Page 1

Page 2

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

1

Page 3

04.2012 EvoBus GmbH

Not to be reprinted, reproduced or translated in any form without prior permission.

Address for orders:

EvoBus GmbH

Service Documentation

D-89077 Ulm, Germany

Printed in Germany

Order no.:

A 629 584 53 73

Page 4

Introduction

The user information supplied with

each bus is intended for use only

by persons who are qualified to

operate the bus. The user

information is split into the

following parts:

The Driver's Operating Instructions

are intended to answer all important questions concerning operation

of the bus in a concise and clearly

understandable manner.

More detailed and complete information, as well as further information

relevant to safety, can be found in

the Operating Instructions.

The Maintenance Record serves as

a guide to the technical care of the

bus. It contains all the information

on maintenance intervals and maintenance tasks as well as pages for

confirming that the maintenance

work has been carried out.

Please make sure that you read the

“Safety” section before you use the

vehicle for the first time. Before the

bus is driven, please make sure that you

have read and understood the contents

of these Operating Instructions.

Items of optional equipment are also described, if their operation needs explanation. The bus delivered to you has been

customised in accordance with your order, therefore some descriptions and

diagrams may differ from the equipment

on your bus.

The Driver's Operating Instructions, the

Operating Instructions and the Maintenance Record are important documents

and must always be carried in the bus.

Our buses are the subject of ongoing

development. You are therefore asked

to appreciate that we reserve the right

to make modifications to the design,

equipment and technical features. For

these reasons, no claims can be made

based upon the contents of this user

information.

Environmental protection

The declared policy of EvoBus GmbH

is one of integrated environmental protection. This policy starts at the root

causes and encompasses in its management decisions all the consequences for

the environment which could arise from

production processes or the products

themselves.

The objectives are for the natural resources which form the basis of our existence on this planet to be used sparingly and in a manner which takes the

requirements of both nature and humanity into account.

Operate your vehicle in an environmentally responsible manner and you will help

to protect the environment. Fuel consumption and wear in the drive train (engine, clutch, transmission, axles, brakes,

tyres) are extremely dependent on your

driving style.

We hope you enjoy driving your bus.

EvoBus GmbH

Page 5

Setra Omnibusse

Page 6

Table of contents

Vehicle identification . . . . . . . . . . . 1

Safety . . . . . . . . . . . . . . . . . . . . . . . 3

The use of symbols and their mean-

ings . . . . . . . . . . . . . . . . . . . . . . . . . 4

Notes on vehicle safety . . . . . . . . . . . 4

Operating safety . . . . . . . . . . . . . . . . 5

EU Directive 2001/85 . . . . . . . . . . . 5

Stickers . . . . . . . . . . . . . . . . . . . . . . 6

Navigation and global positioning

system . . . . . . . . . . . . . . . . . . . . . . 6

Operation of the radio and mobile

communications equipment . . . . . . . . 7

Operation of mobile phones and

radio equipment without an exterior

aerial . . . . . . . . . . . . . . . . . . . . . . . . 7

Washing the outside of the bus in an

automatic vehicle wash . . . . . . . . . . . 8

Storage space for hand luggage . . . . . 9

Driver's rest area safety precau-

tions . . . . . . . . . . . . . . . . . . . . . . . . 9

Windscreen wiper system safety

precautions . . . . . . . . . . . . . . . . . . . 9

Safety precautions for the air-

conditioning system . . . . . . . . . . . . 10

Operation of auxiliary heating . . . . . 10

General . . . . . . . . . . . . . . . . . . . . . 13

Preparation for the journey - daily

tasks . . . . . . . . . . . . . . . . . . . . . . . 14

Preparation for the journey - weekly

tasks . . . . . . . . . . . . . . . . . . . . . . . 15

Preparation for the journey - monthly

tasks . . . . . . . . . . . . . . . . . . . . . . . 16

Additional maintenance tasks

dependent on bus use . . . . . . . . . . 16

General bus care and mainten-

ance . . . . . . . . . . . . . . . . . . . . . . . 16

Care and cleaning . . . . . . . . . . . . . . 17

Operation . . . . . . . . . . . . . . . . . . . 19

Running-in guideline . . . . . . . . . . . . 22

Starting the engine . . . . . . . . . . . . . 22

Driving . . . . . . . . . . . . . . . . . . . . . . 24

Stopping the engine . . . . . . . . . . . . 25

Towing and tow-starting . . . . . . . . . 26

Trailer towing . . . . . . . . . . . . . . . . . 29

Loading a trailer . . . . . . . . . . . . . . . 30

Driving with a trailer . . . . . . . . . . . . 30

Ball hitch trailer coupling (fixed)

(option) . . . . . . . . . . . . . . . . . . . . . 31

Ball hitch trailer coupling and

open-jaw trailer coupling (detachable)

(option) . . . . . . . . . . . . . . . . . . . . . 32

Connecting the power supply . . . . . 32

Trailer coupling maintenance . . . . . . 33

Refuelling (diesel fuel) . . . . . . . . . . . 33

BlueTec exhaust gas cleaning

system . . . . . . . . . . . . . . . . . . . . . 35

AdBlue service product . . . . . . . . . . 37

Filling with AdBlue . . . . . . . . . . . . . 39

Operating/malfunction displays: fuel

system . . . . . . . . . . . . . . . . . . . . . 41

Function of the accident data

recorder (ADR) (option) . . . . . . . . . . 44

Brake system safety precautions . . . 45

Emergency braking . . . . . . . . . . . . . 45

Braking and stopping . . . . . . . . . . . 46

Brakes with anti-locking protec-

tion . . . . . . . . . . . . . . . . . . . . . . . . 46

Applying the parking brake . . . . . . . 47

Releasing the parking brake . . . . . . 48

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

I

Page 7

Table of contents

Emergency braking in the event of

failure of both brake circuits . . . . . . 48

EBS brake system . . . . . . . . . . . . . 49

Acceleration skid control (ASR) . . . . 50

Brake Assist . . . . . . . . . . . . . . . . . . 50

Adaptive brake lamps . . . . . . . . . . . 50

Electronic Stability Program (ESP)

(system description) . . . . . . . . . . . . 51

Electronic Stability Program (ESP)

(function description) . . . . . . . . . . . 52

Deactivating the Electronic Stability

Program (ESP) . . . . . . . . . . . . . . . . 54

Operating/malfunction displays:

brake system . . . . . . . . . . . . . . . . . 54

Operating 230/400 V systems

(option) . . . . . . . . . . . . . . . . . . . . . 61

Fitting the skibox (option) . . . . . . . . 62

Swivelling the skibox (option) . . . . . 64

Further skibox (option) operating

instructions . . . . . . . . . . . . . . . . . . 65

Note on maintenance work . . . . . . . 65

Cleaning the underbody . . . . . . . . . 66

Care and cleaning . . . . . . . . . . . . . . 70

Care/cleaning of light-alloy

wheels . . . . . . . . . . . . . . . . . . . . . . 72

Care and cleaning of covers and

upholstery . . . . . . . . . . . . . . . . . . . 73

Care/cleaning of fabric covers . . . . 73

Care/cleaning of micro-fibre

covers . . . . . . . . . . . . . . . . . . . . . . 74

Care/cleaning of leather covers . . . . 76

At a glance . . . . . . . . . . . . . . . . . . 79

Driver's area overview . . . . . . . . . . . 82

Switches on the left section of the

instrument panel . . . . . . . . . . . . . . 83

Switches on the right section of the

instrument panel . . . . . . . . . . . . . . 88

Instrument cluster . . . . . . . . . . . . . 90

DTCO tachograph . . . . . . . . . . . . . . 92

Tachograph (display) . . . . . . . . . . . . 94

Door pushbuttons in the driver's

area . . . . . . . . . . . . . . . . . . . . . . . 94

Location of tools and emergency

equipment on the bus . . . . . . . . . . . 95

Location of the fire extinguish-

ers . . . . . . . . . . . . . . . . . . . . . . . . 96

Location of the first-aid kits . . . . . . 96

Tow bar location (option) . . . . . . . . 97

Location of the replacement mirror

(option) . . . . . . . . . . . . . . . . . . . . . 97

Reversing aid display in the exterior

mirror (option) . . . . . . . . . . . . . . . . 97

Emergency hammer (option) . . . . . . 99

Driver's rest area (bus with

roof-mounted air-conditioning

system) . . . . . . . . . . . . . . . . . . . . 100

Driver's rest area (bus with TopAir integrated air-conditioning

system) . . . . . . . . . . . . . . . . . . . . 102

Windscreen washer reservoir . . . . . 104

Reversing camera washer fluid

reservoir (option) . . . . . . . . . . . . . 106

Seat belt reminder display . . . . . . . 107

Exterior flaps on S 411 HD . . . . . . 108

Exterior flaps on S 415 HD . . . . . . 110

Exterior flaps on S 415/416/417

HDH . . . . . . . . . . . . . . . . . . . . . . 112

Layout and function description: fire extinguishing system

(option) . . . . . . . . . . . . . . . . . . . . 113

Fire extinguishing system operating

and malfunction displays . . . . . . . . 114

Driver's area controls . . . . . . . . . 115

Ignition switch . . . . . . . . . . . . . . . 119

Adjustable steering column . . . . . . 119

II

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

Page 8

Table of contents

Exterior lighting . . . . . . . . . . . . . . 120

Steering column switch for light

and wiper functions . . . . . . . . . . . 123

Steering column switch for retarder

and cruise control (overview) . . . . . 125

Overview of steering wheel buttons

and display screen . . . . . . . . . . . . 132

Steering wheel buttons . . . . . . . . . 133

Display screen . . . . . . . . . . . . . . . 134

Display screen (description) . . . . . . 135

Permanent displays . . . . . . . . . . . . 136

Trailer turn signals . . . . . . . . . . . . 137

Overview of main menus and

submenus . . . . . . . . . . . . . . . . . . 138

Menu structure . . . . . . . . . . . . . . . 139

Display screen menu control

logic . . . . . . . . . . . . . . . . . . . . . . 146

Event notifications . . . . . . . . . . . . 148

Instrument cluster buttons . . . . . . 152

Resetting the trip meter . . . . . . . . 153

RESET button (to reset trip

computer data) . . . . . . . . . . . . . . . 153

Menu button . . . . . . . . . . . . . . . . 155

DIAG button (on-board dia-

gnostics) . . . . . . . . . . . . . . . . . . . 155

SET button . . . . . . . . . . . . . . . . . . 156

Setting the language . . . . . . . . . . . 156

Adjusting the volume of the turn

signal buzzer . . . . . . . . . . . . . . . . 158

Setting the wipe interval/rain

sensor sensitivity . . . . . . . . . . . . . 159

Setting the courtesy lighting

switch-on duration . . . . . . . . . . . . 160

Switching the daytime driving lights

on/off . . . . . . . . . . . . . . . . . . . . . 162

Activating the transmission shift

system failsafe mode (GO 240-8

PowerShift) . . . . . . . . . . . . . . . . . 163

Adjusting the display brightness

(daytime brightness) . . . . . . . . . . . 164

Adjusting the display brightness

(night brightness) . . . . . . . . . . . . . 165

Right-hand steering wheel but-

tons . . . . . . . . . . . . . . . . . . . . . . 168

Volume adjustment . . . . . . . . . . . . 169

Radio volume adjustment . . . . . . . 170

Driver's area on-board PA system

volume adjustment . . . . . . . . . . . . 171

Adjusting the volume of the intercom in the driver's rest area/

on-board kitchenette . . . . . . . . . . . 172

Telephone volume adjustment . . . . 173

Initiating an outgoing call using

the driver's rest area/kitchenette

intercom (option) . . . . . . . . . . . . . 174

Initiating an outgoing call using the

driver's area intercom (option) . . . . 174

Answering an incoming call using the driver's area intercom

(option) . . . . . . . . . . . . . . . . . . . . 176

Mobile phone Bluetooth link . . . . . 177

Initiating an outgoing call using a

mobile phone (option) . . . . . . . . . . 179

Answering an incoming call using a

mobile phone (option) . . . . . . . . . . 181

Operating/malfunction displays:

telephone (intercom) . . . . . . . . . . . 182

Parking brake and emergency

release device . . . . . . . . . . . . . . . 183

Air suspension safety precau-

tions . . . . . . . . . . . . . . . . . . . . . . 184

Raising/lowering the bus . . . . . . . 184

Normal level . . . . . . . . . . . . . . . . . 185

Operating/malfunction displays:

level control . . . . . . . . . . . . . . . . . 186

Activating and deactivating the

trailing axle axle load transfer . . . . 187

Activating/deactivating the bus

stop brake (option) . . . . . . . . . . . . 188

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

III

Page 9

Table of contents

Drive-off lock at door II with hinged

step (HDH only) . . . . . . . . . . . . . . 189

Important notes on the steering

system . . . . . . . . . . . . . . . . . . . . 190

Turning the steering wheel when

the bus is stationary . . . . . . . . . . . 190

Switching on the panorama camera

(option) . . . . . . . . . . . . . . . . . . . . 191

Switch descriptions . . . . . . . . . . 193

Master safety switch (emergency-off

switch) (national variant) . . . . . . . . 196

Switch for windscreen roller

sunblind (option) . . . . . . . . . . . . . 197

Switch for co-driver's roller sunblind

(option) . . . . . . . . . . . . . . . . . . . . 197

Switch for upper wiper (option) . . . 198

Driver's area lighting switch . . . . . 198

Attendant call system switch

(option) . . . . . . . . . . . . . . . . . . . . 198

Passenger stop request system

enable switch (option) . . . . . . . . . . 199

Club corner lighting switch

(option) . . . . . . . . . . . . . . . . . . . . 199

Reading lamps switch . . . . . . . . . . 199

Centre aisle lighting switch . . . . . . 200

Passenger-compartment lighting

switch positions I+II . . . . . . . . . . . 200

Switch for school bus operation

(option) . . . . . . . . . . . . . . . . . . . . 200

Headlamp cleaning system OFF

switch . . . . . . . . . . . . . . . . . . . . . 201

Horn changeover switch (op-

tion) . . . . . . . . . . . . . . . . . . . . . . 201

Kitchenette enable switch (op-

tion) . . . . . . . . . . . . . . . . . . . . . . 201

Lavatory enable switch (option) . . . 202

Switch for electrical circuits > 100

V (option) . . . . . . . . . . . . . . . . . . 202

Active Brake Assist OFF pushbutton

(option) . . . . . . . . . . . . . . . . . . . . 202

Switch for the driver's window

heating/mirror heating . . . . . . . . . 203

Windscreen heating switch

(option) . . . . . . . . . . . . . . . . . . . . 203

Central locking switch for the

left-side luggage compartment . . . . 204

Central locking switch for the right-

side luggage compartment . . . . . . 204

Neutral gearshift pushbutton . . . . . 204

Driver's power window pushbut-

ton . . . . . . . . . . . . . . . . . . . . . . . 205

PA system switch . . . . . . . . . . . . . 205

Lane assistant warning system

pushbutton (option) . . . . . . . . . . . 205

Bus stop brake emergency release

switch (option) . . . . . . . . . . . . . . . 206

Mirror adjuster . . . . . . . . . . . . . . . 206

Door I pushbutton . . . . . . . . . . . . 207

Door II pushbutton . . . . . . . . . . . . 208

Switch for deactivating pedal-

activated continuous braking . . . . . 208

Axle load transfer switch (3-axle

buses only) . . . . . . . . . . . . . . . . . 209

Electronic Stability Program (ESP)

OFF pushbutton . . . . . . . . . . . . . . 209

Hazard warning lamps pushbut-

ton . . . . . . . . . . . . . . . . . . . . . . . 209

Bus stop brake pushbutton

(option) . . . . . . . . . . . . . . . . . . . . 210

Pushbutton for reversing camera

washer system (option) . . . . . . . . . 210

Roof hatch switch - air in/air

out . . . . . . . . . . . . . . . . . . . . . . . 211

Multichannel system switch

(option) . . . . . . . . . . . . . . . . . . . . 211

Reverse warning buzzer switch

(option) . . . . . . . . . . . . . . . . . . . . 212

IV

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

Page 10

Table of contents

Pushbutton for raising/lowering the

bus . . . . . . . . . . . . . . . . . . . . . . . 212

Normal-level pushbutton . . . . . . . . 212

Tank changeover switch (op-

tion) . . . . . . . . . . . . . . . . . . . . . . 213

Driver’s seat/passenger

seats . . . . . . . . . . . . . . . . . . . . . 215

Driver’s seat safety precau-

tions . . . . . . . . . . . . . . . . . . . . . . 216

Grammer driver's seat controls . . . 218

ISRI 6860/875 driver's seat control

elements (option) . . . . . . . . . . . . . 220

Operation of the jump seat . . . . . . 222

Using the driver's seat belt . . . . . . 223

Operating the jump-seat seat

belt . . . . . . . . . . . . . . . . . . . . . . . 223

Passenger-compartment-seating

seat belt . . . . . . . . . . . . . . . . . . . 224

Adjusting a passenger seat (new

seat generation) . . . . . . . . . . . . . . 224

Removing a seat squab (new seat

generation) . . . . . . . . . . . . . . . . . 225

Fitting a seat squab (new seat

generation) . . . . . . . . . . . . . . . . . 225

Passenger seat service set . . . . . . 226

Transmission shift systems . . . . 229

Transmission shift system safety

precautions . . . . . . . . . . . . . . . . . 230

Operating the PSH (pneumatic shift

aid) transmission shift system . . . . 230

ZF-AS TRONIC transmission shift

system (option) safety precau-

tions . . . . . . . . . . . . . . . . . . . . . . 231

ZF-AS TRONIC transmission shift

system (option) overview . . . . . . . . 232

ZF-AS TRONIC transmission

shift system (option) (system

description) . . . . . . . . . . . . . . . . . 233

Operating the ZF-AS TRONIC trans-

mission shift system (option) . . . . . 234

ZF-AS TRONIC transmission shift

system operating/malfunction

displays . . . . . . . . . . . . . . . . . . . . 246

GO 240-8 PowerShift transmission shift system (option) (system

description) . . . . . . . . . . . . . . . . . 250

GO 240-8 PowerShift transmission

shift system (option) gearshift unit

(selector lever) . . . . . . . . . . . . . . . 252

Operation of the GO 240-8

PowerShift transmission shift

system (option) . . . . . . . . . . . . . . 253

Operation of the GO 240-8

PowerShift failsafe mode using the

steering wheel keypad (option) . . . 264

Driving systems . . . . . . . . . . . . . 267

Driving systems (overview) . . . . . . 269

Automatic speed limiter . . . . . . . . 270

Automatic speed limiter (function

description) . . . . . . . . . . . . . . . . . 270

Variable speed limiter (Tem-

poset) . . . . . . . . . . . . . . . . . . . . . 271

Activating the variable speed limiter

(Temposet) . . . . . . . . . . . . . . . . . . 271

Drive/brake cruise control . . . . . . 274

Activating drive/brake cruise

control . . . . . . . . . . . . . . . . . . . . . 275

Distance cruise control (ART)

(option) . . . . . . . . . . . . . . . . . . . . 278

Distance sensor for distance cruise

control (ART) . . . . . . . . . . . . . . . . 279

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

V

Page 11

Table of contents

Activating distance cruise control

(ART) (option) . . . . . . . . . . . . . . . . 280

Setting the specified distance . . . . 282

Vehicle ahead detected . . . . . . . . . 284

How to respond to a distance

warning . . . . . . . . . . . . . . . . . . . . 285

Operating/malfunction displays:

distance cruise control (ART) . . . . . 286

Active Brake Assist (ABA) (system

description) . . . . . . . . . . . . . . . . . 287

Activation/deactivation of Active

Brake Assist (automatic) . . . . . . . . 288

Activating Active Brake Assist (ABA)

(manually) . . . . . . . . . . . . . . . . . . 289

Deactivating Active Brake Assist

(ABA) (manually) . . . . . . . . . . . . . . 289

Sequence of events when emergency braking initiated by Active

Brake Assist (ABA) . . . . . . . . . . . . 292

Function description: warning levels

and emergency braking . . . . . . . . . 293

Operating/malfunction displays:

Active Brake Assist (ABA) . . . . . . . 297

Special driving situations with distance cruise control/Active Brake

Assist . . . . . . . . . . . . . . . . . . . . . 301

Important information on the

lane assistant warning system

(option) . . . . . . . . . . . . . . . . . . . . 305

Deactivating the lane assistant

warning system . . . . . . . . . . . . . . 307

Operating/malfunction displays:

lane assistant warning system . . . . 308

Heating/ventilation/air-condi-

tioning . . . . . . . . . . . . . . . . . . . . 311

Operating instructions for the air-

conditioning system . . . . . . . . . . . 312

Heating/ventilation/air-conditioning

(HVAC) control panel . . . . . . . . . . 314

Manually regulating the blower

speed in the driver's area . . . . . . . 317

Preselecting the passenger-

compartment temperature . . . . . . . 318

Manually regulating the blower

speed in the passenger compart-

ment . . . . . . . . . . . . . . . . . . . . . . 320

Activating the air-conditioning . . . . 321

Switching on air-recirculation mode

in the driver's area and passenger

compartment . . . . . . . . . . . . . . . . 322

Activating the reheat function . . . . 323

Activating the auxiliary heating

unit . . . . . . . . . . . . . . . . . . . . . . . 324

Programming auxiliary heating

switch-on times . . . . . . . . . . . . . . 325

Activating a programmed auxiliary

heating switch-on time . . . . . . . . . 328

Deactivating an activated switch-on

time . . . . . . . . . . . . . . . . . . . . . . 329

Programming the auxiliary heating

switch-on duration . . . . . . . . . . . . 330

Switches/controllers in the driver's

rest area (bus with roof-mounted

air-conditioning system) . . . . . . . . 332

Switches/controllers in the driver's

rest area (bus with TopAir integ-

rated air-conditioning system) . . . . 334

Opening/locking . . . . . . . . . . . . . 337

Anti-entrapment protection (reversing) in the door closing

direction . . . . . . . . . . . . . . . . . . . 338

Anti-entrapment protection

(reduced-power pushback) in the

door opening direction . . . . . . . . . 338

VI

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

Page 12

Table of contents

Door II anti-entrapment protection

(reduced-power pushback) activated

by hinged step (HDH only) . . . . . . 339

Emergency operation of the doors

in the event of an electrical system

failure or CAN bus malfunction . . . 340

Operating/malfunction displays:

doors . . . . . . . . . . . . . . . . . . . . . 341

Unlocking the door circuit (using

the remote control, front right door

or driver's door front left) . . . . . . . 345

Unlocking the luggage compartment

flaps using the remote control . . . . 347

Unlocking the luggage compartment

flaps using the pushbuttons in the

driver's area . . . . . . . . . . . . . . . . . 347

Locking (using the remote con-

trol) . . . . . . . . . . . . . . . . . . . . . . . 348

Central locking system (system

description) . . . . . . . . . . . . . . . . . 350

Operating/malfunction displays:

central locking . . . . . . . . . . . . . . . 354

Emergency operation (depressurising the doors using the

emergency valves) . . . . . . . . . . . . 355

Emergency closing of the

doors . . . . . . . . . . . . . . . . . . . . . 357

Emergency unlocking of the luggage

compartment flaps in the event of a

compressed-air supply failure . . . . 359

Emergency exit through emergency

operation of the roof hatches . . . . 360

On-board kitchenette (op-

tion) . . . . . . . . . . . . . . . . . . . . . . 363

General information . . . . . . . . . . . 366

Instructions for operating a

microwave oven . . . . . . . . . . . . . . 367

Use for the intended purpose . . . . 369

Approved personnel . . . . . . . . . . . 369

First use of the galley . . . . . . . . . . 370

Switching on the galley . . . . . . . . . 371

Filling the fresh water tank inside

the bus . . . . . . . . . . . . . . . . . . . . 372

Filling the fresh water tank outside

the bus . . . . . . . . . . . . . . . . . . . . 374

Checking and cleaning the fresh

water filter . . . . . . . . . . . . . . . . . . 374

Drawing water from the water

tap . . . . . . . . . . . . . . . . . . . . . . . 375

Switching on the boiler . . . . . . . . . 376

Descaling the boiler . . . . . . . . . . . 377

Switching on the sausage heat-

er . . . . . . . . . . . . . . . . . . . . . . . . 379

Cleaning the sausage heater . . . . . 383

Descaling the sausage heater . . . . 383

Switching on the 40-cup coffee

machine . . . . . . . . . . . . . . . . . . . . 383

Brewing coffee in winter . . . . . . . . 387

Cleaning the 40-cup coffee

machine . . . . . . . . . . . . . . . . . . . . 388

Switching on the 2-carafe filter

system . . . . . . . . . . . . . . . . . . . . 389

Brewing 1/2 a carafe of coffee (10

cups of coffee) . . . . . . . . . . . . . . . 389

Brewing 1 carafe of coffee (20 cups

of coffee) . . . . . . . . . . . . . . . . . . . 390

Brewing 2 carafes of coffee (40

cups of coffee) . . . . . . . . . . . . . . . 391

Manual operation of the 2-carafe

filter system . . . . . . . . . . . . . . . . . 392

Descaling the coffee machine . . . . 392

Winter operation . . . . . . . . . . . . . . 394

Draining the fresh water tank . . . . 394

Draining the water lines . . . . . . . . 395

Draining the boiler . . . . . . . . . . . . 395

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

VII

Page 13

Table of contents

Draining the 40-cup coffee

machine . . . . . . . . . . . . . . . . . . . . 396

Draining the 2-carafe filter sys-

tem . . . . . . . . . . . . . . . . . . . . . . . 397

Draining the siphon . . . . . . . . . . . 398

Replacing fuses . . . . . . . . . . . . . . 398

Malfunctions . . . . . . . . . . . . . . . . 400

Restoring boiler operation following

a malfunction . . . . . . . . . . . . . . . . 400

Using the sausage heater again

after a malfunction . . . . . . . . . . . . 401

Using the 40-cup coffee machine

again after a malfunction . . . . . . . 402

Using the 2-carafe filter system

again after a malfunction . . . . . . . 403

Other malfunctions . . . . . . . . . . . . 404

Switching off the galley . . . . . . . . . 405

On-board kitchenette (integrated into the lavatory cabin)

(option) . . . . . . . . . . . . . . . . . . . . 407

Safety precautions/general

information . . . . . . . . . . . . . . . . . 409

Use for the intended purpose . . . . 410

Approved personnel . . . . . . . . . . . 410

First use of the galley . . . . . . . . . . 410

Switching on the galley . . . . . . . . . 411

Filling the fresh water tank inside

the bus . . . . . . . . . . . . . . . . . . . . 413

Filling the fresh water tank outside

the bus . . . . . . . . . . . . . . . . . . . . 414

Checking and cleaning the fresh

water filter . . . . . . . . . . . . . . . . . . 414

Drawing water from the water

tap . . . . . . . . . . . . . . . . . . . . . . . 415

Switching on the sausage heat-

er . . . . . . . . . . . . . . . . . . . . . . . . 415

Cleaning the sausage heater . . . . . 418

Descaling the sausage heater . . . . 418

Switching on the coffee ma-

chine . . . . . . . . . . . . . . . . . . . . . . 419

Brewing 1/2 a carafe of coffee (10

cups of coffee) . . . . . . . . . . . . . . . 419

Brewing 1 carafe of coffee (20 cups

of coffee) . . . . . . . . . . . . . . . . . . . 420

Descaling the coffee machine . . . . 421

Dispensing cups of hot water

(alternative to coffee machine) . . . 422

Water heater (option) . . . . . . . . . . 423

Setting the thermostat of the water

heater . . . . . . . . . . . . . . . . . . . . . 424

Descaling the water heater

boiler . . . . . . . . . . . . . . . . . . . . . . 425

Winter operation . . . . . . . . . . . . . . 426

Draining the fresh water tank . . . . 427

Draining the water lines . . . . . . . . 427

Draining the boiler . . . . . . . . . . . . 428

Draining the siphon . . . . . . . . . . . 429

Replacing fuses . . . . . . . . . . . . . . 430

Malfunctions . . . . . . . . . . . . . . . . 432

Using the sausage heater again

after a malfunction . . . . . . . . . . . . 433

Using the coffee machine again

after a malfunction . . . . . . . . . . . . 433

Using the water heater (option)

again after a malfunction . . . . . . . 434

Other malfunctions . . . . . . . . . . . . 436

Switching off the galley . . . . . . . . . 437

Lavatory . . . . . . . . . . . . . . . . . . . 439

Enabling the lavatory . . . . . . . . . . 440

Switchover between water (WC)

and chemical (CC) operation

(option) . . . . . . . . . . . . . . . . . . . . 442

Flushing the WC . . . . . . . . . . . . . . 443

VIII

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

Page 14

Table of contents

Drawing water at the handwash

basin . . . . . . . . . . . . . . . . . . . . . . 444

Filling the soap dispenser . . . . . . . 444

Adding paper hand towels . . . . . . . 445

Adding toilet paper . . . . . . . . . . . . 445

Opening the basin undercabin-

et . . . . . . . . . . . . . . . . . . . . . . . . 445

Changing waste bags . . . . . . . . . . 446

Filling the fresh water storage

tank . . . . . . . . . . . . . . . . . . . . . . 446

Emptying the fresh water storage

tank . . . . . . . . . . . . . . . . . . . . . . 447

Emptying the holding tank . . . . . . . 448

Winter operation . . . . . . . . . . . . . . 449

Checking the residual current

device for the 230 V socket

(option) . . . . . . . . . . . . . . . . . . . . 450

Lavatory cabins with air heater

(option) . . . . . . . . . . . . . . . . . . . . 451

Greasing the impeller of the CC

pump . . . . . . . . . . . . . . . . . . . . . . 453

Practical advice . . . . . . . . . . . . . 455

Overview of the operating, function

and malfunction display screen . . . 461

Engine oil level display . . . . . . . . . 468

Oil level alerts . . . . . . . . . . . . . . . 469

Oil level information . . . . . . . . . . . 471

Checking the engine oil level with

the dipstick (option) . . . . . . . . . . . 474

Checking the engine oil level with

the dipstick (OM 501/502 LA)

(option) . . . . . . . . . . . . . . . . . . . . 475

Safety instructions for working in

the engine compartment . . . . . . . . 476

Removing the drive belts

(OM 457 LA) . . . . . . . . . . . . . . . . 476

Fitting the drive belts (OM 457 LA) . .479

Removing the drive belts (OM 501

LA) . . . . . . . . . . . . . . . . . . . . . . . 482

Fitting the drive belts (OM 501

LA) . . . . . . . . . . . . . . . . . . . . . . . 484

Removing the drive belts (OM 502

LA) . . . . . . . . . . . . . . . . . . . . . . . 486

Fitting the drive belts (OM 502 LA) . .488

Engine cooling system fan drive

emergency operation . . . . . . . . . . 490

Checking the coolant level of the

engine and heating system . . . . . . 491

Tyres - operating safety and

roadworthiness . . . . . . . . . . . . . . . 492

Tyre pressure . . . . . . . . . . . . . . . . 492

Tyre tread . . . . . . . . . . . . . . . . . . 493

Tyre condition . . . . . . . . . . . . . . . 493

Tyre age . . . . . . . . . . . . . . . . . . . 494

Invisible tyre damage . . . . . . . . . . 494

Tyre load capacity, top speed of

tyres and types of tyres . . . . . . . . 494

Retreaded tyres . . . . . . . . . . . . . . 495

Tyre pressures table 295/80 R

22.5 . . . . . . . . . . . . . . . . . . . . . . 496

Safety measures to be taken in

the event of a flat tyre or a wheel

change . . . . . . . . . . . . . . . . . . . . 497

Fitting snow chains . . . . . . . . . . . . 498

Removing the spare wheel from the

spare wheel cover . . . . . . . . . . . . 498

Positioning the jack . . . . . . . . . . . 499

Removing the wheel trims . . . . . . . 500

Removing the wheels . . . . . . . . . . 501

Fitting the spare wheel . . . . . . . . . 505

Fitting the wheel trims . . . . . . . . . 507

Inflating tyres using the tyre inflator

connection . . . . . . . . . . . . . . . . . . 508

Pneumatic system test ports under

the driver's area, vehicles with

Raufoss unions . . . . . . . . . . . . . . . 512

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

IX

Page 15

Table of contents

Pneumatic test ports behind door

2 . . . . . . . . . . . . . . . . . . . . . . . . . 514

Other pneumatic test ports . . . . . . 516

Charging the compressed-air

system of another bus . . . . . . . . . 517

Operating the bus stop brake emer-

gency release switch (option) . . . . 519

Operating/malfunction displays:

steering system . . . . . . . . . . . . . . 520

Checking the oil level in the power-

steering expansion tank . . . . . . . . 521

Draining the fuel prefilter . . . . . . . 522

Replacing the filter element for the

fuel prefilter . . . . . . . . . . . . . . . . . 522

Changing the main fuel filter

(OM 457 LA) . . . . . . . . . . . . . . . . 524

Replacing the main fuel filter (OM

501 LA) . . . . . . . . . . . . . . . . . . . . 526

Changing the main fuel filter

(OM 502 LA) . . . . . . . . . . . . . . . . 529

Changing the water heater fuel

filter . . . . . . . . . . . . . . . . . . . . . . 531

Bleeding the fuel system . . . . . . . . 532

Electrical system safety precau-

tions . . . . . . . . . . . . . . . . . . . . . . 532

Safety precautions for handling

batteries . . . . . . . . . . . . . . . . . . . 533

Measures required for the prevention of damage to buses or

components during electric welding

work . . . . . . . . . . . . . . . . . . . . . . 534

Electrical system overview - TopClass 400 (illustration shows S 415

HD (2-axle bus) as an example)

. . . . . . . . . . . . . . . . . . . . . . . . . . 536

Driver's area interior switch

panel . . . . . . . . . . . . . . . . . . . . . . 538

Main switch panel (under the

driver’s area) . . . . . . . . . . . . . . . . 540

Auxiliary switch panel . . . . . . . . . . 542

Ceiling switch panel . . . . . . . . . . . 544

PDB fuse switch panel . . . . . . . . . 546

Battery compartment in 2-axle

buses . . . . . . . . . . . . . . . . . . . . . 548

Battery compartment in 3-axle

buses . . . . . . . . . . . . . . . . . . . . . 550

Notes on fuse assignments . . . . . . 551

Fuse assignment for the driver’s

area interior switch panel, TopClass

400 . . . . . . . . . . . . . . . . . . . . . . . 552

Fuse assignment for the main

switch panel (under the driver’s

area), TopClass 400 . . . . . . . . . . . 556

Fuse assignment for auxiliary

switch panel, S 411 HD and

S 415 HDC . . . . . . . . . . . . . . . . . 558

Fuse assignment for auxiliary

switch panel with PDB (S 415/

416/417 HDH) . . . . . . . . . . . . . . 562

Fuse assignment for PDB on

auxiliary switch panel (S 415/

416/417 HDH) . . . . . . . . . . . . . . 566

Fuse assignment for auxiliary switch

panel, S 415 HD . . . . . . . . . . . . . 568

Fuse assignment for power distribution board (PDB), S 411/415 HD

and S 415 HDC . . . . . . . . . . . . . . 572

Fuse assignment for the ceiling

switch panel, TopClass 400 . . . . . . 576

Handling fuses . . . . . . . . . . . . . . . 578

Disconnecting vehicle batteries . . . 579

Recharging vehicle batteries . . . . . 580

Notes on jump-starting . . . . . . . . . 581

Jump-start procedure . . . . . . . . . . 582

Activating the on-board dia-

gnostics . . . . . . . . . . . . . . . . . . . . 582

Interpreting the on-board dia-

gnostics screen display . . . . . . . . . 584

Clearing the fault memory of the

selected system . . . . . . . . . . . . . . 585

X

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

Page 16

Ending on-board diagnostics . . . . . 585

Changing bulbs . . . . . . . . . . . . . . 585

Adjusting the headlamps for driving

on the left or right . . . . . . . . . . . . 592

Changing the batteries in the radio

remote control . . . . . . . . . . . . . . . 594

Removing the exterior mirror, fitting

the emergency mirror (option) . . . . 594

Emergency operation of the passen-

ger compartment heating . . . . . . . 596

Maintenance tasks on the bus air-

conditioning system . . . . . . . . . . . 597

Scopes of maintenance for the

roof-mounted air-conditioning

system . . . . . . . . . . . . . . . . . . . . 600

Scopes of maintenance for the

TopAir integrated air-conditioning

system . . . . . . . . . . . . . . . . . . . . 603

Cleaning the heating system water

filter . . . . . . . . . . . . . . . . . . . . . . 606

Bleeding the coolant circuit for the

“TopAir” heating system in the S

415 HD. . . . . . . . . . . . . . . . . . . . 609

Bleeding the coolant circuit for the

“TopAir” heating system in the S

415/416/417 HDH . . . . . . . . . . . 616

Cleaning the reversing camera . . . . 622

Table of contents

Technical data . . . . . . . . . . . . . . 623

Vehicle data . . . . . . . . . . . . . . . . . 624

Overview of bulbs . . . . . . . . . . . . . 626

Index . . . . . . . . . . . . . . . . . . . . . 627

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

XI

Page 17

Table of contents

XII

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

Page 18

Vehicle identification

No. Designation Value

M00_00-0083-01

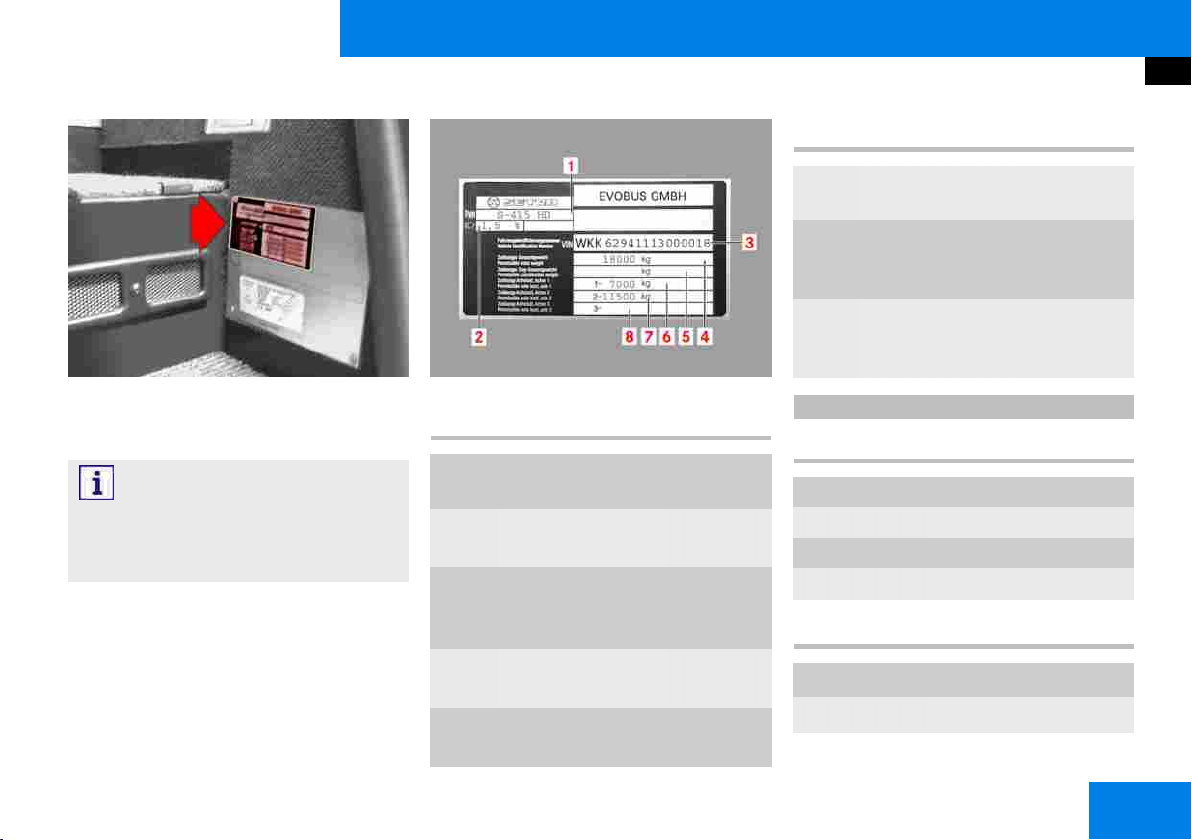

The identification plate is located at the

front entrance on the right

Note:

It is very important to identify the vehicle

exactly so that the correct “vehicle data”

can be assigned.

M00_00-0155-01

No. Designation Value

1

Vehicle designation

2

Headlamp basic

setting

3

Vehicle identification number

(VIN)

4

Permissible gross

vehicle weight

5

Permissible gross

towing weight

6

Permissible axle

load for front axle

7

Permissible axle

load for driven

axle

8

Permissible axle

load for trailing

axle

S 415 HD

415 Vehicle length

411 10.16 m

415 12.20 m or 12.30 m

416 13.19 m

417 14.05 m

HD Vehicle height

HD

HDH

High decker

High decker, high

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

1

Page 19

Vehicle identification

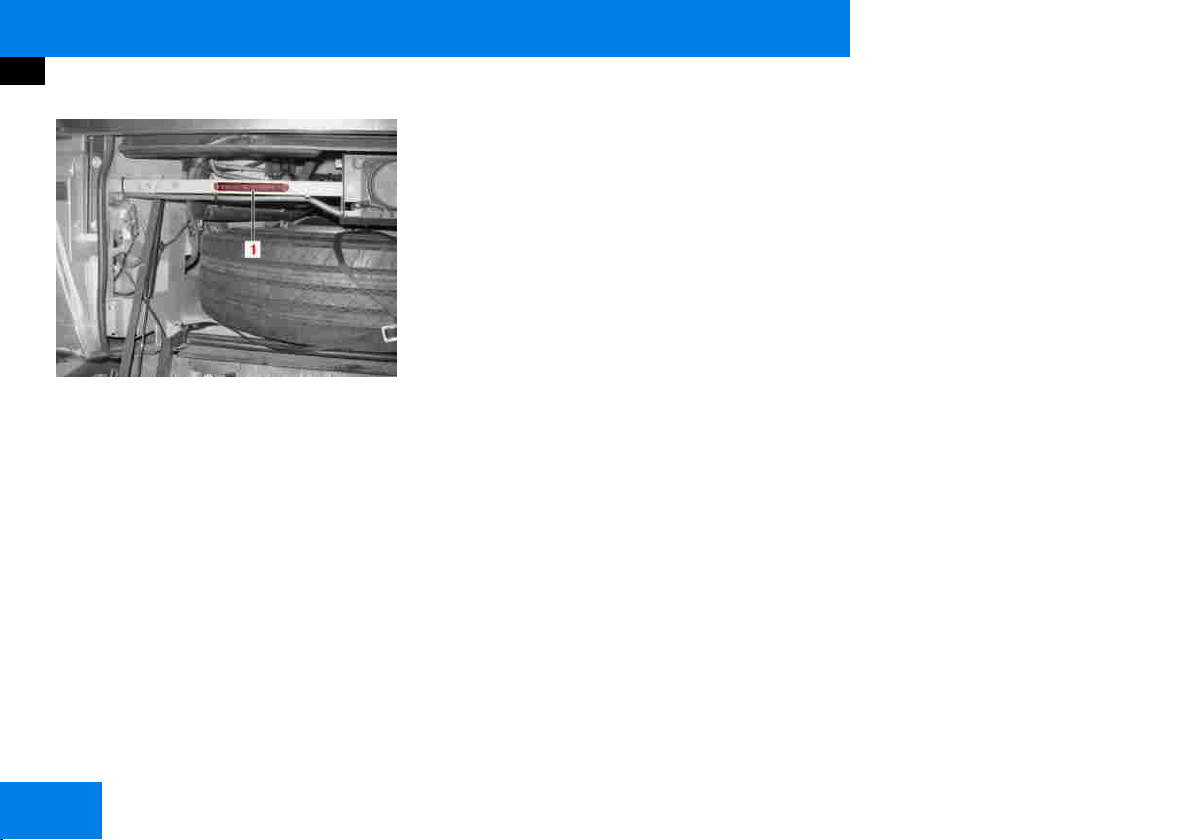

M00_00-0552-71

Vehicle identification number (1) is also

marked on the skeleton at the front of

the bus. It can be accessed via the

spare wheel cover (to open, use the

lever in the front right doorway).

2

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

Page 20

Safety

Table of contents

The use of symbols and their meanings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Notes on vehicle safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

EU Directive 2001/85 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Stickers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Navigation and global positioning system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operation of the radio and mobile communications equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation of mobile phones and radio equipment without an exterior aerial . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Washing the outside of the bus in an automatic vehicle wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Storage space for hand luggage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Driver's rest area safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Windscreen wiper system safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety precautions for the air-conditioning system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation of auxiliary heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

3

Page 21

Safety

The use of symbols and their meanings

The use of symbols and their

meanings

Safety precautions and other important

instructions are highlighted by symbols.

In addition to the instructions listed in

the contents, the safety and accident

prevention regulations issued by German

Employer's Liability Insurance Associations must be observed.

Instructions and information printed on

the packaging for components, tools and

service products must also be observed.

Where information and instructions are

to be observed, it is also assumed that

the user information is intended for persons who are suitably qualified to carry

out the tasks by nature of their education, training and experience.

At the same time, these persons should

be able to identify risks that may arise in

the undertaking of their tasks and take

the necessary measures to avoid them.

Meaning of symbols:

Note:

Notes about important additional information

Caution:

Warning notes about damage that may

occur in the event of non-compliance

Danger.

Warning notes for risks to persons

Environmental protection

Notes about environmental protection

measures

Reference to more detailed and addi-

tional user information

Notes on vehicle safety

We recommend that you:

Use only genuine parts that are

OMNIplus quality tested and conversion parts and accessories that

have been expressly approved by

EvoBus for the bus model concerned

in order to rule out the possibility

of jeopardising road safety and

invalidating the warranty and general

operating permit. These parts have

been specially tested for their safety,

reliability and suitability.

You can obtain further information from

any EvoBus Service Partner.

4

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

Page 22

Safety

Operating safety

Operating safety

Important notes:

Any work or modifications that have

been carried out incorrectly on the

bus may result in malfunctions.

Tampering with electronic components and their software may cause

malfunctions. As electronic components are networked, these malfunctions may also cause other, indirectly related systems to malfunction.

These malfunctions may jeopardise

the operating safety and reliability of

the bus.

Retrofitted electrical or electronic

devices must possess type-approval

complying with Directive 95/54/EC

or ECE Directive 10/02.

Materials that are fitted in the bus

during the course of installation, conversion or modification work and

that are subject to mandatory firetesting requirements must also satisfy the conditions of EU Directive

95/28/EC.

Materials and components in

seats and seat fixtures that are

also fitted in the bus during the

course of installation, conversion or

modification must also satisfy the

following directives: 76/115/EEC

as amended by 96/38/EC, 74/

408/EEC as amended by 96/

37/EC, 77/541/EEC as amended by

96/36/EC

When such materials and components are purchased or installed, care

shall be taken to ensure that they

are appropriately certified. Use of

materials and components that do

not possess the certificate referred

to above can result in the operating

permit being invalidated.

We recommend that you have any

work or modifications carried out by

an EvoBus Service Partner.

EU Directive 2001/85

Registration as class 1: city public

service bus

Vehicles constructed with areas for

standing passengers, to allow frequent passenger movement

Registration as class 2: long-distance

public service bus

Principally for the carriage of seated

passengers. Designed to allow the

carriage of standing passengers in

the gangway and/or in an area which

does not exceed the space provided

for two double seats.

Registration as class 3: tourist coach

Exclusively for the carriage of seated

passengers.

Important information for buses

classified in accordance with EU

Directive 2001/85 into class 2 and 3

(mixed approval):

The operator of the bus is responsible for ensuring that the bus is restored to the condition consistent

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

5

Page 23

Safety

Stickers

with the permissible type of operation of the class concerned.

For instance, this means that, in the

case of a bus being used in accordance with class 2, it is necessary to

ensure that the bus is operated with

seating having no aisle-side sideways

adjustment.

Stickers

There are various warning stickers affixed to your bus. These are intended to

make you and others aware of various

dangers. Therefore, do not remove any

warning stickers unless it is expressly

stated on the sticker that you may do

so.

Danger.

If you remove warning stickers, this could

result in you or other persons failing to

recognise dangers. You or others could

be injured as a result.

Navigation and global positioning system

Please follow the instructions below if

your bus is fitted with a navigation system:

Danger.

Please devote your attention primarily to

road and traffic conditions. Do not operate the navigation and positioning system unless the bus is stationary. Please

remember that your bus covers 14 m

every second when it is only travelling

at approximately 30 mph (50 km/h).

The navigation system is unable to detect the maximum load-bearing capacity

for bridges or the maximum permissible

height for driving through underpasses.

The driver is responsible for ensuring that

bridge load-bearing capacities and maximum headroom clearance are not exceeded.

6

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

Page 24

Safety

Operation of the radio and mobile communications equipment

Operation of the radio and mobile

communications equipment

(e.g. telephone, radio, fax machine, etc.)

Danger.

Please devote your attention primarily

to road and traffic conditions. Do not

operate the display unit, radio or mobile

communications equipment unless the

traffic situation permits this to be done

safely. Please remember that your bus

covers 14 m every second when it is only

travelling at approximately 30 mph (50

km/h).

Note:

In the Federal Republic of Germany, Section 23, Paragraph 1a of the German road

traffic regulations (StVO) prohibit a vehicle

driver from using a mobile phone or an

on-board telephone/intercom if this use

involves lifting up or holding the mobile

phone or the telephone/intercom handset.

Danger.

Please observe local legal requirements

governing the use of mobile phones or

on-board telephones/intercoms in force in

the country of vehicle operation.

Operation of mobile phones and radio equipment without an exterior aerial

We advise against making or receiving

telephone calls in buses not equipped

with an exterior aerial as the operation

of radio transmitters, which include but

are not limited to radio telephones (mobile phones), may cause inadequately

shielded equipment (cardiac pacemakers

included) to malfunction.

Note:

If a mobile phone, radio system or fax

machine is retrofitted in the bus in a

manner that does not comply with EvoBus

installation specifications, the operating

permit for the bus could be invalidated

(EU Directive 95/54/EC).

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

7

Page 25

Safety

Washing the outside of the bus in an automatic vehicle wash

Note:

Older peripherals (e.g. ticket-printing machines, ticket-cancelling machines, destination displays, etc.) that are still used in

new buses must comply with the technical requirements of EC Directive 72/245

EEC.

Danger.

Please observe local legal requirements

governing the use of mobile phones or

on-board telephones/intercoms in force in

the country of vehicle operation.

Washing the outside of the bus in

an automatic vehicle wash

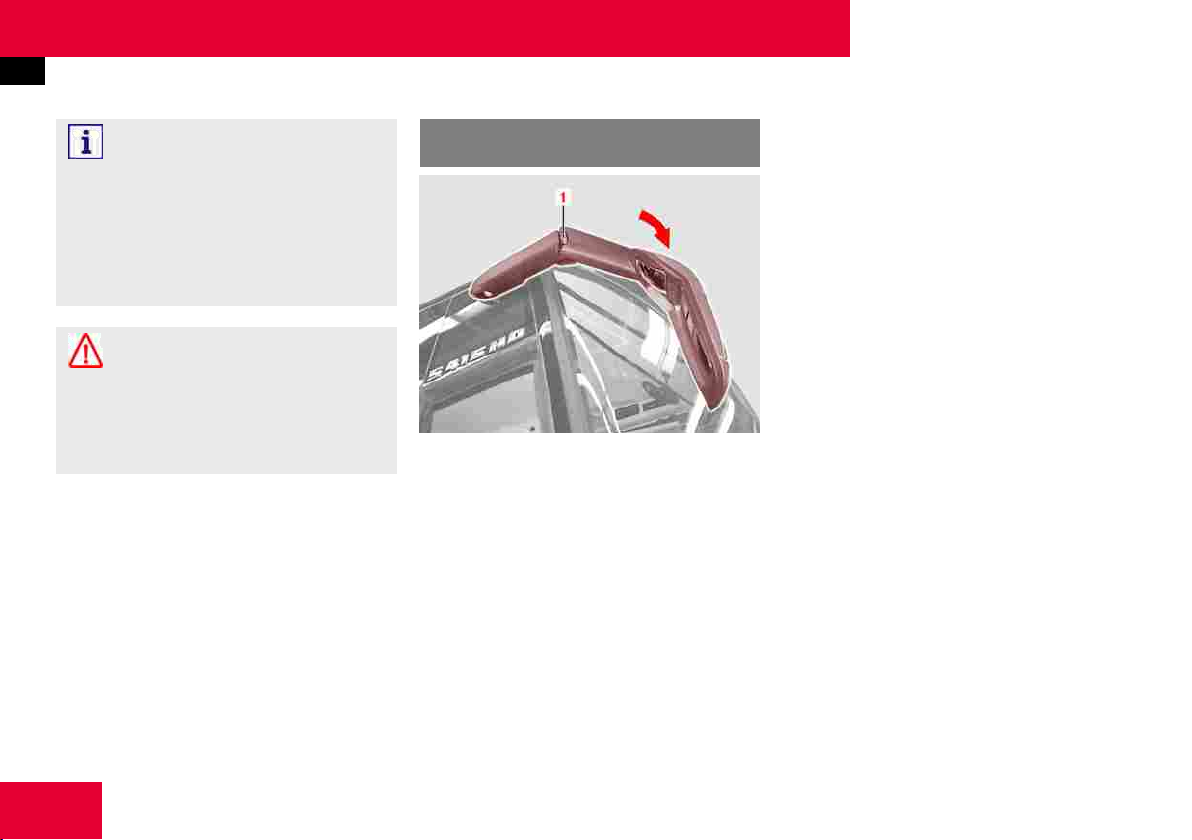

M88_00-0013-01

Prior to washing the bus you must check

that the roof hatches, driver's window

and the doors are closed.

Set the heating/ventilation/air-conditioning system to air-recirculation mode

(Smog button).

The windscreen wiper must be set to

speed 0, otherwise the rain sensor could

be activated and trigger undesired wiping. This could result in damage to the

vehicle.

Before you wash the bus, fold both integral mirrors inwards towards the windscreen either manually by means of pivot

joint (1) on the mirror arm or, with electric mirrors, using the mirror adjustment

button on the instrument panel (option).

Remove any attachment parts that may

be fitted (e.g. satellite receiver on the

roof) prior to washing.

After the bus has been washed, you

must fold the integral mirrors outwards

again (manually or electrically, depending

on vehicle equipment).

8

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

Page 26

Safety

Storage space for hand luggage

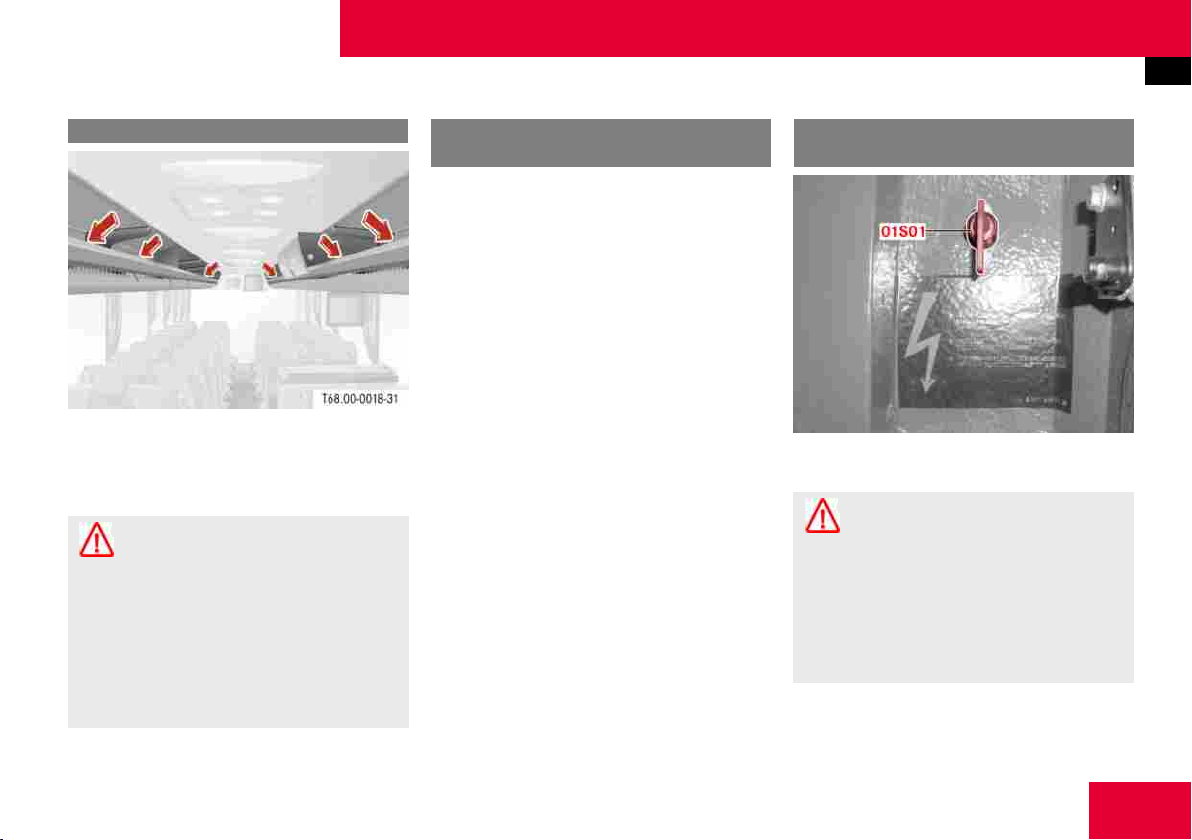

Storage space for hand luggage

T68_00-0018-31

The storage spaces above the passenger

seats are suitable for light hand luggage

items only.

Danger.

Occupants may be injured if the bus is

braked sharply, changes direction suddenly or is involved in an accident due

to objects being thrown around the bus.

Heavy or hard objects should therefore

not be carried inside the bus without being secured.

Driver's rest area safety precautions

The driver's rest area must only be used

by the bus driver (second driver).

The on-board telephone may only be

used by the driver in accordance with

legal requirements. Observe the legal

requirements of the country concerned.

Windscreen wiper system safety precautions

M54_00-1058-71

Danger.

RISK OF INJURY. The battery isolating

switch 01S01 must always be switched

off before any work is carried out on the

windscreen wiper system (wiper blade

cleaning, replacement of wiper blades or

wiper motor etc.).

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

9

Page 27

Safety

Safety precautions for the air-conditioning system

Safety precautions for the airconditioning system

Air-conditioning systems that are operated with refrigerant R 134 a are labelled with appropriate stickers and/or

plates on the compressor.

Never mix R 134 a refrigerant and the

corresponding Triton SE 55 refrigerator

oil with other products.

In accordance with current good engineering practices, it is prohibited to allow

refrigerant to escape into the environment when operating, servicing or decommissioning air-conditioning systems.

Refrigerants and refrigerator oils must

be disposed of or recycled separately by

type and nature.

Only persons having the relevant and

necessary specialist knowledge, technical equipment and official approval (by

health and safety inspectorate, local authority, TÜV or equivalent) are permitted

to carry out maintenance work on airconditioning systems and take back refrigerants and oils.

The operator must maintain a logbook

auditing the consumption of refrigerant

and refrigerator oils.

Danger.

In automatically controlled air-conditioning

systems, the ventilation blowers of condenser or evaporator units may start up

at any time. Therefore, always switch

the ignition starter switch to OFF before any cleaning work is carried out.

Do not reach into the fan blades or fan

rollers. Avoid any contact with refrigerant as there is a risk of frostbite. Treat

affected skin areas as for frostbite, and

seek medical attention immediately. Carry

out maintenance and repair tasks with the

engine switched off whenever possible.

Keep a safe distance from moving parts

(e.g. belt drive) when the engine is running.

Operation of auxiliary heating

Danger.

Risk of fire and burns. There is a risk of

fires and burns due to the high exhaust

temperatures and the hot exhaust pipe

for the auxiliary heating. For this reason,

do not stop or park the bus over ignitable

materials (e.g. grass) when the auxiliary

heating is in operation, has recently been

in operation or has been operated by the

immediate heating button/preset clock.

Danger.

Risk of poisoning and suffocation. The

auxiliary heating must not be used in enclosed spaces such as garages or workshops due to the risk of poisoning and

suffocation. It must also not be used in

timer or preselection mode.

10

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

Page 28

Danger.

Risk of explosion. The auxiliary heating

must be switched off at filling stations

and fuel dispensing systems due to the

risk of explosion.

Danger.

Risk of fire. The auxiliary heating must

remain switched off in places where ignitable vapours or dust can accumulate (e.g.

in the vicinity of filling stations, fuel, coal,

sawdust and grain stores or similar).

Safety

Operation of auxiliary heating

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

11

Page 29

12

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

Page 30

General

Table of contents

Preparation for the journey - daily tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Preparation for the journey - weekly tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Preparation for the journey - monthly tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Additional maintenance tasks dependent on bus use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

General bus care and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Care and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

13

Page 31

General

Preparation for the journey - daily tasks

Preparation for the journey - daily

tasks

Check the windscreen washer fluid level and the operation of the

windscreen washer system and windscreen wipers.

Check the fuel supply for the bus

engine and water heater (option)

Danger.

Switch off the engine and auxiliary heating before refuelling.

Check the AdBlue additive reservoir

for the BlueTec exhaust gas cleaning

system

Check the electrical system, paying

particular attention to the headlamps,

turn signals, tail lamps, brake lamps

and licence plate lamps.

Note:

Under certain weather and operating conditions, moisture may form on the inside

of the headlamps and other lights when

the bus is stationary. This does not indicate a fault or defect. The ventilation

openings in the headlamps allow this

moisture to dry off automatically after

the bus has been driven for a short time.

Check that the luggage compartment

flaps and the service covers are securely locked

Check the emergency exits

Insert the tachograph recording disc

or the driver card.

Note:

The indicator lamp in the speedometer

lights up if no disc or driver card has

been inserted.

Check that the emergency equipment is accessible and complete, e.g.

first-aid kit, fire extinguisher, warning

triangle, emergency hammer for side

windows, jack.

Check the adjustment of the

rear-view mirrors, clean the mirrors,

check the mirror heating for correct

function.

Check tyre pressures and tyre condition (including the spare wheel).

Check that the wheel nuts are firmly

seated.

14

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

Page 32

General

Preparation for the journey - weekly tasks

M40_00-0115-71

Check wheel hubs (1) on all wheels

for leaks inside and out (visual

check).

Note:

If the wheel hubs are leaking, there may

be grease or oil residue on the tyres

themselves or deposits on the parking

area on which the bus is standing. Consult an EvoBus Service Partner in the

event of a leak.

Preparation for the journey - weekly

tasks

Check the coolant level in the cooling system and top it up if necessary.

Check the corrosion inhibitor/antifreeze concentration each time the

coolant has been topped up and correct if necessary.

Note:

Observe the Specifications for Service

Products.

Check the oil level in the hydraulic

steering system and top it up if necessary.

Caution:

If the oil level is low, have the steering

system checked at an authorised specialist workshop.

Check the belt tension of all belt

drives.

Carry out a visual check to ensure

there are no leaks in the engine,

transmission, driven axle, steering

or the cooling and heating systems.

Check the seat belts (belt arrester).

Check the belt straps for damage

(visual check).

Drain the fuel prefilter in the engine

compartment.

Note:

Refer to the “Practical advice” section.

Check the acid level in the starter

batteries (only on buses with leadacid batteries).

Danger.

Observe the safety precautions in the

“Practical advice” section.

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

15

Page 33

General

Preparation for the journey - monthly tasks

Preparation for the journey monthly tasks

Check the residual current device

for the 230 V socket (option) in the

lavatory.

Note:

Refer to the “Lavatory” section

Additional maintenance tasks dependent on bus use

The bus operator must plan further

maintenance tasks for the heating/

ventilation/air-conditioning system

(driver’s area and passenger compartment) in addition to those indicated in the Maintenance Record.

General bus care and maintenance

Carry out the work specified in the

Maintenance Record

Caution:

Regular maintenance of the chassis and

drive train is essential to maintaining

the operating safety and roadworthiness

of the bus. The time intervals and the

scope of work required are specified in

the Maintenance Record supplied with the

bus.

Caution:

It is strongly recommended that the specified maintenance intervals be observed.

Note:

Our terms and conditions of sale and

delivery do not permit us to recognise

claims made under the warranty if the

periodic service and maintenance tasks

have not been carried out at the specified

distances (odometer reading) or times.

Have confirmation of the completion of

16

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

Page 34

General

Care and cleaning

the work specified in the Maintenance

Record recorded by an EvoBus Service

Partner.

Care and cleaning

You will find instructions for and notes

on cleaning and caring for your bus in

the “Operation” section.

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

17

Page 35

18

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

Page 36

Operation

Table of contents

Running-in guideline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Starting the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Stopping the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Towing and tow-starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Trailer towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Loading a trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Driving with a trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Ball hitch trailer coupling (fixed) (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Ball hitch trailer coupling and open-jaw trailer coupling (detachable) (option) . . . . . . . . . . . . . . . . . . . . . . . . 32

Connecting the power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Trailer coupling maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Refuelling (diesel fuel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

BlueTec exhaust gas cleaning system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

AdBlue service product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Filling with AdBlue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

19

Page 37

Operation

Table of contents

Operating/malfunction displays: fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Function of the accident data recorder (ADR) (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Brake system safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Emergency braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Braking and stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Brakes with anti-locking protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Applying the parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Releasing the parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Emergency braking in the event of failure of both brake circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

EBS brake system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Acceleration skid control (ASR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Brake Assist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Adaptive brake lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Electronic Stability Program (ESP) (system description) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Electronic Stability Program (ESP) (function description) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Deactivating the Electronic Stability Program (ESP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

20

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

Page 38

Operation

Table of contents

Operating/malfunction displays: brake system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Operating 230/400 V systems (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Fitting the skibox (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Swivelling the skibox (option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Further skibox (option) operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Note on maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Cleaning the underbody . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Care and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Care/cleaning of light-alloy wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Care and cleaning of covers and upholstery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Care/cleaning of fabric covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Care/cleaning of micro-fibre covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Care/cleaning of leather covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

21

Page 39

Operation

Running-in guideline

Running-in guideline

Running in the chassis and drive train

Note:

The way in which the chassis and drive

train of the new bus are treated during

the first 3,000 miles (5,000 km) is critical to the bus' future performance and

service life.

Note:

The load to which the bus is subjected

during this period should be increased

only gradually. The maintenance and lubrication tasks specified in the Maintenance Record should be carried out conscientiously.

Caution:

Do not place the engine under full load

during the running-in period. Up to

1,200 miles (2,000 km): run in with

care. Drive at no higher than 3/4 of the

maximum rpm in each gear. After 1,200

miles (2,000 km): slowly increase to the

economic rpm in each gear. During the

running-in period, do not drive the bus for

long distances at the same road speed =

same rpm. Varying engine speeds and

therefore varying loads demanded of the

entire drive train are favourable to the

running-in of the bus.

Starting the engine

The parking brake must be applied.

Transmission in neutral.

Note:

Do not depress the clutch pedal while

starting the engine.

Note:

At outside temperatures of below -20 °C,

preheat the engine with the water heater

(refer to “Heating/ventilation/air-conditioning control panel”).

Note:

The bus is equipped with an immobiliser

as standard. The engine cannot be started without one of the authorised keys.

22

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

Page 40

Operation

Starting the engine

M54_00-0083-01

Turn the ignition switch to position

2, the bus carries out an indicator

lamp check (all indicator lamps must

light up briefly), then turn the ignition switch to position 3 but do not

depress the accelerator pedal.

If necessary, cancel the starting

procedure after a maximum of 15

seconds and wait for about 1 minute

before repeating the starting procedure. Turn the key fully back before

making a further attempt to start the

engine.

Note:

After a maximum of 3 starting attempts,

wait (about 15 minutes) before trying

again.

If this icon appears on the display

screen in conjunction with a yellow

alert, you have made 5 starting attempts using an invalid key. The immobiliser has been activated.

Note:

Use a valid key or valid spare key.

Note:

Each further starting attempt with an invalid key increases the waiting period by

1 further minute.

Note:

For emergencies, we recommend that you

always carry a spare key to which you

have access at all times.

Release the key when the engine

starts.

Caution:

It is not permitted to increase the engine

speed while the “Oil pressure too low”

symbol is shown on the display screen.

If the “Oil pressure too low” symbol appears for more than 10 seconds, turn off

the engine immediately and establish the

cause.

Observe the screen display: if malfunction messages appear, determine

the cause and rectify it.

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

23

Page 41

Operation

Driving

Danger.

If there is insufficient pressure in the

compressed-air supply system (supply

pressure operating displays remain on

the display screen), a warning signal

sounds until the required pressure has

been reached. Do not release the parking

brake until there is sufficient operating

pressure.

Driving

Note:

Under certain conditions, the driver may

feel a slight judder when stationary (3axle bus). This is due simply to a function

test of the steering system and should

not be regarded as a fault.

Environmental protection

Never warm up the engine by allowing it

to idle with the bus stationary. Instead,

drive off and operate the engine at moderate engine speeds.

Danger.

All doors must be unlocked before the

bus is driven off.

Danger.

The freedom of movement of the pedals must not be restricted. The operating safety and roadworthiness of the bus

would otherwise be at risk. Objects could

fall and get caught between the pedals if

you were to accelerate or brake suddenly,

with the result that you would no longer

be able to brake, depress the clutch pedal or accelerate. You could cause an accident and endanger yourself and others.

24

Note:

The engine should not be placed under

full load until it has reached normal operating temperature (75 °C - 90 °C depending on operating conditions and the

outside temperature).

S 411/415 HD, S 415 HDC, S 415/416/417 HDH/04.2012 GB

Check the freedom of movement of

the pedals

Page 42

Operation

Stopping the engine

Danger.

Where floormats and carpets are fitted,