Drive Technology \ Drive Automation \ System Integration \ Services

Operating Instructions

Electronic Motor

DRC.-...-SNI

Single Line Network Installation

Edition 02/2012 19376413 / EN

SEW-EURODRIVE—Driving the world

Contents

Contents

1 General Information ............................................................................................ 6

1.1 Use of this documentation .......................................................................... 6

1.2 Structure of the safety notes ....................................................................... 6

1.3 Rights to claim under limited warranty ........................................................ 7

1.4 Exclusion of liability..................................................................................... 7

1.5 Copyright..................................................................................................... 7

1.6 Product names and trademarks.................................................................. 7

2 Safety Notes ........................................................................................................ 8

2.1 General Information .................................................................................... 8

2.2 Target group ............................................................................................... 8

2.3 Designated use ........................................................................................... 9

2.4 Other applicable documentation ............................................................... 9

2.5 Transportation, storage ............................................................................. 9

2.6 Installation................................................................................................. 10

2.7 Electrical connection ................................................................................. 10

2.8 Safe disconnection.................................................................................... 10

2.9 Operation .............................................................................................. 11

3 Unit Structure .................................................................................................... 12

3.1 DRC drive unit ...................................................................................... 12

3.2 Cable entry positions .............................................................................. 13

3.3 Example nameplate and type designation of drive units ........................ 14

3.4 Electronics ............................................................................................ 15

3.5 Application options .............................................................................. 17

3.6 Example nameplate and type designation of electronics ...................... 19

3.7 DRC drive units in ASEPTIC / ASEPTIC

4 Mechanical Installation..................................................................................... 23

4.1 Installation notes ................................................................................... 23

4.2 Required tools and resources ................................................................... 23

4.3 Installation requirements........................................................................... 24

4.4 Setting up the drive unit ............................................................................ 25

4.5 Application options .............................................................................. 28

4.6 Tightening torques ............................................................................... 30

4.7 Drive units with optional ASEPTIC / ASEPTIC

5 Electrical Installation ........................................................................................ 39

5.1 Installation planning considering EMC aspects .................................... 39

5.2 Installation instructions.............................................................................. 41

5.3 Installation topology (example) ............................................................. 47

5.4 Terminal assignment .............................................................................. 48

5.5 Connecting DRC drive units ................................................................... 50

5.6 Cable routing and shielding .................................................................... 51

5.7 EMC cable glands ................................................................................. 55

5.8 Prescribed power leads ....................................................................... 56

5.9 Plug connectors .................................................................................... 57

plus

design ............................. 21

plus

design ...................... 33

Operating Instructions – Electronic Motor DRC.-..-SNI

3

Contents

5.10 Assignment of optional plug connectors ............................................... 62

5.11 Application options .............................................................................. 71

6 Startup................................................................................................................ 73

6.1 Startup notes ......................................................................................... 73

6.2 Lifting applications .................................................................................. 74

6.3 Prerequisties for startup ........................................................................ 74

6.4 Description of DIP switches .................................................................. 75

6.5 Startup procedure ................................................................................ 77

6.6 Starting up the GIO13B application option .......................................... 79

7 Operation of MOVITOOLS

7.1 About MOVITOOLS

7.2 First steps ................................................................................................ 83

7.3 Connection mode...................................................................................... 85

7.4 Executing functions of the units ................................................................ 87

8 Parameters ..................................................................................................... 89

8.1 Overview of parameters of the command PCB ....................................... 89

8.2 Overview of parameters for application options ..................................... 91

8.3 Overview of power section parameters ................................................... 93

8.4 Description of command PCB parameters.............................................. 106

8.5 Description of application option parameters ........................................ 109

8.6 Description of power section parameters................................................ 113

®

MotionStudio .................................................. 82

®

MotionStudio .......................................................... 82

9 Operation ..................................................................................................... 140

9.1 Local mode (only in conjunction with optional plug connector) ............. 140

9.2 Releasing the brake without drive enable signal ................................. 141

10 Service ............................................................................................................. 143

10.1 Malfunctions of the mechanical DRC drive ........................................... 143

10.2 Evaluating error messages ................................................................. 144

10.3 Switch-off responses ............................................................................. 145

10.4 Reset of error messages .................................................................. 145

10.5 Description of status and operating displays ...................................... 146

10.6 Error table ........................................................................................... 149

10.7 Unit replacement ................................................................................. 152

10.8 SEW-EURODRIVE Service ................................................................... 153

10.9 Shutdown ............................................................................................ 154

10.10 Storage ................................................................................................... 154

10.11 Extended storage .................................................................................... 154

10.12 Disposal ............................................................................................... 155

11 Inspection and Maintenance .......................................................................... 156

11.1 Determining the operating hours ......................................................... 156

11.2 Inspection and maintenance intervals ................................................... 157

11.3 Inspection and maintenance work .......................................................... 158

4

Operating Instructions – Electronic Motor DRC.-..-SNI

Contents

12 Technical Data and Dimension Sheets ......................................................... 160

12.1 Technical data ..................................................................................... 160

12.2 Technical data of application options ................................................ 163

12.3 Braking resistors ................................................................................... 165

12.4 Technical data of the brake ................................................................... 177

12.5 ASEPTIC / ASEPTIC

12.6 Surface protection ................................................................................. 179

12.7 Screw fittings........................................................................................... 181

12.8 Connection cables .......................................................................... 182

12.9 Dimension drawings ........................................................................... 184

13 EC Declaration of Conformity ...................................................................... 188

14 Address List .................................................................................................... 189

Index................................................................................................................. 200

plus

variants ......................................................... 178

Operating Instructions – Electronic Motor DRC.-..-SNI

5

1

General Information

Use of this documentation

1 General Information

Electronic Motor DRC.-..-SNI

1.1 Use of this documentation

The documentation is an integral part of the product and contains important information

on operation and service. The documentation is written for all employees who assemble,

install, start up, and service this product.

The documentation must be accessible and legible. Make sure that persons responsible

for the system and its operation, as well as persons who work independently on the unit,

have read through the documentation carefully and understood it. If you are unclear

about any of the information in this documentation, or if you require further information,

contact SEW-EURODRIVE.

1.2 Structure of the safety notes

1.2.1 Meaning of the signal words

The following table shows the grading and meaning of the signal words for safety notes,

notes on potential risks of damage to property, and other notes.

Signal word Meaning Consequences if disregarded

DANGER Imminent danger Severe or fatal injuries

WARNING Possible dangerous situation Severe or fatal injuries

CAUTION Possible dangerous situation Minor injuries

NOTICE Possible damage to property Damage to the drive system or its

INFORMATION Useful information or tip:

Simplifies the handling of the

drive system.

environment

1.2.2 Structure of the section-related safety notes

Section-related safety notes do not apply to a specific action, but to several actions

pertaining to one subject. The used symbols indicate either a general or a specific

hazard.

This is the formal structure of a section-related safety note:

SIGNAL WORD

Type and source of danger.

Possible consequence(s) if disregarded.

• Measure(s) to prevent the danger.

1.2.3 Structure of the embedded safety notes

Embedded safety notes are directly integrated in the instructions just before the description of the dangerous action.

This is the formal structure of an embedded safety note:

• SIGNAL WORD Nature and source of hazard.

Possible consequence(s) if disregarded.

– Measure(s) to prevent the danger.

6

Operating Instructions – Electronic Motor DRC.-..-SNI

Rights to claim under limited warranty

1.3 Rights to claim under limited warranty

A requirement of fault-free operation and fulfillment of any rights to claim under limited

warranty is that you adhere to the information in the documentation. Read the documentation before you start working with the unit!

1.4 Exclusion of liability

You must comply with the information contained in this documentation to ensure safe

operation and to achieve the specified product characteristics and performance

features. SEW-EURODRIVE assumes no liability for injury to persons or damage to

equipment or property resulting from non-observance of these operating instructions. In

such cases, any liability for defects is excluded.

1.5 Copyright

© 2012 – SEW-EURODRIVE. All rights reserved.

Unauthorized duplication, modification, distribution or any other use of the whole or any

part of this documentation is strictly prohibited.

General Information

1

1.6 Product names and trademarks

All brands and product names in this documentation are trademarks or registered trademarks of their respective titleholders.

Operating Instructions – Electronic Motor DRC.-..-SNI

7

2

Safety Notes

General Information

2 Safety Notes

2.1 General Information

The following basic safety notes must be read carefully to prevent injury to persons and

damage to property. The operator must ensure that the basic safety notes are read and

adhered to. Ensure that persons responsible for the system and its operation, as well as

persons who work independently on the unit, have read through the operating

instructions carefully and understood them. If you are unclear about any of the information in this documentation, or if you require further information, please contact SEWEURODRIVE.

Never install damaged products or take them into operation. Submit a complaint to the

shipping company immediately in the event of damage.

During operation, DRC drive units can have live, bare and movable or rotating parts as

well as hot surfaces, depending on their degree of protection.

Removing covers without authorization, improper use as well as incorrect installation or

operation may result in severe injuries to persons or damage to property.

Refer to the documentation for additional information.

2.2 Target group

Only qualified electricians are authorized to install, start up or service the units or

correct unit faults (observing IEC 60364 or CENELEC HD 384 or DIN VDE 0100 and

IEC 60664 or DIN VDE 0110 as well as national accident prevention guidelines).

Qualified electricians in the context of these basic safety notes are all persons familiar

with installation, assembly, startup and operation of the product who possess the

necessary qualifications.

All persons involved in any other work, such as transportation, storage, operation and

disposal, must be trained appropriately.

8

Operating Instructions – Electronic Motor DRC.-..-SNI

2.3 Designated use

DRC drive units are components intended for installation in electrical systems or machines.

In case of installation in machines, taking the DRC drive units into operation (i.e. start of

designated operation) is prohibited until it is determined that the machine meets the requirements stipulated in EC Directive 2006/42/EC (Machinery Directive).

Startup (i.e. the start of designated use) is only permitted under observance of EMC

directive 2004/108/EC (EMC Directive).

DRC drive units comply with the regulations of the Low Voltage Directive 2006/95/EC.

The standards given in the declaration of conformity are applied to the DRC drive units.

You must observe the technical data and information on the connection requirements

as provided on the nameplate and in the documentation.

2.3.1 Safety functions

DRC drive units may not

and expressly permitted.

Safety Notes

Designated use

perform safety functions unless these functions are described

2

2.3.2 Lifting applications

DRC drive units are not designed for use as safety devices in lifting applications.

2.4 Other applicable documentation

Note also the following documentation:

• "DRC Gearmotors" catalog

• Operating instructions for the gear unit (only for DRC gearmotors)

You can download or order these publications on the Internet (http://www.sew-

eurodrive.com under the heading "Documentation").

2.5 Transportation, storage

You must observe the notes on transportation, storage and proper handling. Comply

with the requirements for climatic conditions stated in chapter "Technical Data". Tighten

installed eyebolts securely. They are designed for the weight of the DRC drive unit. Do

not attach any additional loads. Use suitable, sufficiently rated handling equipment (e.g.

rope guides) if required.

Operating Instructions – Electronic Motor DRC.-..-SNI

9

2

Safety Notes

Installation

2.6 Installation

2.7 Electrical connection

The units must be installed and cooled according to the regulations and specifications

in the corresponding documentation.

Protect the DRC drive units from improper strain.

The following applications are prohibited unless explicitly permitted:

• Use in potentially explosive atmospheres.

• Use in areas exposed to harmful oils, acids, gases, vapors, dust, radiation, etc.

• Use in non-stationary applications that are subject to mechanical vibration and shock

loads as stated in the documentation for DRC drive units.

Important: DRC drive units and corresponding mount-on parts must not protrude into

footways.

Working on live parts of DRC drive units is not permitted.

The drive is operated as a generator due to the kinetic energy of the system/machine.

Secure the output shaft against rotation before opening the wiring compartment.

Electrical installation must be carried out in compliance with pertinent regulations (e.g.

cable cross sections, fusing, protective conductor connection). For any additional information, refer to the applicable documentation.

You find notes on EMC-compliant installation, such as shielding, grounding, arrangement of filters and routing of lines, in the documentation of the DRC drive units. The

manufacturer of the system or machine is responsible for maintaining the limits established by EMC legislation.

Protective measures and protection devices must comply with the regulations in force

(e.g. EN 60204-1 or EN 61800-5-1).

2.8 Safe disconnection

DRC drive units meet all requirements for safe disconnection of power and electronics

connections in accordance with EN 61800-5-1. All connected circuits must also satisfy

the requirements for safe disconnection to ensure reliable isolation.

10

Operating Instructions – Electronic Motor DRC.-..-SNI

2.9 Operation

Safety Notes

Operation

Systems with integrated DRC drive units must be equipped with additional monitoring

and protection devices according to the applicable safety guidelines, such as the law

governing technical equipment, accident prevention regulations, etc. Additional protective measures may be necessary for applications with increased potential risk. Changes

to DRC drive units using the operating software are permitted.

Do not touch live components and power connections immediately after separation of

the DRC drive units from the supply voltage because some capacitors might still be

charged. Wait at least for 10 minutes after the supply voltage has been switched off.

The connection boxes must be closed and screwed on before the supply voltages are

connected to DRC drive units.

The unit may still be live and connected to the power supply even if the operation LEDs

and other display elements are no longer illuminated.

Mechanical blocking or internal safety functions of the unit can cause a motor standstill.

Eliminating the cause of the problem or performing a reset may result in the drive restarting automatically. If, for safety reasons, this is not permitted for the driven machine,

disconnect the unit from the supply system before correcting the error.

Caution: Danger of burns: The surface temperatures of DRC drive units can be more

than 60 °C during operation.

2

Operating Instructions – Electronic Motor DRC.-..-SNI

11

3

3 Unit Structure

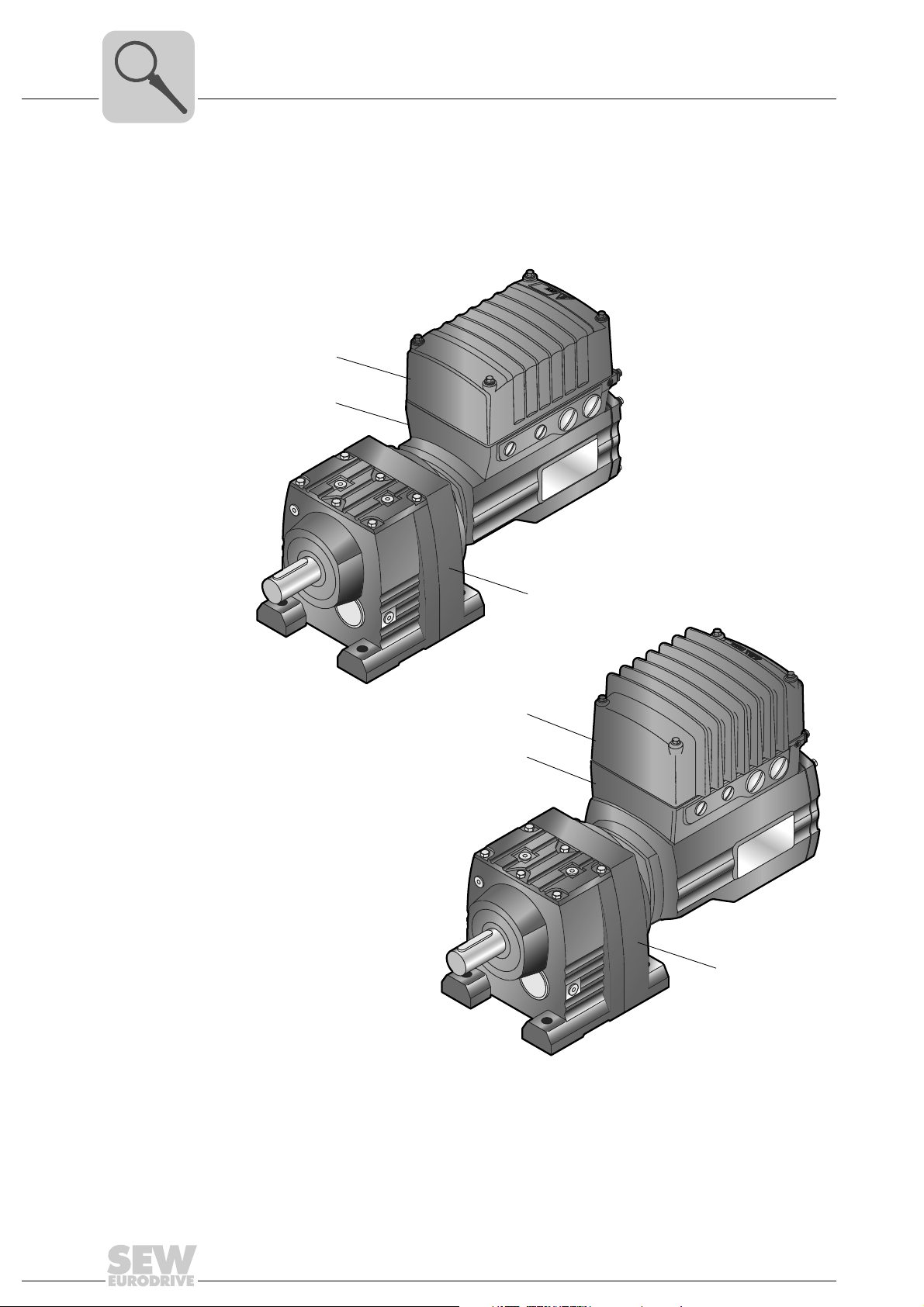

3.1 DRC drive unit

Unit Structure

DRC drive unit

The following figure depicts drive units consisting of DRC1/DRC2 electronic motor and

R gear unit:

R..DRC1-...

[1]

[2]

[3]

[1]

[2]

R..DRC2-...

[3]

12

9007203299592075

[1] Electronics cover

[2] DRC electronic motor with connection unit

[3] Gear unit (in the figure: R gear unit)

Operating Instructions – Electronic Motor DRC.-..-SNI

3.2 Cable entry positions

RUN

NET

DRIVE

3

X

2

The DRC electronic motor generally comes equipped with the following cable entries1):

• Position X + 2 + 3

– X: 2 x M25 x 1.5 + 2 x M16 x 1.5

– 2: 2 x M25 x 1.5 + 2 x M16 x 1.5

– 3: 2 x M25 x 1.5 + 2 x M16 x 1.5

Unit Structure

Cable entry positions

3

9007203301611787

1) 1 x M16 x 1.5 reserved for pressure compensation fitting (only in conjunction with ASEPTIC/ASEPTIC

variants as well as brakemotors operated at ambient temperatures of < 20 °C)

Operating Instructions – Electronic Motor DRC.-..-SNI

plus

13

3

[1]

[2]

76646 Bruchsal/Germany

kg AMB 1845 494 1.50°C

M

A

M

BR

Ma

pk

Nm

IM

Nm

Nm

i

kW

Iso.Kl. M.L. Hz 50-60 V A

nR

r/min IP

eff%

26.000

85...0.04

TENV

87,1 IE4

1.04

156

-20...40 Made in Germany

M1CLP 220 Miner.Öl/0.65 l

1/2000

23.59 62

155

0.55 S1

(F)

380...500

65

3~IEC61800

RF47 DRC1-005-SNI-A-ECR/IV

01.1751709009.0001.11

Inverter duty VPWM

Unit Structure

Example nameplate and type designation of drive units

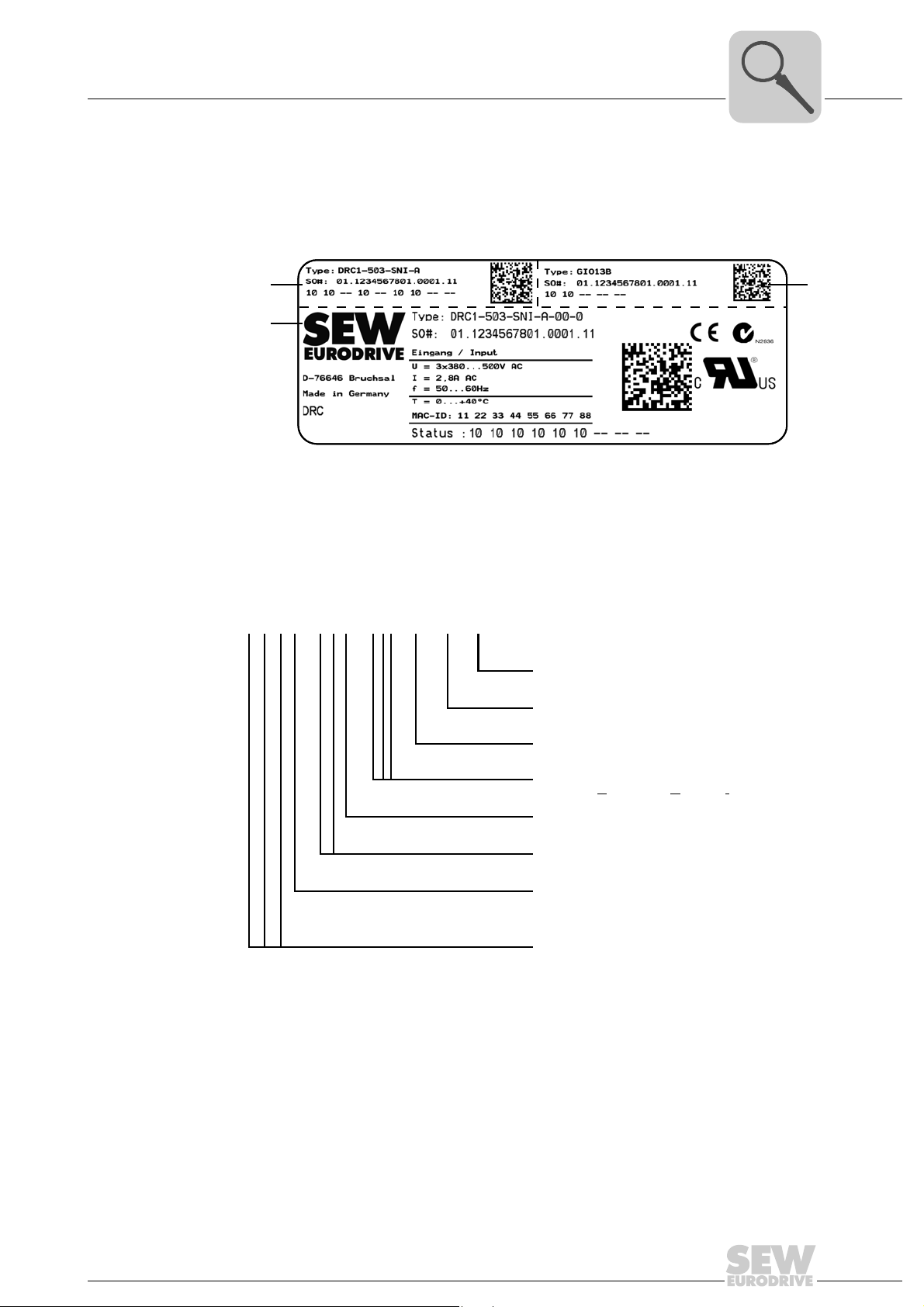

3.3 Example nameplate and type designation of drive units

3.3.1 Nameplate

The following figure gives an example of a DRC nameplate. For the structure of the type

designation, refer to chapter "Type designation".

[1] Unique serial number

[2] The bar code on the nameplate (code 39) according to ISO/IEC 16388 represents the unique

serial number (with a period as separator).

4762054411

3.3.2 Type designation

The following table shows the type designation of the DRC drive unit:

RF 47 DRC 1 - 005 - SNI - A - ECR / IV

DRC option

IV = Plug connector

BY1C = Brake DRC1

BY2C = Brake DRC2

BW1 = Integrated braking resistor DRC1

BW2 = Integrated braking resistor DRC2

Extended control range (standard)

Version

DRC installation technology

SNI = S

ingle Line Network Installation

Power rating

005 = 0.55 kW

015 = 1.5 kW

Electronic motor size

1 = DRC1

2 = DRC2

14

Product line

DRC = Electronic motor

Gear unit size

Gear unit series

Operating Instructions – Electronic Motor DRC.-..-SNI

3.4 Electronics

[2][1]

[7]

[6]

[7] [7][7]

[6]

[8]

[10][9]

[11]

[12]

[3] [4] [5]

[1]

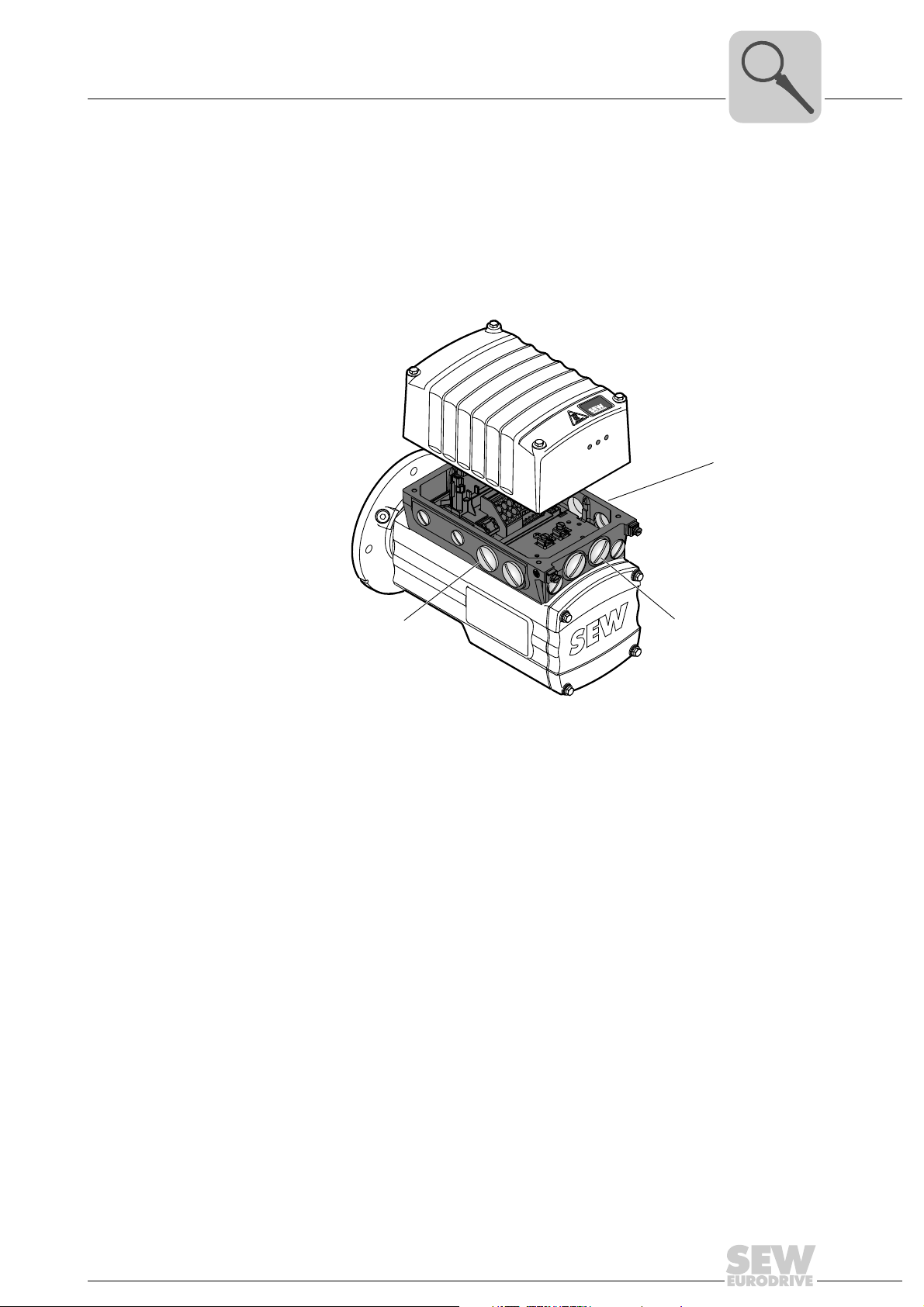

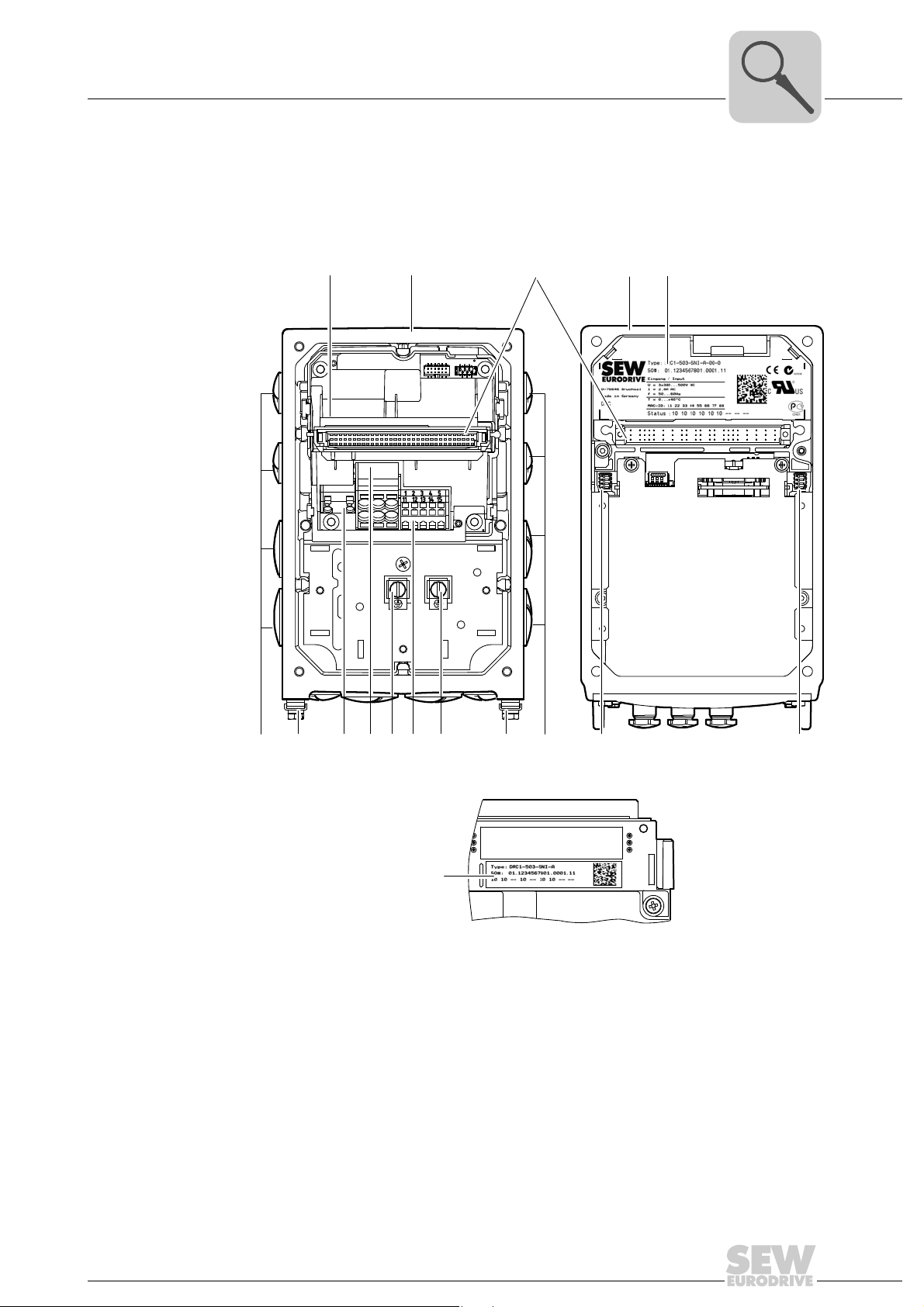

3.4.1 DRC electronics cover (inside) and connection box

The following figure shows the connection box and the bottom side of the DRC electronics cover:

Unit Structure

Electronics

3

4762915211

[1] Nameplate of drive unit, see following detailed view

[2] Connection box

[3] Plug connector connection unit for DRC electronics cover

[4] DRC electronics cover

[5] Electronics cover nameplate

[6] Cable glands

[7] Screws for PE connection

[8] Braking resistor connection

[9] Line connection L1, L2, L3

[10] Electronics terminal strips

[11] DIP switches S2/1 – S2/4

[12] DIP switches S1/1 – S1/4

4853331979

Operating Instructions – Electronic Motor DRC.-..-SNI

15

3

NET

RUN

DRIVE

NET

RUN

DRIVE

[1]

[1] [2] [3] [4]

AB

Unit Structure

Electronics

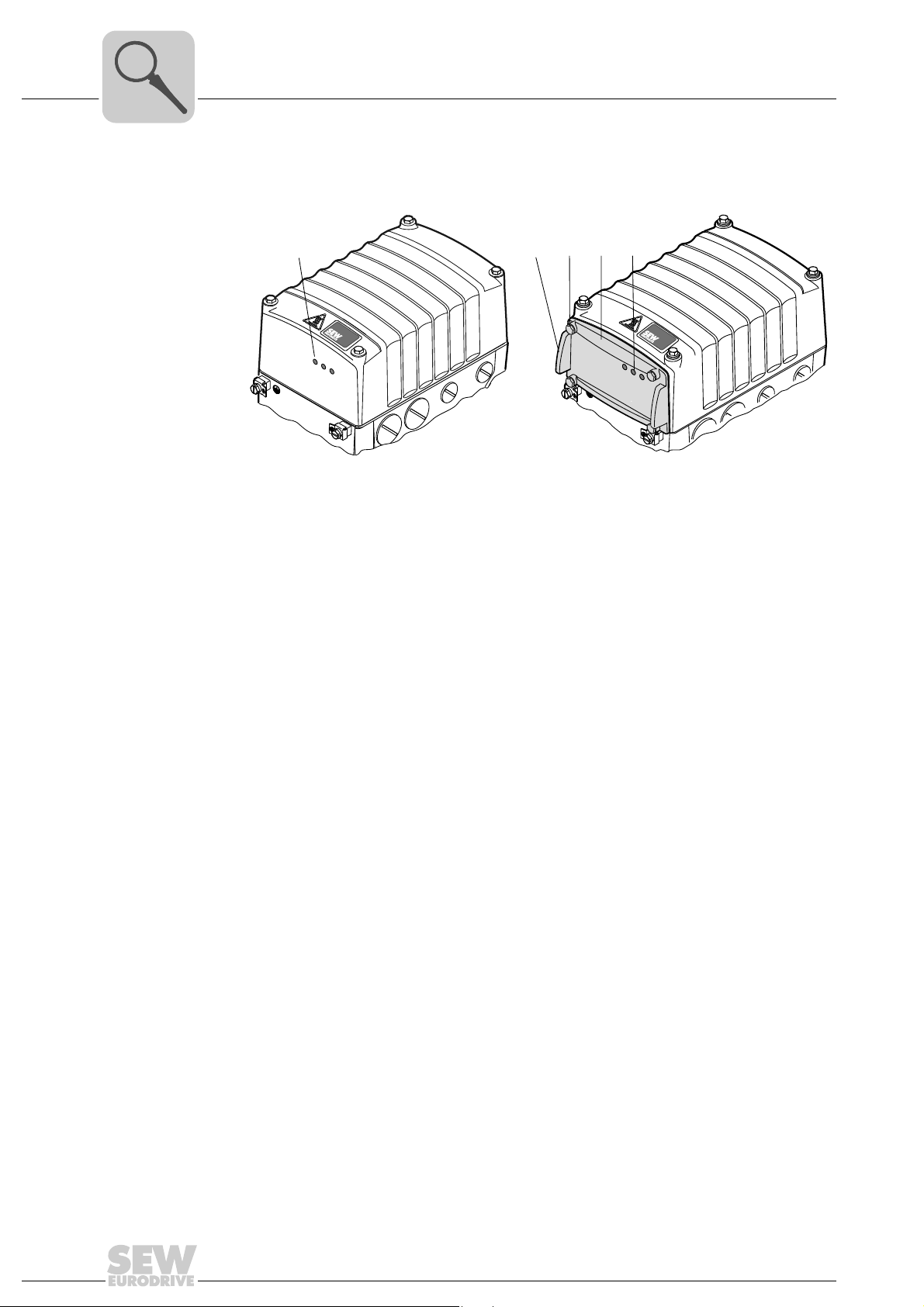

3.4.2 Electronics cover (outside)

The following figure shows possible types of the electronics cover:

A Electronics cover without application slot B Electronics cover with application slot

9007201622689931

[1] LED displays [1] Assembly/disassembly handle

[2] Retaining screws (4x)

[3] Application cover

[4] LED displays

16

Operating Instructions – Electronic Motor DRC.-..-SNI

3.5 Application options

[1] [2] [3]

NET

RUN

DRIVE

X4

X3

X2

X1

[1]

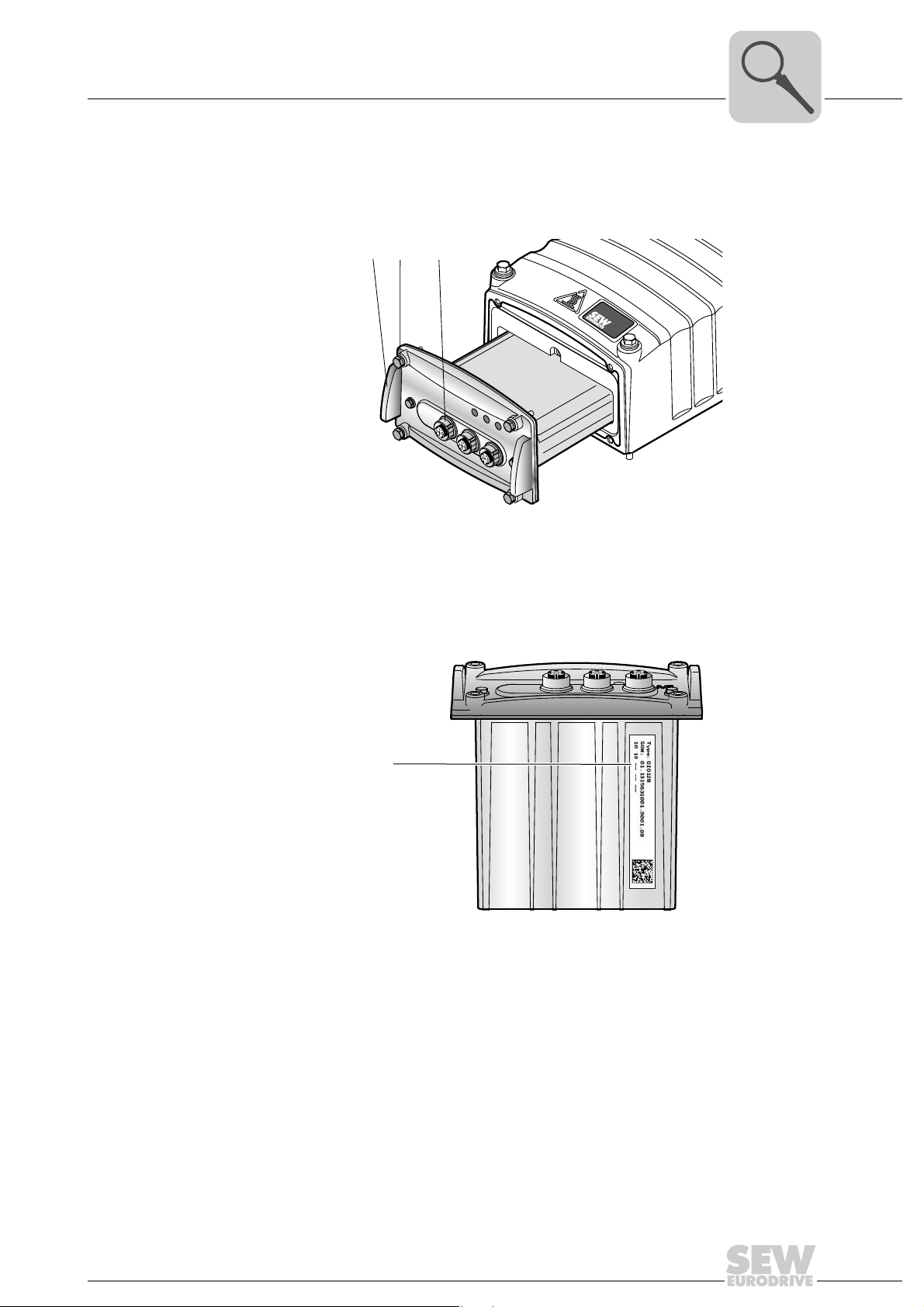

3.5.1 GIO12B application option

The following figure shows the GIO12B application option:

Unit Structure

Application options

3

[1] Assembly/disassembly handle

[2] Retaining screws (4x)

[3] M12 plug connector for digital I/Os

The following figure shows the position of the GIO12B nameplate:

[1] Nameplate

9007201622841227

18014401210968331

Operating Instructions – Electronic Motor DRC.-..-SNI

17

3

NET

RUN

DRIVE

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

S1

S2

S3

ON

1234

[1]

Unit Structure

Application options

3.5.2 GIO13B application option

The following figure shows the GIO13B application option:

[1] [2] [3]

X4

X3

X2

X1

9007201839769867

[1] Assembly/disassembly handle

[2] Retaining screws (4x)

[3] M12 plug connector for digital/analog I/Os

The following figure shows the DIP switches S1 to S3 of the GIO13B application option:

18014401245670283

[1] Nameplate

18

Operating Instructions – Electronic Motor DRC.-..-SNI

Unit Structure

[1]

[3]

[2][1]

[3]

[2]

Example nameplate and type designation of electronics

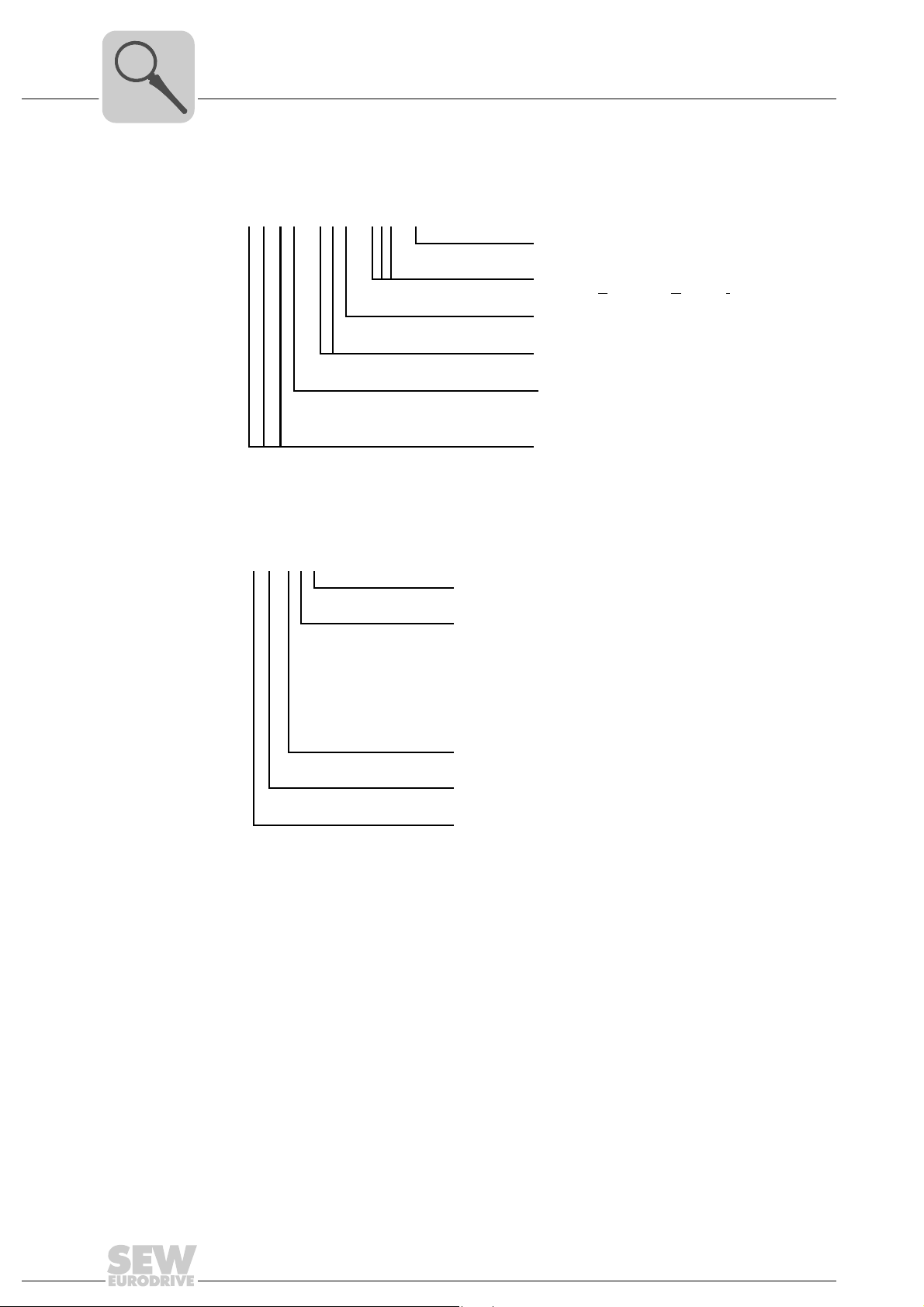

3.6 Example nameplate and type designation of electronics

3.6.1 Nameplate

The following figure gives an example of a DRC nameplate. For the structure of the type

designation, refer to chapter "Type designation".

[1] Nameplate of connection unit

[2] Nameplate of application option

[3] Nameplate of electronics cover

3

4766392075

3.6.2 Type designation electronics cover

The following table shows the type designation of the electronics cover:

D R C 1–5 0 3–SNI–A – 00 – A

Electronics cover variant

0 = Without application slot

A = With application slot

Variant

00 = Standard

DRC version

DRC installation technology

SNI = S

Connection type

3 = 3-phase (AC)

Supply voltage

50 = AC 380 – 500 V

Size

1

2

Product line

DRC = Electronic motor

ingle Line Network Installation

==DRC 1

DRC 2

Operating Instructions – Electronic Motor DRC.-..-SNI

19

3

Unit Structure

Example nameplate and type designation of electronics

3.6.3 Type designation of connection unit

The following table shows the type designation of the connection unit:

D R C 1–5 0 3–SNI–A

3.6.4 Type designation of application options

The following table shows the type designation for the available application options:

DRC version

DRC installation technology

SNI = Single Line Network Installation

Connection type

3 = 3-phase (AC)

Supply voltage

50 = AC 380 – 500 V

Size

1

==DRC 1

2

Product line

DRC = Electronic motor

DRC 2

G IO 1 2 B

Version

Variant

2 = 4 digital inputs + 2 digital outputs

3 = 4 digital inputs

(2 inputs can be used as primary frequency input)

+ 1 digital output

+ 1 analog input

+ 1 analog output

Version

Functionality

IO = Digital inputs/outputs

Product line

G = Option for MOVIGEAR

®

/ DRC

20

Operating Instructions – Electronic Motor DRC.-..-SNI

Unit Structure

MOVIGEAR

®

B

SNI

A

B

[B 2]

[B 1]

Y

X

X

Y

[A3]

[A3]

[A2]

[A1]

[A7]

[A6]

[A5]

DRC drive units in ASEPTIC / ASEPTICplus design

3

3.7 DRC drive units in ASEPTIC / ASEPTIC

NOTICE

Loss of degree of protection IP66 and incompatibility with cleaning agents.

Possible damage to property.

• To achieve degree of protection IP66 and compatibility with cleaning agents, you

have to replace the plastic screw plugs delivered as standard by suitable screw

fittings made of stainless steel.

The following picture shows the additional characteristics of DRC drive units in

ASEPTIC / ASEPTIC

plus

design:

plus

design

DRC

NET

RUN

DRIVE

All illustrations with ASEPTIC / ASEPTIC

tion) in this publication

plus

design are displayed with a shading (= HP200 surface protec-

4766218123

Operating Instructions – Electronic Motor DRC.-..-SNI

21

3

Unit Structure

DRC drive units in ASEPTIC / ASEPTICplus design

A Scope of delivery

[A1] Mounting screws for cover made of stainless steel

[A2] Surface protection OS2 to OS4 for ASEPTIC design / OS4 for ASEPTIC

plus

design, see chapter

"Technical data and dimension sheets"

[A3] The delivered plastic screw plugs must be replaced by suitable screw plugs made of stainless

steel.

[A5] Pre-installed pressure compensation fitting (M16) with mounting positions M5, M6

[A6] Pre-installed pressure compensation fitting (M16) with mounting position M1, M2, M4, M4

Optional plug connectors (see chapter "Electrical installation") are available in connection with the

ASEPTIC / ASEPTIC

plus

version.

[A7] Features of gear units in ASEPTIC design

– Surface protection finish OS2 to OS4

Features of gear units in ASEPTIC

plus

design

– Available for gear units with solid shaft, hollow shaft with key or TorqLOC for the following gear

unit sizes: R27-87, F27-87, K37-87 and W37

– Gear unit output shaft including all retaining parts on the output shaft, such as screws, keys,

shrink disk, etc., are made of stainless steel

– If technically possible, the oil seals on the output are configured as double oil seals made from

FKM (Viton

®

)

– The breather valve of the gear units is made from stainless steel

– Surface protection finish OS4 for compatibility with common cleaning agents and disinfectants

– All surface recesses sprayed with elastic rubber compound

– All gear unit options can be selected

– All mounting positions M1 to M6 are available

B Required screw fittings

[B1] Screw plugs made of stainless steel

[B2] Cable glands made of stainless steel

1)

1)

The required screw fittings can be ordered from SEW-EURODRIVE. For an overview, refer to chapter

"Technical Data / Optional metal screw fittings".

1) Make sure to select plug seals that are compatible with the cleaning agents used

22

Operating Instructions – Electronic Motor DRC.-..-SNI

4 Mechanical Installation

4.1 Installation notes

INFORMATION

Adhere to the safety notes during installation.

WARNING

Improper installation/disassembly of DRC drive units and mount-on components.

Risk of injury.

• Adhere to the notes about installation and disassembly.

• Before releasing shaft connections, make sure that there are no active torsional

moments present (tensions within the system).

WARNING

Risk of injury if the drive starts up unintentionally and danger of electrical voltage.

Mechanical Installation

Installation notes

4

Dangerous voltages may still be present for up to 10 minutes after disconnection from

the power supply.

Severe or fatal injuries.

• Disconnect the DRC drive unit from the power supply before you start working on

the unit and secure it against unintentional reconnection to the power supply.

• Secure the output shaft against rotation.

• Wait for at least 10 minutes before removing the electronics cover.

4.2 Required tools and resources

• Set of wrenches

• Torque wrench

• Mounting device

• Compensation elements (shims and spacing rings), if necessary

• Mounting materials for output components

• Lubricant (e.g. NOCO

• Standard parts are not included in the delivery

4.2.1 Installation tolerances for shaft ends

The following table shows the permitted tolerances of shaft ends and flanges of the

DRC motor.

®

Fluid)

Shaft end Flanges

Diameter tolerance according to EN 50347

• ISO j6 with Ø ≤ 26 mm

• Center bore in accordance with DIN 332,

shape DR..

Operating Instructions – Electronic Motor DRC.-..-SNI

Centering shoulder tolerance in accordance

with EN 50347

• ISO j6 with Ø ≤ 250 mm

23

4

Mechanical Installation

Installation requirements

4.3 Installation requirements

Check that the following conditions have been met:

• The entries on the nameplate of the DRC unit match the voltage supply system.

• The drive is undamaged (no damage caused by transportation or storage)

• Ambient temperature according to the operating instructions, nameplate and

lubricant table in chapter "Technical data and dimension sheets / Lubricants".

• The drive must not be assembled in the following ambient conditions:

– Potentially-explosive atmosphere

– Oils

–Acids

– Gases

– Vapors

– Radiation

• For special designs: The drive is designed in accordance with the actual ambient

conditions.

• You must clean the output shafts and flange surfaces thoroughly to ensure they are

free of anti-corrosion agents, contamination or similar. Use a commercially available

solvent. Do not expose the sealing lips of the oil seals to the solvent – damage to the

material.

• When the drive is installed in abrasive ambient conditions, protect the output end oil

seals against wear.

24

Operating Instructions – Electronic Motor DRC.-..-SNI

4.4 Setting up the drive unit

4.4.1 Notes

• Only install the DRC drive unit on a level, low-vibration, and torsionally rigid support

structure.

• Observe the mounting position specified on the motor nameplate.

• Thoroughly remove any anti-corrosion agent from the shaft end. Use a commercially

available solvent. Do not allow the solvent to penetrate the bearings and shaft seals

– this could damage the material.

• Align the motor carefully to avoid placing any unacceptable strain on the motor

shafts. Observe the permitted overhung and axial loads specified in the "DRC Gearmotors" catalog.

• Do not jolt or hammer the shaft end.

• Ensure that cooling air supply is unobstructed and that air discharged by other units

does not influence cooling.

• Balance components that were subsequently mounted to the shaft with a half key

(output shafts are balanced with a half key).

• Use suitable cable glands for the supply leads (use reducing adapters if necessary).

• Seal the cable entry properly.

Mechanical Installation

Setting up the drive unit

4

• Thoroughly clean the sealing surfaces of the DRC cover before re-assembly.

• If the corrosion protection coating is damaged, restore the coating.

• Check whether the degree of protection specified in the operating instructions and

on the nameplate is permitted in the ambient conditions on site.

Operating Instructions – Electronic Motor DRC.-..-SNI

25

4

NET RUN DRIVE

MOVIGEAR

®

B

SNI

NET RUN DRIVE

MOVIGEAR

®

B

SNI

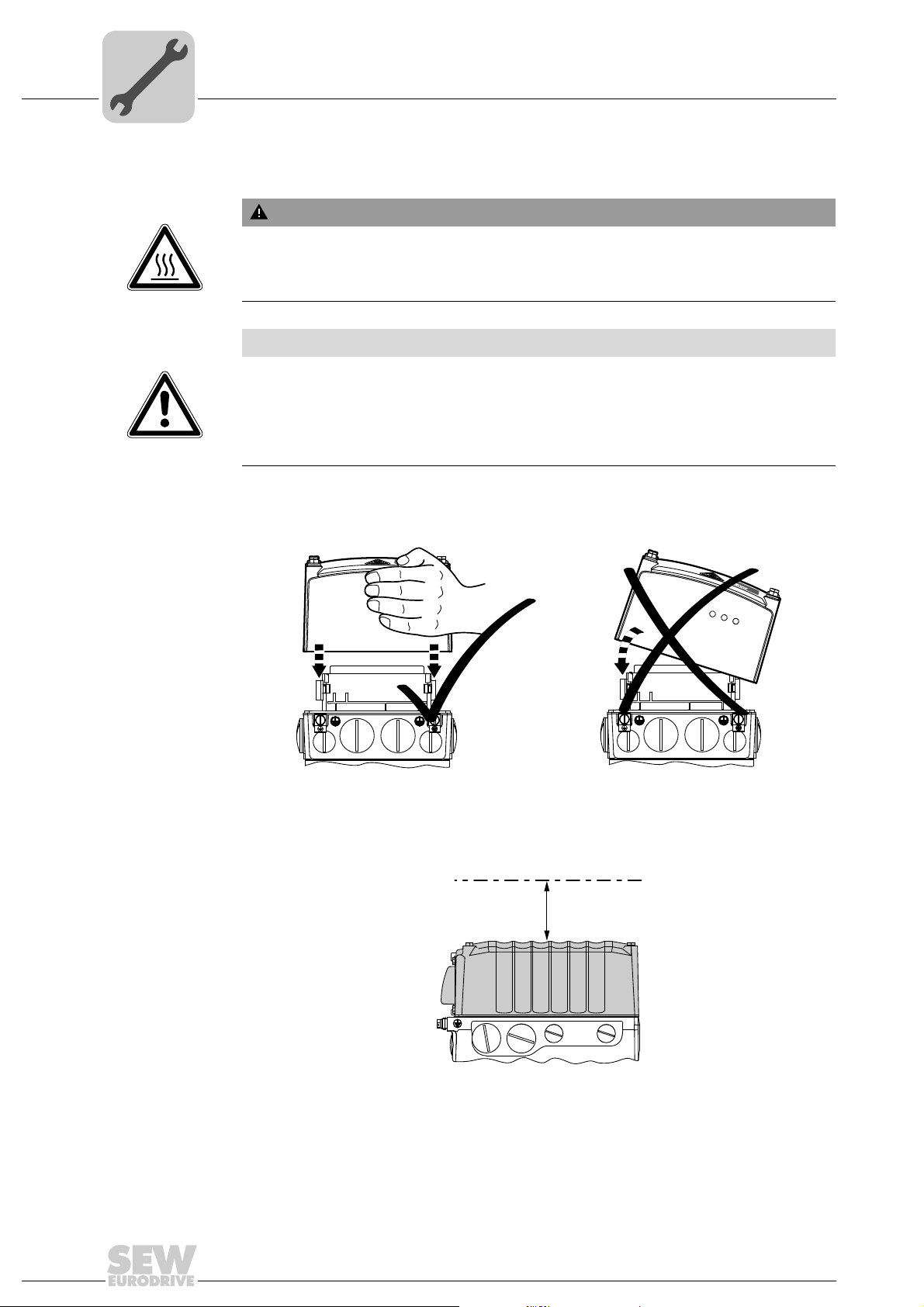

4.4.2 Electronics cover

Mechanical Installation

Setting up the drive unit

WARNING

Burns caused by hot surfaces.

Severe injuries.

• Let the units cool down before touching them.

NOTICE

Loss of the guaranteed degree of protection.

Possible damage to property.

• When the DRC electronics cover is removed from the connection box, you have to

protect it from humidity, dust or foreign particles.

• Check to see that the DRC electronics cover was mounted properly.

Installing the

electronics cover

Min. installation

clearance

• Use only electronics covers that match the size.

• Be careful not to tilt the electronics cover when placing it on the connection box.

4813126155

Note the minimum installation clearance (see following figure) required to remove the

DRC electronics cover. For detailed dimension drawings, see chapter "Technical data

and dimension sheets".

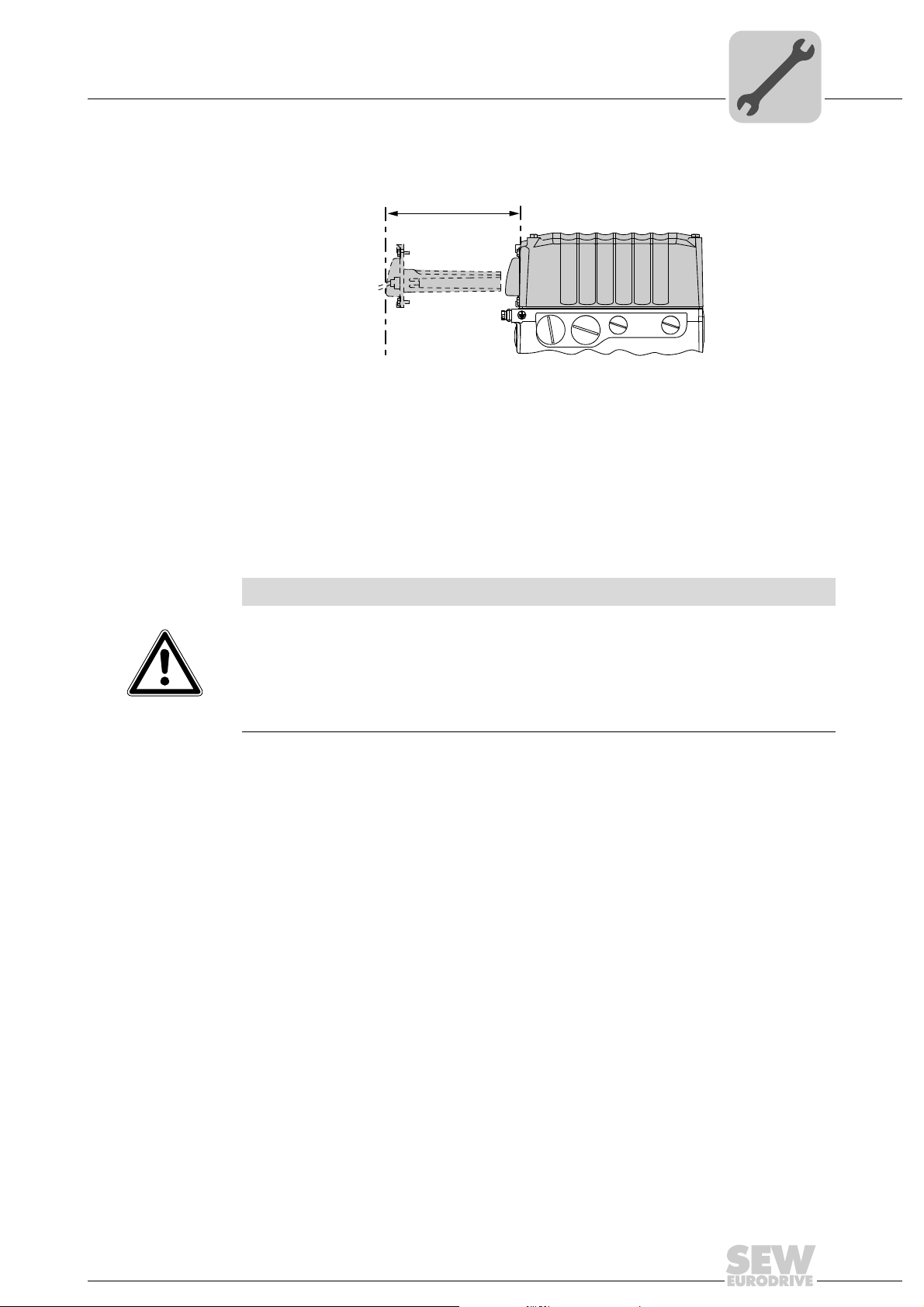

100

26

9007201604838411

Operating Instructions – Electronic Motor DRC.-..-SNI

Mechanical Installation

Setting up the drive unit

4

Min. installation

clearance of

application options

4.4.3 Installation in damp locations or in the open

4.4.4 Painting drive units

Note the minimum installation clearance (see following figure) required to install and

remove the application options.

200

Drives are supplied in corrosion-resistant versions for use in damp areas or in the open.

Repair any damage to the paint work if necessary.

Observe the notes in chapter "Drive units with optional ASEPTIC / ASEPTIC

NOTICE

Breather valves and oil seals may be damaged during painting or re-painting.

9007201604871563

plus

design".

Potential damage to property.

• Clean the surface of the drive unit and make sure it is free from grease.

• Thoroughly cover the breather valves and sealing lip of the oil seals with strips prior

to painting.

• Remove the strips after painting.

Operating Instructions – Electronic Motor DRC.-..-SNI

27

4

4 x

NET

RUN

DRIVE

Mechanical Installation

Application options

4.5 Application options

WARNING

Burns caused by hot surfaces.

Severe injuries.

• Let the units cool down before touching them.

4.5.1 Removing the application cover

DRC drive units with application slot in the electronics cover are delivered with an application cover as standard.

You have to remove the application cover in order to install an application option:

1. Loosen the 4 retaining screws.

2. Remove the application cover.

18014400859806987

NET

RUN

DRIVE

18014400859827339

28

Operating Instructions – Electronic Motor DRC.-..-SNI

4.5.2 Installing the application options

NET

RUN

DRIVE

X4

X3

X2

X1

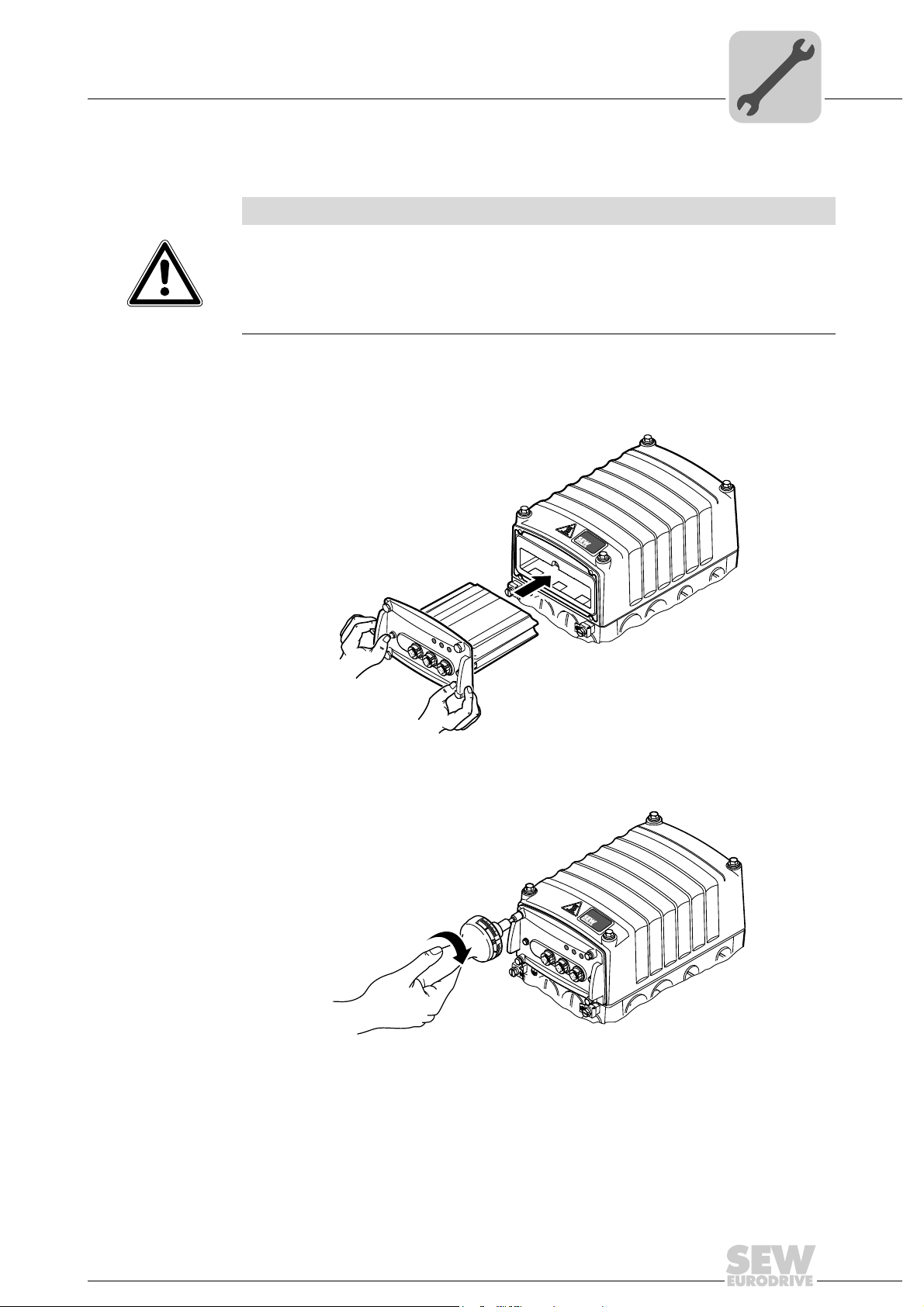

NOTICE

Loss of the guaranteed degree of protection.

Possible damage to property.

• In disassembled condition, you have to protect the GIO13 application option from

moisture, dust or foreign particles as there are openings for DIP switches.

• Make sure that the application cover is mounted properly.

1. You have to remove the application cover or, depending on the design, the paint

protector in order to install an application option:

2. Insert the option into the application slot.

Mechanical Installation

Application options

4

18014400859846539

3. Secure the option with the 4 retaining screws. The permitted tightening torque for the

retaining screws is 1.4 - 1.6 Nm.

4 x

NET

RUN

X4

DRIVE

X3

X2

X1

18014400859865739

Operating Instructions – Electronic Motor DRC.-..-SNI

29

4

Mechanical Installation

Tightening torques

4.6 Tightening torques

4.6.1 Blanking plugs

WARNING

Burns caused by hot surfaces.

Severe injuries.

• Let the units cool down before touching them.

Tighten the blanking plugs included in the delivery

Example The following figure shows an example.

with 2.5 Nm:

30

9007203306591371

Operating Instructions – Electronic Motor DRC.-..-SNI

4.6.2 Cable glands

Tightening torques Tighten the EMC cable glands optionally

torques:

Screw fitting Part number Content Size Tightening torque

EMC cable glands (nickel-plated

brass)

EMC cable glands (stainless steel) 1821 636 6 10 pcs M16 x 1.5 3.5 Nm to 4.5 Nm

1820 478 3 10 pcs M16 x 1.5 3.5 Nm to 4.5 Nm

1820 480 5 10 pcs M25 x 1.5 6.0 Nm to 7.5 Nm

1821 638 2 10 pcs M25 x 1.5 6.0 Nm to 7.5 Nm

The cable retention in the cable gland must withstand the following removal force of the

cable from the cable gland:

• Cable with outer diameter from 4 to 8 mm: Min. 24 N

• Cable with outer diameter from 8 to 11 mm: Min. 34 N

• Cable with outer diameter from 11 to 16 mm: Min. 44 N

Example The following figure shows an example.

Mechanical Installation

Tightening torques

supplied by SEW-EURODRIVE to the following

4

Operating Instructions – Electronic Motor DRC.-..-SNI

9007203306596107

31

4

1

2

4

3

4

2

3

1

Mechanical Installation

Tightening torques

4.6.3 DRC electronics cover

Tighten the screws on the DRC cover using 6.0 Nm working diagonally across.

9007203306627211

32

Operating Instructions – Electronic Motor DRC.-..-SNI

Mechanical Installation

Drive units with optional ASEPTIC / ASEPTICplus design

4

4.7 Drive units with optional ASEPTIC / ASEPTIC

4.7.1 Installation notes

NOTICE

Loss of degree of protection IP66 and incompatibility with cleaning agents.

Possible damage to property.

• To achieve degree of protection IP66 and compatibility with cleaning agents, you

have to replace the plastic screw plugs delivered as standard by suitable screw

fittings made of stainless steel.

Adhere to the following additional notes for DRC drive units in optional ASEPTIC /

ASEPTIC

• Make sure to prevent moisture and dirt from entering the unit during installation.

• After electrical installation, make sure that the sealing and sealing surfaces are clean

• When performing maintenance work, check the condition of the gaskets as well as

• Make sure to install the cables with a drip loop.

• Use only stainless steel cable glands and connection glands offered by SEW-

plus

design:

during assembly.

the tightening torques of the screw fittings. If damaged: Consult SEW-EURODRIVE.

EURODRIVE, see chapter "Technical data and dimension sheets".

plus

design

• You must seal unused cable bushings and plug connectors with suitable screw

plugs, see chapter "Technical data and dimension sheets".

Operating Instructions – Electronic Motor DRC.-..-SNI

33

4

MOVIGEAR

®

B

SNI

[1]

[3]

[2]

Mechanical Installation

Drive units with optional ASEPTIC / ASEPTICplus design

Example The following figure gives an example of a cable entry with drip loop and the replace-

ment of the plastic screw plugs supplied as standard with suitable stainless steel screw

fittings.

4768361227

[1] The delivered plastic screw plugs must be replaced by suitable screw plugs made of stainless steel.

[2] Required stainless steel screw plugs

(see chapter "Technical data and dimension sheets")

[3] Required stainless steel cable glands

(see chapter "Technical data and dimension sheets")

34

Operating Instructions – Electronic Motor DRC.-..-SNI

Mechanical Installation

3

2

NET

RUN

DRIVE

M3

x

3

2

MOVIGEAR

®

B

SNI

NET

RUN

DRIVE

MOVIGEAR

®

B

SNI

M1

M2

M4

M5

M6

2

3

2

3

2

x

2

3

x

3

x

x

x

Drive units with optional ASEPTIC / ASEPTICplus design

4

Mounting positions DRC drive units in optional ASEPTIC / ASEPTIC

plus

design are delivered with pressure

compensation and breather valve installed according to the mounting position.

plus

This is why DRC drive units in optional ASEPTIC / ASEPTIC

design must only be

used in the mounting position specified in the order.

• Mounting position

–M1

–M2

–M3

–M4

–M5

–M6

• Cable entries

– Position 3 (not permitted for M4 mounting position)

– Position 2 (not permitted for M5 mounting position)

– Position X (not permitted for M6 mounting position)

Mounting positions The following figure shows the position of the DRC drive unit when installed in mounting

positions M1 to M6:

4768583819

Operating Instructions – Electronic Motor DRC.-..-SNI

35

4

Mechanical Installation

Drive units with optional ASEPTIC / ASEPTICplus design

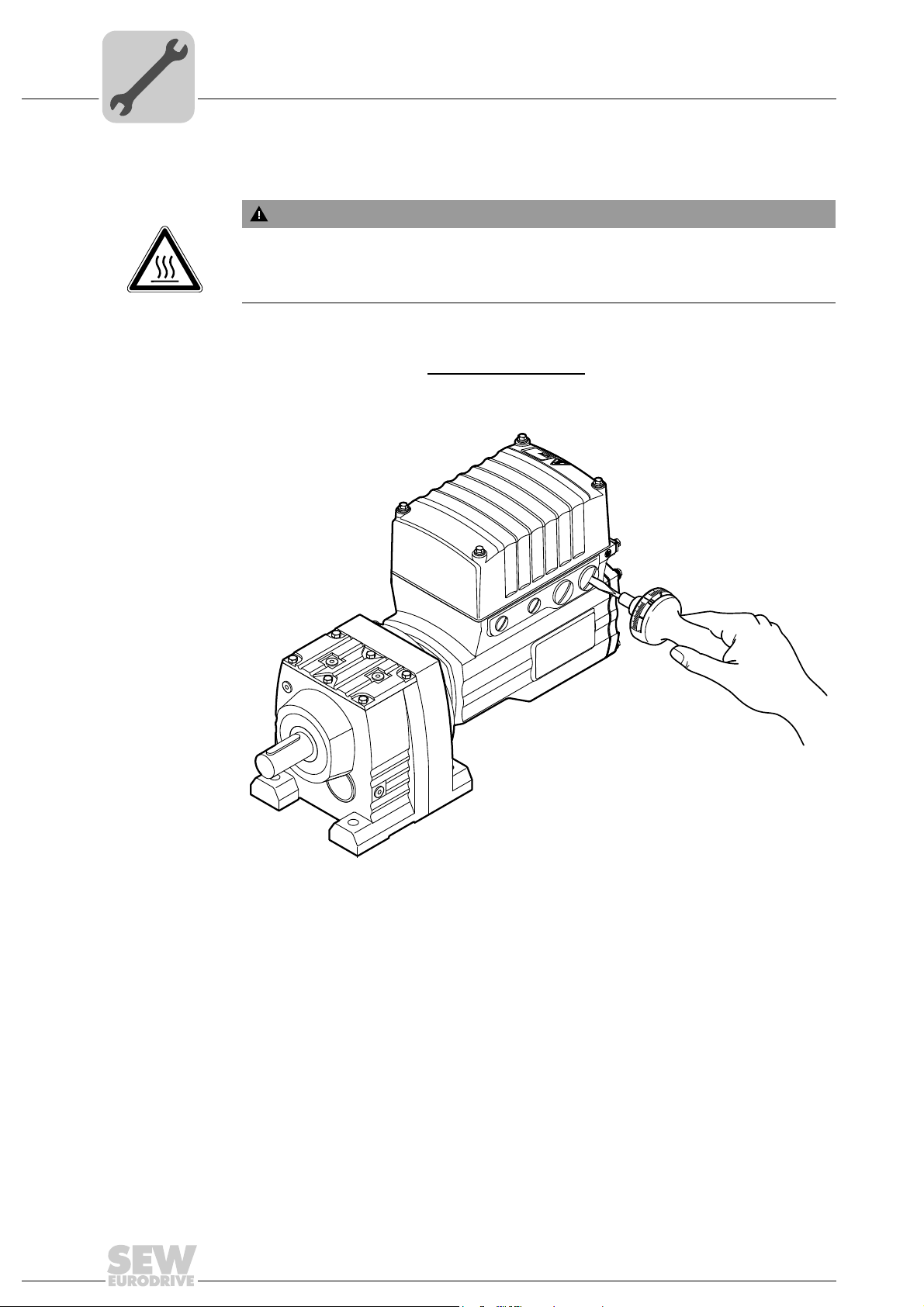

4.7.2 Tightening torques when using optional ASEPTIC

plus

design

WARNING

Burns caused by hot surfaces.

Severe injuries.

• Let the units cool down before touching them.

Blanking plugs Tighten the blanking plugs optionally

with 2.5 Nm:

Type of screw fitting Content Size Part number

Screw plugs

hexagon

(made of stainless steel)

Example The following figure shows an example. The number and position of cable entries

depends on the variant you have ordered.

included in the delivery by SEW-EURODRIVE

10 pcs M16 x 1.5 1 824 734 2

10 pcs M25 x 1.5 1 824 735 0

B

®

SNI

MOVIGEAR

36

4768590091

Operating Instructions – Electronic Motor DRC.-..-SNI

Mechanical Installation

Drive units with optional ASEPTIC / ASEPTICplus design

4

DRC electronics

cover

Proceed as follows when installing the DRC electronics cover:

B

®

SNI

MOVIGEAR

3

2

4

3

1

4

1

2

4768799755

Steps 1. Fix the DRC cover in position on the connection box with a tightening torque of 2 Nm

2. Tighten screws diagonally with 4 Nm.

3. Tighten screws with 6 Nm.

Operating Instructions – Electronic Motor DRC.-..-SNI

37

4

MOVIGEAR

®

B

SNI

Mechanical Installation

Drive units with optional ASEPTIC / ASEPTICplus design

EMC cable glands Tighten the EMC cable glands optionally included in the delivery by SEW-EURODRIVE

with the following tightening torques:

Screw fitting Part number Content Size Tightening torque

EMC cable glands (nickel-plated

brass)

EMC cable glands (stainless steel) 1821 636 6 10 pcs M16 x 1.5 3.5 Nm to 4.5 Nm

1820 478 3 10 pcs M16 x 1.5 3.5 Nm to 4.5 Nm

1820 480 5 10 pcs M25 x 1.5 6.0 Nm to 7.5 Nm

1821 638 2 10 pcs M25 x 1.5 6.0 Nm to 7.5 Nm

The cable retention in the cable gland must withstand the following removal force of the

cable from the cable gland:

• Cable with outer diameter > 10 mm: ≥ 160 N

• Cable with outer diameter < 10 mm: = 100 N

Example The following figure shows an example. The number and position of cable entries

depends on the variant you have ordered.

38

4769055499

Operating Instructions – Electronic Motor DRC.-..-SNI

Electrical Installation

Installation planning considering EMC aspects

5 Electrical Installation

INFORMATION

Adhere to the safety notes during installation.

5.1 Installation planning considering EMC aspects

5.1.1 Notes on arranging and routing installation components

Successful installation of decentralized drives depends on selecting the correct cables,

providing correct grounding and a functioning equipotential bonding.

Always apply the relevant standards.

Note the following:

5.1.2 EMC-compliant installation

5

INFORMATION

This drive system is not designed for operation on a public low voltage supply system

that supplies residential areas.

This is a product with restricted availability in accordance with IEC 61800-3. This

product may cause EMC interference. In this case, it is recommended for the operator

to take suitable measures.

For detailed information on EMC compliant installation, refer to the publication

"Electromagnetic Compatibility in Drive Engineering" from SEW-EURODRIVE.

With respect to the EMC regulation, frequency inverters cannot be operated as standalone units. Regarding EMC, they can only be evaluated when they are integrated in a

drive system. Conformity is declared for a described, CE-typical drive system. These

operating instructions contain further information.

5.1.3 Cable selection, routing and shielding

WARNING

Electric shock caused by faulty installation.

Severe or fatal injuries.

• Take the utmost care when installing the units.

• Observe the connection examples.

For more information on cable selection, routing and shielding, refer to chapter "Cable

routing and shielding".

Operating Instructions – Electronic Motor DRC.-..-SNI

39

5

NET

RUN

DRIVE

[1]

[3] [2]

[4]

Electrical Installation

Installation planning considering EMC aspects

5.1.4 Equipotential bonding

Example

Regardless of the protective earth connection, it is essential that low-impedance, HFcapable equipotential bonding is provided (see also EN 60204-1 or DIN VDE 0100-

540):

• Establish a connection over a wide surface area between the DRC drive unit and the

mounting rail.

• To do so, use a ground strap (HF litz wire), for example, to connect the DRC drive

unit and the plant's grounding point.

4867596683

[1] Conductive connection over a large area between drive unit and mounting plate

[2] PE conductor in the supply cable

[3] 2nd PE conductor via separate terminals

[4] EMC-compliant equipotential bonding, for example using a ground strap (HF litz wire)

• Do not use the cable shield of data lines for equipotential bonding.

40

Operating Instructions – Electronic Motor DRC.-..-SNI

5.2 Installation instructions

5.2.1 Connecting power supply cables

• The rated voltage and rated frequency of the DRC drive unit must correspond with

the data of the power supply system.

Electrical Installation

Installation instructions

5

• Cable cross section: According to input current I

at rated power (see chapter

line

"Technical data and dimension sheets").

• Install line fuses at the beginning of the power supply cable behind the supply bus

junction. Select the fuse size according to the cable cross section.

• Use only copper cables with a minimum temperature range of 85 °C as connection

cable.

• DRC drive units are intended to be operated on voltage supply systems with

grounded star point (TN and TT systems).

5.2.2 Permitted cable cross section of terminals

Line terminals Adhere to the permitted cable cross sections for installation:

Line terminals X2 without conductor end sleeve with conductor end sleeve (with

2

External braking

resistor terminals

Connection cross section

2

)

(mm

Connection cross section

(AWG)

Stripping length 13 mm – 15 mm

Current carrying capacity 24 A (max. continuous current)

0.5 mm

AWG20 – AWG10

Adhere to the permitted cable cross sections for installation:

External braking resistor

terminals X5

Connection cross section

2

)

(mm

Connection cross section

(AWG)

Stripping length 8 mm – 9 mm

without conductor end sleeve with conductor end sleeve

0.08 mm

2

– 4.0 mm

AWG28 – AWG12 AWG 23 – AWG 14

2

– 6 mm

or without insulating shroud)

2

(with or without insulating

shroud)

0.25 mm2 – 2.5 mm

2

Control terminals Adhere to the permitted cable cross sections for installation:

Control terminals X7 without conductor

Connection cross section

2

)

(mm

Connection cross section

(AWG)

Stripping length 5 mm – 6 mm

Current carrying capacity 3.5 A max. continuous current

Operating Instructions – Electronic Motor DRC.-..-SNI

end sleeve

0.08 mm

AWG 28 – AWG 14 AWG 23 – AWG 16

with conductor end

sleeve (without

insulating shroud)

2

– 2.5 mm

2

with conductor end

sleeve (with insulat-

ing shroud)

0.25 mm2 – 1.5 mm

2

41

5

1.

2.

2.

1.

5.2.3 Terminal activation for the braking resistor

5.2.4 Line terminal actuation

Electrical Installation

Installation instructions

Adhere to the following sequence when activating the terminals for the braking resistor:

Terminals for the braking resistor (the following figure shows a schematic illustration)

Adhere to the following sequence when actuating the line terminals:

4055861259

Line terminals (the following figure shows a schematic illustration)

5.2.5 Control terminal actuation

Adhere to the following sequence when actuating the control terminals:

Control terminals (the following figure shows a schematic illustration)

9007203310525451

2.

1.

42

3.

9007203462751499

Operating Instructions – Electronic Motor DRC.-..-SNI

Electrical Installation

Installation instructions

5.2.6 Line protection and residual current device (RCD or RCM)

WARNING

Electric shock due to incorrect earth-leakage circuit breaker type.

Severe or fatal injuries.

• The connected DRC drive units can cause direct current in the protective earth conductor. In cases where an earth-leakage circuit breaker is used for protection

against direct or indirect contact, only a type B earth-leakage circuit breaker is permitted on the power supply side of DRC drive units.

• Install the fuses at the beginning of the power supply cables behind the supply bus

junction.

• A conventional residual current device is not permitted. Residual current devices

sensitive to universal current (trip current 300 mA) are permitted. During normal

operation of DRC, earth-leakage currents of > 3.5 mA can occur.

• SEW-EURODRIVE recommends to not use residual current devices. However, if a

residual current device is stipulated for direct or indirect protection against contact,

observe the above note in accordance with EN 61800-5-1.

5

5.2.7 Line contactor

NOTICE

Damage to the DRC inverter due to jogging of the line contactor.

Damage to the DRC inverter.

• Do not use the line contactor (see wiring diagram) for jog mode but only for

• Observe a minimum switch-off time of 2 s for the line contactor.

• Use only a contactor of utilization category AC3 (EN 60947-4-1) as a line contactor.

switching the inverter on and off. For jog mode, use the control commands.

Operating Instructions – Electronic Motor DRC.-..-SNI

43

5

[1]

M5

2.5 mm²

M5

Electrical Installation

Installation instructions

5.2.8 Notes on PE connection

Electric shock due to incorrect connection of PE.

Severe or fatal injuries.

• The permitted tightening torque for the screw is 2.0 – 2.4 Nm (18 – 21 lb.in).

• Observe the following notes regarding PE connection.

WARNING

Prohibited assembly Recommendation:

Assembly with forked cable lug

Permitted for all cross sections

2377711243

[1] Forked cable lug suitable for M5 PE screws

2377688075

Assembly with solid connecting wire

Permitted for cross sections up to

max. 2.5 mm

2

2377672587

44

Earth-leakage currents ≥ 3.5 mA may occur during normal operation. To meet the

requirements of EN 61800-5-1, observe the following notes:

• The protective earth (PE) connection must meet the requirements for plants with high

earth-leakage currents.

• This usually means

– installing a PE connection cable with a minimum cross section of 10 mm

2

– or installing a second PE connection cable in parallel with the original PE connec-

tion.

Operating Instructions – Electronic Motor DRC.-..-SNI

5.2.9 Installation above 1000 m asl

Electrical Installation

Installation instructions

5

You can install DRC drive units at altitudes from 1000 m to a maximum of 4000 m above

sea level

• The nominal continuous power is reduced due to the reduced cooling above 1000 m

(see chapter "Technical data and dimension sheets").

• Above 2000 m above sea level, the air and creeping distances are only sufficient for

overvoltage class 2. If the installation requires overvoltage class 3, you will have to

install additional external overvoltage protection to limit overvoltage peaks to 2.5 kV

phase-to-phase and phase-to-ground.

• If safe electrical disconnection is required, it must be implemented outside the unit

for altitudes of 2000 m above sea level and higher (safe electrical disconnection in

accordance with EN 61800-5-1).

• At installation altitudes between 2000 m and 4000 m above sea level, the permitted

rated power supply voltages are reduced as follows:

– By 6 V per 100 m

5.2.10 Protection devices

• DRC drive units are equipped with integrated protection devices against overload.

• Cable protection must be implemented using external overload devices.

• Observe the relevant standards concerning cable cross section, voltage drop and

installation type.

1)

provided the following conditions are met:

INFORMATION

It is essential that you adhere to the installation instructions in the documentation of

the controller you use.

1) The maximum altitude is limited by the reduced electric strength due to the lower air density.

Operating Instructions – Electronic Motor DRC.-..-SNI

45

5

5.2.11 UL-compliant installation (in preparation)

Power terminals Observe the following notes for UL-compliant installation:

Electrical Installation

Installation instructions

• Use only copper cables with a rated thermal value of 75 °C.

• DRC uses cage clamp terminals

Short circuit

current rating

Branch circuit

protection

Motor overload

protection

Ambient

temperature

Wiring diagrams For wiring diagrams, refer to chapter "Electrical installation".

Suitable for use in current circuits with a maximum short circuit current of 200 000 A

• DRC, the max. voltage is limited to 500 V.

Integral solid state short circuit protection does not provide branch circuit protection.

Branch circuit protection must be provided in accordance with the National Electrical

Code and any additional local codes.

The table below list the permitted maximum fusing.

Series Max. fuse rating

DRC 40 A / 600 V

DRC is provided with motor overload protection with a trip current adjusted to 150% of

the rated motor current.

DRC is suitable for an ambient temperature of 40 °C, max. 60 °C with derated output

current. To determine the output current rating at temperatures above 40 °C, the output

current should be derated by 3.0% per K between 40 °C and 60 °C.

eff

:

46

Operating Instructions – Electronic Motor DRC.-..-SNI

5.3 Installation topology (example)

DRC...SNI

Single Line Installation [2]

[1]

DRC...SNI

MOVIGEAR

®

...SNI

Communication

Power

Power

Controller - SNI

Controller / PLC

Control cabinet level

Field level

Line filter

INFORMATION

The following figure shows the basic installation topology with DRC-SNI.

It is essential that you observe the installation instructions in the documentation of the

controller you use.

Electrical Installation

Installation topology (example)

5

[1]

A maximum of 10 SNI actuators in total

[2]

Operating Instructions – Electronic Motor DRC.-..-SNI

Permitted cable length between controller and last actuator max. 100 m

4727073035

47

5

PE

PE PE

PE

12 3

11 12 13

1

2

Braking resistor

terminals

Line terminals

X5

X2

12345

11 12 13 14 15

Control terminals

X7

12345

11 12 13 14 15

Electrical Installation

Terminal assignment

5.4 Terminal assignment

Electric shock due to regenerative operation when the shaft turns.

Severe or fatal injuries.

• Secure the output shaft against rotation when the electronics cover is removed.

The following figure shows the terminal assignment of DRC-SNI:

WARNING

4729233035

Assignment

Ter min al No. Name Marking Function (permitted tightening torque)

X2 line

terminals

1L1 Brown Actuator supply phase L1 with SNI communication – IN

2L2 Black Actuator supply phase L2 with SNI communication – IN

3L3 Gray Actuator supply phase L3 with SNI communication – IN

11 L 1 Brown Actuator supply phase L1 with SNI communication – OUT

12 L2 Black Actuator supply phase L2 with SNI communication – OUT

13 L3 Gray Actuator supply phase L3 with SNI communication – OUT

– PE – Protective earth connection (2.0 to 3.3 Nm )

X5 braking

resistor

terminals

1BW– Braking resistor connection

2BW– Braking resistor connection

INFORMATION

The communication method requires that you must observe the order of the line

phases L1, L2, L3 between SNI controller and DRC-SNI 1 to 10.

48

Operating Instructions – Electronic Motor DRC.-..-SNI

Electrical Installation

Terminal assignment

Assignment

Ter min al No. Name Marking Function

X7 control

terminals

1STO + Yellow Input STO +

2STO − Yellow Input STO –

3 +24 V_SEN – Input for DC 24 V voltage supply for sensors

The sensor supply voltage is then available at the

optional plug connector

4 0V24_SEN – Input for 0V24 reference potential for sensors

5 24V_O – DC 24 V output

11 STO + Yellow Output STO + (to loop through)

12 STO − Yellow Output STO – (to loop through)

13 +24V_SEN – Looping of the DC 24 V voltage supply for sensors

14 0V24_SEN – Looping of the 0V24 reference potential for sensors

15 0V24_O – 0V24 reference potential output

5

Operating Instructions – Electronic Motor DRC.-..-SNI

49

5

Electrical Installation

Connecting DRC drive units

5.5 Connecting DRC drive units

WARNING

No safe disconnection of the DRC drive unit.

Severe or fatal injuries.

• Do not use the 24 V output (terminals 5, 15) for safety-related applications with

DRC drive units.

• You may only jumper the STO input with 24 V when the DRC drive unit need not

fulfill any safety function.

[1] SNI controller connection

[7]

L1 IN1L2 IN

X2

Line terminals [2]

Control

terminals [2]

X7

2 STO IN

1 STO + IN

11 STO + OUT

L3 IN

L1 OUT11L2 OUT12

2

3

[3] [4] [5]

5 24V_O

12 STO OUT

L3 OUT

13

15 0V24_O

13 + 24V_SEN

3 + 24V_SEN

BW

BW

1

2

X5

Braking resistor

terminals [2]

[6] Connection the

for sensor inputs

4 0V 24V_SEN

14 0V 24V_SEN

DRC.-...-SNI

optional

plug connector

X5132

4729927435

50

[1] See documentation of the SNI controller

[2] See chapter "Terminal assignment"

[3] DC 24 V output

[4] Sensor supply input, the sensor supply voltage is then available at the optional plug

connector for sensor inputs

[5] Looping of the sensor supply input

[6] See chapter "Optional plug connector assignment"

[7] Braking resistor connection

Operating Instructions – Electronic Motor DRC.-..-SNI

5.6 Cable routing and shielding

A1:

A2:

B:

2x

2x

3x

3x

M4x10

(2.0 Nm)

M4x10

(2.0 Nm)

20mm

20mm

3x

2x

5.6.1 Installation material kit (part no. 1 824 826 8)

1)

Each DRC drive unit

material for cable shielding:

• A1: Installation material for line and hybrid cables:

2 x shield clamps and screws

(outer shield).

• A2: Conductive film:

2 x pieces of conductive film to wind around the braid shield. Use the conductive film

if required.

• B: Installation material for control cables and data cables:

3 x shield clamp with screw

(STO, CAN, binary signals).

is delivered with an accessory bag that contains installation

2)

Electrical Installation

Cable routing and shielding

2)

to connect the shield of line cables or hybrid cables

to connect the shield of control cables or data cables

5

INFORMATION

For some installation variants, you do not need all the parts of the accessory kit.

1) Exception: Not for plug connector variants

2) Self cutting, which is why the holes in the connection box do not have a thread

Operating Instructions – Electronic Motor DRC.-..-SNI

4071209995

51

5

5.6.2 General installation options

Electrical Installation

Cable routing and shielding

The following figure shows the general installation options. The following chapters show

common examples and contain important notes on cable selection and routing.

4071462539

52

Operating Instructions – Electronic Motor DRC.-..-SNI

5.6.3 Notes on cable routing and shielding

Note the following when routing and shielding the cables:

• Cable selection

– Only use cable types prescribed by SEW-EURODRIVE.

– It is essential that you observe chapter "Technical data and dimension sheets /

Specification of recommended connection cables for single line installation" in the

operating instructions.

– Always use metal cable glands due to their attenuation properties.

– Use shielded cables for the optional external braking resistor.

– The shield must have good EMC properties (high shield attenuation) and must not

be used for mechanical protection of the cable.

• Cable shielding – Control cables

– Connect the shields of the control cables to the metal housing of the unit using

the shield clamps of the installation material kit. To do so, strip off the cable

sheath around the shield connection surface.

– As an alternative, you can use optionally available EMC cable glands to connect

the shield of control cables, see chapter "EMC cable glands".

Electrical Installation

Cable routing and shielding

5

• Cable shield – external braking resistor

– Connect the cable shield of the cable for an external braking resistor to the metal

housing of the unit using the shield clamps of the installation material kit. To do

so, strip off the cable sheath around the shield connection surface.

• Cable shielding – Supply system cable (single line)

– Wind the conductive film included in the installation material kit around the braid

shield three times, if required.

– Connect the cable shields of the supply system cable (single line) to the metal

housing of the unit using the shield clamps of the installation material kit.

Operating Instructions – Electronic Motor DRC.-..-SNI

53

5

Single Line

(SNI)

STO

STO

External

braking

resistor

20mm

3x

Single Line (SNI)

STO

STO

External

braking resistor

20mm

3x

Recommended cable routing

Electrical Installation

Cable routing and shielding

Alternative cable routing

4731813899

54

Operating Instructions – Electronic Motor DRC.-..-SNI

4732273419

5.7 EMC cable glands

5.7.1 Cable shielding (alternative) – Control cables

As an alternative to using shield clamps for control cables (STO, binary signals), you can

use EMC cable glands, which are available as an option, to connect the shield.

Electrical Installation

EMC cable glands

5

3388566411

5.7.2 Assembly of EMC cable glands

Fit the EMC cable glands supplied by SEW-EURODRIVE according to the following

figure:

[1]

[1] Important: Cut off the insulating foil, do not just fold it back.

Operating Instructions – Electronic Motor DRC.-..-SNI

2661188747

55

5

Electrical Installation

Prescribed power leads

5.8 Prescribed power leads

The following table shows the available SNI supply system cables:

SNI supply system cable

Part no. 1 330 330 9 Cable reel 30 m

Cable reel 100 m

Cable reel 200 m

Open cable end

(bulk cable)

Part no. 1 330 550 6 Cable reel 30 m

Cable reel 100 m

Cable reel 200 m

Cable cross

section/cable type

2

2.5 mm

HELUKABEL

®

TOPFLEX

UV-2YSLCYK-J

TOPFLEX

UV-2YSLCYK-J

– EMV-

2

4 mm

HELUKABEL

®

– EMV-

Open cable end

(bulk cable)

56

Operating Instructions – Electronic Motor DRC.-..-SNI

5.9 Plug connectors

The wiring diagrams of the plug connectors depict the contact end of the connection.

5.9.1 Designation key

The designation of plug connectors is specified according to the following key:

X 2 0 1 2 _

Electrical Installation

Plug connectors

Sequence number (optional)

In case of several plug connectors in one group

Group number (optional)

For several plug connectors with the same function

Typ e

Connection diagram of the plug connector within a function

Function

Function of a plug connector within a group

Group

1 = Power input

2 = Power output

3 = Encoder

4 = Bus

5 = Inputs and outputs

5

5.9.2 Connection cables

Connection cables are not included in the scope of delivery.

You can order prefabricated cables from SEW-EURODRIVE. They are described in the

following sections. Specify the part number and length of the required cable in your

order.

The number and type of required connection cables depend on the design of the units

and the components to be connected. This is why not all cables in the list are actually

required.

The following figures show the various cable types:

Cable Length Installation type

Ter minal

Fixed length

Variable length

Suitable for cable

carrier installation

Not suitable for

cable carrier

installation

INFORMATION

For detailed information about cable types, see chapter "Technical data and

dimension sheets".

Operating Instructions – Electronic Motor DRC.-..-SNI

57

5

[1]

X5502

X1241_1

X1241_1 X1241_1

X1241_2

X1241_2

X1241_2

X5503

X5131X5131

X5131

[1]

X

2

3

Electrical Installation

Plug connectors

5.9.3 Plug connector positions

The following figure shows possible plug connector positions. A difference is made

between plug connectors with selectable position and plug connectors with fixed

position:

Plug connector Color Position Location

X5131: Digital inputs/outputs – As

X5502: STO – IN Orange Fixed 3 (left)

X5503: STO – OUT Orange Fixed 3 (right)

X1241_1: AC 400 V connection with SNI

1)

X1241_2: AC 400 V connection with SNI Red As

2)

[1] Pressure compensation

1) Plug connector X1241_1 is also available separately (i.e. without plug connector X1241_2).

2) Only in conjunction with the optional design for use in wet areas (with MOVIGEAR

(with DRC).

Red As

– Fixed Depends on mounting position

required

required

required

X, 2 or 3,

not together with X1241_1, X1241_2

X, 2 or 3, not together with X5131

X, 2 or 3, not together with X5131

®

) / ASEPTIC design

58

9007201923558283

Operating Instructions – Electronic Motor DRC.-..-SNI

Electrical Installation

[1]

5.9.4 Restrictions in conjunction with pressure compensation

The position for STO plug connectors is occupied by the pressure compensation fitting

[1] when using the optional design for use in wet areas (with

MOVIGEAR

case, plug connectors for STO are not possible:

®

)/ASEPTIC

plus

design (with DRC) and M5, M6 mounting position. In this

Plug connectors

5

9007201700846347

Operating Instructions – Electronic Motor DRC.-..-SNI

59

5

5.9.5 Plug connector variant

Electrical Installation

Plug connectors

NOTICE

Possible damage of the right-angle connector in case of rotation without mating

connector.

Irreparable damage to the thread, damage to the sealing surface.

• Do not use pliers to adjust the right-angle connector before connecting it.

NOTICE

Adjusting the right-angle connector too often can damage it.

Potential damage to property

• Adjust the plug connector only when installing and connecting the drive unit.

• Do not turn the plug connector regularly once it has been installed.

M23 plug connectors are available in the following variants:

• [1] "Straight" plug connector variant

• [2] "Right-angle" plug connector variant

Once the mating connector has been plugged in, the "right-angle" connector can be

adjusted without using additional tools.

60

Operating Instructions – Electronic Motor DRC.-..-SNI

Example

[2]

[1]

90 °

Electrical Installation

Plug connectors

5

9007203327550219

INFORMATION

Only cable outlet on the side is possible with plug connector position 3 and "rightangle" plug connector variant.

Operating Instructions – Electronic Motor DRC.-..-SNI

61

5

A

6

4

5

PE

B

C

D

SHLD

1

2

3

Electrical Installation