SEW Movidrive mdx61b User Manual

Drive Technology \ Drive Automation \ System Integration \ Services

Manual

MOVIDRIVE

"

DriveSync via Fieldbus

®

MDX61B

"

Application

Edition 08/2010 17004411 / EN

SEW-EURODRIVE—Driving the world

Contents

Contents

1 General Information ............................................................................................ 6

1.1 Use of the manual....................................................................................... 6

1.2 Structure of the safety notes ....................................................................... 6

1.2.1 Meaning of the signal words ........................................................ 6

1.2.2 Structure of the section-related safety notes ............................... 6

1.2.3 Structure of the embedded safety notes...................................... 6

1.3 Right to claim under warranty ..................................................................... 7

1.4 Exclusion of liability..................................................................................... 7

1.5 Copyright..................................................................................................... 7

1.6 Applicable documentation........................................................................... 7

2 Safety Notes ........................................................................................................ 8

2.1 General information .................................................................................... 8

2.2 Designated use ........................................................................................... 8

2.3 Target group ............................................................................................... 8

2.4 Bus systems................................................................................................ 9

2.5 Operating mode "synchronous operation" .................................................. 9

3 System Description........................................................................................... 10

3.1 Areas of application .................................................................................. 10

3.2 Application examples ................................................................................ 11

3.2.1 Finite (linear) movement of the master and slave axis .............. 11

3.2.2 Finite (linear) movement of the slave

axis and infinite movement of the master axis........................... 12

3.2.3 Finite movements with master and slave axes .......................... 12

3.3 Program identification ............................................................................... 14

4 Project Planning................................................................................................ 15

4.1 Prerequisites ............................................................................................. 15

4.1.1 PC and software ........................................................................ 15

4.1.2 Inverters, motors and encoders ................................................. 15

4.1.3 Possible combinations ............................................................... 15

4.1.4 Additional notes ......................................................................... 15

4.2 Functional description ............................................................................... 16

4.2.1 Functional characteristics .......................................................... 16

4.2.2 Additional startup functions........................................................ 17

4.3 Scaling of the drive ................................................................................... 18

4.3.1 Drive without external encoder (positive connection) ................ 18

4.3.2 Drive with external encoder (non-positive connection) .............. 19

4.4 Limit switches, reference cams and machine zero ................................... 20

4.5 Process data assignment.......................................................................... 21

4.5.1 Process output data................................................................... 22

4.5.2 Process input data ..................................................................... 23

4.6 Software limit switches.............................................................................. 24

4.6.1 General information ................................................................... 24

4.6.2 Moving clear of the software limit switches................................ 24

4.7 Safe stop................................................................................................... 26

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

3

Contents

5 Installation ......................................................................................................... 27

5.1 MOVITOOLS

5.1.1 MOVITOOLS

5.1.2 Application variant ..................................................................... 27

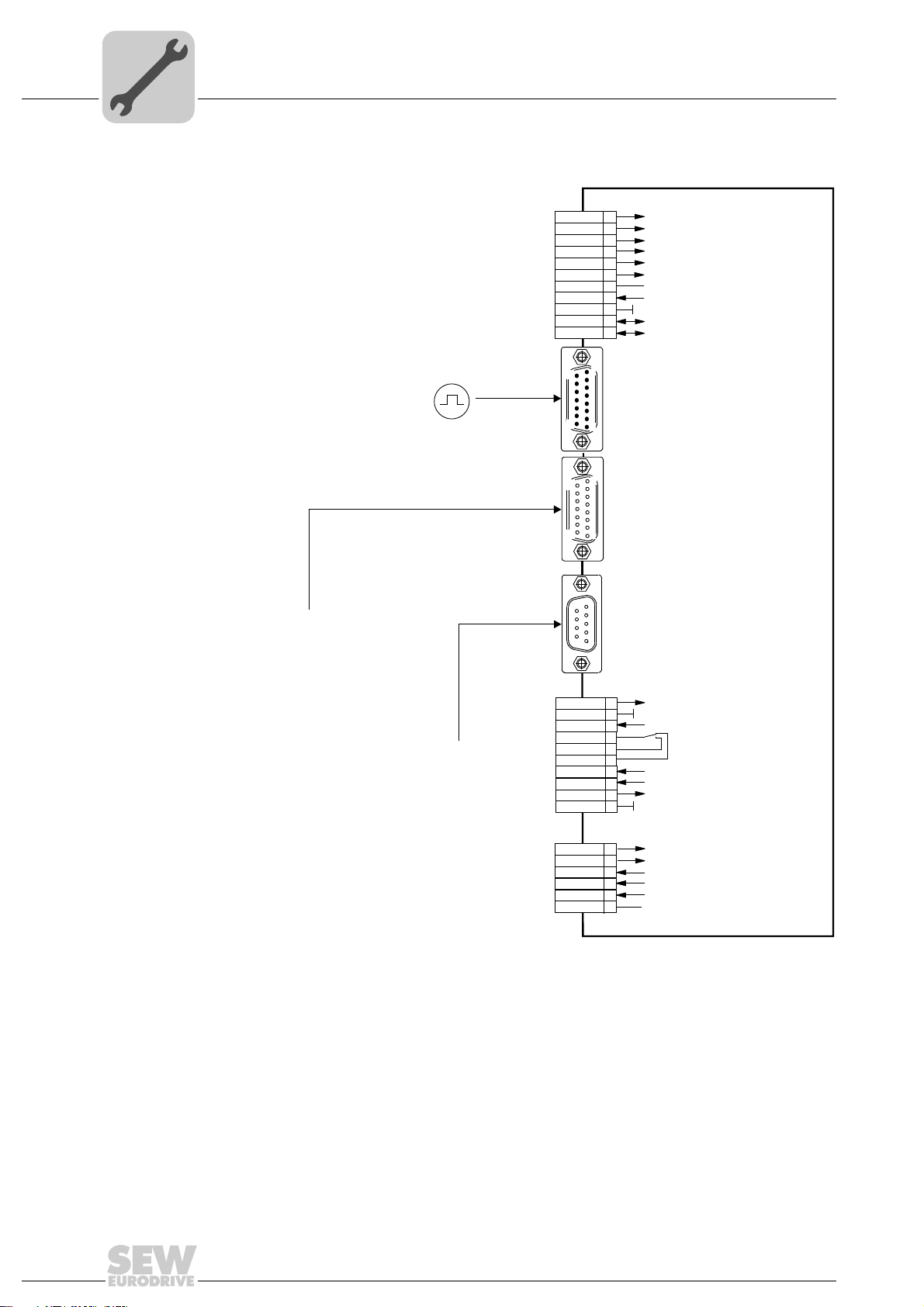

5.2 Wiring diagram for incremental encoder master / MDX61B slave ............ 28

5.3 Wiring diagram for MDX61B master / MDX61B slave .............................. 29

5.4 MOVIDRIVE

5.4.1 Overview.................................................................................... 30

5.4.2 PROFIBUS (DFP21B) ............................................................... 31

5.4.3 INTERBUS with fiber optic cable (DFI21B) ............................... 32

5.4.4 INTERBUS (DFI11B) ................................................................. 33

5.4.5 CANopen (DFC11B) .................................................................. 34

5.4.6 DeviceNet (DFD11B) ................................................................. 35

5.4.7 Ethernet (DFE11B) .................................................................... 36

5.5 Connecting the system bus (SBus 1)........................................................ 37

5.5.1 SBus wiring diagram.................................................................. 37

6 Startup................................................................................................................ 39

6.1 General information .................................................................................. 39

6.2 Preliminary work ....................................................................................... 39

6.3 Starting the "DriveSync via fieldbus" program .......................................... 40

6.3.1 General information ................................................................... 40

6.3.2 Initial screen............................................................................... 41

6.3.3 Fieldbus parameters and drive configuration............................. 42

6.3.4 Setting distance and velocity scaling factors ............................. 44

6.3.5 Determining the modulo parameters

6.3.6 Setting limits .............................................................................. 51

6.3.7 Configuring the master-slave interface ...................................... 53

6.3.8 Setting parameters for synchronous operation (part 1) ............. 56

6.3.9 Setting parameters for synchronous operation (part 2) ............. 62

6.3.10 Download ................................................................................... 64

6.4 Parameters and IPOS

6.5 Recording IPOS

6.5.1 Example..................................................................................... 68

7 Operation and Servicing................................................................................... 69

7.1 Starting the drive....................................................................................... 69

7.1.1 Operating modes ....................................................................... 69

7.2 Monitor mode ............................................................................................ 70

7.2.1 Diagnostics monitor: Control mode............................................ 72

7.2.2 Diagnostics monitor: Status of internal synchronous operation. 73

7.3 Jog mode .................................................................................................. 74

7.3.1 Cancelation conditions............................................................... 75

7.4 Referencing mode..................................................................................... 76

7.4.1 Cancelation conditions............................................................... 77

®

software ............................................................................ 27

®

........................................................................... 27

®

MDX61B bus installation.................................................... 30

for infinite motion sequences ..................................................... 48

plus®

variables ........................................................ 65

plus®

variables ................................................................. 68

4

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

Contents

7.5 Positioning mode ...................................................................................... 77

7.5.1 Cancelation conditions............................................................... 78

7.6 Synchronous operation ............................................................................. 79

7.6.1 Cancelation conditions............................................................... 80

7.6.2 Example for synchronous operation .......................................... 80

7.7 Cycle diagrams ......................................................................................... 82

7.7.1 Jog mode ................................................................................... 83

7.7.2 Referencing mode ..................................................................... 84

7.7.3 Positioning mode ....................................................................... 85

7.7.4 Synchronous operation.............................................................. 86

7.7.5 Moving clear of hardware limit switches .................................... 88

7.8 Error information ....................................................................................... 89

7.8.1 Error memory............................................................................. 89

7.8.2 Switch-off responses ................................................................. 89

7.8.3 Reset ......................................................................................... 89

7.8.4 Inverter waiting for data ............................................................. 90

7.9 Error messages and list of errors.............................................................. 90

7.9.1 Error message via 7-segment display ....................................... 90

7.9.2 Suberror code display................................................................ 90

7.9.3 Error list ..................................................................................... 91

Index................................................................................................................... 94

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

5

1

General Information

Use of the manual

1 General Information

1.1 Use of the manual

The manual is part of the product and contains important information. The manual is for

everyone working with this product.

The manual must be accessible and legible. Make sure that persons responsible for the

system and its operation, as well as persons who work independently with the software

and the connected units from SEW-EURODRIVE, have read through the manual carefully and understood it. If you are unclear about any of the information in this documentation, or if you require further information, contact SEW-EURODRIVE.

1.2 Structure of the safety notes

1.2.1 Meaning of the signal words

The following table shows the grading and meaning of the signal words for safety notes,

notes on potential risks of damage to property, and other notes.

Signal word Meaning Consequences if disregarded

DANGER Imminent danger Severe or fatal injuries

WARNIN G Possible dangerous situation Severe or fatal injuries

CAUTION Possible dangerous situation Minor injuries

NOTICE Possible damage to property Damage to the drive system or its envi-

INFORMATION Useful information or tip: Simpli-

fies the handling of the drive

system.

1.2.2 Structure of the section-related safety notes

Section safety notes do not apply to a specific action, but to several actions pertaining

to one subject. The used symbols indicate either a general or a specific hazard.

This is the formal structure of a section safety note:

SIGNAL WORD

Type and source of danger.

Possible consequence(s) if disregarded.

• Measure(s) to prevent the danger.

1.2.3 Structure of the embedded safety notes

Embedded safety notes are directly integrated in the instructions just before the description of the dangerous action.

ronment

This is the formal structure of an embedded safety note:

• SIGNAL WORD Nature and source of hazard.

Possible consequence(s) if disregarded.

– Measure(s) to prevent the danger.

6

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

1.3 Right to claim under warranty

You must observe this manual as the prerequisite for fault-free operation and fulfillment

of any right to claim under warranty. Therefore, read the documentation before you start

working with the software and the connected units from SEW-EURODRIVE.

Make sure that the documentation is available to persons responsible for the machinery

and its operation as well as to persons who work independently on the devices. You

must also ensure that the documentation is legible.

1.4 Exclusion of liability

You must observe this manual and the documentation of the connected devices from

SEW-EURODRIVE to ensure safe operation and to achieve the specified product characteristics and performance requirements.

SEW-EURODRIVE assumes no liability for injury to persons or damage to equipment or

property resulting from non-observance of the documentation. In such cases, any liability for defects is excluded.

General Information

Right to claim under warranty

1

1.5 Copyright

© 2010 - SEW-EURODRIVE. All rights reserved.

Copyright law prohibits the unauthorized duplication, modification, distribution, and use

of this document, in whole or in part.

1.6 Applicable documentation

Observe the following applicable documentation:

•"MOVIDRIVE

®

MDX60B/61B" operating instructions

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

7

2

Safety Notes

General information

2 Safety Notes

2.1 General information

The following basic safety notes must be read carefully to prevent injury to persons and

damage to property. The operator must ensure that the basic safety notes are read and

observed. Ensure that persons responsible for the machinery and its operation as well

as persons who work independently have read through the documentation carefully and

understood it. If you are unclear about any of the information in this documentation,

please contact SEW-EURODRIVE.

The following safety notes refer to the use of the software. Also take into account the

supplementary safety notes in the individual sections of this manual and in the documentation of the connected devices from SEW-EURODRIVE.

Read through this manual carefully before you begin working with the software.

This document does not replace detailed operating instructions of the connected devices. This manual assumes that the user has access to and is familiar with the documentation for all connected units from SEW-EURODRIVE.

2.2 Designated use

The "DriveSync via fieldbus" application module is used to implement applications in

which drives move at a synchronous angle to one another permanently or occasionally.

The "DriveSync via fieldbus" application module must only be used in connection with

MOVIDRIVE

terfaces.

2.3 Target group

Any work with the used software may only be performed by adequately qualified personnel. Qualified personnel in this context are persons who have the following qualifications:

• Appropriate instruction.

• Knowledge of this documentation and other applicable documentation.

• SEW-EURODRIVE recommends additional product training for the products which

are operated with this software.

In addition to that, they must be familiar with the relevant safety regulations and laws,

especially with the requirements of the performance levels according to

DIN EN ISO 13849-1 and all other standards, directives and laws specified in this documentation. The persons mentioned must have the authorization expressly issued by

the company, to operate, program, configure, label and ground units, systems and circuits in accordance with the standards of safety technology.

®

MDX61B as application variant (0T) with the corresponding fieldbus in-

All work in further areas of transportation, storage, operation and waste disposal must

only be carried out by persons who are trained appropriately.

8

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

2.4 Bus systems

A bus system makes it possible to adapt frequency inverters and/or motor starters to the

particulars of the machinery within wide limits. There is the risk that a change of parameters that cannot be detected externally can result in unexpected, though not uncontrolled, system behavior.

2.5 Operating mode "synchronous operation"

The motion controller in synchronous operation processes setpoint changes at the master drive. Set the application module in such a way that an unintended motor start is not

possible.

The following measures increase operational safety:

• Deactivating the synchronous operation mode

– when warnings or errors occur within the sync group or when the drives are not

ready for operation

– when the sync group has been stopped

• Selecting the synchronous operation mode with querying the "ready for operation"

message and the "technology options" operating status of all drives.

Safety Notes

Bus systems

2

• If an absolute position reference is required, arrange the individual drives in the positioning operation mode (no offset control).

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

9

3

System Description

Areas of application

3 System Description

3.1 Areas of application

The "DriveSync via fieldbus" application module makes it possible to implement conveyor systems and machinery with drives that have to move at a synchronous angle occasionally or permanently.

The program can be used for the master drive and the slave drive. The master works in

the "Jog" and "Positioning" operating modes, for example, while the slave drives are operated in "synchronous operation" mode.

If the "Synchronous operation" mode is deselected for the slave drives, they can be operated with free-running in "Jog" and "Positioning" operating modes.

The "DriveSync via fieldbus" application offers the following advantages:

• One program for the master and slave drive.

• Guided startup and extensive diagnostics functions.

• High degree of similarity with the "Extended positioning via bus" application module.

• The selected IPOS encoder source (X13, X14, DIP) is also effective in synchronous

operation.

• The master value for "synchronous operation" mode can be adjusted.

• A mechanical vertical shaft can be replaced by transferring the virtual master value

via an SBus connection.

• Endless rotary movements can be implemented by the modulo function.

Features of synchronous operation:

• The electrical connection of the master/slave can be made using the X14 connection

or an SBus connection.

• The contents of the send object can be adjusted when the SBus connection is used.

For example, the value of any IPOS

plus®

IPOS

• Time or position-related sequence of motion for synchronization procedures.

• The engaging process can also be started with interrupt control.

variable of the master drive.

plus®

variable can be transferred instead of the

10

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

3.2 Application examples

The "DriveSync via fieldbus" application module offers a wide range of possible applications. Some examples are given in this section.

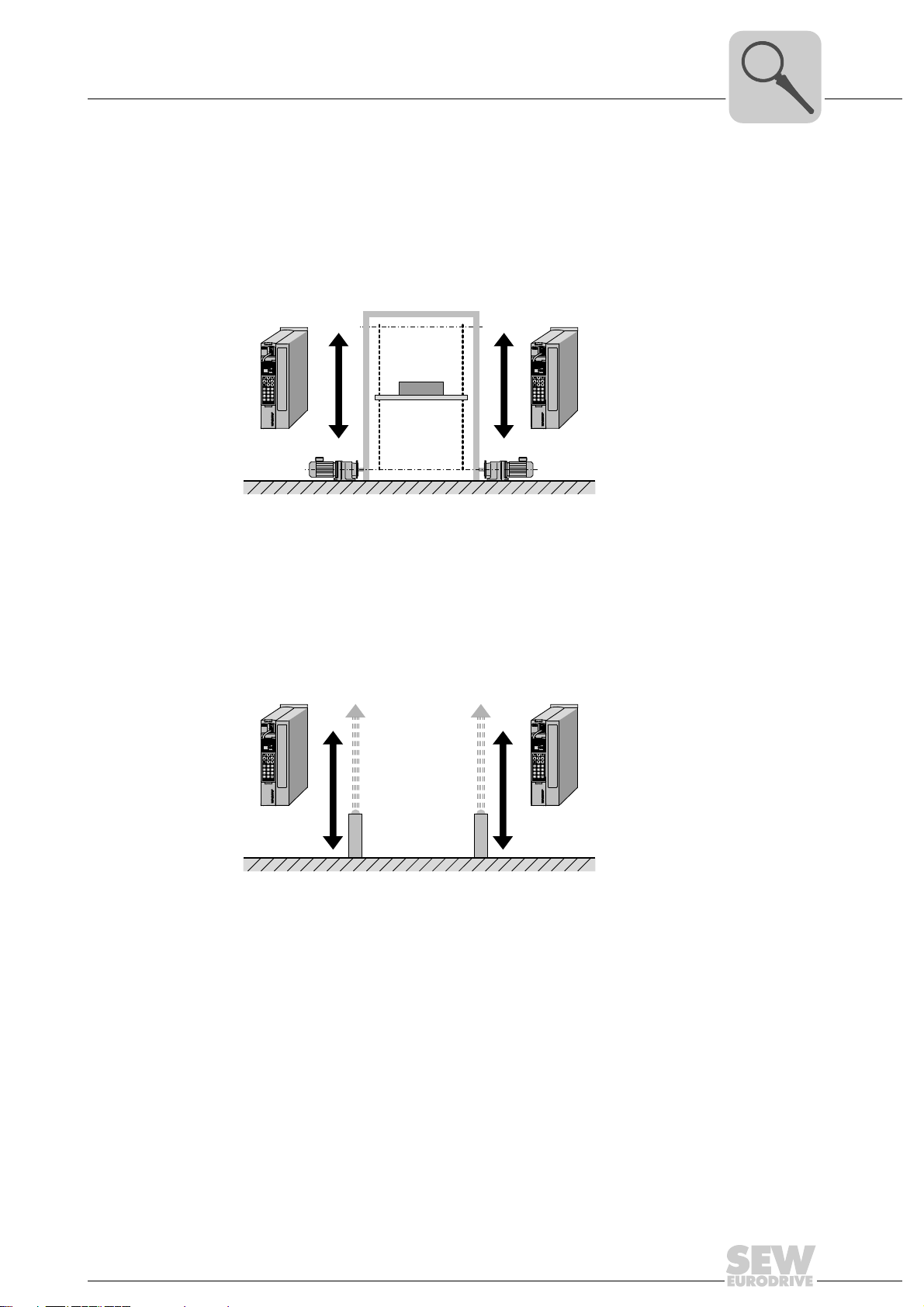

3.2.1 Finite (linear) movement of the master and slave axis

Example 1: Hoist

System Description

Application examples

3

Master

• Master axis: Linear axis

Operating mode: Positioning mode

• Slave axis: Linear axis

Operating mode: Synchronous operation

Example 2: Gantry crane with slip compensation through absolute encoder evaluation

Master

Slave

3031192715

Slave

• Master axis: Linear axis

Operating mode: Positioning mode using additional absolute encoder (IPOS encoder)

• Slave axis: Linear axis

Operating mode: Synchronous operation using an additional absolute encoder

• Master value: Master position (absolute value encoder position) is transferred via

SBus

• Features: Slip between motor and absolute encoder is compensated by the firmware.

Additional performance is achieved by controlling the master and slave axis using the

virtual encoder. Both drives are controlled in "Synchronous operation" mode for this

purpose. The master drive is started with the master value "virtual encoder" and

transfers the setpoint position to the slave drive via SBus.

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

3031194635

11

3

Slave

Master

[1]

[2]

System Description

Application examples

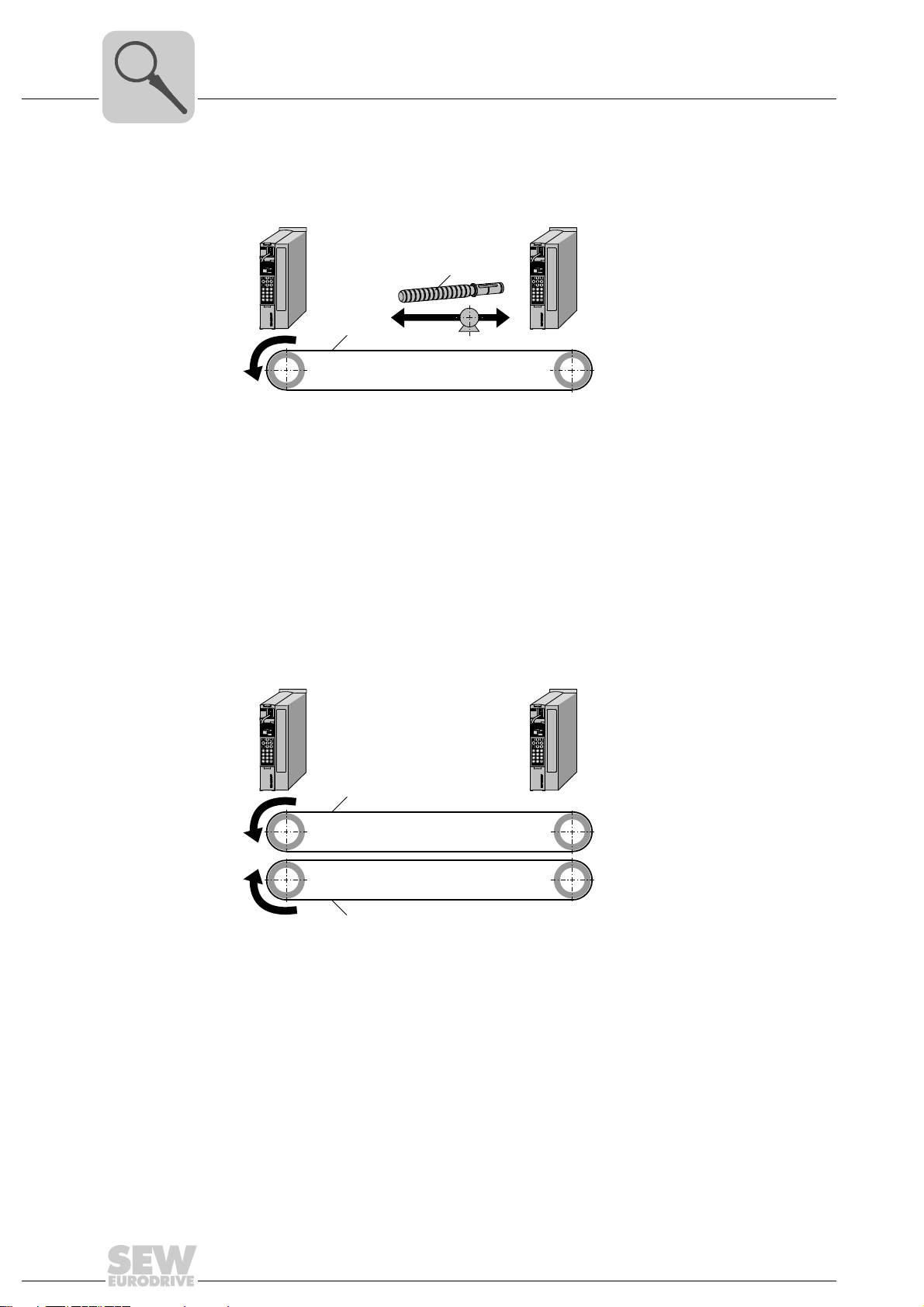

3.2.2 Finite (linear) movement of the slave axis and infinite movement of the master axis

Example 3: Belt drive with embossing punch (flying saw)

Master

[2]

[1]

• Master axis: Belt drive [1]

Operating mode: Speed specification, i.e. jog mode

• Slave axis: Spindle drive [2]

Operating mode: Synchronous operation forward; Start cycle via interrupt event.

Once a certain actual position has been reached, the operating mode changes to

"Positioning mode".

• Features: Interrupt-controlled engaging

3.2.3 Finite movements with master and slave axes

Example 4: Caterpillar drive with position reference (360°)

Slave

3031391755

12

3031395851

• Master axis: Belt drive [1]

Operating mode: Positioning mode with position specified in modulo format

• Slave axis: Belt drive [2]

Operating mode: Synchronous operation with feedback in modulo format

• Features: Retained position reference due to modulo function with infinite division

factors of the gear ratio (i gear unit).

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

System Description

[A] [A]

Slave 1 Slave n

Master

[1] [2] [2]

Application examples

Example 5: Electronic replacement of the mechanical vertical shaft.

3031399179

• Master axis: Belt drive [1]

Operating mode: Synchronous operation with master value transfer to the subsequent slaves via SBus object.

• Slave axis: Belt drive [2]

Operating mode: Synchronous operation

Fluctuating actual speeds of the master drive are not transferred to the subsequent

slave drives because the virtual master encoder position is transferred.

3

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

13

3

System Description

Program identification

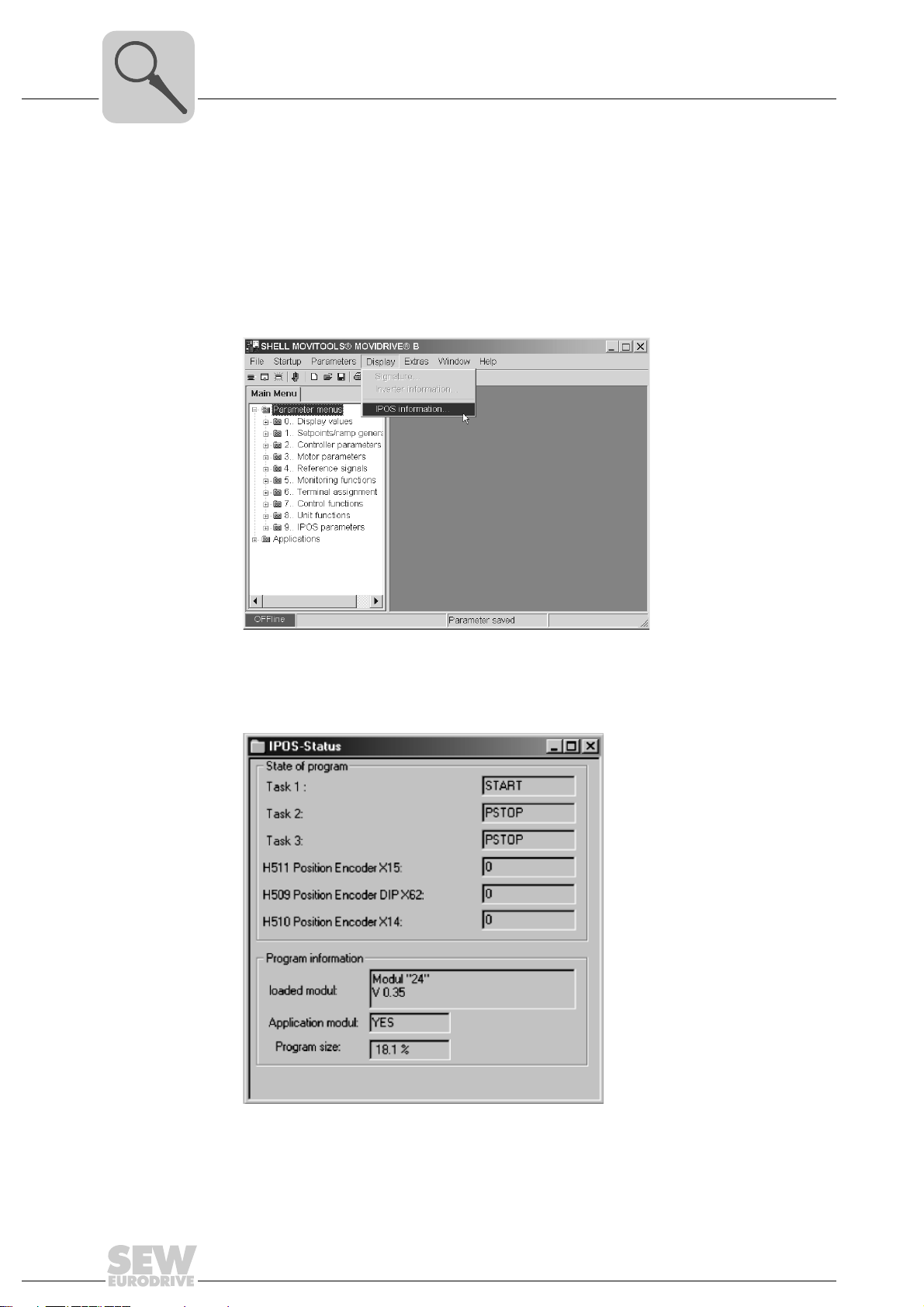

3.3 Program identification

You can use the MOVITOOLS® software package to identify which application program

was last loaded into the MOVIDRIVE

• Connect MOVIDRIVE

• Start MOVITOOLS

• In MOVITOOLS

• In the Shell program, choose [Display] / [IPOS Information...].

®

to the PC via the serial port.

®

.

®

, start the program "Shell".

®

MDX61B unit. Proceed as follows:

3032097291

• The "IPOS status" window appears. The entries in this window tell you which application software is stored in MOVIDRIVE

®

MDX61B.

3032102155

14

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

4 Project Planning

4.1 Prerequisites

4.1.1 PC and software

The "DriveSync via fieldbus" application module is implemented as an IPOS

gram and forms part of the SEW MOVITOOLS

order to use MOVITOOLS

tems: Windows

Windows

®

4.1.2 Inverters, motors and encoders

• Inverter

The application module is controlled via fieldbus with 6 process data words and can

only be implemented with MOVIDRIVE

• Motors and encoders

All motors with a connected motor encoder are supported.

®

2000.

Project Planning

Prerequisites

plus®

®

®

, you must have a PC with one of the following operating sys-

software package from version 4.30. In

95, Windows® 98, Windows® NT 4.0, Windows® XP, or

®

MDX61B units in application version (...0T).

pro-

4

4.1.3 Possible combinations

•MOVIDRIVE

Encoder type (external encoder)

Bus type

(required option)

Additional

MOVIDRIVE

required

4.1.4 Additional notes

• The source of the actual position is the motor encoder. In systems subject to slip, an

external encoder can additionally be fitted or an absolute encoder can be used in

combination with the "DIP11B absolute encoder card" option.

• If operated with asynchronous motors, the drive inverter must be started up in the

"CFC & IPOS" operating mode.

• If operated with synchronous servomotors, the drive inverter must be started up in

the "SERVO & IPOS" operating mode.

• In the "VFC n-control & IPOS" operating mode, the master and slave drives must not

be connected via SBus.

®

MDX61B with the following fieldbus interfaces

Connection of motor shaft and load

®

option

Interlocking:

External encoder is not

required

- Incremental

PROFIBUS (DFP) / INTERBUS (DFI) / CAN bus (DFC) / DeviceNet (DFD) /

Ethernet (DFE) / system bus (SBus) no option required

DEH11B or DER11B DIP11B / DEH11B /

Non-positive:

External encoder required

encoder

Absolute encoder

DER11B

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

15

4

Project Planning

Functional description

4.2 Functional description

4.2.1 Functional characteristics

The "DriveSync via fieldbus" application offers the following functional characteristics:

• Jog mode

• Referencing mode

• Positioning mode

The drive is moved clockwise or counterclockwise using two bits for direction selection. The speed and the ramp can be varied via fieldbus.

Reference travel is started with the start signal. Reference travel establishes the reference point (machine zero) for absolute positioning operations. The axis must be

referenced for selecting "positioning mode".

The machine control specifies the target position via process output data words PO2

and PO3. The speed and the ramp can be varied using the fieldbus. The current actual position is reported back via process input data words PI2 and PI3.

The program cyclically queries the target position so that position changes are possible during positioning. Positioning is only performed when the axis has been referenced.

• Synchronous operation

"Synchronous mode" is motion control based on the technology function "Internal

synchronous operation" (ISYNC).

After "synchronous operation" has been selected, the engaging process is started by

a engaging event that is defined during the startup procedure. Once the slave drive

has been synchronized with the master, the slave moves synchronously with the

master.

Synchronous operation is exited by resetting the “start bit” or deselecting "synchronous operation".

"Synchronous operation" can be started without prior reference travel.

In addition, a bus offset value (PO6) can be specified in synchronous mode to shift

the reference to the master axis without having to exit the operating mode.

16

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

4.2.2 Additional startup functions

You can choose the following additional functions at startup:

• Encoder in positioning mode (IPOS encoder source)

– Positive connection:

The incremental encoder, sin/cos encoder, or Hiperface

nected to terminal X15 of the DEH11B / DER11B option.

– Non-positive connection:

An encoder for slip compensation can be connected to terminal X14 of the

DEH11B / DER11B option in addition to the motor encoder. Alternatively, slip can

be compensated via the evaluation of an SSI absolute encoder (requires absolute

encoder card DIP11B option).

• Selecting the master drive source in "synchronous operation"

– Incremental encoder input X14 of the DEH11B / DER11B option for reading in the

master encoder value (is not allowed to be used if the input is already being used

as an IPOS encoder source).

– Simulation with the virtual master encoder. Variable specification of the position,

speed as well as acceleration via process output data words PO2 to PO5.

– Received "SBus data object" with read-in master encoder actual value of the mas-

ter drive. For example, each application module can operate as master and transfer the specified IPOS encoder source via SBus.

Project Planning

Functional description

®

encoder can be con-

4

• Control via fieldbus

– Fieldbuses with communication via 6 process data words (PROFIBUS, INTER-

BUS, DeviceNet, CANopen, Ethernet, SBus 2) are supported.

• Special function "positioning in modulo format" for endless movements

– Positioning can be in modulo format for endless movements (e.g. conveyor belts).

As a result, it is possible to achieve endless movements without losing the position reference to the reference position.

– The modulo travel range is limited to 0 ... < 360°

– The modulo travel strategy can be changed as follows in positioning mode:

Jog + = FALSE and Jog – = FALSE

The setpoint position is always reached on the "shortest route".

Jog+ = TRUE and Jog– = FALSE

The setpoint position is always reached by traveling "clockwise".

Jog+ = FALSE and Jog– = TRUE

The setpoint position is always reached by traveling "counterclockwise".

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

17

4

Project Planning

Scaling of the drive

4.3 Scaling of the drive

The controller must be able to detect the number of encoder pulses (increments) per

travel unit to position the drive. The scaling function is used to set a user unit suitable to

the application.

4.3.1 Drive without external encoder (positive connection)

In drives without an external encoder, the system can calculate the scaling automatically

during startup of the application module. Enter the following data:

• Diameter of the drive wheel (d

• Gear ratio of the gear unit (i

• Gear ratio of the additional gear (i

The following scaling factors are calculated:

• Pulses / distance scaling factor [inc/mm] using the formula:

Pulses = 4096 × i

Distance = π × d

gear unit

drive wheel

• Speed scaling factor

Numerator factor in [rpm] and denominator value in "speed units".

× i

drive wheel

gear unit

additional gear

additional gear

or π × s

) or slope of the spindle (s

speed-reduction)

speed-reduction)

spindle

spindle

)

You can also enter the distance and velocity scaling factors directly. If you enter a unit

other than [mm] or [1/10 mm] for the travel unit, this user unit will also be used for the

position of the software limit switches, the reference offset and the maximum travel distances.

18

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

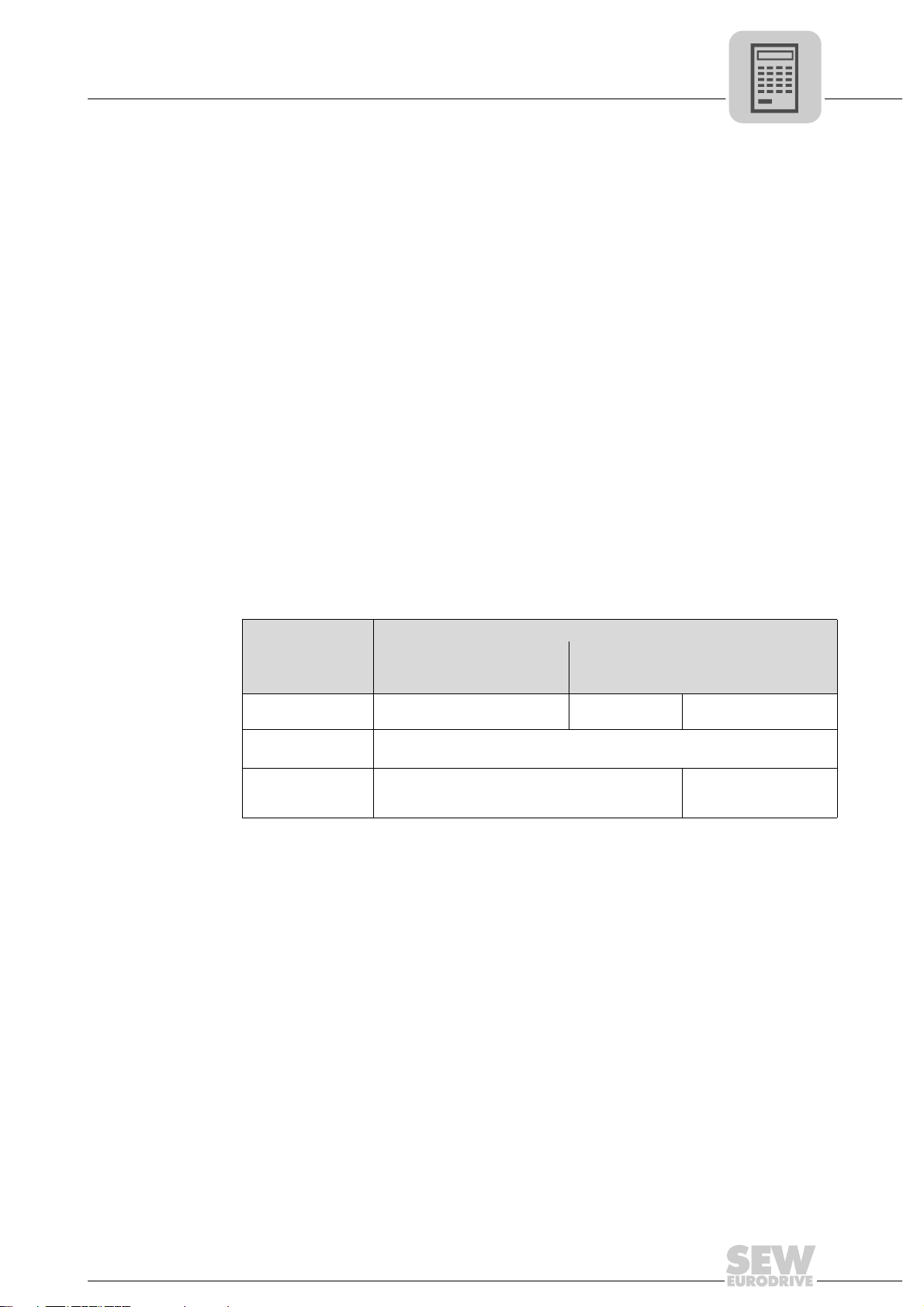

4.3.2 Drive with external encoder (non-positive connection)

In this case, you must have activated and scaled the external encoder before starting

up the "DriveSync via fieldbus" application module. To do so, make the following set-

tings in the Shell program before starting up the "DriveSync via fieldbus" application

module.

• P941 Source actual position

Project Planning

Scaling of the drive

4

3032773387

If an incremental encoder or an absolute encoder (DIP11) is connected, set P941 to

"EXT. ENCODER (X14)". You can also make this setting during the startup procedure of the application module.

• P942 Encoder factor numerator / P943 Encoder factor denominator / P944 Encoder

scaling ext. Encoder

Calculation of the scaling is blocked during startup of the application module.

INFORMATION

• For more information about scaling an external encoder, refer to the "IPOS

Positioning and Sequence Control System" manual.

• When using an absolute encoder, note the startup instructions in the

"MOVIDRIVE

®

MDX61B Absolute Encoder Card DIP11B" manual.

plus®

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

19

4

Project Planning

Limit switches, reference cams and machine zero

4.4 Limit switches, reference cams and machine zero

Note the following points during project planning:

• The software limit switches must be located within the travel range of the hardware

limit switches.

• When defining the reference position (position of the reference cam) and the software limit switches, make sure they do not overlap. Error message F78 "IPOS SW

limit switch" is generated in the event of an overlap during referencing.

• You can enter a reference offset during startup if you do not want the machine zero

to be located on the reference cam. The following formula applies: Machine zero =

reference position + reference offset. This way, you can alter the machine zero without having to move the reference cam.

INFORMATION

Please also refer to the information in chapter "Software limit switches".

20

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

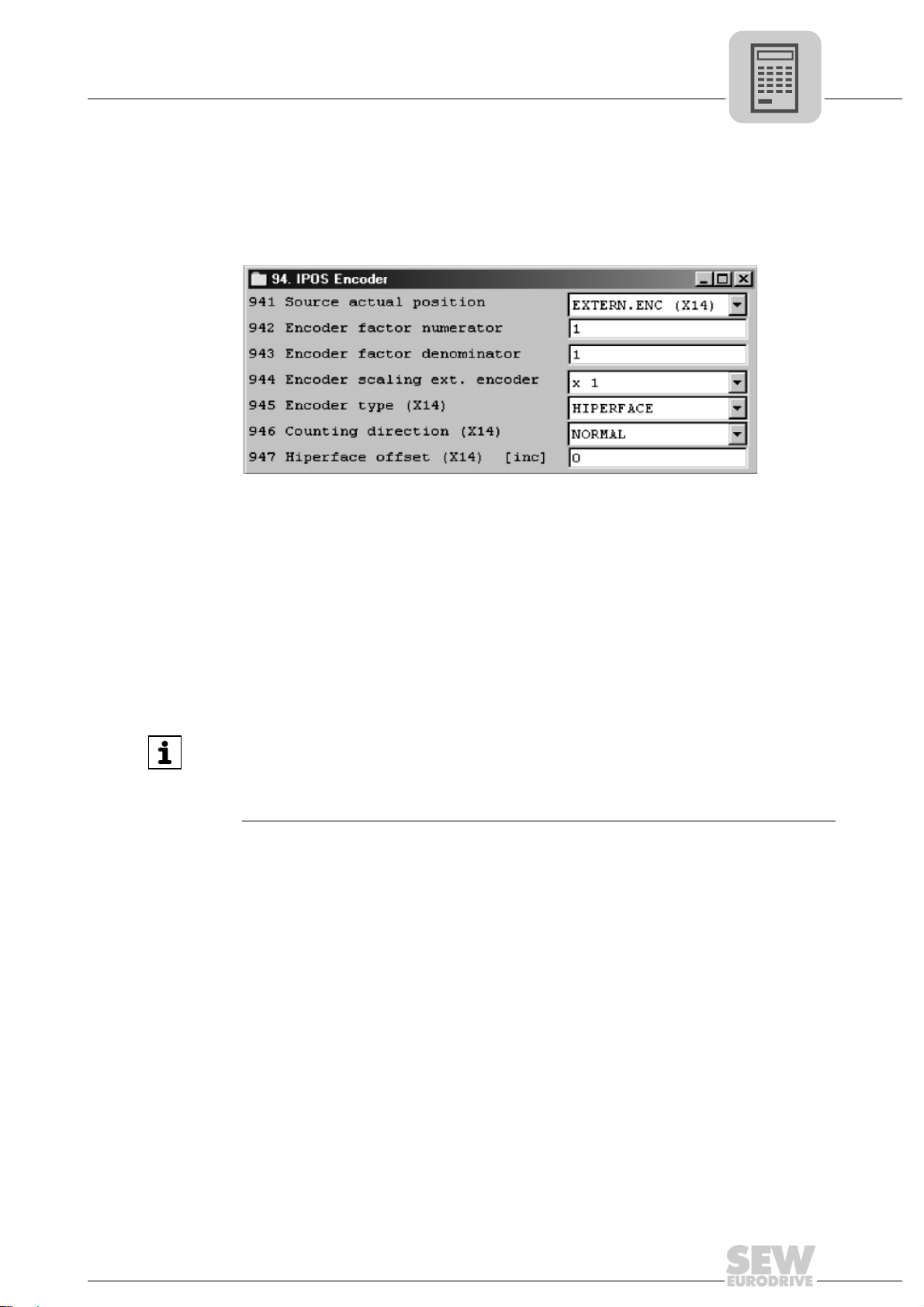

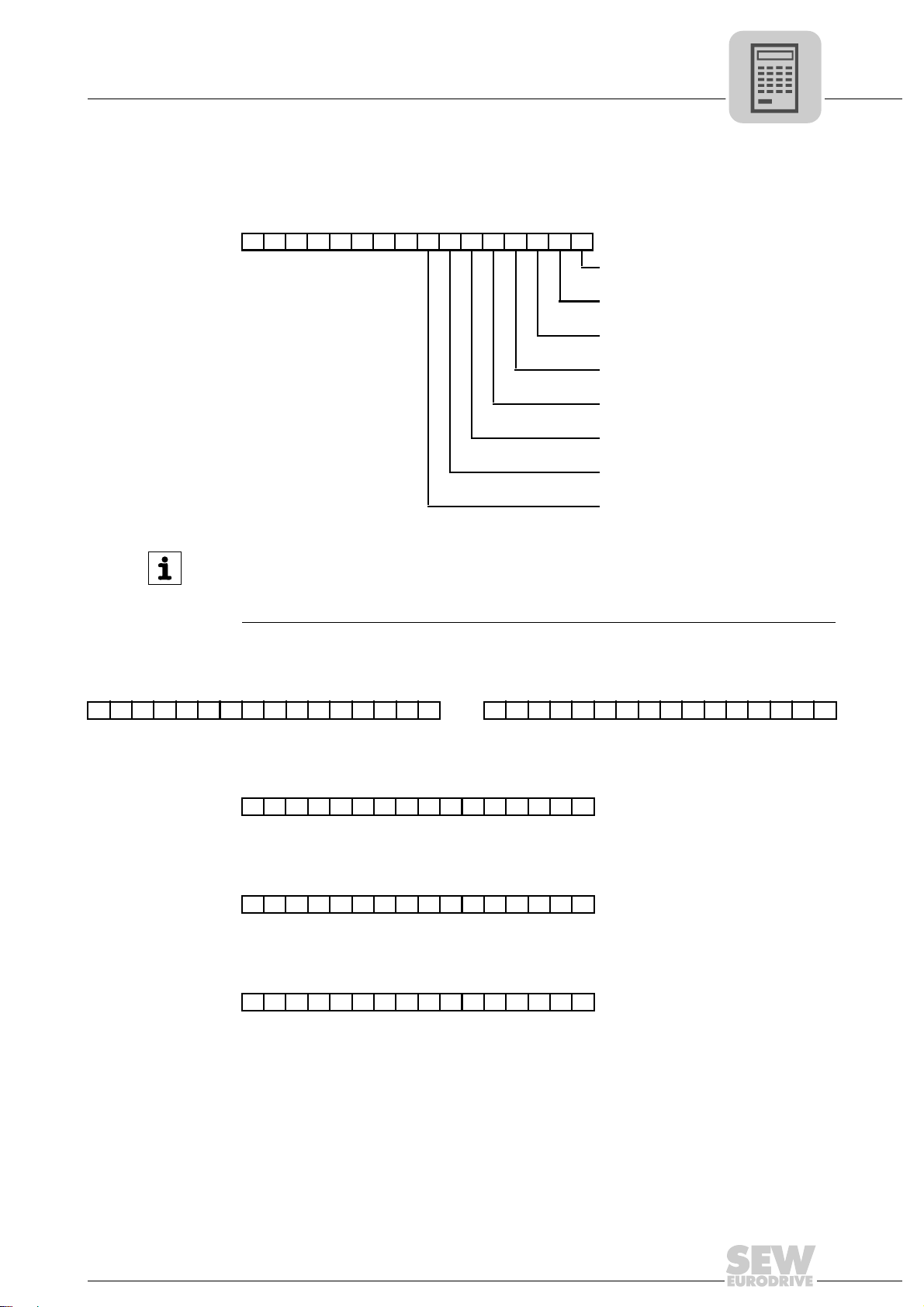

4.5 Process data assignment

PI

PO

PO1

PI1

PO2

PI2

PO3 PO4 PO5 PO6

PI3 PI4 PI5 PI6

The machine control (PLC) sends 6 process output data words (PO1 – PO6) to the inverter and receives 6 process input data words (PI1 – PI6) from the inverter.

PO= Process output data

PO1 = Control word 2

PO2 = Target position high

PO3 = Target position low

PO4 = Setpoint speed (IPOS PO data)

PO5 = Acceleration and deceleration ramp (IPOS PO data)

PO6 = Offset (IPOS PO data)

PI= Process input data

PI1 = Status word (IPOS PI data)

PI2 = Actual pos. high (IPOS PI data)

PI3 = Actual pos. low (IPOS PI data)

PI4 = Actual speed (IPOS PO data)

PI5 = Master/slave position difference (IPOS PI data)

PI6 = Active current (IPOS PI data)

Project Planning

Process data assignment

4

3044175371

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

21

4

4.5.1 Process output data

Project Planning

Process data assignment

The process output data words are assigned as follows:

• PO1: Control word 2

1514131211109876543210

/SW LS off

Offset Enable/rapid stop

Set zero point Enable/stop

Mode high /Hold control

Mode low Ramp switchover

Controller inhibit/

enable

Jog –

Jog + Error reset

Start Reserved

Parameter set

switchover

• PO2 + PO3: Target position

PO2 Target position high PO3 Target position low

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Target position [user unit]

• PO4: Setpoint speed

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Setpoint speed [user unit]

• PO5: Ramp up and down

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Ramp up and down [ms]

• PO6: Offset

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Bus offset [user-defined units]

22

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

4.5.2 Process input data

The process input data words are assigned as follows:

• PI1: Status word

1514131211109876543210

Inverter status/error code

Project Planning

Process data assignment

Drive synchronous

Inverter ready

IPOS reference (= drive referenced)

Target position reached

Brake released

Error/warning

Limit switch right

Limit switch left

4

INFORMATION

The fault code is displayed in the high byte (bits 8 to 15) of the status word if bit 5

"Fault/warning" is set. If there is no fault, the current unit status is displayed in the high

byte of the status word.

• PI2 + PI3: Actual position

PI2 Actual position high PI3 Actual position low

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

• PI4: Actual speed

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Velocity [user units]

• PI5: Master/slave position difference

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Lag distance [user units]

• PI6: Active current

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Active current [% I

]

N

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

23

4

SWLS CCW

SWLS CW

Motor position

Project Planning

Software limit switches

4.6 Software limit switches

4.6.1 General information

The "software limit switch" monitoring function is used to ensure that the target position

is set to appropriate values. During this process, it is not important where the drive is

positioned. Unlike the monitoring of the hardware limit switches, the monitoring function

for the software limit switches makes it possible to detect whether there is an error in the

target specifications before the axis starts to move. The software limit switches are active when the axis is referenced; that is, when the bit "IPOS reference" is set in PI1.

INFORMATION

The "software limit switch" monitoring function is disabled in synchronous mode.

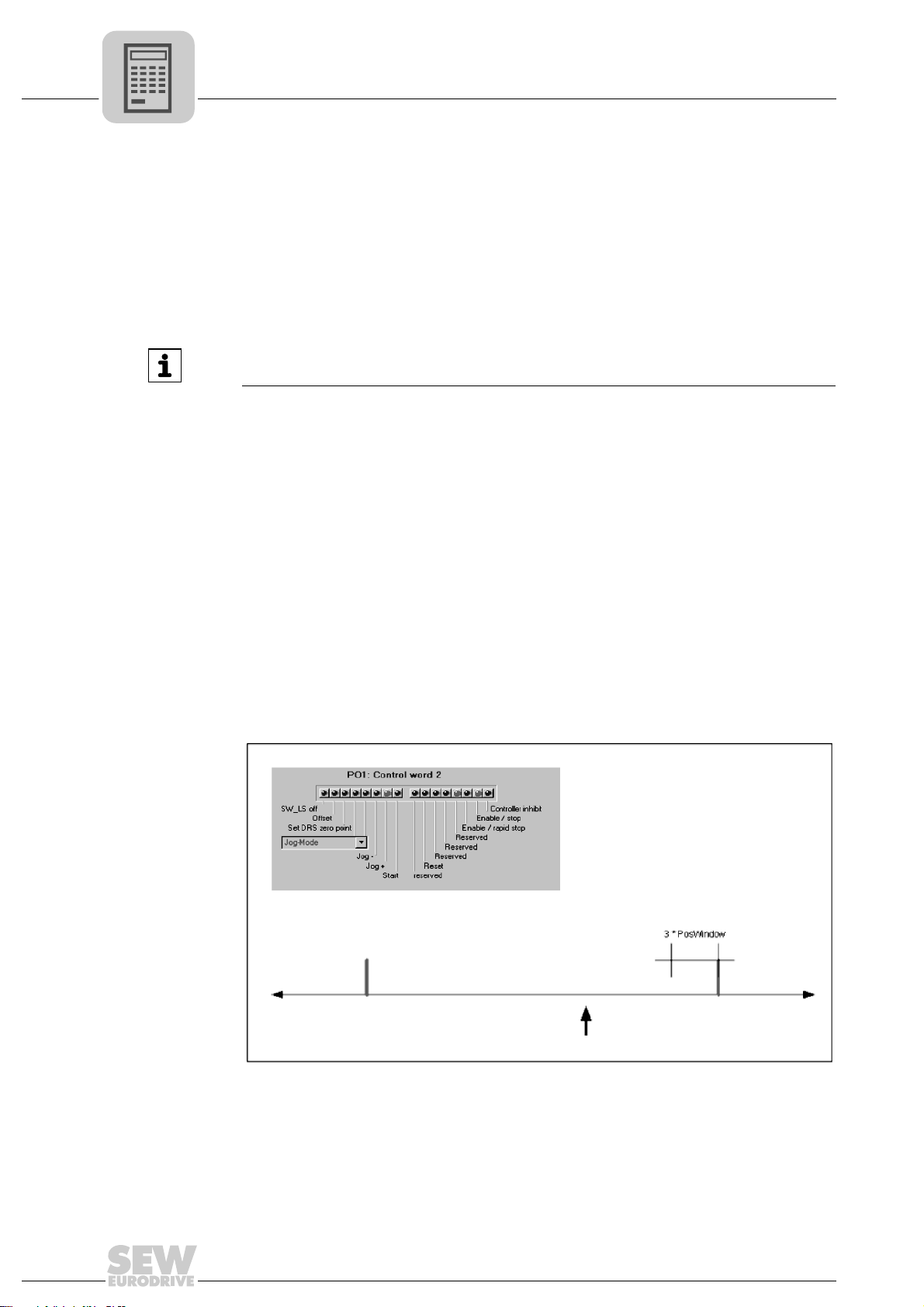

4.6.2 Moving clear of the software limit switches

When using an absolute encoder or multi-turn Hiperface

for the drive to be moved within the range of the software limit switches (for example,

after an encoder has been replaced). For this purpose, Bit 15 in the process output data

word 1 (PO1) is set to "/SWLS" (= Moving clear of the software limit switches).

®

encoder it may be necessary

Bit 15 "/SWLS" is only available in "jog mode" and "referencing mode". If bit 15 is set,

the drive can be moved out of the valid positioning range into the area of the software

limit switches (→ example 3).

Case no. 1 It is necessary to differentiate between the following three examples:

• Requirements:

– Bit 15 "/SWLS" in the process output data word 1 (PO1) is not set.

– Drive is within valid positioning area.

– Software limit switch monitoring function is active.

24

3044199819

In jog mode, the drive runs until it is three position windows (P922) before the software limit switch and then stays there.

In positioning mode, the drive can be positioned up to the software limit switches

but not beyond.

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

In referencing mode, the software limit switches are not active, which means the

SWLS CCW

SWLS CW

Motor position

Reference speed 2 (P902)

drive can move past the software limit switches during reference travel.

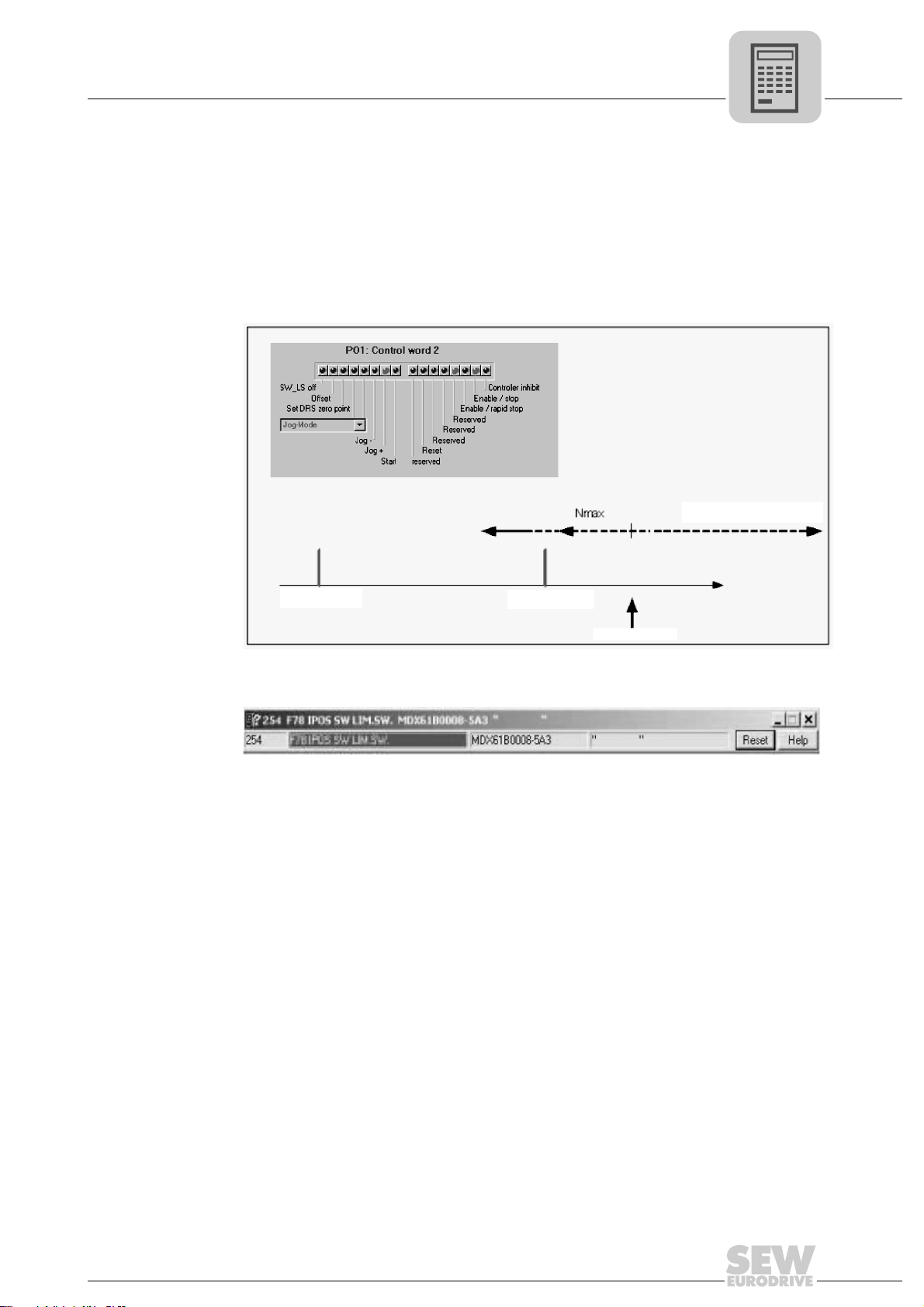

Case no. 2 • Requirements:

– Bit 15 "/SWLS" in the process output data word 1 (PO1) is not set.

– The drive is outside the software limit switches.

Project Planning

Software limit switches

4

3044204811

The following error message appears once the drive is enabled:

3044227851

Click <Reset> to acknowledge the error message. The monitoring function is deactivated. For example, if the drive is right to the software limit switch (see above figure), the drive can be moved at two different velocities depending on the specified

direction of the motor rotation:

– Closer toward the travel range of the software limit switch at reference speed 2

(P902).

– Away from the travel range of the software limit switches at maximum speed.

The monitoring function is reactivated when:

– The actual position of the drive set using P941 enters the permitted positioning

range again.

– A positioning job is issued via the opposite software limit switch.

– The unit is switched off and on again.

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

25

4

SWLS CCW

SWLS CW

Case no. 3 • Requirement:

Project Planning

Safe stop

– Bit 15 "/SWLS" in the process output data word 1 (PO1) is set.

4.7 Safe stop

3044210443

The monitoring function is deactivated in the modes "jog" and "referencing". The

drive can be moved within the travel area of the software limit switches and from the

valid positioning range into the area of the software limit switches without an error

message being generated. The speed can be varied.

WARNING

Risk of crushing if the motor starts coasting.

Severe or fatal injuries.

• You must not change the monitoring function of the software limit switches (PO1,

Bit 15 "/SWLS") during operation (i.e. when the axis is in motion).

• Observe startup notes.

A "Safe stop" can only be achieved by safe disconnection of the jumpers at terminal X17

(with safety switch or safety PLC).

The "Safe stop active" state is indicated by a "U" in the 7-segment display. In the application module, this state is treated in the same way as the "CONTROLLER INHIBIT"

state.

26

INFORMATION

For more information on the Safe stop function, refer to the following publications:

• Safe disconnection for MOVIDRIVE

• Safe disconnection for MOVIDRIVE

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

®

MDX60B/61B - Conditions

®

MDX60B/61B - Applications

5 Installation

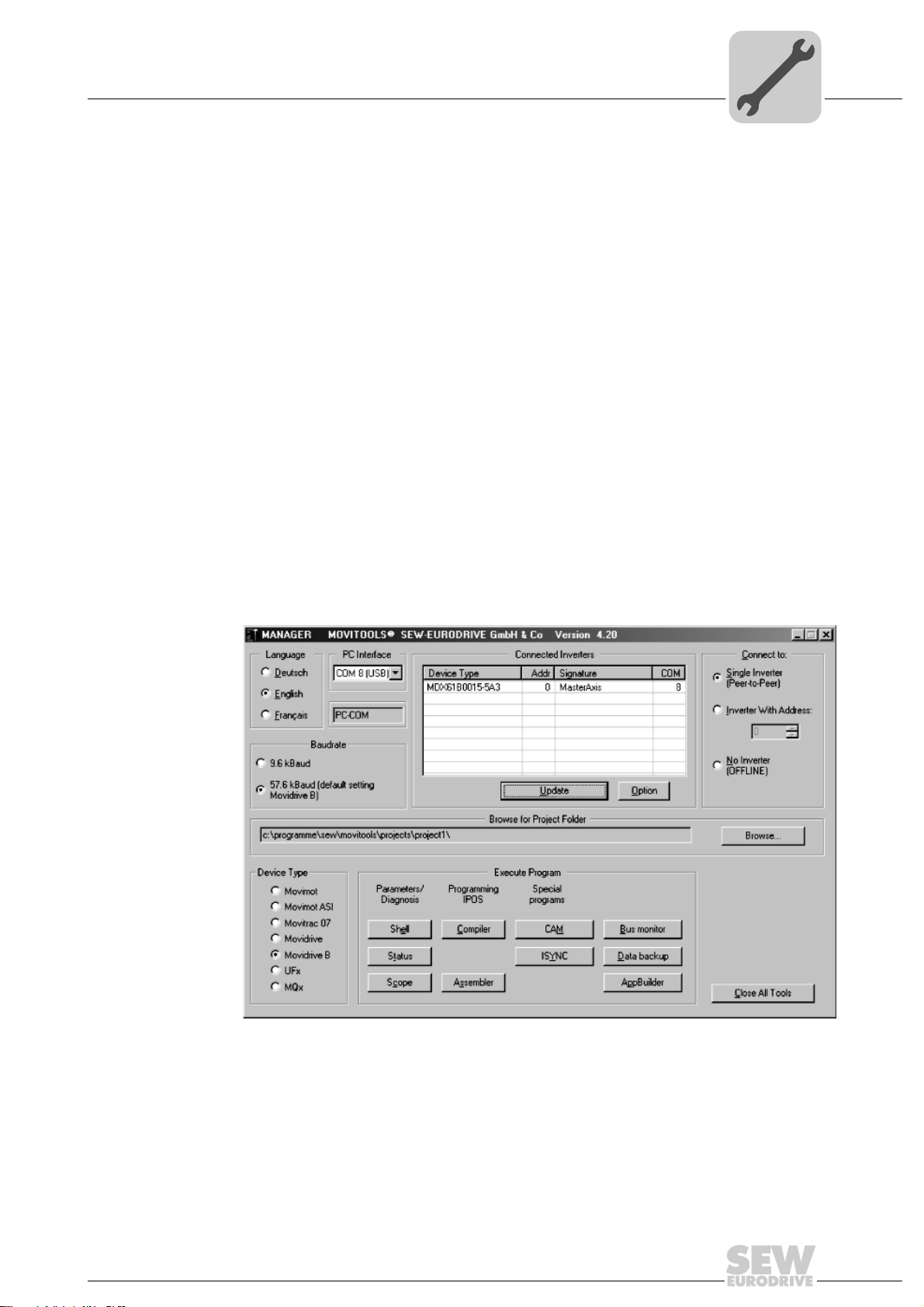

5.1 MOVITOOLS® software

5.1.1 MOVITOOLS

®

The "DriveSync via fieldbus" application module is part of the MOVITOOLS® software

(version 4.30 and higher). Proceed as follows to install MOVITOOLS

puter:

• Insert the MOVITOOLS

• The MOVITOOLS

process: Follow the instructions.

You can now use the Program Manager to start MOVITOOLS

perform startup for the inverter using the MOVITOOLS

• Select the language you want in the "Language" group.

• In the "PC COM" selection field, select the PC port (e.g. COM 1) to which the inverter

is connected.

Installation

MOVITOOLS® software

®

on your com-

®

CD into the CD-ROM drive of your PC.

®

setup menu is started. You will be guided through the installation

®

®

Manager:

. Proceed as follows to

5

• In the "Device type" group, select "MOVIDRIVE B".

• In the "Baud rate" field, select the baud rate set on the basic unit with the DIP switch

S13 (standard setting "57.6 kbaud").

• Click [Update] to display the connected inverter.

5.1.2 Application variant

The "DriveSync via fieldbus" application module can be used with the MOVIDRIVE

plication variant (-0T). The application modules cannot be used on units in the standard

version (-00).

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

3044477835

®

ap-

27

5

X13:

X14:

X15:

X15:

1

2

3

4

5

6

7

8

9

10

11

DEH11B / DER11B option

1

8

9

15

X10:

TF1

DGND

DBØØ

DOØ1-C

DOØ1-NO

DOØ1-NC

DOØ2

VO24

VI24

DGND

1

2

3

4

5

6

7

8

9

10

TF/TH input

Reference potential for binary signals

/Brake

Relay contact/Ready *

Relay N/O contact

Relay N/C contact

/Fault *

DC+24V output

DC+24V input

Reference potential for binary signals

DIØØ

DIØ1

DIØ2

DIØ3

DIØ4

DIØ5

DCOM

VO24

DGND

ST11

ST12

/Controller inhibit

No enable

IPOS input (material sensor)

Reference cam

/LS CW or no function

/LS CCW or no function

Reference

X13:DIØØ...DIØ

5

DC+24V output

Reference potential bianry signals

RS-485+

RS-485-

MOVIDRIVE® MDX61B slave

External encoder input

DEH11B option

DER11B option

Resolver

(Connection: Operating instr. MOVIDRIVE

®

)

15

1

8

9

1

5

6

9

DEH11B option (motor encoder):

high resolution sin/cos encoder,

Hiperface encoder or incremental encoder

(CT/CV or DT/DV/D motors)

DER11B option (motor encoder):

Resolver (DS/CM motors)

Motor encoder

(Connection: Operating instr. MOVIDRIVE

®

(Connection: Operating instr. MOVIDRIVE

®

)

®

DEH11B / DER11B option (master):

Incremental encoder TTL/RS-422

with DC 24 V supply, I

max

= 180 mA

* Factory setting

X16:

1

2

3

4

5

6

DIØ6

DIØ7

DOØ3

DOØ4

DOØ5

DGND

Drive synchronous

IPOS reference

IPOS in position

Reference potential for binary signals

No function

Fault reset

Installation

Wiring diagram for incremental encoder master / MDX61B slave

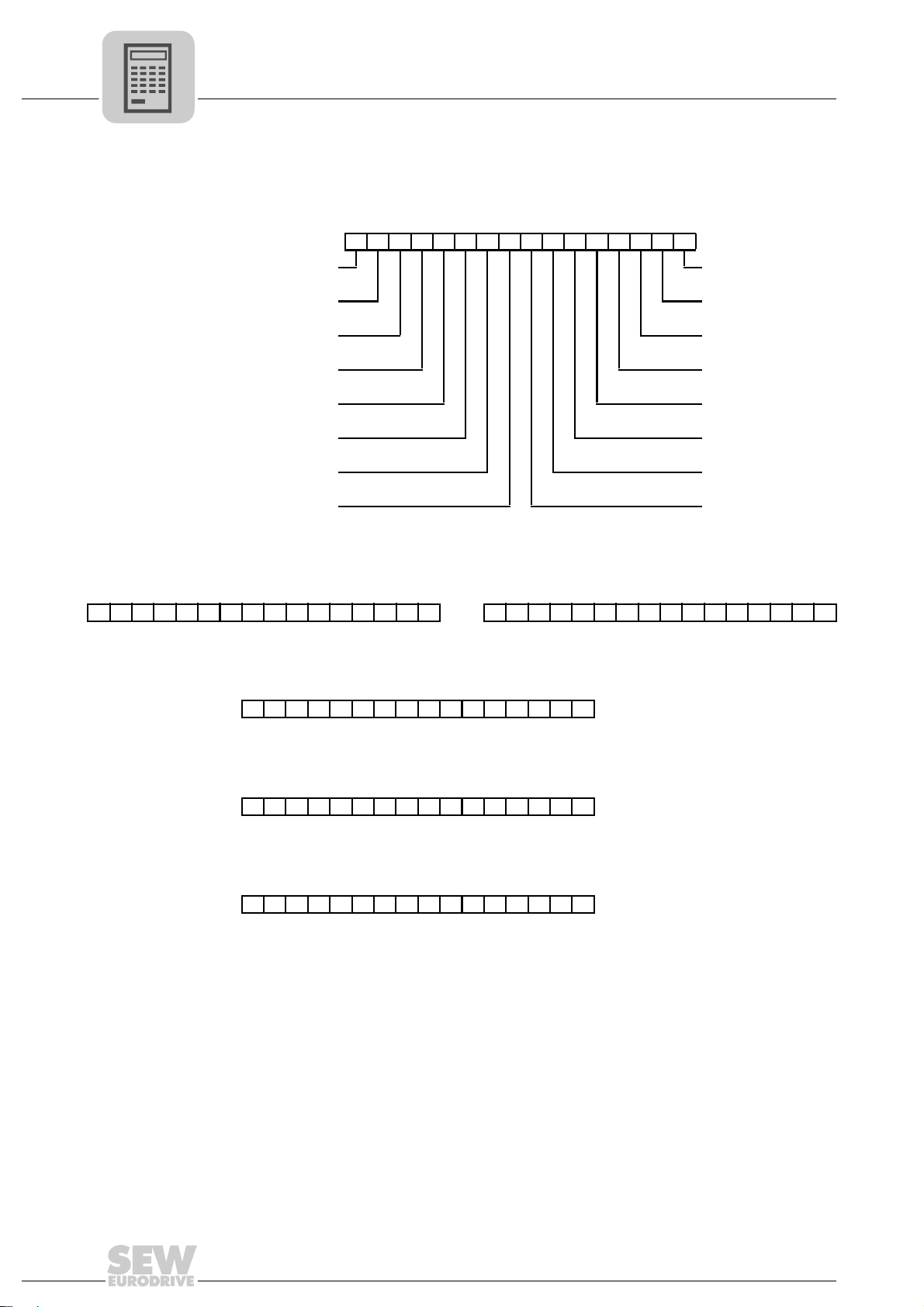

5.2 Wiring diagram for incremental encoder master / MDX61B slave

3044591755

28

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

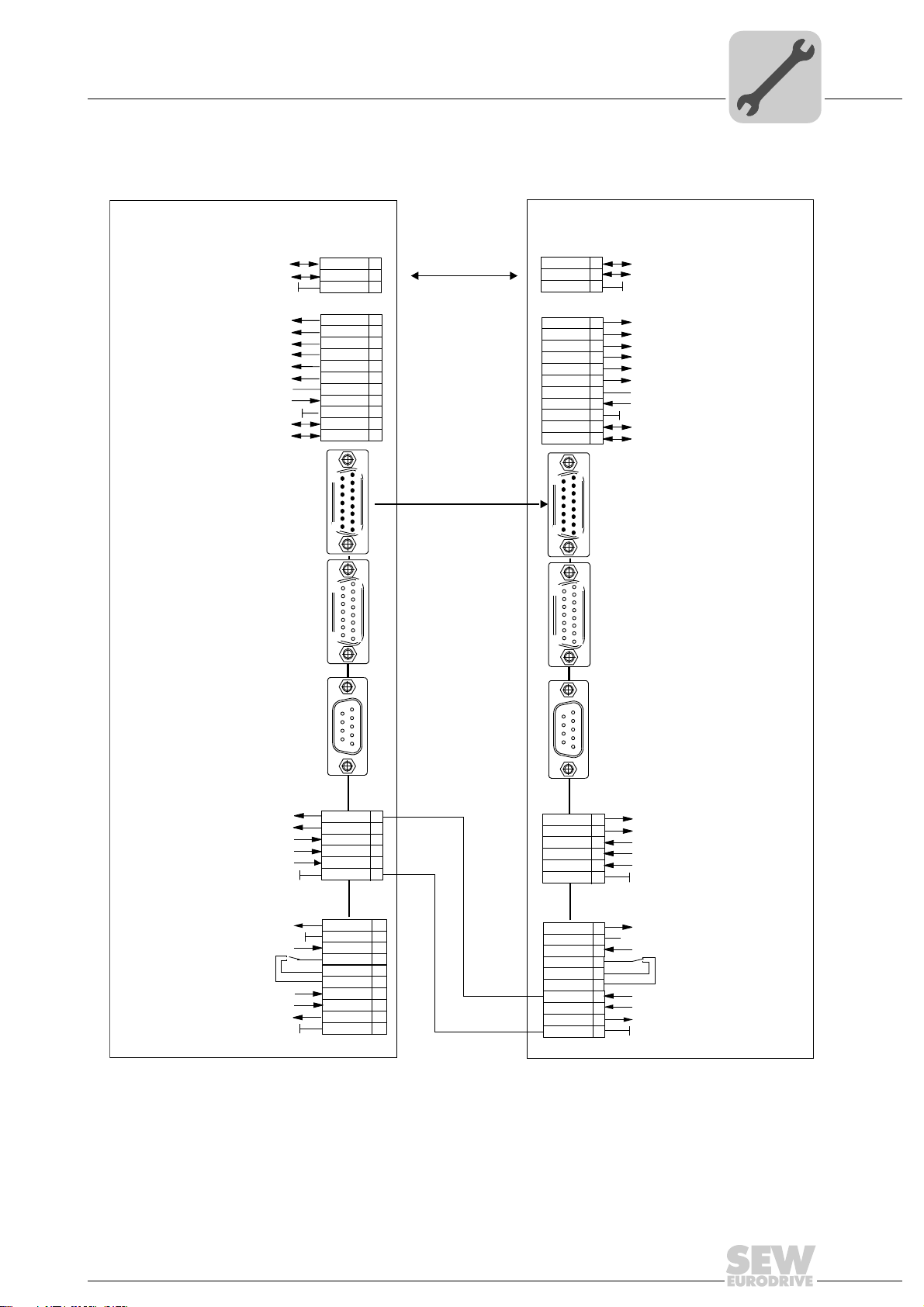

Wiring diagram for MDX61B master / MDX61B slave

5.3 Wiring diagram for MDX61B master / MDX61B slave

Installation

5

MOVIDRIVE MDX61B - Master

System bus reference

/Controller inhibit

IPOS input (material sensor)

Reference X13:DIØØ...DIØ5

Reference potential for binary signals

Option DEH11B / DER11B

®

System bus high

System bus low

No enable

Reference cam

/LS CW

/LS CCW

DC+24V output

RS-485+

RS-485-

External encoder input

Option DEH11B

Motor encoder

X14:

X15:

DGND

SC11

SC12

DIØØ

DIØ1

DIØ2

DIØ3

DIØ4

DIØ5

DCOM

VO24

DGND

ST11

ST10

9

15

15

9

X12:

X13:

1

8

8

1

MOVIDRIVE MDX61B - Slave

®

X12:

DGND

1

2

3

1

2

3

4

5

6

7

8

9

10

11

[1]

[2]

S

c

1

S

c1

DIØØ

DIØ1

DIØ2

DIØ3

DIØ4

DIØ5

DCOM

VO24

DGND

ST11

ST12

9

15

15

9

1

System bus reference

2

1

2

3

System bus high

System bus low

X13:

/Controller inhibit

1

No enable

2

IPOS input (material senor)

3

Reference cam

4

/LS C W

5

/LS CCW

6

Reference X13:DIØØ...DIØ5

7

8

DC+24V output

9

Reference potential for binary signals

10

RS-485+

11

RS-485-

X14:

1

Option DEH11B / DER11B

External encoder input

8

X15:

8

Option DEH11B

Motor encoder

(Connection: MOVIDRIVE

1

®

operating instructions)

Option DER11B

/Ext. error

Error reset

(drive synchronous)

IPOS reference

Reference potential for binary signals

Reference potential for binary signals

Relay contact/ready f. operation*

Reference potential for binary signals

IPOS in position

TF/TH input

NO contact relay

NC contact relay

DC+24V output

DC+24V input

/Brake

/Fault*

X15:

Resolver

5

9

6

1

DIØ6

DIØ7

DOØ3

DOØ4

DOØ5

DGND

TF1

DGND

DBØØ

DOØ1-C

DOØ1-NO

DOØ1-NC

DOØ2

VO24

VI24

DGND

X16:

X10:

[3a]

[3b]

DIØ6

DIØ7

DOØ3

DOØ4

DOØ5

DGND

DOØ1-NO

DOØ1-NC

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

10

X15:

Option DER11B

5

9

Resolver

6

1

(Connection: MOVIDRIVE

X16:

1

2

3

4

5

6

X10:

1

TF1

2

DGND

3

DBØØ

4

DOØ1-C

5

6

7

DOØ2

8

VO24

9

VI24

10

DGND

®

operating instructions)

No function

Error reset

Drive synchronous

IPOS reference

IPOS in position

Reference potential for binary signals

TF/TH input

Reference potential for binary signals

/Brake

Relay contact/ready f. operation*

NO contact relay

NC contact relay

/Fault*

DC+24V output

DC+24V input

Reference potential for binary signals

1359027979

[1] Synchronous mode master value is transferred via SBus connection (e.g. with a number of slaves > 1)

[2] Synchronous mode master value is transferred via DEH11B / DER11B option, X14

[3a, 3b] Wiring when using the "Immediate switch-off of the master drive in case of slave faults via (/ext. fault)"

function

Manual – MOVIDRIVE® MDX61B "DriveSync via Fieldbus" Application

29

Loading...

Loading...