SEW MOVIFIT FDC Operating Instructions Manual

Drive Technology \ Drive Automation \ System Integration \ Services

Operating Instructions

Decentralized Drive Controller

MOVIFIT

Edition 10/2012 19471211 / EN

®

FDC

SEW-EURODRIVE—Driving the world

Contents

Contents

1 General Information ............................................................................................ 5

1.1 How to use this documentation................................................................... 5

1.2 Structure of the safety notes ....................................................................... 5

1.3 Rights to claim under limited warranty ........................................................ 6

1.4 Exclusion of liability..................................................................................... 6

1.5 Copyright..................................................................................................... 6

2 Safety Notes ........................................................................................................ 7

2.1 Preliminary information ............................................................................... 7

2.2 General information .................................................................................... 7

2.3 Target group ............................................................................................... 7

2.4 Designated use ........................................................................................... 8

2.5 Other applicable documentation ................................................................. 8

2.6 Transportation and storage......................................................................... 9

2.7 Installation................................................................................................... 9

2.8 Electrical connection ................................................................................... 9

2.9 Safe disconnection...................................................................................... 9

2.10 Operation .................................................................................................. 10

3 Unit Structure .................................................................................................... 11

3.1 MOVIFIT

3.2 Overview ................................................................................................... 12

3.3 EBOX (active electronics unit) .................................................................. 13

3.4 ABOX (passive connection unit) ............................................................... 17

3.5 Version for wet areas / corrosion protection (optional) ............................. 19

3.6 Type designation MOVIFIT

4 Mechanical Installation..................................................................................... 23

4.1 General information .................................................................................. 23

4.2 Permitted mounting position ..................................................................... 23

4.3 Mounting ................................................................................................... 24

4.4 Central opening/closing mechanism ......................................................... 29

4.5 Tightening torques .................................................................................... 32

4.6 MOVIFIT

5 Electrical Installation ........................................................................................ 37

5.1 General information .................................................................................. 37

5.2 Installation planning taking EMC aspects into account............................. 37

5.3 Installation instructions (all versions) ........................................................ 40

5.4 Installation topologies ............................................................................... 46

5.5 EBOX "MTC...-R9...-00"............................................................................ 49

5.6 Standard ABOX "MTA...-S04.-...-00" ........................................................ 50

5.7 Hybrid ABOX "MTA...-S54.-...-00" ............................................................ 62

5.8 Hybrid-ABOX "MTA...-S64.-...-00" ............................................................ 64

5.9 Electrical connections ............................................................................... 66

5.10 Required SNI cables ................................................................................. 82

5.11 Recommended hybrid cables ................................................................... 83

®

FDC......................................................................................... 11

®

FDC............................................................. 21

®

FDC version for wet areas....................................................... 34

Operating Instructions – MOVIFIT® FDC

3

Contents

5.12 Connection examples ............................................................................... 84

5.13 Wiring check ............................................................................................. 87

6 Startup................................................................................................................ 88

6.1 General information .................................................................................. 88

6.2 Requirements............................................................................................ 89

6.3 Description of the DIP switches ................................................................ 89

6.4 Startup procedure ..................................................................................... 91

6.5 PC/laptop connection................................................................................ 92

6.6 Startup of MOVIFIT

6.7 First steps with MOVITOOLS

7 Operation ........................................................................................................... 95

7.1 Status LEDs of MOVIFIT

8 Service ............................................................................................................. 100

8.1 Unit diagnostics....................................................................................... 100

8.2 Unit replacement..................................................................................... 100

8.3 SEW Electronics Service ........................................................................ 102

8.4 Storage ................................................................................................... 103

8.5 Disposal .................................................................................................. 103

®

FDC ........................................................................ 92

®

MotionStudio............................................ 93

®

FDC................................................................ 95

9 Technical Data................................................................................................. 104

9.1 CE marking and UL approval.................................................................. 104

9.2 Basic unit ................................................................................................ 105

9.3 Electronics data ...................................................................................... 106

9.4 Communication and control unit ............................................................. 107

9.5 Interfaces ................................................................................................ 108

9.6 Options and accessories......................................................................... 110

9.7 Required connection cables for single-line installation ........................... 111

9.8 Specification of recommended hybrid cable ........................................... 113

9.9 Dimension drawings................................................................................ 115

10 Declaration of Conformity .............................................................................. 118

11 Address List .................................................................................................... 119

Index................................................................................................................. 131

4

Operating Instructions – MOVIFIT® FDC

General Information

How to use this documentation

1

1 General Information

MOVIFIT® FDC

1.1 How to use this documentation

This documentation is an integral part of the product and contains important information

on operation and service. The documentation is intended for all employees who perform

assembly, installation, startup and service work on the product.

The documentation must be kept accessible and legible. Ensure that persons responsible for the system and its operation, as well as persons who work independently on the

unit, have read through the entire documentation and have understood it. If you are unclear about any of the information in this documentation or require further information,

please contact SEW-EURODRIVE.

1.2 Structure of the safety notes

1.2.1 Meaning of the signal words

The following table shows the grading and meaning of the signal words for safety notes,

notes on potential risks of damage to property, and other notes.

Signal word Meaning Consequences if disregarded

DANGER Imminent danger Severe or fatal injuries

WARNING Possible dangerous situation Severe or fatal injuries

CAUTION Possible dangerous situation Minor injuries

NOTICE Possible damage to property Damage to the drive system or its envi-

INFORMATION Useful information or tip: Simpli-

fies the handling of the drive

system.

ronment

1.2.2 Structure of the section-related safety notes

Section-related safety notes do not apply to a specific action, but to several actions pertaining to one subject. The used symbols indicate either a general or a specific hazard.

This is the formal structure of a section-related safety note:

SIGNAL WORD

Type and source of danger.

Possible consequence(s) if disregarded.

• Measure(s) to prevent the danger.

1.2.3 Structure of the embedded safety notes

Embedded safety notes are directly integrated in the instructions just before the description of the dangerous action.

This is the formal structure of an embedded safety note:

• SIGNAL WORD Nature and source of hazard.

Possible consequence(s) if disregarded.

– Measure(s) to prevent the danger.

Operating Instructions – MOVIFIT® FDC

5

1

General Information

Rights to claim under limited warranty

1.3 Rights to claim under limited warranty

A requirement of fault-free operation and fulfillment of any rights to claim under limited

warranty is that you adhere to the instructions in the documentation. Read the documentation before you start working with the unit.

1.4 Exclusion of liability

You must comply with the information contained in this documentation to ensure safe

operation and to achieve the specified product characteristics and performance features. SEW-EURODRIVE assumes no liability for injury to persons or damage to equipment or property resulting from non-observance of these operating instructions. In such

cases, any liability for defects is excluded.

1.5 Copyright

© 2012 – SEW-EURODRIVE. All rights reserved.

Copyright law prohibits the unauthorized reproduction, modification, distribution, and

use of this instruction manual, in whole or in part.

6

Operating Instructions – MOVIFIT® FDC

2 Safety Notes

The following basic safety notes must be read carefully to prevent injury to persons and

damage to property. The operator must ensure that the basic safety notes are read and

adhered to. Ensure that persons responsible for the system and its operation, as well as

persons who work independently on the unit, have read through the operating instructions carefully and understood them. If you are unclear about any of the information in

this documentation, or if you require further information, please contact SEWEURODRIVE.

2.1 Preliminary information

The following safety notes are primarily concerned with the use of MOVIFIT® FDC units.

If you use other SEW components, also refer to the safety notes for the respective

components in the corresponding documentation.

Please also observe the supplementary safety notes in the individual sections of this

documentation.

Safety Notes

Preliminary information

2

2.2 General information

Never install damaged products or take them into operation. Submit a complaint to the

shipping company immediately in the event of damage.

During operation, MOVIFIT

can have live, bare and movable or rotating parts as well as hot surfaces, depending on

their degree of protection.

Removing covers without authorization, improper use or incorrect installation and operation may result in severe injuries to persons or damage to machinery.

Refer to the documentation for additional information.

2.3 Target group

Only qualified electricians are authorized to install, startup or service the units or

correct unit faults (observing IEC 60364 or CENELEC HD 384 or DIN VDE 0100 and

IEC 60664 or DIN VDE 0110 as well as national accident prevention guidelines).

Qualified personnel in the context of these basic safety notes are persons familiar with

installation, assembly, startup and operation of the product who possess the necessary

qualifications.

Any activities regarding transportation, storage, operation, and disposal must be carried

out by persons who have been instructed appropriately.

®

FDC and the connected MOVIGEAR® and DRC drive units

Operating Instructions – MOVIFIT® FDC

7

2

2.4 Designated use

2.4.1 Safety functions

Safety Notes

Designated use

MOVIFIT® FDC and the connected MOVIGEAR® and DRC drive units are components

intended for installation in electrical plants or machines.

In case of installation in machines, startup of MOVIFIT

DRC drive units (i.e. start of designated operation) is prohibited until it is determined that

the machine meets the requirements stipulated in the Machinery Directive 2006/42/EC.

Startup (i.e. the start of designated use) is only permitted under observance of EMC

Directive 2004/108/EC.

MOVIFIT

regulations of the Low Voltage Directive 2006/95/EC. The standards given in the declaration of conformity are used for MOVIFIT

You must observe the technical data and information on the connection requirements

as provided on the nameplate and in the documentation.

MOVIFIT

safety functions unless these functions are described and expressly permitted.

®

FDC and the connected MOVIGEAR® and DRC drive units comply with the

®

FDC.

®

FDC and the connected MOVIGEAR® and DRC drive units may not perform

®

FDC and the MOVIGEAR® and

For safety applications, ensure that the information in the following publication is

observed:

• Manual on the functional safety of the drive unit.

Use only those components in safety applications that were explicitly designed and

delivered for this purpose by SEW-EURODRIVE.

2.5 Other applicable documentation

Also observe the documentation for MOVIGEAR® and DRC drive units:

• Operating instructions of the connected MOVIGEAR

as:

"MOVIGEAR

"MOVIGEAR

"DRC.-...-SNI" operating instructions

"DRC.-...-DSC" operating instructions

• Manual of the fieldbus interface

e.g. "Communication Controller DHR21B/41B and MOVIFIT

Interface PROFINET IO" manual

• "Application Configurator" manual

®

SNI-B" operating instructions

®

DSC-B" operating instructions

®

and/or DRC drive units, such

®

FDC with Fieldbus

8

Operating Instructions – MOVIFIT® FDC

2.6 Transportation and storage

Observe the notes on transportation, storage and proper handling. Observe the climatic

conditions as stated in the "Technical Data" sections. Do not attach any additional loads.

Use suitable, sufficiently rated handling equipment (e.g. rope guides) if required.

2.7 Installation

The units must be installed and cooled according to the regulations and specifications

in the corresponding documentation.

Protect MOVIFIT

The following applications are prohibited unless explicitly permitted:

• Use in potentially explosive atmospheres.

• Use in areas exposed to harmful oils, acids, gases, vapors, dust, radiation, etc.

• Use in non-stationary applications with strong mechanical oscillation and impact

loads; see chapter "Technical Data".

®

FDC and the MOVIGEAR® and DRC drive units from improper strain.

Safety Notes

Transportation and storage

2

2.8 Electrical connection

Observe applicable national accident prevention guidelines (e.g. BGV A3) when working

on a live MOVIFIT

Perform electrical installation according to the pertinent regulations (e.g. cable cross

sections, fusing, protective conductor connection). For any additional information, refer

to the applicable documentation.

You find notes on EMC-compliant installation, such as shielding, grounding, arrangement of filters, and routing of lines in the documentation for MOVIFIT

MOVIGEAR

responsible for maintaining the limits established by EMC legislation.

Protective measures and protection devices must comply with the regulations in force

(e.g. EN 60204-1 or EN 61800-5-1).

2.9 Safe disconnection

MOVIFIT® FDC and the MOVIGEAR® and DRC drive units meet all requirements for

safe disconnection of power and electronics connections in accordance with EN 618005-1. All connected circuits must also satisfy the requirements for safe disconnection to

ensure reliable isolation.

®

FDC unit.

®

®

and DRC drive units. The manufacturer of the system or machine is

FDC and the

Operating Instructions – MOVIFIT® FDC

9

2

2.10 Operation

Safety Notes

Operation

Systems with integrated MOVIFIT® FDC and MOVIGEAR® and DRC drive units must

be equipped with additional monitoring and protection devices according to the applicable safety guidelines, such as the law governing technical equipment, accident prevention regulations, etc. Additional protective measures may be necessary for applications

with increased potential risk. It is permitted to modify MOVIFIT

MOVIGEAR

®

and DRC drive units using the operating software.

Do not touch live components or power connections immediately after disconnecting

MOVIFIT

®

FDC as well as MOVIGEAR® and DRC drive units from the supply voltage

because some capacitors may still be charged. Wait at least 5 minutes after having

switched off the supply voltage.

As soon as supply voltage is present at the MOVIFIT

®

FDC or MOVIGEAR® and DRC

drive units, the terminal boxes of the units must be closed (i.e. the MOVIFIT

well as any connectors of SNI cables or hybrid cables must be plugged in and screwed

on). The degree of protection of MOVIFIT

®

FDC specified in the technical data chapter

applies only if the EBOX is installed on the ABOX.

Never disconnect power plug connectors during operation. Doing so can lead to danger-

ous electric arcs forming, which can cause irreparable damage to the unit (fire risk,

irreparable contacts).

Important: The maintenance switch of MOVIFIT

®

disconnects only the MOVIGEAR

and DRC drive units from the power supply system. The terminals of the MOVIFIT® FDC

unit are still connected to the power supply after the maintenance switch is activated.

The unit may still be live and connected to the supply system, even if the operation LEDs

and other display elements are no longer illuminated.

The bus cycle and timeout times effective in the system must be taken into account

during project planning and when dimensioning the system.

®

FDC as well as

®

EBOX as

®

Mechanical blocking or internal safety functions of the unit can cause a motor standstill.

Removing the cause of this problem or performing a reset can result in the MOVIGEAR

and DRC drive unit re-starting on its own. If this is not permitted for the driven machine

for safety reasons, disconnect the unit from the supply system before correcting the error.

Caution: Danger of burns: The temperature of the surface of MOVIFIT

of MOVIGEAR

®

and DRC drive units can exceed 60 ˚C during operation.

®

FDC as well as

®

10

Operating Instructions – MOVIFIT® FDC

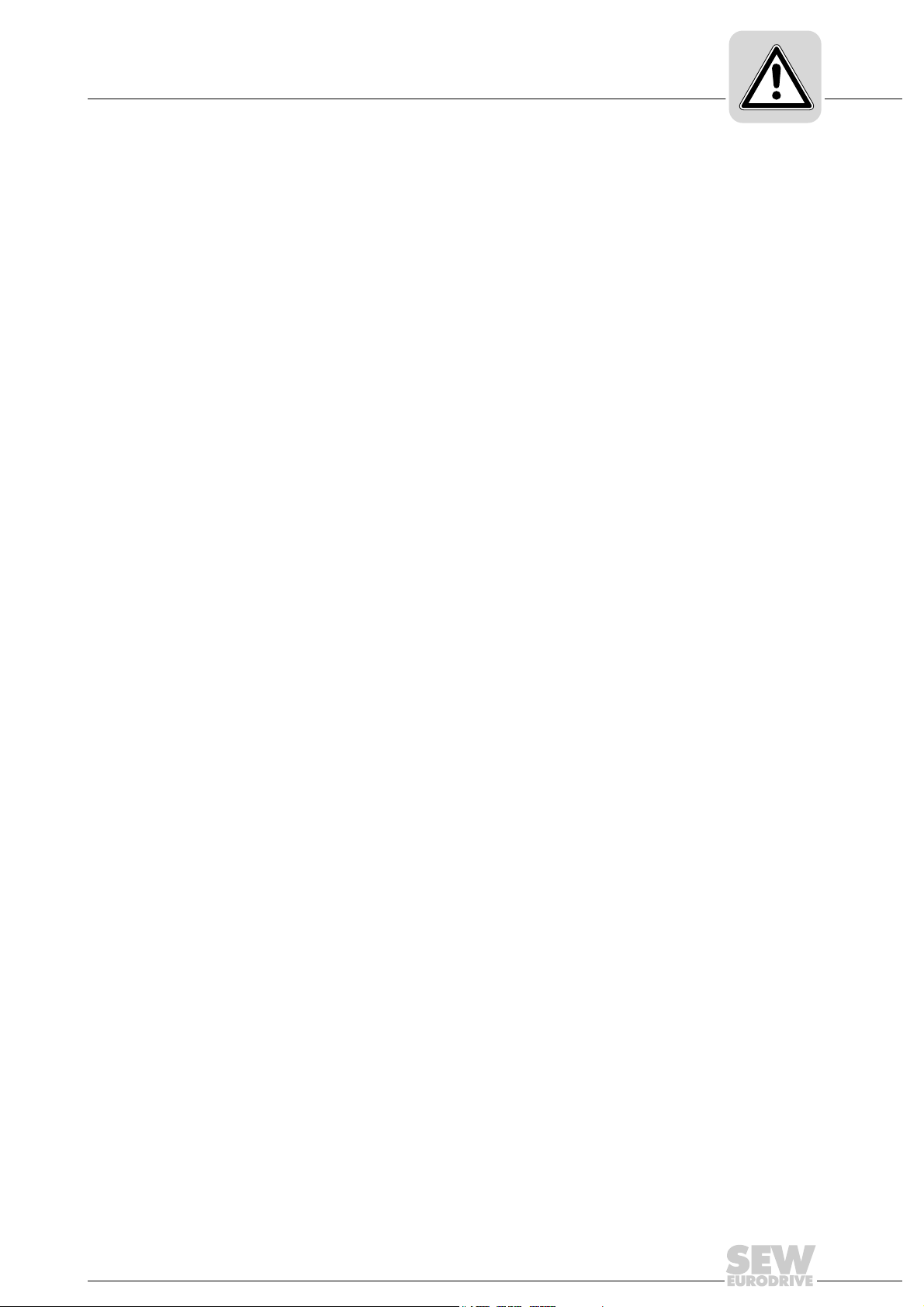

3 Unit Structure

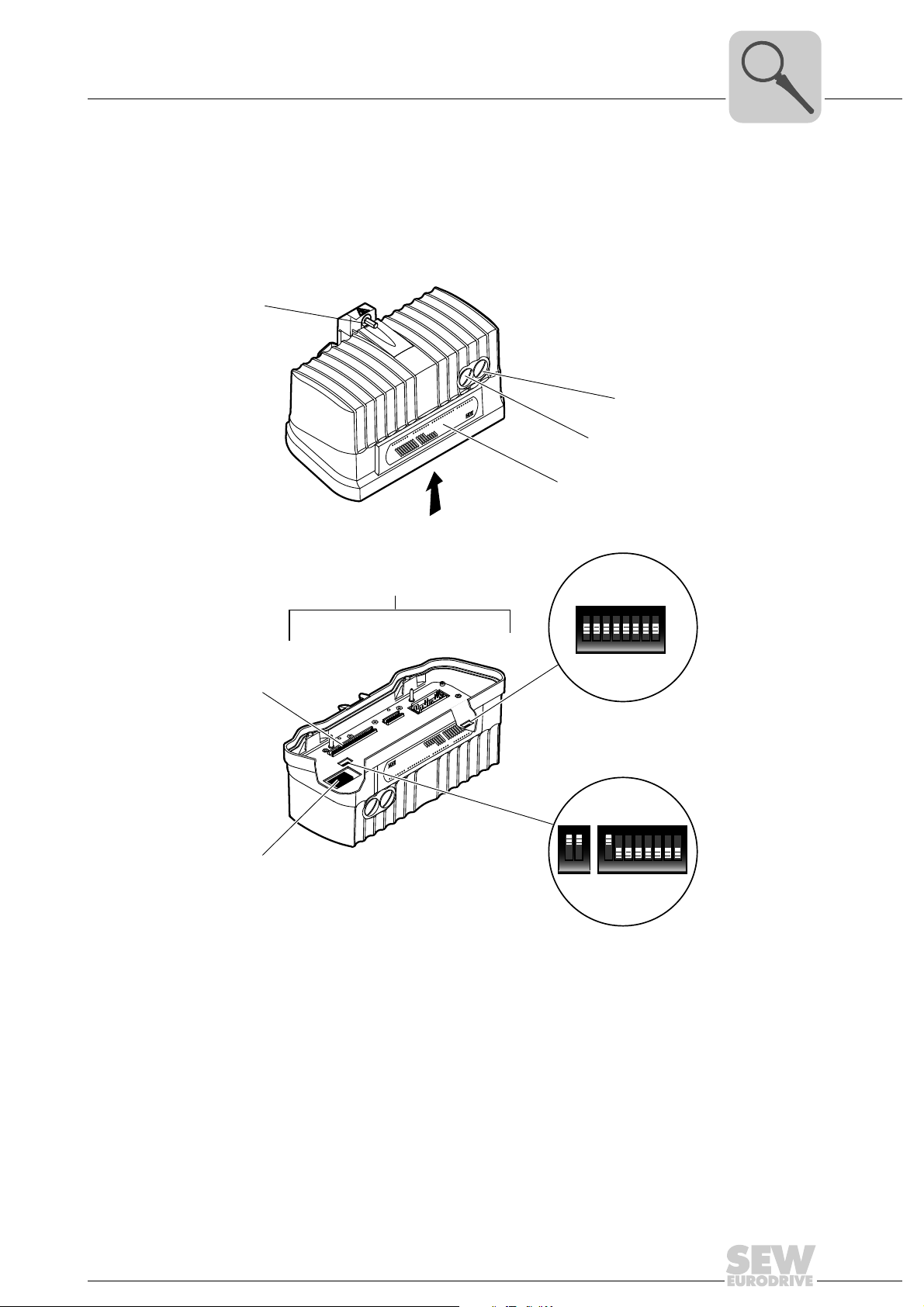

[1]

[2]

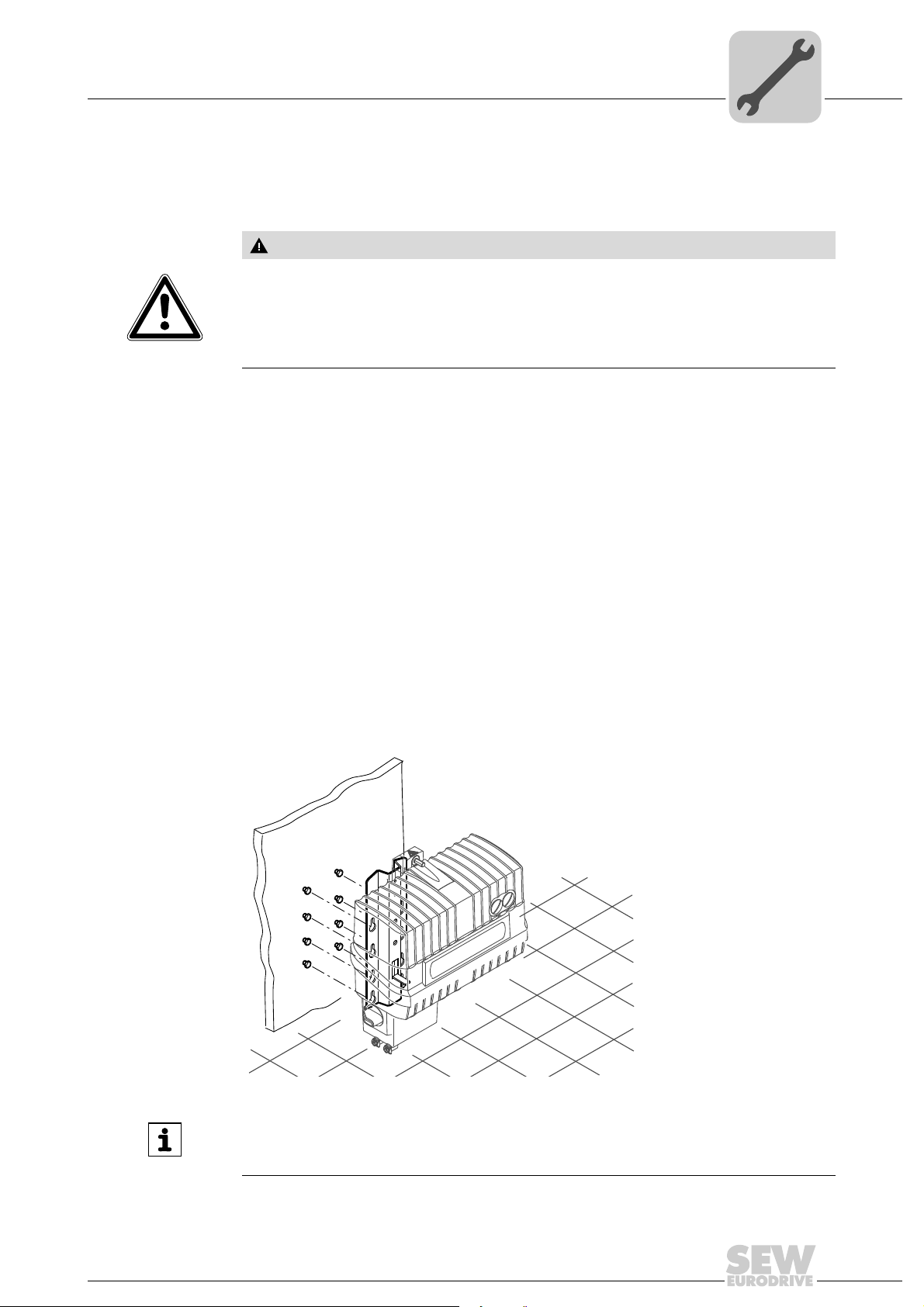

3.1 MOVIFIT® FDC

MOVIFIT® FDC is a decentralized drive controller for controlling the following units:

• MOVIGEAR

• MOVIGEAR

• DRC-SNI drive units

• DRC-DSC drive units

• MOVIFIT

The following figure shows the standard version of a MOVIFIT

example:

®

SNI-B drive units

®

DSC-B drive units

®

FC slave units

Unit Structure

MOVIFIT® FDC

®

FDC-SNI unit as an

3

[1] EBOX (active electronics unit)

[2] ABOX (passive connection unit)

3.1.1 Features of MOVIFIT

MOVIFIT

• Up to 10 SNI actuators or 16 SBus actuators can be connected

• Single-Line Network Installation (SNI) and/or SBus communication

• Industrial Ethernet with the following protocols:

• PROFINET IO

• Modbus/TCP

• EtherNet/IP

• Service interface via:

–USB

– Ethernet

• Maintenance switch

• 12 binary inputs + 4 binary inputs/outputs

• Configurable application modules

®

FDC

®

FDC is characterized by the following features:

4285335307

• User-defined programming in accordance with IEC 61131-3

• Easy data management with SD memory card

Operating Instructions – MOVIFIT® FDC

11

3

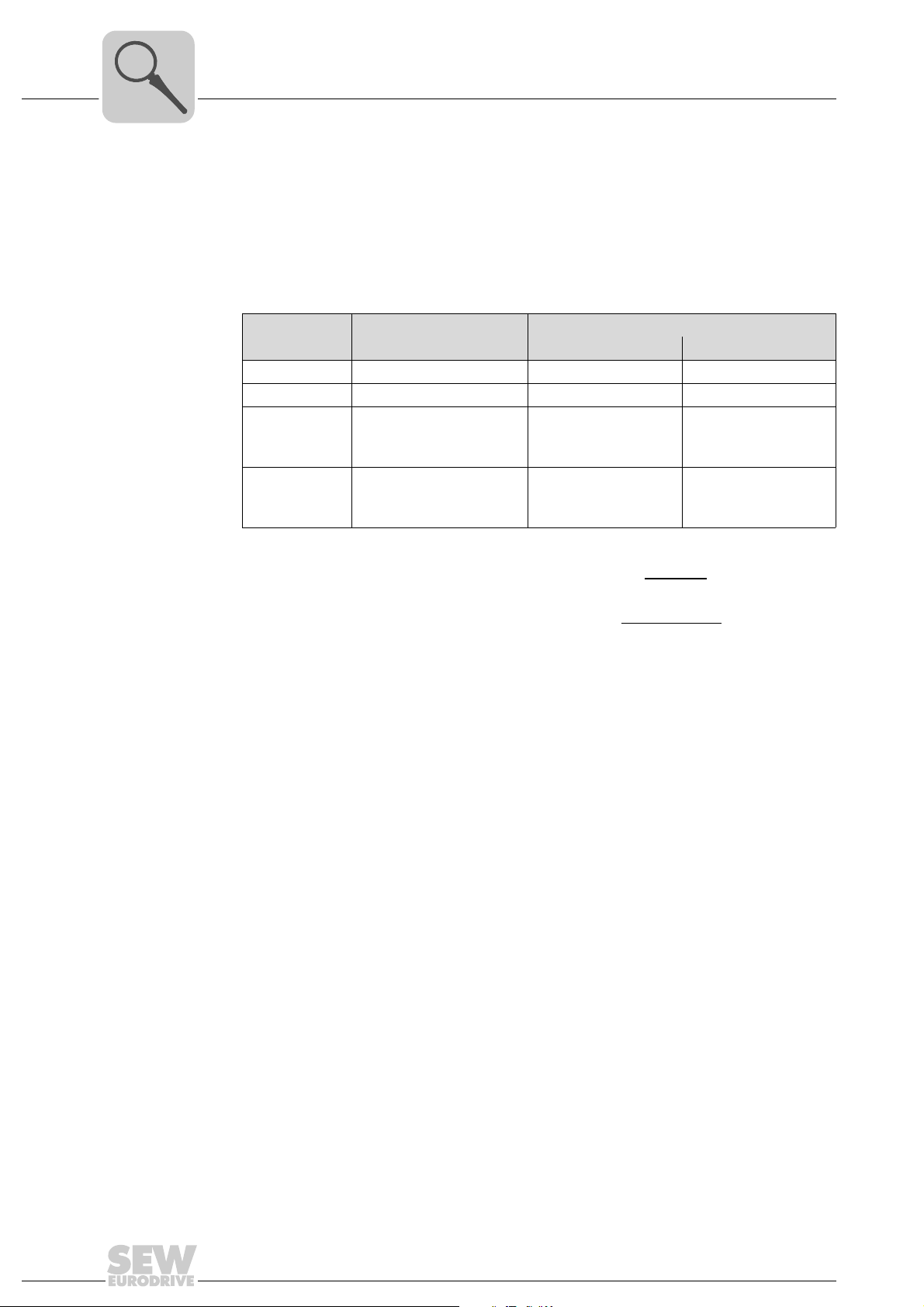

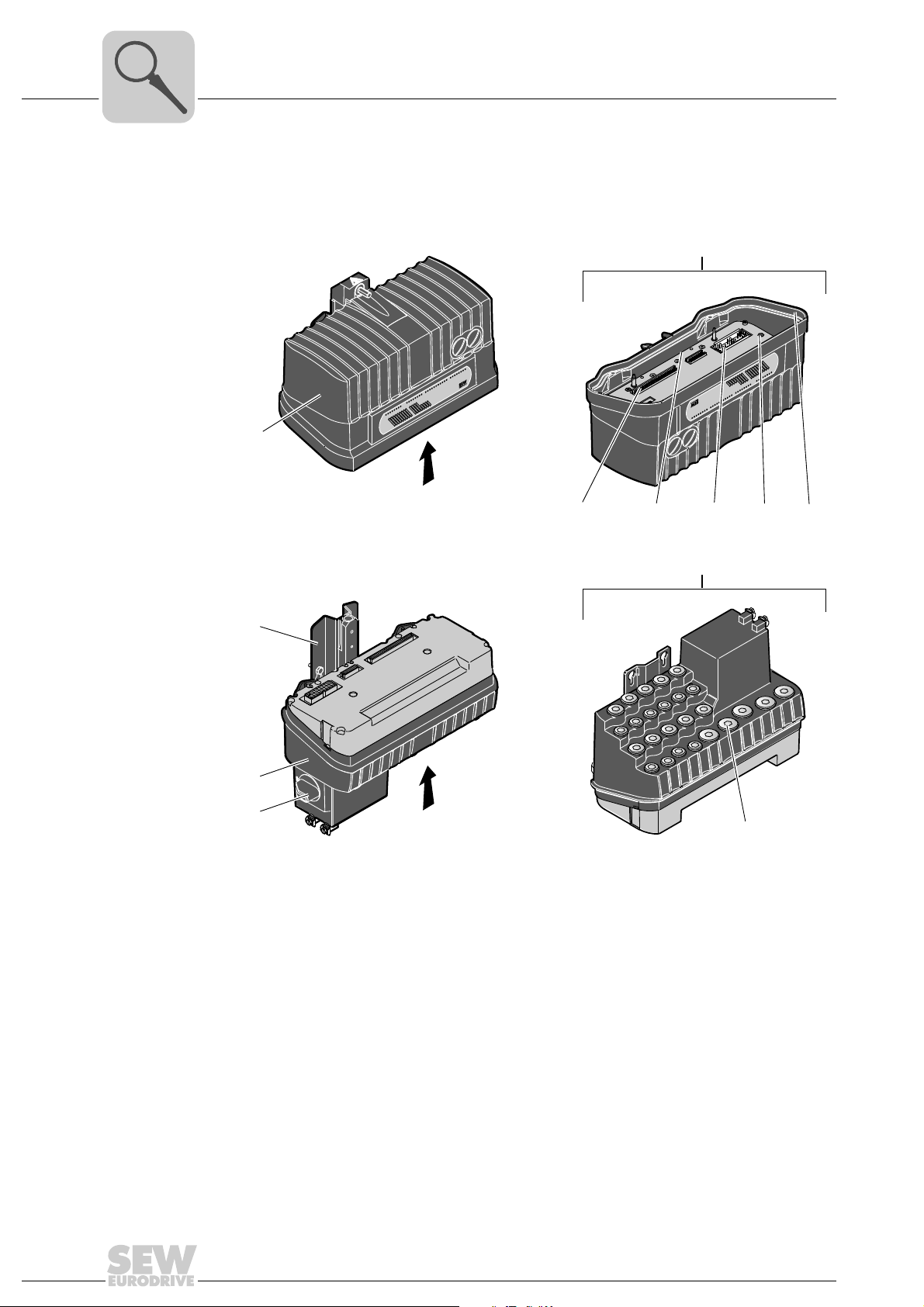

3.2 Overview

Unit Structure

Overview

The following figure shows the MOVIFIT® FDC variants described in these operating

instructions with the standard ABOX and the hybrid ABOX.

EBOX ABOX Variant

MTA...-S04.-...-0

Standard ABOX

with terminals and cable bushings

MTC...-...-00

MOVIFIT

for controlling

MOVIGEAR

®

FDC

®

and DRC drive

units

↑

X

ABOX

MTA...-S54.-...-00

Hybrid ABOX

with M23 plug connector for MOVIGEAR

DRC

and M12 for I/Os and bus

MTA...-S64.-...-00

Hybrid ABOX

with M23 plug connector for MOVIGEAR

DRC

with M12 for I/Os and push-pull RJ45 for bus

®

/

®

/

12

Detailed view of the EBOX from bottom

X:

Operating Instructions – MOVIFIT® FDC

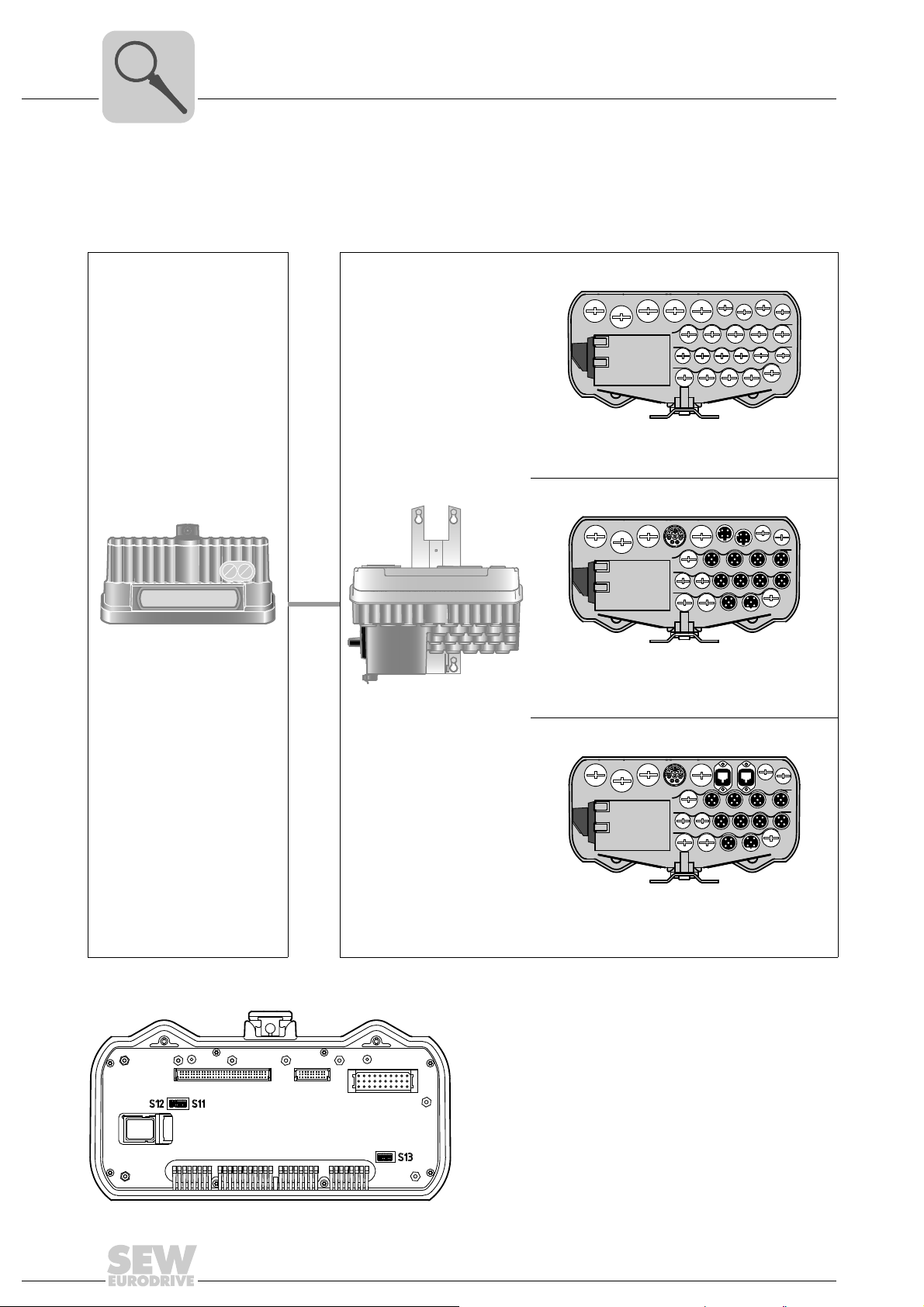

3.3 EBOX (active electronics unit)

EBOX "

MTC...-....-00"

DI03

DI01

DI02

DI00

DI04

DI05

DI06

DI07

DI08

DI09

DI10

DI11

DI12/DO00

DI13/DO01

DI14/DO02

DI15/DO03

ICE Prog

PLC

L2

A2

L1

A1

USR

NET

CAN

FDO01

FDO00

FF-STATE

RUN/MS

BF/MS

Eng-E

24V_C

MOVIFIT

®

FDC

X

S11S12

X

DI03

DI01

DI02

DI00

DI04

DI05

DI06

DI07

DI08

DI09

DI10

DI11

DI12/DO00

DI13/DO01

DI14/DO02

DI15/DO03

ICE Prog

PLC

L2

A2

L1

A1

USR

NET

CAN

FDO01

FDO00

FF-STATE

RUN/MS

BF/MS

Eng-E

24V_C

MOVIFIT

®

FDC

[1]

[4]

[9]

[3]

[2]

[7] [6]

[8]

ON

12345678

ON

12

S13

[5]

ON

12345678

Unit Structure

EBOX (active electronics unit)

3

The MOVIFIT® FDC EBOX is a closed electronics unit with communication interface and

I/Os for controlling MOVIGEAR

®

and DRC drive units:

3041019531

[1] Central opening/closing mechanism

[2] EtherNet service interface (underneath the screw plug)

Use only screw plugs with part number 1 813 062 3.

[3] USB interface (underneath the screw plug)

Use only screw plugs with part number 1 813 062 3.

[4] Operation LEDs for I/Os (can be labeled), communication, and device status

[5] DIP switch S13 (reserved) Do not change the DIP switch setting.

[6] DIP switch S11 (reserved) Do not change the DIP switch setting.

[7] DIP switch S12 for selecting the communication protocol

PROFINET or EtherNet/IP

[8] SD memory card

[9] Connection to connection box

Operating Instructions – MOVIFIT® FDC

13

3

3.3.1 SD memory card

Unit Structure

EBOX (active electronics unit)

The SD memory card is used for central data management of MOVIFIT

allows for easily replacing the EBOX during servicing. It contains the firmware, the IEC

program, and user data.

You find the memory card slot inside the EBOX. This position ensures the degree of

protection of MOVIFIT

MOVIFIT

Code Performance class SD card

R95 CCU standard OMC41B-T0 Parameterizable

R96 MOVI-PLC® standard OMH41B-T0 Programmable

R97 CCU advanced OMC41B-T0

R98 MOVI-PLC

®

FDC is available with the following memory cards:

®

FDC and enables easy access.

Type Property

OMC41B-T25

®

advanced OMH41B-T0

OMH41B-T25

Parameterizable

to

Programmable

to

®

FDC and

• When using the SD memory card OMC41B-T.., you can freely set

MOVIFIT

®

FDC.

the parameters for

• When using SD memory card OMH41B-T, you can freely program

(programming languages in accordance with IEC 61131-3).

MOVIFIT® FDC

14

Operating Instructions – MOVIFIT® FDC

EBOX (active electronics unit)

3.3.2 Configurable application controller (control card)

When using an SD card of the type OMC41B-T0, you can use MOVIFIT

configurable application controller (CCU). The Application Configurator program module

can be used to execute standardized application modules created by SEWEURODRIVE. The application modules can be started up quickly and conveniently by

graphical configuration. A defined process data interface provides this functionality to

the higher-level controller. A process data monitor with control mode is available to

support the startup procedure.

Unit Structure

®

FDC as

3

Performance class

CCU standard

Performance class

CCU advanced

The performance class CCU standard is intended for application modules with singleaxis functionality and medium response times. A maximum of 16 axes (max. 10 of them

SNI axes) can be connected to a configurable application controller. The following application modules are available and can be started up using the Application Configurator

tool.

• Speed control

• Cam positioning

• Bus positioning with 6 process data

• Single-axis universal module

The performance class CCU advanced is intended for application modules with singleaxis and multi-axis functionality and fast response times. The following application

modules are available:

• Single-axis functionality:

– Speed control

– Cam positioning

– Bus positioning with 6 process data words

– Single-axis universal module

• Multi-axis functionality (in preparation):

– SyncCrane

– Energy-efficient SRU

Operating Instructions – MOVIFIT® FDC

15

3

Unit Structure

EBOX (active electronics unit)

3.3.3 Freely programmable motion and logic controller card (MOVI-PLC®)

When using an SD card of the type OMH41B-T0, you can use MOVIFIT

programmable motion and logic controller MOVI-PLC

grammable motion and logic controllers. It allows drive solutions, logic processes and

sequence controls to be automated simply and efficiently using IEC 61131-3 compliant

programming languages.

•MOVI-PLC

®

is a universal solution because it is able to control the entire portfolio

of SEW inverters and offers a simple upgrade to a more powerful MOVI-PLC

version thanks to the universal execution of the programs.

•MOVI-PLC

®

is scalable due to several different hardware platforms (standard,

advanced, etc.) and modular software concepts (libraries for numerous applications).

•MOVI-PLC

®

is powerful due to extensive technologies (such as electronic cam,

synchronous operation) and the control of demanding applications (such as material

handling).

Performance-class

MOVI-PLC

®

standard

The control card of the performance class MOVI-PLC

single axis movements and integration of external inputs/outputs as well as drive operator panels (DOP). The control card is therefore suitable for use as a module controller

or stand-alone controller for machines of medium complexity. SEW-EURODRIVE recommends the program module MultiMotion Light for programming.

®

®

. MOVI-PLC® is a series of pro-

®

standard enables coordinated

FDC as freely

®

Performance class

MOVI-PLC

®

advanced

The performance class MOVI-PLC

MOVI-PLC

technology functions, such as synchronous operation, electronic cam or robotics. SEWEURODRIVE recommends the program module MultiMotion for programming.

3.3.4 Actuator module (SNI)

The actuator module of the EBOX modulates the SNI signal onto the supply system cable. This means the same SNI cable is used for communication and power supply of the

connected MOVIGEAR

See chapter "Operation" > "Status LEDs" (page 95) for more information.

®

®

standard by short response times and the possibility of executing complex

®

and DRC drive units (SNI = Single Line Network Installation).

advanced supplements the performance class

16

Operating Instructions – MOVIFIT® FDC

3.4 ABOX (passive connection unit)

X

ABOX "MTA...-S04.-...-00"

ABOX "MTA...-S64.-...-00"

ABOX "MTA...-S54.-...-00"

X

[1]

[6]

[5]

[3]

[2]

[4]

S3

ON

OFF

The following figure shows the MOVIFIT® standard ABOX "MTA...-S04.-...-00 as an example:

Unit Structure

ABOX (passive connection unit)

3

Operating Instructions – MOVIFIT® FDC

[1] Mounting rail

[2] Connection to EBOX

[3] Protection cover

[4] DIP switch S3 for SBus bus termination

[5] Grounding screws

[6] Maintenance switch

3041002251

17

3

3.4.1 Maintenance switch

Unit Structure

ABOX (passive connection unit)

The maintenance switch of the ABOX is used to disconnect the AC 400 V power supply

in the ABOX. The maintenance switch can be secured with 3 locks.

When the maintenance switch is in "0" position, the MOVIGEAR

are disconnected from the 400 V voltage supply. Voltage is still present on some terminals in the ABOX.

®

and DRC drive units

WARNING

Electric shock due to dangerous voltages present in the ABOX.

Severe or fatal injuries.

• Disconnect the power interface from the power supply before you perform any work

on the unit.

• Observe a minimum switch-off time of 5 minutes after disconnecting the power

supply.

INFORMATION

When a valid enable signal for a MOVIGEAR® or DRC drive unit is pending at

MOVIFIT

is set to "1".

®

FDC, the motor is supplied with current as soon as the maintenance switch

NOTICE

Increased wear of the switch contacts.

Destruction of the switch contacts.

• Do not operate the maintenance switch under load.

As an alternative, the ABOX is equipped with the following line and equipment protection:

Cable cross section

SNI cable / hybrid cable

2

4 x 2.5 mm

4 x 4.0 mm

/ 4 x AWG14 M16 15 A

2

/ 4 x AWG12 M20 20 A

Short designation Line and equipment protection

18

Operating Instructions – MOVIFIT® FDC

Unit Structure

Version for wet areas / corrosion protection (optional)

3.5 Version for wet areas / corrosion protection (optional)

3.5.1 Characteristics

The version for wet areas has the following characteristics:

• IP65 in accordance with EN 60529 (MOVIFIT

and plug connection sealed according to the relevant degree of protection)

• Easy-to-clean housing (self-draining design)

• Specially treated surface with anti-stick properties (= surface protection HP200)

• High impact resistance of the surface against mechanical damage

• Specifically treated mounting rail with anti-stick properties

(= HP200 surface treatment)

®

housing closed and all cable entries

INFORMATION

The version for wet areas is only available in connection with the standard ABOX

"MTA13...-S04.-...-00".

3

Operating Instructions – MOVIFIT® FDC

19

3

Unit Structure

Version for wet areas / corrosion protection (optional)

The following figure depicts the additional features of MOVIFIT® units in the version for

wet areas:

EBOX "

MTC13...-....-00"

DI04

DI03

DI02

DI01

DI00

[1]

ABOX "MTA13...-S04.-...-00"

[7]

X

L2

A2

L1

A1

USR

®

Eng-E

FDC

24V_C

NET

CAN

FDO01

MOVIFIT

FDO00

FF-STATE

RUN/MS

BF/MS

PLC

ICE Prog

DI15/DO03

DI14/DO02

DI13/DO01

DI12/DO00

DI11

DI10

DI09

DI08

DI07

DI06

DI05

FF-STATE

FDO00

MOVIFIT

FDO01

CAN

NET

24V_C

FDC

Eng-E

®

USR

A1

L1

A2

L2

DI00

DI01

DI02

DI03

DI04

DI05

DI06

DI07

DI08

DI09

DI10

DI11

DI12/DO00

DI13/DO01

DI14/DO02

DI15/DO03

ICE Prog

PLC

BF/MS

RUN/MS

X

[2] [4] [6]

[3]

[5]

Y

[8]

[9]

Y

[1] EBOX with special surface treatment (available only in one color)

[2] Signal plug connector

[3] Gasket between ABOX and cover plate

[4] Power plug connector

[5] Screws with thread sealant

[6] Replaceable profile seal

[7] Mounting rail with special surface treatment

[8] ABOX with special surface treatment (available only in one color)

[9] Maintenance switch

[10] Stainless steel screw plugs (optionally available)

[10]

3041025291

20

Operating Instructions – MOVIFIT® FDC

Unit Structure

[A]

[B]

[1]

[1]

Type designation MOVIFIT® FDC

3.6 Type designation MOVIFIT® FDC

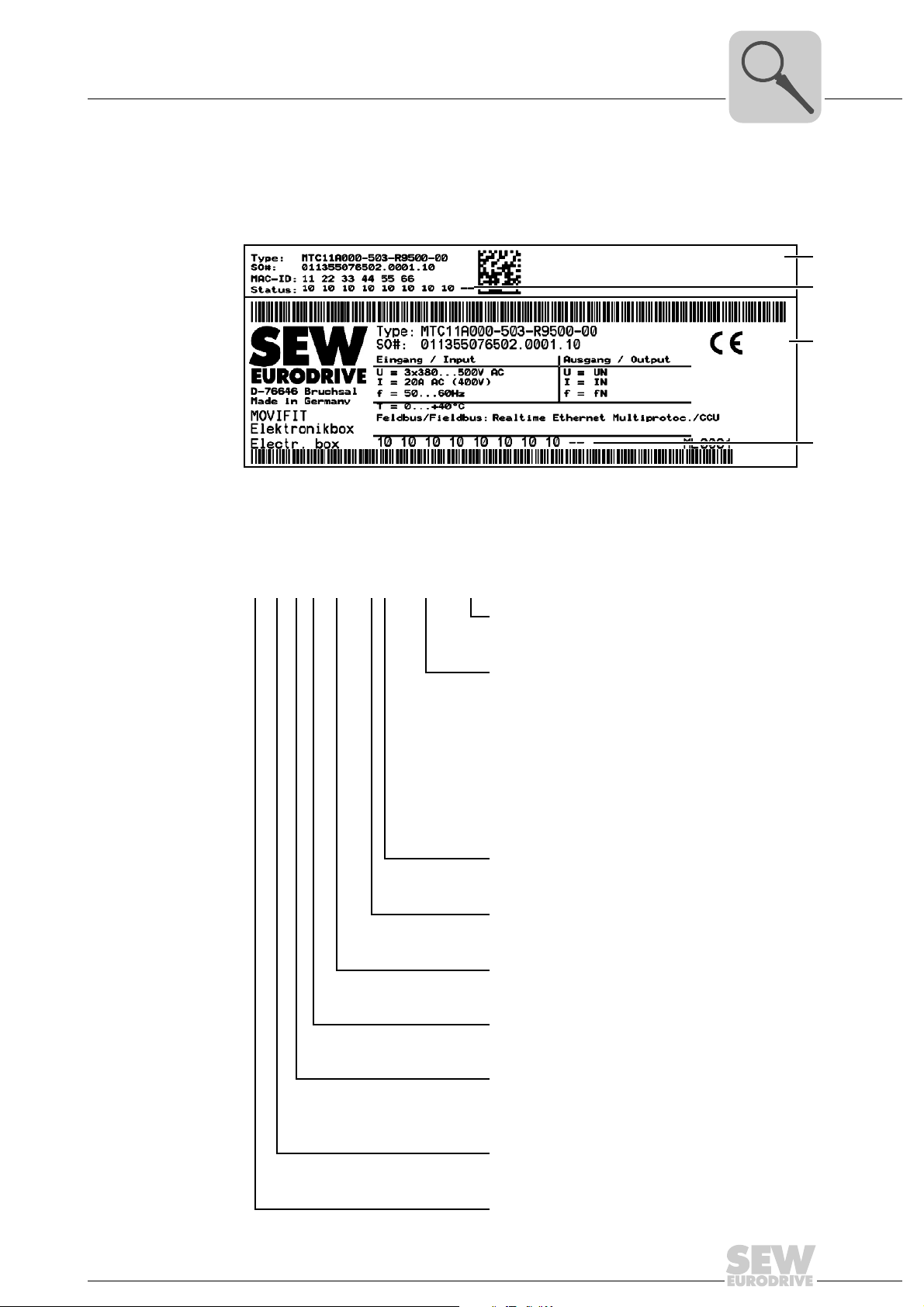

3.6.1 EBOX

Nameplate The following figure shows an example nameplate of the EBOX of MOVIFIT

®

FDC:

3

[A] External nameplate

[B]

Internal nameplate

[1]

EBOX status field

Type designation The following table shows the type designation of the EBOX of MOVIFIT

MT C 11 A 000 - 503 - R9500 - 00

EBOX variant

00 = Series

Performance class type (SD card)

R95.. = OMC41B-T0

(CCU standard, parameterizable)

R96.. = OMH41B-T0

(MOVI-PLC

R97.. = OMC41B-T0 – OMC41B-T25

(CCU advanced, parameterizable)

R98.. = OMH41B-T0 – OMH41B-T25

(MOVI-PLC

Supply phases

3 = 3-phase (AC)

Supply voltage

50 = 380 V – 500 V

®

standard, programmable)

®

advanced, programmable)

3299552907

®

FDC:

Operating Instructions – MOVIFIT® FDC

Power

000 = MTC variant (MOVIFIT

Version A

Series

11 = Standard (IP65)

13 = Variant for wet areas (IP65)

Unit type

C = MOVIFIT

MT = MOVIFIT

®

FDC

®

unit series

®

FDC)

21

3

[1]

Unit Structure

Type designation MOVIFIT® FDC

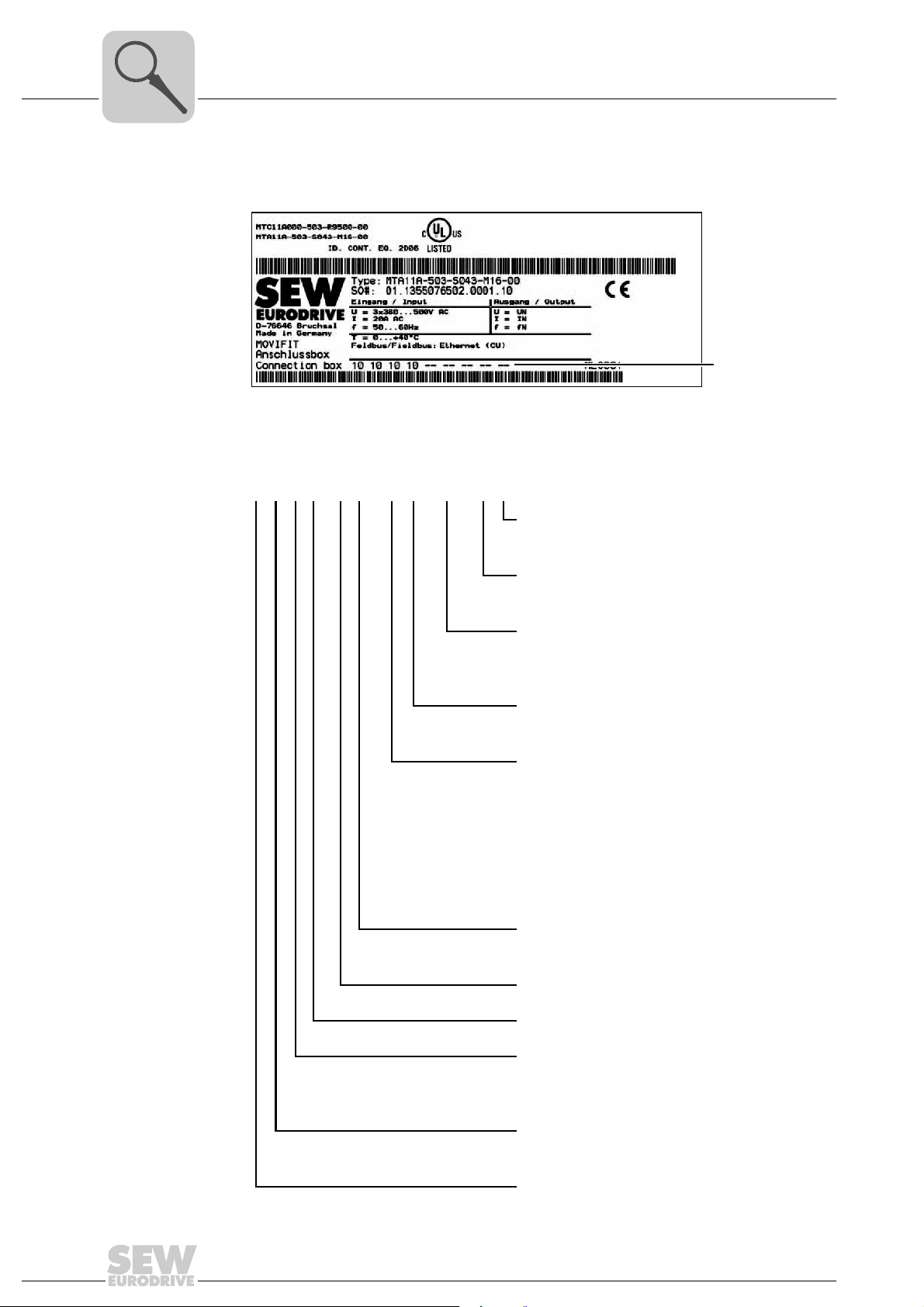

3.6.2 ABOX

Nameplate The following figure shows an example nameplate of the ABOX of MOVIFIT

[1] ABOX status field

®

FDC:

3304573579

Type designation The following table shows the type designation of the ABOX of MOVIFIT

MT A 11 A - 50 3 - S04 3 - M16 - 00 /M11

ABOX option

M11 = Stainless steel mounting rail

ABOX variant

00 = Series

Maintenance switch

M16 = Load disconnector + line protection up to 15 A

M20 = Load disconnector + line protection up to 20 A

Fieldbus

3 = PROFINET IO, EtherNet/IP, Modbus/TCP

Connection configuration

S04 = Standard ABOX

with terminals and cable bushings

S54 = Hybrid ABOX with M12 for I/Os + bus

and plug connector for MOVIGEAR

S64 = Hybrid ABOX with M12 for I/Os,

push-pull RJ45 for bus

and plug connector for MOVIGEAR

®

FDC:

®

/ DRC

®

/ DRC

22

Supply phases

3 = 3-phase (AC)

Supply voltage

50 = 380 V – 500 V

A = Version

Series

11 = Standard (IP65)

13 = Version for wet areas (IP65)

Unit type

A = ABOX (connection box)

MT = MOVIFIT

®

unit series

Operating Instructions – MOVIFIT® FDC

4 Mechanical Installation

4.1 General information

CAUTION

Risk of injury due to protruding parts, especially the mounting rail.

Risk of cutting or crushing.

• Cover sharp and protruding parts, especially the mounting rail, to protect against

injury and damage.

• MOVIFIT

Observe the following notes on mechanical installation:

• Only install MOVIFIT

structure, see "Permitted mounting position" chapter.

• Observe the general safety notes.

• Strictly observe all instructions as to the technical data and the permissible conditions regarding the place of installation.

®

FDC may only be installed by qualified personnel.

Mechanical Installation

General information

®

FDC on a level, low-vibration, and torsionally rigid support

4

• Use only the provided attachment options when mounting the unit.

• When selecting and dimensioning the mounting and safety elements, observe the

applicable standards, the technical data of the unit, and the local circumstances.

4.2 Permitted mounting position

The following figure shows the permitted mounting positions for MOVIFIT® FDC:

MOVIFIT

installed in the mounting surface. Refer to the "Mounting" chapter for more information.

®

FDC is attached by means of a mounting plate using the 4 screws already

INFORMATION

This chapter gives an example of the standard version with terminals and cable bushings. However, the installation notes apply to all variants.

Operating Instructions – MOVIFIT® FDC

3041017611

23

4

66

334.5

303.5

280

140

37,9

min. 40

15

min. 50

[1]

[2]

7.0 (6x)

13.9 (6x)

Mechanical Installation

Mounting

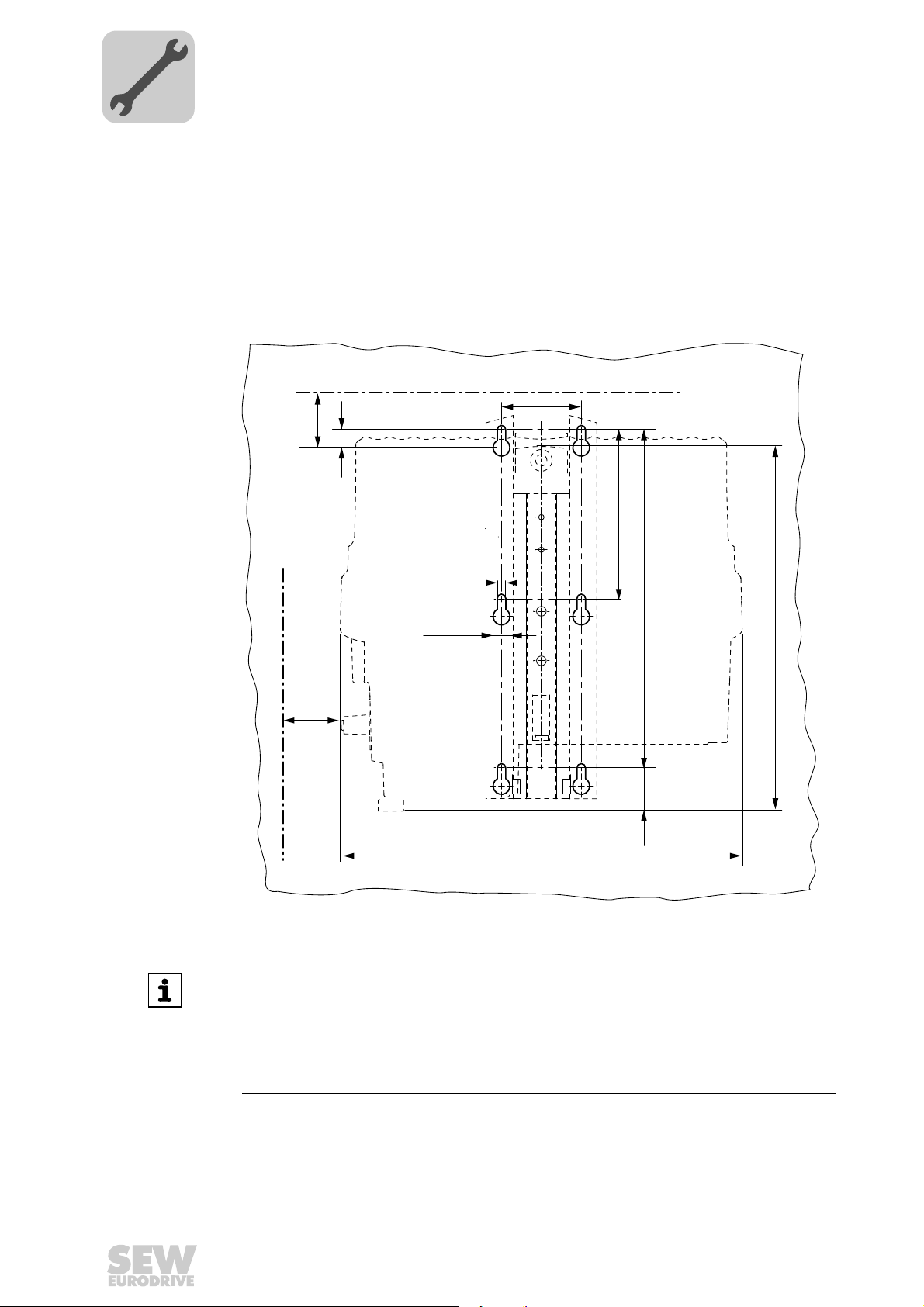

4.3 Mounting

4.3.1 Mounting rail

MOVIFIT

tion mounting surface using screws of size M6.

For bore dimensions of the respective type of fixture, see the following figures.

Drilling template for the standard mounting rail

®

FDC is equipped with a mounting rail to attach the unit to a level, low-vibra-

24

9007202299435147

INFORMATION

• [1] Observe the minimum installation clearance so that the EBOX can be removed

from the ABOX.

• [2] Observe the minimum installation clearance required to operate the maintenance switch and to ensure heat dissipation for the unit.

• Make sure that the permitted bending radii of the cables used are not exceeded

when connecting the cables.

You find detailed dimension drawings in the "Dimension drawings" (page 115) chapter.

Operating Instructions – MOVIFIT® FDC

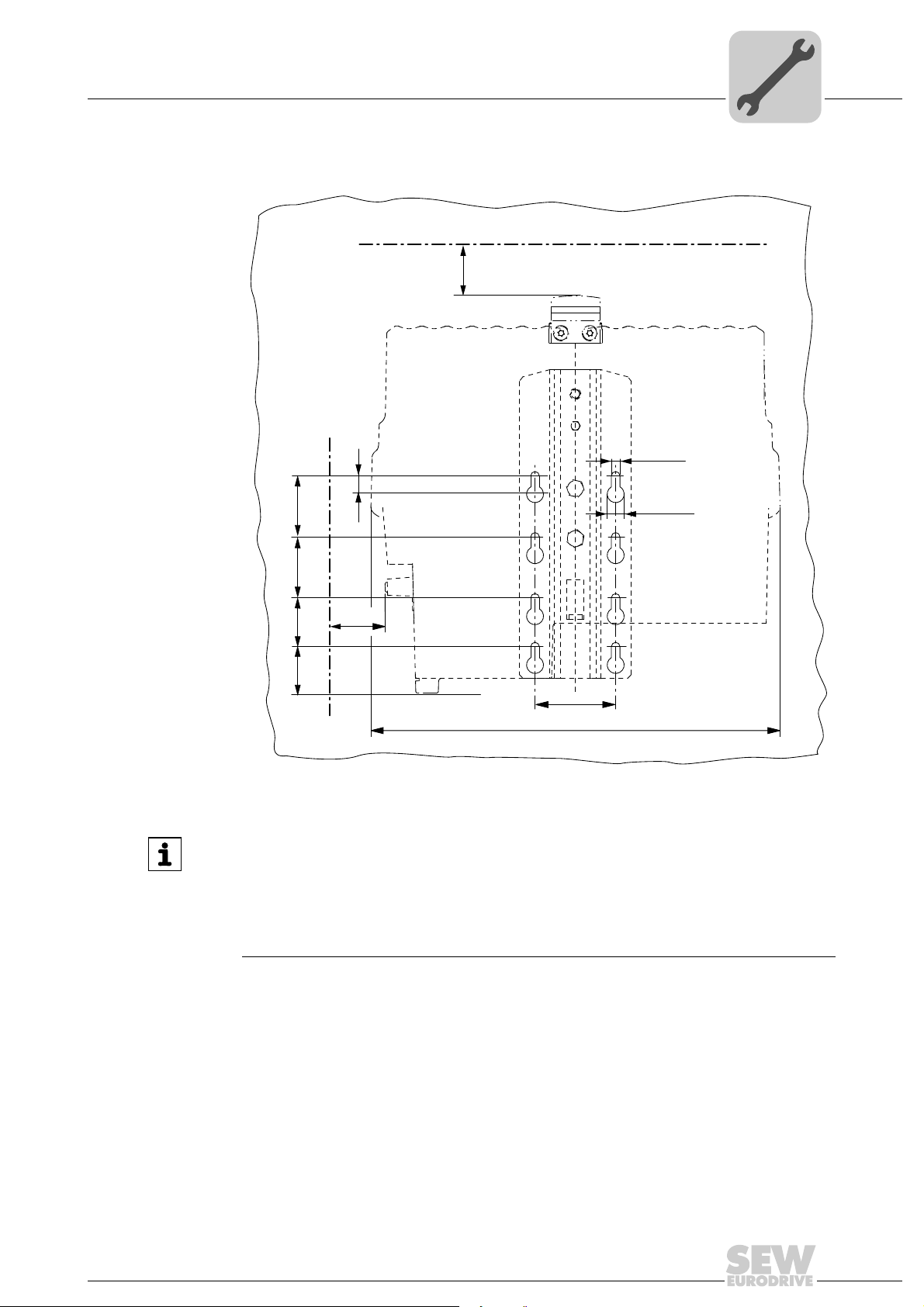

Drilling template for the optional stainless mounting rail M11

334.4

66

min. 40

min. 50

[1]

[2]

15

37.9

40 50 50

7.0 (8x)

13.9 (8x)

Mechanical Installation

Mounting

4

Operating Instructions – MOVIFIT® FDC

9007202299484811

INFORMATION

• [1] Observe the minimum installation clearance so that the EBOX can be removed

from the ABOX.

• [2] Observe the minimum installation clearance required to operate the maintenance switch and to ensure heat dissipation for the unit.

• Make sure that the permitted bending radii of the cables used are not exceeded

when connecting the cables.

You find detailed dimension drawings in the "Dimension drawings" (page 115) chapter.

25

4

min.

4 x M6

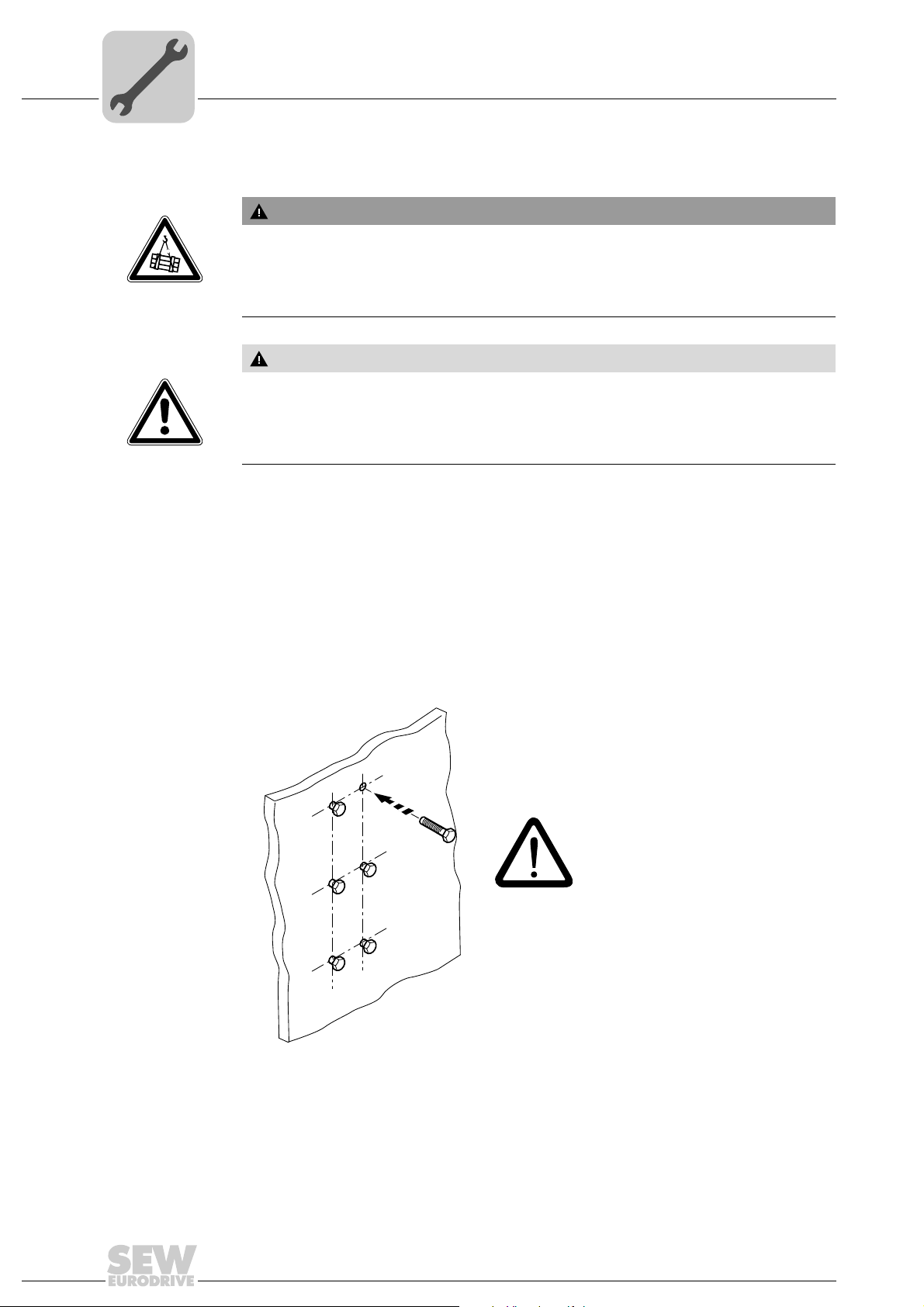

4.3.2 Mounting

Mechanical Installation

Mounting

WARNING

Risk of crushing if the load falls.

Severe or fatal injuries.

• Do not stand under the load.

• Secure the danger zone.

CAUTION

Risk of injury due to protruding parts.

Risk of cutting or crushing.

• Cover sharp and protruding parts.

• The installation must only be carried out by qualified personnel.

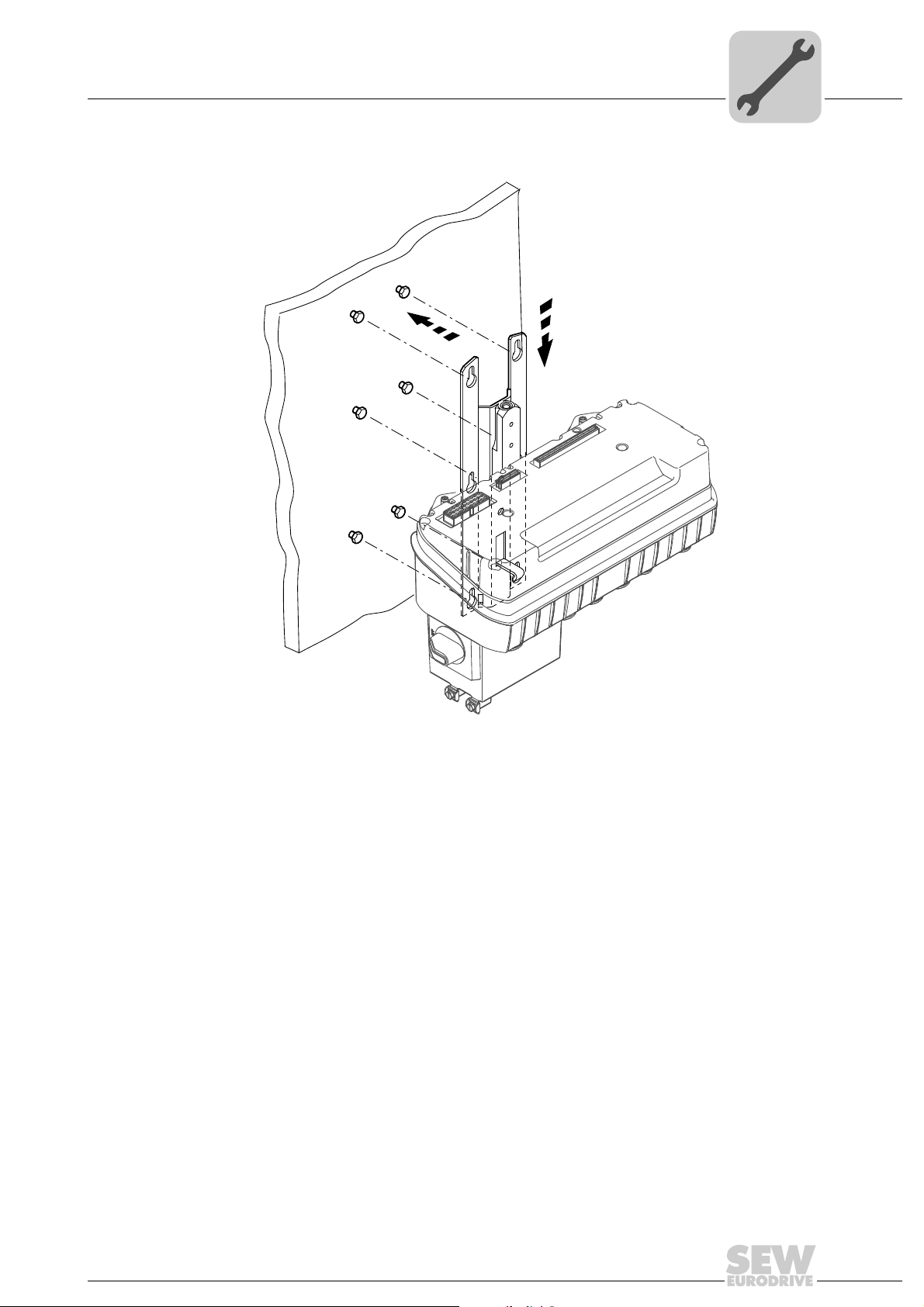

1. Bore the holes required for mounting at least 4 screws into the mounting surface according to the previous figures. SEW-EURODRIVE recommends screws of size M6

and suitable dowel pins, if necessary.

2. Mount at least 4 screws on the mounting surface.

Use appropriate washers or screw and washer assemblies for the mounting plates

with special surface treatment for versions used in wet areas.

26

758550411

Operating Instructions – MOVIFIT® FDC

Mechanical Installation

1.

2.

3. Hang the ABOX with the mounting rail into the screws.

Mounting

4

3045024523

Operating Instructions – MOVIFIT® FDC

27

4

Mechanical Installation

Mounting

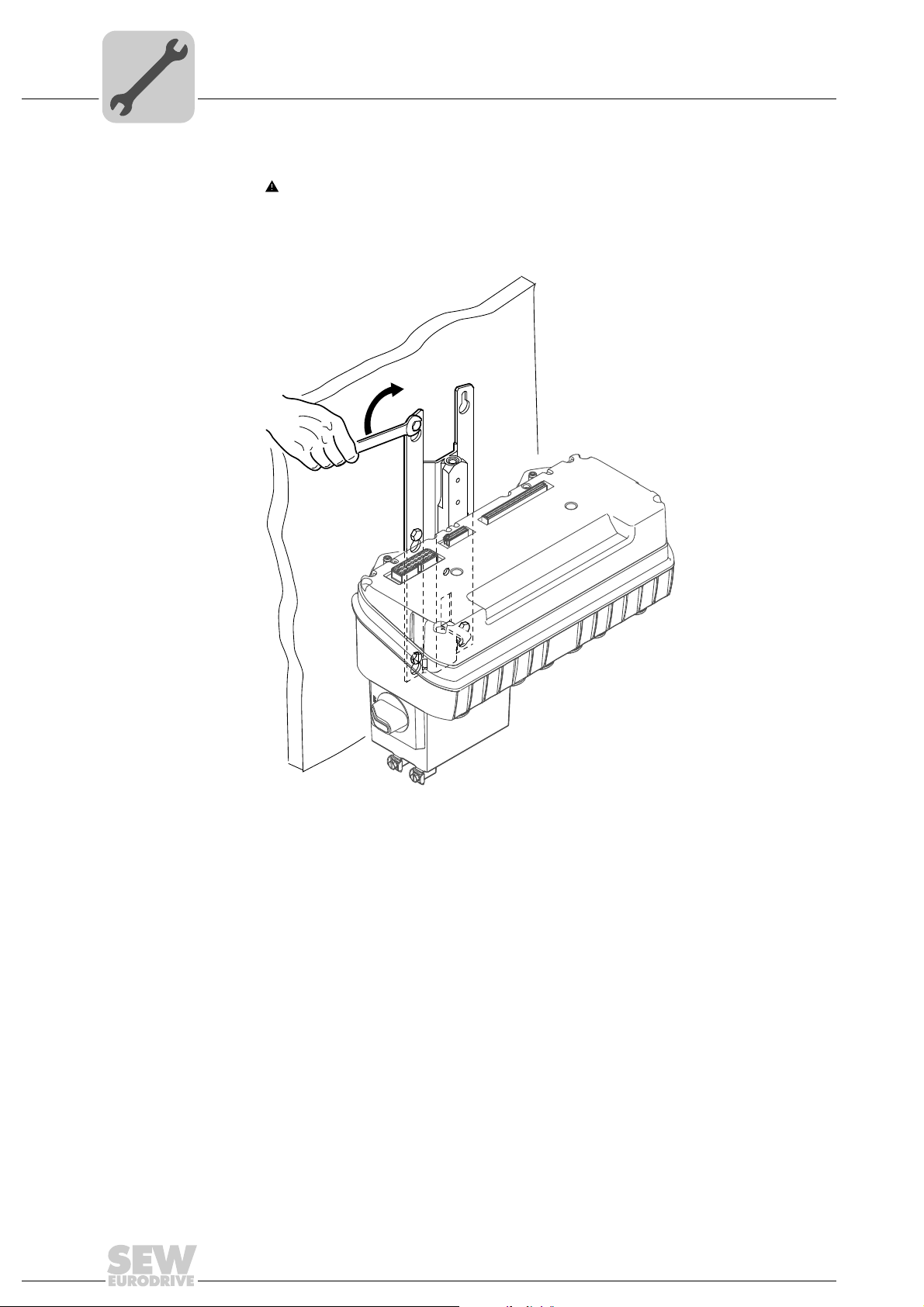

4. Tighten the screws.

CAUTION Risk of injury if the load falls.

Minor injuries

• Tighten at least 4 wall screws to ensure a secure fit after mounting.

3045189003

28

Operating Instructions – MOVIFIT® FDC

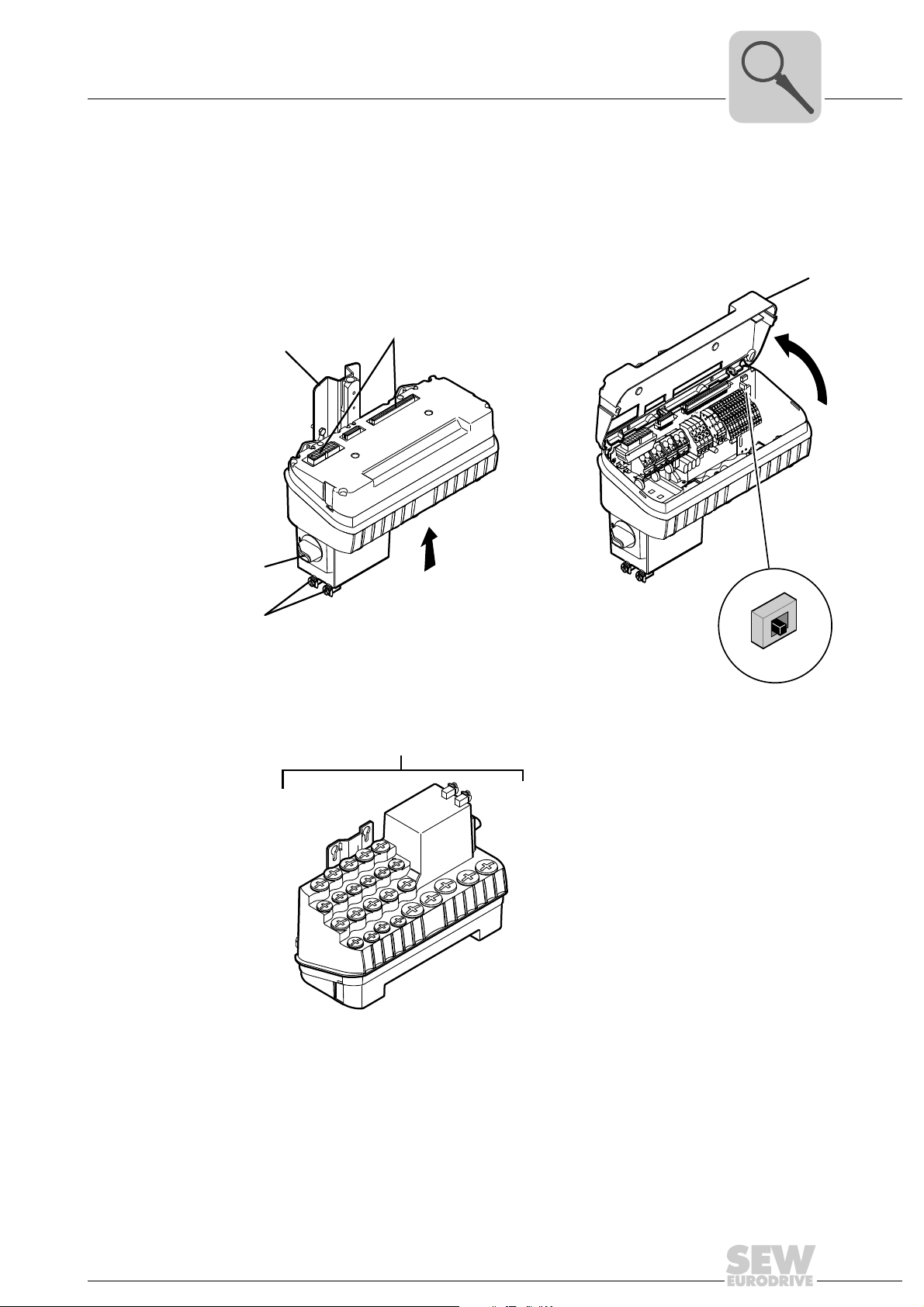

Central opening/closing mechanism

EBOX

ABOX

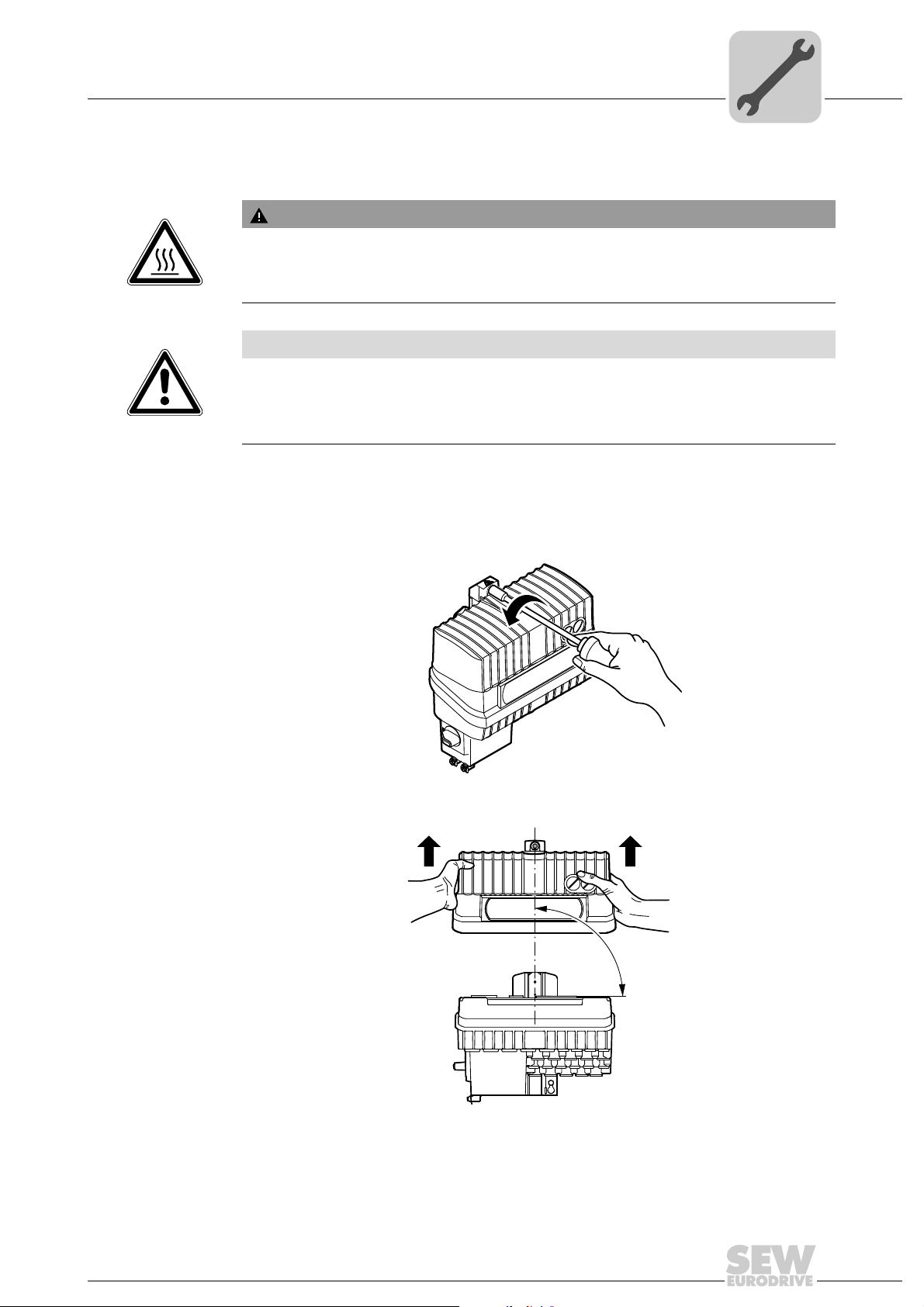

4.4 Central opening/closing mechanism

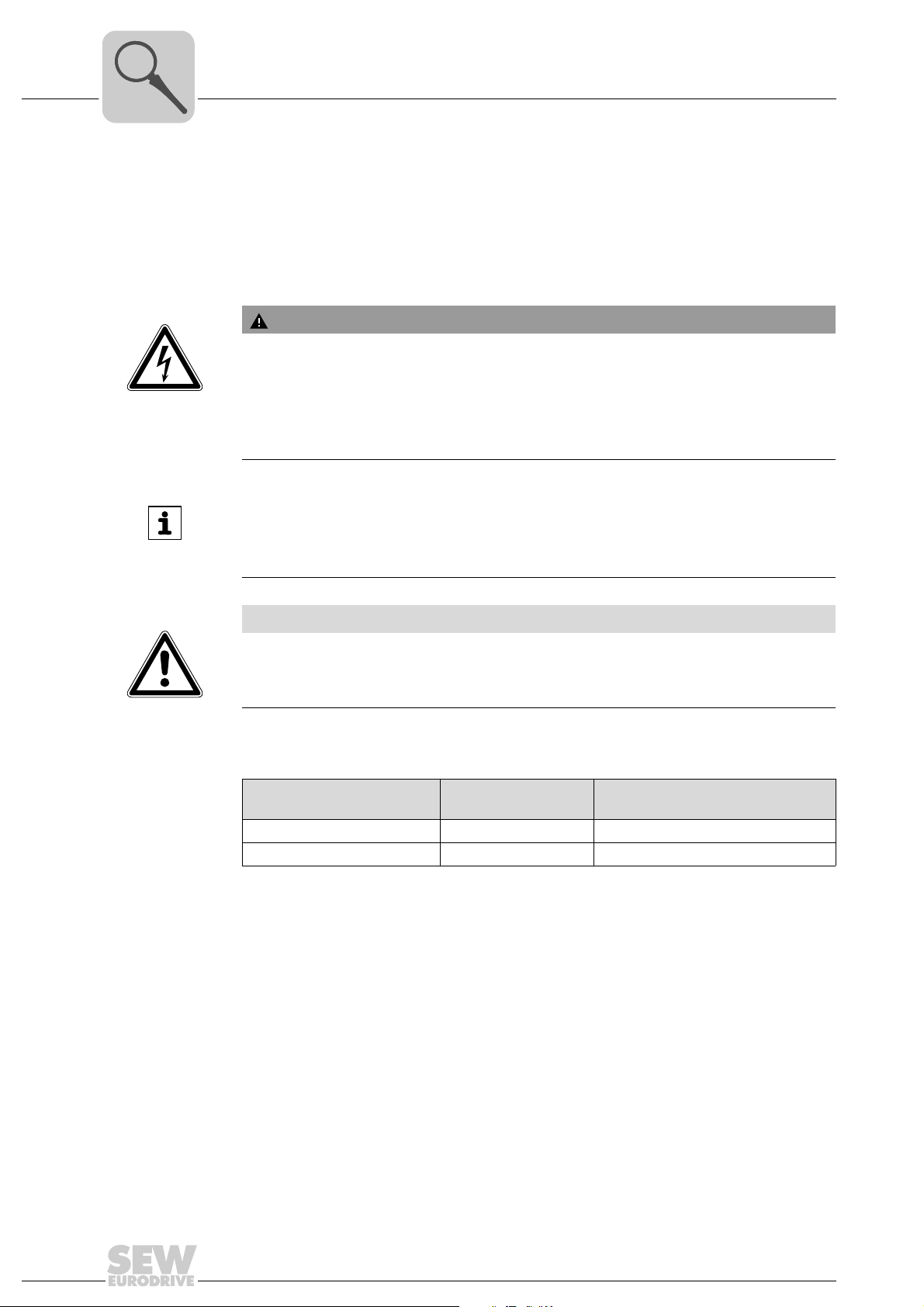

WARNING

Danger of burns due to hot surfaces of the MOVIFIT® unit.

Severe injuries.

• Do not touch the MOVIFIT

NOTICE

The enclosure specified in the technical data only applies when a unit is mounted correctly. MOVIFIT

EBOX is removed from the ABOX.

• Protect the ABOX and the EBOX when the unit is open.

4.4.1 Open

A socket wrench (SW8) is required for the central retaining screw.

®

can be damaged by moisture, dust or foreign particles when the

Mechanical Installation

®

until it has cooled down sufficiently.

4

1. Loosen the central retaining screw and continue to turn in counterclockwise direction

until the EBOX does not move further up.

3041000331

2. Remove the EBOX from the ABOX by lifting it upwards. Do not twist the EBOX.

EBOX

90°

Operating Instructions – MOVIFIT® FDC

ABOX

3041015691

29

4

4.4.2 Closing

Mechanical Installation

Central opening/closing mechanism

A socket wrench (SW8) is required for the central retaining screw.

1. NOTICE An improperly seated gasked in the EBOX creates a strong counterforce

when closing the MOVIFIT

The central opening/closing mechanism may be damaged as a result.

• Make sure that the gasked is properly seated in the groove of the EBOX.

This means that

– the gasket is inserted into the groove over the entire circumference

– and does not protrude from the groove.

2. Position the EBOX on the ABOX.

– Do not twist the EBOX in the process.

– Hold the EBOX only on the sides during the process (see following picture).

®

unit.

90°

3041013771

30

Operating Instructions – MOVIFIT® FDC

Loading...

Loading...