SEW movidrive MDX60B,movidrive MDX61B User Manual

Drive Technology \ Drive Automation \ System Integration \ Services

MOVIDRIVE

®

MDX60B/61B

Communication and Fieldbus Unit Profile

Edition 04/2009

11264926 / EN

Manual

SEW-EURODRIVE – Driving the world

1 General Information ............................................................................................... 6

1.1 How to use the documentation ...................................................................... 6

1.2 Structure of the safety notes .......................................................................... 6

1.3 Rights to claim under limited warranty ........................................................... 7

1.4 Exclusion of liability ........................................................................................ 7

1.5 Copyright........................................................................................................ 7

2 Safety Notes ........................................................................................................... 8

2.1 Other applicable documentation .................................................................... 8

2.2 General notes on bus systems....................................................................... 8

2.3 Safety functions ............................................................................................. 8

2.4 Hoist applications ........................................................................................... 8

2.5 Waste disposal............................................................................................... 8

3 Introduction ............................................................................................................ 9

3.1 Content of the manual.................................................................................... 9

3.2 Additional documentation............................................................................... 9

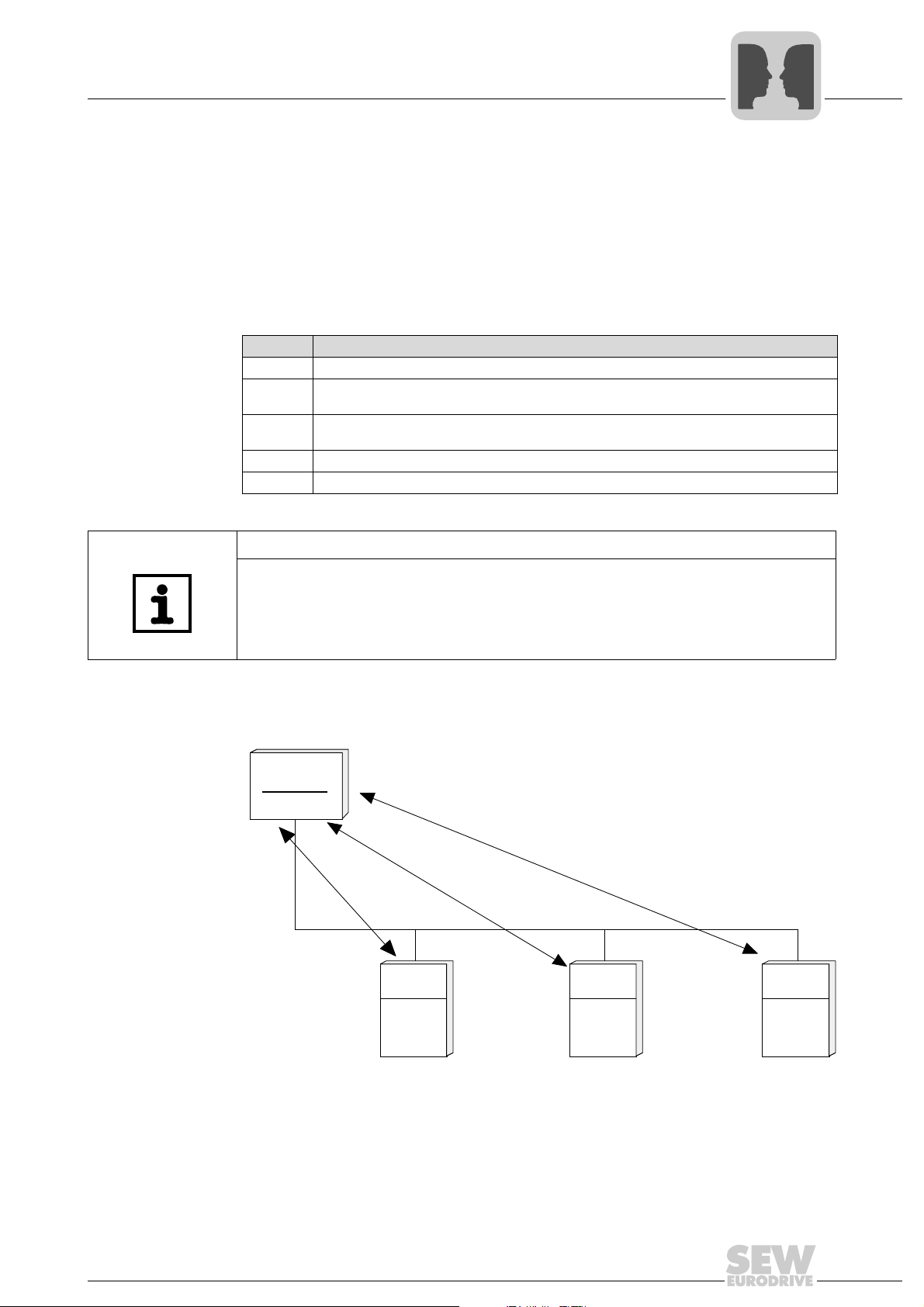

3.3 Communication interfaces of MOVIDRIVE

®

B............................................. 10

3.3.1 Overview of communication interfaces ............................................. 11

4 Serial Interfaces of MOVIDRIVE

®

B .................................................................... 12

4.1 Connecting and installing RS485 interfaces ................................................ 12

4.1.1 Connection using socket XT ............................................................. 12

4.1.2 Connection using terminals X13:10 and X13:11 ............................... 15

4.1.3 Shielding and routing cables ............................................................. 16

4.2 Configuration parameters of the serial interfaces ........................................ 17

4.3 MOVILINK

®

protocol via RS485 transmission method ................................ 18

4.3.1 Transmission method ........................................................................ 18

4.3.2 Telegrams ......................................................................................... 21

4.3.3 Addressing and transmission method ............................................... 23

4.3.4 Structure and length of user data ..................................................... 26

4.4 Other unit functions via RS485 interfaces.................................................... 29

4.4.1 Using RS485 interfaces for master/slave operation .......................... 29

4.4.2 Using the RS485 interfaces in IPOS

plus®

......................................... 33

4.4.3 Using RS485 interfaces for manual operation .................................. 33

5 CAN Interfaces of MOVIDRIVE

®

B ...................................................................... 34

5.1 Connecting and installing CAN .................................................................... 34

5.1.1 Connecting the two CAN interfaces CAN 1 and CAN 2 .................... 34

5.1.2 Shielding and routing cables ............................................................. 36

5.2 Configuration parameters of the CAN interfaces ......................................... 38

5.3 MOVILINK

5.3.1 Telegrams ......................................................................................... 39

5.3.2 Parameter setting via CAN (SBus MOVILINK

®

profile via CAN......................................................................... 39

®

) ............................... 44

5.4 CANopen profile via CAN............................................................................. 45

5.4.1 Configuring the CANopen interface of MDX B and

network management (NMT) ............................................................ 46

5.4.2 Process data exchange .................................................................... 48

5.4.3 SYNC object ..................................................................................... 52

5.4.4 The emergency object ...................................................................... 53

5.4.5 Heartbeat and lifetime ....................................................................... 54

5.4.6 Parameter access via SDO ............................................................... 55

5.4.7 Hard synchronization for synchronous operation

or positioning several MDX-B units ................................................... 56

5.4.8 Other unit properties in the CANopen profile .................................... 57

5.4.9 CANopen-specific objects of MOVIDRIVE

®

B .................................. 57

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

3

5.5 Other unit functions via CAN interfaces ....................................................... 60

5.5.1 Using CAN interfaces for master/slave operation ............................. 60

5.5.2 Using CAN interfaces in IPOS

5.5.3 Using CAN interfaces in IPOS

plus®

(depending on the profile) ......... 61

plus®

(independent of the profile) ....... 62

5.5.4 Using CAN interfaces for integrated synchronous

operation (ISYNC via SBus) ............................................................. 63

6 Fieldbus Interfaces via Option Card for MOVIDRIVE

6.1 Installing a fieldbus option card in MOVIDRIVE

®

B.................................. 67

®

MDX61B ......................... 68

6.1.1 Before you start ................................................................................ 69

6.1.2 Basic procedure for installing/removing an option card

(MDX61B, sizes 1 - 6) ....................................................................... 70

6.2 Parameters for configuring communication via fieldbus option.................... 71

6.3 Process and parameter access via fieldbus................................................. 73

6.4 Other unit functions via fieldbus option card ................................................ 73

6.4.1 Using the fieldbus options in IPOS

plus®

............................................ 73

6.4.2 Engineering via fieldbus .................................................................... 73

6.4.3 Engineering via fieldbus and controller ............................................ 73

6.4.4 Diagnostics via WEB server .............................................................. 74

6.4.5 Motion control ................................................................................... 74

7 SEW Unit Profile................................................................................................... 75

7.1 Process data ................................................................................................ 76

7.2 Process data configuration .......................................................................... 78

7.3 Process data description.............................................................................. 79

7.4 Sequence control ......................................................................................... 87

7.4.1 Definition of the control word ............................................................ 87

7.4.2 Linking safety-relevant control commands ....................................... 88

7.4.3 Control commands ............................................................................ 89

7.4.4 Control word 1 .................................................................................. 91

7.4.5 Control word 2 .................................................................................. 92

7.4.6 Status word definition ....................................................................... 93

7.4.7 Status word 1 .................................................................................... 94

7.4.8 Status word 2 .................................................................................... 95

7.4.9 Status word 3 .................................................................................... 96

7.4.10 Fault number and unit status ........................................................... 97

7.5 Monitoring functions ..................................................................................... 99

7.6 Setting the inverter parameters.................................................................. 101

7.6.1 Structure of the MOVILINK

®

parameter channel ............................ 102

7.6.2 Return codes of parameterization ................................................... 106

7.6.3 Example: Reading a parameter (READ) ......................................... 109

7.6.4 Example: Writing a parameter (WRITE) ......................................... 110

7.7 Notes on parameterization ......................................................................... 113

8 Operating MOVITOOLS

8.1 About MOVITOOLS

®

MotionStudio............................................................ 114

®

MotionStudio ........................................................... 114

8.1.1 Tasks .............................................................................................. 114

8.1.2 Establishing communication with the units ..................................... 114

8.1.3 Executing functions with the units ................................................... 114

8.2 First steps .................................................................................................. 115

8.2.1 Starting the software and creating a project ................................... 115

8.2.2 Establishing communication and scanning the network ................. 115

8.3 Communication mode ................................................................................ 116

8.3.1 Overview ......................................................................................... 116

8.3.2 Selecting communication mode (online or offline) .......................... 117

4

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

8.4 Serial communication (RS485) via interface adapters ............................... 118

8.4.1 Engineering via interface adapters (serial) ..................................... 118

8.4.2 Taking the USB11A interface adapter into operation ...................... 118

8.4.3 Configuring serial communication ................................................... 121

8.4.4 Serial communication parameter (RS485) ...................................... 123

8.5 Communication SBus (CAN) via interface adapter .................................... 124

8.5.1 Engineering via interface adapters (SBus) ..................................... 124

8.5.2 Taking the USB-CAN interface into operation ................................ 124

8.5.3 Configuring communication via SBus ............................................. 126

8.5.4 Communication parameters for SBus ............................................. 128

8.6 Communication via Ethernet, fieldbus or SBUSplus .................................. 129

8.6.1 Connecting the unit with the PC via Ethernet ................................. 129

8.7 Executing functions with the units .............................................................. 129

8.7.1 Parameterizing units in the parameter tree ..................................... 129

8.7.2 Reading/changing unit parameters ................................................. 129

8.7.3 Starting up the units (online) ........................................................... 130

8.7.4 Unit-internal scope .......................................................................... 131

8.8 Bus monitor................................................................................................ 131

8.8.1 Diagnostic mode of the bus monitor .............................................. 131

8.8.2 Control using bus monitor ............................................................... 131

8.9 Manual operation ....................................................................................... 131

9 Bus Diagnostics ................................................................................................. 132

9.1 Checking the parameter setting ................................................................. 132

9.2 Diagnostics of process input and output data ............................................ 134

9.3 Diagnostic options for RS485 communication ........................................... 135

9.4 Diagnostic options for CAN communication............................................... 137

9.5 Diagnostic options for communication via fieldbus option card.................. 139

10 Index .................................................................................................................... 140

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

5

1

General Information

How to use the documentation

1 General Information

Handbuch

1.1 How to use the documentation

The documentation is an integral part of the product and contain important information

on operation and service. The documentation is written for all employees who assemble,

install, startup, and service this product.

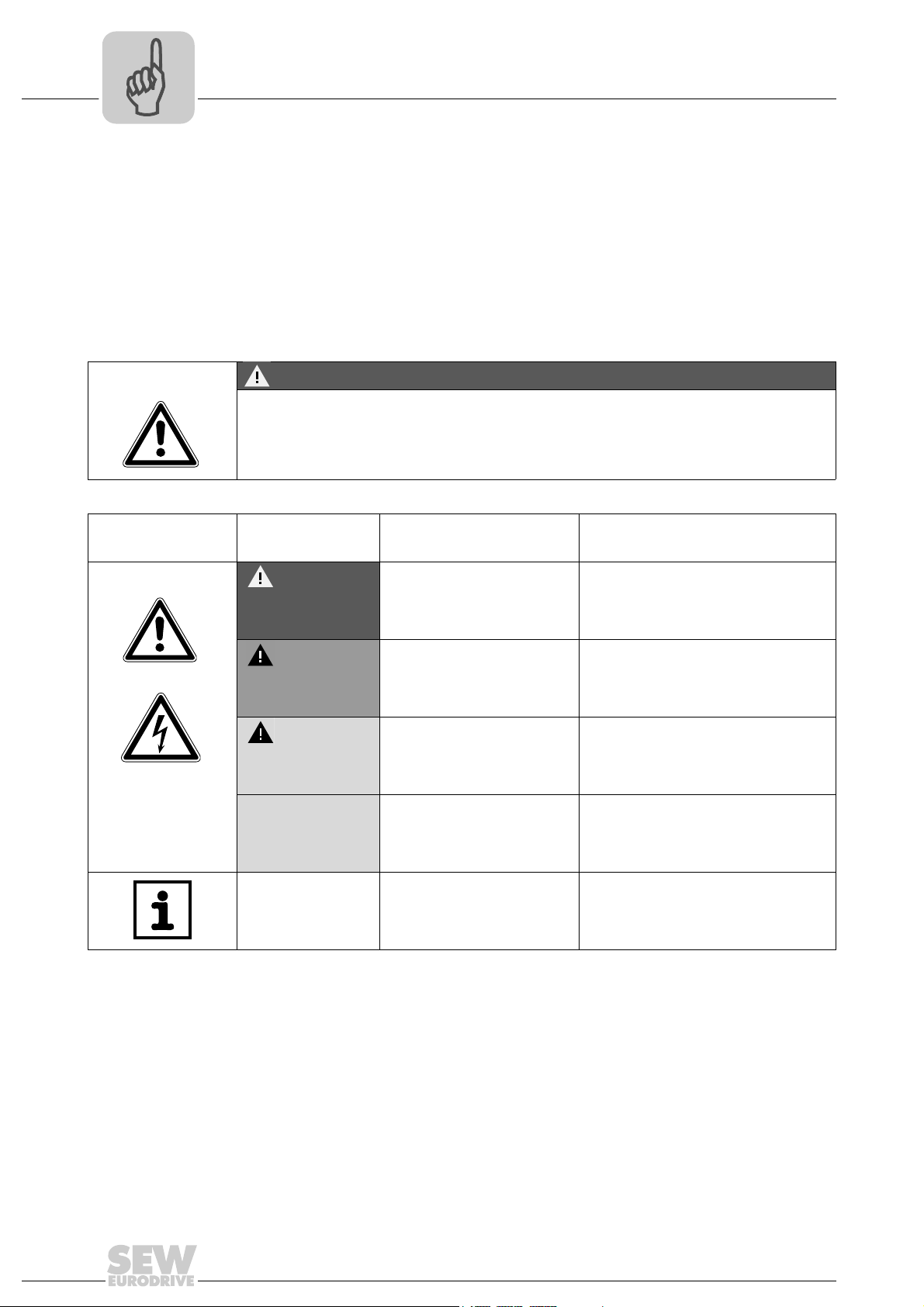

1.2 Structure of the safety notes

The safety notes in this documentation are structured as follows:

Pictogram SIGNAL WORD

Type and source of danger.

Possible consequence(s) if disregarded.

• Measure(s) to prevent the danger.

Pictogram Signal word Meaning Consequences if

disregarded

Example:

DANGER Imminent danger Severe or fatal injuries

General danger

Specific danger,

e.g. electric shock

WARNING Possible dangerous situation Severe or fatal injuries

CAUTION Possible dangerous situation Minor injuries

NOTICE Possible damage to property Damage to the drive system or its

environment

TIP Useful information or tip.

Simplifies the handling of the

drive system.

6

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

Rights to claim under limited warranty

1.3 Rights to claim under limited warranty

A requirement of fault-free operation and fulfillment of any rights to claim under limited

warranty is that you adhere to the information in the documentation. Read the documentation before you start working with the unit!

Make sure that the documentation is available to persons responsible for the system and

its operation as well as to persons who work independently on the unit. You must also

ensure that the documentation is legible.

1.4 Exclusion of liability

You must observe this documentation and the documentation of the connected units

from SEW-EURODRIVE to ensure safe operation and to achieve the specified product

characteristics and performance requirements. SEW-EURODRIVE assumes no liability

for injury to persons or damage to equipment or property resulting from non-observance

of the operating instructions. In such cases, any liability for defects is excluded.

1.5 Copyright

General Information

1

© 2008 - SEW-EURODRIVE. All rights reserved.

Copyright law prohibits the unauthorized duplication, modification, distribution, and use

of this document, in whole or in part.

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

7

2

Safety Notes

Other applicable documentation

2 Safety Notes

2.1 Other applicable documentation

Only electrical specialists are allowed to perform installation and startup observing

relevant accident prevention regulations and the MOVIDRIVE

instructions.

Read through these documents carefully before you commence installation and startup

of the communication interfaces of MOVIDRIVE

As a prerequisite to fault-free operation and fulfillment of warranty claims, you must

adhere to the information in the documentation.

2.2 General notes on bus systems

MOVIDRIVE® B has communication interfaces that make it possible to adapt the

MOVIDRIVE

bus systems, there is a danger of invisible, external (as far as the inverter is concerned)

modifications to the parameters which give rise to changes in the unit behavior. This

may result in unexpected (not uncontrolled) system behavior.

®

B inverter to the particulars of the machinery within wide limits. As with all

2.3 Safety functions

The MOVIDRIVE® MDX60B/61B inverters may not perform safety functions without

higher-level safety systems. Use higher-level safety systems to ensure protection of

equipment and personnel. For safety applications, ensure that the information in the

following publications is observed: "Safe Disconnection for MOVIDRIVE

MDX60B/61B".

®

MDX60B/61B operating

®

B.

®

2.4 Hoist applications

MOVIDRIVE® MDX60B/61B is not designed for use as a safety device in hoist applications.

Use monitoring systems or mechanical protection devices as safety equipment to avoid

possible damage to property or injury to people.

2.5 Waste disposal

Observe the applicable national regulations.

Dispose of the following materials separately in accordance with the country-specific

regulations in force, as:

• Electronics scrap

• Plastic

• Sheet metal

• Copper

8

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

3 Introduction

3.1 Content of the manual

The manual describes the communication interfaces of the MOVIDRIVE® MDX60B/61B

inverter:

• 2 serial interfaces

• 2 CAN interfaces, one via DFC11B option card

• Fieldbus or Ethernet interface depending on the installed option card

The manual provides a description of the connection, configuration parameters, as well

as of the process and parameter data exchange via the communication interfaces of

MOVIDRIVE

The manual also describes how MOVITOOLS

MOVIDRIVE

controllers (PLC) can control MOVIDRIVE

3.2 Additional documentation

®

B.

®

B using the communication interfaces, and how programmable logic -

Introduction

Content of the manual

®

MotionStudio communicates with

®

B via the communication interfaces.

3

For simple connection of MOVIDRIVE® B to fieldbus systems, have the following

documents at hand in addition to the manual:

•MOVIDRIVE

•MOVIDRIVE

The MOVIDRIVE

device firmware and includes a list of all device indices and error codes. It supplements the system manual as the latter is not rewritten for every firmware version.

• The manual of the fieldbus option used (e.g. DFP21B)

The manuals on the fieldbus options and the manual at hand describe the access to

process and parameter data in general and do not include a detailed description of

all the possible control concepts.

®

MDX60/61B system manual

®

B list of parameters

®

B list of parameters describes the device parameters for every

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

9

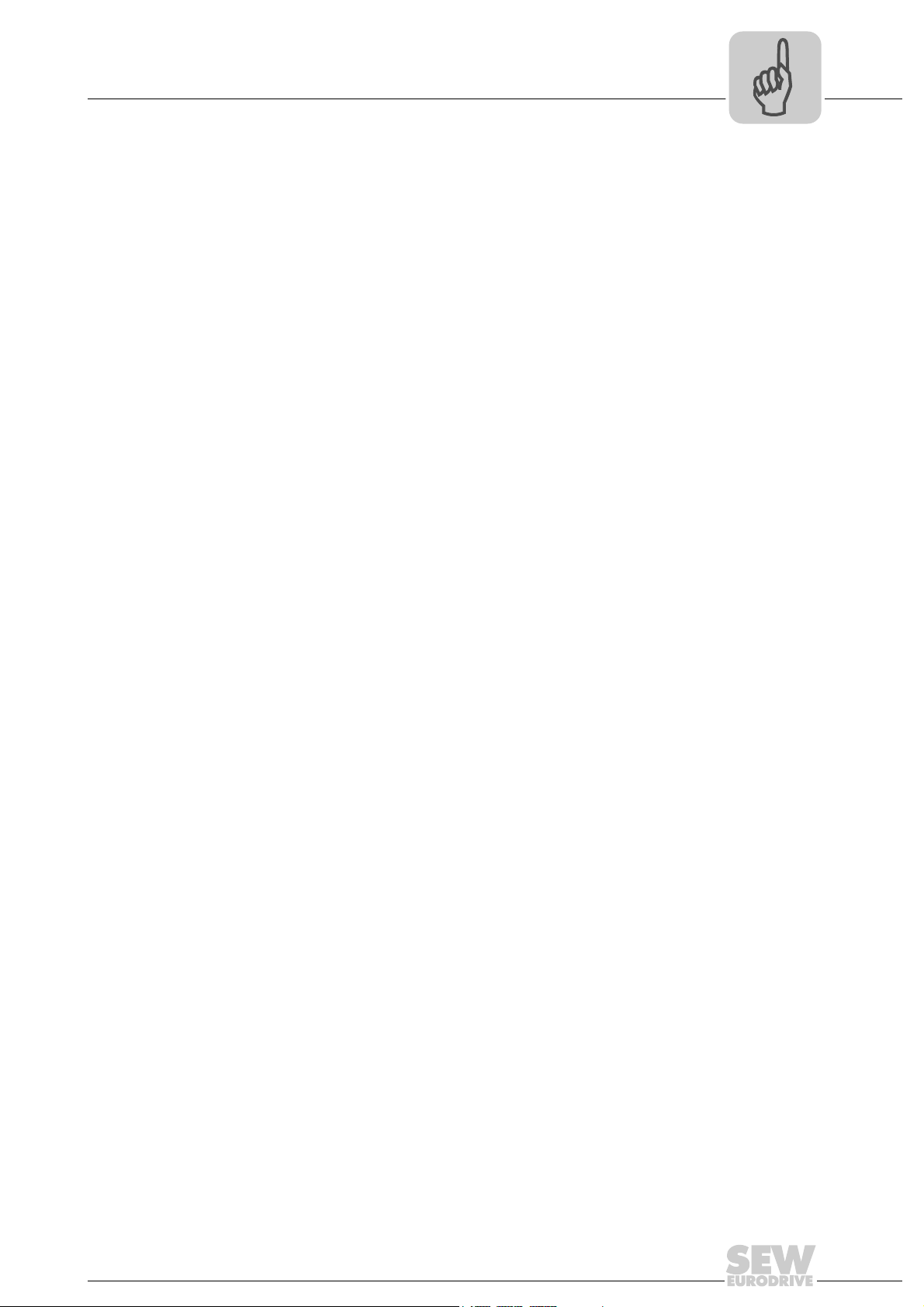

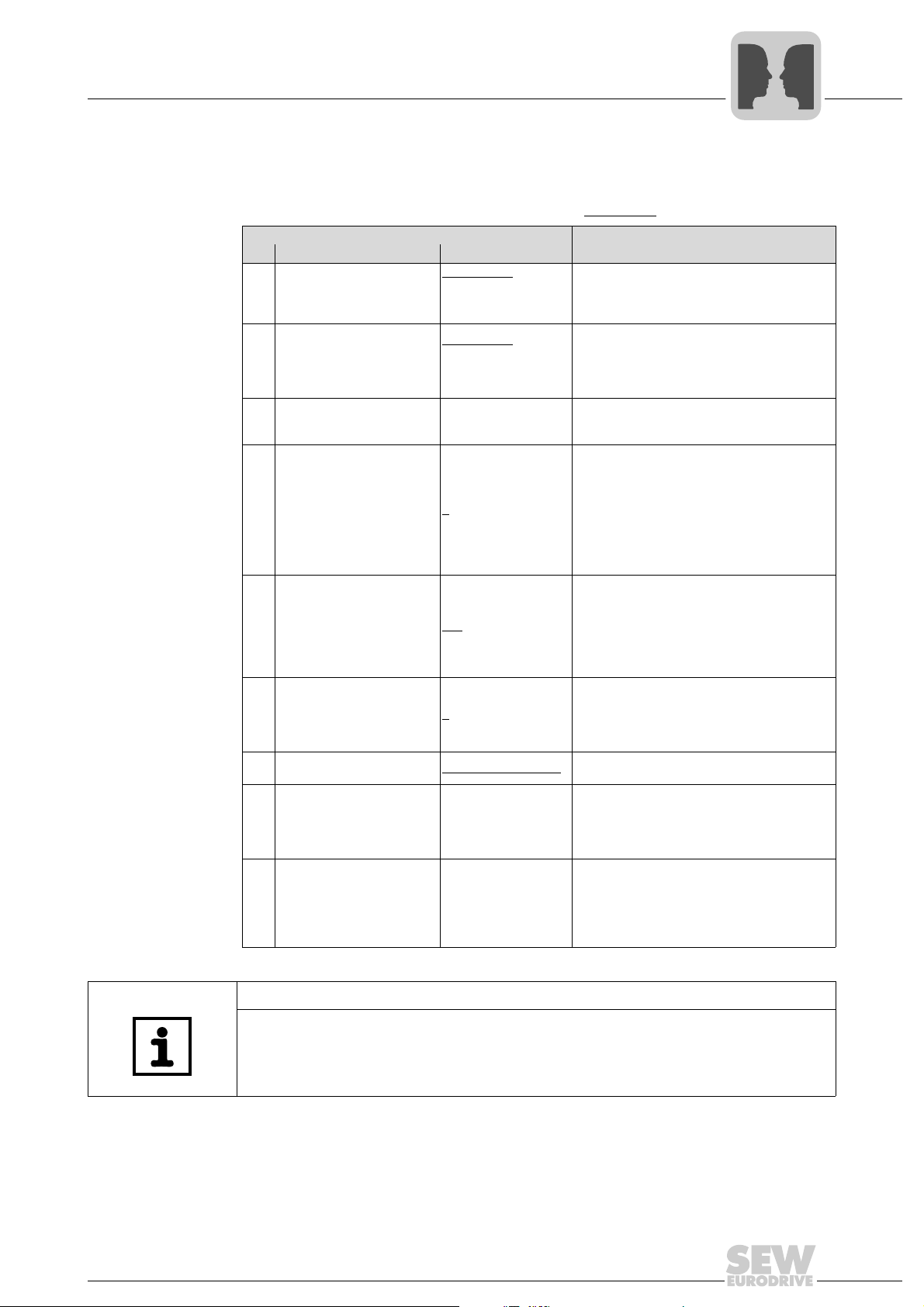

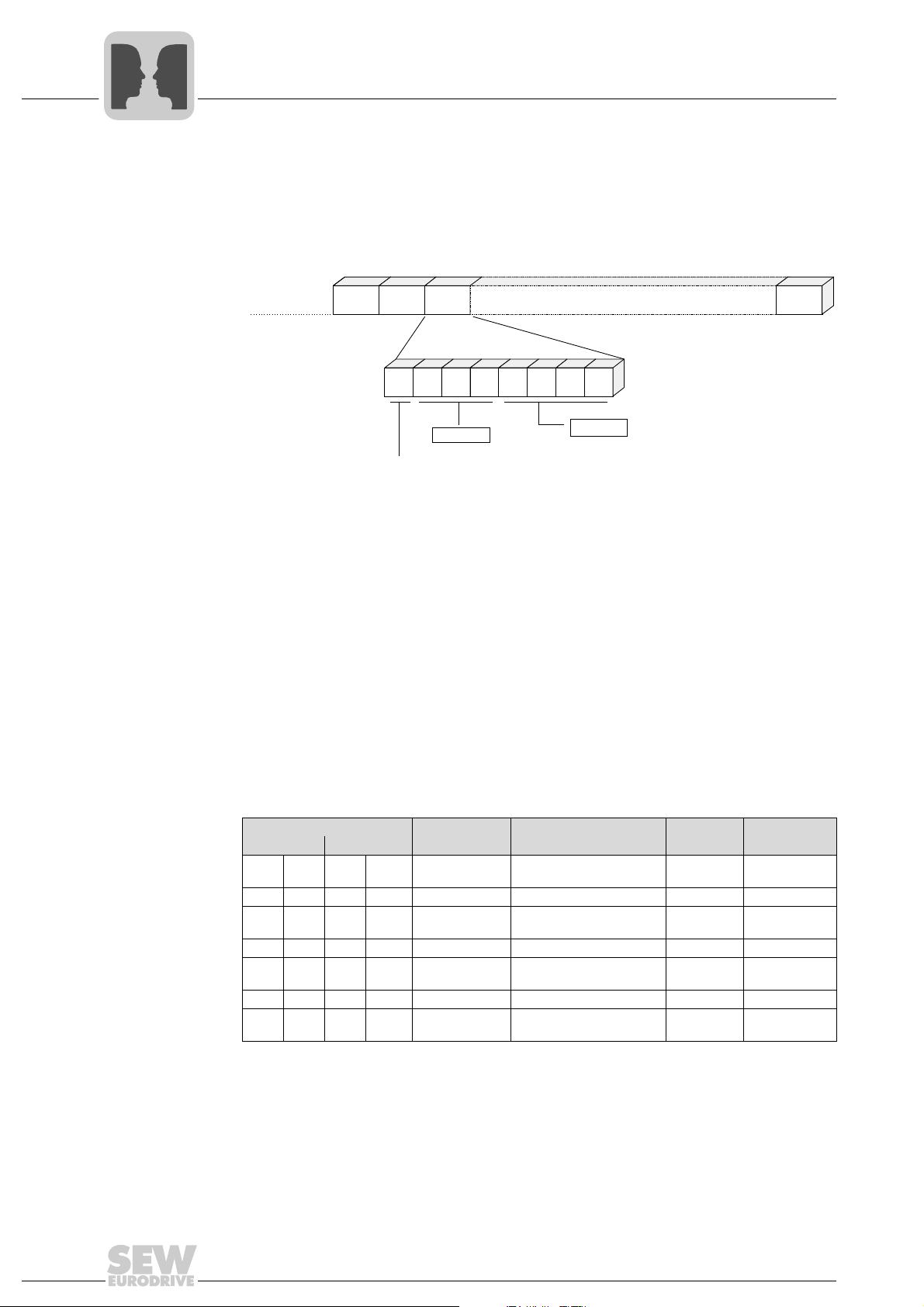

3

2

2

2

4

5

6

2

2

2

2

0

1

2

3

XT

S

S

3

0

2

2

2

4

5

6

2

2

2

2

0

1

2

3

nc

ADDRESS

X30

[1]

[2]

[3]

[4

DGND

SC1

1

SC12

1

2

3

System bus reference

System bus High

System bus Low

DIØØ

DIØ1

DIØ2

DIØ3

DIØ4

DIØ5

DCOM*

*

VO24

1

2

3

4

5

6

7

8

DGND

ST11

ST12

9

10

11

RS485 -

RS485 +

S

S

Ø

Ø

D

IØ1

Ø

D

I

Ø

3

Ø

D

I

Ø

5

DCOM

VO

2

3

4

5

6

7

DFP 21B

Introduction

Communication interfaces of MOVIDRIVE® B

3.3 Communication interfaces of MOVIDRIVE® B

12

13

14

X1

8

64323AEN

10

[1] Terminal XT

[2] Terminal X12:SBus 1 (CAN)

[3] Terminal X13:10 / X13:11 (RS485)

[4] Fieldbus port

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

Introduction

Communication interfaces of MOVIDRIVE® B

[1] Terminal XT:

RS485 interface for point-to-point connection of a keypad (e.g. DBG60B or

DOP11B) or an interface adapter, such as USB11A or UWS21B for connection

to an engineering PC.

[2] X12: SBus 1 (CAN) for connection

• directly to controllers (CANopen or MOVILINK

• via an SEW fieldbus gateway to fieldbus systems, such as PROFIBUS,

DeviceNet, etc.

• to an engineering PC via PC via PC CAN interface or SEW fieldbus gateway

[3] Terminal X13:10 / X13:11

RS485 interface for networking up to 32 devices, for example for connecting

MOVIDRIVE

®

B to a DOP11B operator panel or for connection to an engeering

PC via interface adapter (e.g. UWS11A, COM server, or similar)

[4] Fieldbus port

• for installing the DFC11B option card for the SBus 2 (CAN) interface with the

same functionality as X12 (SBus1), or

• for installing a fieldbus option, for example PROFIBUS DFP21B, DeviceNet

DFD11B, etc. for direct connection to the relevant fieldbus system for

exchanging process and parameter data.

®

protocol)

3

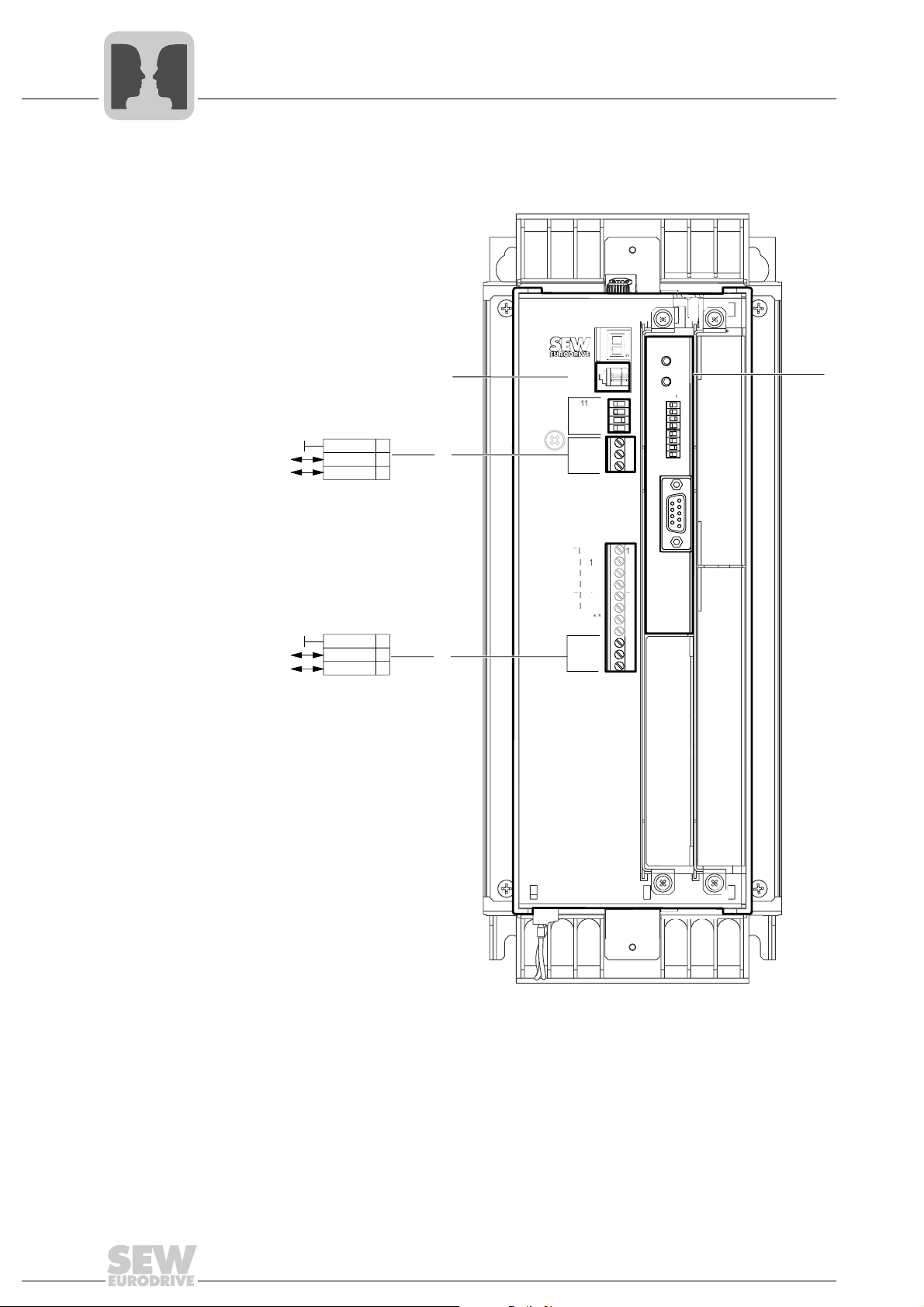

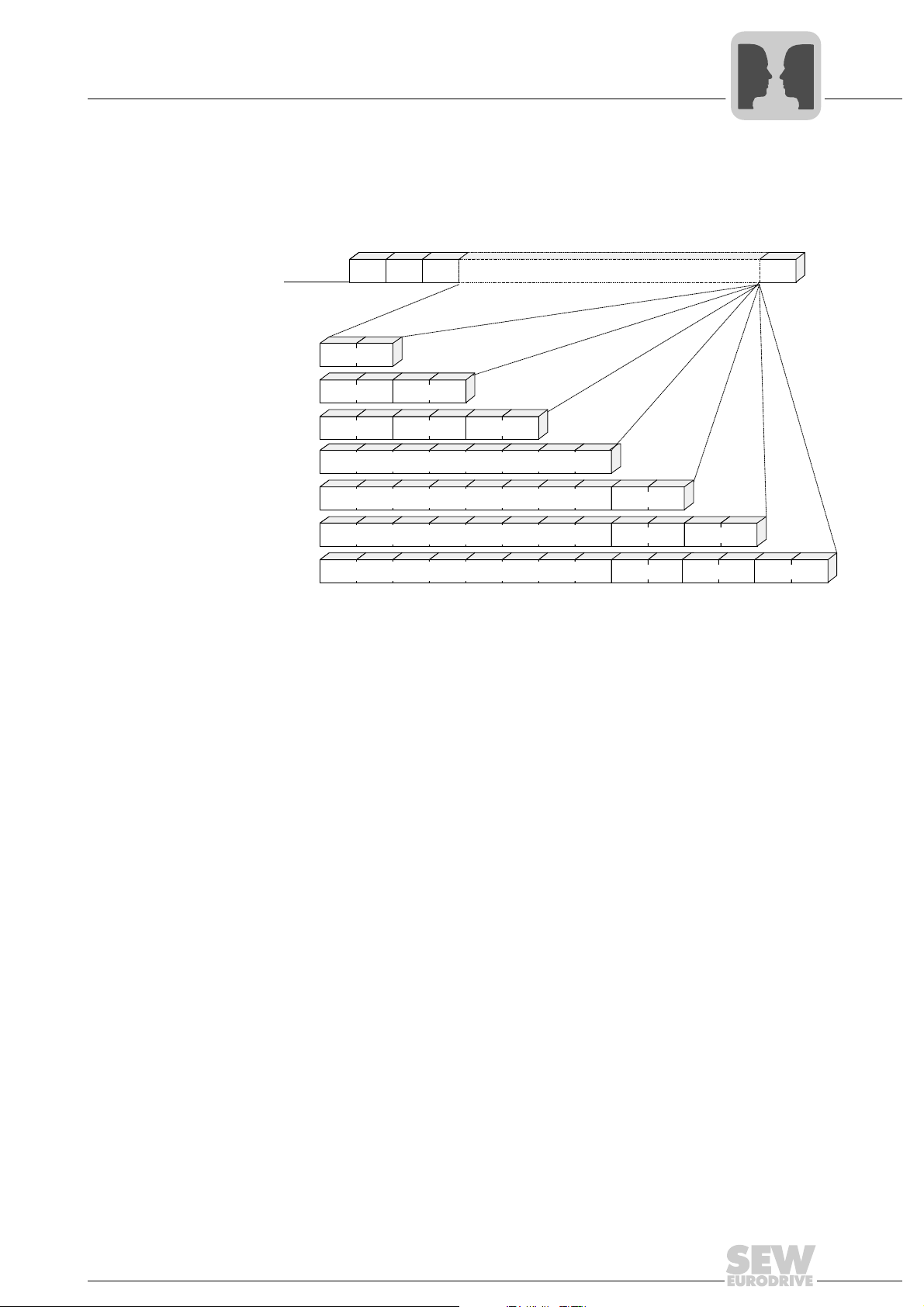

3.3.1 Overview of communication interfaces

Serial interfaces CAN interfaces Fieldbus

Terminal / socket Socket XT [1] X13:10 / X13:11 [3] Terminal X12 [2] Fieldbus port [4]

Typ e RS485 CAN1 CAN2 or fieldbus option

Profile MOVILINK

Baud rate 9.6 / 57.6 kBaud

Electrical

isolation

Connector RJ10 Terminal Terminal

Bus termination Point-to-point Dynamic DIP switch S12 DIP switch R Depending on option card

Control/setpoint

source

P100/P101

Timeout

monitoring

Configuration of

the interface

(address, baud

rate, etc.)

Process data Configuration using P870 - P876

Master/slave No Yes Yes No No

Manual operation

(MOVITOOLS

plus®

IPOS

type

bus

®

)

(via S13)

No No No

Shared monitoring via P812, P833 Via P883 and P836 Via P893 and P837 Via P819 and P831

P810, P811 P88x P89x

12 5 8 3

®

9.6 kBaud 1000, 500, 250,

RS485 SBus 1 SBus 2 Fieldbus

Yes No

MOVILINK® or CANopen

125 kBaud

(with P884)

1000, 500, 250,

125 kBaud

(with P894)

Yes, on the

DFC11B option

Terminal and Sub

D9 (according to

CiA)

PROFIBUS DP, DeviceNet,

INTERBUS, etc.

Depending on option card

Yes

Depending on option card

Depending on the option

card via DIP switch or with

P78x

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

11

4

[1]

[4]

Serial Interfaces of MOVIDRIVE® B

Connecting and installing RS485 interfaces

4 Serial Interfaces of MOVIDRIVE® B

As standard, MOVIDRIVE® B is equipped with two separate, serial RS485 interfaces:

•Socket XT

• Terminals X13:10 and X13:11

Telegrams received via a serial interface of MOVIDRIVE

other serial interface.

4.1 Connecting and installing RS485 interfaces

4.1.1 Connection using socket XT

The "XT socket" serial interface is designed as RJ10 plug connector (see following

figure).

Assignment of XT

connector (RJ10)

®

B are not passed on via the

Connection

options

64788AXX

[1] DC 5 V (from electronics supply)

[2] RS485 + (Rx/Tx)

[3] RS485 - (Rx/Tx)

[4] GND (electronics ground)

You can connect one of the following SEW options to the XT socket:

• DBG60B keypad

12

64252AXX

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

Serial Interfaces of MOVIDRIVE® B

USB11A

COM 1-99

MOVIDRIVE

®

MDX60/61B

[1] [2]

Connecting and installing RS485 interfaces

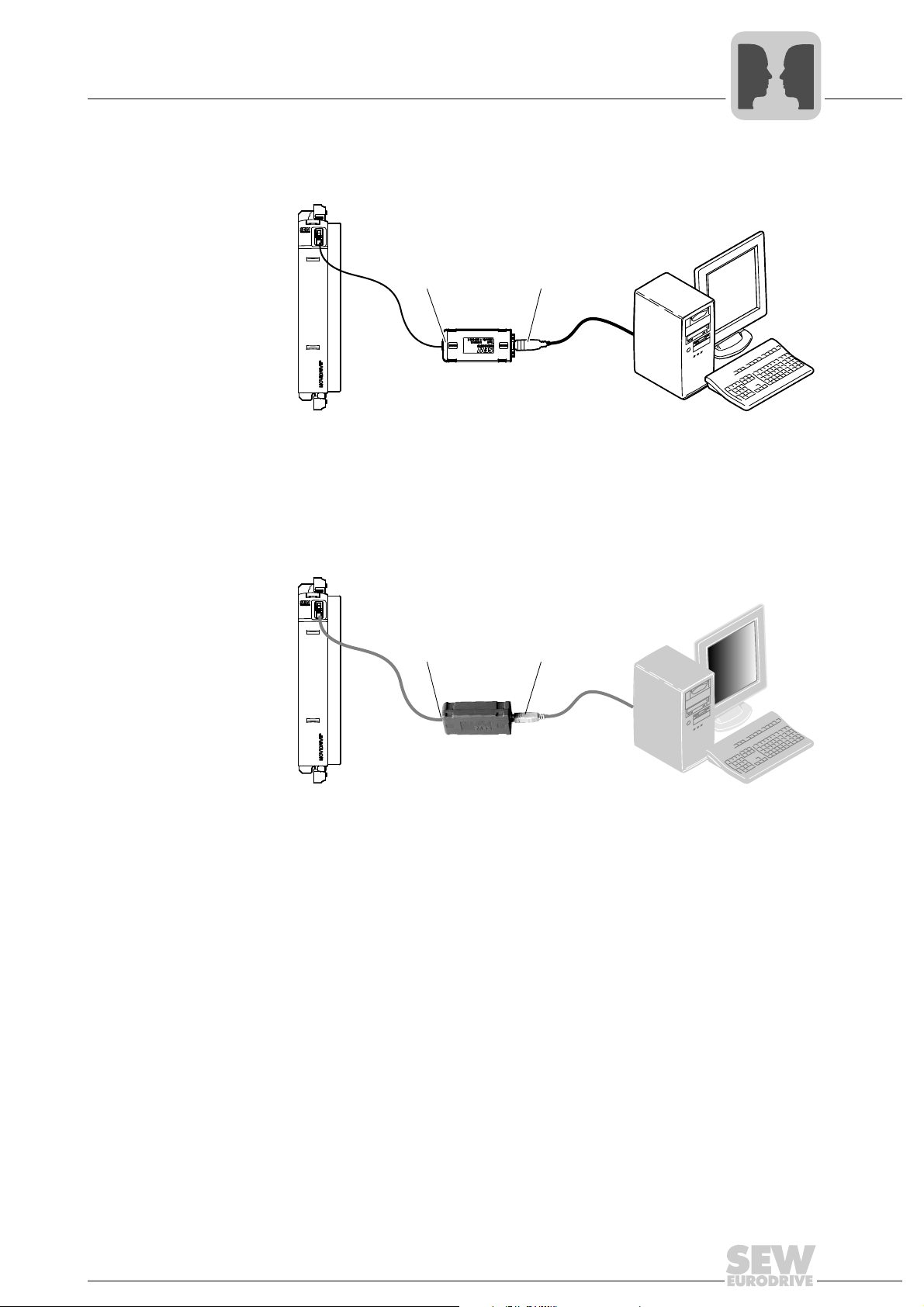

• UWS21B interface adapter (RS485 signals [1] to RS232 signals [2])

MOVIDRIVE® MDX60/61B

COM 1-99

[1] [2]

UWS21B

®

The UWS21B option is used to equip a MOVIDRIVE

interface. The RS232 interface is designed as a 9-pole sub-D socket (EIA standard).

A Sub D9 extension cable (1:1 connection) is supplied for connection to the PC.

B with a potential-free RS232

4

64306AXX

• USB11A interface adapter (RS485 signals [1] to USB signals [2])

You can use the USB11A option for potential-free connection of a MOVIDRIVE

to an engineering PC via USB. When installing the USB driver, a virtual COM port is

created in the PC for communication with MOVIDRIVE

®

B.

64297AXX

®

B

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

13

4

MOVIDRIVE® B

DOP11B

PCS21A

Serial Interfaces of MOVIDRIVE® B

Connecting and installing RS485 interfaces

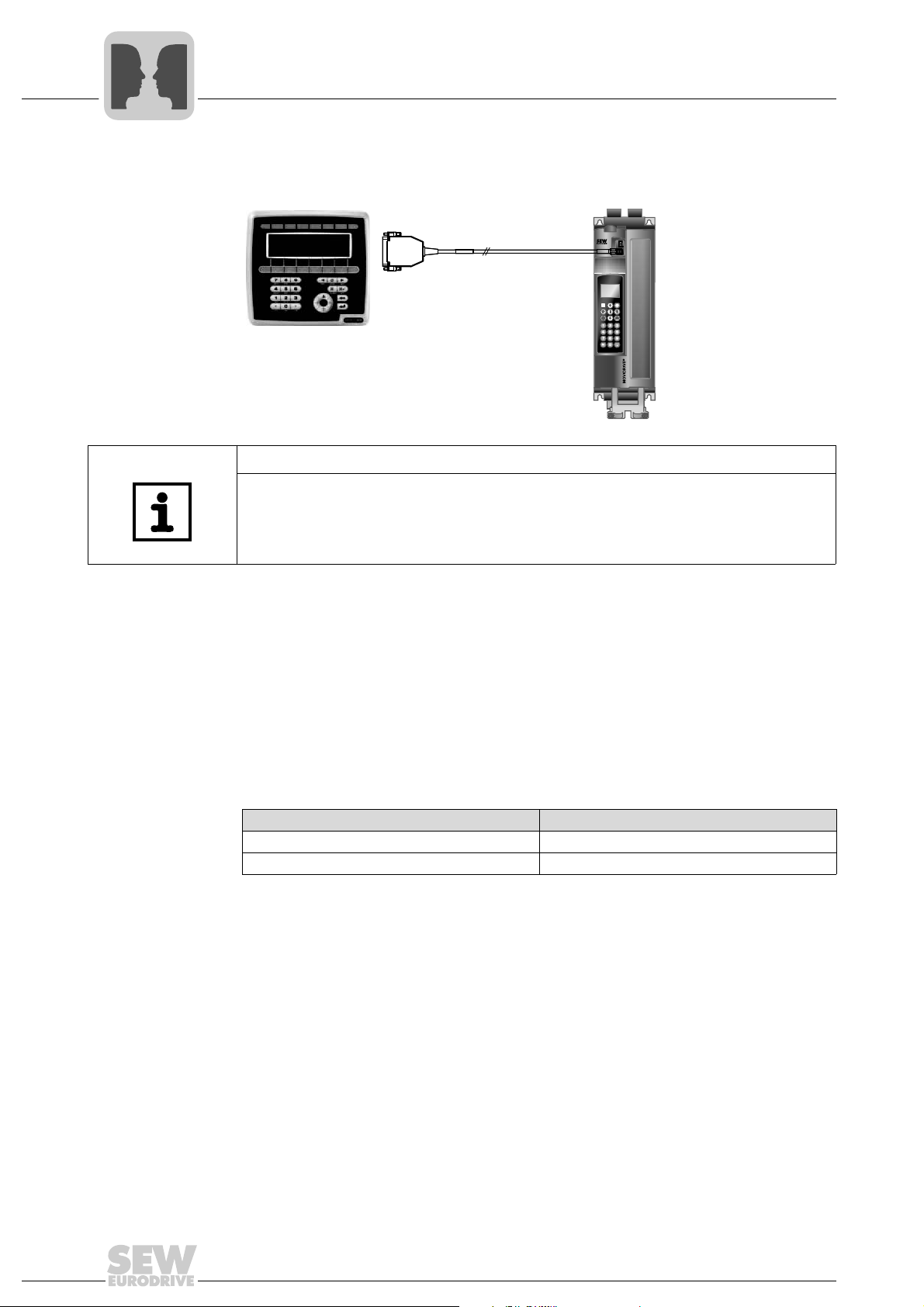

• DOP11B operator terminal

64282AXX

TIP

The DBG60B, UWS21B and USB11A options are connected to the XT socket. The

options cannot be used at the same time.

Electrical

isolation

Terminating

• The serial interface XT is not electrically isolated. It must be used for point-to-point

connections only.

• Matching terminating resistors are integrated in all SEW components.

resistor

Cable length • Maximum cable length: 3 m (5 m for shielded cables)

Baud rate • The baud rate for RS485 communication is set using DIP switch S13 (on the front of

MOVIDRIVE

Baud rate DIP switch S13

9.6 kBaud ON

57.6 kBaud

1) Factory setting

®

B beneath the XT socket).

1)

OFF

1)

The set baud rate takes effect once the DIP switch position has been changed.

14

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

Serial Interfaces of MOVIDRIVE® B

X13:

X13:

X13:

DGND

ST11

ST12

DGND

ST11

ST12

DGND

ST11

ST12

DIØØ

DIØ1

DIØ2

DIØ3

DIØ4

DIØ5

DCOM

VO24

DIØØ

DIØ1

DIØ2

DIØ3

DIØ4

DIØ5

DCOM

VO24

DIØØ

DIØ1

DIØ2

DIØ3

DIØ4

DIØ5

DCOM

VO24

9

10

11

9

10

11

9

10

11

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

RS485-

RS485-

RS485-

RS485+

RS485+ RS485+

Connecting and installing RS485 interfaces

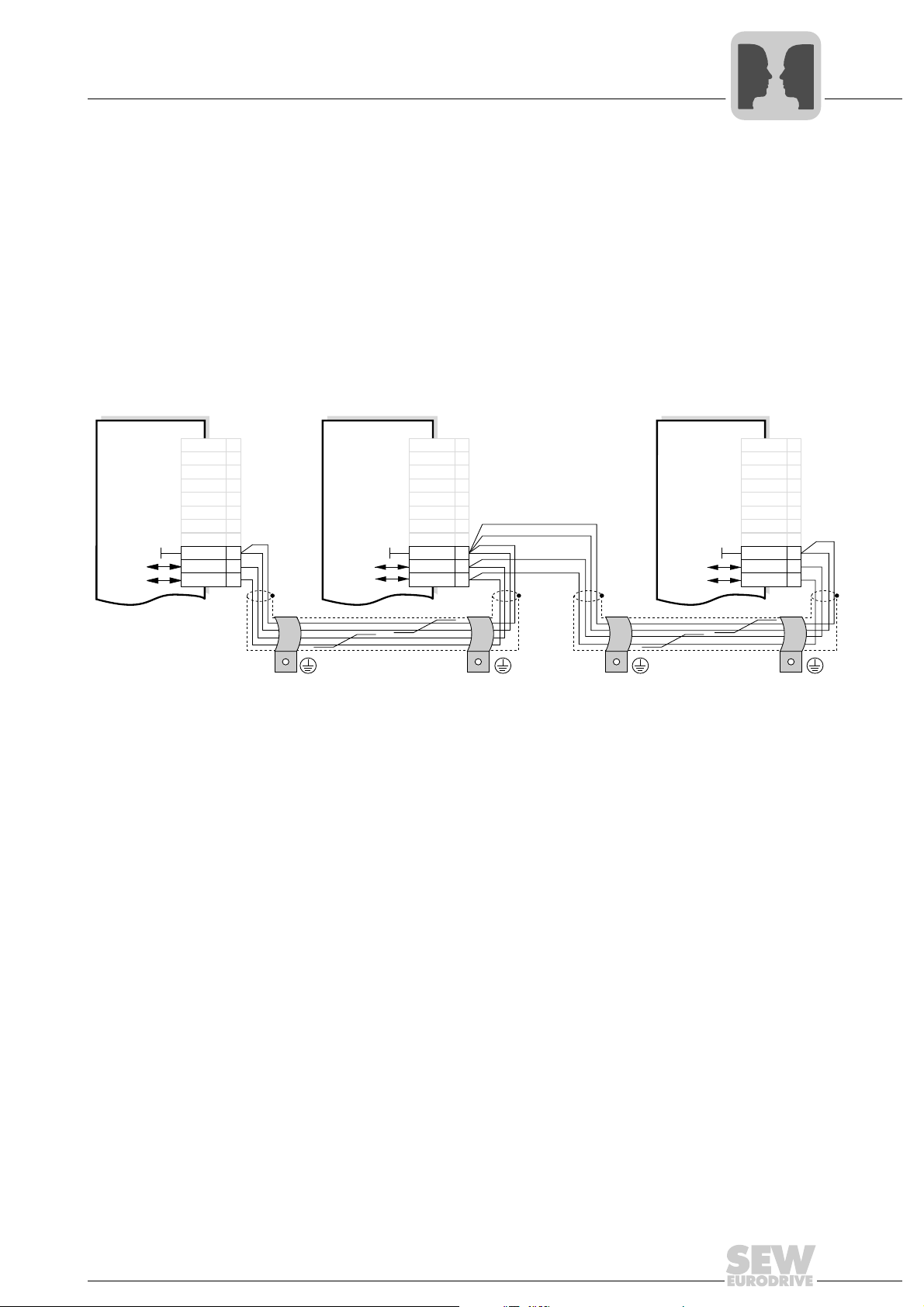

4.1.2 Connection using terminals X13:10 and X13:11

4

Another RS485 interface is provided via terminals X13:10 and X13:11. This RS485

interface can be used to interconnect several MOVIDRIVE

other options at the same time.

• Interface adapter UWS11A (RS232 signals to RS485 signals)

• DOP11B operator terminal

• Other SEW drives, such as MOVIMOT

• Other interface adapters, such as COM server or other RS485 master devices

Wiring diagram of the RS485 interface (X13)

®

B units and connect the

®

Electrical isolation • The RS485 interface X13 is not electrically isolated. Do not connect more than 32

MOVIDRIVE

®

B units with one another,

Cable specification • Use a 4 core twisted pair and shielded copper cable (data transmission cable with

braided copper shield). The cable must meet the following specifications:

– Cable cross section 0.25 - 0.75 mm

2

(AWG 23 - AWG 19)

– Cable resistance 100 - 150 Ω at 1 MHz

– Capacitance per unit length ≤ 40 pF/m at 1 kHz

Cable length • The permitted total cable length is 200 m (656 ft).

Shielding • Connect the shield to the electronics shield clamp on the inverter or higher-level

controller and make sure it is connected over a wide area at both ends.

Baud rate • The baud rate is set to 9.6 baud by default.

Terminating

resistor

• Dynamic terminating resistors are installed. Do not connect any external terminat-

ing resistors.

54535AXX

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

15

4

Serial Interfaces of MOVIDRIVE® B

Connecting and installing RS485 interfaces

TIPS

• When interconnecting the units, make sure that always only one master (e.g.

• Operating several masters on an RS485 network with SEW drives is not permitted

• There must not be any potential displacement between the units connected via the

4.1.3 Shielding and routing cables

Correct shielding of the bus cable attenuates electrical interference that can occur in

industrial environments. The following measures ensure the best possible shielding:

• Manually tighten the mounting screws on the connectors, modules, and equipotential

• Apply the shielding of the bus cable on both ends over a large area.

• Route signal and bus cables in separate cable ducts. Do not route them parallel to

• Use metallic, grounded cable racks in industrial environments.

• Route the signal cable and the corresponding equipotential bonding close to each

• Avoid using plug connectors to extend bus cables.

• Route the bus cables closely along existing grounding surfaces.

DOP11B, engineering PC) is connected and active.

(see chapter "MOVILINK

RS485. This may affect the functionality of the units.

Take suitable measures to avoid potential displacement, such as connecting the

unit ground connectors using a separate cable.

bonding conductors.

power cables (motor leads).

other using the shortest possible route.

®

via RS485").

CAUTION

In case of fluctuations in the ground potential, a compensating current may flow via the

bilaterally connected shield that is also connected to the protective earth (PE). Make

sure you supply adequate equipotential bonding according in accordance with relevant

VDE regulations in such a case.

16

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

Serial Interfaces of MOVIDRIVE® B

Configuration parameters of the serial interfaces

4.2 Configuration parameters of the serial interfaces

The following parameters are used to set communication via the two serial interfaces.

The factory setting of the individual parameters is underlined

Parameter

No. Name Setting Meaning

TERMINALS

100 Setpoint source

101 Control signal source

750 Slave setpoint

810 RS485 Address 0

811 RS485 group address 100

812 RS485 Timeout interval 0

833 Response to RS485 timeout RAPID STOP/WARN.

870

Setpoint description PO1

871

Setpoint description PO2

872

Setpoint description PO3

RS485

FIELDBUS

SBus

TERMINALS

RS485

FIELDBUS

SBus

... 99

... 199

... 650 s

Factory set to:

CONTROL WORD 1

SPEED

NO FUNCTION

.

This parameter is used to set the setpoint

source for the inverter.

This parameter is used to set the source of the

control signals for the inverter (CONTROLLER

INHIBIT, ENABLE, CW, CCW, ...). Control via

plus®

IPOS

disregarding of P101.

The setpoint to be transferred to the master is

set on the master. The "MASTER-SLAVE OFF"

setting must be retained on the slave.

P810 is used to set the address by means of

which communication can take place with

MOVIDRIVE

Note:

MOVIDRIVE

address 0 on delivery. To avoid problems

during data exchange in serial communication

with several inverters, we recommend that you

do not use address 0.

P811 allows for grouping several MOVIDRIVE

B units in one group for communication via the

serial interface. For example, the RS485 group

address allows for sending setpoint selections

to a group of MOVIDRIVE

neously. Group address 100 means that the

inverter is not assigned to a group.

P811 sets the monitoring time for data transmission via the serial interface. No monitoring

of serial data transmission takes place when

P812 is set to 0. Monitoring is activated with the

first cyclical data exchange.

P833 programs the fault response that is triggered by the RS485 timeout monitoring.

P870/P871/P872 define the content of the process output data words PO1/PO2/PO3.

and terminal is taken into account

®

via the serial interfaces.

®

B units are always set to the

®

B inverters simulta-

4

®

Factory set to:

Actual value description PI1

873

Actual value description PI2

874

Actual value description PI3

875

Enable PO data

876

STATUS WORD 1

SPEED

NO FUNCTION

ON

The content of process input data words

PI1/PI2/PI3 is defined.

TIP

Refer to the MOVIDRIVE® MDX60B/61B system manual for a detailed description of

the parameters.

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

17

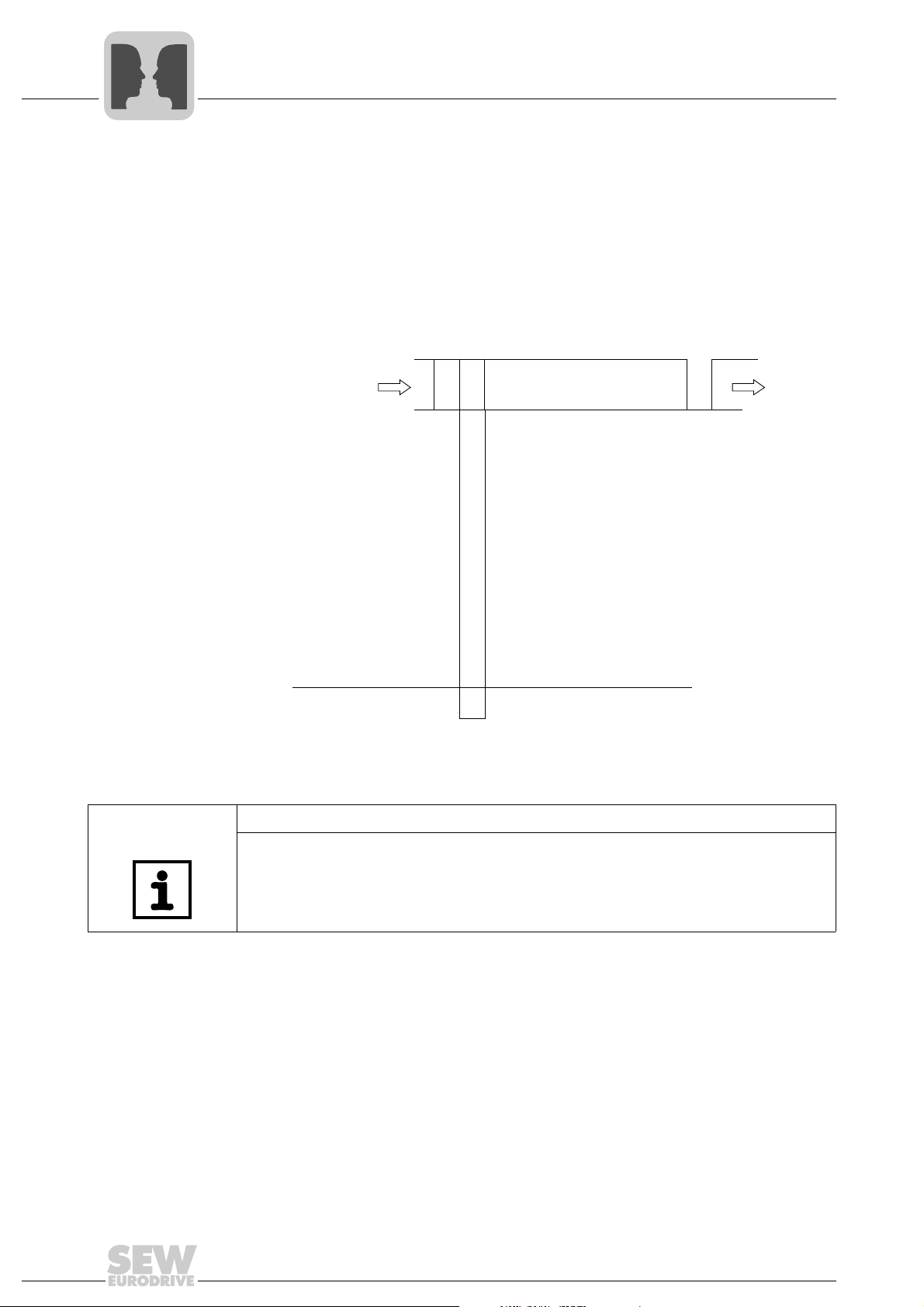

4

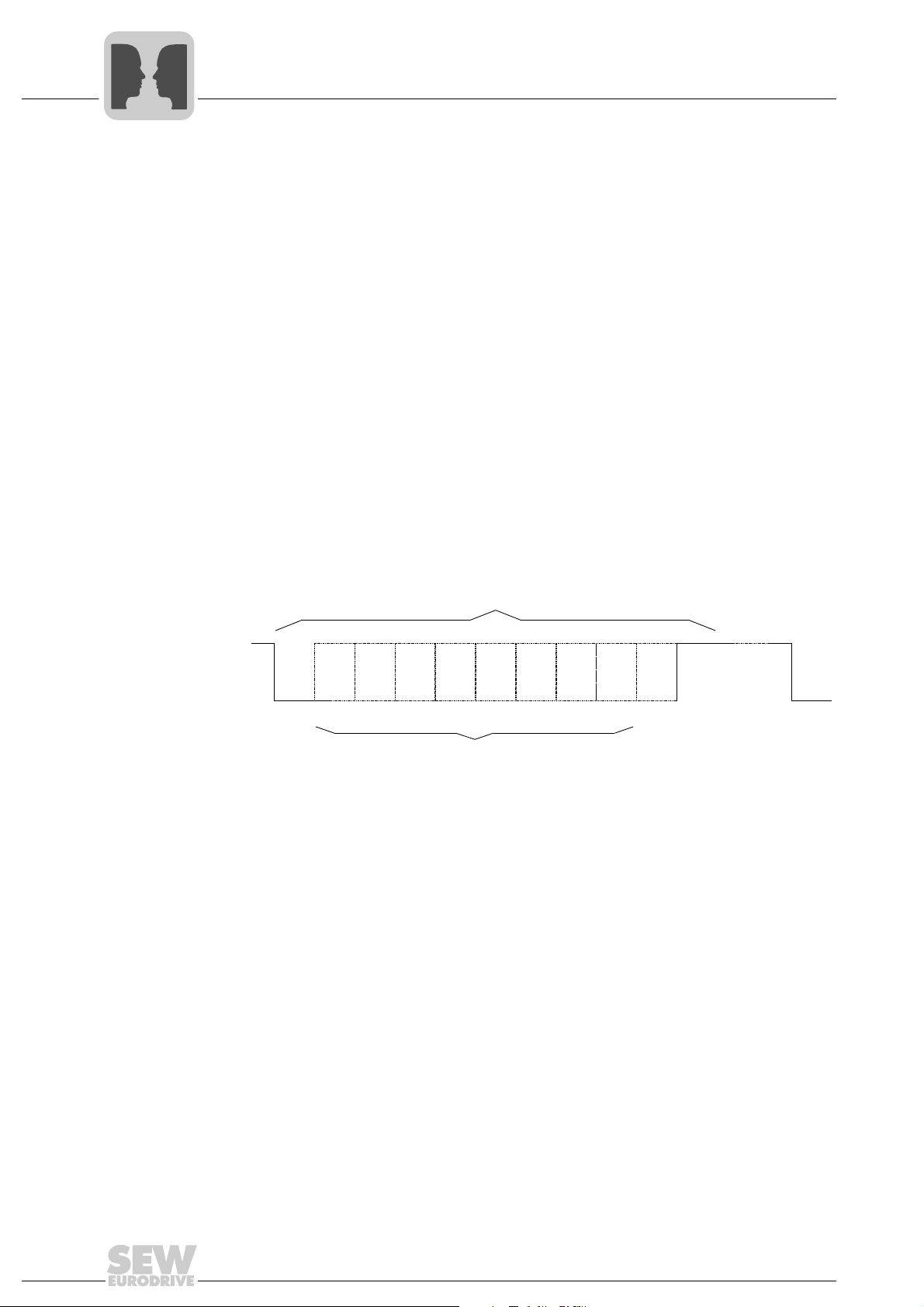

01234567

LSB MSB even

Start

Parity

Stop

Start

Character

8 data bits

Serial Interfaces of MOVIDRIVE® B

MOVILINK® protocol via RS485 transmission method

4.3 MOVILINK® protocol via RS485 transmission method

4.3.1 Transmission method

An asynchronous, serial transmission method is used which is supported by the UART

modules common in digital technology. This means the MOVILINK

implemented in nearly all controllers and master modules.

®

protocol can be

Characters Each character in the MOVILINK

lows:

• 1 start bit

• 8 data bits

• 1 parity bit, completing for even parity (even parity)

•1 stop bit

Each transmitted character begins with a start bit (always logical 0). The start bit is followed by 8 data bits and the parity bit. The parity bit is set in such a way that the number

of logical ones in the data bits including the parity bit is even-numbered. The last bit of

a character is a stop bit, which is always set to logical level 1. This level remains on the

transmission medium until a new start bit signals the transmission of another character.

®

protocol consists of 11 bits and is structured as fol-

Transmission

rate and

transmission

mechanisms

Response delay of

the master

Start delimiter

(idle)

Character delay The interval between the time when a character of a telegram is sent must be shorter

18

The transmission rate is 9600 baud or 57.6 kBaud (via XT only). The communications

link is monitored by the master and the inverter itself. The master monitors the response

delay time. The inverter monitors the reception of cyclic request telegrams of the master.

A response delay is usually programmed on the higher-level master system. The

response delay is the interval between the time when the last character of the request

telegram is sent (BCC) and the time when the response telegram is sent (SD2). The

maximum permitted response delay interval is 50 ms. A transmission error has occurred

if the inverter does not respond within this interval. Check the interface cable and the

coding of the sent request telegram. Depending on the application, the request telegram

should now be repeated and the next inverter be addressed.

To interpret a character as start delimiter (02

pause of at least 3.44 ms.

than the time preceeding the start delimiter (which means max. 3.43 ms). Else, the

telegram is invalid.

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

hex

or 1D

), it must be preceeded by a

hex

64767AEN

Serial Interfaces of MOVIDRIVE® B

MOVILINK® protocol via RS485 transmission method

4

RS485 timeout

interval of the

inverter

For MOVIDRIVE®, the maximum permitted time inverval between two cyclic request

telegrams is set using parameter P812 RS485 Timeout interval. The system must

receive a valid request telegram during this time period. Else, the inverter will trigger an

RS485 timeout error and execute a defined error response.

After power on or a fault reset, MOVIDRIVE

first request telegram is received. When the inverter is enabled, "t" (= timeout active)

appears on the 7-segment display and the enable is ineffective. Only when the first telegram is received, enable will take effect and the drive is set in motion.

If the inverter is controlled via RS485 interface (P100 "Setpoint source" = RS485 / P101

"Control signal source" = RS485) and a fault response with warning was programmed,

the last received process data will be active after an RS485 timeout and reestablished

communication.

®

is maintained in a safe condition until the

NOTICE

If a timeout is not recognized, the drive will continue to move despite disconnected

controller.

Possible consequences: Damage to the system.

Only one of the two RS485 must be used for timeout monitoring.

RS485 timeout is active for both RS485 interfaces. Therefore, timout monitoring for the

second interface has no effect with plugged-in DBG60B keypad. The DBG60B keypad

permanently sends request telegrams to the inverter and in this way triggers the timeout mechanism.

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

19

4

Serial Interfaces of MOVIDRIVE® B

MOVILINK® protocol via RS485 transmission method

Processing

request/response

telegrams

The inverter only processes request telegrams that were received without errors and

were correctly addressed. The following reception errors are detected:

• Parity error

• Character frame error

• Exceeded character delay of request telegrams

• Incorrect address

• Incorrect PDU type

• Incorrect BCC

• RS485 timeout (slave)

• Elapsed response time (master)

The inverter does not respond to incorrectly received request telegrams! These

reception errors have to be evaluated in the master to ensure correct data transmission.

TIPS

If RS485 or RS232 communication is to be transmitted via gateways, COM server, or

modem connections, make sure that not only the character (start bit, 8 data bits, 1 stop

bit, even parity) is correct but also that start delimiter and character delay time are

complied with:

• Max. character delay of 3.43 ms between 2 characters of a telegram

• Min. 3.44 pause before the start delimiter

Else, the individual characters cannot be clearly assigned to the various telegrams.

20

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

4.3.2 Telegrams

Serial Interfaces of MOVIDRIVE® B

MOVILINK® protocol via RS485 transmission method

4

Telegram

transmission

Cyclical data

exchange

Acyclical data

exchange

Telegram

structure

Both cyclic and acyclic data exchange is used in drive engineering. Cyclic telegrams via

the serial interface are mainly used for drive control in automation tasks. In this case,

the master station has to ensure cyclic data exchange.

Cyclic data exchange is mainly used for controlling inverters via the serial interface. The

master continuously sends telegrams with setpoints (request telegrams) to an inverter

(slave) and expects a response telegram with actual values from the inverter. Once the

request telegram is sent to an inverter, the master expects the response telegram within

a defined time (response delay time). The inverter will only send a response telegram if

it has correctly received a request telegram with its slave address. During cyclic data

exchange, the inverter monitors data communication and triggers a timeout response if

it has not received another request telegram from the master within a specified time.

MOVILINK

communication without having to change the telegram type.

Acyclic data exchange is primarily used for startup and diagnostic purposes. In this

case, the inverter does not monitor the communication connection. In acyclic mode, the

master can send telegrams to the inverter at irregular intervals.

Data exchange is carried out with only two telegram types. The master sends a request

with data in the form of a request telegram to the inverter. The inverter responds with a

response telegram. In case of word information (16 bit) within user data, always the high

byte will be sent first followed by the low byte. In case of double-word information (32

bit), always the high byte will be sent first, followed by the low word. The protocol does

not include coding of the user data. The content of user data is explained in detail in the

"SEW unit profile" chapter.

®

allows for performing acyclic service and diagnostic tasks during cyclic

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

21

4

....Idle...

SD1

ADR

TYP

PDU BCC

Start delimiter 1

02 hex

PDU type

Block check character

Start pause Slave address Protocol data unit

....Idle...

SD2

ADR

TYP

PDU BCC

Start delimiter 2

02 hex

PDU type

Block check character

Start pause Slave address Protocol data unit

Serial Interfaces of MOVIDRIVE® B

MOVILINK® protocol via RS485 transmission method

Structure of the

request telegram

Structure of the

response telegram

The following figure shows the structure of the request telegram, which the master

sends to the inverter. Each telegram starts with an idle time on the bus, the so-called

start pause, followed by a start delimiter. Different start characters are used to clearly

distinguish between request and response telegrams. The request telegram begins with

the start character SD1 = 02hex, followed by the slave address and PDU type.

01485BEN

The following figure shows the structure of the response telegram, which the inverter

(slave) sends as response to a request from the master. Each response telegram begins

with a start pause, followed by a start delimiter. To clearly distinguish request and response telegrams, the response telegram begins with the start character SD2 = 1Dhex,

followed by the slave address and PDU type.

Start characters

(SD1 / SD2)

22

The start character identifies the beginning and direction of data of a new telegram. The

following table depicts the assignment of start character to direction of data.

SD1 02

SD2 1D

hex

hex

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

Request telegram Master → inverter

Response telegram Inverter → master

01487BEN

Serial Interfaces of MOVIDRIVE® B

Master

Slave SlaveSlave

ADR: 1 ADR: 3

ADR: 12

Inverter Inverter

Inverter

Request to ADR 12

Response from ADR 12

Request to ADR 3

Response from ADR 3

Request to ADR 1

Response from ADR 1

MOVILINK® protocol via RS485 transmission method

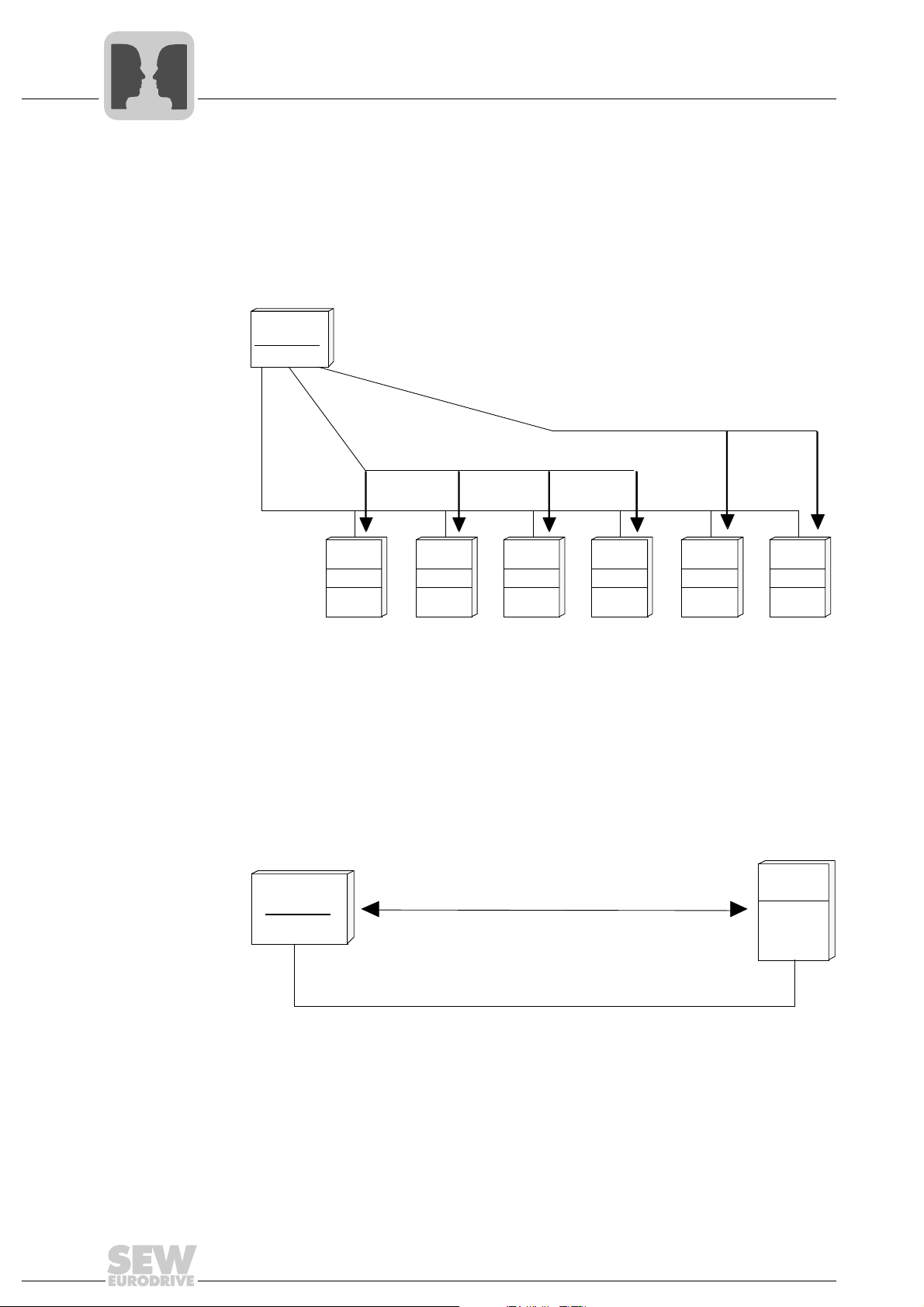

4.3.3 Addressing and transmission method

4

Address byte

(ADR)

The address byte indicates the slave address independent of the direction of data. This

means the ADR character in a request telegram specifies the address of the inverter that

is to receive the request. In opposite direction, the master recognizes the inverter that

has sent the response telegram. The master is not addressed because the system is

generally a single-master system. The MOVILINK

®

protocol offers other addressing

variants in addition to single addressing. The table below shows the address ranges and

what they mean.

ADR Meaning

0-99 Single addressing within the RS485 bus.

100 - 199

253

254 Universal address for point-to-point communication.

255 Broadcast address. No response is sent.

Group addressing (multicast)

Special case group address 100: "Meaning not assigned to any group", i.e. not effective.

plus®

Local address: Only effective in conjunction with IPOS

command. For unit internal communication

as master and the MOVILINK®

TIP

MOVIDRIVE® basically is a slave unit. However, master functions are also available

using IPOS

plus®

, the MOVILINK® command, and the master/slave function.

Single addressing Every inverter can be directly addressed using addresses 0 - 99. The inverter responds

to every request telegram from the master with a response telegram.

01488BEN

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

23

4

Master

Slave Slave Slave Slave Slave Slave

ADR: 1 ADR: 2 ADR: 3 ADR: 4 ADR: 5 ADR: 6

Inveter

Inverter Inverter

Inverter

Inverter

Inverter

Group

adr.: 101

Group

adr.: 101

Group

adr.: 101

Group

adr.: 101

Group

adr: 102

Group

adr.: 102

Request telegram to group adr. 102

Request telegram to group adr. 101

Master

Slave

ADR: 1

Inverter

Request telegram via universal adr. 254

Response telegram from slave

Serial Interfaces of MOVIDRIVE® B

MOVILINK® protocol via RS485 transmission method

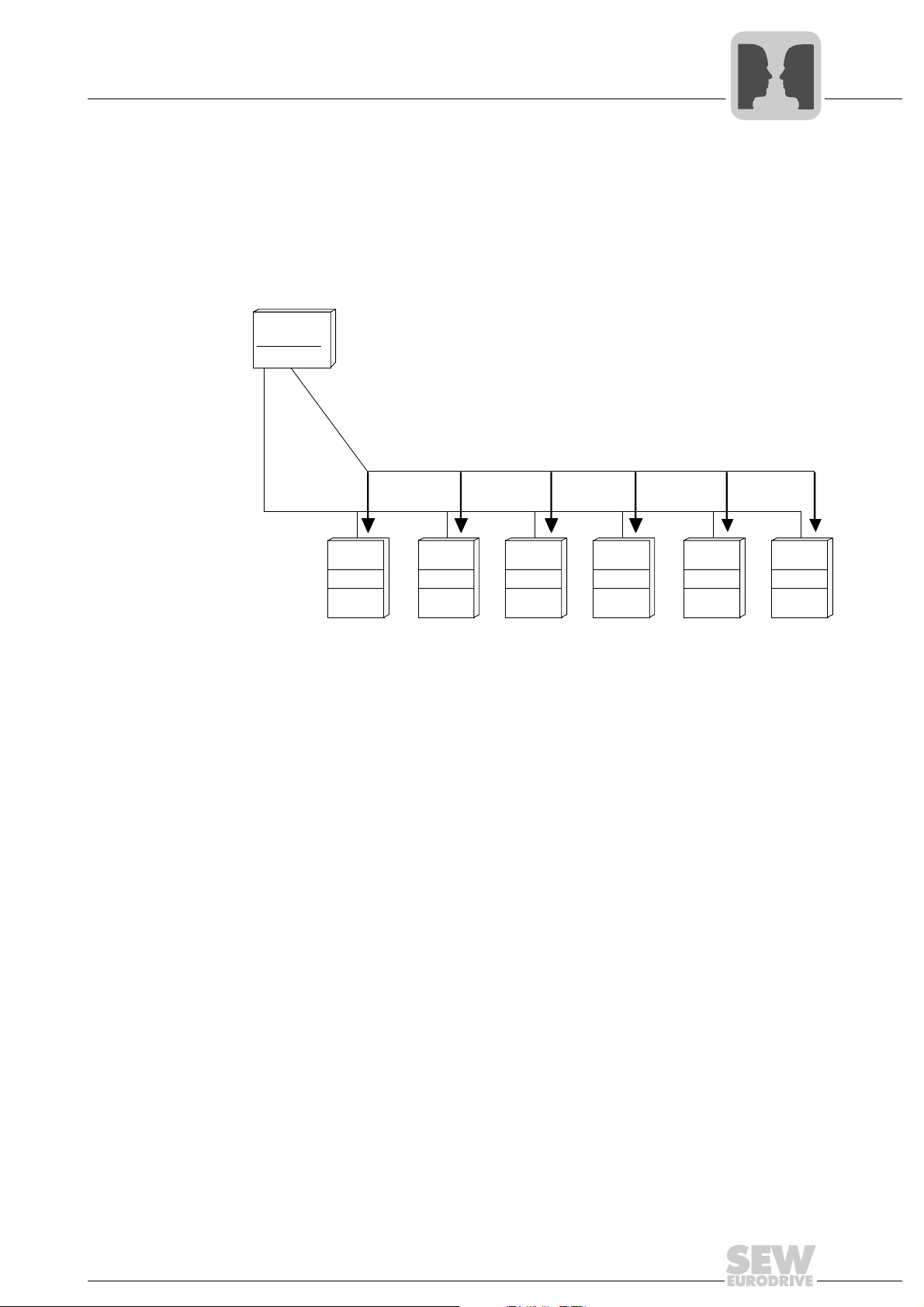

Group addressing

(multicast)

Every inverter has a setable group address in addition to its individual address. In this

way, the user can group various participants and address the individual participants of

a group simultaneously using group addressing. With group addressing, the master

does not receive a response telegram. This means that no data can be requested from

the inverter. And there is no response when writing data. A maximum of 99 groups can

be set up.

Universal addressing for point-topoint communication

01489BEN

Basically, every inverter can be addressed using universal address 254 independent of

the set single address. The advantage of this variant is that point-to-point connections

can be established without having to know the individual address. As each inverter of

the group is addressed using this universal address, it must not be used for multi-point

connections (e.g. RS485 bus). Else, data collisions would occur on the bus because

every inverter would send a response telegram once it receives a request telegram.

01490BEN

24

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

Serial Interfaces of MOVIDRIVE® B

Master

Slave Slave Slave Slave Slave Slave

ADR: 1 ADR: 2 ADR: 3 ADR: 4 ADR: 5 ADR: 6

Inveter

Inverter Inverter

Inverter

Inverter

Inverter

Group

adr.: 101

Group

adr.: 101

Group

adr.: 101

Group

adr.: 101

Group

adr: 102

Group

adr.: 102

Request telegram to all slaves via broadcast adr. 255

MOVILINK® protocol via RS485 transmission method

Broadcast address Broadcast address 255 can be used to address all inverter stations. The request

telegram with broadcast address 255 sent by the master is received by all inverters but

is not responded to. This means, this addressing method is mainly used to transmit

setpoints. The master can send broadcast telegrams at a minimum interval of every

25 ms. Consequently, an idle time of at least 25 ms is mandatory between the last sent

character of a request telegram (BCC) and the start of a new request telegram (BCC).

4

01491BEN

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

25

4

...Idle... SD1 ADR TYP PDU BCC

Bit: 7 6 5 4 3 2 1 0

PDU type

reserved

transmission variant

0: cyclical

1: acyclical

Serial Interfaces of MOVIDRIVE® B

MOVILINK® protocol via RS485 transmission method

4.3.4 Structure and length of user data

PDU type (TYPE) The TYPE byte describes the structure and length of subsequent user data (protocol

data unit (PDU)). The figure below shows the structure of the TYPE byte.

Besides, bit 7 of the TYPE byte indicates whether the user data are transmitted cyclically

or acyclically. A request telegram with cyclic transmission method signals the inverter

that the data sent by the master is updated cyclically. Consequently, response monitoring can be triggered in the inverter. This means if the inverter does not receive a new

cyclic request telegram within a timeout time, which can be set, a timeout response will

be triggered.

The following tables show the PDU types for cyclic and acyclic transmission. The

telegram length depends on the PDU type used and is calculated as follows:

Telegram length = PDU length + 4.

Transmission

methods

The following tables show the PDU types for ACYCLIC and CYCLIC transmission

methods.

TYPE byte PDU name Description PDU length

Cyclic Acyclic

00

hex0dec

01

hex1dec

02

hex2dec

03

hex3dec

04

hex4dec

05

hex5dec

06

hex6dec

80

81

82

83

84

85

86

hex

hex

hex

hex

hex

hex

hex

128

129

130

131

132

133

134

PAR A M + 1PD

dec

dec

PAR A M + 2PD

dec

dec

PAR A M + 3PD

dec

dec

PAR A M + 0PD

dec

1PD 1 process word 2 6

2PD 2 process data words 4 8

3PD 3 process data words 6 10

8 byte parameter channel +

1 process data word

8 byte parameter channel +

2 process data words

8 byte parameter channel +

3 process data words

8 byte parameter channel

without process data

The standard PDU types consist of the MOVILINK

data channel. For the coding of the parameter channel and process data, refer to

chapter "SEW unit profile".

01492BEN

in bytes

10 14

12 16

14 18

®

parameter channel and a process

Tel egr am

length in bytes

812

26

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

Serial Interfaces of MOVIDRIVE® B

...Idle... SD1 ADR TYP PDU BCC

TYP 1/129

TYP 3/131

TYP 5/133

TYP 6/134

TYP 0/128

TYP 2/130

TYP 4/132

PD1

PD1

PD1

PD1

PD2

PD2

PD1

PD1

PD2

PD2

PD3

PD3

8 byte parameter channel

8 byte parameter channel

8 byte parameter channel

8 byte parameter channel

MOVILINK® protocol via RS485 transmission method

The following figure shows the structure of a request telegram with the standard PDU

types. The associated response telegram has the same structure except for the SD2

start character.

4

Block check character

Transmission

reliability

Transmission reliability with the MOVILINK

character parity and block parity. The parity bit is set for each character of the telegram

in such a way that the number of binary ones including the parity bit is even-numbered.

Block parity provides for additional reliability and means that a block check character

(BCC = Block Check Character) is added to the telegram. Each bit of the block check

character is set in such a way that the result is an even parity for all information bits of

the same value of the telegram character. In programming, the block parity is implemented by EXORing all telegram characters. The result is entered in the BCC at the end

of the message. The block check character itself is also ensured with the even character

parity.

01493BEN

®

protocol is increased by a combination of

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

27

4

SD1: 02 hex

ADR: 01 hex

TYP: 05 hex

PD1 high: 00 hex

PD1 low: 06 hex

PD2 high: 3A hex

PD2 low: 98 hex

PD3 high: 01 hex

PD3 low: F4 hex

57 hex

Stop

Parity

Start

1

1

0

0

0

0

1

1

1

1

0

0

0

0

0

0

1

0

1

0

0

0

0

0

0

0

0

0

1

1

0

0

0

0

0

1

0

0

1

0

0

0

0

0

0

1

1

0

1

1

0

0

0

0

0

1

1

0

0

0

0

0

1

0

1

0

0

0

1

1

1

0

0

0

1

1

0

0

0

1

0

1

1

0

0

0

0

1

0

1

EXOR

EXOR

EXOR

EXOR

EXOR

EXOR

EXOR

EXOR

calculated BCC:

Serial Interfaces of MOVIDRIVE® B

MOVILINK® protocol via RS485 transmission method

Creating the block

check character

The following figure gives an example of how a block check character is created for a

cyclical telegram of type PDU 5 with 3 process data words. The EXOR logic operation

of the characters SD1 - PD3

results in the value 57

low

as the block check character

hex

BCC. This block check character will be sent as the last character of the telegram. The

recipient checks the character parity after having received the individual characters.

Next, the block check character is created from the received characters SD1 - PD3

low

according to the pattern described above. The telegram has been correctly transmitted

if the calculated and received block check characters are identical and there is no

character parity error. Any other result will be displayed as a transmission error.

28

TIP

For a description of process data and the structure of the 8-byte parameter data

channel, refer to chapter "SEW unit profile".

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

01494BEN

Serial Interfaces of MOVIDRIVE® B

Other unit functions via RS485 interfaces

4.4 Other unit functions via RS485 interfaces

4

In addition to process and parameter data exchange between PC, keypad and

MOVIDRIVE

• Master/slave operation

•IPOS

• Manual operation

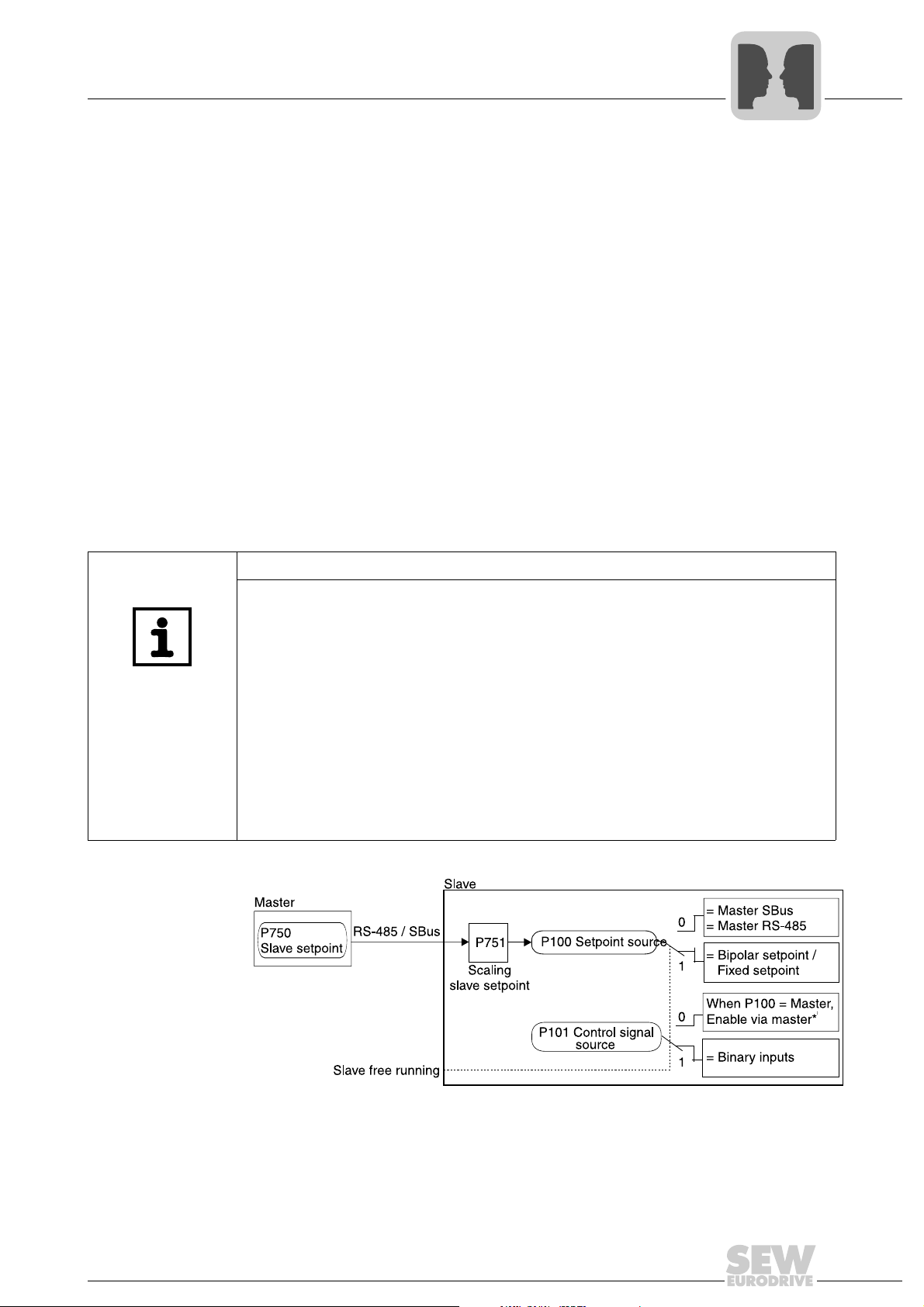

4.4.1 Using RS485 interfaces for master/slave operation

The master/slave function shown in the figure below allows for implementing automatic

functions such as speed synchronization, shared load and torque control (slave). The

RS485 interface (X13:10/X13:11) or the system bus interface (CAN 1) can be used as

communication link. P100 Setpoint source = Master SBus or P100 Setpoint source =

Master RS485 must be set on the slave. The process output data PO1 - PO3 (P870,

P871, P872) are automatically set by the firmware. A programmable terminal function

"Slave free run. "P60x binary inputs basic unit /P61x binary inputs option, it is possible

to separate the slave from the master setpoint and switch to local control mode.

®

B, the RS485 interfaces can also be used for the following functions:

plus®

TIP

For the slave, the process data P87x are automatically assigned as follows:

– PO1 = Control word 1

– PO2 = Speed or current in M-control

– PO3 = IPOS PO data

– PI1 = Status word 1

– PI2 = Speed

– PI3 = IPOS PI data

PI3 and PO3 are not used. They are available in IPOS

If a fieldbus card is plugged in the slave, only the parameter channel is available for the

output data. The master can read the automatically assigned process input data via

fieldbus.

plus®

as required.

*) DIØØ "/Controller inhibit" and the programmed binary inputs Enable, CW and CCW

must also receive a "1" signal.

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

01311BEN

29

4

Serial Interfaces of MOVIDRIVE® B

Other unit functions via RS485 interfaces

TIP

P811 RS485 group address must be set to the same value for master and slave. For

master/slave operation via RS485 interface, set P811 RS485 Group address to a value

greater than 100. If you have made the setting in parameter P750 slave setpoint that

slave setpoints are used via RS485, then MOVIDRIVE

quests (process and parameter telegrams) from another RS485 master (P100/101 ≠

RS485) as slave via this RS485 interface.

®

can no longer respond to re-

Connection

check

A connection check is always active for communication link via RS485 interface. P812

RS485 timeout interval is without function. The slave inverters must receive a valid

RS485 telegram within the fixed time interval of t = 500 ms. If the time is exceeded, the

slave drives will stop at the emergency stop ramp and error message F43 "RS485

timeout" will be issued.

NOTICE

If a timeout is not recognized, the drive will continue to move despite disconnected

controller.

Possible consequences: Damage to the system.

Only one of the two RS485 interfaces must be used for timeout monitoring.

As the RS485 timeout is active for both RS485 interfaces, the second interface is not

monitored for timeout when the DBG60B keypad is installed. The DBG60B keypad

permanently sends request telegrams to the inverter and in this way triggers the timeout mechanism.

30

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

Loading...

Loading...