Page 1

Model SRPM

Room Pressure Monitor

Installation and Operating Manual

1

Page 2

Setra SRPM Room Pressure Monitor

The Setra SRPM Room Pressure Monitor is designed for critical low

differential pressure applications that require stringent pressure monitoring

and alarming. The SRPM can be congured to monitor positive, negative

or neutral pressure in protected environments and hospital isolation rooms

per CDC guidelines. The SRPM is a complete system that includes a backlit

RGB LCD display with a graphic user interface, which enables access to

pressure, security, calibration, and alarm setup. The touch-screen displays

menus that guide the user through setup, as well as setting up password

protection. Red and green LED’s and a local audible alarm (with time delay

feature) alert personnel to system status. The SRPM has a NEMA 1 (IP20)

rated re retardant plastic housing for indoor applications. True differential

pressure is displayed with a resolution of .0001”. Setra’s patented very low

pressure capacitance sensor is dead ended and avoids the potential for

cross contamination of the room and reference space as well as eliminating

drift that results from fouling of ow based sensors, which by nature have a

ow path connecting the protected and reference spaces. Additionally there

are 2 levels of password protection available as well as optional BACnet

MSTP communications.

2

Page 3

Table of Contents

1.0 Intended Use ..................................................................................4

1.1 Specications ............................................................................4

1.2 SRPM Function .........................................................................5

2.0 Parts ..............................................................................................6

2.1 SRPM Included parts.................................................................6

2.2 SRAN Included parts ................................................................. 6

2.3 RPS included parts .................................................................... 6

2.4 Parts required and to be supplied by installer ...........................6

3.0 Installation ......................................................................................7

3.1 Wiring (Rough in).......................................................................7

3.2 Plumbing ...................................................................................9

3.3 Wiring (Finish) ........................................................................10

3.3.1 Alarm Relay ..........................................................................10

3.3.2 Remote Annunciator .............................................................10

3.3.3 Door status input .................................................................. 11

3.3.4 Analog Output ....................................................................... 11

3.3.5 BACnet .................................................................................12

4.0 Startup and Operation ..................................................................13

4.1 Menu Tree ...............................................................................13

4.2 Power Up ................................................................................. 13

4.3 Monitoring Screen ...................................................................13

4.4 Main Menu ............................................................................... 14

4.5 Setup Unit ................................................................................ 15

4.6 Setup Room.............................................................................17

4.7 Setup Alarms ...........................................................................18

4.8 Self Test ...................................................................................19

4.9 Calibration ...............................................................................20

4.10 BACnet Setup Screen ............................................................21

5.0 Remote Annunciator ..................................................................... 23

6.0 Maintenance ................................................................................. 24

7.0 Agency Electrical Standards .........................................................25

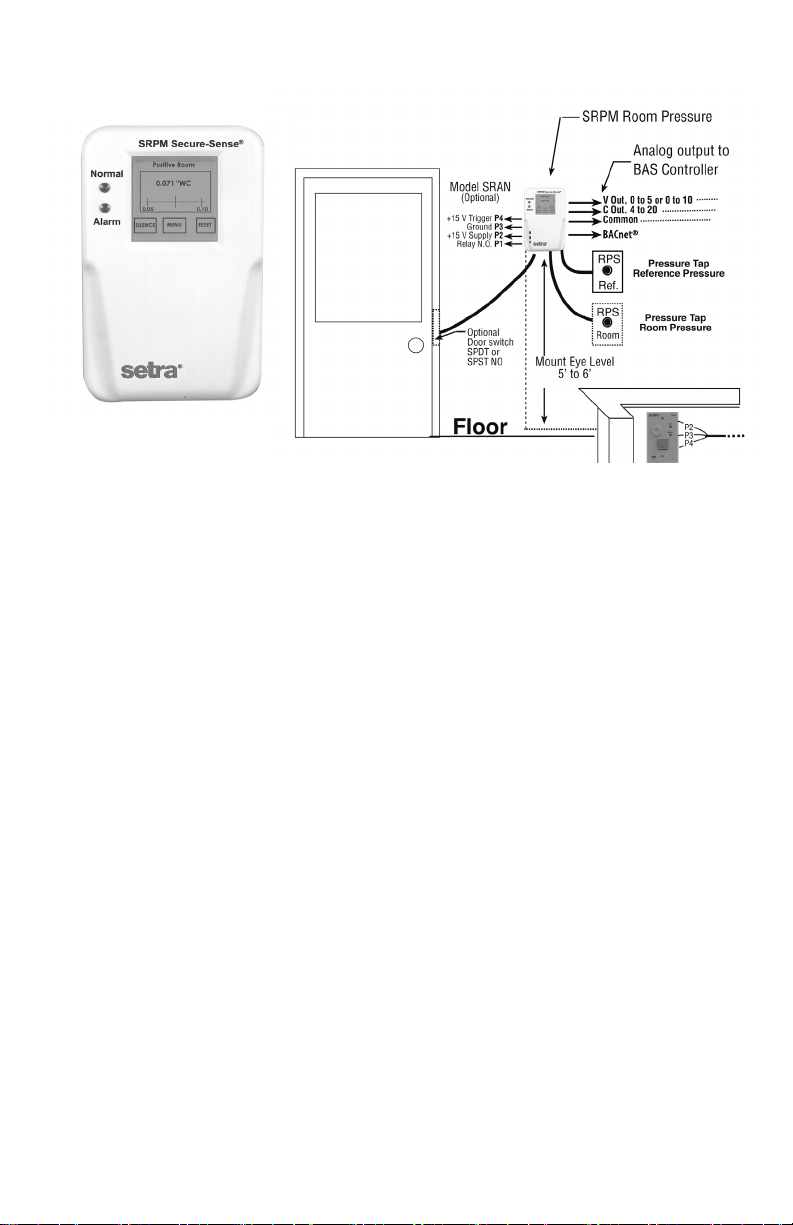

8.0 Wiring and Plumbing Overview ....................................................26

9.0 Menu Tree ....................................................................................27

3

Page 4

1.0 INTENDED USE

The SRPM is designed to monitor critical environments by providing

differential pressure indication. Typically this is between a monitored

room and a reference space such as a corridor or ante room. The unit

also provides monitoring, alarm and communications functions.

Installation must be indoors, Polution Degree 2, Installation Category II.

Failure to install per these instructions may impair the safety of the unit.

Typical Applications:

1. Hospitals – patient isolation and protection rooms, operating

suites, intensive care, and emergency rooms.

2. Pharmaceutical, semiconductor, precision manufacturing, and

clean rooms.

3. Laboratories – medical research, BSL (Bio safety labs), radiation,

vivarium, toxic metals and chemicals. Indoor use only.

1.1 SPECIFICATIONS

Service Air or nonconductive, nonexplosive gas

Accuracy ±0.5% F.S., ±0.25% FS optional

Operating Temperature Limits 32 to 120°F (0 to 50°C)

Operating Humidity Limits 5 to 95% Relative humidity (non condensing)

Altitude 2000 meters (max)

Thermal Eects ±0.03% F.S./ °F (± 0.05% F.S./ °C)

Overpressure ±15” W.C.

Supply Voltage Code V1 and V2 85-265 VAC, 50-60 Hz

Code A1 and A2 18-32 VAC, 50-60 Hz

Power Consumption (Voltage Output) 5 W.

Output Selectable 4-20 mA (2-wire), 0-5 VDC (3-wire), or

0-10 VDC (3-wire)

Loop Resistance (4-20mA Output) 0-510 OHMS

Electrical Connection Removable terminal block

Pressure Fittings Barbed ttings for 1/4” O.D. tubing

Housing Fire retardant plastic (NEMA 1, IP20 rated for indoor

applications)

Mounting Mounts to customer supplied 4” plaster ring

(mounts to 2-gang electrical box)

Dimensions 8½ H x 5.4½ W x 1.8½ D (20.3 H x 13.7 W x 4.1

Weight (approx.) 1.5 lbs (680 g)

Agency Approval

Communications

CE, CAN/CSA-C22.2 NO. 61010-1-04

BACnet MSTP ASC, optional, see setra.com

for detailed PICS statement

4

Page 5

1.2 SRPM FUNCTION

The SRPM senses very low differential pressure using high accuracy

capacitive sensor technology. The pressure difference for these

applications is the difference in static pressure between a critical

environment room and its surrounding reference area (usually a hallway

or another room). Maintaining and monitoring a static room pressure

difference ensures that the critical environment room is either protected

or isolated from a surrounding environment. Protection strategy requires

a net positive room static pressure difference, while isolation requires a

net negative static pressure difference. The SRPM can be programmed

to monitor either positive or negative room static pressure. Low pressure

sensing technology is coupled with multifunctional alarming and simple

touch screen user interface with password security protection. The BACnet

communication option allows the device to communicate with other

BACnet devices to allow the supervisory system to change conguration

setups and monitor alarms in an open network.

User Interface: LCD Display 128 x 128 COG module, with custom RGB

LED backlight and custom 4-wire resistive touch screen

RGB Backlight. The SRPM indicates the status of the room being

monitored using visual backlight color.

Color Status

Green Room Pressure is within alarm limits

Yellow Door is open. (Door input must be enabled)

Red Room Pressure is outside alarm limits and

alarm delay period has been exceeded and

room is not in “No Isolation” mode.

Visual Feedback: LEDs, green for normal, red for alarm

Audible Feedback: Beeper will sound when pressure is out of range and

alarm delay has timed out. Volume can be adjusted between 1 to 4 in

relative sound levels up to the maximum level specication of the beeper

of 85 dB at 4”. Audible alarm can also be disabled.

Quick Room Mode Change: Sometimes the room needs to be changed

quickly from in use (Occupied) to out of use (No Isolation). This is

accomplished by using 2 levels of password protection. The Operator

level allows access to change room modes but no other changes. The

Supervisor Level allows full access to all menus. In No Isolation mode

no alarms are generated even if the pressure is outside limits. To change

modes see page 22, Room Mode Change, for directions to change modes.

5

Page 6

2.0 PARTS

2.1 SRPM (Setra Room Pressure Monitor) INCLUDED

PARTS

Quantity

1 SRPM assembly

2 Barbed Couplings, with Silicone Tubing

4 6-32 x 1/2” Mounting Screws for connecting

the SRPM Base to the plaster ring

2.2 SRAN (Setra Remote Annunciator) INCLUDED

PARTS

Quantity

1 Annunciator Assembly

2.3 RPS (Room Pressure Snubber) INCLUDED PARTS

Quantity

1 Room pressure snubber Assembly

2.4 Parts required and to be supplied by installer

MOUNTING AND WIRING

To mount and install properly, the following components are required:

NOT INCLUDED and required for each SRPM

Quantity

1 2-Gang Metal Electrical Box with Grounding Stud

1 4 inch Metal Plaster Ring

1 Door Switch SPDT or SPST, N.O., as needed

NOT INCLUDED and required for each remote annunciator and

room pressure snubber

Quantity

1 1-Gang Electrical Box

1/4 “ tubing as required to connect between the RPS

(Room Pressure Snubbers) and the SRPM

6

Page 7

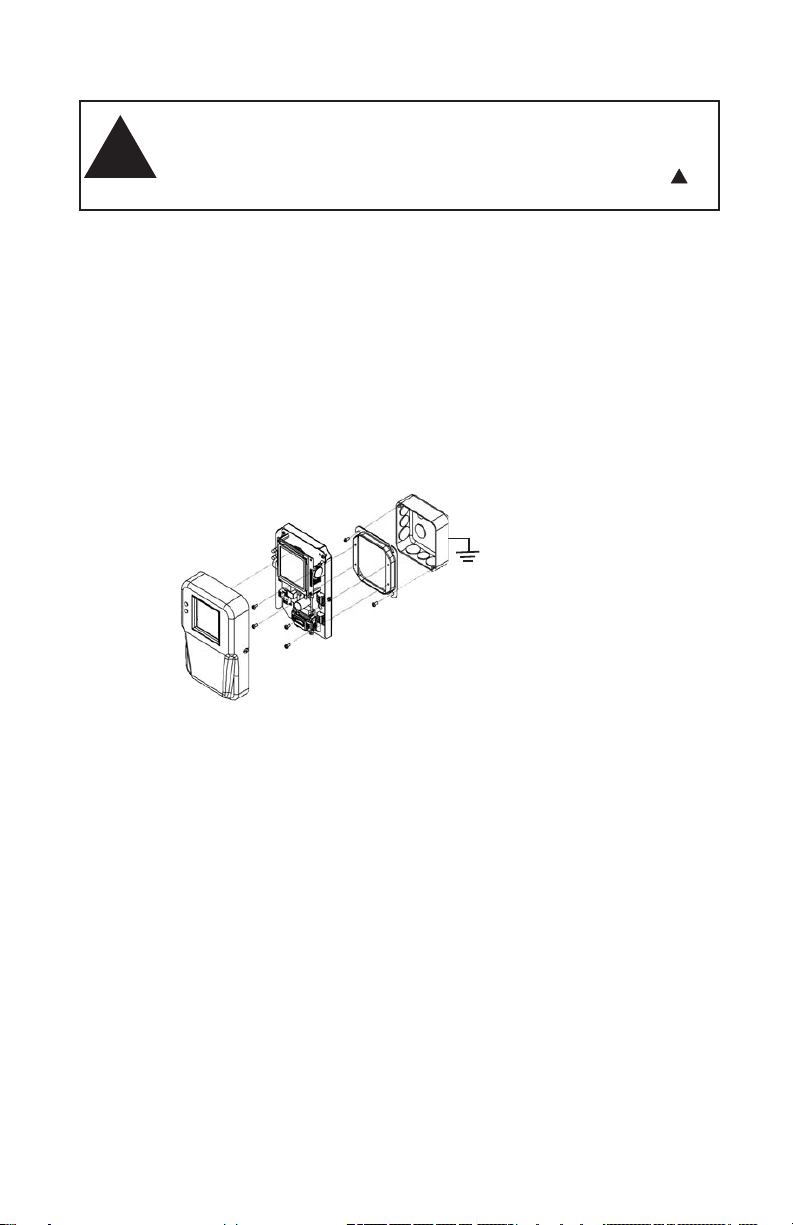

3.0 INSTALLATION (See Section 8.0 for overview)

For 120/240 VAC Version, only

The SRPM is designed to be mounted on a standard double gang metal

electrical box using a 4 x 4 inch plaster ring adaptor. After the rough in

wiring and plumbing is performed remove the cover and mount the baseplate

to the plaster ring adaptor using the supplied 6-32 x 1/2” long mounting

screws. Note: The plaster ring external mounting face needs to be positioned

ush to recessed, relative to the surface of the wall. Also note the orientation

of the 4 mounting screws in the plaster ring, as the plaster ring is rotated

90° from conventional mounting.

Note: In the following wiring sections, abbreviations are used (e.g. J1, P3).

Please see section 8.0 for complete wiring diagrams with abbreviations.

CAUTION: Do not open or remove SRPM cover (tool required) with input power applied unless performed by a licensed electrician. “Hazardous Live” voltage is present

!

at connector J3 when power is applied. Please observe the warning symbol ( )

near the J3 power connector.

Electrical Box

4 x 4 inch Plaster Ring

(Rotated 90°)

SRPM Metal Base

!

SRPM Cover

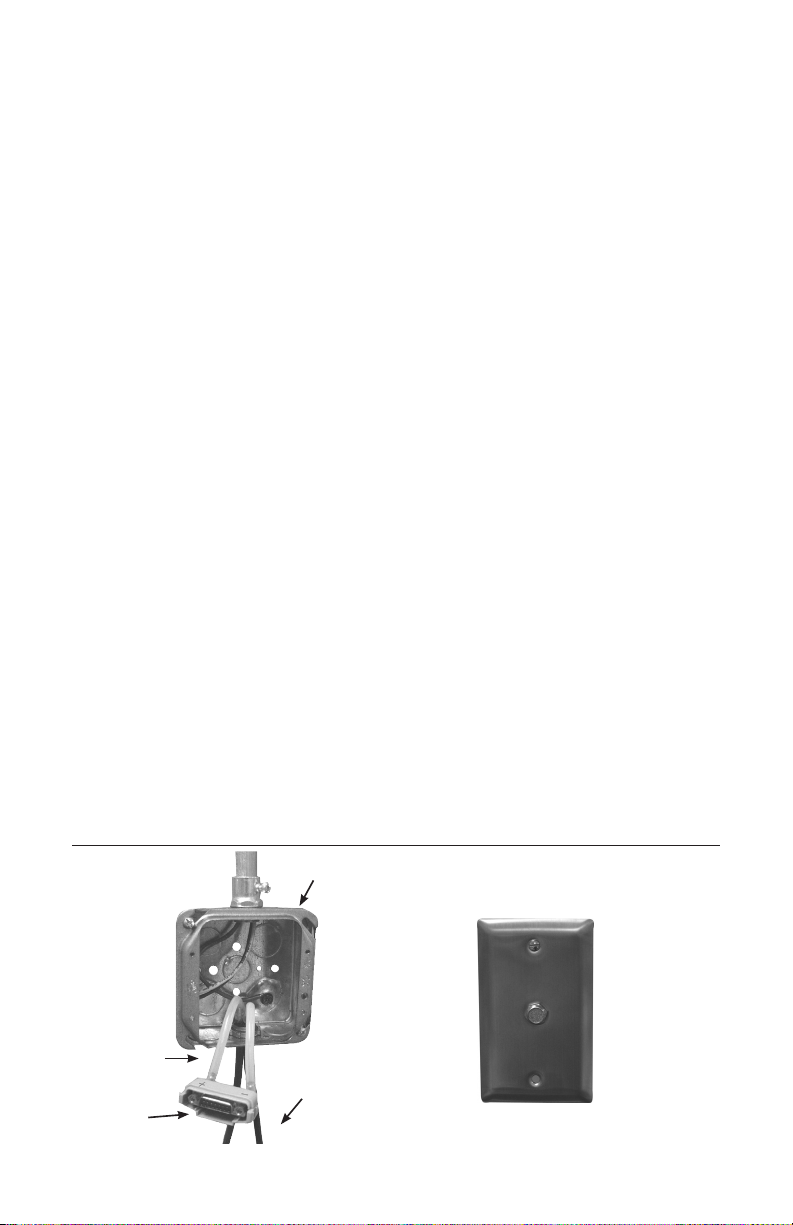

3.1 WIRING ELECTRICAL BOX (ROUGH IN)

Layout the system in terms of wiring: power, annunciator, analog output,

BACnet, relay output and plumbing to connect to the monitored spaces

(pressure taps).

Bring all power, earth ground, signal, communications and analog output

wiring into the 4x4 electrical box.

Bring 1/4” O.D. tubing for 3/6” Barb tting into box.

In order to conform to the CSA safety standard the electrical installer

must comply with the following earth ground instructions:

1. Pre-wire the electrical box with power (24 VAC or 120/240 VAC), and

provide earth grounding to the electrical box. The safety ground path

consists of four 6-32 x 1/2” metal screws that connect the SRPM metal

base to the 4½ x 4½ metal plaster ring. The plaster ring must be grounded to the 4½ x 4½ electrical box by 2 metal mounting screws. The 4½ x

4½ electrical box must be connected to the building earth ground. In addition, the marked ground wire included in 120/240 VAC version, should

7

Page 8

be connected to the electrical box earth ground connection. It is also

highly recommended to use armored cable (Type AC) for all the wiring in

applications where high levels of radio interference may be present.

2. For the 120/240 VAC version only, a switch or circuit-breaker should

be included in the building installation. It is advised to indicate the location of the switch or circuit-breaker by means of a label on or nearby the

installed device. The disconnection switch or circuit-breaker should disconnect all current-carrying con ductors. Any line-connected single-pole

switch should be connected to a terminal intended for connection to the

ungrounded conductor of the supply circuit.

Power leads, analog output, door status, and annunciator wiring should be

14 to 22 AWG stranded wire.

BACnet suggested wiring is 22 AWG stranded wire in a shielded cable,

a +,-, Gnd (S) and shield should be run. This can be 2 twisted pairs with

a separate cable shield. One twisted pair is used for communications,

the second twisted pair can be used for communications ground and the

shield wire can be connected to the other device shield wires. For CE

compliance, a properly grounded shielding cable is requried.

8

Page 9

3.2 PLUMBING (ATTACHING PRESSURE TUBING)

Warning: Always attach tubing to the SRPM header and then place Header onto

SRPM. This will prevent overpressure from crimped or collapsed tubes.

Use the following procedure for all room types: positive, negative or

neutral:

Typically a Room Pressure Snubber (RPS) is installed in the monitored

room. Often stiff nylon ¼” tubing is used for running pressure signals

from the SRPM to the monitored spaces. To prevent buckling and

collapse of this stiff tubing inside the electrical box, use the supplied soft

silicone tubing and tubing adaptors to transition from the eld tubing to

the pressure ttings on the SRPM.

Attach pressure tubing as follows:

1. Connect the 1/4 inch O. D. tubing running from the RPS (or

other pressure connection from the monitored space) to the 2-gang

electrical box for the SRPM. Install one of the supplied 1/4 inch male

to male barbed tube adaptors onto the end of the tube then push the

4” length silicone tube (supplied) onto the other end. Thread the tubes,

with installed adaptor, through the conduit opening at the bottom of the

electrical box.

2. Next push the open end of the silicone tubing onto the SRPM

pressure tube header (H1) port labeled “+”. Note: The header is an

Electro-Pneumatic (EP) assembly. “+” indicates (Positive) pressure, and

“-” indicates negative or reference pressure.

3. For the most pressure stable operation, an RPS installed in the

reference pressure area is also recommended. In this case, install the

RPS in a hallway or reference space. Attach the tube to the SRPM in the

same way as for the + port, except attach the tube to the “-” port on the

pressure tube header. Tighten swivel ttings on the SRPM Header H1

assembly if they become loose, 9 in lb. max. Verify that the tubes are not

buckled, which could close off pressure signal at end of installation.

Silicone

Tubing

SRPM

Header H1

Electrical Box

RPS Tubing

RPS Room Pressure SnubberPlumbing inside Electrical Box

9

Page 10

3.3 WIRING, FINISH

3.3.1 ALARM RELAY OUTPUT

The Single Pole Single Throw (SPST) relay output can be used for remote

signaling of alarm condition. A form “C” contact rated at 1A is available.

Connect to J4, P1 and P4 (See Section 8.0 for Diagram of J4). This relay

can be used as a dry contact for remote indication or can drive an SRAN

remote annunciator.

3.3.2 OPTIONAL REMOTE ANNUNCIATOR WIRING

Setra SRAN wiring

In the gure below, the SRAN remote annunciator connector is at left, and

the SRPM connector is at right:

On J4 of the SRPM, jumper P1 to P2, this will connect the internal

15V supply to the common of the internal alarm relay. Connect P2 to

A1 (Located on Remote Annunciator), this supplies 15V exc. to the

Annunciator for powering the circuit during normal conditions. Connect P3

of J4 to A2 of SRAN J1, this is the 15V power return. Finally connect P4

of SRPM J4 to A3 terminal of SRAN J1, this is the alarm trigger.

When an alarm occurs and after the programmed alarm delay times out

the internal relay will supply 15 V to the Annunciator circuit to actuate the

audible beeper and the red LED.

J1: SRAN

+15 VDC Excitation A1

Ground A2

+15 VDC Trigger A3

Jumper

J4: SRPM

P4 (Annunciator Trigger

P3 (Ground)

P2 (+15 VDC Excitation)

P1 (Relay N.O.)

Non-Setra Remote Annunciator

The SRPM can drive other annunciators that are powered by a 15V supply, 50 mA max current draw., and accept a 15V trigger (wire as above).

10

Page 11

Audible Alarm

Potentiometer

The volume control on the Annunciator is a potentiometer that can be

adjusted from 0 to 85 dB. Using a small at bladed screwdriver, rotate

potentiometer (remote annunciator PC board) clockwise to increase

volume and counterclockwise to decrease volume.

3.3.3 DOOR STATUS SWITCH WIRING

Install the door switch into the door jamb. Wire to the normally open (N.O.)

side of the door jamb contact switch. The SRPM will indicate the status of

door position. A contact closure indicates that the door is closed. This is a

low voltage circuit (5 VDC). Run 2 wires from the door switch to connector

J6 on the SRPM (See Section 8.0). The door input status function is

enabled in the SETUP ALARMS menu screen, section 4.7

3.3.4 ANALOG OUTPUT

The SRPM can be congured to have either current (4 to 20 mA) or

voltage (0 to 5 or 0 to 10 VDC) outputs. Voltage output--pin 1, Current

output--pin 2, Common--pin 3. Note: No external excitation is required.

Note1: No external excitation is required.

Note 2: Electro-pneumatic header (page 9) must be connected.

Note 3: For CE compliance a properly grounded shielding cable is required.

Current Output

The SRPM supplies it’s own loop power, do not wire in a separate power

supply.

Voltage Output

1. V Out: 0 to 5, 0 to 10 VDC

2. C Out: 4 to 20 mA

3. Common

+

–

l

l

Receiver

(mA)

11

Page 12

1. V Out: 0 to 5, 0 to 10 VDC

2. C Out: 4 to 20 mA

+

l

Receiver

(V)

3. Common

3.3.5 BACnet

BACnet hardware is implemented as isolated RS485. Wire to Connector

J2, labeled RS-485. Connect tx line to +, rx to – and ground wires to S.

Connect Shields together with wire nut.

Hardware conguration is done using a 5 position dip switch (S1) located

in the upper right hand section of the PCBA as well as through the touch

screen interface, see Section 4.4. and 4.9.

Position Function

1

2

3

4

5

Use a small at blade screwdriver or pen to push the switch to the right

to turn that function on, otherwise it is off.

There is a BACnet setup screen that is enabled by pushing position 1

switch to the “on” position. After conguration the switch must be moved

to the “off” position.

MAC address enable

N/C Not Connected

Pull Up Resistor

Termination Resistor

Pull Down Resistor

l

–

12

Page 13

4.0 STARTUP AND OPERATION

The SRPM is designed with as an easy to use, intuitive, touch screen

interface. In its normal (default) state the Monitoring Screen displays the actual

room static pressure, also a slider bar shows the actual pressure relative

to the alarm limits. The RGB backlight is used to indicate the condition of

the room. The buttons at the bottom of the screen give you access to the

functions that can be performed.

4.1 MENU TREE See section 9.0

4.2 POWER-UP

Apply power and observe the welcome screen and subsequent transition

to the pressure monitor screen. The actual room static pressure is shown

as a number in the center of the LCD and visually as a moving bar

indicator operating between the preset alarm units. The vertical bar is an

indicator of the pressure.

4.3 MONITORING SCREEN

BUTTON DESCRIPTION

Silence

Menu

Reset

Shuts off Alarm

Access to Main Menu Functions

Resets the unit in “Latched” mode.

13

Page 14

The following screens are conguration screens, they can be congured

so that Password protection is required to make changes. If no entry is

made to the screen the unit will return to the default screen after approx.

1 minute.

4.4 MAIN MENU SCREEN

BUTTON DESCRIPTION

Unit

Room

Alarm

BACnet Conguration of BACnet Communications

Self Test

Calibration Perform zero and span calibration.

Back Returns to monitoring screen.

Setup Supervisor password, output, engineering

units, and display averaging.

Set up high and low pressure limits to monitor

a positive, negative, or neutral room.Operator

password setup.

Setup latch alarm, audible alarm, door alarm input,

mute time out, alarm delay, and volume.

Identies product model and software version, and

serial #.

Veries memory and performs alarm test.

14

Page 15

4.5 SETUP UNIT OPERATION

ENTERING DATA Press (or tap) button to select an output or

engineering unit. Selected button background will change from clear to

black.

PASSWORD PROTECTION

Lightly pressing (or tapping) the “Yes” button activates Supervisor

password protection. With Supervisor password protection enabled,

operators can not access menu screens to update setup. Pressing “No”

disables password protection. Pressing “Change” will open “Password

Setting Screen”. To change the password, enter the present password

(numeric value), followed by the new password in the “New Password”

and “Conrm New Password” entry boxes, then press save. Be careful to

store password for future reference.

Analog Output

Select : 4-20, 0-5, or 0-10

Eng. Unit

Select: “WC, Pa, cmWC

DISPLAY AVERAGING

Lightly pressing (or tapping) the “Display Averaging” box activates the

“Data Entry Screen”). Enter from 0 to 60 seconds. Display averaging

affects the analog output. Increase the display averaging time to smooth

out the pressure readings, this will also reduce the display update rate.

15

Page 16

Press Save and Exit.

DATA ENTRY SCREEN

Enter numbers by pressing each key in sequence until the desired

character is displayed in the data entry box above the keypad. (Note:

The cursor will blink for one to two seconds then stop and display the

character.) Erase any mistakes by using the “Back Space” key. When

nished entering data, press the “Enter” key to return to SETUP UNIT

screen.

Note: Use the eraser end of a pencil or back-end of a pen to press (or

tap) box on screen to increase accuracy of inputs.

16

Page 17

4.6 SETUP ROOM SCREEN

SETUP ROOM OPERATION

Setup alarm limits for “protective” positive room static pressure,

“isolating” negative room static pressure or neutral (where the limits can

be – to +).

ENTERING DATA

Press lightly or tap in the Lower Limit data entry box. Enter the lower

limit pressure. Enter the Upper Limit pressure. The Room type box will

change depending on the lower and upper limits. If both entries are

positive, the room will be a Positive Room. If both are negative, the room

will be a Negative Room and if the Lower Limit is negative and the Upper

Limit is positive the room will be a Neutral Room.

OPERATOR PASSWORD

The operator can only change the room from Occupied to No Isolation

and vice versa.

Lightly pressing (or tapping) the “Yes” button activates Operator

password protection. With Operator password protection enabled, room

Occupied/No Isolation status can not be changed without entering a

valid Operator password. Pressing “No” disables password protection.

Pressing “Change” will open “Password Setting Screen”. To change the

password, enter the present password, followed by the new password

in the “New Password” and “Conrm New Password” entry boxes,

then press save. Be careful to save the operator password for future

reference.

17

Page 18

4.7 SETUP ALARMS SCREEN

From this screen the user can access the following:

a. Latched Alarm requires the pressure to return to normal and the

alarm to be acknowledged before the alarm can be silenced and

reset.

b. Enable the audible alarm by selecting “Yes” or use visual only alarm

by selecting “No”.

c. Provide a “door open” warning visual indication. When a door jamb

contact switch is used and this button is activated by pressing “Yes”,

the door status “open” condition is indicated by the touch screen

display turning from green to yellow, and door open indicated on the

monitoring (default) screen.

d. Set the time (in seconds) that the alarm can be silenced in the

latched alarm mode before the alarm resumes. This assumes that

the room static pressure is still outside the normal or set operating

limits. The Mute Time Out can be set from 0 to 9999 seconds.

e. Set the Alarm Delay (in seconds) from the time that the room

pressure goes out of the preset limits until the alarm activates. The

alarm delay may be set from 0 to 9999 seconds.

f. Set the alarm volume or sound level. Using the Up and Down keys,

the volume can be set at level 1-4. Level 4 alarm volume is the

loudest and corresponds to a sound level of 85 dB at a distance of 4

inches.

ALARM SETUP OPERATION

Lightly press (or tap) button to select “Yes” or “No” for Latch Alarm,

Audible Alarm, or Door Alarm Inputs. Selected box background will

change from clear to black when selected.

MUTE TIME OUT/ALARM DELAY

Pressing (or tapping) the “Mute Time Out” or “Alarm Delay” box activates

the Data Entry screen to set the time delay duration.

18

Page 19

4.8 SELF TEST SCREEN

Self Test Operation

This screen identies the Product Model Part Number and Software

Version. User can also perform a Self Test of the unit to verify that the

data in protected area of the EEPROM memory hasn’t been corrupted

and also test the alarm to verify the sound level and alarm setup.

Press “Self Test” button to initiate EEPROM memory checksum test

sequence.

Press “Alarm Test” to test beeper, visual Red LED Alarm, and relay

output. This can be used to verify the system in alarm mode.

Press “Cancel Test” to stop the alarm test.

Press “Exit” to return to Main Menu.

19

Page 20

4.9 CALIBRATION SCREEN

CALIBRATION

To re-zero the device, disconnect the pneumatic tubing from Header

H1 so that room pressures are not applied to the pressure sensor and

lightly press (or tap) the “Zero” button. If a sufciently accurate Pressure

Calibrator is available, apply a steady full-scale pressure signal to the

“+” on the header tting and press (or tap) the “Span” button. Reconnect

the room pressure tube and calibration is complete. Calibration must

be within ±5% of original calibration for this to occur otherwise an error

message will occur.

The original factory pressure calibration can be restored, if desired, by

pushing the “Restore Factory Setting” button.

20

Page 21

4.10 BACnet Setup Screen

BACnet Setup

To setup up BACnet communications, the MAC address enable switch

(S1 [See Section 8]) on the dip switch must be enabled by pushing it to

the right.

Set MAC address, input the address of the device.

Select Device Instance by inputting the device instance into the data

entry box.

Select baud rate by pressing the correct baud rate button, 9600 to

76800.

Save and Exit to save settings or Cancel to cancel setting changes.

Once complete disable the BACnet setup by moving the dip switch

position 1 to “off” (left) position.

If the unit will be at the end of the line, the pull up resistor can be enabled

by pushing position 3 to “on”.

The termination resistor can be inserted by pushing position 4 switch

“on”. The pull down resistor can be enabled by turning position 5 to “on”.

Save and Exit. After the unit returns to the main menu screen

disconnect the power to the unit, then re-connect to boot up with

the proper MAC address and Device Instance.

Position Function

1 MAC address enable

2 Not Used

3 Pull Up Resistor

4 Termination Resistor

5 Pull Down Resistor

See Setra website for information on Points list and PICS and BIBBS

statements.

21

Page 22

Click here to access

ROOM MODE Screen

PRESSURE MONITORING SCREENS

At completion of setup, the main display will be the pressure monitoring

screen, which displays the actual room static pressure.The room static

pressure is shown as a number on the LCD as well as a “Moving Bar”

indicator operating between the preset pressure limits. Normal room

pressure conditions within the preset pressure limits are veried by

a green colored screen. When the door is opened under conditions

within the preset pressure limits, the screen turns to yellow. Room static

pressure outside of the preset limits is indicated by a Red screen after

the alarm’s time delay expires.

CHANGING ROOM MODES

The SRPM can quickly be changed from active monitor and alarming to

No Isolation (or unoccuped). To do this touch the room mode indicator at

the top of the pressure monitoring screen (see above).

OCCUPIED/NO ISOLATION

Use these buttons to quickly change the room to Occupied (Standby)

or No Isolation status. If No Isolation is used there will be no alarms

generated if the room is outside pressure limits.

Press Save and Exit.

22

Page 23

5.0 REMOTE ANNUNCIATOR

The Remote Annunciator provides remote indication of room status.

Audible

Alarm

Green LED

Red LED

Audible Alarm

Acknowledge

Switch

Green LED

Red LED

Acknowledge

Switch

Visual indication of normal room

condition.

Visual indication of a breach in room

pressure protection.

Beeper sounds to indicate breach in

room pressure protection.

Press to silence beeper.

OPERATION

Under normal conditions, the green LED remains on. When an alarmed

condition occurs (i.e., room pressure falls outside preset range), a signal

is triggered by the SRPM, the green LED shuts off, the red LED ashes,

and the audible alarm sounds. The acknowledge button can be pressed

to momentarily turn-off the audible alarm and the red LED will continue

to ash until the alarmed condition is corrected. When the alarmed

condition is corrected the annunciator will reset itself. The green LED

will turn on, and the red LED and audible alarm will shut-off. If the SRPM

reaches the mute time out limit it will re-sound the alarm.

23

Page 24

6.0 MAINTENANCE

The SRPM is designed to operate in an indoor environment, monitoring

clean, dry air.

Upon nal installation of the SRPM Room Pressure Monitor, no routine

maintenance is required. A periodic check of system calibration is

recommended. The SRPM is not eld serviceable and should be

returned if repair is needed (eld repair should not be attempted and may

void warranty). Be sure to include a brief description of the problem plus

any relevant application notes. Contact customer service to receive a

return goods authorization number before shipping.

CLEANING Important

Do not blow into the pressure tubing or ttings with mouth, compressed

air, or canned air. Such actions may permanently damage the pressure

sensor. Do not clean or wash-down the SRPM with industrial cleaners

or solvents. The housing may be wiped down with soap and water or

isopropyl alcohol. The LCD may only be cleaned with isopropyl alcohol.

Do not immerse unit.

24

Page 25

7.0 AGENCY ELECTRICAL STANDARDS

This device falls into CSA “Pollution Degree 2” for PCB insulation and

CSA “Installation Category 2”.

The SRPM meets the following requirements:

CSA Standard C22.2 No 0-M 91: General Requirements - Canadian

electrical code, Part 1

CAN/CSA C22.2 No. 0.4-04: Bonding of Electrical Equipment

CAN/CSA-C22.2 No. 61010-1-04: Safety requirements for electrical

equipment for measurement, control and laboratory Use Part-1: General

Requirements

ANSI/UL61010-1 (Third Edition): Safety requirements for electrical

equipment for measurement, control and laboratory use Part 1: General

Requirements.

25

Page 26

8.0 LOCATION OF COMPONENTS AND ACCESSORIES

26

Page 27

9.0 MENU TREE

27

Page 28

10.0 RETURNING PRODUCTS FOR REPAIR

Before returning the unit for repair, please contact a Setra application engineer (800-257-3872,

978-263-1400) to review information relative to your application . Many times only minor eld

adjustments may be necessary. When returning a product to Setra, the unit should be carefully

packaged and shipped prepaid to:

Setra Systems, Inc.

159 Swanson Road

Boxborough, MA 01719-1304

Attn: Repair Department

To assure prompt handling, please refer to return instructions on our Web site at: http://www.setra.

com/tra/repairs/cal_rep.htm.

Allow approximately 3 weeks after receipt at Setra for the repair and return of the unit.

Non-warranty repairs will not be made without customer approval and a purchase order to cover

repair charges.

Calibration Services

Setra maintains a complete calibration facility that is traceable to the National Institute of Standards

& Technology (NIST). If you would like to recalibrate or recertify your Setra pressure transducers

or transmitters, please call our Repair Department at 800-257-3872 (978-263-1400) for scheduling.

11.0 WARRANTY AND LIMITATIONS OF LIABILITY

Setra warrants its products to be free from defects in materials and workmanship, subject to the

following terms and conditions:

Without charge, Setra will repair or replace products to be found to be defective in materials or

workmanship within the warranty period; provided that:

a.) the product has not been subjected to abuse, neglect, accident, incorrect wiring not our own,

improper installation or servicing, or use in violation of instructions furnished by Setra;

b.) the product has not been repaired or altered by anyone except SETRA or its authorized service

agencies;

c) the serial number or product code has not been removed, defaced, or otherwise changed; and

d) examination discloses, in the judgement of SETRA, the defect in materials or workmanship

developed under normal installation, use and service;

e) SETRA is notied in advance of and the product is returned to SETRA transportation prepaid.

Unless otherwise specied in a manual or warranty card, or agreed to in a writing signed by a

SETRA ocer, SETRA pressure and acceleration products shall be warranted for one year from date

of sale.

The foregoing warranty is in lieu of all warranties, express, implied or statutory, including but not

limited to, any implied warranty of merchantability for a particular purpose.

SETRA’s liability for breach of warranty is limited to repair or replacement, or if the goods cannot

be repaired or replaced, to a refund of the purchase price. SETRA’s liability for all other breaches

is limited to a refund of the purchase price. In no instance shall SETRA be liable for incidental or

consequential damages arising from a breach of warranty, or from the use or installation of its

products.

No representative or person is authorized to give any warranty other than as set out above or to

assume for SETRA any other liability in connection with the sale of its products.

For all CE technical questions, contact Setra Systems, USA. EU customers may contact our EU

representative Hengstler GmbH, Uhlandstr 49, 78554 Aldingen, Germany (Tel: +49-7424-890; Fax:

+49-7424-89500).

159 Swanson Road, Boxborough, MA 01719

Tel: 800-257-3872 Fax: 978-264-0292

Email: sales@setra.com Web: www.setra.com

SS-SRPM351 Rev F 12/13/13

28

Loading...

Loading...