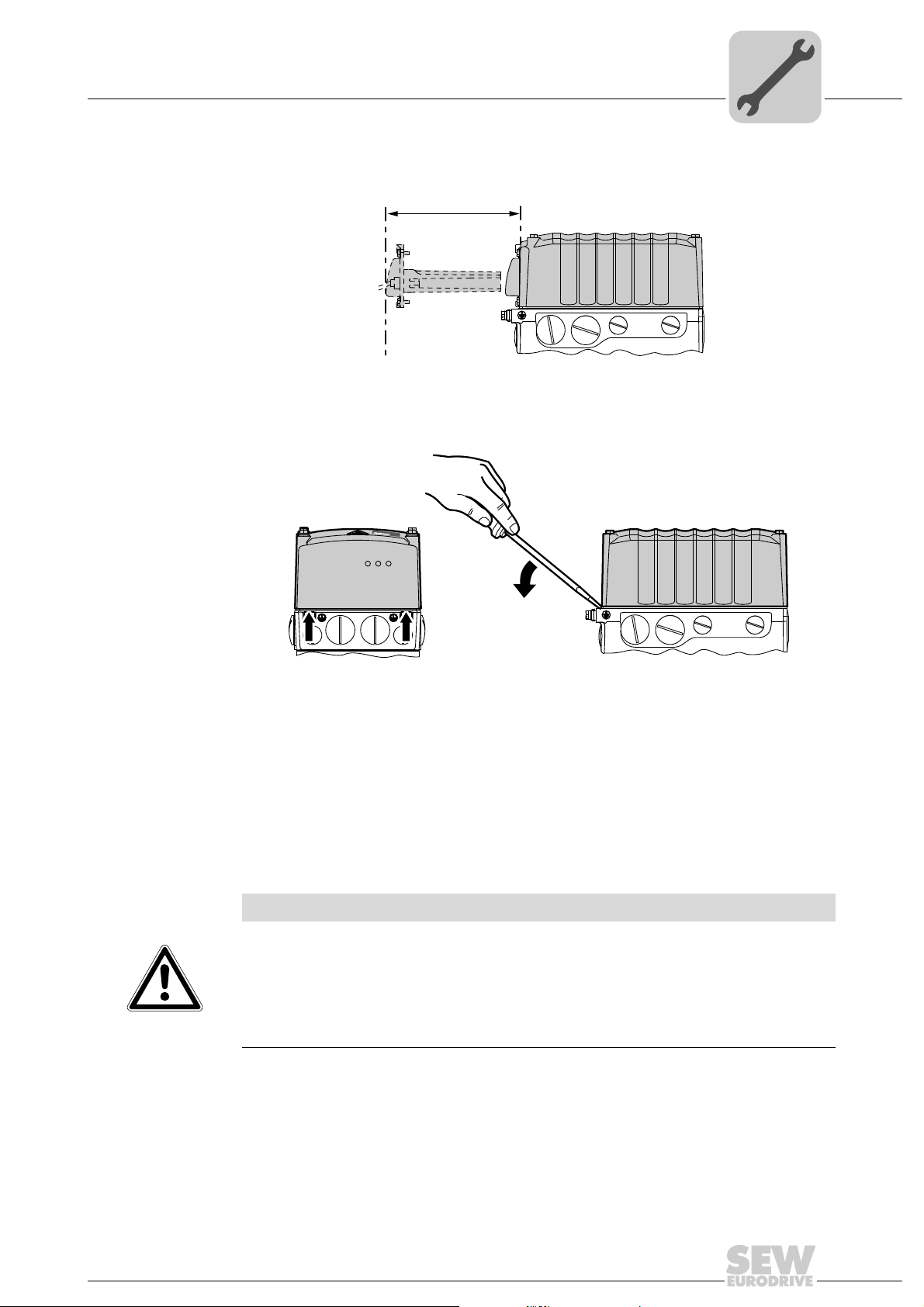

Note the minimum installation clearance (see following figure) required to remove the

MOVIGEAR

®

electronics cover. For detailed dimension drawings, refer to chapter

"Technical Data".

100

28

9007201604838411

Operating Instructions – MOVIGEAR® SNI-B

Mechanical installation

Setting up the drive unit

4

Min. installation

clearance of

application options

Removing the

electronics cover

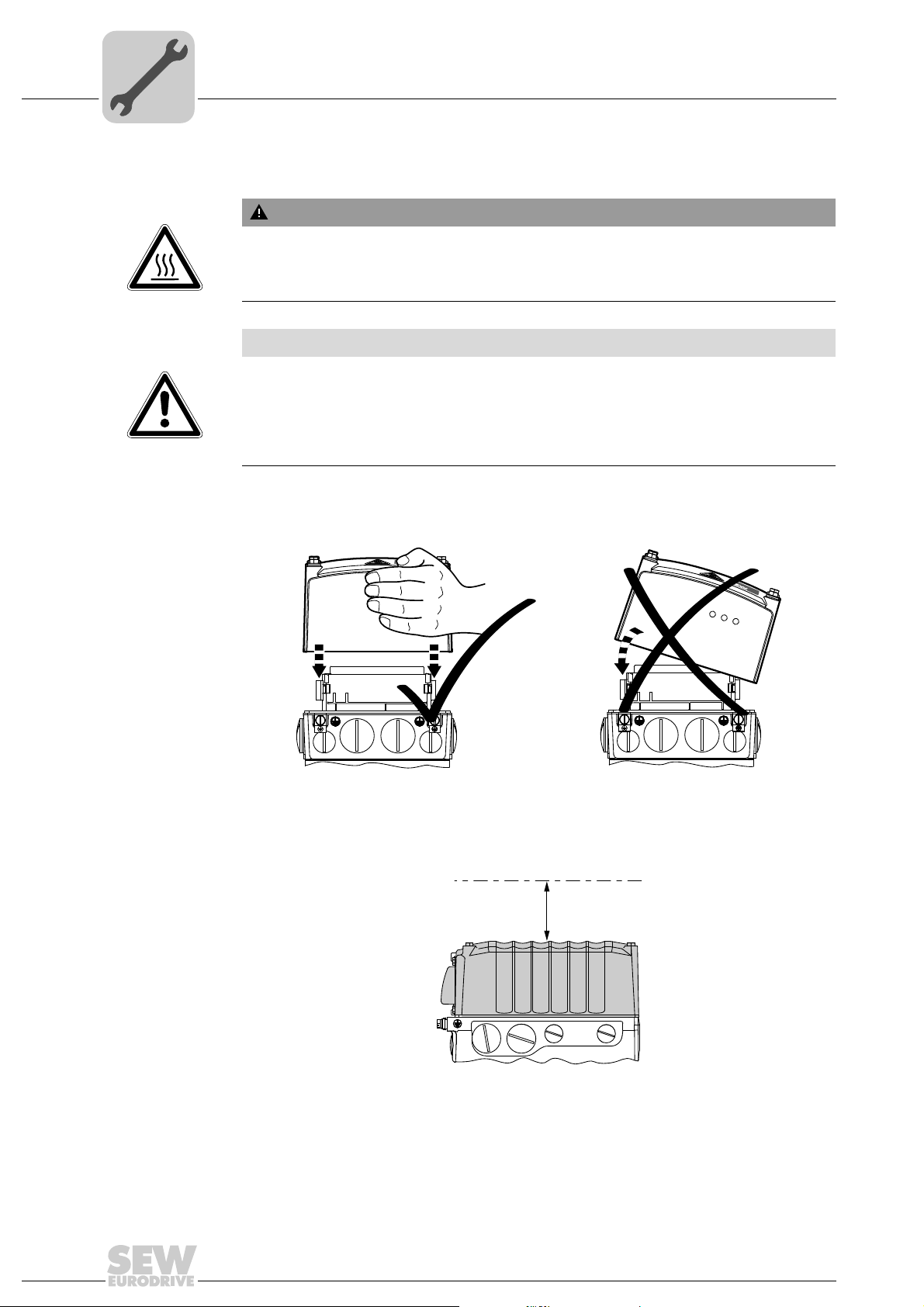

Note the minimum installation clearance (see following figure) required to install and

remove the application options.

200

9007201604871563

The following figure shows how you can lever off the electronics cover in the intended

places.

NET RUN DRIVE

4.4.3 Installation in damp locations or in the open

Drives are supplied in corrosion-resistant versions for use in damp areas or in the open.

Repair any damage to the paint work if necessary.

For variants with HP200 surface treatment, observe the notes in chapter "Drive units

with optional design for wet areas".

4.4.4 Painting drive units

NOTICE

Breather valves and oil seals may be damaged during painting or re-painting.

Potential damage to property.

• Clean the surface of the drive unit and make sure it is free from grease.

• Thoroughly cover the breather valves and sealing lip of the oil seals with strips prior

to painting.

• Remove the strips after painting.

8962548363

Operating Instructions – MOVIGEAR® SNI-B

29

4

4.4.5 Gear unit venting

Drive units with

installed breather

valve

Mechanical installation

Setting up the drive unit

Except for the M3 mounting position, SEW-EURODRIVE delivers all MOVIGEAR

units ordered for a specific mounting position with a breather valve that is activated and

installed according to the specific mounting position.

MOVIGEAR

the activated breather valve installed corresponding to the respective mounting position.

®

drive units with optional "design for wet areas" are generally delivered with

®

drive

Drive units with

separately

included breather

valve

Activating the

breather valve

SEW-EURODRIVE delivers MOVIGEAR

position with a separately included breather valve.

In this case, the breather valve is delivered in the hollow shaft of the drive unit. Before

startup, you must replace the highest oil screw plug with the provided breather valve.

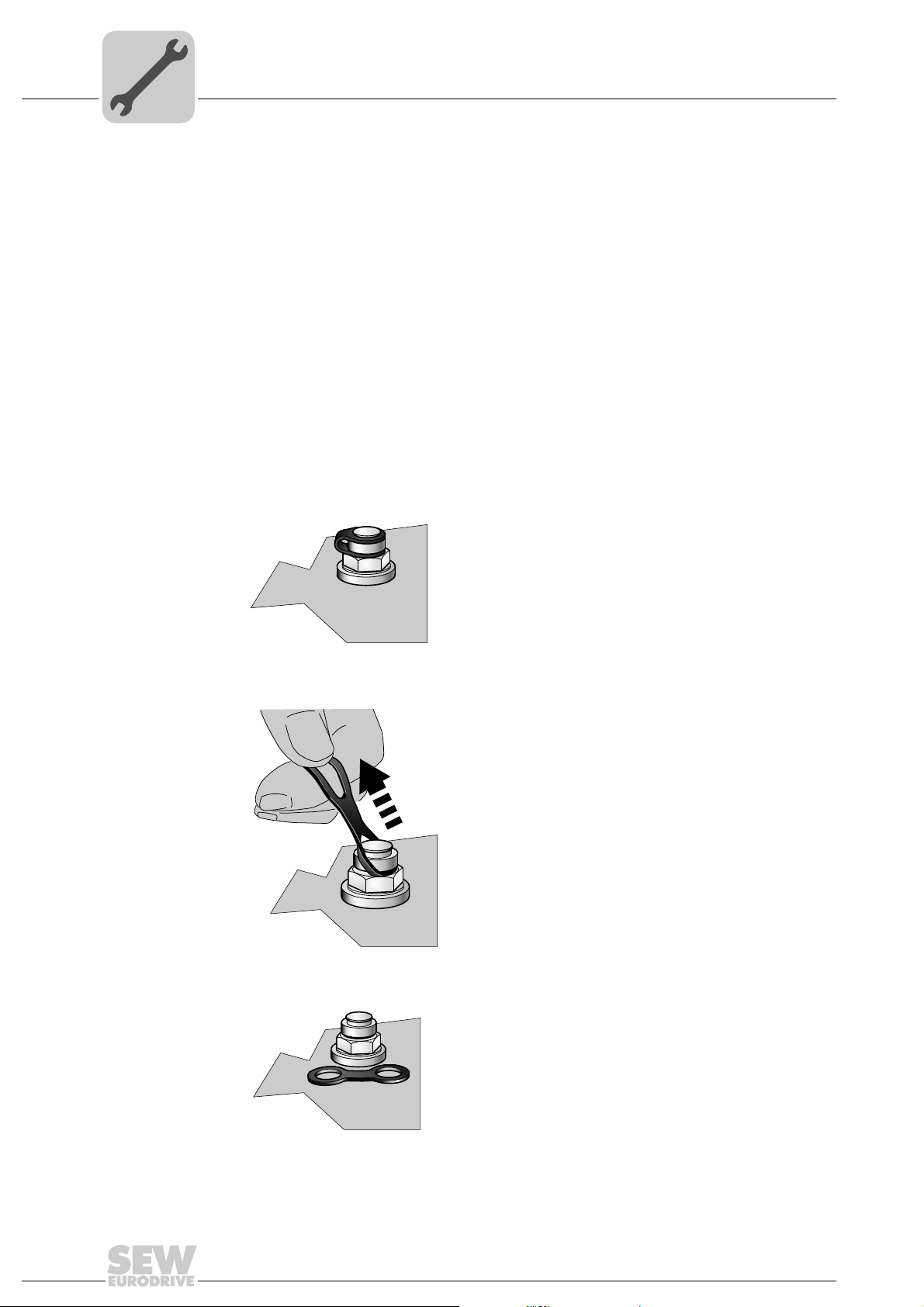

Once you have installed the breather valve, activate it as follows. For designs with the

breather valve screwed in: Check whether the breather valve is activated. If not, you

have to remove the transport fixture of the breather valve before you start up the drive

unit.

1. Breather valve with transportation protection device

2350149003

2. Remove the transport fixture

®

drive units ordered for a universal mounting

30

2350216203

3. Activated breather valve

2350269835

Operating Instructions – MOVIGEAR® SNI-B

Loading...

Loading...