SEW MOVIDRIVE MDX60B, MOVIDRIVE MDX61B System Manual

Drive Technology \ Drive Automation \ System Integration \ Services

System Manual

MOVIDRIVE

Edition 09/2010 16838017 / EN

®

MDX60B/61B

SEW-EURODRIVE—Driving the world

Contents

Contents

1 System Description............................................................................................. 8

1.1 System overview of MOVIDRIVE

1.2 Functions/features .................................................................................... 21

1.3 Additional functions of the application variants ......................................... 24

1.4 Application modules for MOVIDRIVE

1.5 MOVITOOLS

®

MotionStudio engineering software .................................. 37

2 Technical Data of Basic Unit............................................................................ 39

2.1 CE marking, UL approval and C-Tick ....................................................... 39

2.2 General technical data .............................................................................. 40

2.3 MOVIDRIVE

2.4 MOVIDRIVE

2.5 MOVIDRIVE

2.6 MOVIDRIVE

2.7 MOVIDRIVE

2.8 IPOS

plus®

®

MDX60/61B...-5_3 (AC 400/500 V units)........................... 42

®

MDX61B...-2_3 (AC 230 V units)....................................... 51

®

MDX60/61B electronics data ............................................. 55

®

MDX60B dimension drawings............................................ 57

®

MDX61B dimension drawings............................................ 59

.................................................................................................. 69

2.9 DBG60B keypad option ............................................................................ 71

2.10 DBM60B/DKG60B housing option for DBG60B........................................ 73

3 Technical Data of Regenerative Power Supply Units ................................... 74

3.1 MOVIDRIVE

®

MDR60A regenerative power supply units ........................ 74

4 Technical Data of Options ............................................................................... 82

4.1 DEH11B Hiperface

®

encoder card option................................................. 82

4.2 DER11B resolver card option ................................................................... 83

4.3 DEU21B multi-encoder card option .......................................................... 84

4.4 DEH21B/DIP11B absolute encoder card option ....................................... 85

4.5 Connector adapter for unit replacement MD_60A - MDX60B/61B ........... 88

4.6 DWE11B/12B interface adapter option ..................................................... 90

4.7 UWS11A interface adapter option ............................................................ 92

4.8 UWS21B interface adapter option ............................................................ 94

4.9 USB11A interface adapter option ............................................................. 96

4.10 DWI11A DC 5 V encoders supply option ................................................. 98

4.11 DIO11B input/output card option............................................................. 100

4.12 DFP21B PROFIBUS fieldbus interface option ........................................ 102

4.13 DFI11B INTERBUS fieldbus interface option.......................................... 103

4.14 DFI21B INTERBUS optical fiber fieldbus interface option ...................... 104

4.15 DFE32B PROFINET IO RT fieldbus interface option.............................. 105

4.16 DFE33B EtherNet/IP and Modbus/TCP fieldbus interface option........... 107

4.17 DFE24B EtherCAT

®

fieldbus interface option......................................... 109

4.18 DFD11B DeviceNet fieldbus interface option.......................................... 110

4.19 DFC11B CAN/CANopen fieldbus interface option .................................. 111

4.20 DRS11B synchronous operation card option.......................................... 112

®

MDX60B/61B....................................... 8

®

MDX61B...................................... 28

System Manual – MOVIDRIVE® MDX60B/61B

3

Contents

4.21 DFS11B fieldbus interface option PROFIBUS DP-V1 with PROFIsafe .. 113

4.22 DFS12B fieldbus interface option PROFIBUS DP-V1 with PROFIsafe .. 115

4.23 DFS21B fieldbus interface option PROFINET IO with PROFIsafe ......... 116

4.24 DFS22B fieldbus interface option PROFINET IO with PROFIsafe ......... 118

4.25 MOVISAFE

4.26 MOVI-PLC

4.27 OST11B option ....................................................................................... 123

4.28 DHE/DHF/DHR21 and DHE/DHF/DHR41B controller option ................. 124

4.29 BST safety-related brake module option................................................. 130

5 Technical Data of External Accessories ....................................................... 132

5.1 DMP11B mounting panel option ............................................................. 132

5.2 DLB11B touch guard option.................................................................... 133

5.3 DLB21B touch guard option (for size 7).................................................. 134

5.4 DLS11B mounting base option (for size 7) ............................................. 135

5.5 DLH11B wall bracket (for size 7) ............................................................ 136

5.6 DLA11B connection kit option (for size 7)............................................... 137

5.7 DLK11B air duct option (for size 7) ......................................................... 138

5.8 DLZ11B DC link coupling option (for size 7) ........................................... 139

5.9 2Q DLZ12B DC link adapter option (for size 7) ...................................... 140

5.10 4Q DLZ14B DC link adapter option (for size 7) ...................................... 141

®

DCS21B/31B safety module option................................... 119

®

basic DHP11B controller option.......................................... 122

6 Technical Data of Braking Resistors, Chokes and Filters .......................... 142

6.1 BW... braking resistor option / BW...-T / BW...-P .................................... 142

6.2 ND.. line choke option............................................................................. 153

6.3 NF...-... line filter option........................................................................... 155

6.4 HD... output choke option ....................................................................... 159

6.5 HF... output filter option........................................................................... 162

7 Prefabricated Cables ...................................................................................... 166

7.1 Overview ................................................................................................. 166

7.2 Cable sets for DC link connection MDR → MDX .................................... 166

7.3 CM motor cables with connector on motor end ...................................... 167

7.4 CM brakemotor cables with connector on motor end ............................. 168

7.5 CMD/CMP motor cables with connector on motor end........................... 169

7.6 CMP brakemotor cables for BP brake with connector at motor end ....... 169

7.7 CMP brakemotor cables for BY brake with connector at motor end ....... 170

7.8 Encoder cable selection: Meaning of the symbols.................................. 171

7.9 Encoder cables for DR motors on X15 DEH11B/DEH21B/DEU21B ...... 172

7.10 Encoder cable for DT/DV/CMP, CM, (DS) motors on

X15 DEH11B/DEH21B and DEU21B...................................................... 179

7.11 Encoder cables for distance encoders on X14,

DEH11B / DER11B / DEU21B ................................................................ 185

7.12 Encoder cables for resolvers on X15 DER11B ....................................... 190

4

System Manual – MOVIDRIVE® MDX60B/61B

Contents

8 Parameters....................................................................................................... 193

8.1 Menu structure in DBG60B ..................................................................... 194

8.2 Overview of parameters.......................................................................... 194

8.3 Explanation of the parameters ................................................................ 203

8.4 Operating modes .................................................................................... 282

9 Project Planning.............................................................................................. 294

9.1 Schematic procedure .............................................................................. 294

9.2 Control characteristics ............................................................................ 295

9.3 Description of the applications ................................................................ 297

9.4 Basic recommendations for motor selection ........................................... 299

9.5 Motor selection for asynchronous AC motors (VFC) .............................. 300

9.6 Motor selection for asynchronous AC and servomotors (CFC) .............. 316

9.7 Motor selection for synchronous servomotors (SERVO) ........................ 382

9.8 SL2 synchronous linear motors .............................................................. 403

9.9 Overload capacity of the inverter ............................................................ 403

9.10 Braking resistor selection........................................................................ 437

9.11 Connecting AC brakemotors................................................................... 446

9.12 Permitted voltage systems for MOVIDRIVE

9.13 Line contactors and line fuses ................................................................ 447

9.14 Power connection for size 7.................................................................... 448

9.15 Line and motor cables............................................................................. 451

9.16 Group drive in VFC mode ....................................................................... 458

9.17 Connecting explosion-proof AC motors .................................................. 459

9.18 EMC-compliant installation in accordance with EN 61800-3 .................. 460

9.19 HF… output filter type ............................................................................. 463

9.20 Electronics cables and signal generation................................................ 466

9.21 External voltage supply DC 24 V ............................................................ 467

9.22 Parameter set switchover ....................................................................... 469

9.23 Priority of operating states and interrelation between control signals ..... 470

9.24 Limit switches.......................................................................................... 471

10 General Information ........................................................................................ 472

10.1 How to use the operating instructions..................................................... 472

10.2 Structure of the safety notes ................................................................... 472

10.3 Rights to claim under limited warranty .................................................... 473

10.4 Exclusion of liability................................................................................. 473

10.5 Copyright notice ...................................................................................... 473

10.6 Product names and trademarks.............................................................. 473

®

B...................................... 447

11 Safety Notes .................................................................................................... 474

11.1 General information ................................................................................ 474

11.2 Target group ........................................................................................... 474

11.3 Designated use ....................................................................................... 475

11.4 Transportation, storage........................................................................... 475

11.5 Installation............................................................................................... 476

System Manual – MOVIDRIVE® MDX60B/61B

5

Contents

11.6 Electrical connection ............................................................................... 476

11.7 Safe disconnection.................................................................................. 476

11.8 Operation ................................................................................................ 477

12 Unit Structure .................................................................................................. 478

12.1 Type designation, nameplates and scope of delivery ............................. 478

12.2 Scope of delivery .................................................................................... 480

12.3 Size 0 ...................................................................................................... 482

12.4 Size 1 ...................................................................................................... 483

12.5 Size 2S.................................................................................................... 484

12.6 Size 2 ...................................................................................................... 485

12.7 Size 3 ...................................................................................................... 486

12.8 Size 4 ...................................................................................................... 487

12.9 Size 5 ...................................................................................................... 488

12.10 Size 6 ...................................................................................................... 489

12.11 Size 7 ...................................................................................................... 490

13 Installation ....................................................................................................... 492

13.1 Installation instructions for the basic unit ................................................ 492

13.2 Removing/installing the keypad .............................................................. 510

13.3 Removing/installing the front cover......................................................... 511

13.4 Information regarding UL ........................................................................ 513

13.5 Shield clamps.......................................................................................... 516

13.6 Touch guard for power terminals ............................................................ 519

13.7 Wiring diagram for basic unit .................................................................. 524

13.8 Assignment of braking resistors, chokes and filters................................ 530

13.9 Connecting the system bus (SBus 1)...................................................... 535

13.10 Connecting the RS485 interface ............................................................. 536

13.11 Connecting the interface adapter option type DWE11B/12B .................. 538

13.12 Connection of interface adapter option UWS21B (RS232)..................... 540

13.13 Connecting the interface adapter option USB11A .................................. 542

13.14 Option combinations for MDX61B........................................................... 544

13.15 Installing and removing option cards ...................................................... 546

13.16 Connecting encoders and resolvers ....................................................... 548

13.17 Connection and terminal description of the DEH11B

(Hiperface

13.18 Connection and terminal description of the DEH21B option................... 553

13.19 Connection and terminal description of the DEU21B option................... 555

13.20 Connection and terminal description of the DER11B

(resolver) option ...................................................................................... 557

13.21 Connecting external encoders to X:14.................................................... 559

13.22 Connection of encoder options .............................................................. 560

13.23 Connection of incremental encoder simulation ....................................... 566

13.24 Master/slave connection ......................................................................... 567

13.25 Connection and terminal description of the DIO11B option .................... 568

13.26 Connection and terminal description of the DFC11B option ................... 571

®

) option ................................................................................. 550

6

System Manual – MOVIDRIVE® MDX60B/61B

Contents

14 Startup.............................................................................................................. 572

14.1 General startup instructions .................................................................... 572

14.2 Preliminary work and resources.............................................................. 574

14.3 Startup with DBG60B keypad ................................................................. 575

14.4 Operation of MOVITOOLS

14.5 Starting the motor ................................................................................... 589

14.6 Complete parameter list.......................................................................... 595

15 Operation ......................................................................................................... 609

15.1 Operating Displays.................................................................................. 609

15.2 Information messages............................................................................. 610

15.3 Functions of the DBG60B keypad........................................................... 612

15.4 Memory card ........................................................................................... 616

16 Service ............................................................................................................. 618

16.1 Error information ..................................................................................... 618

16.2 Error messages and list of errors............................................................ 619

16.3 SEW Electronics Service ........................................................................ 637

16.4 Extended storage.................................................................................... 637

16.5 Disposal .................................................................................................. 638

17 Address Directory ........................................................................................... 639

®

MotionStudio.............................................. 585

Index................................................................................................................. 659

System Manual – MOVIDRIVE® MDX60B/61B

7

1

3 x AC 380...500 V

3 x AC 200...240 V

MOVIDRIVE

MDX60/61B...-5_3

®

MOVIDRIVE

MDX61B...-2_3

®

®

Regenerative power supply option

MOVIDRIVE MDR60A

Output

filter option

Output

choke option

Braking

resistor option

Line

filter option

Line

choke option

DC link

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

System Description

System overview of MOVIDRIVE® MDX60B/61B

1 System Description

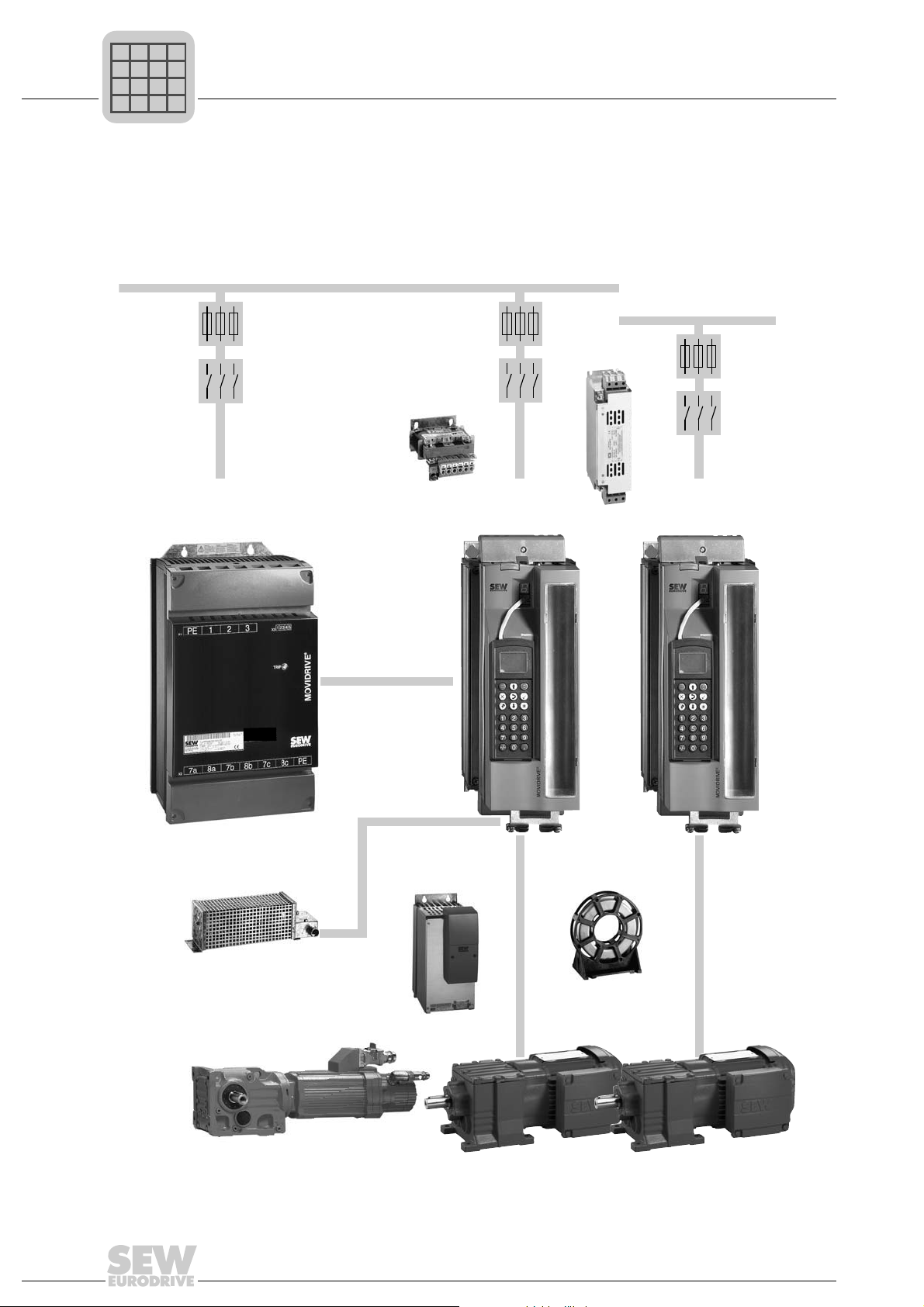

1.1 System overview of MOVIDRIVE® MDX60B/61B

1.1.1 Power components

1452332683

8

System Manual – MOVIDRIVE® MDX60B/61B

System overview of MOVIDRIVE® MDX60B/61B

MASTER

SLA VE

MOVIT OOL S

MDX60/61B standard variant with IPOS

plus®

DBG60B keypad option

MDX60/61B application version for

the use of "electronic cam", "Internal

synchronous operation" or the application modules.

System bus

(SBus)

MOVITOOLS® engineering software

Interface adapter option:

Encoder options:

USB 11AUWS 21B

UWS 11A

DEH 11BDEU 21B DEH 21B DER 11B DIP 11B DIO 11B DRS 11B

DEU 21B

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

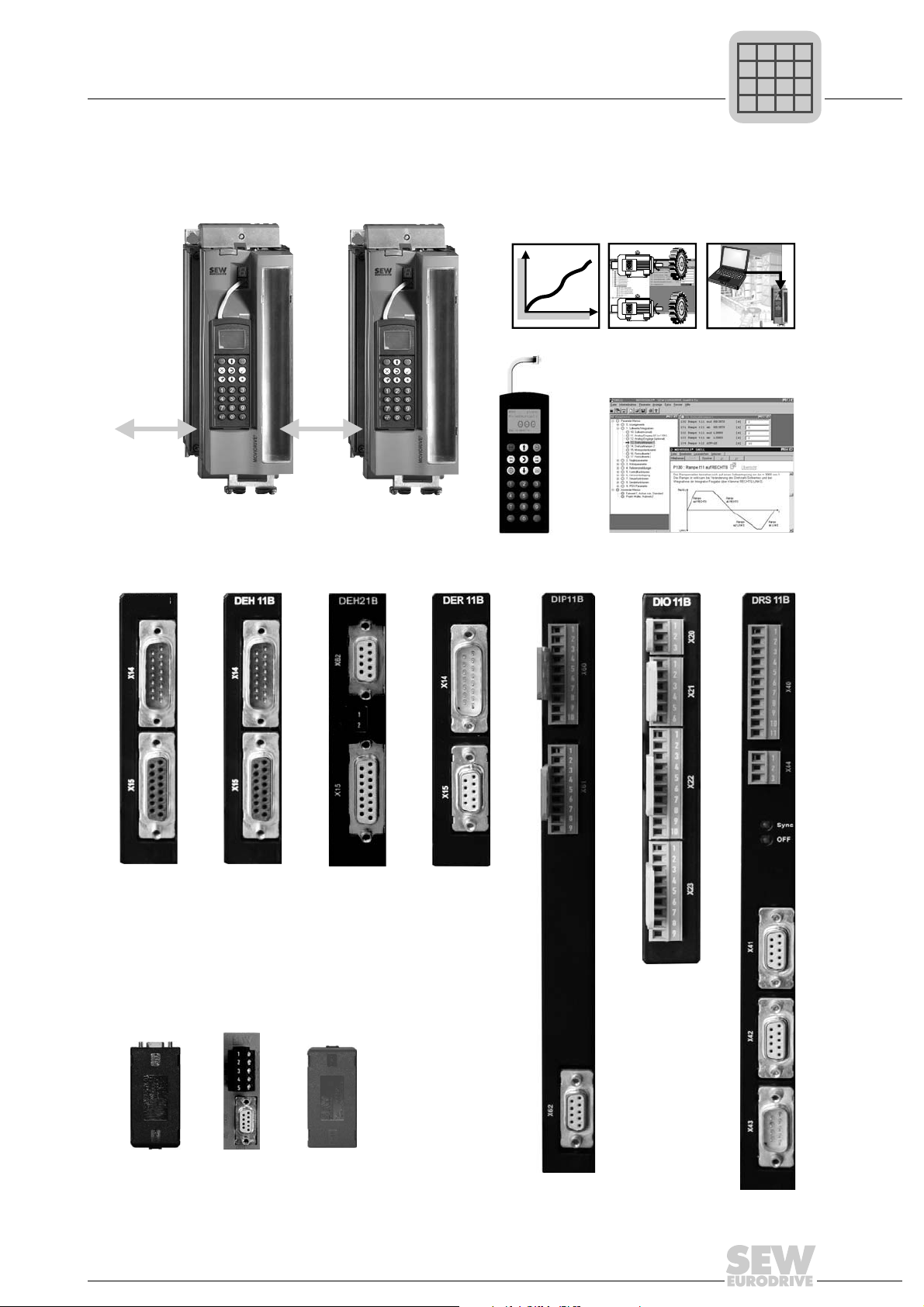

1.1.2 Encoder and communication options

System Description

1

System Manual – MOVIDRIVE® MDX60B/61B

1452369291

9

1

DFC 11B DFD 11B

DFE 32B

DFE 24B

DFI 11B

DFI 21B DFP 21B

DFE 33B

DFE33B

ETHERNET/IP

MODULE

STATUS

NETWORK

STATUS

xx xx xx xx

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

1.1.3 Fieldbus options

System Description

System overview of MOVIDRIVE® MDX60B/61B

1452375307

10

System Manual – MOVIDRIVE® MDX60B/61B

1.1.4 Control options

DHE 41B DHF 41B DHR 41BDHP 11B OST 11B

MOVI-PLC

®

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

System Description

System overview of MOVIDRIVE® MDX60B/61B

1

1452634507

System Manual – MOVIDRIVE® MDX60B/61B

11

1

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

1.1.5 Safety options

System Description

System overview of MOVIDRIVE® MDX60B/61B

DFS 11B DFS 21BDFS 12B DFS 22B

DCS 21B

DCS 31B

1452640907

12

System Manual – MOVIDRIVE® MDX60B/61B

1.1.6 General description

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

MOVIDRIVE

EURODRIVE. The new MOVIDRIVE

provide enhanced functions in the lower power range, more basic functions, and greater

overload capacity.

AC drives with the latest digital inverter technology can now be used without restrictions

in the 0.55 to 315 kW power range. The levels of dynamic performance and control

quality that can now be achieved with MOVIDRIVE

previously only possible using servo drives or DC motors. The integrated control functionality and the option to extend the drive using technology and communication options

creates drive systems that are designed to be particularly cost-effective with regard to

the application range, project planning, startup and operation.

1.1.7 Low-emission

The MOVIDRIVE

emission regulations, but with the usual high level of quality. One particular feature is

the consistent use of lead-free soldering materials in the production of electronics

products. These lead-free processes are in line with the RoHS EU Directive and the law

on electronic equipment.

System Description

System overview of MOVIDRIVE® MDX60B/61B

®

MDX60B/61B is the new generation of drive inverters from SEW-

®

MDX60B/61B inverters are produced according to particularly low-

®

B series inverters feature a modular design,

®

for asynchronous AC motors were

1

1.1.8 Product family

®

The MOVIDRIVE

• MOVIDRIVE® MDX60B: Drive inverter for asynchronous AC motors without encoder feed-

• MOVIDRIVE

• MOVIDRIVE

product family includes three series:

®

MDX61B: Drive inverter for asynchronous AC motors with or without

®

MDR60A: Regenerative power supply unit; MOVIDRIVE® inverters (400/

back. The units are not option-capable.

encoder feedback, or for asynchronous and synchronous servomotors. The units are option-capable.

500 V units) operate in regenerative mode to feed energy back

into the supply system.

System Manual – MOVIDRIVE® MDX60B/61B

13

1

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

1.1.9 Unit variants

System Description

System overview of MOVIDRIVE® MDX60B/61B

®

MOVIDRIVE

standard variant and the application variant. MOVIDRIVE

inverters are only available as application variants with coated pcbs (-0T/L).

MDX60/61B size 0-6 inverters are available in two variants, namely the

®

MDX60B/61B size 7

Standard variant The units are equipped with integrated IPOS

standard. MOVIDRIVE

"00" at the end of the type designation indicates the standard variant.

Application variant In addition to the features of the standard variant, these units include the technology

functions "electronic cam" and "internal synchronous operation". Furthermore, you can

use all the application modules available in the MOVITOOLS

ing software with the application variants.

The application variant is indicated by "0T" following the type designation.

Variants with

coated printed

circuit boards

The units are designed for use in harsh environments. The coating of the printed circuit

boards increases their resistivity against environmental conditions.

The variant with coated pcbs is indicated by "00/L" or "0T-/L" at the end of the type

designation.

®

MDX61B can be expanded with the available options.

plus®

positioning and sequence control as

®

MotionStudio engineer-

14

System Manual – MOVIDRIVE® MDX60B/61B

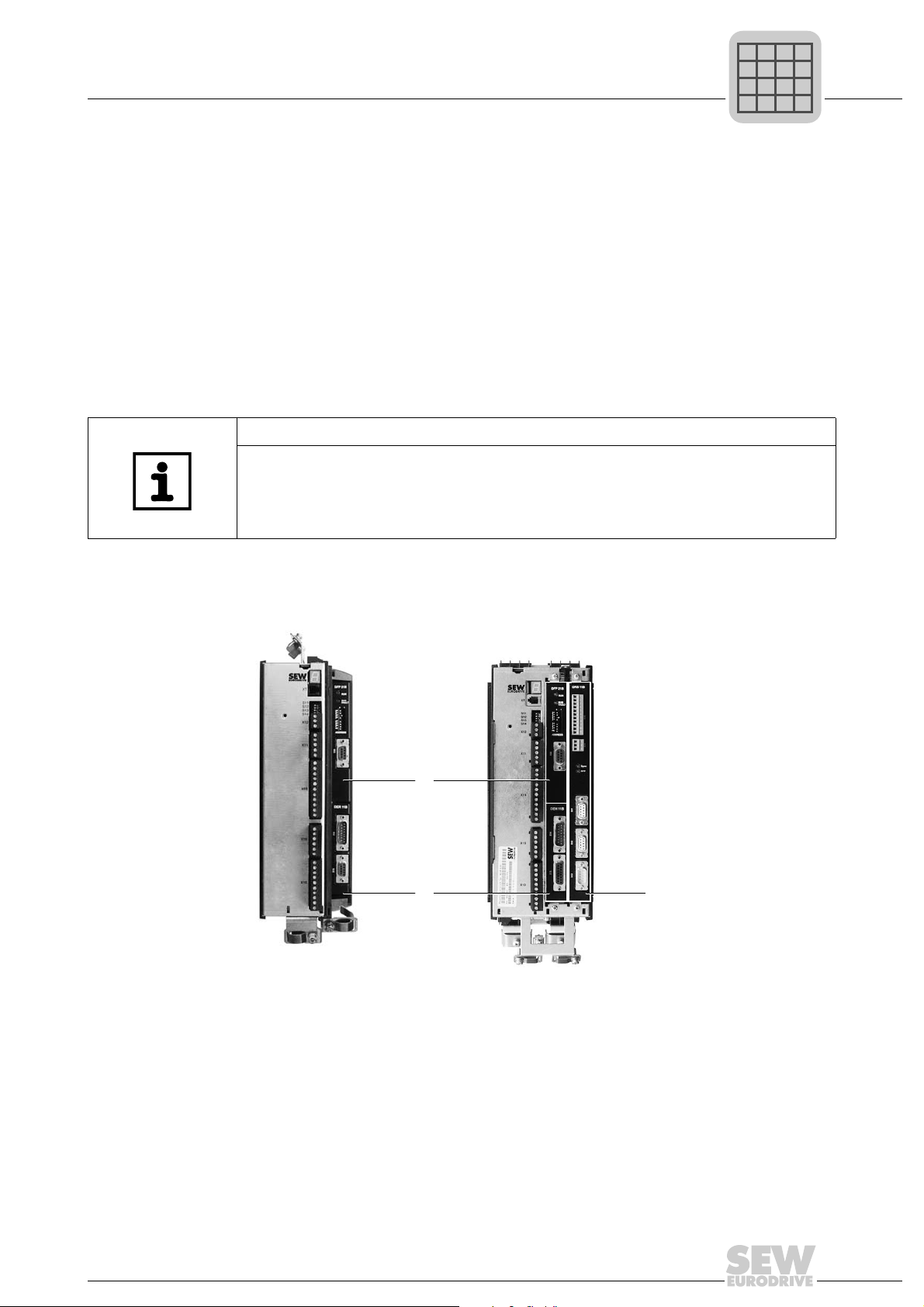

1.1.10 Modular unit concept

[2]

[1]

[3]

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

The option-capable MOVIDRIVE

• Size 0 (0005 ... 0014) → 2 option card slots

– 1 option card slot for encoder connection

– 1 option card slot for a communication option

• Sizes 1 ... 7 (0015 ... 2500) → 3 option card slots

– 1 option card slot for encoder connection

– 1 option card slot for a communication option

– 1 option card slot for an expansion option

INFORMATION

• Customers can only install or remove option cards later on in MDX61B sizes

1 to 7. The firmware of the option cards and the basic unit must be compatible.

•For MDX61B size 0 units, option cards can only be installed and removed later

on by SEW-EURODRIVE. Please take this aspect into account when you place

your order/perform project planning.

System Description

System overview of MOVIDRIVE® MDX60B/61B

®

MDX61B units have the following option slots:

1

1.1.11 Option card slots of MOVIDRIVE

Size 0 (0005 ... 0014) Size 1 ... 7 (0015 ... 2500)

[1] Encoder slot for encoder option

[2] Fieldbus slot for communication option

[3] Expansion slot for communication option (only sizes 1 - 7)

®

MDX61B

1806023691

System Manual – MOVIDRIVE® MDX60B/61B

The modular unit concept allows you to choose the right option according to your application. For example, when you have an asynchronous AC motor with encoder feedback

(Hiperface

DEH11B.

®

, sin/cos, or TTL), you would need the Hiperface® encoder card type option

15

1

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

System Description

System overview of MOVIDRIVE® MDX60B/61B

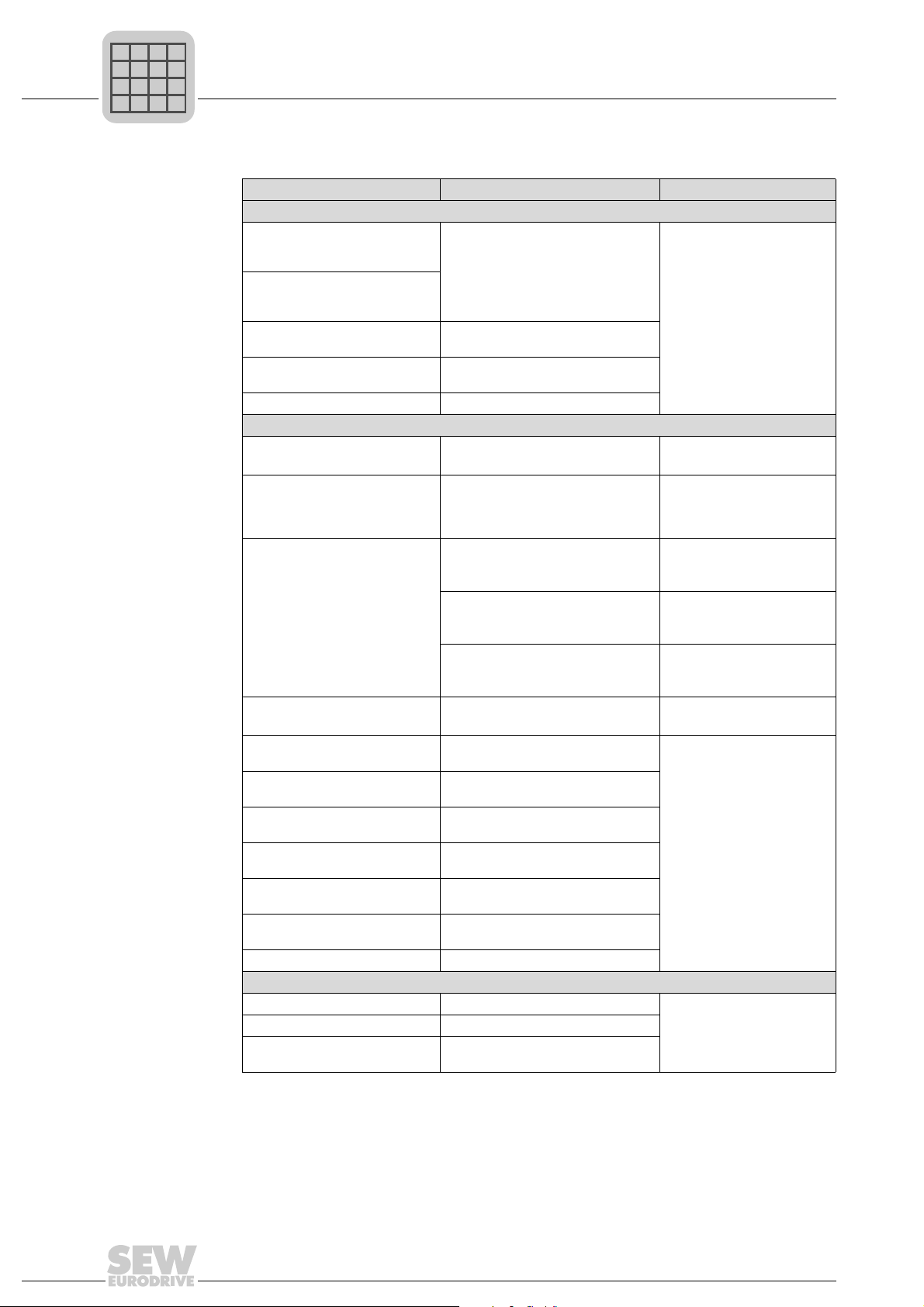

Use Required option Option card slot

Encoder option

Asynchronous AC motor with

encoder feedback (Hiperface

sin/cos, TTL)

Asynchronous or synchronous

servomotor with Hiperface®

encoder

Synchronous servomotor with

resolver

Asynchronous or synchronous

motors with absolute encoder

SSI encoder interface DEH21B absolute encoder card

Communication options (fieldbus, control)

User-programmable MOVI-PLC

controller

Additional RS485 interface (only

in combination with option

DHP11B)

Freely programmable motion and

logic controller (MOVI-PLC

Additional analog and binary

inputs/outputs are required

Integration into a PROFIBUS

system

Integration into a PROFIBUS

system with PROFIsafe

Integration into an INTERBUS

system

Integration into an Ethernet

system with PROFIsafe

Integration into an EtherCAT

system

Integration into a DeviceNet

system

Integration into a CANopen ystem CANopen interface type DFC11B

Expansion option

SSI encoder interface DIP11B absolute encoder card

Phase-synchronous operation Synchronous operation card DRS11B

Safety module DCS21B option (only in conjunction

®

,

®

Hiperface

Resolver card type DER11B

DEU21B multi-encoder card

®

MOVI-PLC®basic DHP11B controller 2

DHP11B + OST11B • DHP11B in 2, OST11B in

Controller

• DHE21B (standard)

• DHE41B (advanced)

Controller

®

• DHF21B (standard)

)

• DHF41B (advanced)

Controller

• DHR21B (standard)

• DHR41B (advanced)

Input/output card type DIO11B

PROFIBUS interface type DFP21B

DFS11B fieldbus interface

INTERBUS interface type DFI11B /

DFI21B

DFS21B fieldbus interface

®

EtherCAT

DeviceNet interface type DFD11B

with DFS12B/22B option) / DCS31B

encoder card DEH11B

®

interface type DFE24B

1

(3 only if slot 2 is occupied)

1

• If 1 is occupied:

DHP11B + OST11B in 3

2

(3 only if slot 2 is occupied)

3

3

2

(3 only if slot 2 is occupied)

2

3

16

System Manual – MOVIDRIVE® MDX60B/61B

1.1.12 Control modes

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

System Description

System overview of MOVIDRIVE® MDX60B/61B

1

The VFC (Voltage Mode Flux Control) and CFC (Current Mode Flux Control)/SERVO

control modes are features of MOVIDRIVE

calculation of the complete motor model forms the basis for both control modes.

VFC control mode

(Voltage Mode Flux Control)

Voltage-controlled control mode for asynchronous

AC motors with and without encoder feedback.

• With encoder feedback

– At least 150% torque, with a power-

– Characteristics similar to servo operation

• Without encoder feedback

– min. 150% torque up to 0.5 Hz, with a

1.1.13 System bus (SBus)

The system bus (SBus), which is installed as standard, allows several MOVIDRIVE

inverters to be networked together. This system bus enables fast data exchange

between the units. The MOVILINK

MOVILINK

SBus can be switched to CANopen.

1.1.14 MOVILINK

®

MOVILINK® always uses the same message format independent of the selected interface (SBus, RS232, RS485, fieldbus interfaces). As a result, the control software is

independent of the selected interface.

®

MDX60B/61B inverters. The continuous

Control modes

CFC (Current Mode Flux Control)/SERVO

Current-controlled control mode for asynchronous

and synchronous servomotors. Encoder feedback is

always required.

matched, stopped motor

power-matched motor

®

®

is the universal SEW-EURODRIVE standard for serial communication. The

unit profile is used for communication via the SBus.

• At least 160% torque, with a power-matched,

stopped motor

• Maximum precision and concentric running

characteristics right down to standstill.

• Servo characteristics and torque control even

for asynchronous AC motors

• Reacts to load changes within a few milliseconds

®

1.1.15 IPOS

plus®

A significant feature of MOVIDRIVE® inverters is that the IPOS

sequence control system is integrated as standard. IPOS

plus®

plus®

positioning and

enables you to control

motion sequences directly in the inverter close to the machine. This way, load is taken

off the higher-level controller and modular concepts can be implemented more easily.

System Manual – MOVIDRIVE® MDX60B/61B

17

1

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

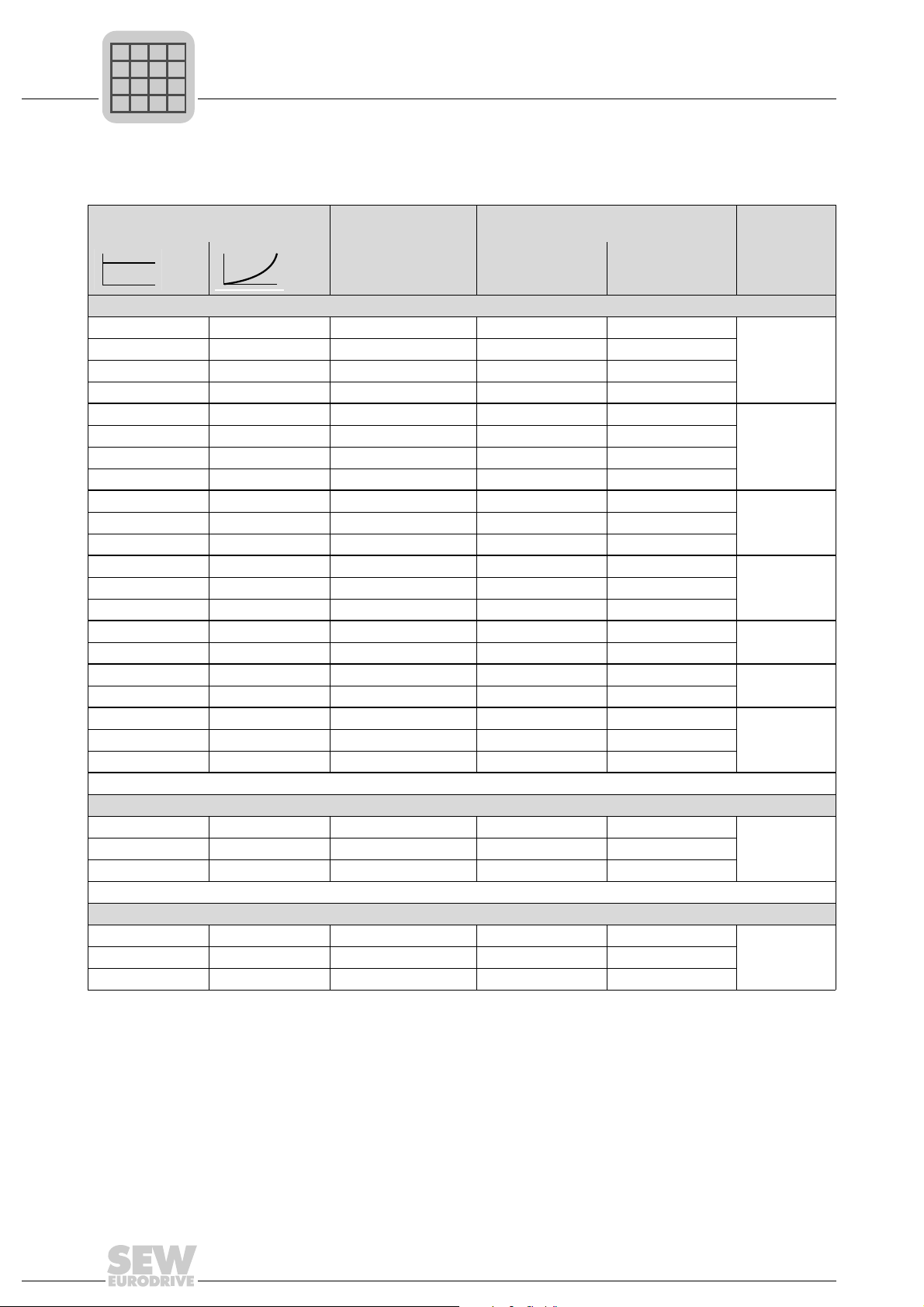

1.1.16 Overview of the units

MOVIDRIVE

®

MDX60/61B for 3 × AC 380 ... 500 V supply voltage (400/500 V units):

System Description

System overview of MOVIDRIVE® MDX60B/61B

Recommended motor power (VFC)

4Q units (with brake chopper)

0.55 kW (0.74 HP) 0.75 kW (1.0 HP) AC 2.0 A 0005-5A3-4-.. 0005-5A3-4-..

0.75 kW (1.0 HP) 1.1 kW (1.5 HP) AC 2.4 A 0008-5A3-4-.. 0008-5A3-4-..

1.1 kW (1.5 HP) 1.5 kW (2.0 HP) AC 3.1 A 0011-5A3-4-.. 0011-5A3-4-..

1.5 kW (2.0 HP) 2.2 kW (3.0 HP) AC 4.0 A 0014-5A3-4-.. 0014-5A3-4-..

1.5 kW (2.0 HP) 2.2 kW (3.0 HP) AC 4.0 A - 0015-5A3-4-..

2.2 kW (3.0 HP) 3.0 kW (4.0 HP) AC 5.5 A - 0022-5A3-4-..

3.0 kW (4.0 HP) 4.0 kW (5.4 HP) AC 7.0 A - 0030-5A3-4-..

4.0 kW (5.4 HP) 5.5 kW (7.4 HP) AC 9.5 A - 0040-5A3-4-..

5.5 kW (7.4 HP) 7.5 kW (10 HP) AC 12.5 A - 0055-5A3-4-..

7.5 kW (10 HP) 11 kW (15 HP) AC 16 A - 0075-5A3-4-..

11 kW (15 HP) 15 kW (20 HP) AC 24 A - 0110-5A3-4-..

15 kW (20 HP) 22 kW (30 HP) AC 32 A - 0150-503-4-..

22 kW (30 HP) 30 kW (40 HP) AC 46 A - 0220-503-4-..

30 kW (40 HP) 37 kW (50 HP) AC 60 A - 0300-503-4-..

37 kW (50 HP) 45 kW (60 HP) AC 73 A - 0370-503-4-..

45 kW (60 HP) 55 kW (74 HP) AC 89 A - 0450-503-4-..

55 kW (74 HP) 75 kW (100 HP) AC 105 A - 0550-503-4-..

75 kW (100 HP) 90 kW (120 HP) AC 130 A - 0750-503-4-..

90 kW (120 HP) 110 kW 148 HP) AC 170 A - 0900-503-4-..

110 kW (148 HP) 132 kW (177 HP) AC 200 A - 1100-503-4-..

132 kW (177 HP) 160 kW (215 HP) AC 250 A - 1320-503-4-..

-

2Q units (without brake chopper)

160 kW (215 HP) 200 kW (268 HP) AC 300 A - 1600-503-2-0T/L

200 kW (268 HP) 250 kW (335 HP) AC 380 A - 2000-503-2-0T/L

250 kW (335 HP) 315 kW (422 HP) AC 470 A - 2500-503-2-0T/L

Continuous output

current

(CFC)

MOVIDRIVE® type Size

MDX60B

not option-capable

MDX61B

option-capable

(techn.

data)

0

(page 42)

1

(page 44)

2S, 2

(page 45)

3

(page 46)

4

(page 47)

5

(page 48)

6

(page 49)

7

(page 50)

4Q units (with brake chopper)

160 kW (215 HP) 200 kW (268 HP) AC 300 A - 1600-503-4-0T/L

200 kW (268 HP) 250 kW (335 HP) AC 380 A - 2000-503-4-0T/L

250 kW (335 HP) 315 kW (422 HP) AC 470 A - 2500-503-4-0T/L

18

System Manual – MOVIDRIVE® MDX60B/61B

7

(page 50)

System Description

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

System overview of MOVIDRIVE® MDX60B/61B

MOVIDRIVE® MDX60/61B for 3 × AC 200 ... 240 V supply voltage (230 V units):

1

Recommended motor power (VFC)

1.5 kW (2.0 HP) 2.2 kW (3.0 HP) AC 7.3 A 0015-2A3-4-..

2.2 kW (3.0 HP) 3.7 kW (5.0 HP) AC 8.6 A 0022-2A3-4-..

3.7 kW (5.0 HP) 5.0 kW (7.0 HP) AC 14.5 A 0037-2A3-4-..

5.5 kW (7.4 HP) 7.5 kW (10 HP) AC 22 A 0055-2A3-4-..

7.5 kW (10 HP) 11 kW (15 HP) AC 29 A 0075-2A3-4-..

11 kW (15 HP) 15 kW (20 HP) AC 42 A 0110-203-4-..

15 kW (20 HP) 22 kW (30 HP) AC 54 A 0150-203-4-..

22 kW (30 HP) 30 kW (40 HP) AC 80 A 0220-203-4-..

30 kW (40 HP) 37 kW (50 HP) AC 95 A 0300-203-4-..

®

MOVIDRIVE

MOVIDRIVE® MDR60A regenerative power supply units Size (technical data) MOVIDRIVE®MDX60B/61B...-5_3

0150-503-01 I

0370-503-00 I

0750-503-00 I

1320-503-00 I

1320-503-00

As of series no.

DCV2000100

MDR60A regenerative power supply units for 400/500 V units:

= AC 29 A, I

line

= AC 66 A, I

line

= AC 117 A, I

line

= AC 225 A, I

line

I

= AC 260 A, I

line

Continuous output

current

(CFC)

= DC 35 A

DC link

= DC 70 A 0005 ... 0370

DC link

= DC 141 A 0005 ... 0750

DC link

= DC 270 A 0005 ... 1320

DC link

= DC 324 A 0005 ... 1600

DC link

3, 4, 6

(page 76)

MOVIDRIVE® type Size

MDX61B

option-capable

(technical

data)

1

(page 51)

2

(page 52)

3

(page 53)

4

(page 54)

0005 ... 0150

System Manual – MOVIDRIVE® MDX60B/61B

19

1

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

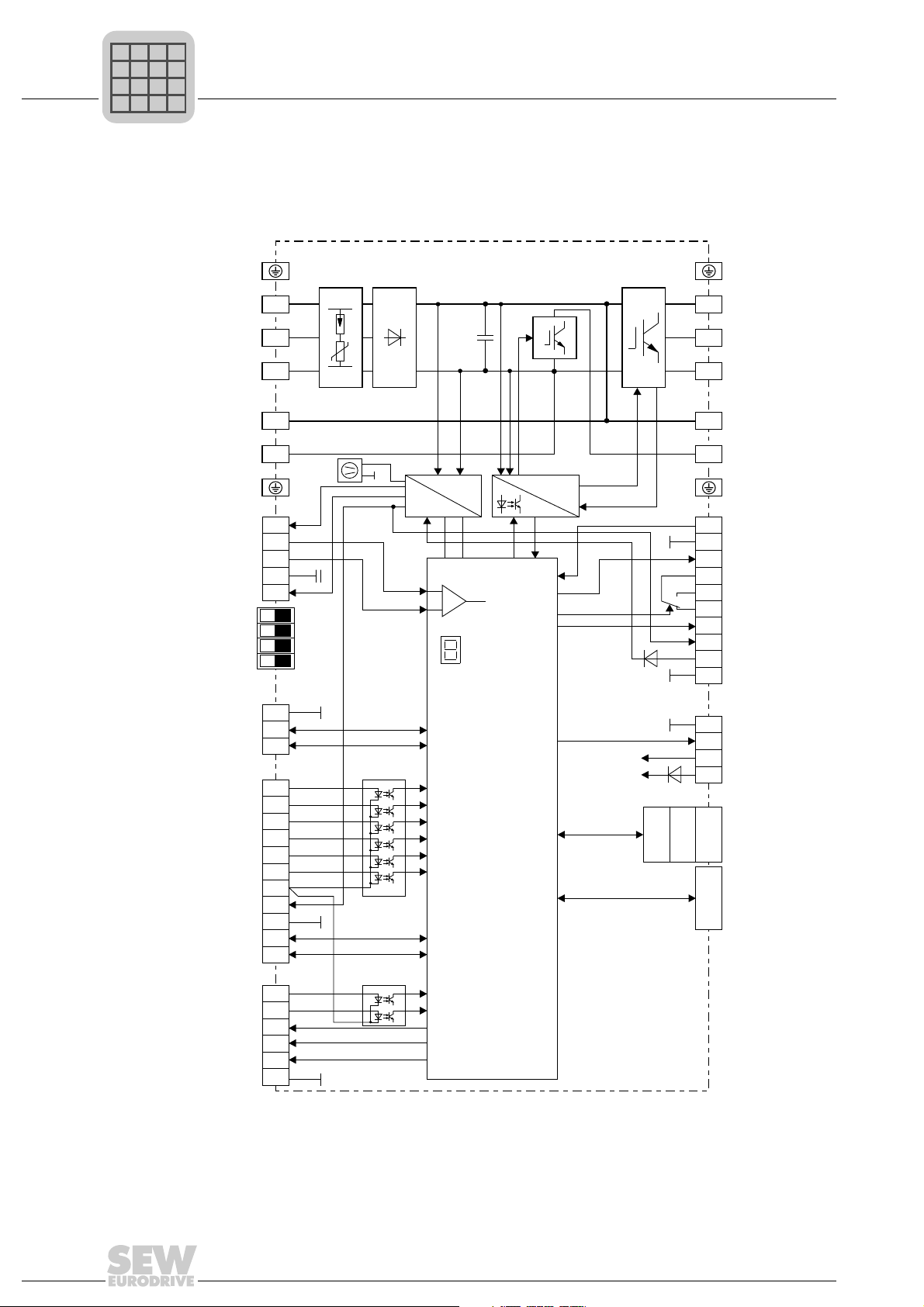

1.1.17 Block circuit diagram

System Description

System overview of MOVIDRIVE® MDX60B/61B

Power

supply

Analog input

and reference

voltages

AGND

I-Signal U-Signal

Terminating resistor SBus

Frequency input active

RS485 baud rate

GND

System bus

Potential-free

binary inputs

Reference

DC+24 V output

RS485

interface

Potential-free

binary inputs

Binary outputs

The following block circuit diagram shows the basic structure and theory of operation of

®

MOVIDRIVE

PE

1

L1

L2

2 5

L3

3

DC link

connection

8 8

7

1

2

3

4

5

ON OFF

1

2

3

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

MDX60B/61B inverters.

Input

X1:

protection

circuit

X4:

Fan

X11:

S11

S12

S13

S14

X12:

X13:

X16:

DC link Brake

Power supply

unit

Control unit

+

-

7-segment

display

Micro processor

X2:

chopper

BRC

ON

U

Z

InverterRectifier

Control

signals

Current

measurement

X3:

X10:

X17:

OPTION2

OPTION1

PE

4

U

V

W

6

Braking resistor

connection

9

1

TF/TH/KTY input

2

GND

3

Binary output

4

5

Relay output

6

7

Binary output

8

DC+24 V output

9

DC+24 V input

GND

10

1

2

STO

3

4

OPTION3 Xterminal

Option

slots

(not in MDX60B)

Keypad

or

interface

adapter

Motor

1452719115

20

System Manual – MOVIDRIVE® MDX60B/61B

1.2 Functions/features

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

1.2.1 Unit features

• Wide voltage range

– 400/500 V units for the voltage range 3 × AC 380 ... 500 V

– 230 V units for the voltage range 3 × AC 200 ... 240 V

• High overload capacity

– Size 0: 200% I

– Sizes 1 ... 6: 150% I

– All sizes: 125% I

• Sizes 0 ... 6:

– With 4 kHz switching frequency, I

ϑ =50°C

– 4Q capability due to integrated brake chopper installed as standard

•Size 7:

– With 2.5 kHz switching frequency, I

ϑ =50°C

System Description

Functions/features

for at least 60 s

N

for at least 60 s

N

, continuous operation without overload (pumps, fans)

N

is permitted for an ambient temperature of

N

is permitted for an ambient temperature of

N

1

• Compact unit design for minimum control cabinet space requirement and optimum

• Integrated input filter fitted as standard in sizes 0, 1, 2S and 2, adherence to class

• 8 isolated binary inputs and 6 binary outputs, one of which is a relay output; program-

• 1 TF/TH/KTY input for motor protection using a PTC thermistor or thermocontact

• 7-segment display for operating and fault states

• Separate DC 24 V voltage input for powering the inverter electronics (parameter

• Separable electronic terminals

• Separable power terminals for size 0 and 1 units

• STO in accordance with EN 61800-5-2, up to

1.2.2 Control functions

• VFC or CFC control modes for field-oriented operation (asynchronous servo)

•IPOS

• Two complete parameter sets

• Automatic motor calibration

– 2Q units without brake chopper or 4Q units with brake chopper can be selected

utilization of control cabinet volume

C2 limit on the input side without any additional measures

mable inputs/outputs

setting, diagnostics and data storage even when the supply system is switched off)

– Category 3 according to EN 954-1

– Performance level d according to EN ISO 13849-1

plus®

positioning and sequence control system integrated as standard

• Automatic brake control by the inverter

• DC braking to decelerate the motor even in 1Q mode

• Energy-saving function for optimizing the magnetization current automatically

System Manual – MOVIDRIVE® MDX60B/61B

21

1

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

System Description

Functions/features

• Slip compensation for high stationary speed accuracy, even without encoder

feedback

• Flying restart function for synchronizing the inverter to an already rotating SEW

motor

• Hoist capability with all motor systems that can be connected

• Motor stall protection through sliding current limitation in the field weakening range

• Function to hide speed window to avoid mechanical resonances

• Heating current to avoid condensation build-up in the motor

• Parameter lock for protection against changes to parameters

®

• Speed controller and encoder input for incremental, Hiperface

resolvers. User-friendly controller setting tool in the operator interface.

• Protective functions for complete protection of the inverter and motor (short-circuit,

overload, overvoltage/undervoltage, ground fault, excess temperature in the inverter,

motor stall prevention, excess temperature in the motor)

• Speed monitoring and monitoring of the motor and regenerative limit power

or SSI encoders and

• Programmable signal range monitoring (speed, current, maximum current)

• Memory for displaying X/t diagrams using SCOPE process data visualization

(8 channels, real-time capable)

• Fault memory (5 memory locations) with all relevant operating data at the time of the

fault

• Operating hours counter for hours of operation (unit connected to supply system or

DC 24 V) and enable hours (output stage energized)

• Modular option technology for application-specific unit configuration

• Uniform operation, identical parameter setting and the same unit connection technology for the entire MOVIDRIVE

1.2.3 Setpoint technology

• Ramp switchover (total of 4 ramps)

• Motor potentiometer, can be combined with analog setpoint and internal fixed

setpoints

• External setpoint selections: DC (0 ... +10 V, -10 V ... +10 V, 0 ... 20 mA, 4 ... 20 mA)

• S pattern for jerk-free speed changes

• Programmable input characteristic curve for flexible setpoint processing

• 6 bipolar fixed setpoints which can be mixed with external setpoints and motor

potentiometer function

• Primary frequency input

®

unit series

• Adjustable jerk limitation

1.2.4 Communication/operation

®

• System bus for networking max. 64 MOVIDRIVE

• RS485 interface for communication between one PLC/IPC and up to 31 inverters

• Simple startup and parameter setting using a keypad or PC

• Pluggable memory module for quick unit replacement during service

22

System Manual – MOVIDRIVE® MDX60B/61B

units to one another

1.2.5 System expansion

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

• Extensive expansion options, for example:

– Removable plain text keypad with parameter memory

– USB11A, RS232 ↔ RS485 interface adapter

– Fieldbus interface, either PROFIBUS, INTERBUS, Ethernet, DeviceNet, CAN/

– Input/output card

– Braking resistors, line filters, line chokes, output chokes, output filters

• MOVITOOLS

• Application version with access to technology functions and application modules to

solve drive tasks quickly and easily

•MOVIDRIVE

back into the supply system, which removes the thermal load from the control cabinet

and saves costs.

CANopen

System Description

Functions/features

®

MotionStudio with SCOPE process data visualization

®

MDR60A regenerative power supply unit. Regenerative energy is fed

1

1.2.6 Standards and approvals

• UL, cUL, C-Tick approval. The MOVIDRIVE

have UL or cUL or C-Tick approval. The GOST-R certificate (Russia) has been

approved for the MOVIDRIVE

• Safe disconnection of power and electronic connections according to EN 61800-5-1

• Compliance with all the requirements for CE certification of machines and plants

equipped with MOVIDRIVE

and the EMC Directive 2004/108/EC. Complies with the EMC product standard

EN 61800-3.

• STO in accordance with EN 61800-5-2, up to

– Category 3 according to EN 954-1

– Performance level d according to EN ISO 13849-1

®

MDR60A1320-503-00 unit does not

®

range of units.

®

on the basis of the Low Voltage Directive 2006/95/EC

System Manual – MOVIDRIVE® MDX60B/61B

23

1

MASTER

SLAVE

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

System Description

Additional functions of the application variants

1.3 Additional functions of the application variants

1.3.1 Electronic cam

SEW-EURODRIVE offers additional functions for special applications. You can use

these additional functions with the MOVIDRIVE

The following additional functions are available:

• Electronic cam

• Internal synchronous operation

®

application variants (...-0T).

INFORMATION

Please refer to the "Electronic Cam" and "Internal Synchronous Operation" manuals for

detailed information about the additional functions.

®

You can use the MOVIDRIVE

ever you need to harmonize complex sequences of motion in cyclical machines. This

solution gives you much greater flexibility in comparison to the mechanical cam. As a

result, it meets the needs of modern production and processing lines.

A user-friendly cam editor supports you during startup. You also have the option of

importing existing cam data. You can also set application-specific parameters for the

engagement and disengagement phases using the cam editor.

product series with the "electronic cam" module when-

Note the following points:

®

• The "electronic cam" can only be implemented with the MOVIDRIVE

application version (...-0T).

• Encoder feedback is mandatory. This is why the "electronic cam" can only be

realized in "CFC", "SERVO" and "VFC-n control" operating modes with master/slave

connection via X14-X14 or with an SBus connection.

• "Electronic cam" is only available in parameter set 1.

• The "DRS11B synchronous operation card" option cannot be used together with the

"electronic cam" function.

MDX61B

24

System Manual – MOVIDRIVE® MDX60B/61B

System Description

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

Additional functions of the application variants

1

Motors and

encoders

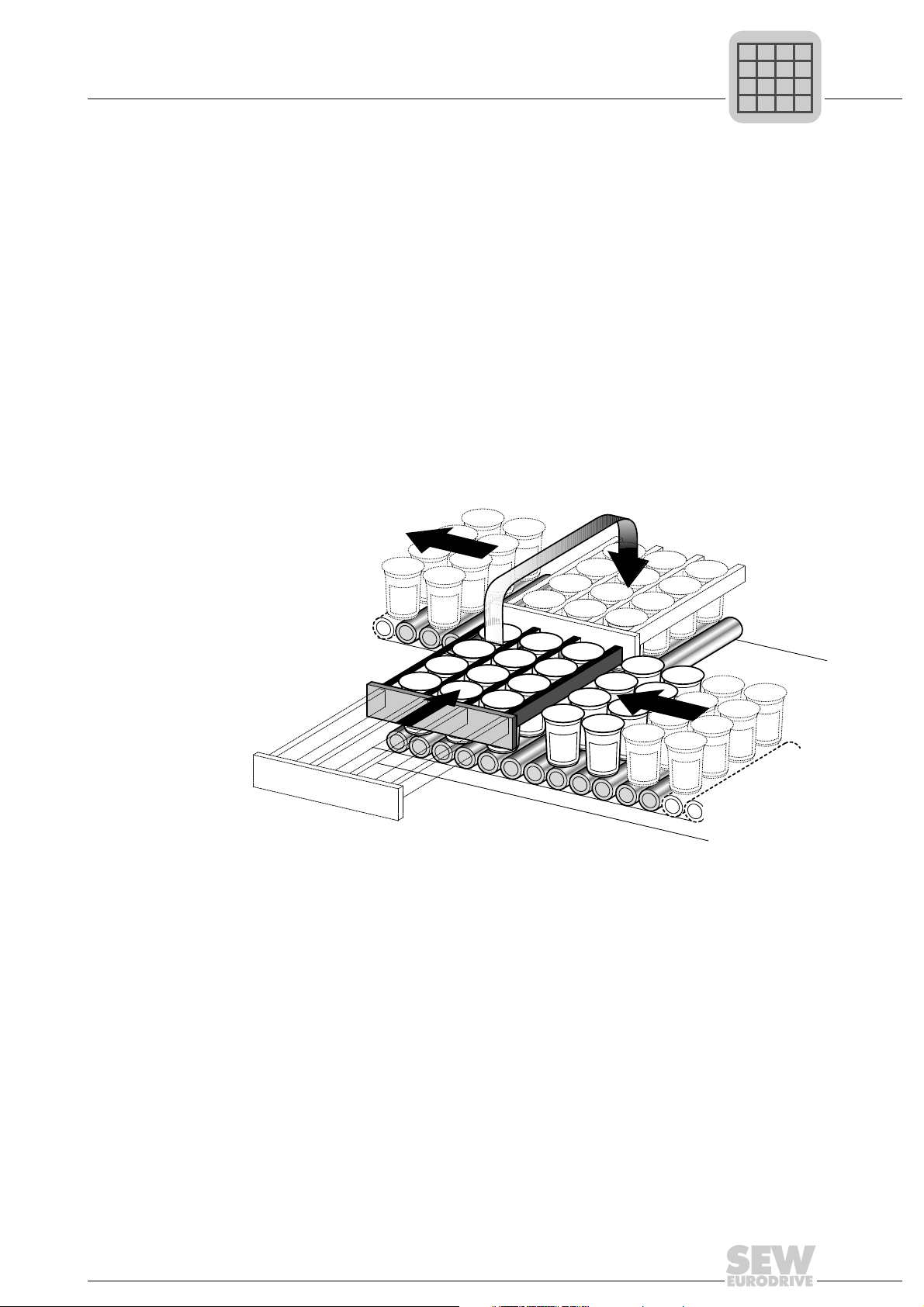

Example The figure below shows a typical application example for the "electronic cam." Filled

Use the following motor types:

®

• For operation with MOVIDRIVE

– CT/CV asynchronous servomotor, high-resolution sin/cos encoder installed as

standard or Hiperface

– DT/DV/D series AC motor with incremental encoder, preferably high-resolution

sin/cos encoder or Hiperface

– Synchronous servomotors DS/CM/CMD/CMP, resolver (installed as standard) or

Hiperface

High-resolution speed measurement is required for optimum operation of the electronic

cam. The encoders installed as standard on CT/CV and DS/CM/CMD/CMP motors fulfill

these requirements. SEW-EURODRIVE recommends using high-resolution sin/cos

encoders as incremental encoders if DR/DT/DV/D motors are used.

yogurt pots are transported for further processing. The "electronic cam" enables smooth

movement, which is an important requirement for this application.

®

encoder

®

MDX61B...-4-0T:

encoder.

®

encoder.

1453201035

System Manual – MOVIDRIVE® MDX60B/61B

25

1

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

1.3.2 Internal synchronous operation

Motors and

encoders

System Description

Additional functions of the application variants

You can use the MOVIDRIVE

ever a group of motors has to be operated at a synchronous angle in relation to one

another or with an adjustable proportional ratio (electronic gear). A user-friendly editor

guides you through the startup procedure.

Note the following points:

• "Internal synchronous operation" can only be implemented with MOVIDRIVE

MDX61B application versions (...-0T).

• Encoder feedback is mandatory. This is why "internal synchronization operation" can

only be realized in "CFC", "SERVO" and "VFC-n control" operating modes with

master/slave connection via X14-X14 or with an SBus connection.

• "Internal synchronous operation" is only available in parameter set 1.

• The "DRS11B synchronous operation card" option cannot be used together with

"internal synchronous operation".

Use the following motor types for operation with MOVIDRIVE

• CT/CV asynchronous servomotor, high-resolution sin/cos encoder installed as

standard or Hiperface

• DT/DV/D series AC motor with incremental encoder, preferably high-resolution sin/

cos encoder or Hiperface

• Synchronous servomotors DS/CM/CMD/CMP, resolver (installed as standard) or

Hiperface

®

encoder

®

unit series with "internal synchronous operation" when-

®

MDX61B...-4-0T:

®

encoder.

®

encoder.

®

High-resolution speed measurement is required for optimum "internal synchronous

operation". The encoders installed as standard on CT/CV and DS/CM/CMD/CMP

motors fulfill these requirements. SEW-EURODRIVE recommends using highresolution sin/cos encoders as incremental encoders if DR/DT/DV/D motors are used.

26

System Manual – MOVIDRIVE® MDX60B/61B

System Description

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

Additional functions of the application variants

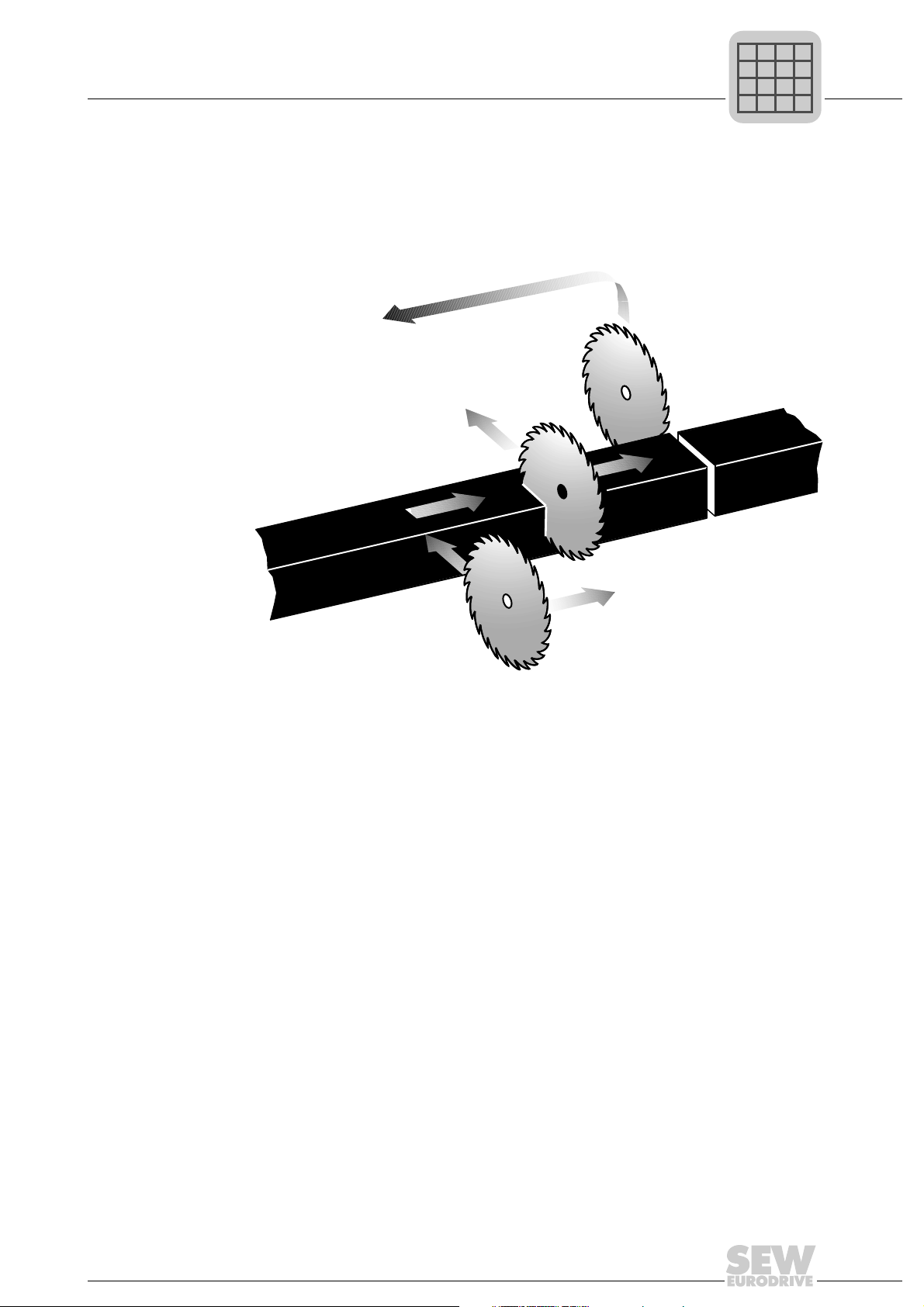

Example The figure below shows a typical application with "internal synchronous operation".

Extruder material must be cut to length. The saw receives a start signal and synchronizes with the material. During the sawing process, the saw moves synchronously with

the material. At the end of the sawing process the saw moves back to its starting

position.

1

41692939

System Manual – MOVIDRIVE® MDX60B/61B

27

1

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

System Description

Application modules for MOVIDRIVE® MDX61B

1.4 Application modules for MOVIDRIVE® MDX61B

1.4.1 The drive task

The drive task often involves more than just adjusting the speed of a motor. The inverter

often has to control motion sequences and take on typical PLC tasks. Increasingly

complex drive applications have to be solved, without this resulting in lengthy configuration and startup processes.

1.4.2 The solution with MOVIDRIVE

SEW-EURODRIVE offers various standardized control programs specifically for

"positioning," "winding," and "controlling" applications. These programs are called

application modules. The application modules are incorporated into MOVITOOLS

MotionStudio and can be used with the application variants.

A user-friendly operator interface guides you through the process of setting the

parameters. All you have to do is enter the parameters you need for your application.

The application module uses this information to create the control program and loads it

into the inverter. MOVIDRIVE

load is taken off the machine control and decentralized concepts are easier to implement.

The advantages at

a glance

• A wide range of functions

• A user-friendly GUI

• You only have to enter the parameters needed for the application

• Guided parameter setting process instead of complicated programming

• No programming experience required

• No lengthy training, therefore quick project planning and startup

• All movements are controlled directly in MOVIDRIVE

• Decentralized concepts can be implemented more easily

®

®

®

takes over complete control of the motion processes, the

®

1.4.3 Scope of delivery and documentation

®

The application modules are part of the MOVITOOLS

software and can be used with MOVIDRIVE

individual application manuals can also be downloaded as PDFs from the SEW website.

28

®

MDX61B application versions (...-0T). The

System Manual – MOVIDRIVE® MDX60B/61B

MotionStudio engineering

System Description

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

Application modules for MOVIDRIVE® MDX61B

1.4.4 Available application modules

The application modules currently available are listed below. These application modules

are explained on the following pages.

Positioning Linear movement; the inverter manages the movement records:

• Table positioning via terminal or fieldbus

Linear movement; the PLC manages the movement records:

• Bus positioning

• Extended positioning via bus

• Absolute positioning (rapid/creep speed positioning)

Rotary movement:

• Module positioning via terminals: The inverter manages the movement records

• Module positioning via fieldbus: The PLC manages the movement records

Winding • Center winder

1

Control • Flying saw

• DriveSync via fieldbus

• Sensor-based positioning

System Manual – MOVIDRIVE® MDX60B/61B

29

1

1.

2.

3.

P

i

f

kVA

Hz

n

P

i

f

kVA

Hz

n

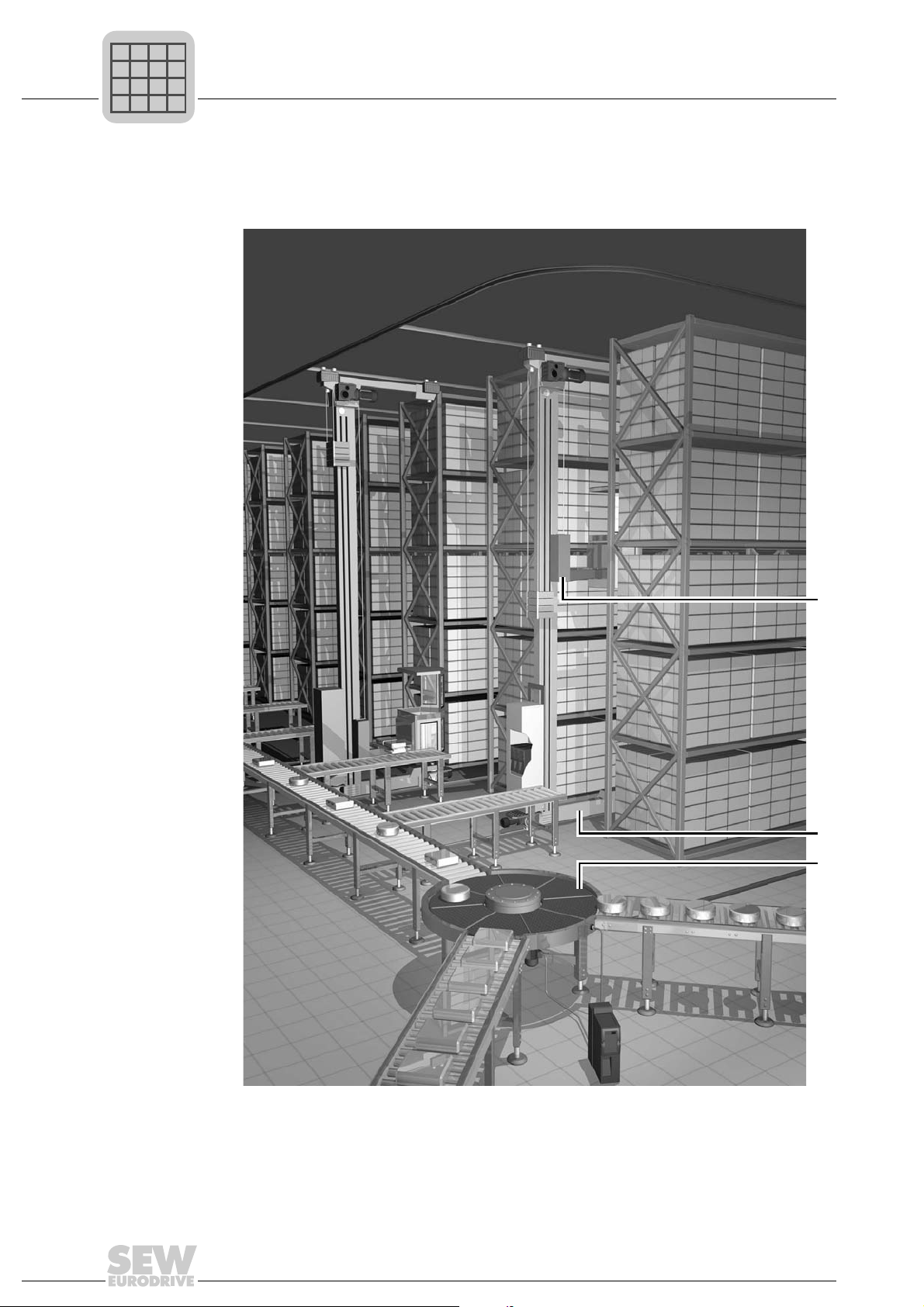

1.4.5 Application

System Description

Application modules for MOVIDRIVE® MDX61B

The following figure shows an example of how the various SEW application modules are

used in a block warehouse.

1. Hoist: Table positioning

2. Travel axis: Absolute or bus positioning

3. Rotary distributor: Modulo positioning

30

System Manual – MOVIDRIVE® MDX60B/61B

1453256971

Loading...

Loading...