Page 1

Setra Model SRH

Relative Humidity Sensor Series

with Active or Passive Temperature Sensing

Installation Instructions

1.0 GENERAL INFORMATION

Every SRH humidity sensor product is tested and calibrated before shipment. Setra’s

Humidity Sensor family consists of a wall mount, duct mount, and outside air unit.

This product line expands the solution opportunities for the HVAC/building automation market and other relative humid ity monitoring applications. All models utilize

a fi eld-replaceable sensor module, NIST traceability, accuracies of ±2%, ±3%, ±5%,

active or passive temperature sensing, and a durable capacitive sensor capable of

full-scale 0 to 100% RH measurement.

2.0 MECHANICAL INSTALLATION

2.1 Environment

The operating temperature limits of the SRH model are as follows:

Operating Temperature Range -40°F to 140°F (-40 to 60°C)

Storage Temperature -40°F to 158°F (-40 to 70°C)

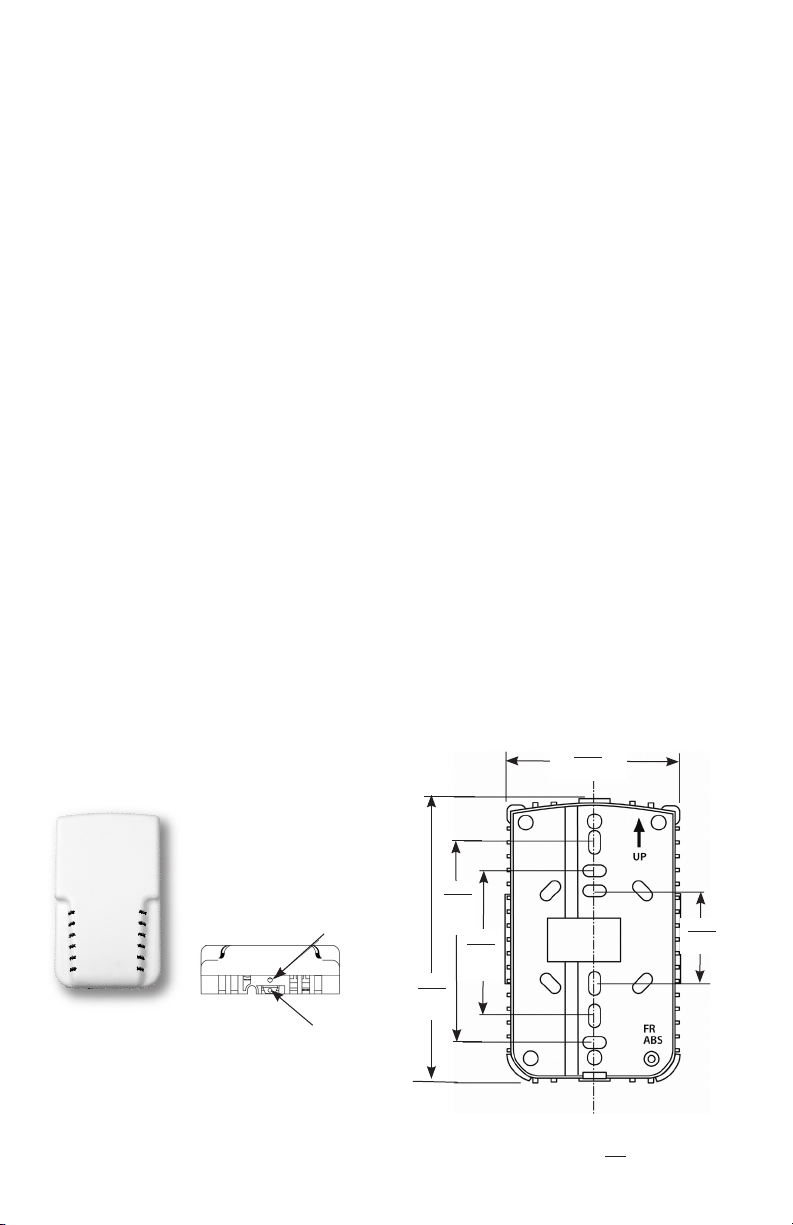

2.1 Wall Mount

It is important to fi nd a place within a room where the transmitter can be exposed to unrestricted air circulation that will represent the average humidity and

temperature within that space. Try to avoid any locations that may be exposed

to fumes, extreme temperatures, and high moisture content. Also, make sure the

location is on an indoor wall that is about 4 to 6 feet above the fl oor. For ease of

Model SRH

Wall Mount Unit

Top View

Security Screw

Security Latch

Front View

To open wall unit, back out the

security set screw (if used), then

press the security latch inward and

lift-up cover.

1

4.69

119

71.50

3.30

84

2.37

60

Wall Mount - Back Plate

2.81

1.41

36

in.

mm

Page 2

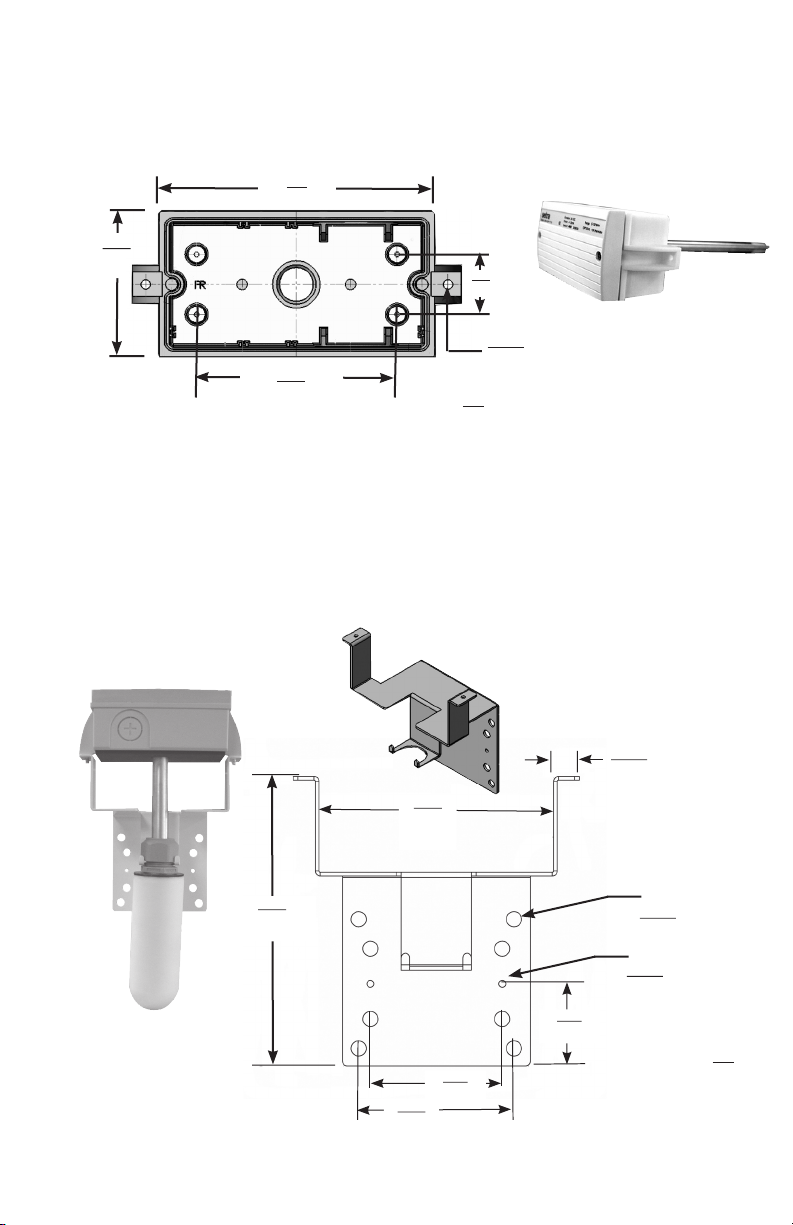

2.2 Duct Mount

For proper operation, it is necessary to locate the transmitter in the center of a section of duct

that receives adequate air flow. Conversely, it must be free of fans, corners, heating/cooling

coils, or any other equipment/ environmentals that could adversely affect relative humidity

measurement.

2.69

68

Duct Mount Base

5.1

130

3.72

94

1.11

28

in.

mm

X2

0.180

5

Model SRH

Duct Unit

shown w/sensing probe

Insert sensing probe through hole (5/8” dia. minimum) and attach full assembly via

the two mounting holes on each side.

2.3 Outside Air Mount

The outside air configuration is supplied with a mounting bracket and two 10-16 x 1/2’ hex

head screws. Locate a position on the building that is clear of exhaust ducts, high exposure

to the sun, direct rain, or other outdoor factors that could adversely affect the operation of

the unit. Ideally, a sheltered area (under an eave) on the north side of the building is best to

protect from the above effects.

Model SRH

Outside Air Unit

shown w/Porous Weather

Shield

4.05

103

5.00

127

1.75

44

2.81

71

3.31

84

Outside Air Mounting Plate

2

X2

0.550

14

X8

0.325

8.3

X2

0.154

4

in.

mm

Page 3

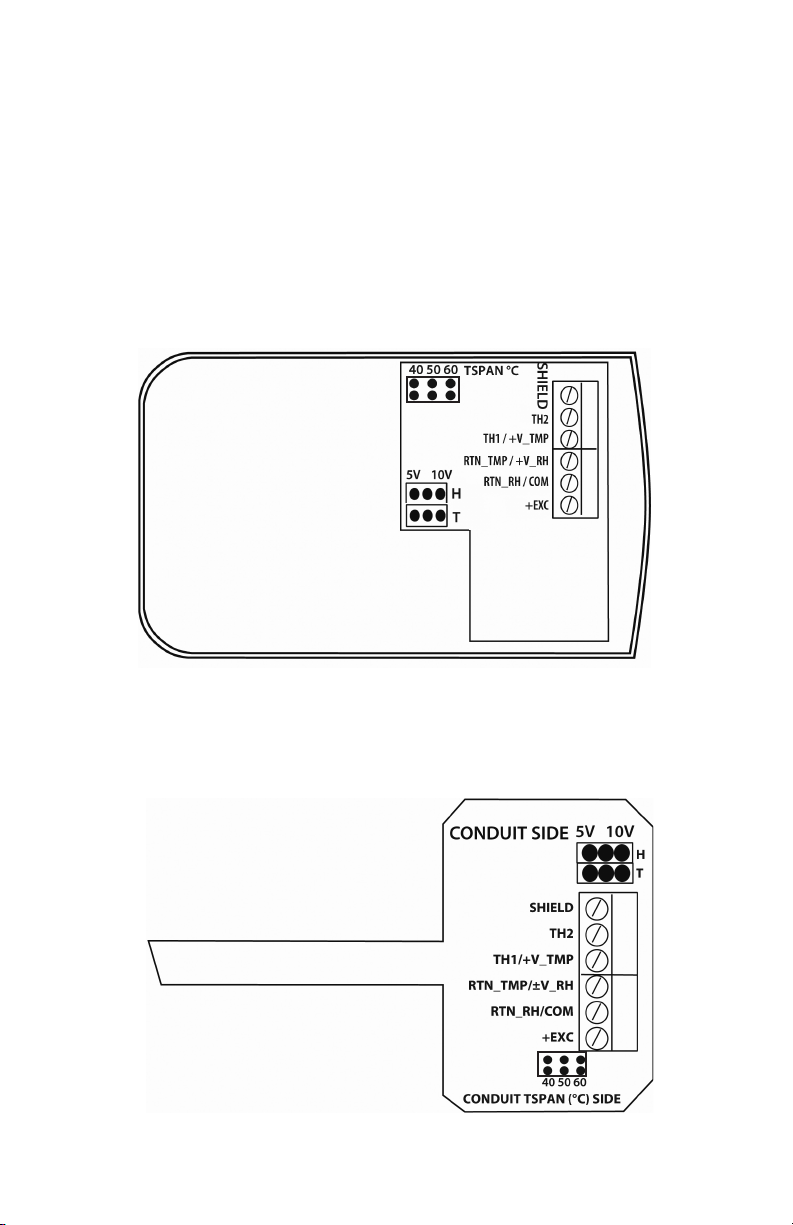

3.0 ELECTRICAL INSTALLATION

3.1 Wiring

Match your transmitter with the corresponding diagrams and set the jumpers and wire

accordingly. Ensure that all of the installation and wiring is in compliance with all national

and local codes. Use 18-22 AWG shielded, twisted pair, copper conductors.

Caution: Do not bundle transmitter wires with AC power wires. Shield must be connected to

earth ground for CE compliance.

Wall Mount

Connector/Jumper Locations - Inside cover

Duct and Outside Mount

Connector/Jumper Locations - Board Assembly/Duct Probe

3

Page 4

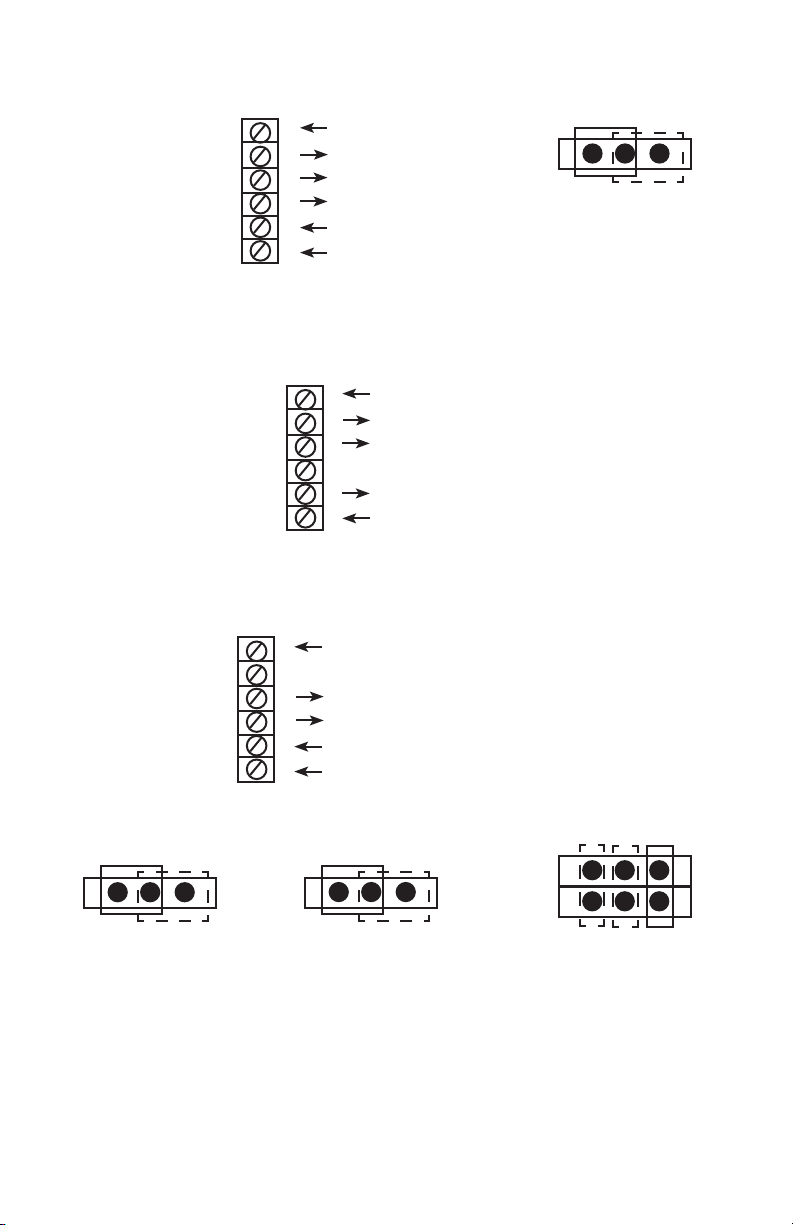

Wiring 0-5 V/0-10 V Output Units (3-wire / T0, T1 & T2)

Shield

TH2

TH1 / +V_TMP

RTN_TMP/ +V_RH

RTN_RH / COM

+EXC

Note: Unit shipped in 0 to 5V Mode. Move jumper to right for 0 to 10V Operation

Wiring 4 to 20 mA Output Units (2-wire / T0, T1 & T2)

6 Earth Ground Connection

5

Thermistor/PRTD

4

3 RH (0 to 5V/0 to 10V) Output

2 Ground

1 Vin

Selectable Outputs

5V

10 V

H

Shield

TH2

TH1 / +V_TMP

RTN_TMP / +V_RH

RTN_RH / COM

+EXC

Wiring 0-5 V/0-10 V Output Units (4-wire / T3 & T5)

Shield

TH2

TH1 / +V_TMP

RTN_TMP/ +V_RH

RTN_RH / COM

+EXC

Selectable Outputs

5V

10 V

H

6 Earth Ground Connection

5

Thermistor/PRTD

4

3 NC

2 RH (4 to 20 mA) Output

1 Vin

6 Earth Ground Connection

5

NC

4

Active Tmp (0-5V/0-10V )Output

3 RH (0 to 5V/0 to 10V) Output

2 Ground

1 Vin

Selectable Tspan

5V

10 V

T

40

50

60

(°C)

Note: Unit shipped in 0 to 5V mode with Tspan set to 60°C. Move Tspan jumper to select

optional ranges.

4

Page 5

Wiring 4 to 20 mA Output Units (3-wire / T3, T5)

Selectable Tspan

Shield

TH2

TH1 / +V_TMP

RTN_TMP / +V_RH

RTN_RH / COM

+EXC

Note: Unit shipped with Tspan set to 60°C. Move Tspan jumper to select optional ranges.

6 Earth Ground Connection

N/C

5

N/C

4

3 Active TMP (4-20 mA) Output

2 RH (4 to 20 mA) Output

1 Vin

40 50

60

(°C)

5

Page 6

4.0 CALIBRATION

All relative humidity products are fully tested and calibrated prior to shipment in

accordance with the National Institute of Standards and Technology (NIST), the

highest quality standard available.

Once installed in the field, no calibration of the units is required. Instead, this

product suite features field-replaceable sensor modules that allow the end user

to replace the sensors on-site. This eliminates time consuming and costly factory

calibration, while reducing downtime during service intervals. Additionally, the

duct mount probe is easily accessed by taking off the front cover, removing the

sensor board assembly, and replacing the sensor module on the tip of the sensor

board. This further contributes to a more user-friendly, lower cost product line

that is focused on customer needs and ease of use.

4.1 Remove/Install the Sensor Tip

Note: Power Must be removed from the main PCBA prior to replacing the sensor

tip module. Failure to comply could possibly damage the sensor tip module

Wall Mount

White

Retaining Clip

Outdoor and Duct Mount

6

Page 7

Replaceable Sensor with Sintered Filter

White

Retaining Clip

Top View

Side View

(PCB to PCB)

Remove the white retaining clip (shown above and on page 6). Remove the

sensor tip module by holdng the sides of the sintered filter along the pcb edges.

Then gently pull the sensor tip module out of the mating connector. Gently push

the replacement sensor tip module into the mating connector (as shown) and

replace the retaining clip to secure the connection.

4.2 Ordering Information - Replacement Sensor Assembly*

Example: Order Part No. SRH3-2P-T0 = Sensor Assembly with 2% accuracy, RH only.

S R H 3

Model Accuracy Temperature Outputs

SRH3 = SRH 2P = 2% T0 = None (RH only)

T3 = -50°C to 60°C (active)

T5

3P = 3% T1 = 10KΩ NTC (passive)

5P = 5%** T2 = 1000Ω RTD (passive)

= -10°C to 60°C (active)

*SRH1 units originally ordered with either a T3 or T5 temperature option MUST

be replaced with the same T(x) version.

**Not available with T3 or T5 option.

7

Page 8

5.0 SPECIFICATIONS

RH Performance Data

Sensing Element Capacitive Polymer

Humidity Operating Range 0 to 99% RH (non-condensing)

Accuracy at 68°F (20°C) 2%, 3%, 5%

Hysteresis <1.5%

Repeatability <0.5%

Long Term Stability <1%/year @ 68°F (20°C), 50% RH

Electrical Data

Signal Outputs

Current (2-wire ckt.) 4 to 20 mA

Field Selectable Voltage (3-wire ckt.) 0 to 5 VDC, 0 to 10 VDC

Excitation

0 to 10 VDC 13.5 to 30 VDC

0 to 5 VDC, 4 to 20 mA 12 to 30 VDC

Maximum Load (Current only) Ω = (Supply - 10) / 0.02

Electrical Termination Pluggable Terminal Block (5mm Pitch)

Wiring Protection Reverse Excitation

CE Compliance EMC Directive 2004/108/EC

Temperature Sensing Options (Passive)

T1 Thermistor Output NTC 10K Ω @ 77°F/25°C (Direct Connect)

Type II

T2 RTD Output 1000 Ω @ 32°F/0°C (Direct Connect)

385 Platinum Curve

Temperature Sensing Options (Active)

Signal Ouput Options (includes humidity output):

Current 4 to 20 mA

Field Selectable Voltage 0 to 5 VDC, 0 to 10 VDC

Available Ranges: Accuracy:

T3 (-50°C to 60°C) ±0.6°C (20°C @ 50%)

T5 (-10°C to 60°C) ±0.4°C (20°C @ 50%)

Environmental Data

Operating Temperature °F (°C) -40 to 140 (-40 to 60)

Storage Temperature °F (°C) -40 to 158 (-40 to 70)

Moisture Resistance IP65, NEMA-4 (Duct & Outside Air)

Solar UV Resistance (Outside Air)

Flammability Rating 94-V0

Compliance RoHS and CE Compliant

Physical Description

Enclosure

Wall Mount ABS 94-V0

Duct & Outside Air Poly Carbonate 94-V0

Probe (Duct & Outside Air) Aluminum

Weather Shield (Outside Air) Porous Polyethylene

8

Page 9

6.0 DIMENSIONAL DRAWINGS

2.81

71.50

5.10

129.5

5.60

142.2

2.68

68.1

4.69

119

0.98

24.7

Wall Mount

6.10

154.9

Security Latch

2.38

60.4

4.50

114.4

2.38

60.4

2.68

68

8,7

221

Duct Probe (5/8” dia.)

Duct Mount

4.04

102.6

12.52

318

4.05

102.7

Duct mount

shown w/optional

Duct Flange

in.

mm

Outside air

9

Page 10

7.0 DUCT MOUNT INSTALLATION

P/N 888415

2.25

57.15

1.125

28.58

1.50

38.10

2.25

57.15

3.00

76.20

Optional Duct Flange

(Top View)

10

4x

ø.180

4.57

1.75

44.45

in.

mm

Page 11

1.62

41.25

Conduit Hole

1.125

28.5

dia.

Optional Duct Flange

0.68

17.27

in.

mm

(Side View)

Mounting the transmitter using the optional duct flange.

1. Drill a 1.125” (28.5 mm) diameter hole into the duct

2. Insert the tapered bushing side into the conduit hole.

3. Press in and all around the outer exposed edge of bushing so the bushing

groove captures the inside edge of the conduit.

4. Secure flange using #10-16 x 1/2” self-drilling screws (recommended)

5. Insert duct probe to desired length plus 1/2”. Pull back unit approximately 1/2”

to create seal.

Note: To remove, simply twist duct housing side to side while pulling outward.

11

Page 12

8.0 RETURNING PRODUCTS FOR REPAIR

When returning a product to Setra Systems, the material should be carefully

packaged and shipped prepaid to:

Setra Systems, Inc.

159 Swanson Road

Boxborough, MA 01719-1304

Attn: Repair Department

To assure prompt handling, please refer to return instructions on our Web site

at http://www.setra.com/tra/repairs/cal_rep.htm.

9.0 WARRANTY AND LIMITATION OF LIABILITY

SETRA warrants its products to be free from defects in materials and workmanship, subject to the

following terms and conditions: Without charge, SETRA will repair or replace products found to be

defective in materials or workmanship within the warranty period; provided that:

a) the product has not been subjected to abuse, neglect, accident, incorrect wiring not our own,

improper installation or servicing, or use in violation of instructions furnished by SETRA;

b) the product has not been repaired or altered by anyone except SETRA or its authorized service

agencies;

c) the serial number or date code has not been removed, defaced, or otherwise changed; and

d) examination discloses, in the judgment of SETRA, the defect in materials or workmanship developed under normal installation, use and service;

e) SETRA is notified in advance of and the product is returned to SETRA transportation prepaid.

Unless otherwise specified in a manual or warranty card, or agreed to in writing and signed by a

SETRA officer, SETRA pressure, humidity, and acceleration products shall be warranted for one year

from date of sale.

The foregoing warranty is in lieu of all warranties, express, implied or statutory, including but not

limited to, any implied warranty of merchantability for a particular purpose.

SETRA’s liability for breach of warranty is limited to repair or replacement, or if the goods cannot be

repaired or replaced, to a refund of the purchase price. In no instance shall SETRA be liable for incidental or consequential damages arising from a breach of warranty, or from the use or installation

of its products. No representative or person is authorized to give any warranty other than as set out

above or to assume for SETRA any other liability in connection with the sale of its products.

For all CE technical questions, contact Setra Systems, USA. EU customers may contact our EU

representative Hengstler GmbH, Uhlandstr 49, 78554 Aldingen, Germany (Tel: +49-7424-890; Fax:

+49-7424-89500).

159 Swanson Road, Boxborough, MA 01719-1304

Tel: 800-257-3872/978-263-1400

Email: sales@setra.com; Web: www.setra.com

SS-SRH Rev. B 2/25/2010

12

Loading...

Loading...