SEW MOVIFIT-SC, MOVIFIT-FC, MOVIFIT-MC User Manual

Gearmotors \ Industrial Gear Units \ Drive Electronics \ Drive Automation \ Services

®

MOVIFIT

Function Level

Edition 05/2007

11591811 / EN

"

Classic

"

M

anual

SEW-EURODRIVE – Driving the world

Contents

1 General Notes .................................................................................................... 5

1.1 Structure of the safety notes ..................................................................... 5

1.2 Right to claim under warranty ................................................................... 5

1.3 Exclusion of liability ................................................................................... 5

1.4 Applicable documents............................................................................... 6

1.5 General safety notes for bus systems....................................................... 6

1.6 Safety functions ........................................................................................ 6

1.7 Hoist applications...................................................................................... 6

2 Index of Changes .............................................................................................. 7

2.1 Changes to the previous version............................................................... 7

3 Introduction ....................................................................................................... 8

3.1 MOVIFIT

®

function level ........................................................................... 8

3.2 "Classic" function level .............................................................................. 8

4 Startup................................................................................................................ 9

4.1 Startup procedure for MOVIFIT

4.2 Startup procedure for MOVIFIT

®

-MC........................................................ 9

®

-SC and -FC ........................................ 10

5 PROFIBUS........................................................................................................ 11

5.1 Project planning for the PROFIBUS master............................................ 11

5.2 Project planning for MOVIFIT

®

-Classic................................................... 16

5.3 Parameter setting using PROFIBUS-DPV1 ............................................ 23

6 PROFINET IO ................................................................................................... 32

6.1 Project planning for the PROFINET IO controller ................................... 32

6.2 Assigning the PROFINET IO unit name.................................................. 34

6.3 Project planning for MOVIFIT

®

-Classic................................................... 36

6.4 PROFINET diagnostic alarms................................................................. 43

7 DeviceNet ......................................................................................................... 46

7.1 Installing the EDS file via RSNetworx ..................................................... 46

7.2 Project planning for MOVIFIT

®

-Classic................................................... 48

7.3 Parameter setting via DeviceNet............................................................. 60

8 Process Data Description............................................................................... 64

8.1 Process image for diagnostics ................................................................ 64

8.2 Process image for digital I/Os ................................................................. 66

8.3 Process image of drive systems ............................................................. 69

9 Fault Responses.............................................................................................. 83

9.1 Fieldbus timeout ..................................................................................... 83

9.2 System fault (SYS-F) .............................................................................. 84

10 Parameter Setting and Diagnostics............................................................... 85

10.1 MOVITOOLS

10.2 Motor/brake startup with MOVIFIT

10.3 Motor/brake startup with MOVIFIT

10.4 Hoist startup with MOVIFIT

10.5 Parameter list for the MOVIFIT

10.6 Parameter description for MOVIFIT

10.7 Parameter list for the MOVIFIT

10.8 Parameter description for MOVIFIT

10.9 Web diagnostics for Ethernet units ....................................................... 126

Manual – MOVIFIT® Function Level "Classic"

®

Motion Studio ................................................................. 85

®

®

-SC.................................................. 88

®

-FC.................................................. 91

-FC in "Expert mode" ................................. 99

®

-SC power section.............................. 100

®

-SC.............................................. 103

®

-FC power section.............................. 113

®

-FC .............................................. 117

3

Contents

11 Technical Data ............................................................................................... 132

11.1 PROFIBUS interface ............................................................................. 132

11.2 MOVIFIT

11.3 PROFINET interface ............................................................................. 133

11.4 DeviceNet interface............................................................................... 133

12 Index ............................................................................................................... 134

®

module IDs and configuration data for PROFIBUS............. 132

4

Manual – MOVIFIT® Function Level "Classic"

General Notes

Structure of the safety notes

1 General Notes

1.1 Structure of the safety notes

The safety notes in these operating instructions are structured as follows:

Symbol SIGNAL WORD

Nature and source of hazard.

Possible consequence(s) if disregarded.

• Measure(s) to avoid the hazard.

Symbol Signal word Meaning Consequences if

disregarded

Example:

DANGER Imminent danger Severe or fatal injuries

1

WARNING Possible hazardous situation Severe or fatal injuries

General hazard

CAUTION Possible hazardous situation Minor injuries

Specific hazard,

e.g. electric shock

STOP Possible damage to property Damage to the drive system or its

NOTE Useful information or tip.

Simplifies handling of the drive

system.

1.2 Right to claim under warranty

As a prerequisite to fault-free operation and fulfillment of warranty claims, you must

adhere to the information in the MOVIFIT

tions before you start working with the unit.

Make sure that the operating instructions are legible and available to persons responsible for the plant and its operation, as well as to persons who work independently on

the unit.

environment

®

documentation. Read the operating instruc-

1.3 Exclusion of liability

You must comply with the information contained in the MOVIFIT® documentation to

ensure safe operation of MOVIFIT

mance features. SEW-EURODRIVE assumes no liability for injury to persons or

damage to equipment or property resulting from non-observance of these operating

instructions. In such cases, any liability for defects is excluded.

Manual – MOVIFIT® Function Level "Classic"

®

and to achieve the specified product and perfor-

5

1

General Notes

Applicable documents

1.4 Applicable documents

• This manual does not replace the detailed operating instructions.

• Only qualified personnel observing all applicable accident prevention guidelines and

the MOVIFIT

version in use) operating instructions may install and take these units into operation.

®

-MC, MOVIFIT®-SC or MOVIFIT®-FC (depending on the MOVIFIT

1.5 General safety notes for bus systems

You are now in possession of a communication system that lets you adapt MOVIMOT

and MOVIFIT® frequency inverters and MOVIFIT® motor starters to the particulars of

your system. As with all bus systems, there is a danger of invisible, external (as far as

the inverter/motor starter is concerned) modifications to the parameters which give rise

to changes in the inverter/motor starter behavior. This may result in unexpected (not

uncontrolled) system behavior.

1.6 Safety functions

®

®

MOVIFIT® may not perform any safety functions unless they are described and

expressly approved.

For safety applications, ensure that the information in the following publication is

observed.

• Safe disconnection for MOVIFIT

Use only those components in safety applications that were explicitly designed and

delivered for this purpose by SEW-EURODRIVE.

1.7 Hoist applications

• Hoist applications can only be implemented with MOVIFIT®-FC in combination with

the "Classic" function level under the following conditions:

– A hoist startup must be performed.

• MOVIFIT

Use monitoring systems or mechanical protection devices as safety equipment to

avoid possible damage to property or injury to people.

®

®

-FC is not designed for use as a safety device in hoist applications.

6

Manual – MOVIFIT® Function Level "Classic"

2 Index of Changes

2.1 Changes to the previous version

The following section lists the main changes made to the individual sections from the

06/2006 edition, part number 11461012 (EN).

Index of Changes

Changes to the previous version

2

"PROFINET IO"

section

"Device Net"

section

"Parameter

Setting and

Diagnostics"

section

"Technical Data"

section

• New section "Project planning for the PROFINET IO controller"

• New section "Assigning the PROFINET IO unit name"

• New section "Project Planning for MOVIFIT

• New section "PROFINET diagnostic alarms"

• New section "Installing the EDS file via RSNetworx"

• New section "Project Planning for MOVIFIT

• New section "Parameter setting via DeviceNet"

• New section "MOVITOOLS

• New section "Web diagnostics for Ethernet units"

• New section "PROFINET interface"

• New section "DeviceNet interface"

®

Motion Studio"

®

-Classic"

®

-Classic"

Manual – MOVIFIT® Function Level "Classic"

7

3

Introduction

MOVIFIT® function level

3 Introduction

3.1 MOVIFIT® function level

Function level indicates the functions included in the software for MOVIFIT® units

regarding operation, system control and diagnostics.

The following figure gives an overview of the MOVIFIT

®

function levels:

Classic

Simple functions

Control as fieldbus gateway

via MOVILINK

Functionality

Easy to use, can be

compared to e.g. control

of SEW field distributors

(Z.3, Z.6, etc.)

®

Classic

Technology

Open programming

Multi-level library concept

Target industry: mechanical

engineering

Functional building blocks

set by parameters

Programming takes place

acc. to IEC 61131

(e. g. in KOP, FUP, AWL,

ST, AS)

Technology

Function level

System

Configurable industry solution

Target industry: materials

handling technology

Central data storage for

decentralized units

Client-server architecture

Parameter and diagnostic

system

Drive-oriented conveyor

functions

Reusability of functions

System

59750AEN

NOTE

This manual describes the MOVIFIT

other MOVIFIT

appropriate manuals.

3.2 "Classic" function level

The Classic function level makes for simple and reliable communication with MOVIFIT

units.

The important drive parameters and the local I/Os can be transferred to and processed

by the higher-level PLC. This means the PLC is capable of controlling drive-related functions.

Operating software is not mandatory for the Classic function level. Communication

between the PLC and MOVIFIT

form MOVILINK

the existing decentralized components from SEW-EURODRIVE.

®

®

function levels, refer to the MOVIFIT® system description and the

®

unit profile from SEW-EURODRIVE. This means it is compatible with

"Classic" function level. For information on the

®

units is based on process data according to the uni-

®

8

Manual – MOVIFIT® Function Level "Classic"

4Startup

Startup

Startup procedure for MOVIFIT®-MC

I

4

00

This publication describes the parameter settings and fieldbus configuration required for

MOVIFIT

®

in combination with the "Classic" function level.

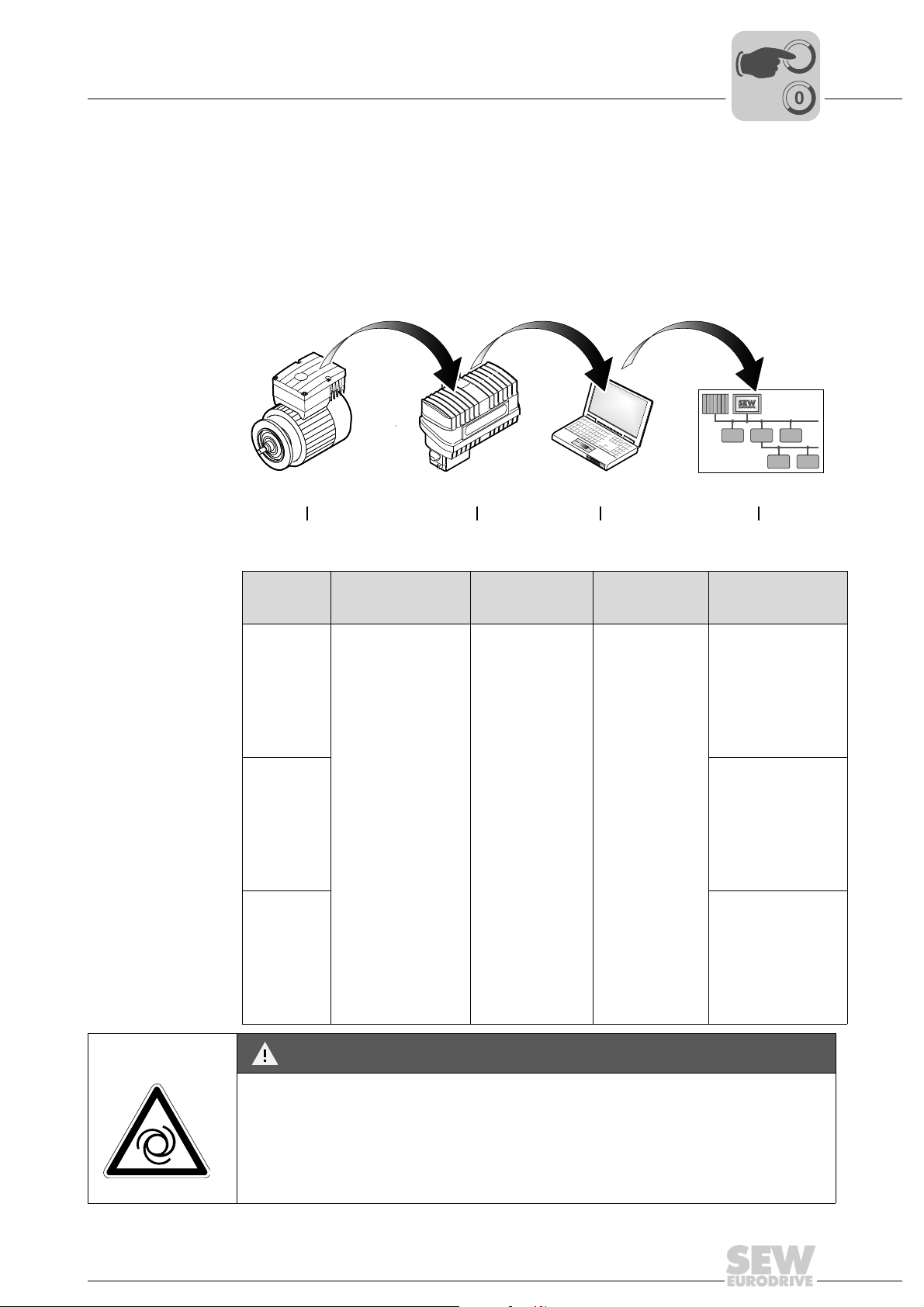

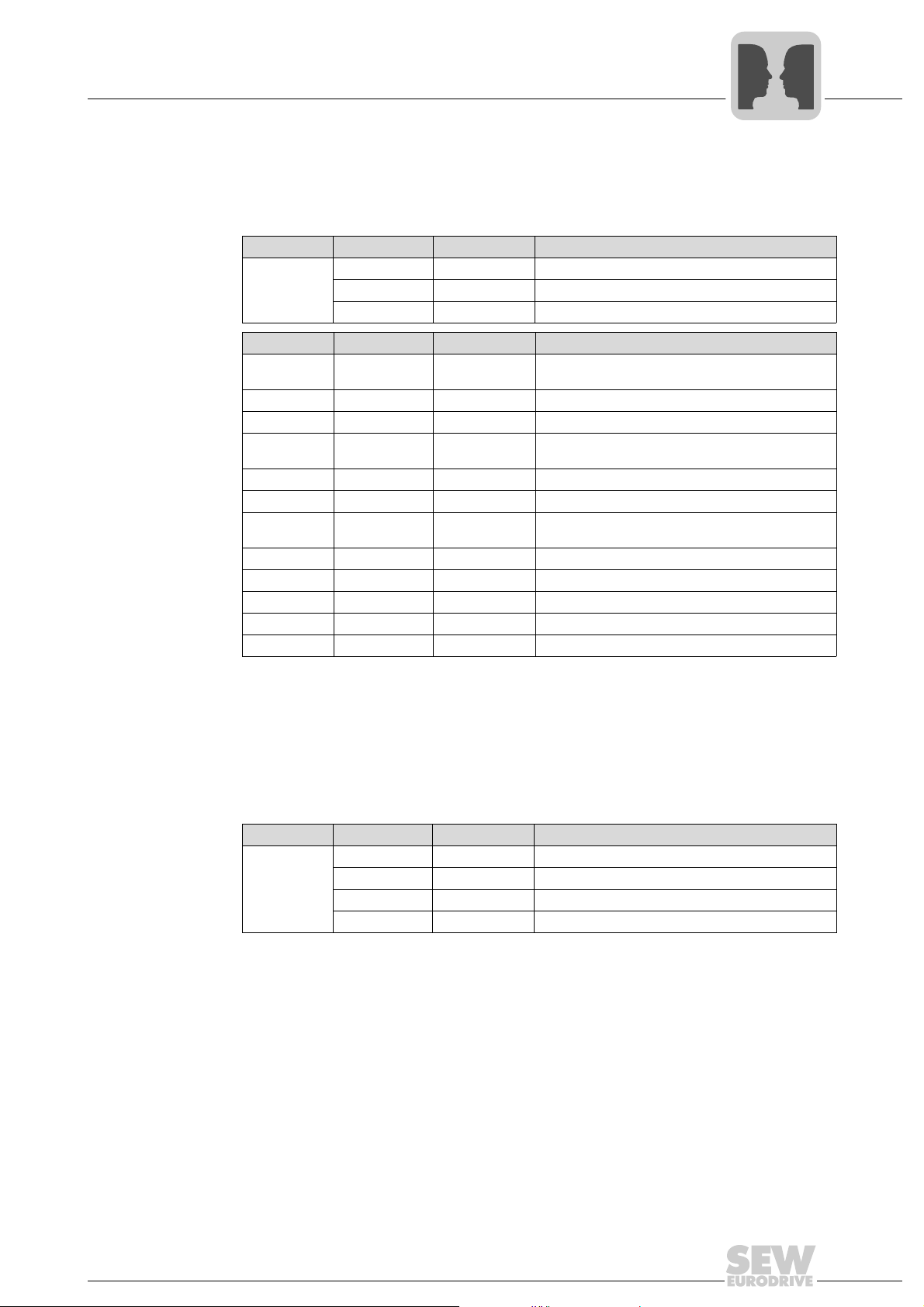

4.1 Startup procedure for MOVIFIT®-MC

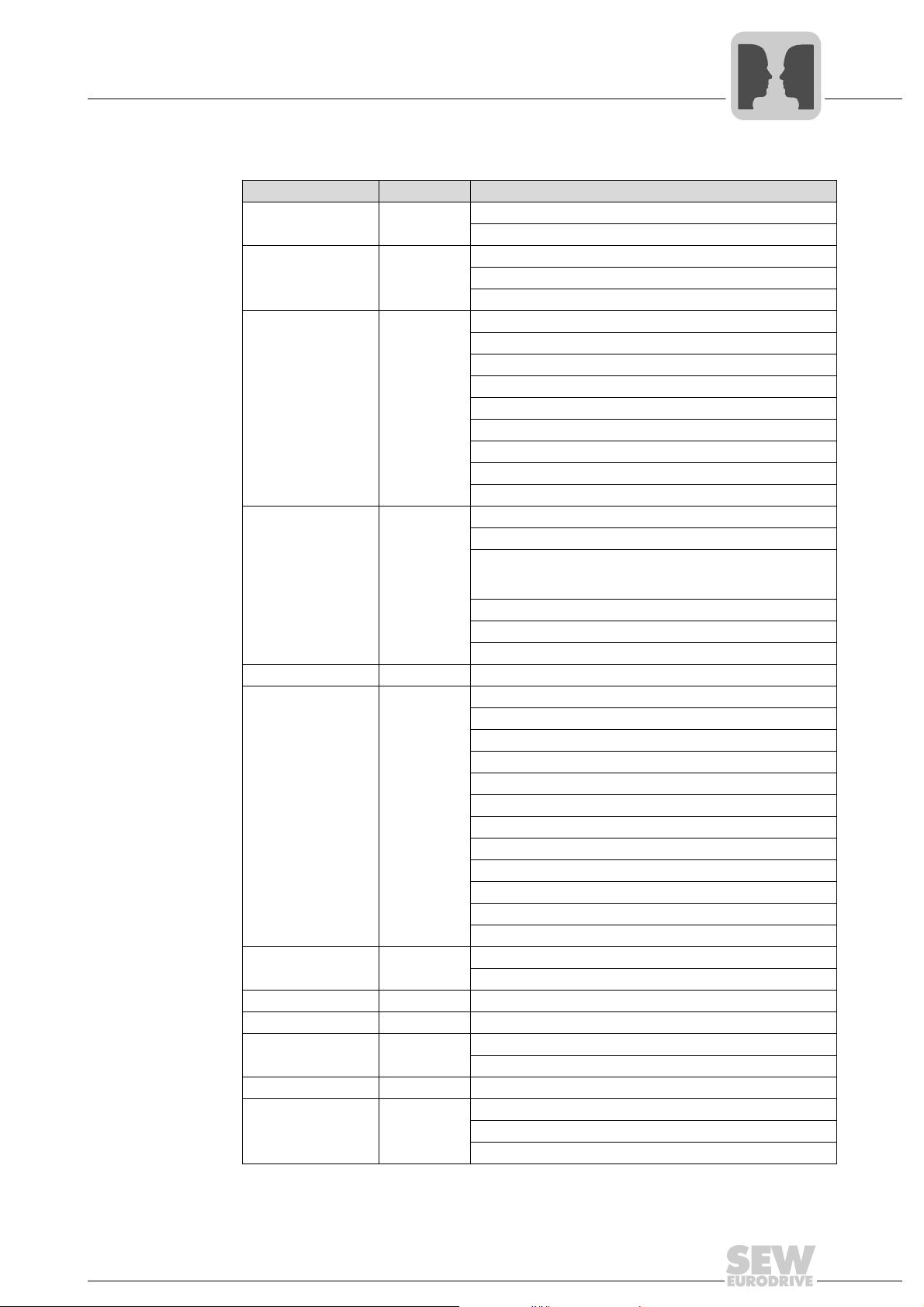

The following table gives an overview of the MOVIFIT®-MC startup procedure and lists

other applicable documentation:

MOVIMOT

Function

level

Classic

PROFIBUS

Classic

PROFINET

IO

Classic

DeviceNet

®

MOVIFIT

1. 2. 4.

1.

Startup

®

-MC

®

®

oper-

MOVIMOT

• MOVIFIT

operating instructions

• MOVIMOT

ating instructions

®

-MC Parameter setting

3.

2.

Startup

®

-MC

®

-MC

MOVIFIT

MOVIFIT

operating instructions

Parameter

–•PROFIBUS-DP,

3.

setting

Fieldbus configuration

58971AEN

4.

Fieldbus

configuration

see page 11

• Process data

description, see

page 64

• Fault responses,

see page 83

• Technical data,

see page 132

• PROFINET IO,

see page 32

• Process data

description,

see page 64

• Fault responses,

see page 83

• Technical data,

see page 133

• DeviceNet,

see page 46

• Process data

description,

see page 64

• Fault responses,

see page 83

• Technical data,

see page 133

DANGER

If you are using applications with safe disconnection (only possible with MOVIFIT

or -FC), you must additionally observe the SEW publication "Safe Disconnection for

MOVIFIT

®

".

Severe or fatal injuries.

• Observe additional startup instructions and safety conditions in the SEW publication

"Safe Disconnection for MOVIFIT

Manual – MOVIFIT® Function Level "Classic"

®

-MC

®

".

9

I

4

Startup

Startup procedure for MOVIFIT®-SC and -FC

00

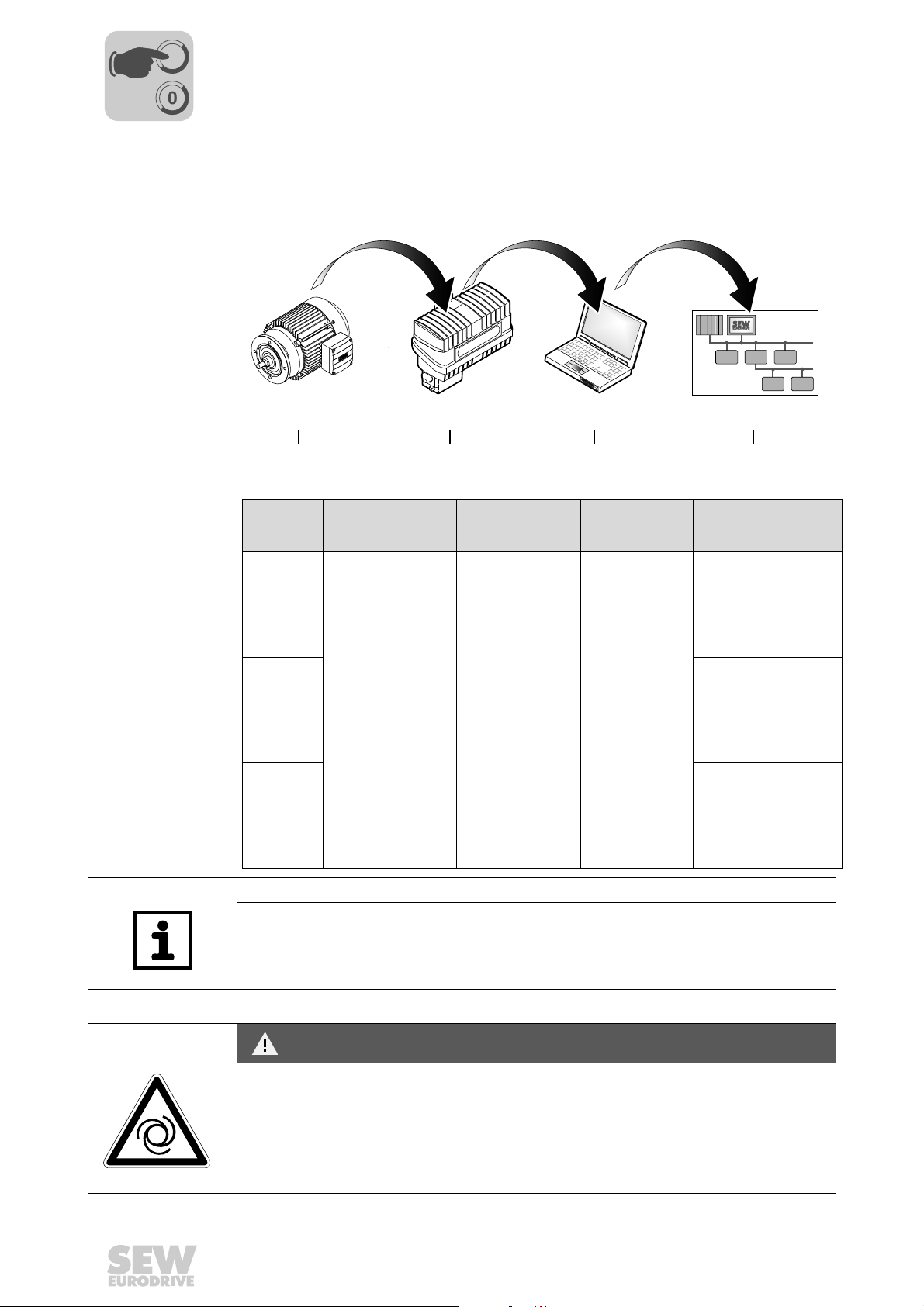

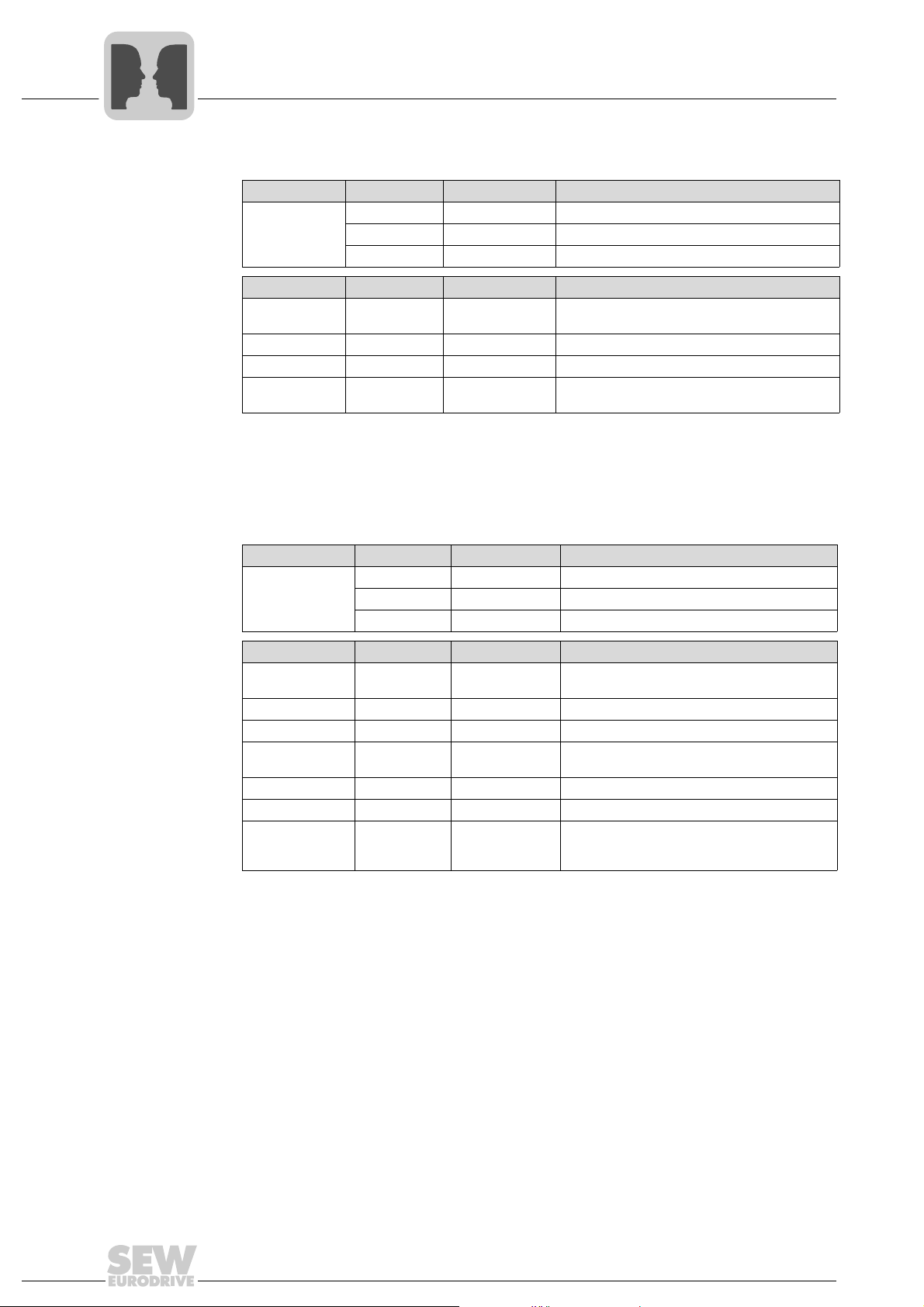

4.2 Startup procedure for MOVIFIT®-SC and -FC

The following table gives an overview of the MOVIFIT®-SC/-FC startup procedure and

lists other applicable documentation:

Motor

1. 2. 4.

Function

level

Classic

PROFIBUS

Classic

PROFINET

IO

Classic

DeviceNet

MOVIFIT®-SC/-FC Parameter setting

1.

Startup

Motor

"DR/DV/DT/DTE/DVE

AC Motors, CT/CV

Asynchronous Servomotors" operating

instructions

2.

Startup

MOVIFIT

• MOVIFIT

• MOVIFIT

®

operating

instructions

operating

instructions

-SC/-FC

®

-SC

®

-FC

3.

3.

Parameter

setting

Parameter setting and diagnostics, see page 85

Fieldbus configuration

59761AEN

4.

Fieldbus

configuration

• PROFIBUS DP,

see page 11

• Process data

description, see

page 64

• Fault responses,

see page 83

• PROFINET IO,

see page 32

• Process data

description,

see page 64

• Fault responses,

see page 83

• DeviceNet,

see page 46

• Process data

description,

see page 64

• Fault responses,

see page 83

10

NOTE

• Parameters only have to be set in the "Classic" function level when "expert mode"

is activated.

• For information about "easy mode", see the relevant MOVIFIT

®

operating instruc-

tions.

DANGER

If you are using applications with safe disconnection (only possible with MOVIFIT

or -FC), you must additionally observe the SEW publication "Safe Disconnection for

MOVIFIT

®

".

®

-MC

Severe or fatal injuries.

• Observe additional startup instructions and safety conditions in the SEW publication

"Safe Disconnection for MOVIFIT

®

".

Manual – MOVIFIT® Function Level "Classic"

Project planning for the PROFIBUS master

5 PROFIBUS

NOTE

For information about PROFIBUS connection, PROFIBUS startup (addressing, etc.) or

the description of the PROFIBUS LED displays, see the relevant MOVIFIT

instructions.

5.1 Project planning for the PROFIBUS master

There are GSD files for project planning of the DP master. These files are read in with

the project planning software of the DP master and are then available for project planning of the DP master. Refer to the relevant project planning software manuals for

details on the procedure.

• Read the information in the PDF files about the GSD file.

• Install the GSD file "SEW_600A.GSD" according to the instructions of the project

planning software for the DP master.

• After successful installation, the "MOVIFIT

slave stations.

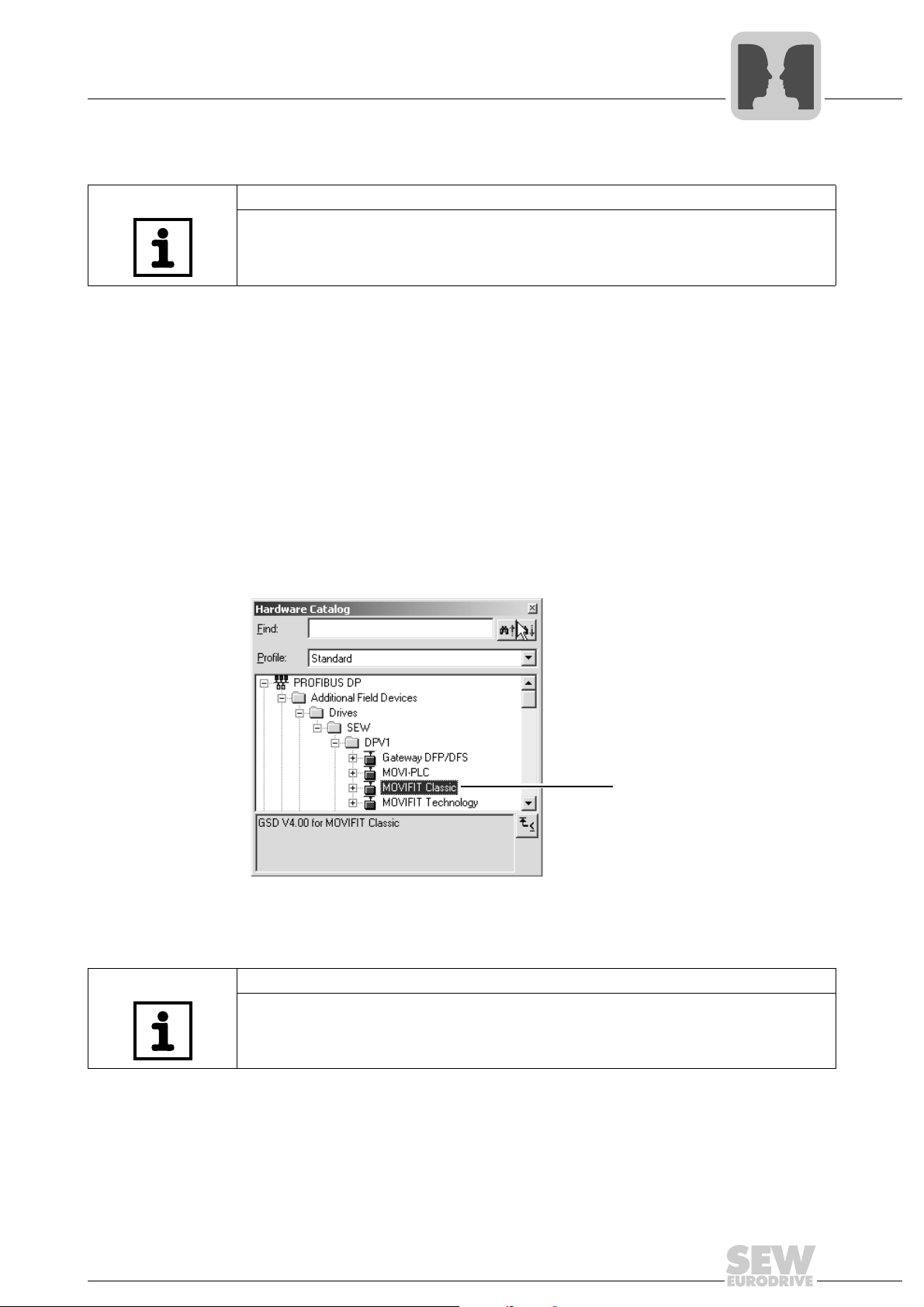

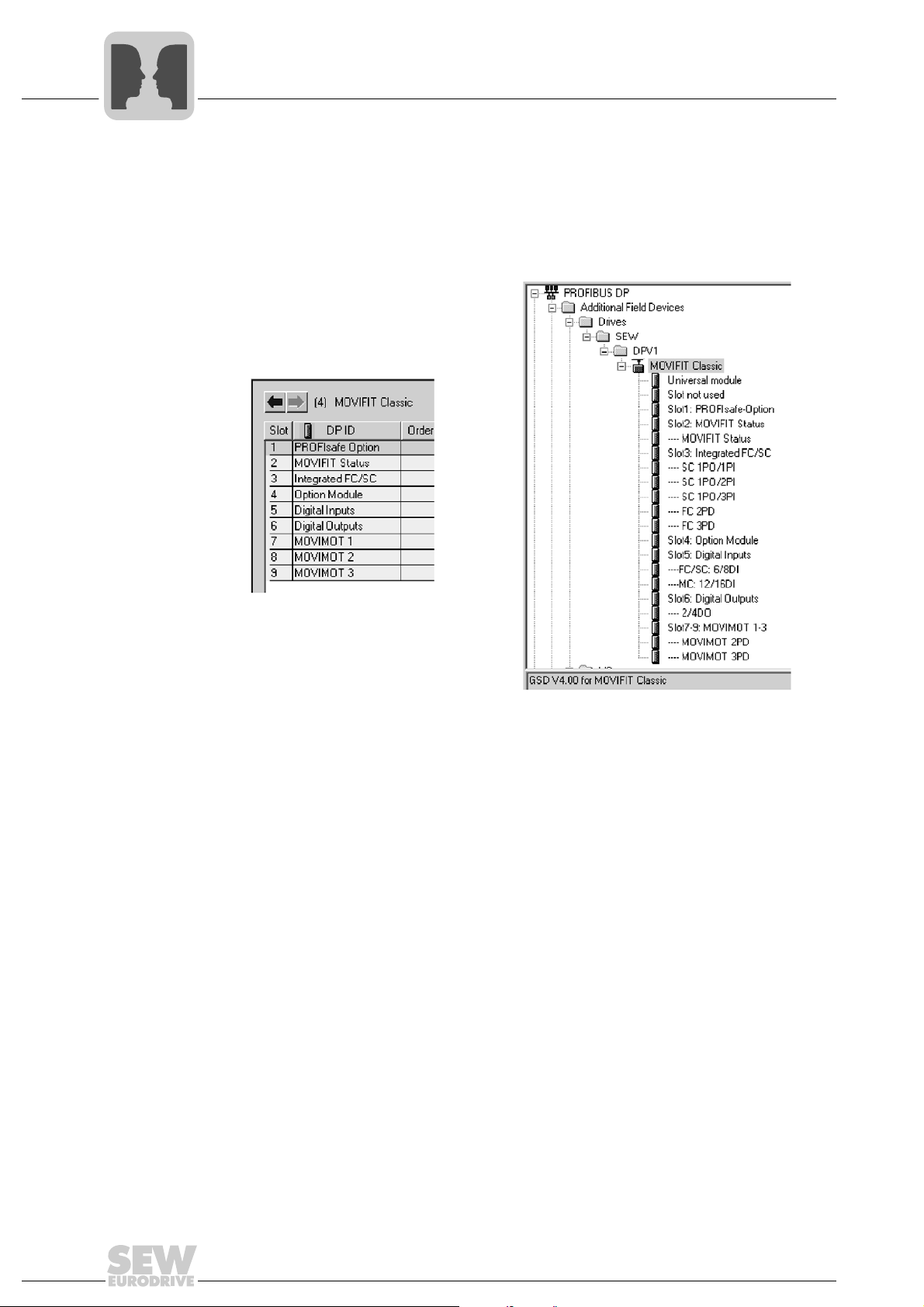

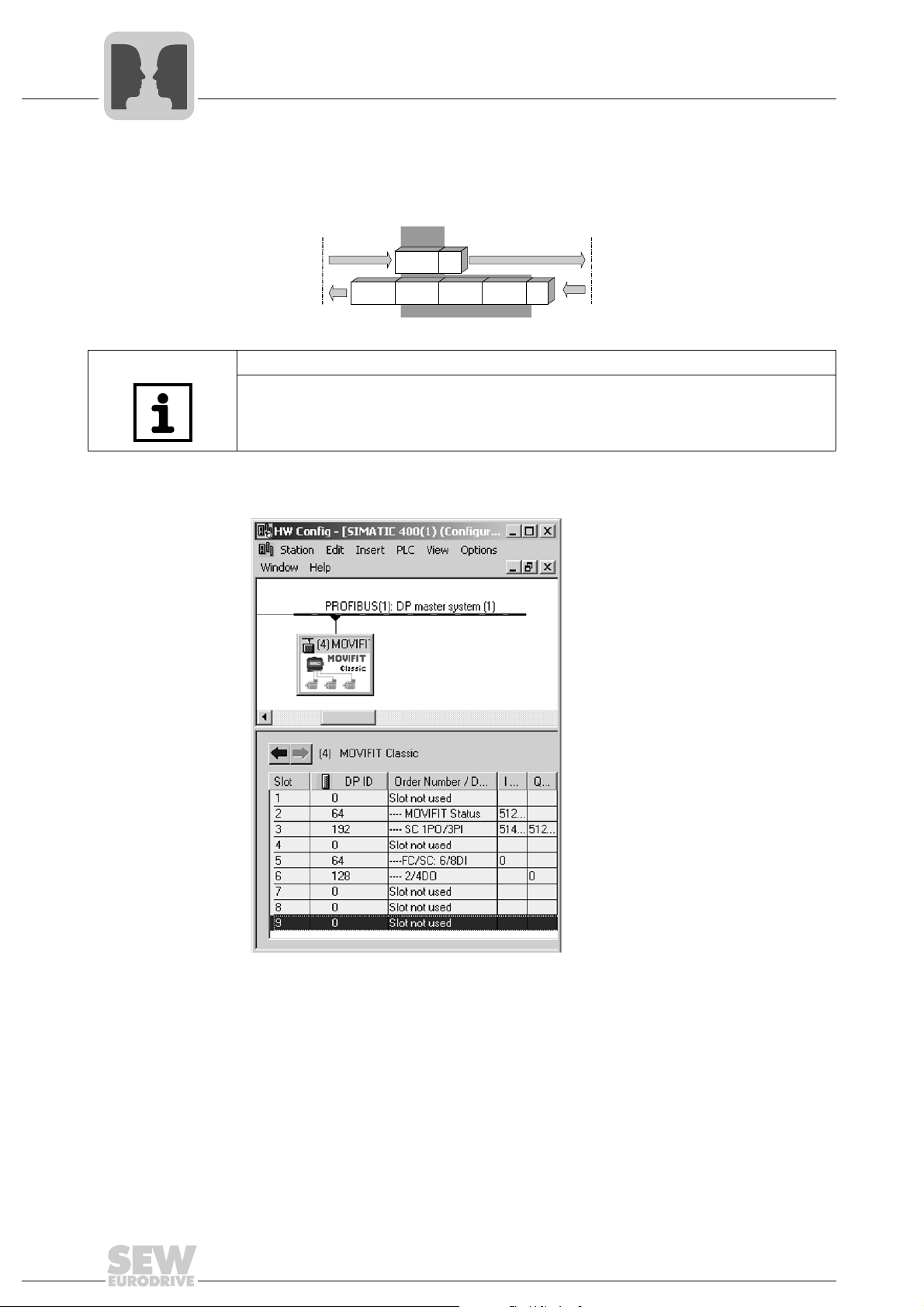

The following screenshot shows how the MOVIFIT

STEP7 HW Config:

PROFIBUS

®

operating

®

-Classic" unit is displayed in the list of

®

-Classic GSD is displayed in the

5

[1]

59741AXX

[1] MOVIFIT®-Classic GSD in STEP7 HW Config

NOTE

The latest version of the GSD files is always available on the Internet at the following

address: http://www.sew-eurodrive.com

Manual – MOVIFIT® Function Level "Classic"

11

5

PROFIBUS

Project planning for the PROFIBUS master

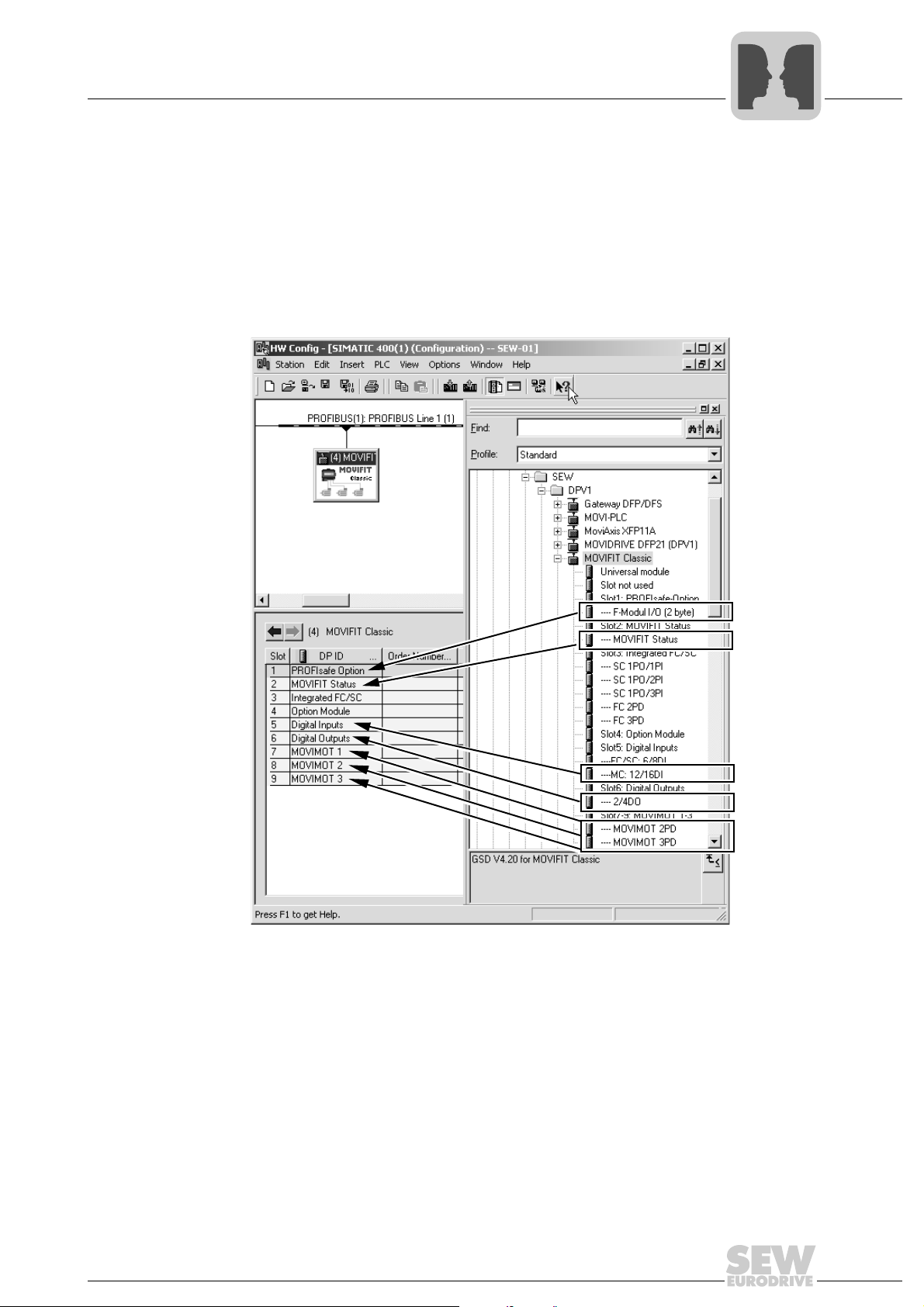

1. Add "MOVIFIT®-Classic" to the PROFIBUS structure and assign the PROFIBUS

address. This address must match the PROFIBUS address you set later in the

MOVIFIT

2. Select all MOVIFIT

3. Delete all slot entries so that you can begin project planning for your application. The

HW Config displays the assignment of the slots in plain text.

The following figure displays points 1 through 3:

®

connection box (see the appropriate MOVIFIT® operating instructions).

®

slots.

3.

1.

2.

59742AXX

12

Manual – MOVIFIT® Function Level "Classic"

PROFIBUS

Project planning for the PROFIBUS master

5

4. Select the process data configuration required for your application (see the following

examples for the various MOVIFIT

assigned to unused slots.

5. If you have performed project planning for a PROFIsafe option, you must also set the

parameters for this option. Information about this is available in the "Safe Disconnection for MOVIFIT

STEP 7 Project planning of a MOVIFIT

®

" manual.

®

versions). Note: An empty module must be

®

-MC:

Manual – MOVIFIT® Function Level "Classic"

61803AXX

13

5

PROFIBUS

Project planning for the PROFIBUS master

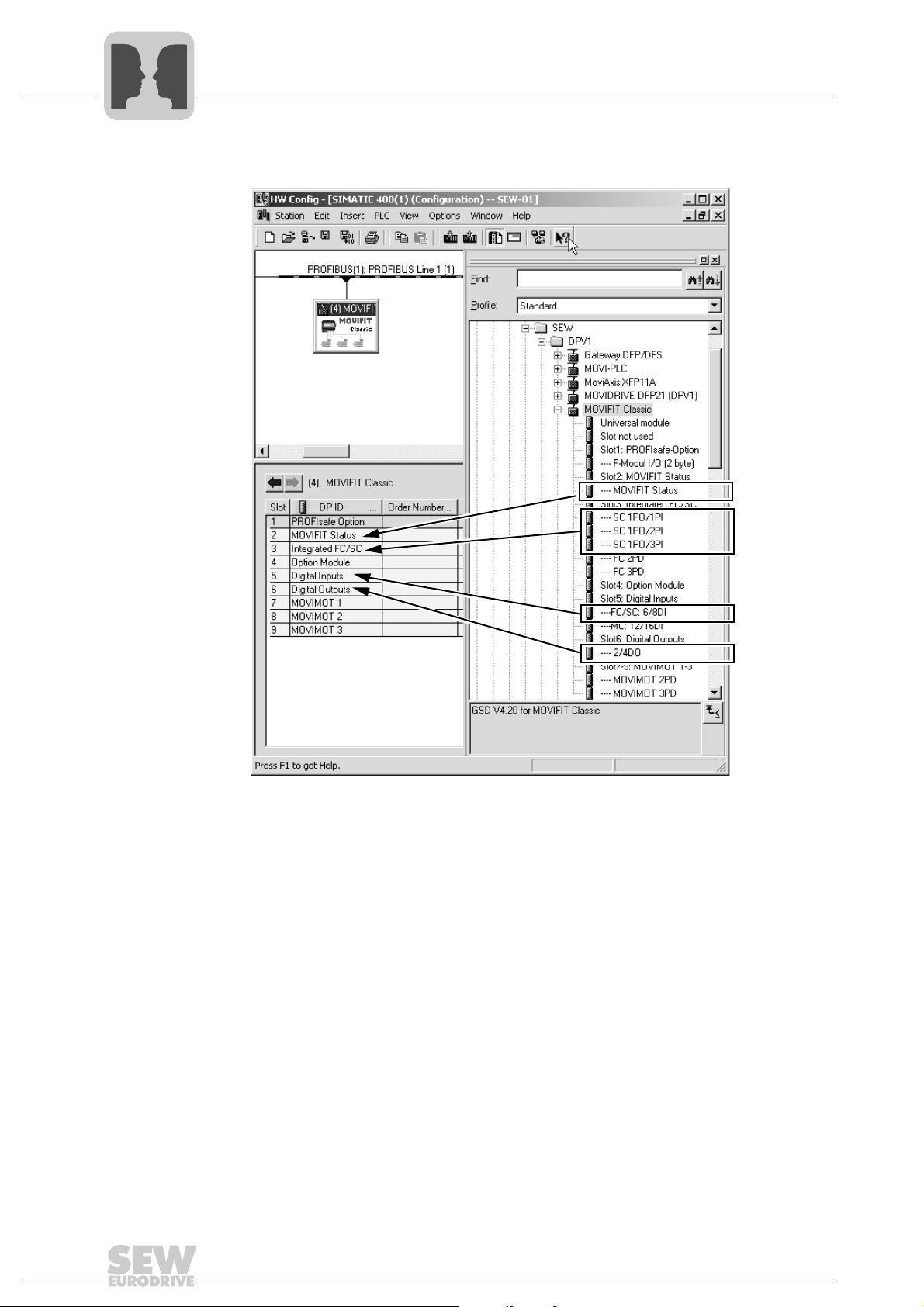

STEP 7 Project planning of a MOVIFIT®-SC:

61804AXX

14

Manual – MOVIFIT® Function Level "Classic"

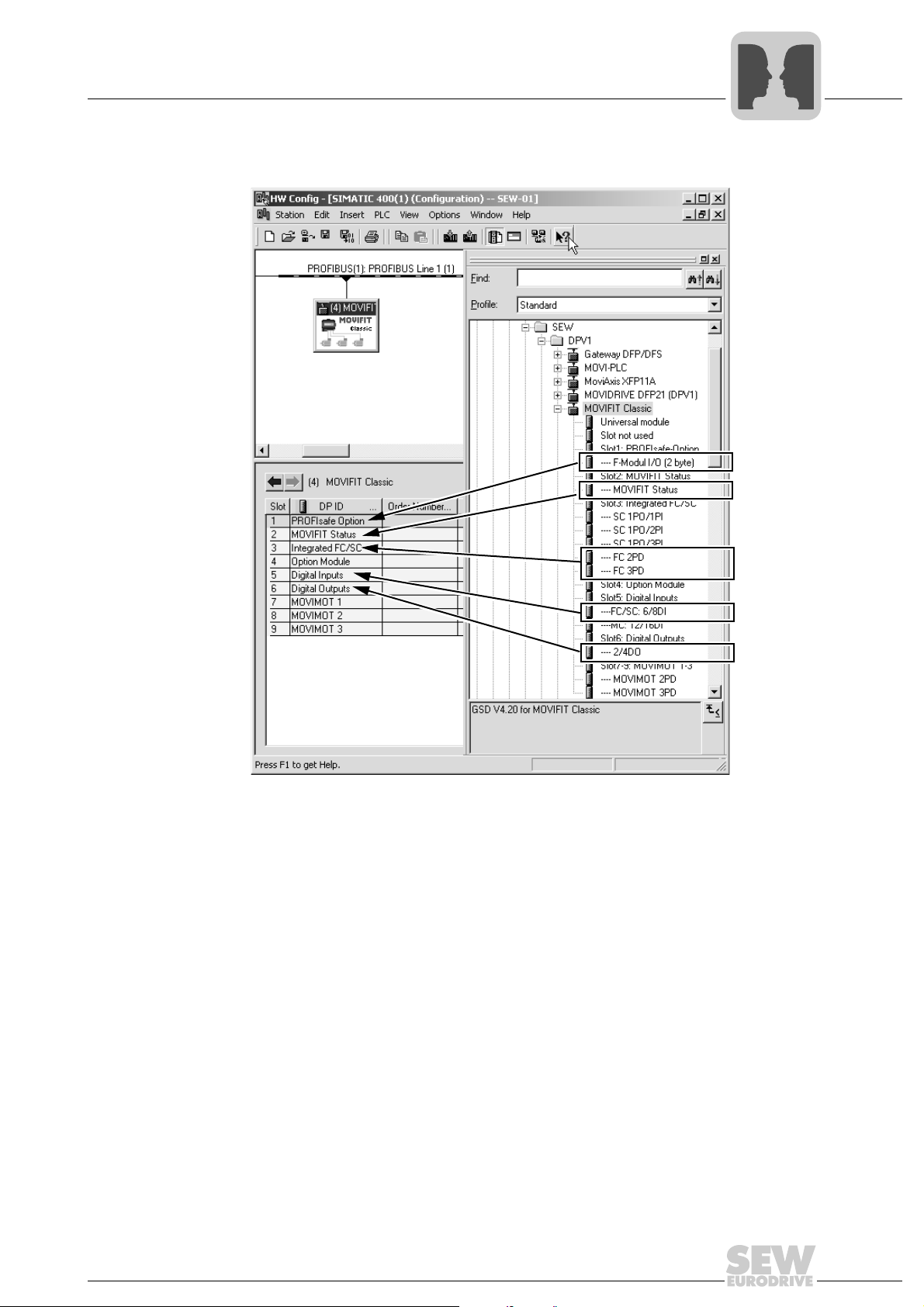

Project planning for the PROFIBUS master

STEP 7 Project planning of a MOVIFIT®-FC:

PROFIBUS

5

61806AXX

6. Enter the I/O or periphery addresses for the configured data widths.

7. Save the configuration.

8. Add data exchange with the MOVIFIT

9. Save the project and load it into the DP master. Once the DP master has been

started, the "BUS-F" LED of the MOVIFIT

check the wiring and terminating resistors of the PROFIBUS and the project planning, especially the PROFIBUS address set in the connection box (see the corresponding MOVIFIT

®

operating instructions).

®

units to your program.

®

should go out. If this is not the case,

Manual – MOVIFIT® Function Level "Classic"

15

5

PROFIBUS

Project planning for MOVIFIT®-Classic

5.2 Project planning for MOVIFIT®-Classic

The slot model is used for project planning with PROFIBUS DPV1. Each slot is assigned

to a MOVIFIT

the entire MOVIFIT

The following figure demonstrates MOVIFIT

®

communication interface. The project planning process is the same for

®

-Classic line. The following division is used:

®

-Classic project planning in STEP7:

11337AXX

16

Manual – MOVIFIT® Function Level "Classic"

PROFIBUS

Project planning for MOVIFIT®-Classic

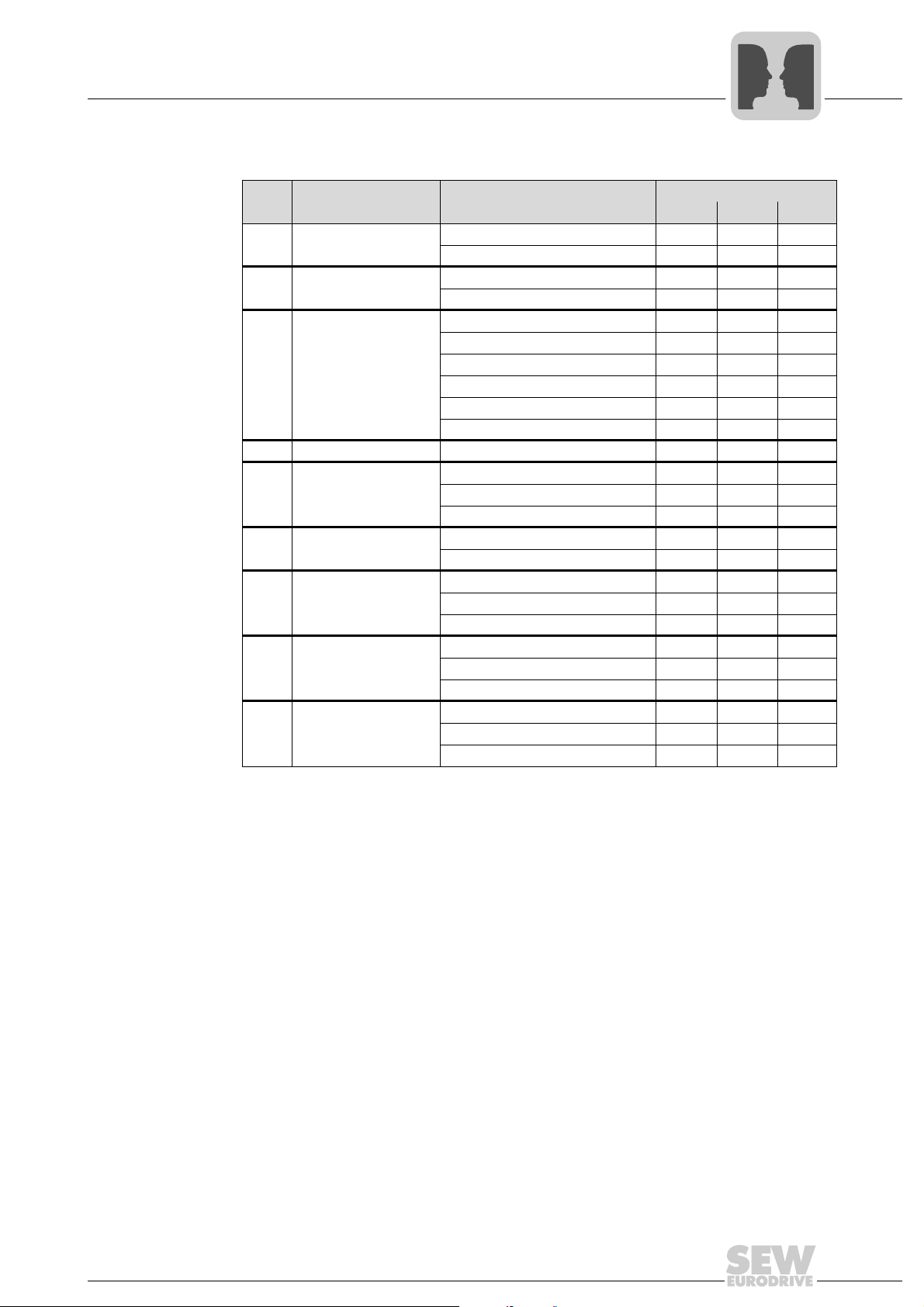

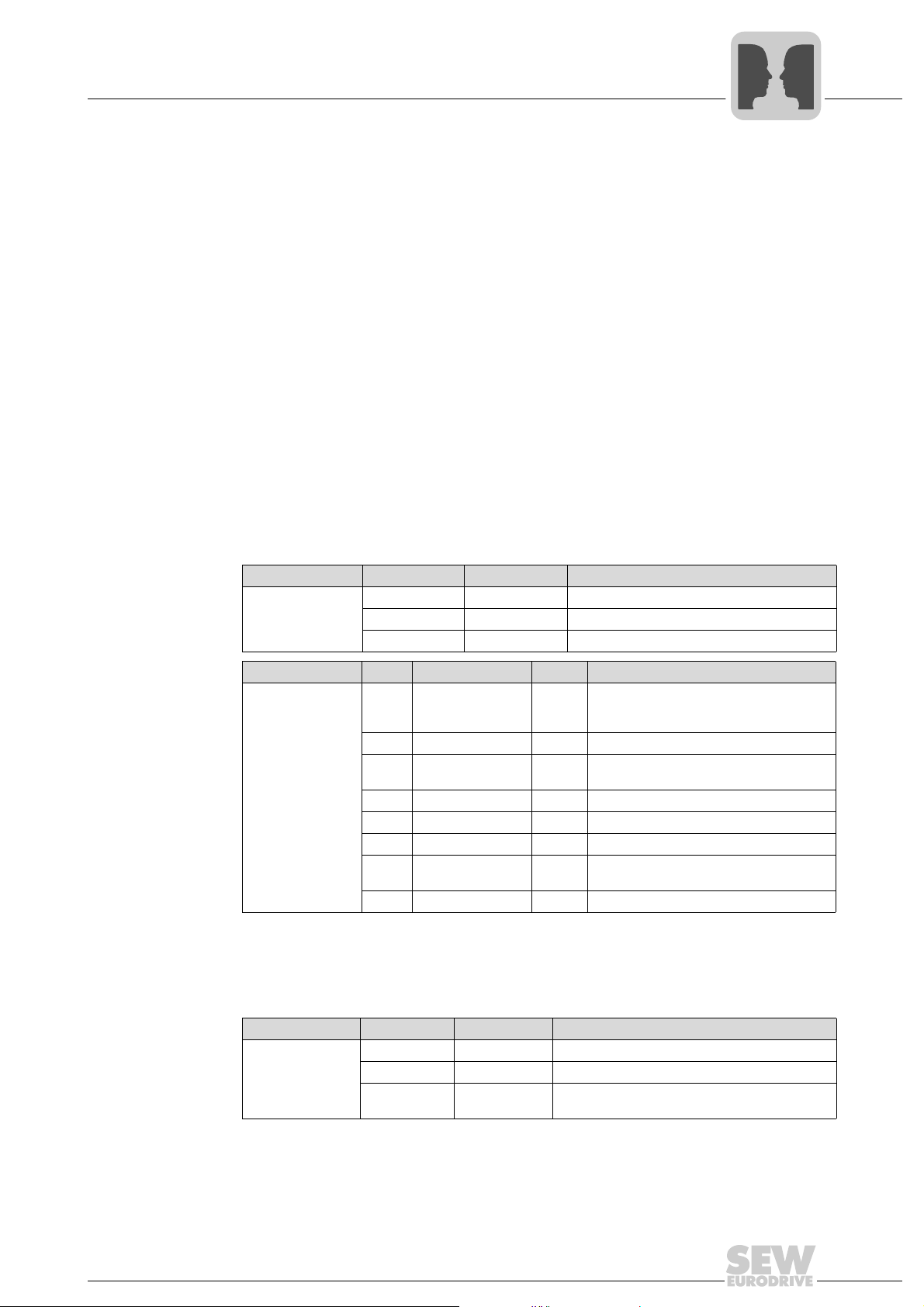

The following table shows PROFIBUS project planning for MOVIFIT®-Classic:

Slot Assignment (DP-ID) Plug-in modules Slot used in

MC FC SC

1 "PROFIsafe-Option" "Slot not used" x x

"F module I/O" (2 byte) x x

®

2"MOVIFIT

3 "Integrated FC/SC" "Slot not used" x x x

4 "Option Module" "Slot not used" x x x

5 "Digital Inputs" "Slot not used" x x x

6 "Digital Outputs" "Slot not used" x x x

7 "MOVIMOT

8 "MOVIMOT

9 "MOVIMOT

Status" "Slot not used" x x x

®

"MOVIFIT

"SC 1PO/1PI" x

"SC 1PO/2PI" x

"SC 1PO/3PI" x

"FC 2PD" x

"FC 3PD" x

"FC/SC: 6/8DI" x x

"MC: 12/16DI" x

"2/4 DO" 4DO 2DO 2DO

®

1" "Slot not used" x x x

"MOVIMOT

"MOVIMOT

®

2" "Slot not used" x x x

"MOVIMOT

"MOVIMOT

®

3" "Slot not used" x x x

"MOVIMOT

"MOVIMOT

Status" x x x

®

2PD" x

®

3PD" x

®

2PD" x

®

3PD" x

®

2PD" x

®

3PD" x

5

Submodule IDs are assigned to ensure unique identification of the unit variants. These

IDs are transferred to the Set PRM User data during startup of the PROFIBUS system.

The Prm structure ID 0x20 (32dec) is used for manufacturer-specific coding. The ID

0x05 defined according to the PROFIsafe specification is used for the F parameter

block.

Manual – MOVIFIT® Function Level "Classic"

17

5

PROFIBUS

Project planning for MOVIFIT®-Classic

5.2.1 Application example MOVIFIT®-MC

The following application requirements should be implemented with MOVIFIT

• Three MOVIMOT

®

that the control word, the speed and the times for acceleration and deceleration

ramps are specified cyclically by the higher-level controller.

• The 12 digital inputs and 4 digital outputs of MOVIFIT

sensors and actuators.

• The sensor/actuator channels and the maintenance switches are to be monitored

within the control program.

• No options are to be used.

The following table shows the configuration example for this MOVIFIT

Slot Assignment (DP-ID) Plug-in module

1 "PROFIsafe-Option" "Slot not used"

®

2 "MOVIFIT

3 "Integrated FC/SC" "Slot not used"

4 "Option Module" "Slot not used"

5 "Digital Inputs" "MC: 12/16DI"

6 "Digital Outputs" "2/4 DO"

7 "MOVIMOT

8 "MOVIMOT

9 "MOVIMOT

Status" "MOVIFIT®-Status"

®

1" "MOVIMOT® 3PD"

®

2" "MOVIMOT® 3PD"

®

3" "MOVIMOT® 3PD"

®

-MC:

drives are controlled with 3 process data words, which means

®

are used to address external

®

-MC application.

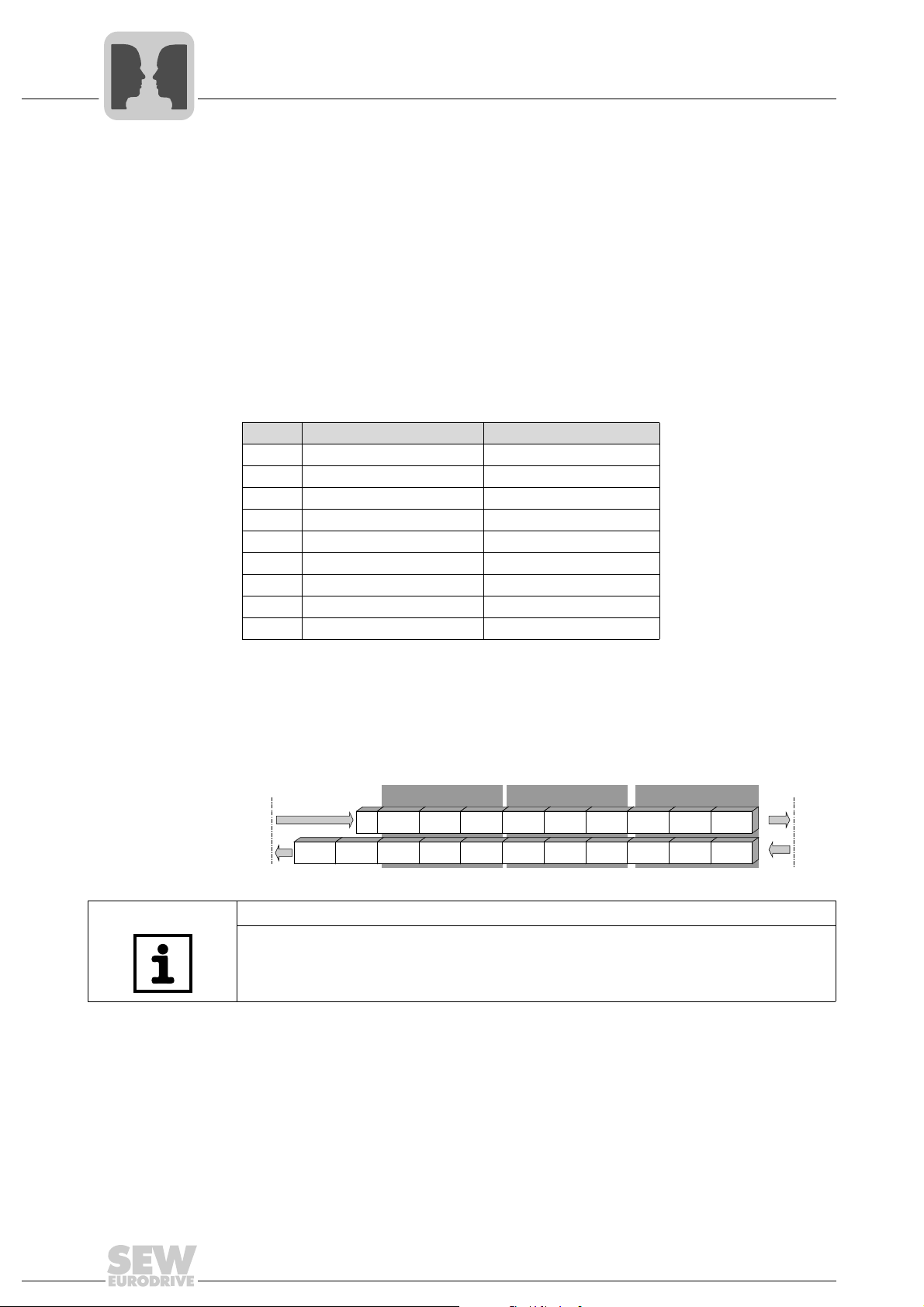

The following figure shows which process data is transferred via the bus system.

19 bytes are sent as output data from the fieldbus master to MOVIFIT

®

-MC and 22 bytes

are sent as input data to the fieldbus master.

Fieldbus

master

Status 12DI

MOVIMOT® 3MOVIMOT® 2MOVIMOT® 1

4DO

PO1 PO2 PO3 PO1 PO2 PO3 PO1 PO2 PO3

PI1 PI2 PI3 PI1 PI2 PI3 PI1 PI2 PI3

MOVIFIT

®

MC

61889AEN

NOTE

For information on the coding of process data for MOVIMOT

®

drives, digital I/Os and

status information (maintenance switches), see the "Process Data Description" section

from page 64.

18

Manual – MOVIFIT® Function Level "Classic"

PROFIBUS

Project planning for MOVIFIT®-Classic

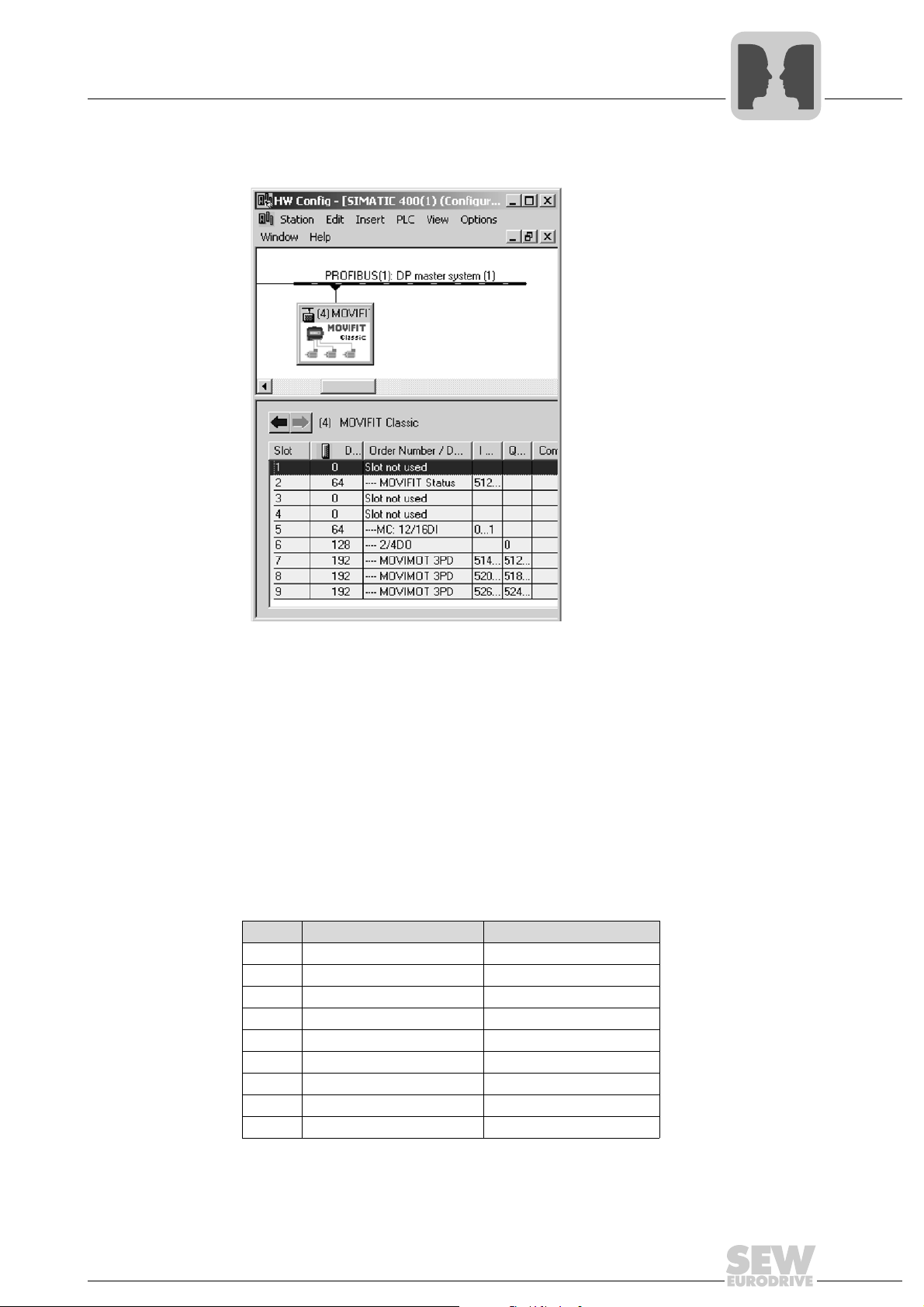

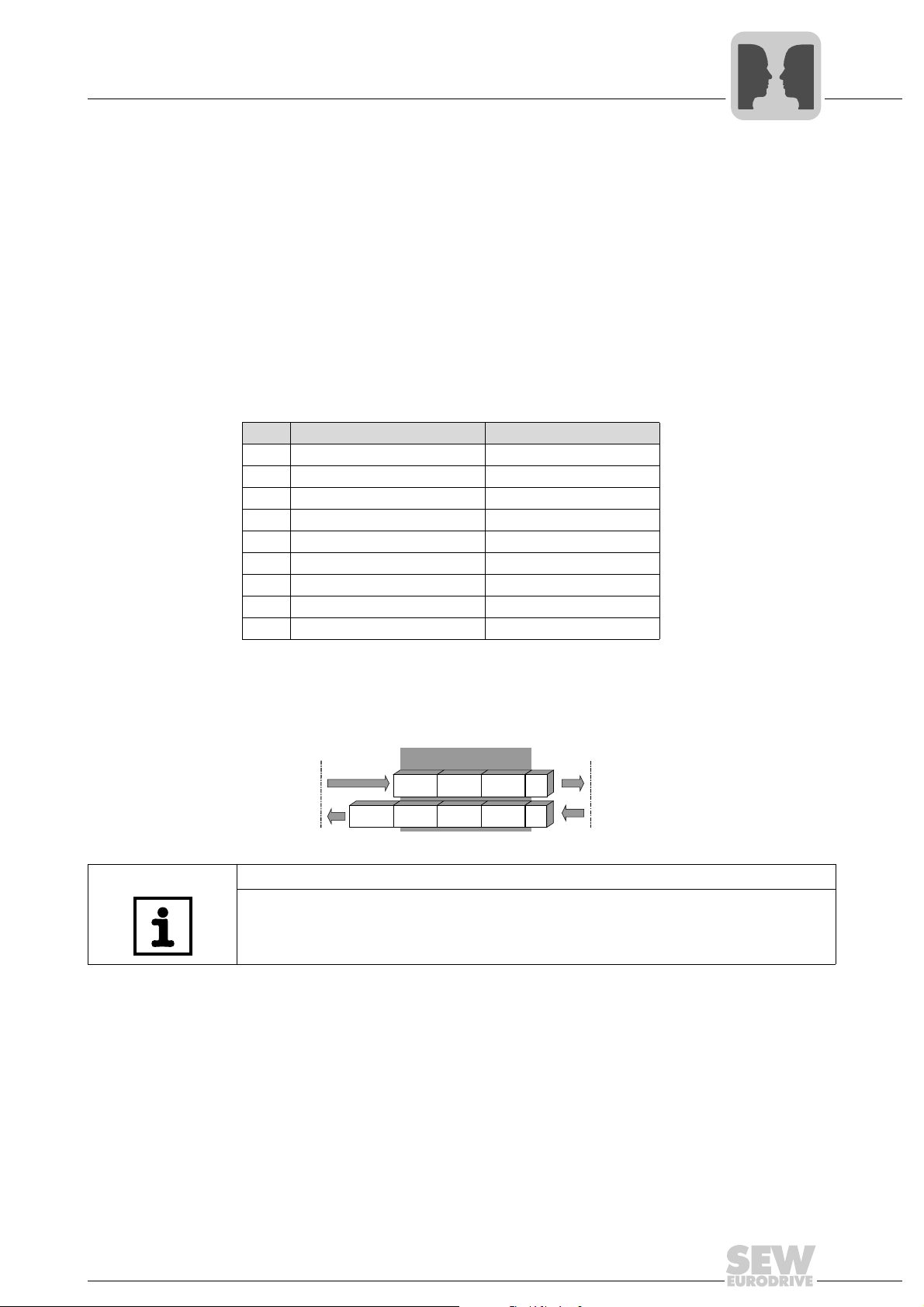

The following figure shows the MOVIFIT®-MC project planning example in STEP7:

5

5.2.2 Application example MOVIFIT

The following application requirements should be implemented with MOVIFIT

• The integrated motor starter (SC) is to operate two motors. The current actual value

is also used for monitoring within the controller.

• Six digital inputs and two digital outputs of MOVIFIT

sensors and actuators around MOVIFIT

• The sensor/actuator channels and the maintenance switches are to be monitored

within the control program.

• No options are to be used.

The following table shows the configuration example for this MOVIFIT

Slot Assignment (DP-ID) Plug-in module

1 "PROFIsafe-Option" "Slot not used"

2 "MOVIFIT

3 "Integrated FC/SC" "SC 1PO/3PI"

4 "Option Module" "Slot not used"

5 "Digital Inputs" "FC/SC: 6/8DI"

6 "Digital Outputs" "2/4 DO"

7 "MOVIMOT

8 "MOVIMOT

9 "MOVIMOT

11338AXX

®

-SC

®

.

®

Status" "MOVIFIT® Status"

®

1" "Slot not used"

®

2" "Slot not used"

®

3" "Slot not used"

®

-SC:

®

-SC are used for external

®

-SC application:

Manual – MOVIFIT® Function Level "Classic"

19

5

PROFIBUS

Project planning for MOVIFIT®-Classic

The following figure shows which process data is transferred via the bus system. 3 bytes

are sent as output data from the fieldbus master to MOVIFIT

®

-SC. 9 bytes are sent as

input data to the fieldbus master.

SC

2DO

Fieldbus

master

Status

PO1

PI1 PI2 PI3

MOVIFIT® SC

6DI

61891AEN

NOTE

For information on the coding of process data for MOVIFIT

®

-SC digital I/Os and status

information (maintenance switches), see the "Process Data Description" section from

page 64.

The following figure shows the MOVIFIT

®

-SC project planning example in STEP7:

20

11340AXX

Manual – MOVIFIT® Function Level "Classic"

PROFIBUS

Project planning for MOVIFIT®-Classic

5

5.2.3 Application example MOVIFIT®-FC

The following application requirements should be implemented with MOVIFIT

• The integrated frequency inverter (FC) is controlled with 3 process data words. In

other words, the control word, the speed and the times for acceleration and deceleration ramps are specified cyclically by the higher-level controller.

• Six digital inputs and two digital outputs of MOVIFIT

sors and actuators around MOVIFIT

• The sensor/actuator channels and the maintenance switches are to be monitored

within the control program.

• No options are to be used.

The following table shows the configuration example for this MOVIFIT

Slot Assignment (DP-ID) Plug-in module

1 "PROFIsafe-Option" "Slot not used"

®

2 "MOVIFIT

3 "Integrated FC/SC" "FC 3PD"

4 "Option Module" "Slot not used"

5 "Digital Inputs" "FC/SC: 6/8DI"

6 "Digital Outputs" "2/4 DO"

7 "MOVIMOT

8 "MOVIMOT

9 "MOVIMOT

Status" "MOVIFIT® Status"

®

1" "Slot not used"

®

2" "Slot not used"

®

3" "Slot not used"

®

-FC:

®

®

.

-FC are used for external sen-

®

-FC application:

The following figure shows which process data is transferred via the bus system. 7 bytes

are sent as output data from the fieldbus master to MOVIFIT

®

-FC and 9 bytes are sent

as input data to the fieldbus master.

FC

Fieldbus

master

Status

PO1 PO2 PO3

PI1 PI2 PI3

2DO

6DI

MOVIFIT® FC

61890AEN

NOTE

For information on the coding of process data for MOVIFIT

®

-FC digital I/Os and status

information (maintenance switches), see the "Process Data Description" section from

page 64.

Manual – MOVIFIT® Function Level "Classic"

21

5

PROFIBUS

Project planning for MOVIFIT®-Classic

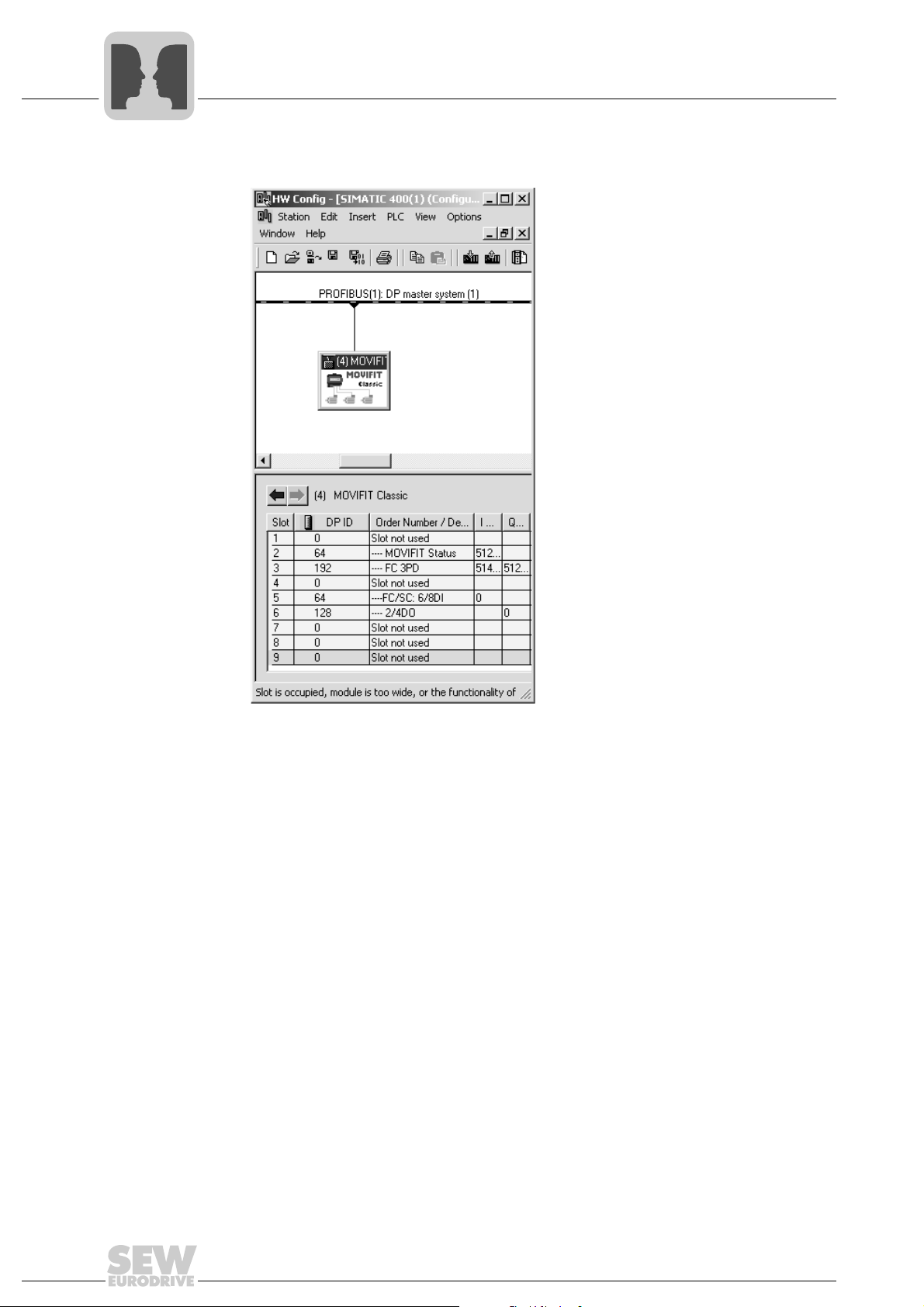

The following figure shows the MOVIFIT®-FC project planning example in STEP7:

59766AXX

22

Manual – MOVIFIT® Function Level "Classic"

Parameter setting using PROFIBUS-DPV1

5.3 Parameter setting using PROFIBUS-DPV1

The PROFIBUS-DPV1 specification introduced new acyclical read/write services within

the context of the PROFIBUS-DP expansions. These acyclical services are added to the

current cyclical bus operation in special telegrams to ensure compatibility of

PROFIBUS-DP (version 0) and PROFIBUS-DPV1 (version 1).

The acyclical read/write services can be used for the exchange of larger volumes of data

between master and slave (drive inverter). The advantage of the acyclical data

exchange via DPV1 lies in the minimum load on the cyclical bus operation since DPV1

telegrams are only added to the bus cycle if required.

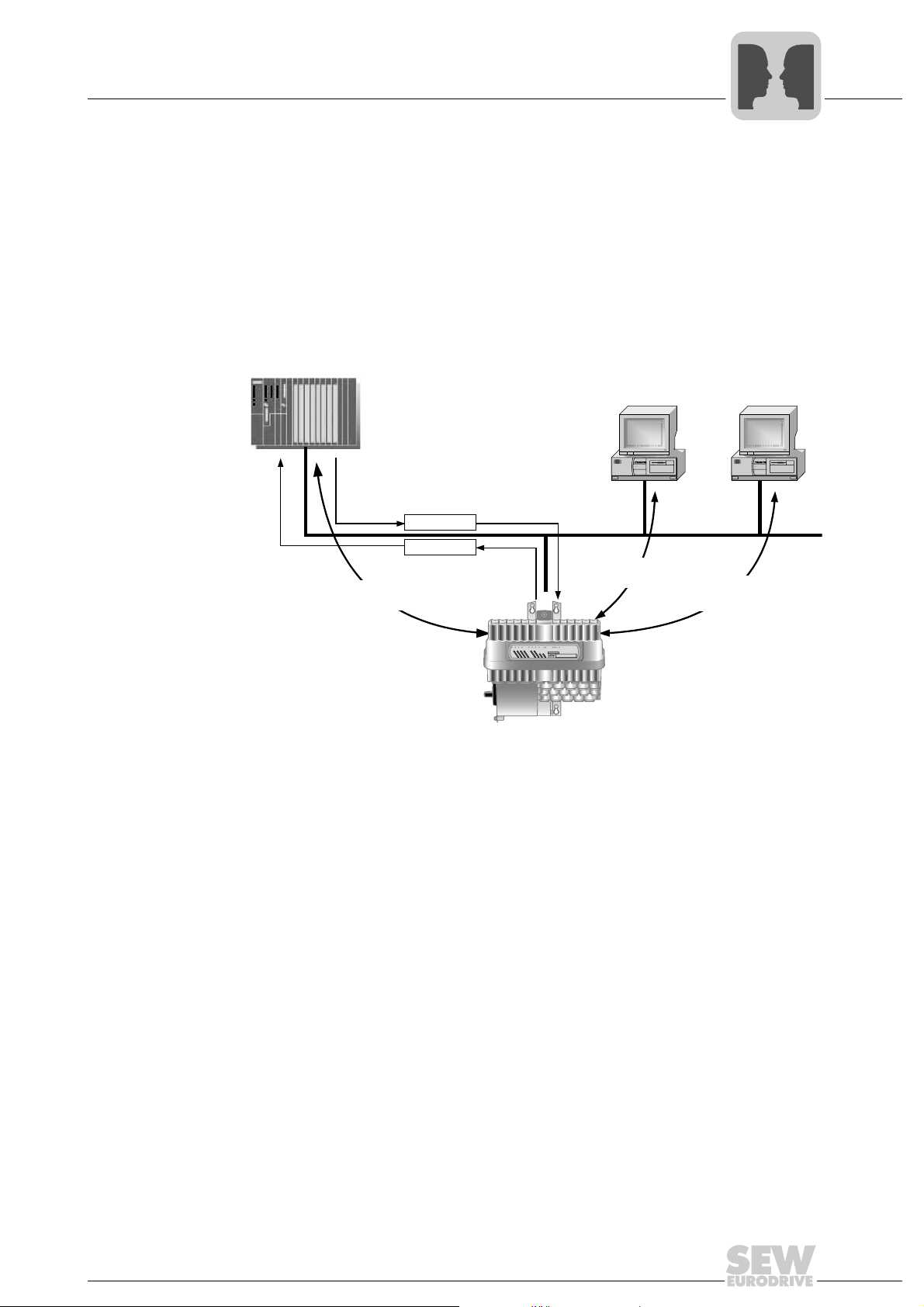

C1-Master

Cyclic OUT Data

PD

PD

Cyclic IN Data

Acyclic DP-V1

C1-Services

PROFIBUS

C2-Master

PROFIBUS DP-V1

Acyclic DP-V1

C2-Services

5

C2-Master

Acyclic DP-V1

C2-Services

D

D

D

D

D

D

D

D

I

I

I

I

I

I

I

I

0

0

0

0

0

0

0

0

1

6

5

2

4

3

0

7

/

D

O

0

0

MOVIFIT

R

2

2

S

B

R

4

4

U

Y

U

U

V

V

S

S

N

N

-

-

-

-

C

S

/

-P

F

F

D

O

S

0

1

®

59616AXX

Manual – MOVIFIT® Function Level "Classic"

23

5

PROFIBUS

Parameter setting using PROFIBUS-DPV1

5.3.1 Structure of the DPV1 parameter channel

Data sets (DS)

The user data transported via a DPV1 service is grouped in a data set. Each data set is

identified uniquely by its length, a slot number and an index. DPV1 communication with

MOVIFIT

®

uses the structure of data set 47, which is defined as a DPV1 parameter

channel for drives starting with V3.1 in the PROFIdrive profile "Drive engineering" of the

PROFIBUS user organization. Different procedures for accessing parameter data in the

drive inverter are provided via this parameter channel.

The drive parameters are usually set according to the PROFIdrive DPV1 parameter

channel of profile version 3.0 via data set index 47. The "Request ID" entry is used

to distinguish between parameter access based on PROFIdrive profile or via SEWEURODRIVE MOVILINK

possible codings of the individual elements. The data set structure is the same for

PROFIdrive and MOVILINK

®

services. The "Elements of data set DS47" section shows the

®

access.

DPV1

Read/Write

The following MOVILINK

•8-byte MOVILINK

PROFIdrive

Parameter channel DS47

®

services are supported:

®

parameter channel with all the services supported by the drive

SEW-EURODRIVE

MOVILINK

®

inverter such as

• Read parameter

• Write parameter

• Write parameter volatile

The following PROFIdrive services are supported:

• Reading (request parameter) individual parameters of type double word

• Writing (change parameter) individual parameters of type double word

24

Manual – MOVIFIT® Function Level "Classic"

PROFIBUS

Parameter setting using PROFIBUS-DPV1

5

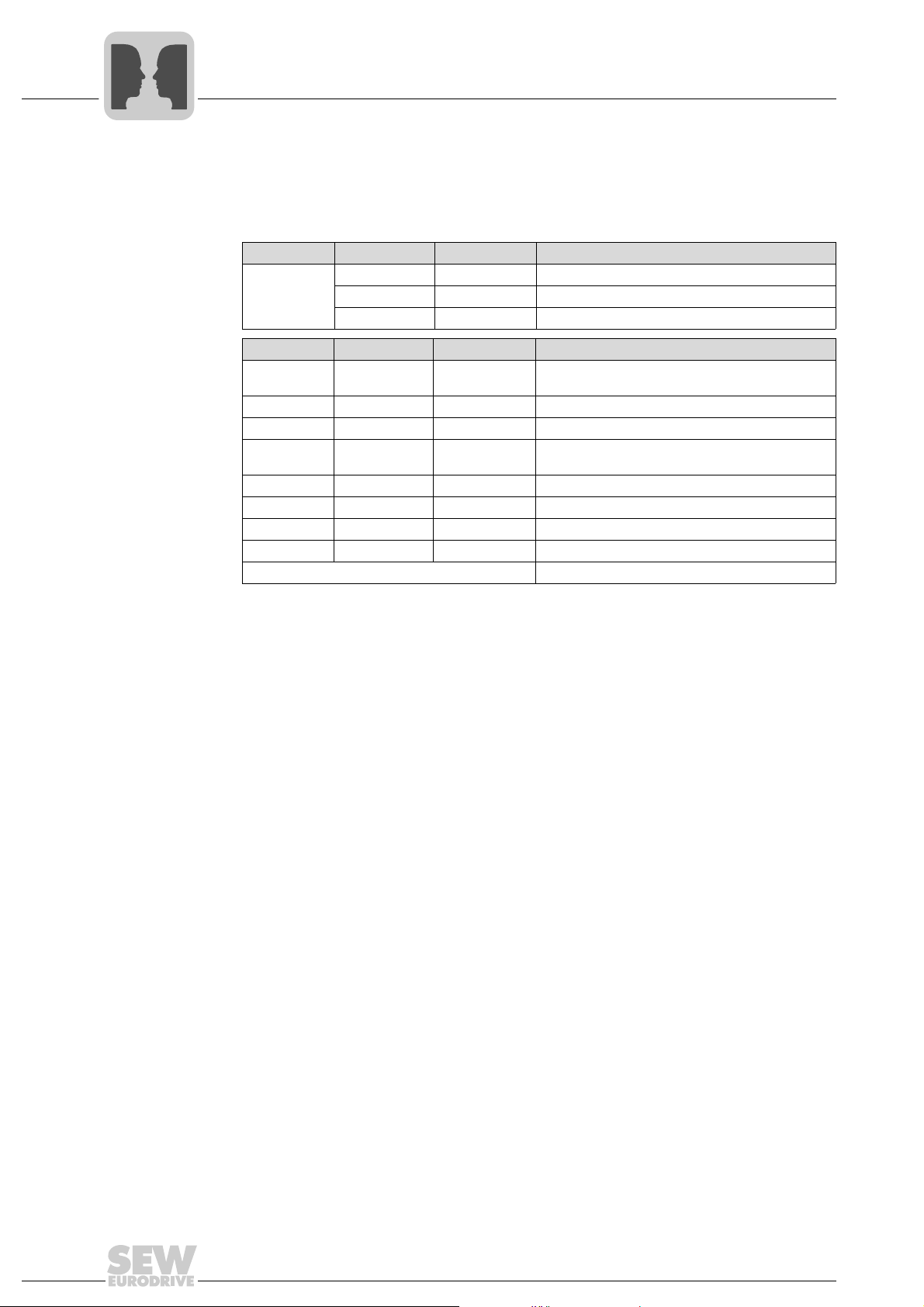

Elements of

data set DS47

The following table shows the elements of data set DS47.

Field Data type Values

Request reference Unsigned8 0x00 reserved

0x01..0xFF

Request ID Unsigned8 0x01 Request parameter (PROFIdrive)

0x02 Change parameter (PROFIdrive)

®

0x40 SEW-EURODRIVE MOVILINK

Response ID Unsigned8 Response (+):

0x00 reserved

0x01 Request parameter (+) (PROFIdrive)

0x02 Change parameter (+) (PROFIdrive)

0x40 SEW-EURODRIVE MOVILINK

Response (-):

0x81 Request parameter (-) (PROFIdrive)

0x82 Change parameter (-) (PROFIdrive)

0xC0 SEW-EURODRIVE MOVILINK

Axis Unsigned8 0x00..0xFF Number of axis 0..255

®

0 = MOVIFIT

1 = MOVIFIT

or

1 = MOVIFIT

2 = MOVIFIT

3 = MOVIFIT

4 = MOVIFIT

No. of parameters Unsigned8 0x01..0x13 1..19 DWORDs (240 DPV1 data bytes)

Attribute Unsigned8 0x10 Value

For SEW-EURODRIVE MOVILINK

0x00 No service

0x10 Read Parameter

0x20 Write Parameter

0x30 Write Parameter volatile

0x40 Read Minimum

0x50 Read Maximum

0x60 Read Default

0x70 Read Scale

0x80 Read Attribute

0xA0..0xF0 reserved

No. of elements Unsigned8 0x00 for non-indexed parameters

0x01..0x75 Quantity 1..117

Parameter Number Unsigned16 0x0000..0xFFFF MOVILINK

Subindex Unsigned16 0x0000..0x00FF

Format Unsigned8 0x43 Double word

0x44 Fault

No. of Values Unsigned8 0x00..0xEA Quantity 0..234

Error Value Unsigned16 0x0000..0x0064 PROFIdrive-Errorcodes

0x0080 + MOVILINK

For SEW-EURODRIVE MOVILINK

fieldbus control unit

®

-FC: Integrated frequency inverter

®

-SC: Integrated motor starter

®

-MC: MOVIMOT® at terminal X71

®

-MC: MOVIMOT® at terminal X81

®

-MC: MOVIMOT® at terminal X91

®

(Request ID = 0x40):

®

parameter index

®

-AdditionalCode Low

®

16 bit error value

service

®

service (+)

®

service (-)

Manual – MOVIFIT® Function Level "Classic"

25

5

Parameter

Processing

PROFIBUS

Parameter setting using PROFIBUS-DPV1

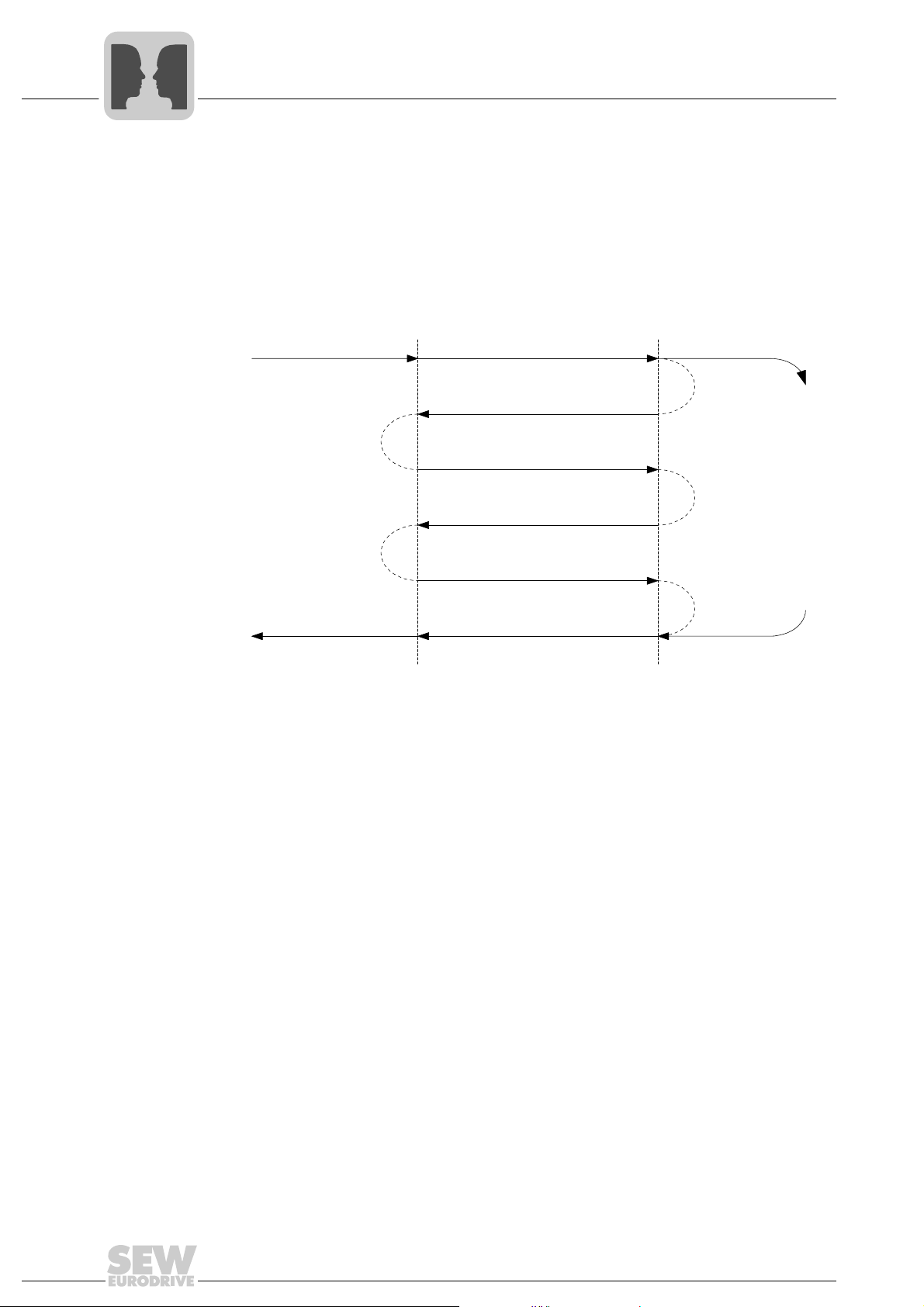

5.3.2 Procedure for setting parameters via data set 47 for PROFIBUS DPV1

Parameter access takes place with the combination of the DPV1 services "Write" and

"Read". The parameter setting service is transferred to the slave with Write.req, followed

by slave-internal processing. The master now sends a Read.req to pick up the parameter setting response. The master repeats the Read.req if the answer (Read.res) from

the slave is negative. As soon as the parameter processing in MOVIFIT

it answers with a positive response (Read.res). The user data now contains the parameter setting response of the parameter setting request that was previously sent with

Write.req (see following figure). This mechanism applies to both a C1 and a C2 master.

®

is concluded,

Parameter

Request

Parameter

Response

Write.req DS47

with data (parameter request)

Write.res

without data

Read.req DS47

without data

Read.res(-)

without data

Read.req DS47

without data

Read.res (+)

with data (parameter response)

Parameter

Request

Parameter

Processing

Parameter

Response

51658AXX

26

Manual – MOVIFIT® Function Level "Classic"

PROFIBUS

Parameter setting using PROFIBUS-DPV1

5

5.3.3 MOVILINK® parameter requests

The parameter channel of MOVIFIT

The Request ID 0x40 (SEW MOVILINK

MOVILINK

®

parameter setting requests. Parameter access with MOVILINK® services

usually takes place according to the structure described below. The typical message

sequence for data set 47 is used.

Request ID: 0x40 SEW MOVILINK

The actual service is defined by the data set element Attribute on the MOVILINK

parameter channel. The high nibble of this element corresponds to the service nibble in

the management byte of the DPV0 parameter channel.

Example for

reading a

The following tables give an example of the structure of the Write.req and Read.res user

data for reading an individual parameter via the MOVILINK

parameter via

MOVILINK

(reading a

parameter via

DPV1)

®

Sending a parameter request:

The following tables show the coding of the user data for the Write.req service including

the DPV1 header. The Write.req service is used to transfer the parameter setting

request to the drive inverter.

DPV1 header

®

is mapped directly in the structure of data set 47.

®

service) is used for the exchange of

®

-Service

®

parameter channel.

Service: Write.request Description

Slot_Number 0 Random (is not evaluated)

Index 47 Index of the data set; constant index 47

Length 10 10-byte user data for parameter request

®

Byte Field Value Description

PROFIdrive

Parameter

channel

0 Request reference 0x01 Individual reference number for the param-

1 Request ID 0x40 SEW MOVILINK

2 Axis 0x01 1: MOVIFIT

3 No. of parameters 0x01 1 parameter

4 Attribute 0x10 MOVILINK

5 No. of elements 0x00 0 = access to direct value, no subelement

6 to 7 Parameter Number 0x2267 Parameter index 8807 = P130 Ramp t11

8 to 9 Subindex 0x0000 Subindex 0

eter setting request is reflected in the

parameter response

®

service

®

inverter

UP

-FC: Integrated frequency

®

service "Read parameter"

Query parameter response:

The following table shows the coding of the Read.req user data including the DPV1

header.

Service: Read.request Description

Slot_Number 0 Random (is not evaluated)

DPV1 header

Index 47 Index of the data set; constant index 47

Length 240 Maximum length of response buffer in the DPV1

master

Manual – MOVIFIT® Function Level "Classic"

27

5

PROFIBUS

Parameter setting using PROFIBUS-DPV1

Positive MOVILINK® parameter response

The following tables show the Read.res user data with the positive response data of the

parameter setting request. The parameter value for index 8300 (firmware version) is

returned as an example.

Service: Read.request Description

Slot_Number 0 Random (is not evaluated)

DPV1 header

Byte Field Va lue Description

0 Response

1 Response ID 0x40 Positive MOVILINK

2 Axis 0x01 Reflected axis number

3 No. of

4 Format 0x43 Parameter format: Double word

5 No. of values 0x01 1 value

6 to 7 Value Hi 0x0000 Higher-order part of the parameter

8 to 9 Value Lo 0x0BB8 Lower-order part of the parameter

Index 47 Index of the data set: constant index 47

Length 10 10-byte user data for order buffer

reference

parameters

0x01 Reflected reference number from the parameter

0x01 1 parameter

setting order

®

response

Decoding: 0x0000 0BB8 = 3000 ms

28

Manual – MOVIFIT® Function Level "Classic"

PROFIBUS

Parameter setting using PROFIBUS-DPV1

5

Example for

writing a

MOVIFIT

®

-FC

parameter via

DPV1 with

MOVILINK

®

The following tables give an example of the structure of write and read services for

writing the value 3000 ms (BB8

) to the parameter "P130 Ramp t11 up" in the non-

hex

volatile memory (parameter index 8807, subindex 0). Note: The parameters of a

MOVIFIT

DPV1 header

Byte Field Va lue Description

0 Request

1 Request ID 0x40 SEW MOVILINK

2 Axis 0x01 1: MOVIFIT

3 No. of

4 Attribute 0x30 MOVILINK

5 No. of elements 0x00 0 = access to direct value, no subelement

6 to 7 Parameter

8 to 9 Subindex 0x0000 Subindex 0

10 Format 0x43 Double word

11 No. of values 0x01 Change 1 parameter value

12 to 13 Value HiWord 0x0000 Higher-order part of the parameter word

14 to 15 Value LoWord 0x0BB8 Lower-order part of the parameter word

®

-FC unit can only be changed in expert mode.

Service: Read.request Description

Slot_Number 0 Random (is not evaluated)

Index 47 Index of the data set: constant index 47

Length 16 16-byte user data for order buffer

reference

parameters

Number

0x01 Individual reference number for the parameter set-

0x01 1 parameter

0x2267 Parameter index 8807 = P130 Ramp t11 UP

ting request is reflected in the parameter response

®

service

®

-FC: Integrated frequency inverter

®

service "Write parameter volatile"

After sending this Write.request, the Write.response is received. If there was no status

conflict in processing the parameter channel, a positive Write.response results. Otherwise, the status fault is located in Error_code_1.

Query parameter response

The following tables show the coding of the Write.req user data including the DPV1

header.

Field Valu e Description

Function_Num Read.req

DPV1 header

Slot_Number X Slot_Number not used

Index 47 Index of data set

Length 240 Maximum length of response buffer in DP master

Manual – MOVIFIT® Function Level "Classic"

29

5

PROFIBUS

Parameter setting using PROFIBUS-DPV1

Positive response to "Write parameter volatile"

DPV1 header

Byte Field Val ue Description

0 Response

1 Response ID 0x40 Positive MOVILINK

2 Axis 0x00 Reflected axis number

3 No. of

5.3.4 Return codes for parameter setting

Negative

parameter

The following tables show the coding of a negative response of a MOVILINK

Bit 7 is entered in the Response ID if the response is negative.

response

DPV1 header

Service Read.response Description

Slot_Number 0 Random (is not evaluated)

Index 47 Index of the data set; constant index 47

Length 4 12-byte user data in response buffer

reference

parameters

Service: Read.response Description

Slot_Number 0 Random (is not evaluated)

Index 47 Index of the data set; constant index 47

Length 8 8-byte user data in response buffer

0x01 Reflected reference number from the parameter

0x01 1 parameter

setting order

®

response

®

service.

Byte Field Value Description

0 Response

reference

1 Response ID 0xC0 Negative MOVILINK

2 Axis 0x00 Reflected axis number

3 No. of

parameters

4 Format 0x44 Error

5 No. of values 0x01 1 error code

6 to 7 Error value 0x0811 MOVILINK

0x01 Reflected reference number from the parameter

0x01 1 parameter

setting order

®

Add.-Code 0x11 (see the table MOVILINK

return codes for DPV1)

return code, e.g. ErrorClass 0x08,

®

response

®

30

Manual – MOVIFIT® Function Level "Classic"

Loading...

Loading...