Page 1

Power Meter

Operating Instructions

Setra Systems, Inc.

159 Swanson Road, Boxborough, MA 01719

800.257.3872 • www.setra.com

Page 2

© 2020 Setra Systems, Inc.

BACnet is a registered trademark of the American Society of Heating, Refrigerating, and AirConditioning Engineers (ASHRAE).

The material in this document is for information purposes only and is subject to change

without notice. Setra Systems assumes no responsibility for any errors or for consequential

damages that may result from the use or misrepresentation of any of the material in this

publication.

2

Page 3

Table of Contents

1.0 Introduction .................................................................................................................... 8

.................................................................. 8

1.2 Field selectable communication............................................................................... 8

1.3 Intended use .............................................................................................................. 8

1.4 Product differentiation .............................................................................................. 9

1.5 Product unpacking .................................................................................................. 10

2.0 Safety information ......................................................................................................11

2.1 Safety symbols ........................................................................................................ 11

2.2 Please note .............................................................................................................. 11

2.3 Safety approval ........................................................................................................11

2.4 General safety requirements...................................................................................13

2.5 Power Meter installation safety requirements.......................................................13

3.0 Meter overview ............................................................................................................. 17

3.1 Installation overview ............................................................................................... 22

3.2 Main assembly and back housing separation/attachment .................................. 22

4.0 Planning for installation ..............................................................................................24

................................................................................. 24

4.2 Meter installation overview .....................................................................................24

.................................................................24

4.4 RTU programming and script overview ..................................................................25

5.0 Changing conduit position ..........................................................................................25

.....................................................................................................26

7.0 Connecting high voltage inputs ..................................................................................27

8.0 Current transformer wiring .......................................................................................... 34

9.0 CTs wiring example ......................................................................................................39

10.0 EIA-485 communication wiring ................................................................................40

11.0 Ethernet communication wiring ................................................................................ 42

3

Page 4

Table of Contents

12.0 Pulse inputs wiring ....................................................................................................43

12.1 Open collector output ...........................................................................................43

13.0 Alarm relay (SPDT) wiring .........................................................................................43

14.0 Installing front cover .................................................................................................45

...................................................................................................46

........................................................ 46

.......................................................................46

15.3 Connect the Meter ................................................................................................. 46

15.4 Web portal setup ...................................................................................................47

15.5 Web portal overview .............................................................................................. 47

15.6 Meter communication bar ....................................................................................48

15.7 Menu navigation sidebar ......................................................................................48

16.0 Halo-dot .................................................................................................................... 49

................................................................................. 49

16.2 Halo ........................................................................................................................ 49

16.3 Numerical indication ............................................................................................. 49

17.0 Setup menu ................................................................................................................ 50

18.0 Setup menu help legend ............................................................................................ 51

19.0 General settings ......................................................................................................... 52

19.1 Device general ....................................................................................................... 52

19.2 Unit defaults ..........................................................................................................53

19.3 Site information ..................................................................................................... 57

19.4 Uploading to meter ................................................................................................57

20.0 Voltage inputs ............................................................................................................58

21.0 Load setup .................................................................................................................. 62

................................................................................................ 63

21.2 Visual load indication ............................................................................................64

22.0 CT inputs ....................................................................................................................65

23.0 Communications/Network settings ......................................................................... 71

4

Page 5

Table of Contents

23.1 Network settings ................................................................................................... 73

24.0 Pulse IO setup ............................................................................................................ 74

24.1 Pulse output ..........................................................................................................75

25.0 Alarm setup ................................................................................................................ 79

.............................................................................................. 80

25.2 Energy usage (Vin) ................................................................................................ 81

25.3 Energy usage (Load) .............................................................................................81

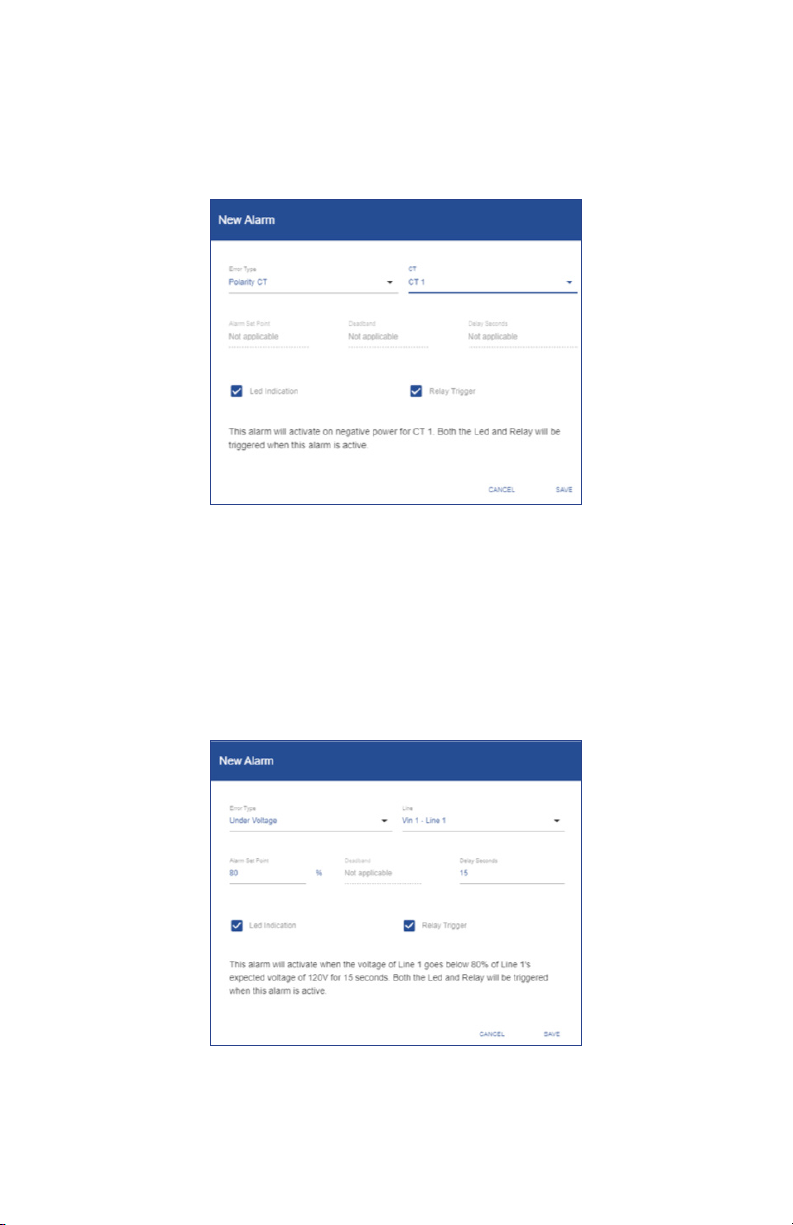

25.4 Polarity CT .............................................................................................................82

25.5 Under voltage ........................................................................................................82

25.6 Under current CT ...................................................................................................83

25.7 Over current CT ......................................................................................................83

25.8 Phase loss CT ........................................................................................................ 84

25.9 Undersized CT .......................................................................................................84

25.10 Excessive voltage ................................................................................................85

25.11 Excessive current ................................................................................................85

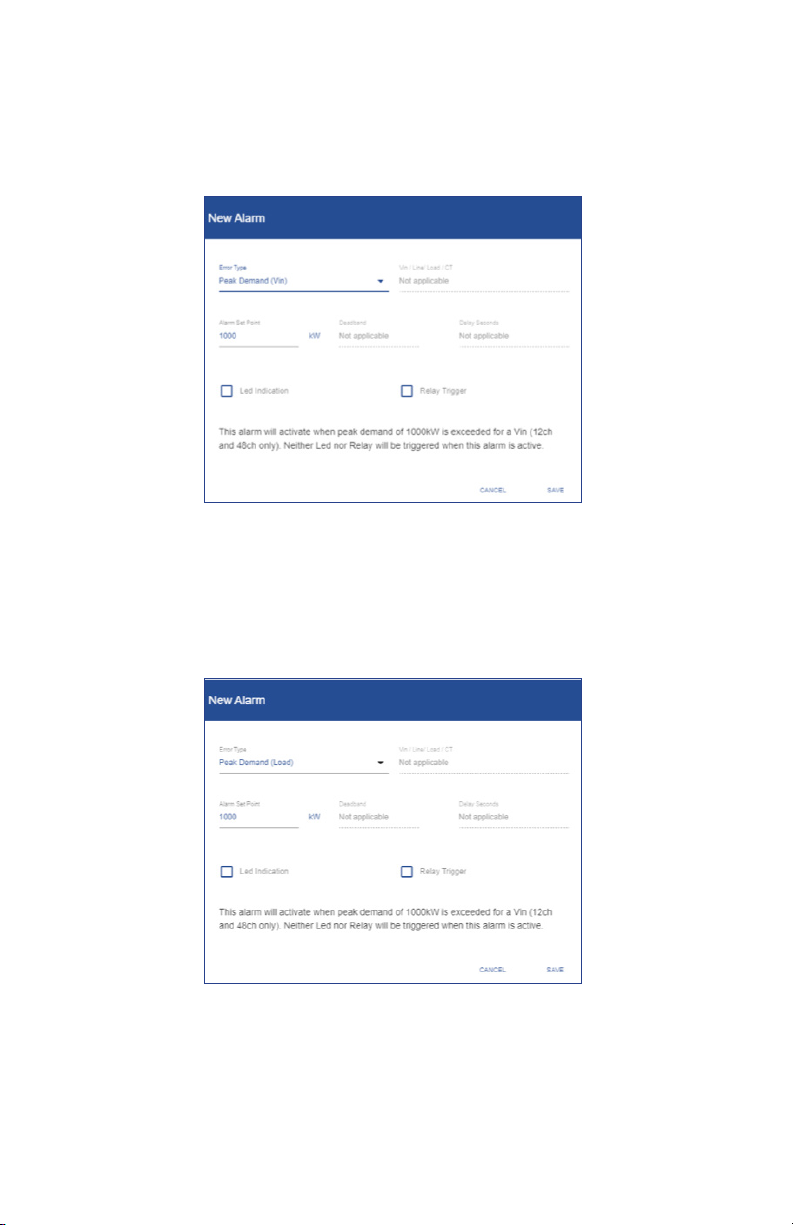

25.12 Peak demand (meter)..........................................................................................86

25.13 Peak demand (Vin) .............................................................................................. 87

25.14 Peak demand (Load) ........................................................................................... 87

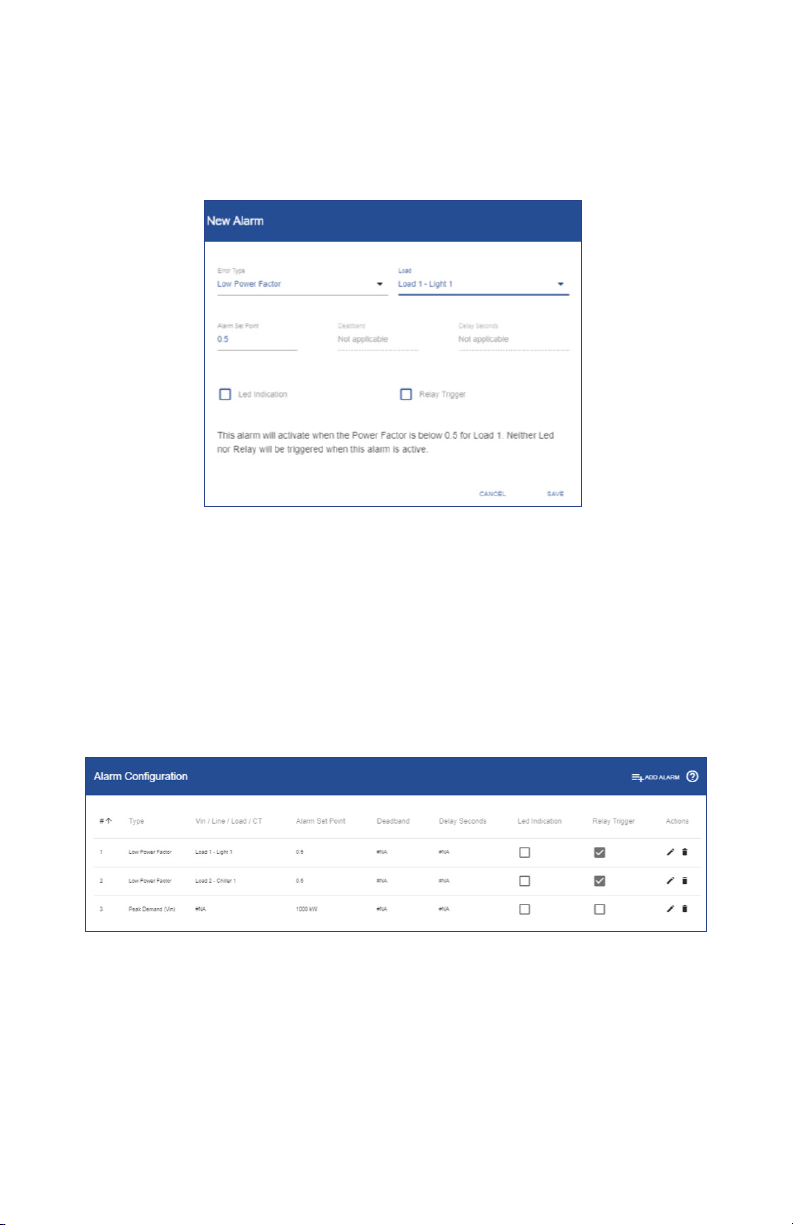

25.15 Low power factor ................................................................................................88

25.16 Summary alarm table..........................................................................................88

26.0 Installation report ......................................................................................................89

26.1 General information ..............................................................................................89

26.2 Meter information..................................................................................................90

26.3 General notes ........................................................................................................90

26.4 Measurements.......................................................................................................91

26.5 Export the report ....................................................................................................92

27.0 Power analytics .......................................................................................................... 92

5

Page 6

Table of Contents

27.1 Parameters within Trends & Odometer menus ...................................................92

27.2 Trends ....................................................................................................................93

27.3 Odometer ............................................................................................................... 95

.........................................................................................96

28.0 Event Log ...................................................................................................................97

29.0 Alarm status ............................................................................................................... 98

29.1 Active alarm states ...............................................................................................98

29.2 Active LED states ..................................................................................................98

29.3 Active relay states .................................................................................................98

29.4 Alarm log ................................................................................................................ 98

30.0 System ........................................................................................................................ 99

30.1 Software version ...................................................................................................99

30.2 Factory reset ..........................................................................................................99

30.3 Trend data rest ....................................................................................................100

30.4 Reboot ..................................................................................................................100

30.5 System log ...........................................................................................................100

................................................................................................101

...........................................................................................101

31.2 Clone/Import meter setup ..................................................................................101

32.0 Help ...........................................................................................................................102

33.0 Troubleshooting .......................................................................................................103

34.0 Replace battery ........................................................................................................104

35.0 User interface ...........................................................................................................106

36.0 Main Menu ................................................................................................................106

37.0 Real-time values ......................................................................................................107

38.0 Odometer ..................................................................................................................108

............................................................................................................109

40.0 Communication .......................................................................................................110

6

Page 7

Table of Contents

41.0 Network ....................................................................................................................110

42.0 About ........................................................................................................................112

43.0 Factory reset at meter .............................................................................................113

44.0 Returning products for repair ..................................................................................114

45.0 Limited warranty & limitation of repair ...................................................................114

46.0 Equipment service & access ...................................................................................115

46.1 Access to equipment ..........................................................................................115

46.2 Servicing the equipment ..................................................................................... 115

46.3 Component servicing .......................................................................................... 115

47.0 Support .....................................................................................................................115

47.1 Setra contact .......................................................................................................115

7

Page 8

1.0 Introduction

The Power Meter from Setra is a networked revenue grade power meter built on a versatile

and powerful platform designed to meet the high demands for any submetering application.

Available in a 3, 12 or 48 load congurations, the meter enclosure & intuitive web portal

interface signicantly reduce installation time and cost per metering point. The Power

Meter 12 & 48 load meters come standard with dual voltage inputs, and all versions are eld

congurable for use of standard or Rogowski style current transformers, enabling safe and

accurate measurement of both low and high amperage services.

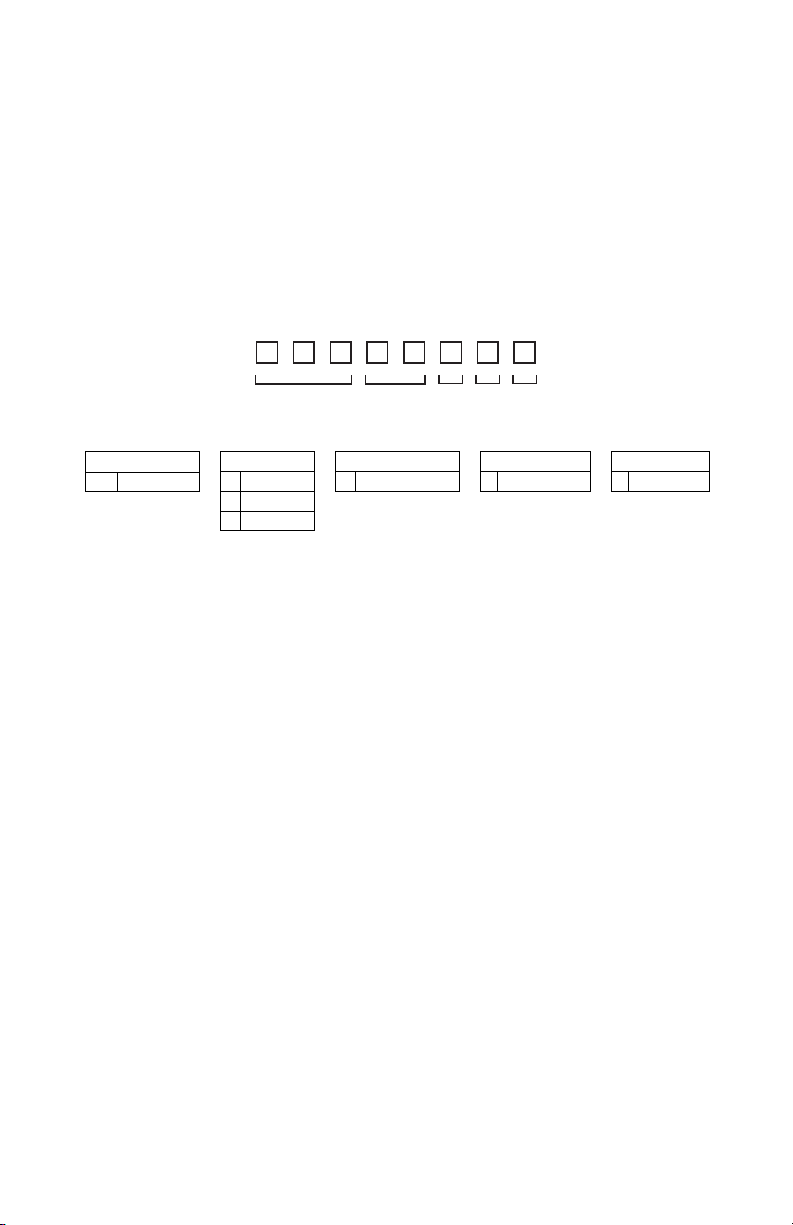

The Setra Power Meter can be ordered in the following congurations, which are identiable

on the part number label.

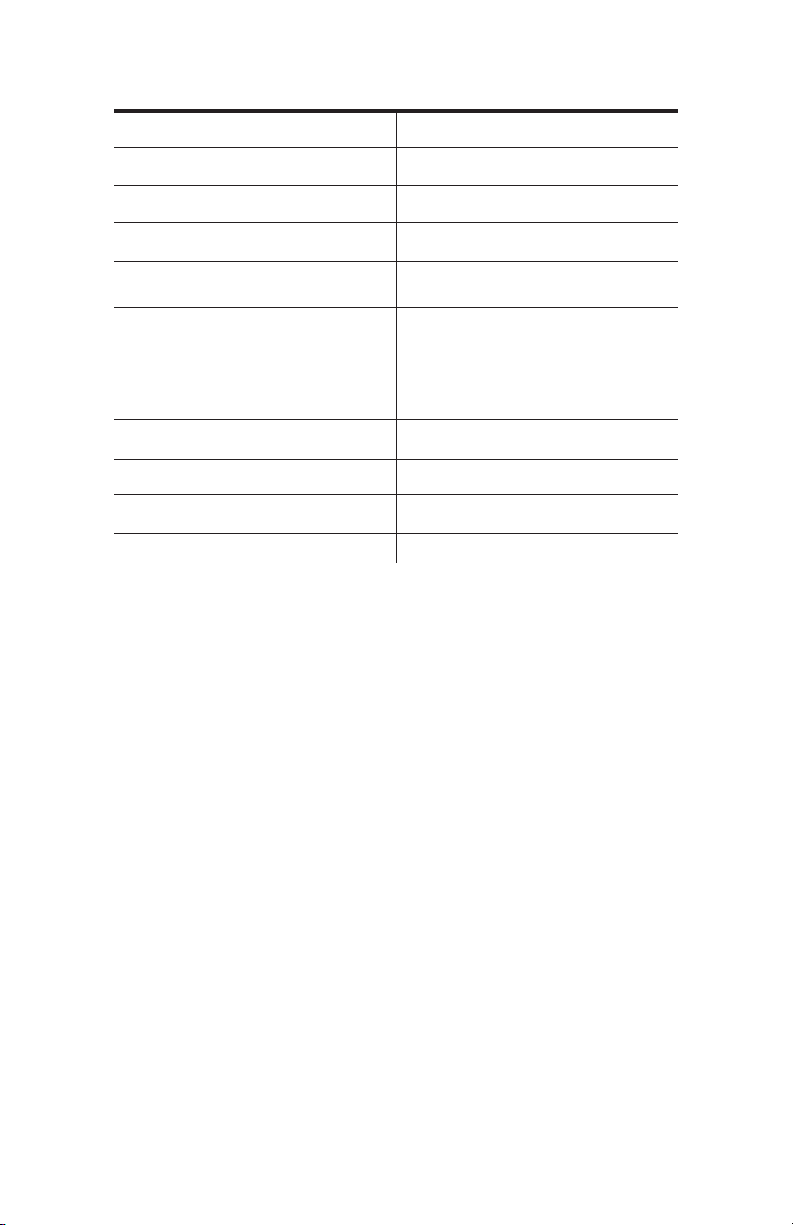

[1] [2] [3] [4] [5]

[1]

Model

SPM Power Meter

[2]

Loads

03 3 loads

12 12 loads

48 48 loads

E Ethernet & serial

[3]

Communication

[4]

Display

D Onboard display

[5]

Option

N None

1.1 Web Portal meter setup & conguration

Setup is both intuitive and time-saving through the Setra Power Meter Web Portal. The software

can be easily accessed through the meter itself, either through simple USB connection to your

PC or through Ethernet connection over a shared network.

1.2 Field selectable communication

Integration with building automation systems is made easy through eld selectable BACnet

and Modbus communication protocols. The meter’s communications interface is enabled

through either an EIA-485 serial connection (BACnet MS/TP or Modbus RTU) or over

Ethernet (BACnet/IP of or Modbus TCP). Along with these advanced network communication

protocols, the Setra Power Meter offers a connection interface with adjacent equipment

through one congurable pulse output and two congurable pulse inputs, enabling even more

data collection through the meter.

1.3 Intended use

Setra Power Meter is designed to closely monitor and provide detailed information of the

building and/or equipment. The meter can be used in varying capacities, measuring varying

loads with up to two different voltage reference points. Typical applications include measuring

power of buildings, leased building space, large machinery or equipment, lighting loads, and

more.

The meter will monitor and provide visual indicators on the Backlit Display, Error Indication

LED and Power Indication LED.

Each Power Meter comes standard with eld selectable BACnet and Modbus communication

protocols. The communications interface is through either an EIA-485 serial connection

(BACnet MS/TP or Modbus RTU) or over Ethernet (BACnet/IP or Modbus TCP). Along with

these advanced network communication protocols, the Power Meter offers one congurable

pulse output and two congurable pulse inputs, enabling more data collection at the meter.

8

Page 9

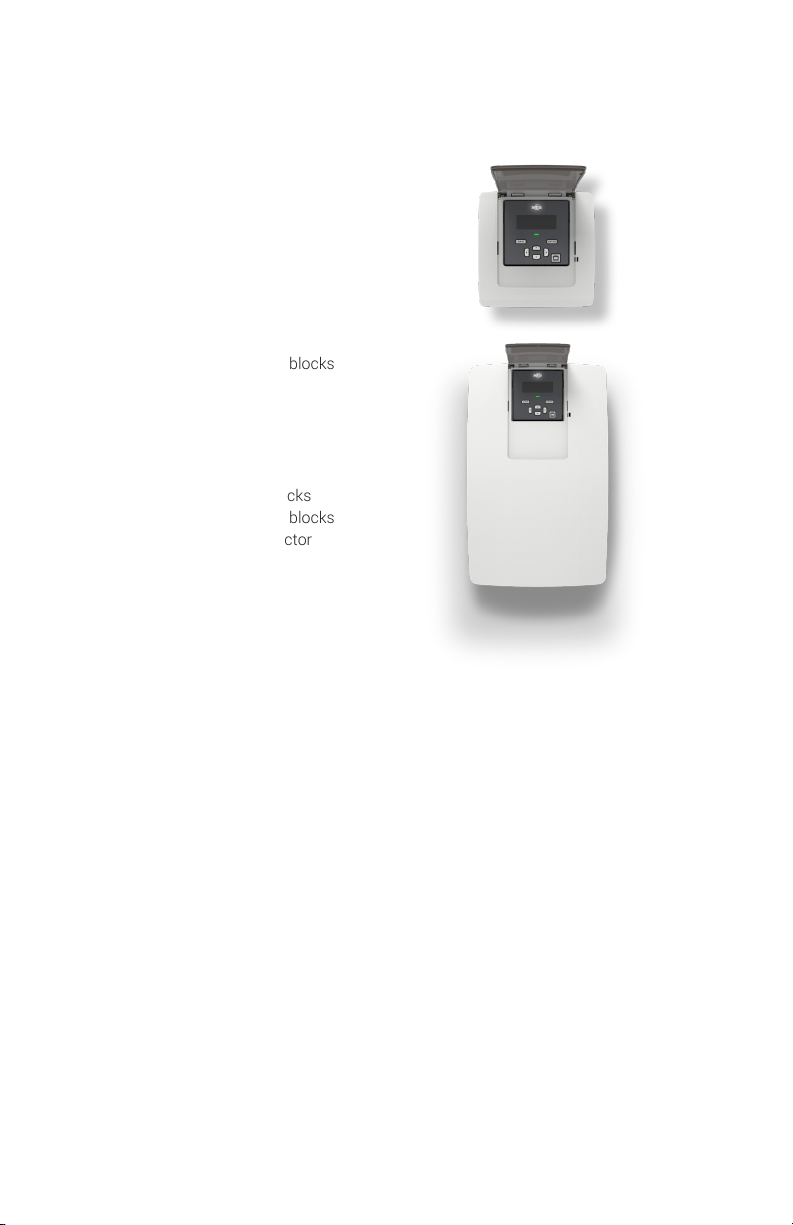

1.4 Product differentiation

The Setra Power Meter has been designed in three different “Load” congurations, with

following differences in each product:

3 Load:

• Three CT terminal blocks

• One voltage input terminal block

• 6.8” x 7” x 3.8” form factor

• Six conduit openings

12 Load:

• Twelve CT terminal blocks

• Two voltage input terminal blocks

• 6.8” x 7” x 3.8” form factor

• Six conduit openings

48 Load:

• Forty-eight CT terminal blocks

• Two voltage input terminal blocks

• 10.8” x 17.2” x 4.4” form factor

• Fifteen conduit openings

9

Page 10

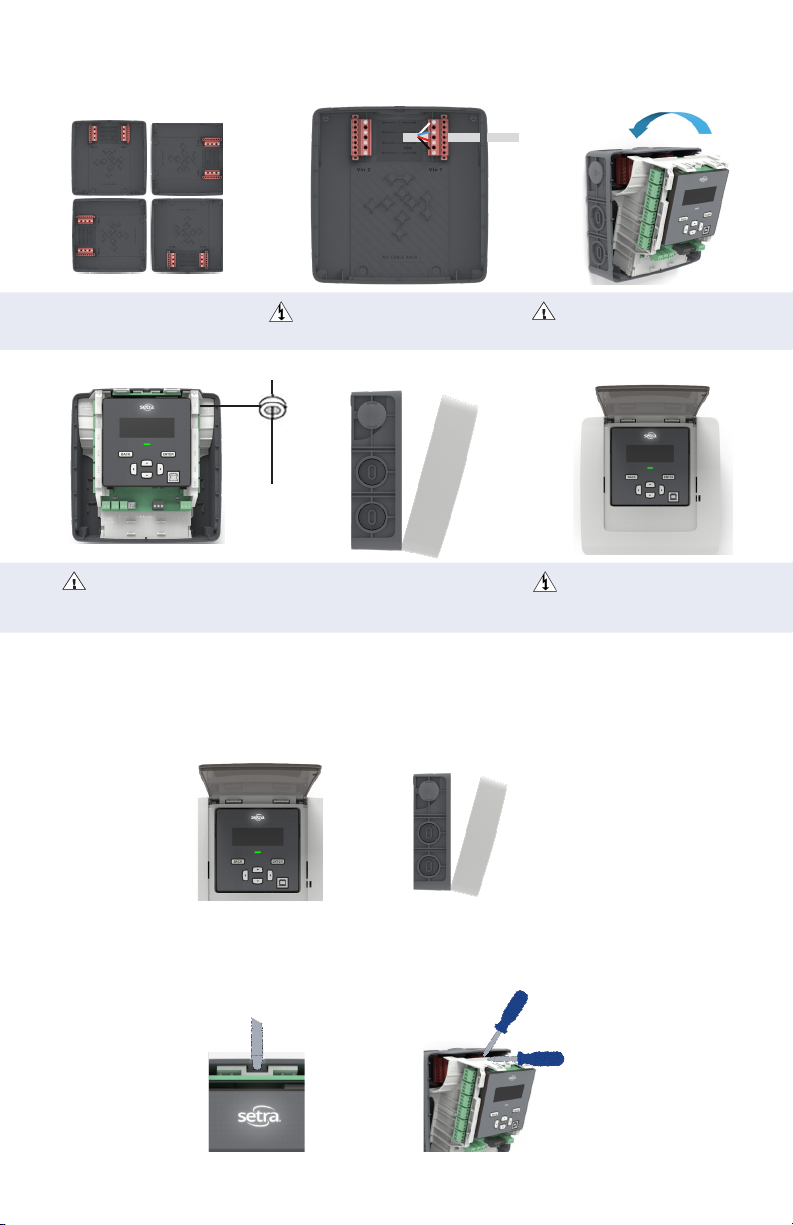

1.5 Product unpacking

What's in the box

CT connector kit

3/12 Load

Remove meter from box

3/12 Load

Mounting screws Wall anchors

48 Load

Preparing for install

48 Load

Flip open dust cover Pull front cover forward

Pull down on tabs

Auxiliary equipment & hardware kit contents

Cable ties

Insert screwdriver

into slot

Cal. Cert.

Pivot screwdriver up to

remove main assemble

Item

Power Meter 1 1 1

CT connector 4 13 49

Hardware kit 1 1 1

1 1 1

P/N: SPM03EDN

Included w/ meter

P/N: SPM12EDN

Included w/ meter

P/N: SPM48EDN

Included w/ meter

10

Page 11

2.0 Safety Information

Read these instructions carefully and look at the equipment to become familiar with the

device before trying to install, operate, service or maintain it. The following special messages

may appear throughout this manual or on the equipment to warn of potential hazards or to

call attention to information that claries or simplies a procedure.

2.1 Safety symbols

The following international symbols are used on the Power Meter and in this manual:

Denotes warning or caution. See manual for a description of the meanings.

DENOTES HIGH VOLTAGE. RISK OF ELECTRICAL SHOCK. LIFE

THREATENING VOLTAGES MAY BE PRESENT. QUALIFIED PERSONNEL ONLY.

Equipment protected throughout by double insulation (IEC 536 Class II)

Contains additional information pertinent to current subject.

2.2 Please note

Electrical equipment should be installed, operated, serviced and maintained only by qualied

personnel. No responsibility is assumed by Setra for any consequences arising out of the

use of this material. A qualied person is one who has skills and knowledge related to the

construction, installation, and operation of electrical equipment and has received safety

training to recognize and avoid the hazards involved.

2.3 Safety approval

The Setra Networked Multi-load Power Meter is UL listed and complies with the following

safety standards for 600V CAT III Pollution Degree 2:

LISTED

E503021

UL 61010-1 Edition 3 (2016),

CSA C22.2 No 61010-1-12 Edition 3 Update 2 (2016),

IEC/EN61010-1 Edition 3 (2013),

Safety Requirements for Electrical Equipment for Measurement, Control and Laboratory Use,

Part 1: General requirements

UL 61010-2-030 Edition 2,

CSA C22.2 No 61010-2-030-12 Edition 1 (2012),

IEC/EN61010-2-030 Edition 1 (2011),

Safety Requirements for Electrical Equipment for Measurement, Control and Laboratory Use,

Part 2-030: Particular Requirements for Testing and Measuring Circuits

11

Page 12

Français

2.0 Informations de sécurité

Lisez attentivement ces instructions et examinez l'équipement pour vous familiariser avec

l'appareil avant d'essayer de l'installer, de le faire fonctionner, de le réparer ou de l'entretenir.

Les messages spéciaux suivants peuvent apparaître dans ce manuel ou sur l'équipement

pour avertir des dangers potentiels ou pour attirer l'attention sur des informations qui clarient

ou simplient une procédure.

2.1 Symboles de sécurité

Les symboles internationaux suivants sont utilisés sur le Power Meter et dans ce manuel:

Indique un avertissement ou une prudence. Voir le manuel pour une

description des signications.

INDIQUE HAUTE TENSION. RISQUE DE CHOC ÉLECTRIQUE. DES TENSIONS

MENACANTES POUR LA VIE PEUVENT ÊTRE PRÉSENTES. PERSONNEL

QUALIFIÉ UNIQUEMENT.

Équipement protégé partout par une double isolation (IEC 536 classe II)

Contient des informations supplémentaires pertinentes au sujet actuel.

2.2 Veuillez noter

L'équipement électrique doit être installé, utilisé, entretenu et entretenu uniquement par

du personnel qualié. Aucune responsabilité est assumée par Setra des conséquences

découlant de l'utilisation de ce matériel. Une personne qualiée est une personne qui

possède des compétences et des connaissances liées à la construction, à l'installation et

au fonctionnement de l'équipement électrique et qui a reçu une formation en sécurité pour

reconnaître et éviter les dangers impliqués.

2.3 Approbation de sécurité

Le Setra Networked Multi-Load Power Meter est UL et conforme aux normes de sécurité

suivantes pour 600V CAT III Degré de pollution 2:

LISTED

E503021

UL 61010-1 Edition 3 (2016),

CSA C22.2 No 61010-1-12 Edition 3 Update 2 (2016),

IEC/EN61010-1 Edition 3 (2013),

Safety Requirements for Electrical Equipment for Measurement, Control and Laboratory Use,

Part 1: General requirements

UL 61010-2-030 Edition 2,

CSA C22.2 No 61010-2-030-12 Edition 1 (2012),

IEC/EN61010-2-030 Edition 1 (2011),

Safety Requirements for Electrical Equipment for Measurement, Control and Laboratory Use,

Part 2-030: Particular Requirements for Testing and Measuring Circuits

12

Page 13

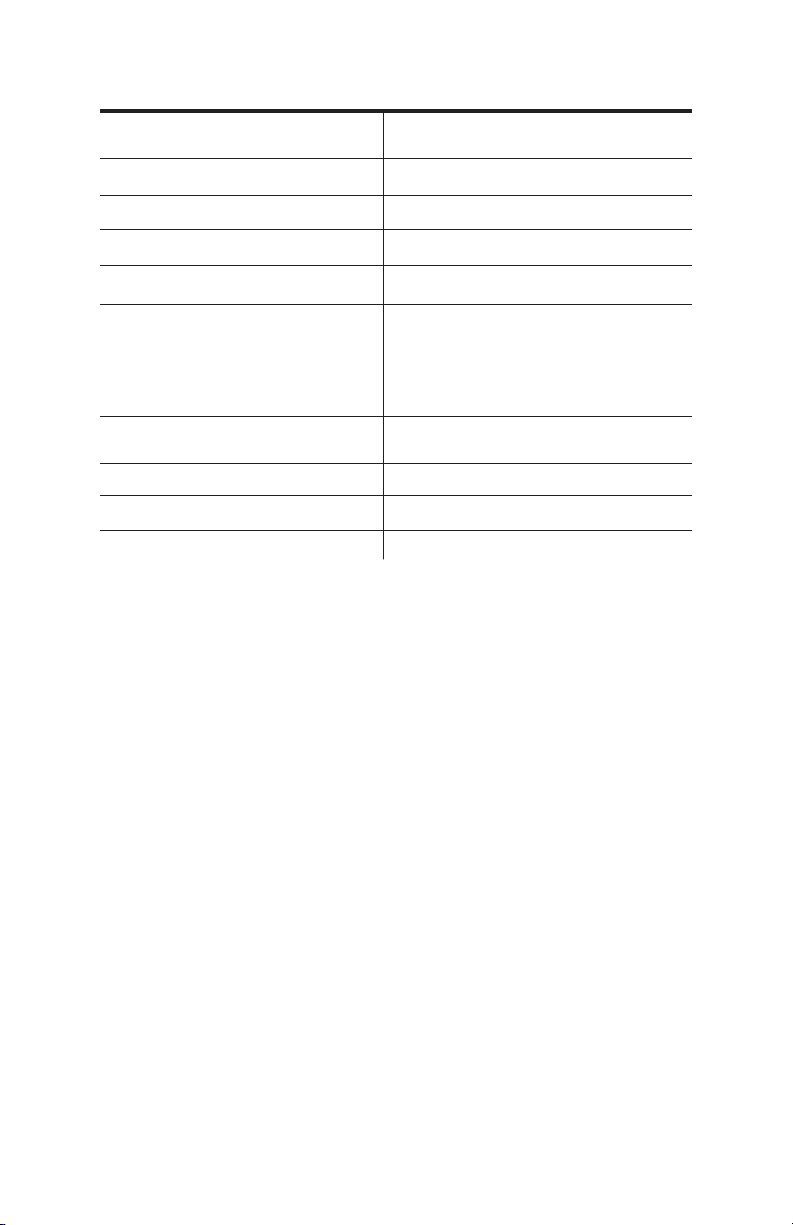

UL Safety Ratings

Equipment function Networked Multi-circuit power meter

Connection to mains supply Permanently

Overvoltage/ Measurement category III

Pollution degree 2

Means of protection Class II (double insulated)

Environmental condition

Temperature:

Humidity:

Altitude:

For use in wet location No

Equipment mobility Wall/surface mounted

Operating conditions Continuous

Marked degree of protection Type 1

Input supply rating: 80-600 Vac (Vin1 L1 & L2), 50/60 Hz, 5W max, Overvoltage Category III

Voltage measurement:

Three phase max. 347/600 Vac WYE earthed

Three phase max. 347 Vac DELTA earthed/unearthed

Split phase max. 240/480 Vac

Single phase max. 480 Vac

Measurement Category III

-20°C to +60°C

5% to 95% non-condensing humidity

Max. 2000 meters

Frequency measurement:

50/60 Hz

Current measurement:

Up to 6000 A (through use of CTs or Rogowski coils with voltage output up to 2V)

Alarm relay output ratings: 30 Vdc/ac, 2 Arms, resistive, Class 2

Pulse I/O: 30 Vdc

13

Page 14

Français

Évaluations de sécurité UL

Fonction d'équipement

Connexion à l'alimentation principale Connecté en permanence

Surtension / Catégorie de mesure III

Degré de pollution 2

Moyens de protection Class II (double isolation)

Conditions environnementales

Température:

Humidité:

Altitude:

Pour une utilisation dans des

endroits humides

Mobilité de l'équipement Montage mural / en surface

Conditions de fonctionnement Continu

Degré de protection marqué Type 1

Capacité d'alimentation d'entrée: 80-600 Vac (Vin1 L1 & L2), 50/60 Hz, 5W max, catégorie

de surtension III

Compteur de puissance multi-circuits

en réseau

-20°C à +60°C

5% à 95% d'humidité sans condensation

Max. 2000 mètres

Non

Mesure de tension:

Triphasé max. 347/600 Vac WYE mis à terre

Triphasé max. 347 Vac DELTA mis à la terre / déterré

Phase divisée max. 240/480 Vac

Monophasé max. 480 Vac

Catégorie de mesure III

Mesure de fréquence:

50/60 Hz

Mesure de courant:

Jusqu'à 6000 A (grâce à l'utilisation de TC ou de bobines Rogowski avec une tension de

sortie jusqu'à 2 V)

Évaluations de sortie de relais d'alarme: 30 Vdc / ac, 2 bras, résistif, classe 2

Puissance d'entrée / sortie d'impulsion: 30 Vdc

14

Page 15

General safety requirements

To ensure the safe operation and service of the device, follow these instructions

closely. Failure to observe warnings can result in severe personal injury or

permanent damage to the device.

• Review the entire manual before use of the Meter and its accessories.

• Comply with local and national safety codes. Use personal protective equipment to

prevent shock and arc flash injury where hazardous live conductors are exposed.

• Only licensed electricians should install this equipment. Such work should be performed

only after reading this entire set of instructions.

• The equipment must be accessible to authorized personnel only. Equipment must be

installed in areas where access can be restricted.

• If the meter appears damaged or defective or internal fuse blowout, rst disconnect all

power to the meter. Then contact Setra technical support for assistance.

• If the products are used in a manner not specied by Setra, the protection provided by

the equipment may be impaired.

Power Meter installation safety requirements

• Use copper conductors only.

• Wiring to voltage input terminals and mains shall have minimal temperature rating of

90°C (194°F) and minimal wire gauge of 14 AWG (1.63 mm).

• External secondary inputs and outputs should be connected to devices meeting the

requirements of IEC 60950.

• For use only with Listed Energy-Monitoring Current Transformers

• Warning - To reduce risk of electric shock, always open or disconnect circuit from powerdistribution system (or service) of building before installing or servicing current-sensing

transformers

• Current transformers may not be installed in equipment where they exceed 75 percent of

the wiring space of any cross-sectional area within the equipment.

• Current transformers may not be installed in an area where they block ventilation

openings.

• Current transformers may not be installed in an area of breaker arc venting.

• Current transformers are not suitable for Class 2 wiring method nor intended for

connection to Class 2 equipment.

• Secure current transformer and route conductors so that they do not directly contact live

terminals or bus.

• Wiring to terminal blocks shall have minimal temperature rating at least 75°C (167°F)

• When connecting power meter to conduit, a threaded hub shall be installed at conduit

entrances. When using rigid conduit connect the hub to the conduit before connecting

to power meter enclosure.

FCC PART 15 Notice

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in an installation

15

Page 16

Français

Règles générales de sécurité

Pour garantir le fonctionnement et l'entretien en toute sécurité de l'appareil, suivez

attentivement ces instructions. Le non-respect des avertissements peut entraîner

des blessures graves ou des dommages permanents à l'appareil.

• Revoir le manuel en entier avant l'utilisation de l'appareil et de ses accessoires.

• Respectez les codes de sécurité locaux et nationaux. Utilisez un équipement de protection

individuelle pour éviter les chocs et les arcs électriques lorsque des conducteurs sous tension

dangereux sont exposés.

• Seuls des électriciens agréés doivent installer cet équipement. Un tel travail ne doit être effectué

qu'après avoir lu l'ensemble de ces instructions.

• L'équipement doit être accessible uniquement au personnel autorisé. L'équipement doit être

installé dans des zones où l'accès peut être restreint.

• Si le compteur semble endommagé ou défectueux ou que le fusible a sauté, débranchez d'abord

l'alimentation du compteur. Contactez ensuite le support technique de Setra pour obtenir de l'aide.

• Si les produits sont utilisés d'une manière non spéciée par Setra, la protection fournie par

l'équipement peut être altérée.

Règles de sécurité pour l'installation du Power Meter

• Utilisez uniquement des conducteurs en cuivre.

• Le câblage aux bornes d'entrée de tension et au secteur doit avoir une température nominale

minimale de 90 ° C (194 ° F) et un calibre de l minimal de 14 AWG (1,63 mm).

• Les entrées et sorties secondaires externes doivent être connectées à des appareils répondant

aux exigences de la CEI 60950.

• À utiliser uniquement avec les transformateurs de courant à surveillance d'énergie répertoriés

• Avertissement - Pour réduire le risque de choc électrique, ouvrez ou déconnectez toujours le circuit

du système de distribution électrique (ou du service) du bâtiment avant d'installer ou d'entretenir

des transformateurs de détection de courant

• Les transformateurs de courant ne doivent pas être installés dans l'équipement où ils dépassent

75 pour cent de l'espace de câblage de toute section transversale de l'équipement.

• Les transformateurs de courant ne doivent pas être installés dans une zone où ils bloquent les

ouvertures de ventilation.

• Les transformateurs de courant ne doivent pas être installés dans une zone d'évacuation d'arc du

discontacteur.

• Les transformateurs de courant ne sont pas adaptés à la méthode de câblage de classe 2 ni

destinés à être connectés à un équipement de classe 2.

• afxez le transformateur de courant et circulez les conducteurs an qu'ils n'entrent pas directement

en contact avec les bornes sous tension ou le bus.

• Le câblage aux borniers doit avoir une température nominale minimale d'au moins 75 ° C (167 ° F)

• Lors de la connexion du wattmètre au conduit, un moyeu fileté doit être installé aux entrées

du conduit. Lorsque vous utilisez un conduit rigide, connectez le moyeu au conduit avant de le

connecter au boîtier du wattmètre.

Avis FCC PARTIE 15

Cet équipement a été testé et déclaré conforme aux limites d'un appareil numérique de classe B, conformément

à la partie 15 des règles de la FCC. Ces limites sont conçues pour fournir une protection raisonnable contre les

interférences nuisibles lorsque l'équipement est utilisé dans un environnement commercial. Cet équipement

génère, utilise et peut émettre de l'énergie radiofréquence et, s'il n'est pas installé et utilisé conformément

aux instructions, peut provoquer des interférences nuisibles aux communications radio. Cependant, il n'y a

aucune garantie qu'aucune interférence ne se produira dans une installation.

16

Page 17

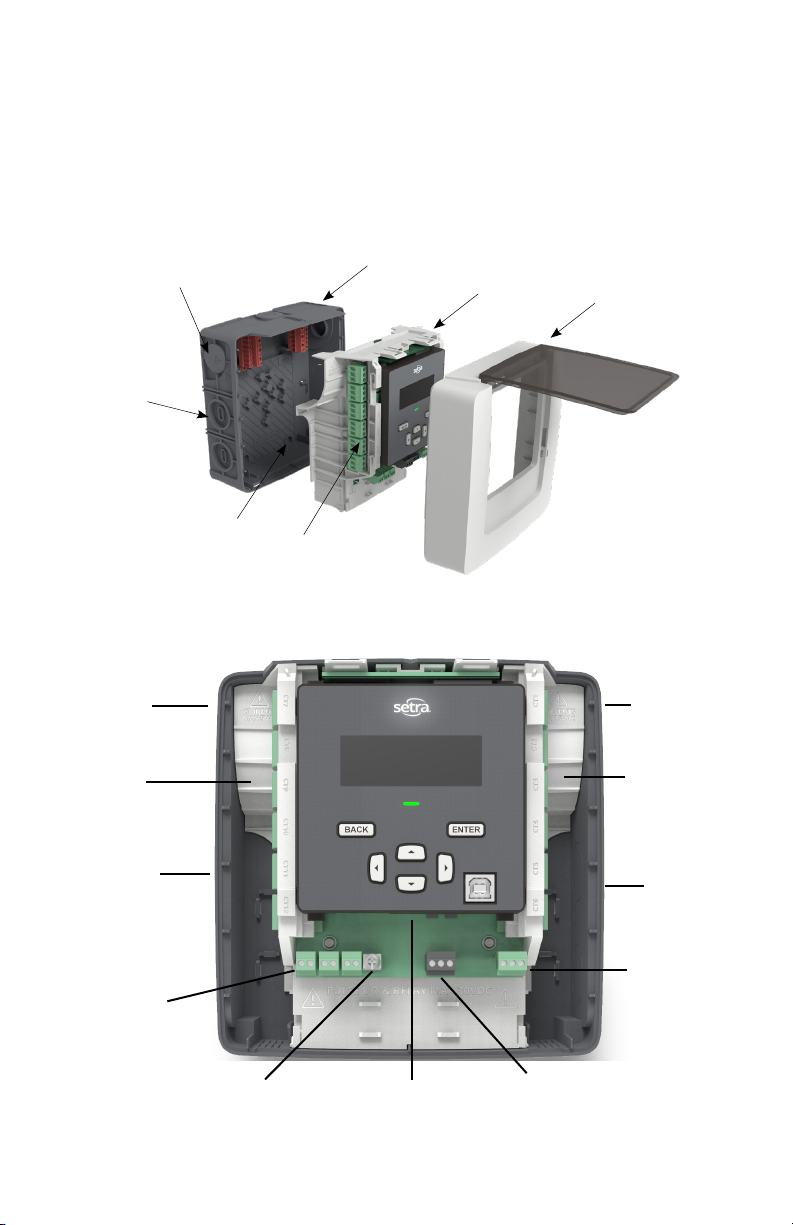

3.0 Meter overview

This section is intended so that you can familiarize yourself with the features of the meter prior

to installation, while size and amount of current transformer connection differ most features

and terminology remain the same between the 3, 12, and 48 load power meters.

Power meter sections

(12 load meter shown)

Conduit plug x2 high

voltage area

Conduit knockout

CT area x4

Back housing

Main assembly

Front housing

Mounting holes (x4)

CT inputs

3/12-load meter

High voltage

conduit entry

CT inputs x6

(12 Load only)

Low voltage

conduit entry

Pulse IO

Input x2

Output x1

Earth ground1

screw terminal

(optional)

1

Earth ground Screw: In noisy environments connect earth ground terminal to electrical panel earth ground to reduce noise

pickup

Ethernet RJ45

connection

EIA-485

communication

terminal

High voltage

conduit entry

CT Inputs

x3 (3 Load meter)

x6 (12 Load meter)

Low voltage

conduit entry

SPDT alarm relay

17

Page 18

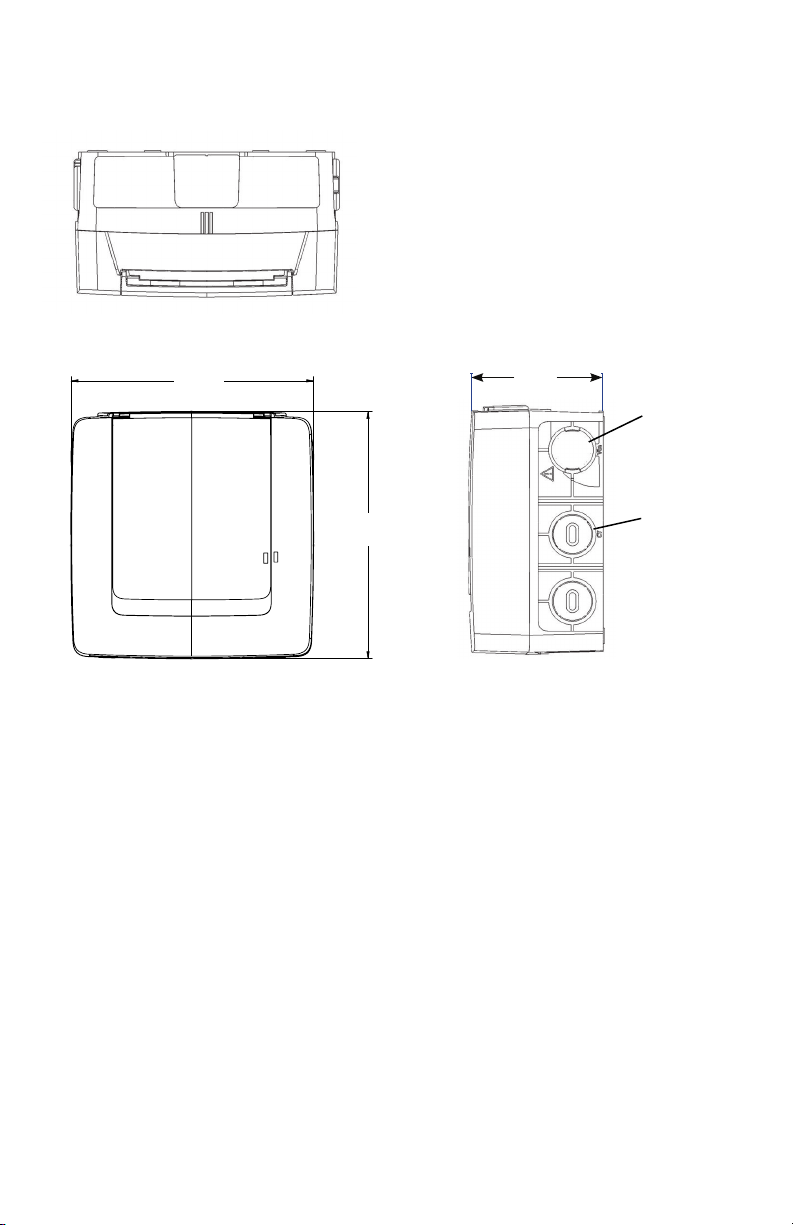

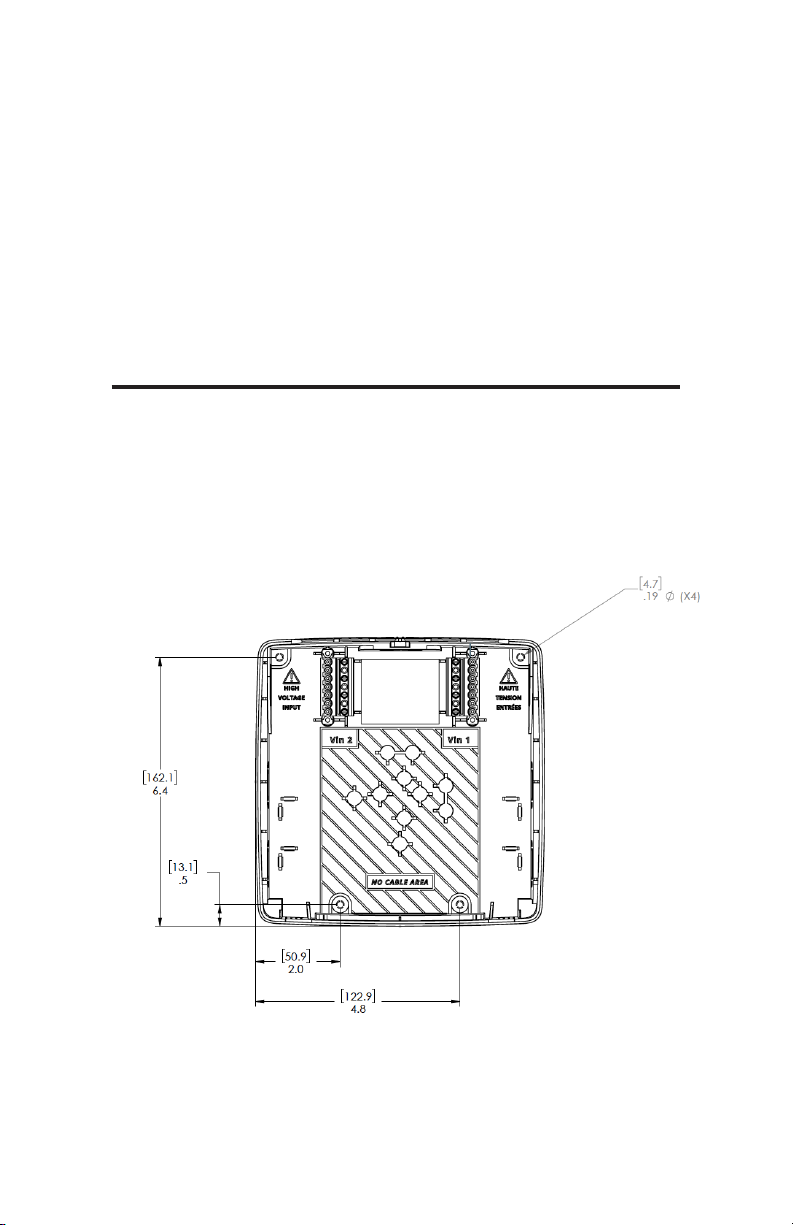

95.9

3.8

Dimensions

6.8

173.9

6.8

[173.9]

3.8

[95.9]

3/4” (Conduit

Opening)

177.1

7.0

7.0

[177.1]

3/4” (Conduit

Opening)

18

Page 19

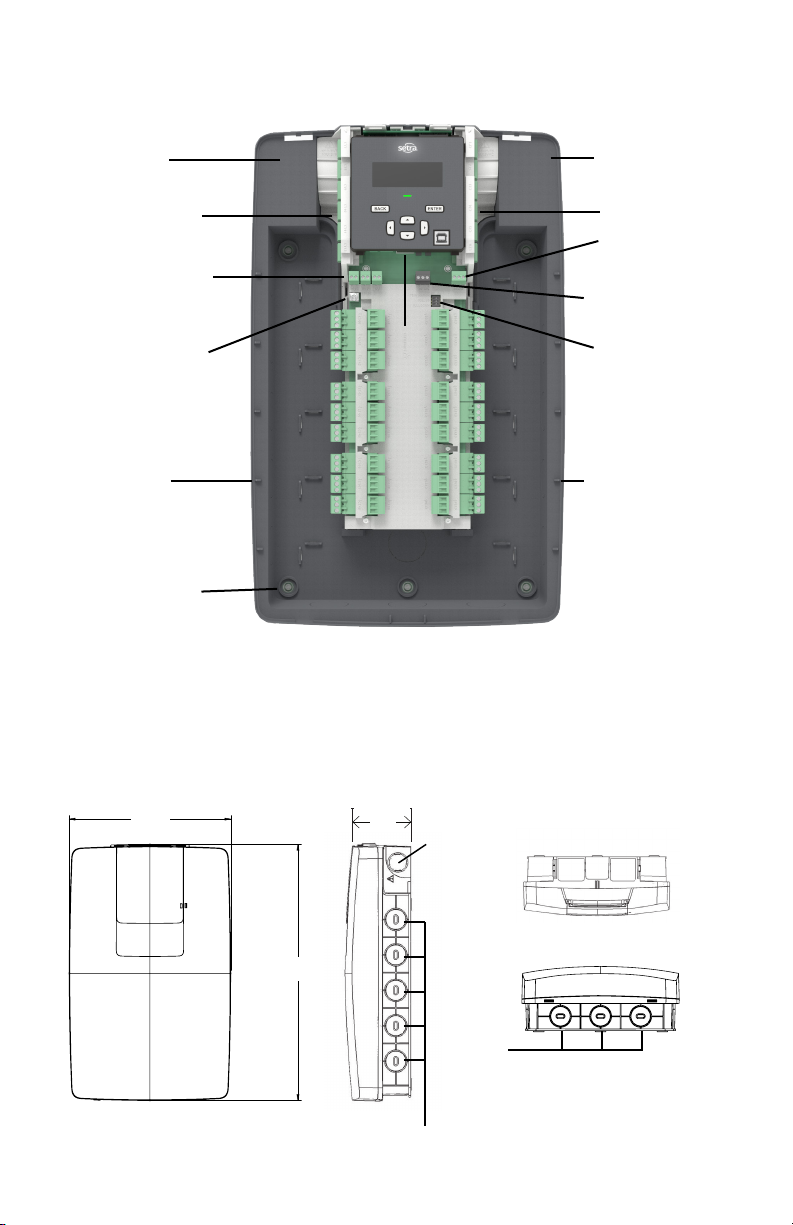

48-Load Meter

112

4.4

435.7

17.2

274.9

10.8

112

4.4

High voltage

conduit entry

CT input x6

Pulse I/O

Input x2

Output x1

Earth ground1

screw terminal

(optional)

Low voltage

conduit entry x5

Mounting hole

x5

Connection

Ethernet RJ45

High voltage

conduit entry

CT input x6

SPDT alarm

relay

EIA-485

Communication

terminal

DIP switches

(EIA-485 Config)

Low voltage

conduit entry

x5

Dimensions

10.8

274.9

10.8

[274.9]

17.2

435.7

17.2

[435.7]

4.4

[112]

1” Conduit Opening

19

3/4”

1” Conduit

Opening

Top view

Bottom view

in.

[mm]

Page 20

Power indication

LED

Error indication

LED

Simple 6-key

user-interface

Display interface

4-Line backlit

display

Type B port USB

20

Page 21

Available conduit

3/12 Load meter 48 Load meter

High voltage area – ¾" EMT conduit tting x2

Low voltage (CT, Comm, I/O) – ¾" EMT conduit tting x4

Typical EMT conduit tting (Not included)

High voltage area – ¾" EMT conduit tting x2

Low voltage (CT, Comm, I/O) – 1" EMT conduit tting x13

21

Page 22

3.1 Installation overview

Vin 1

1. Mount unit in preferred conduit

orientation with provided mounting

screws.

CT

Input

4. Following local electrical codes.

Wire in the current transformers

and communication lines to the

meter.

2. After safely de-energizing the circuit,

properly wire in the lines voltage per

local electrical codes.

L1

5. Install front cover by engaging the

two tabs at the bottom and rotate the

cover until clicked in-place.

3. Install the “Main assembly” into

the back housing until it locks in

place.

6. After meter is fully wired, safely

re-energize the circuit and begin

gathering data.

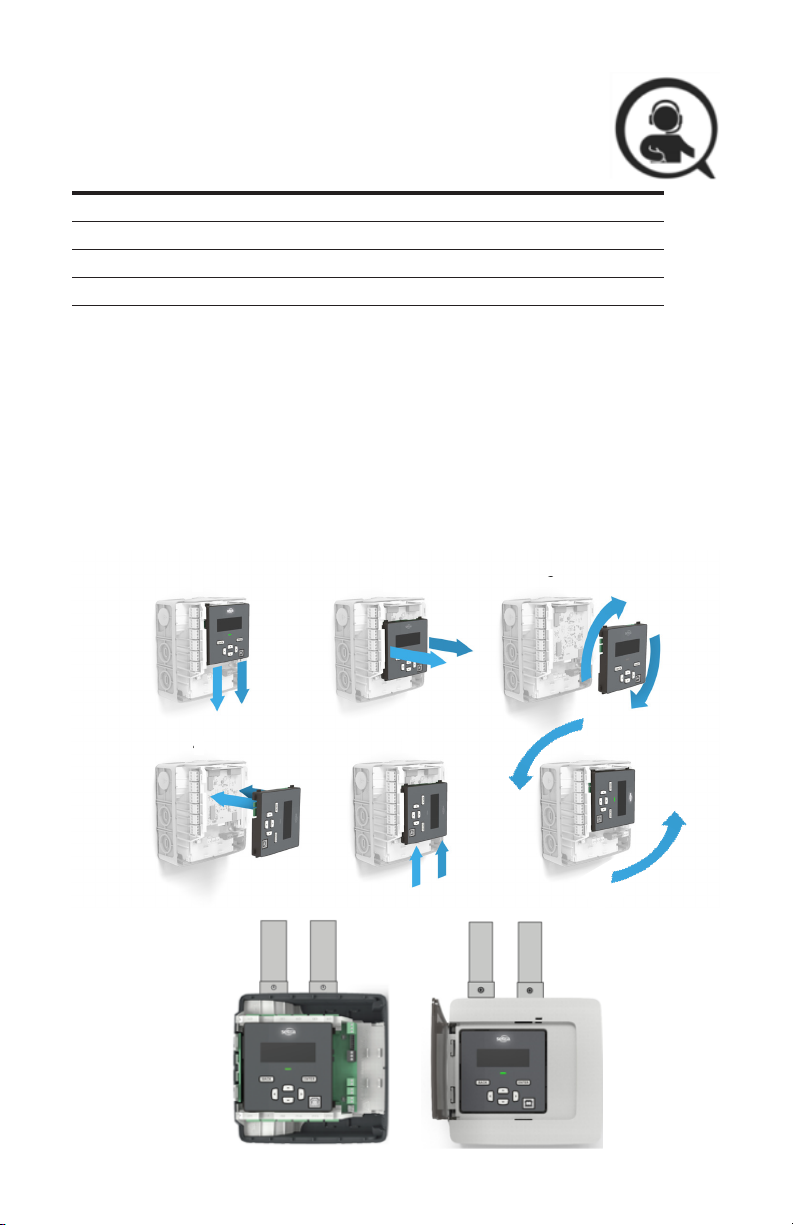

3.2 Main assembly and back housing separation/attachment

1. Remove the power meter’s front housing (cover) by depressing the tab(s) on the bottom

of the meter, found on the main assembly. Simultaneously, lift the front housing off the stillassembled main assembly and back housing.

2. Next, remove the main assembly from back housing by flexing the rear housing away from

the main assembly using a flat screwdriver where indicated on the rear housing. This will

release the locking mechanism. Now, pull delete out the main assembly, rotating from the top.

22

Page 23

3. To reassemble, rst, insert the bottom of the Main Assembly into the Back Housing and

rotate the top of the main assembly into position, connecting high voltage and accompanied

by a "click" to ensure the assembly is in place.

12 Load Meter shown below:

48 Load Meter shown below:

4. Attach the front housing by tilting the cover such that the bottom makes contact with the

Main Assembly rst, locking in the two securement tabs. Once the tabs are resting in their

respective securement slots, rotate and push the top of the cover onto the Back Housing and

Main assembly.

23

Page 24

4.0 Planning for installation

Meter installation often includes coordination between individuals or groups of people with

different responsibilities. Spend a few minutes considering who will be executing each portion

of the installation and what tools are needed at each stage. Things to consider include

determining how to communicate with the meter, setting address conguration, access to

passwords, etc. The more tasks completed before installation means less time in the eld. The

following section gives an overview of these activities followed by details in the next section.

4.1 Meter conguration overview

Work performed ahead of the installation saves time in the eld and allows

a more streamlined installation. Typically performed at the workstation with

a computer.

Tools Typical work

Desktop or laptop PC Connect USB/Ethernet cable from PC to meter

USB type AB cable (preferred) or

Ethernet cable

Web browser and electrical schematics

of project

4.2 Meter installation overview

Performed by a licensed electrician

Tools Typical work

Mounting hardware (customer supplied) Mechanical mounting

Wiring & supplies, labels, wire ties Electrical installation

Laptop PC Install voltage cover

Multimeter, current clamp Apply power to meter

Camera Conrm basic operation of meter

Establish communication with meter

Firmware update (if desired)

Meter setup and conguration generate eld

wiring and installation report

4.3 Verication & communication overview

Can be modied with power applied to the meter

Tools Typical work

Laptop PC/Tablet, BAS system Conrm device communication

On site troubleshooting Add wire terminations (if required)

Multi meter Conrm and correct wiring issues

Current clamp

Osciloscope (optional) Check signal and noise

BACnet or Modbus polling toll (optional) Network verication

Meter health metrics (check for

setup errors)

24

Page 25

4.4 RTU programming and script overview

Tools Typical work

Laptop PC (remote access to RTU) Conrm meter communication setting

Remote trouble shooting Conrm communication protocols

Register Exercise remote connectivity

Run conguration scripting

Conrm integrity

5.0 Changing Conduit Position

The Setra power meter can support various applications via rotatable display to allow the user

to mount in any conguration, without impacting the user interface experience.

To rotate the orientation of the display, remove the front housing cover and slide the display

module along the main assembly, toward the bottom of the meter. Once it becomes dislodged,

simply rotate the display to the desired orientation and slide again toward the top of the meter.

Ensure the meter is de-energized prior to changing orientation.

1 2 3

4 5

25

6

Page 26

6.0 Meter conguration

The following section illustrates the recommended installation of 12-load Power Meter. The

3-load and 48-load meter are slightly different but can follow the same procedure.

1. Remove all packaging material and separate the housing from the other components.

2. Locate a flat, clean portion of wall space for mounting. Decide meter orientation.

3. Remove main assembly for back housing by depressing the tab on the top of the meter, to

release the locking mechanism.

4. Locate, mark, level, and drill wall mounting points. The plastic back cover can be used as

a template for marking the drill locations on the wall. Using the four #8-15 x 5/8 screws

provided, fasten the housing to the wall.

Notes

1

If mounting on masonry wall, use the four blue Topcon screws provided. The

correct masonry drill size for these screws is 5/32 inch diameter

2

If mounting on drywall, use the four plastic drywall anchors in addition to the

#8-15 x 5/8 screws provided.

3

To avoid damage to the housing desired knockouts should be removed prior

to mounting on the wall

26

Page 27

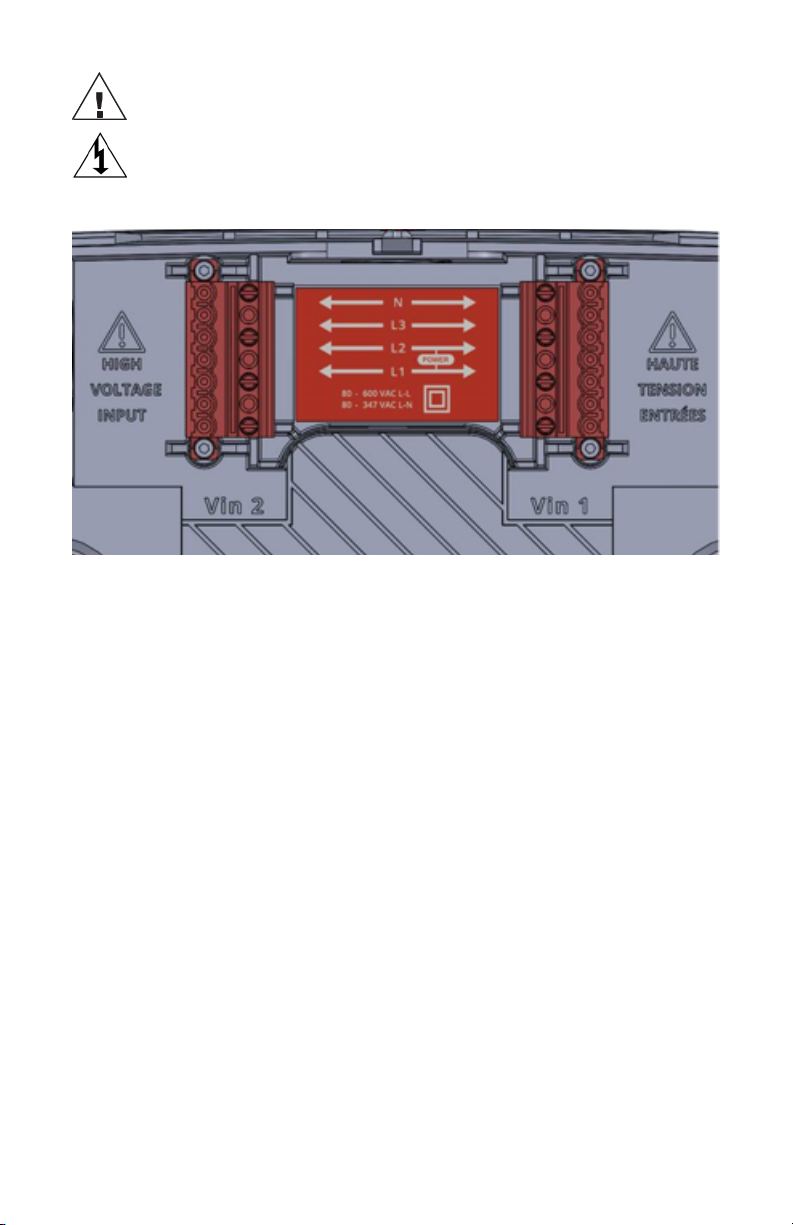

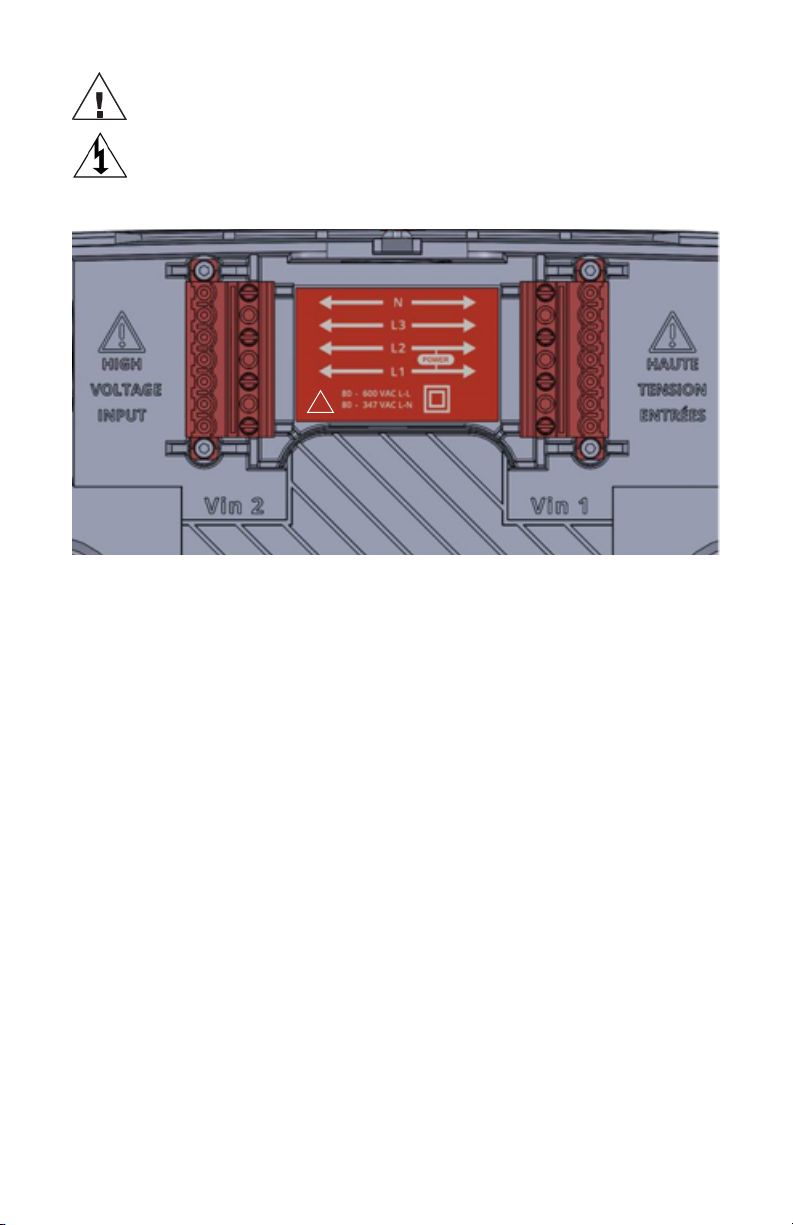

7.0 Connecting high voltage inputs

DANGER- Failure to follow these instructions will result in death or serious injury.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe electrical work

practices. See NFPA 70E.

• This equipment must only be installed and serviced by qualied electrical personnel.

• Turn off all power supplying this equipment before working on or inside equipment.

• The meters voltage leads (L1, L2, L3, and N, as necessary) must be connected to a

dedicated disconnect or a properly rated (15A) breaker.

• A voltage lead of 14 AWG THHN minimum 600VAC rating or equivalent is required.

• Wiring to these terminal blocks shall be tightened to 3.54 lb.-in torque.

• DO NOT EXCEED 347V Line to Neutral or 600V line to line. This meter is equipped to

monitor loads up to 347V L-N. Exceeding this voltage will cause damage to the meter

and danger to the user. Always use a Potential Transformer (PT) for voltages in excess of

347V L-N or 600V line to line. The Setra Power Meters are 600V Over Voltage Category

III device.

• When using rigid conduit, connect the hub to the conduit before connecting to power

meter enclosure.

• All unused conduit openings need to be closed using Setra provided conduit plug.

IMPORTANT- Verify the circuit breaker is marked as the disconnected breaker for the meter.

Setra Power Meter’s high voltage inputs must be connected through properly rated (15 Amp)

disconnects or breakers that disconnect all line wires so that they can be powered down. Each

disconnect or breaker must be located within easy reach of the meter operator and must be

labeled to indicate which set of device inputs it supplies power to. One disconnects is required

for each voltage input. The disconnect device or devices must meet IEC 60947-1, IEC 609473 and/or comply with the local electrical code.

Connection to the mains terminals shall be made with 14 AWG (1.63 mm) minimal wire gauge

THHN 600VAC rating. All high voltage input wires shall be routed through the high voltage

conduit entry and do not mix with other low voltage wiring. Any unused high voltage conduit

holes shall be plugged securely with supplied “safety cap”. Wiring to these terminal blocks

shall be tightened to 3.54 lb.-in torque.

Please note that there are two voltage inputs (Vin1 and Vin2) for 12-load and 48-load power

meter but only one voltage input (Vin1) for 3-load power meter. Each voltage inputs contain

up to four leads, namely L1, L2, L3, and N (neutral) which can be congured by software to

measure up to three phases voltage signal with respect to N (neutral). Vin1 L1 and L2 are also

connected to meter’s 80-600V wide input power supply to power the meter. When installing

a 12 or 48 load power meter, Vin 1 must be used to power the unit. The meter will not power

off of Vin 2.

27

Page 28

Français

7.0 Connexion des entrées haute tension

DANGER- Le non-respect de ces instructions entraînera la mort ou des blessures graves.

RISQUE DE CHOC ÉLECTRIQUE, D'EXPLOSION OU D'ARC ÉLECTRIQUE

• Appliquer d’équipement de protection individuelle (EPI) approprié et suivre les pratiques

de travail électriques sécuritaires. Voir NFPA 70E.

• Cet équipement ne doit être installé et entretenu que par personnel électrique qualié.

• Coupez l'alimentation électrique de cet équipement avant de travailler sur ou à l'intérieur

de l'équipement.

• Les ls de tension des compteurs (L1, L2, L3 et N, si nécessaire) doivent être connectés à

un sectionneur dédié ou à un disjoncteur de calibre approprié (15A).

• Un câble de tension de 14 AWG THHN de 600VAC minimum ou équivalent est requis.

• Le câblage de ces borniers doit être serré à un couple de 3,54 lb-in.

• NE DÉPASSEZ PAS la ligne 347 V au neutre ou la ligne 600 V à la ligne. Ce compteur

est équipé pour surveiller des charges jusqu'à 347V L-N. Le dépassement de cette

tension endommagera le compteur et mettra en danger l'utilisateur. Utilisez toujours un

transformateur de potentiel (PT) pour les tensions supérieures à 347 V L-N ou 600 V ligne

à ligne. Les wattmètres Setra sont des machines de catégorie III de survoltage de 600 V.

• Lorsque vous utilisez un conduit rigide, connectez le moyeu au conduit avant de le

connecter au boîtier du wattmètre.

• Toutes les ouvertures de conduit inutilisées doivent être fermées à l'aide du bouchon de

conduit fourni par Setra.

28

Page 29

DO NOT EXCEED 347V Line to Neutral or 600V line to line. This meter is equipped

to monitor loads up to 347V L-N. Exceeding this voltage will cause damage to

the meter and danger to the user. Always use a Potential Transformer (PT) for

voltages in excess of 347V L-N or 600V line to line. The Setra Power Meters

are 600V Over Voltage Category III device.

29

Page 30

Français

NE DÉPASSEZ PAS la ligne 347 V au neutre ou la ligne 600 V à la ligne. Ce

compteur est équipé pour surveiller des charges jusqu'à 347V L-N. Le

dépassement de cette tension risque d'endommager l'appareil et de danger

pour l'utilisateur. Utilisez toujours un transformateur de potentiel (PT) pour les

tensions supérieures à 347 V L-N ou 600 V ligne à ligne. Les wattmètres Setra

sont des dispositifs de catégorie III de surtension de 600 V

!

30

Page 31

It is important to understand the electrical service type and voltage before voltage input wiring.

Setra power meter supports all major service types.

1. Identify conduit plug(s) to remove for high voltage input. Identify desired conduit holes for

CT and I/O inputs.

2. Power lines can be brought to the meter through any of the top two ports on the housing,

located left side, top, or right side.

3. Once you have identied the convenient routing of conduit to the meter, proceed to step 4

Conduit plug

4. Insert conduit tting through 3/4" opening. Thread nut onto the tting. Tighten until secure.

DO NOT ENERGIZE METER FOR VOLTAGE INPUT WIRING.

SEE SECTION "CONNECTING HIGH VOLTAGE INPUTS" FOR MORE INSTRUCTIONS

31

Page 32

5. Strip back Romex wire sheathing approximately 3-1/2 inches. Strip each wire back

ORIGINAL ARTWORK

- USE FOR REPRODUCTION -

COMPOSITE

ORIGINAL ARTWORK

- USE FOR REPRODUCTION -

DIE LINE

approximately 3/8 inches.

6. Route the power wires beneath the RED power connectors and form the wires using

pliers for easy insertion into the connector according to the owner’s manual wiring

diagram.

WARNING

• Conduit plug – do not allow a pass through to a high voltage area to remain open. Utilize

the provided plugs if conduit is not connected

• Do not route wires around or over the RED connector or allow wires to traverse the safety

“No Cable Area”

7. Upon completion of the wiring, you are ready to insert the Main Assembly. Insert the

two feet of the Main Assembly into the receivers found in the rear housing. Rotating

the Control Board into position, depress the top portion into place, connecting the

two RED power connectors to the Control Board assembly. Correct positioning will be

accompanied by a clicking sound as the assembly becomes locked into place in the

housing.

POWER

32

Figure 6

Page 33

Français

ORIGINAL ARTWORK

- USE FOR REPRODUCTION -

COMPOSITE

ORIGINAL ARTWORK

- USE FOR REPRODUCTION -

DIE LINE

ATTENTION

• Prise Conduit - ne permettent pas de passer à travers une zone à haute tension reste

ouverte. Utiliser les bouchons fournis si le conduit n’est pas connecté

• Ne pas passer les ls autour ou sur le connecteur ROUGE ou permettre des ls de traverser

la sécurité “Non Zone câble ”

POWER

Figure 6

33

Page 34

8.0 Current transformer wiring

Mount conduit ttings and conduits

WARNING

• Conduit grounding – required electrical grounding of the meter through conduit

• EMT tting – EMT tting must comply with all local electrical codes

• Current Transducers may not be installed in a panel where they exceed 75% of the wiring

space of any cross-sectional area within the panel.

• Restrict installation of current transformer in an area where it would block ventilation

openings

• Restrict installation of current transformer in an area of breaker arc venting.

• Not suitable for Class 2 wiring methods

• Not intended for connection to Class 2 equipment

• Secure current transformer and route conductors so that they do not directly contact live

terminals or bus

1. Place tool in the center feature of the molded in knockout

2. Force tool through the knockout

3. Insert conduit tting through knockout

4. Thread nut onto the tting

5. Tighten until secure

34

Page 35

Français

8.0 Câblage du transformateur de courant

ATTENTION

• Mise à la terre conduit – mise à la terre électrique nécessaire du compteur par le conduit

• Montage EMT – raccord EMT doit être conforme à tous les codes locaux

• Transducteurs actuel ne peut pas être installé dans un panneau où ils dépassent 75% de

l'espace de câblage d'une section transversale dans le panneau.

• Restreindre l'installation d'un transformateur de courant dans une zone où il bloquerait les

ouvertures de ventilation

• Restreindre l'installation du transformateur de courant dans une zone de ventilation d'arc

du disjoncteur.

• Ne convient pas aux méthodes de câblage classe 2

• Non destiné à être connecté à un équipement de classe 2

• Fixez le transformateur de courant et acheminez les conducteurs de manière à ce qu'ils

n'entrent pas directement en contact avec les bornes sous tension ou le bus

35

Page 36

WARNING- Failure to follow these instructions may result in safety concern or damage

to meter.

• To reduce the risk of electric shock, always open or disconnect circuit from powerdistribution system (or service) or building before installing or servicing current

transformers.

• The meter shall use Listed Energy-Monitoring Current Transformers

• Setra Power Meter can accept Rogowski Coil and voltage output current transformer up

to 2V rms. Recommended CT rated output is 333 mV (rms). Apply CT output higher than

4Vrms can damage the meter.

• Current Transducers may not be installed in a panel where they exceed 75% of the wiring

space of any cross-sectional area within the panel.

• Wiring to CT terminal blocks shall be tightened to 4.43 lb-in torque.

• All unused conduit opening need to be closed using UL listed conduit plugs.

• When using rogid conduit, connect the hub to the conduit before connecting to power

meter enclosure

Ensure CT orientation & placement:

• Arrow points toward load (or as instructed by CT label)

• Placed on First Conductor of voltage reference (L1-L2)

circuits are placed on L1

• Observe wiring color and polarity

• Use the Shield wire if provided (connect to PCB terminal

marked S)

Setra CT wiring guide

Split Core CTs Rogowski CTs

White: Positive

Black: Negative

(No shield)

6. Attach Main Assembly to Back Housing, ensuring housing is secure and clicks into place.

Red: Positive

Black: Negative

Bare Wire: Shield

36

Page 37

Français

ATTENTION- LE NON-RESPECT DE CES INSTRUCTIONS PEUT ENTRAÎNER

DES PROBLÈMES DE SÉCURITÉ OU DE DOMMAGES MÈTRES.

• Pour réduire le risque de choc électrique, ouvrez ou déconnectez toujours le circuit du

système de distribution électrique (ou du service) ou du bâtiment avant d'installer ou

d'entretenir les transformateurs de courant.

• Le compteur doit utiliser des transformateurs de courant de surveillance de l'énergie

répertoriés

• Le Power Meter de Setra peut accepter une bobine Rogowski et un transformateur de

courant de sortie de tension jusqu'à 2 V eff. La sortie nominale CT recommandée est de

333 mV (valeur efcace). Appliquer une sortie CT supérieure à 4 Vrms peut endommager

le multimètre.

• Les transducteurs de courant ne doivent pas être installés dans un panneau où ils

dépassent 75% de l'espace de câblage de toute section transversale du panneau.

• Le câblage aux borniers CT doit être serré à un couple de 4,43 lb-in.

• Toutes les ouvertures de conduit inutilisées doivent être fermées à l'aide de bouchons de

conduit approuvés UL.

• Lorsque vous utilisez un conduit rogid, connectez le concentrateur au conduit avant de le

connecter au boîtier du wattmètre

37

Page 38

7. Insert CT wire through the conduit and strip the wire approximately 3/8" (if necessary)

8. Connect the CT wires to the CT connectors provided with your meter in accordance to

the wiring diagram provided by the manufacturer

9. Plug connector into mating connection on the Main Assembly and note the CT location

for conguration.

38

Page 39

9.0 CTs wiring example

The image below is the counterpart to the service panel illustration and indicates how

to connect CTs to Setra Power Meter for each service type. For service types that are not

specically listed, it is recommended to choose “single phase” service and congure each

channel individually. Three phase loads are illustrated on the left and split phase loads on the

right as an example only. CT inputs are fully interchangeable on the meter.

3-Phase

39

Page 40

Single Phase

10.0 EIA-485 communication wiring

Setra meter uses a 2-Wire isolated Half Duplex EIA-485 implementation. It is used for BACnet

MS/TP or Modbus RTU communication. Supported baud rate are 9600, 19200, 38400 (default),

57600, and 76800. 8 data bits, no parity, 1 start, 1 stop bit. Maximum distance is 1000m.

The recommended wiring for EIA485 is 20 AWG or 22 AWG shielded twisted pair wires.

Connect the shield to earth/ ground at one end only. Wiring to terminal blocks shall be

tightened to 1.77 lb-in torque.

• Termination Resistors – are NOT included on 3/12-load meter. If the meter is at the end

of a daisy-chain, then connect a 120-ohm leaded resistor between the + and - terminal

at the RS485 connector. For 48-load meter please use the DIP switch to turn it on or off

accordingly.

• Bias Resistors – are not included on 3/12-load meter. Bias resistors are needed if the

idle conditions of the bus are in an indeterminate logic voltage. Bias resistors are usually

located at the master node and are usually 680 ohms for an EIA-485 netword. For 48load meter please use the DIP switch to turn on or off the pull up/pull down bias resistors

accordingly.

• Network Topology – EIA-485 is designed to be implemented as a daisy chain (series

connections) rather than star or cascade topologies.

• Signal Names – Some EIA-485 devices use the terminology A/B while others use +/-.

Note that A is (-) and B is (+). Many manufacturers incorrectly label the terminals.

• Bus Loading – The meter is a 1/8th unit load allowing up to 256 like devices in parallel.

40

Page 41

Français

10.0 Câblage de communication EIA-485

Le câblage recommandé pour EIA485 est de 20 AWG ou 22 AWG câbles blindés à paire

torsadée. Connectez le blindage à la terre / terre à une seule extrémité. Le câblage aux

borniers doit être serré à un couple de 1,77 lb-po.

41

Page 42

Verication includes conrmation of BOTH the physical interface settings (Serial or

Ethernet) and the protocol (Modbus or BACnet) settings.

11.0 Ethernet communication wiring

Connect Setra Power Meter to a 10/100 Basset 802.3-2002 compliant IP network or device

by connecting a CAT5 Ethernet cable to the RJ45 Ethernet port on the Meter. The Ethernet

supports BACnet/IP and Modbus TCP protocol.

1. Install communication and other I/O as your application requires.

42

Page 43

12.0 Pulse inputs wiring

The recommended wiring is 20 AWG or 22 AWG twisted pair wires. Wiring to terminal

blocks shall be tightened to 1.77 lb-in torque.

Setra meters are equipped with 2 isolated pulse inputs. Pulse counting supports accumulation

of consumption data from any external meter (e.g., gas, water, BTU meter) using a dry contact

(Form A relay) or open collector outputs. The minimal ON-state current is 2mA and maximum

OFF-state current is 0.35mA. The maximum input voltage is 30VDC. The pulse inputs are

compatible with "low speed" meters. The minimal pulse width is 20 mS is both the logic low

and high state and pulse rate is 20 Hz.

12.1 Open collector output

The pulse output is electrically isolated from the meter power supply and requires the user

to connect a voltage source (5-30 VDC), a ground wire (connected to the host ground), and a

pull-up resistor. A 10K resistor is the recommended value. The pull up resistor shall be sized

to limit the current through the isolator to 5 mA.

If the collector is connected directly to a source of voltage, the pulse isolator will

immediately burn out and become non-responsive.

Output connections

13.0 Alarm relay (SPDT) wiring

The recommended wiring is 20 AWG or 22 AWG twisted pair wires. Wiring to terminal

blocks shall be tightened to 1.77 lb-in torque.

Setra meter include a single pole double throw electromechanical relay that can be congured

to trigger under loss of voltage conditions. This feature will alert building systems to a “loss

of phase” condition within 100 mSec of occurrence without being polled. Once triggered this

relay will need to be reset via a register command.

Please note this relay shall only be used for Class 2 limited energy wiring. The maximum

contact rating is 2A and 30VDC/30VAC.

43

Page 44

Français

12.0 Câblage des entrées d'impulsion

Le câblage recommandé est des ls à paire torsadée de 20 AWG ou 22 AWG. Le câblage

aux borniers doit être serré à un couple de 1,77 lb-po.

13.0 Alarm relay (SPDT) wiring

Le câblage recommandé est des ls à paire torsadée de 20 AWG ou 22 AWG. Le câblage

aux borniers doit être serré à un couple de 1,77 lb-po.

Veuillez noter que ce relais ne doit être utilisé que pour le câblage à énergie limitée de

classe 2. La valeur nominale maximale des contacts est de 2A et 30VDC / 30VAC.

44

Page 45

14.0 Installing front cover

1. Install front cover by inserting tabs into bottom of the back housing and rotate until it

clicks.

1. Turn on Power. It will take a couple minutes for the meter to start up. When the meter

is fully powered up, the status LED will show either Green (no error detected) or Red

(conguration or measurement error detected). The backlit LCD will show start up

message.

45

Page 46

15.0 Meter conguration

The Setra Power Meter’s congurability allows each product to accurately measure in each

unique application. Simple conguration can be leveraged on the unit’s main LCD display,

and more detailed conguration is best completed using Meter’s integrated Web Portal setup

software. The Web Portal can be accessed using a USB or Ethernet port.

15.1 LCD user interface for simple conguration

To use the LCD display, the meter must be powered either through USB or the high voltage

inputs. The LCD will light up upon receiving power. This will follow with easy-to-follow prompts

that allow the user to simply step through each screen.

15.2 Web portal for main conguration

The meter’s Web Portal is an intuitive, web based setup guide for the 3, 12, and 48 load meters.

To access the meter, the user will rst need to connect with a PC.

15.3 Connect the Meter

USB Connection (Power & Communications)

The preferred method for conguring the meter from a locally connected computer is through

the USB port which provides power to the meter as well as communications. The USB port of

most computers will be able to provide enough current to power the meter for conguration.

However, it shall not be used to measure electrical parameters without the meter connected

to line voltage (Vin 1).

To check the status of the meter, the user can reference both the LCD display and the LED

light indicator. If the LED is green, the status is clear. If the LED is blinking red, there is an error

– which requires investigation; detailed information can be found in the unit through the LCD

display. If LED remains "green" for extended period of time, the meter is not communicating.

Blinking green = Good

Blinking red = Error

Ethernet Port/RS-485 Port Connection (Communications only)

The meter can also be congured through the Ethernet port. Please note that this connection

is for communication only and will not power the unit.

46

Page 47

15.4 Web portal setup

After enabling a connection with the meter, open a web browser on the connected PC and

enter http://10.10.5.2 (this is the static address of the USB port) to start the Web Portal home

page. The user will be prompted to LOGIN to the Portal with a Pin code, for additional security,

if desired.

Upon login, the web portal software will open with the menu navigation sidebar appearing

along the left side.

15.5 Web portal overview

The web portal is structured into three main sections: the meter communication bar, menu

navigation sidebar, and the conguration/data window. The web portal software will allow the

user to congure the meter for their installation as well as view/access data once the meter

fully installed and collecting data.

Menu navigation sidebar

Meter communication bar

Conguration/ Data window

47

Page 48

15.6 Meter communication bar

The meter communication bar is the 3-button user interface that links the web portal software

to the conguration le on the meter.

Send/store the conguration to the meter

Reload/retrieve the current stored conguration from the meter to the portal

Logs out of the current session of the portal, pin code may be needed to log

back in

15.7 Menu navigation sidebar

The menu navigation sidebar allows the user to navigate through the web portal software.

The sidebar is split into seven sections:

1. Setup

Congure unit defaults, dene voltage input(s),

load setup, CT inputs, communication output,

pulse input(s) & output, alarming, and complete

installation report.

2. Power analysis

Access energy & power details for the congured

loads of the meter including: trending, harmonics,

waveform, and running “odometer” measurement.

3. Event log

Access to previously occurring errors and

conguration changes to the meter setup.

4. Alarm status

Access to current alarm status (including LED and

relay state) and previously triggered alarms

5. System

Update current software version, perform factory

and trend data reset, and reboot the meter.

6. Export conguration

Export or import conguration le for a backup of

the fully congured meter or use to import setup to

another meter being installed with a similar setup &

export conguration report.

7. Help

Access technical documentation for the meter and

contact information for technical assistance.

48

Page 49

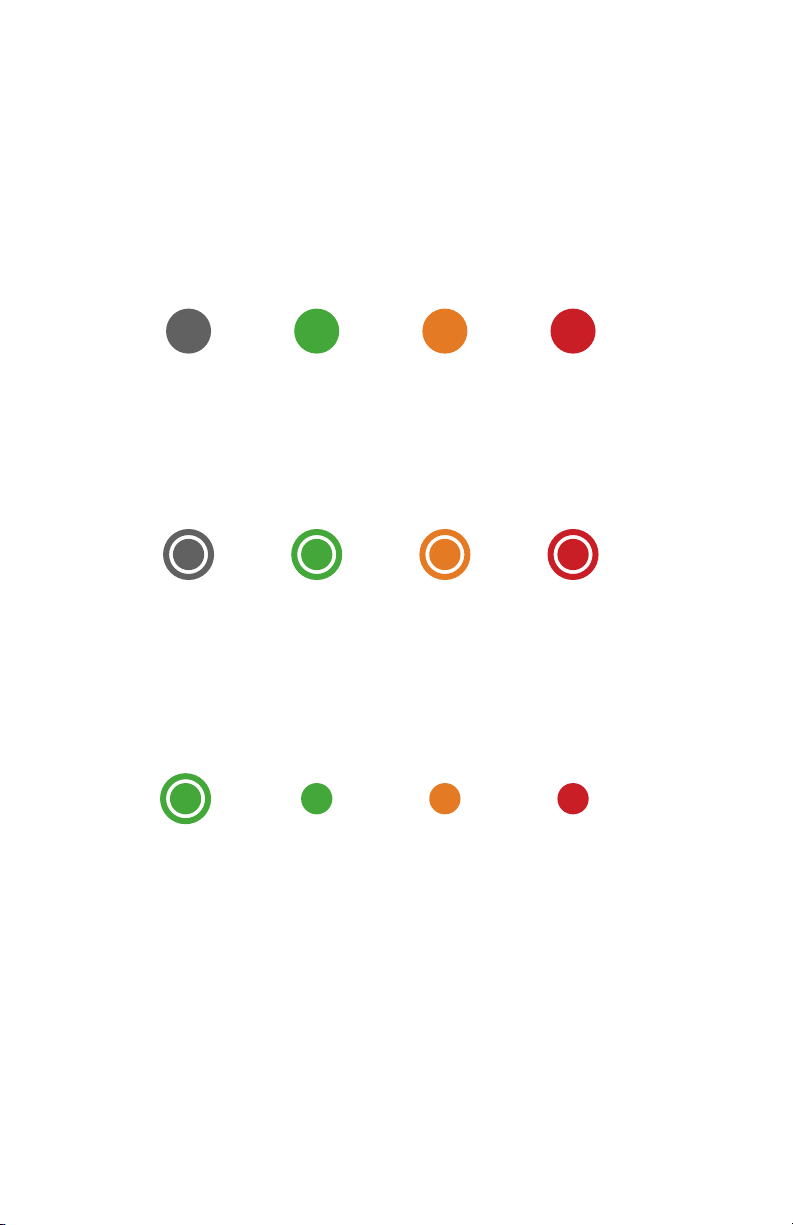

16.0 Halo-dot

The Halo-dot is a visual indication to the user of where to click to begin conguration, current

status of a given attribute, or numeric indication of the item selected.

16.1 Conguration indication dot

The conguration indication dot resides on or next to an input or output that can be congured

or grouped together by the web portal. The color of the indication dot changes based on the

state of conguration,while the meaning of the color may change slightly depending on the

menu.

Unused

(Not congured)

Fully

Congured

Partially

Congured

Error in

Conguration

16.2 Halo

When the indication dot is surrounded by a “Halo”, it indicates the input or output is selected

and currently being congured.

Selected

Unused

(Not congured)

Selected

Fully

Congured

Selected

Partially

Congured

Selected

Error in

Conguration

16.3 Numerical indication

When the conguration indication dot–has a number inside the symbol, it reflects either the

input number, output number, or the load assignment based on the conguration menu the

user is in.

1 2 3 4

49

Page 50

17.0 Setup menu

The power meter’s web portal conguration software is intended to intuitively walk the user

through the setup of all the crucial inputs and outputs to gain insights into energy usage,

allowing them to make better energy management decisions and support energy strategy

initiatives.

The setup menu is divided into eight menu areas:

1. General settings

Congure/edit general settings for the device, edit

unit defaults & add site specic information about

installation (optional)

2. Voltage inputs

Congure/edit expected line voltage (voltage

reference) & dene service type (wiring) of the

voltage input(s)

3. Load setup

Dene/edit the relationship between the voltage

input(s) and CT(s) for the electrical load being

measured

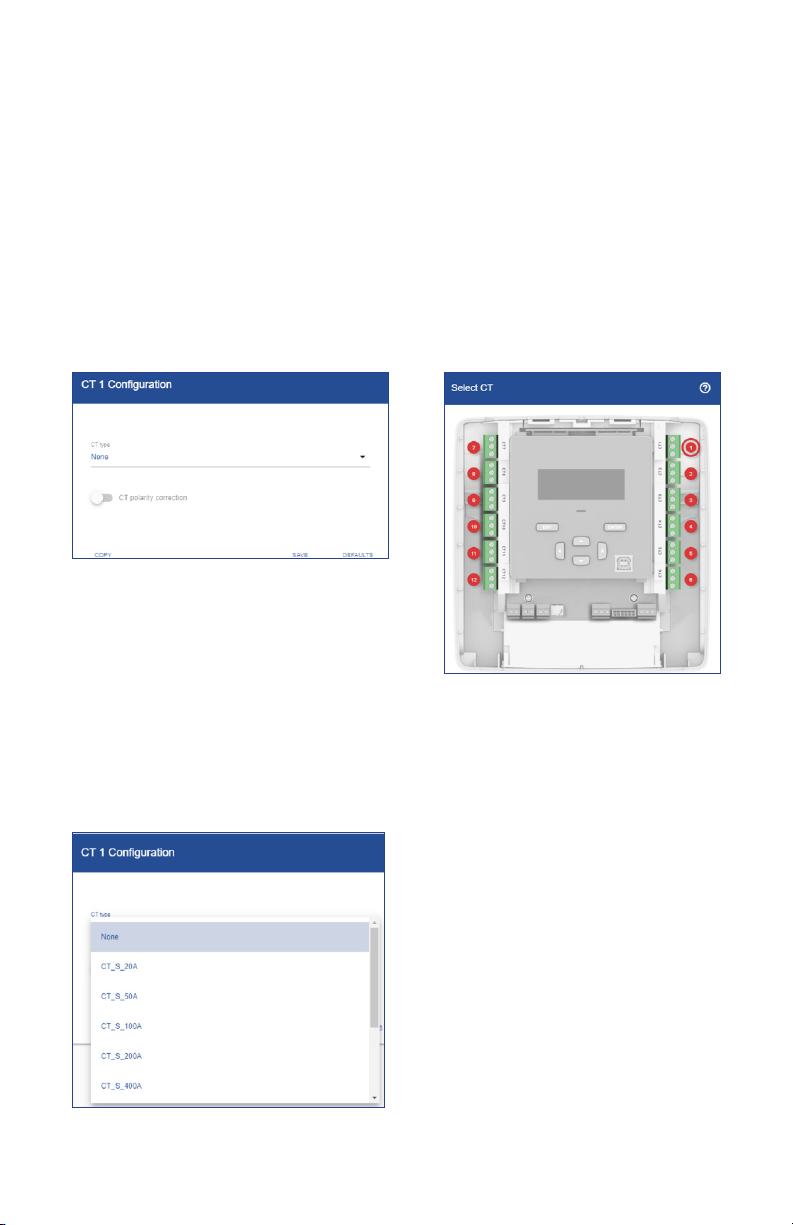

4. CT inputs

Congure/edit the CT type, rated current, voltage at

rated current and CT polarity

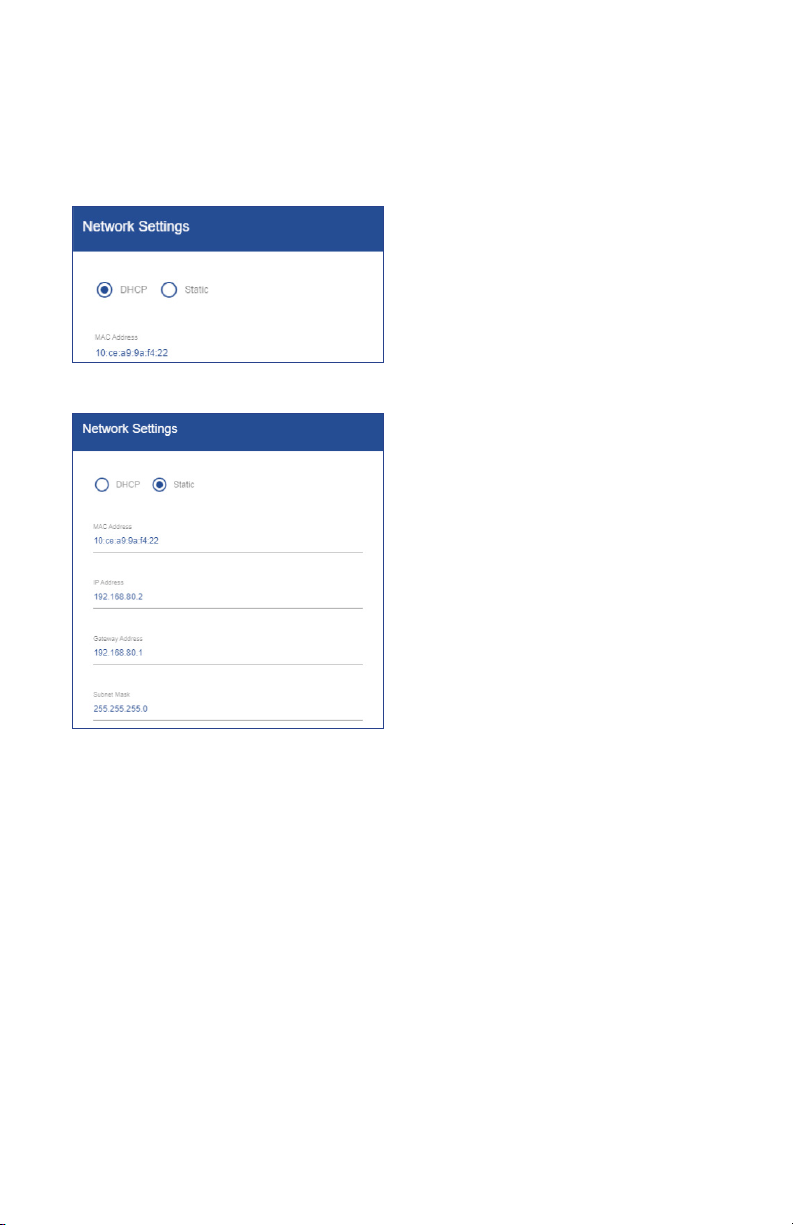

5. Communication

Congure/edit communications type, protocol

parameters, and dene network settings

6. Pulse IO setup

Dene & congure the (2) pulse inputs & (1) pulse

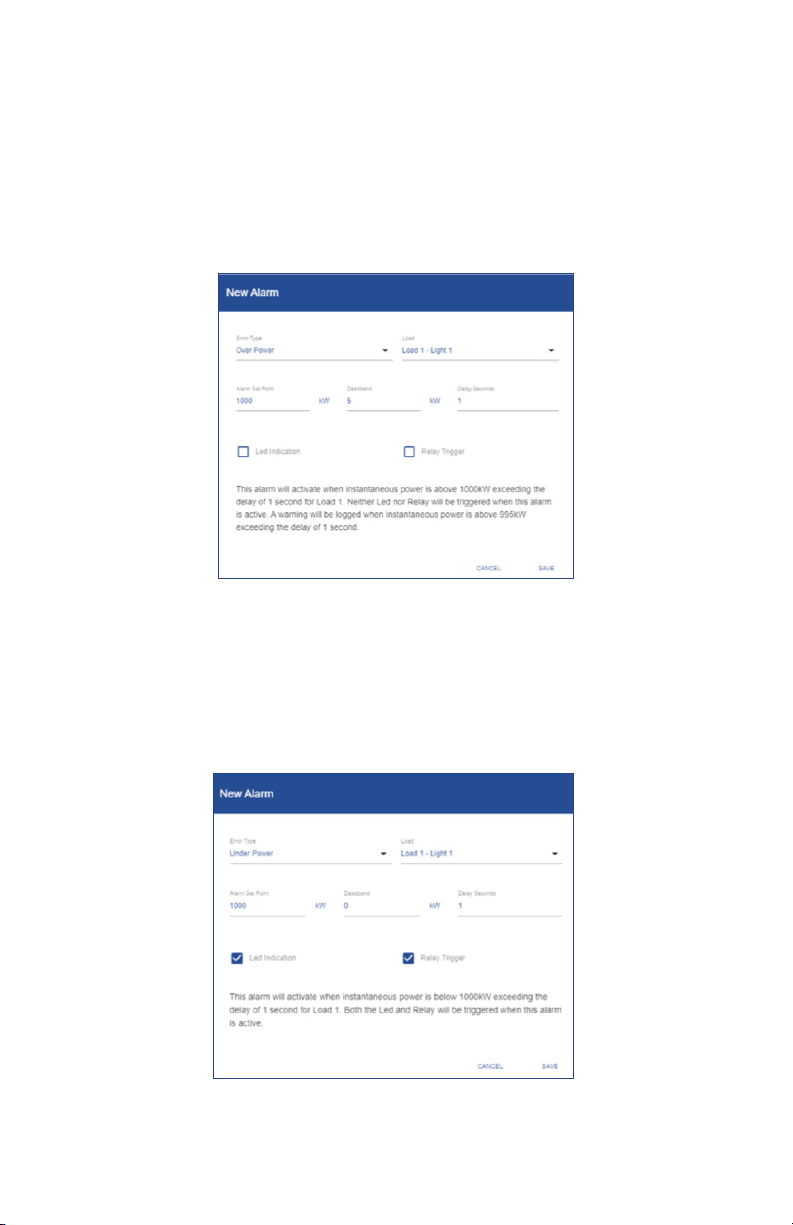

output on the meter

7. Alarm setup

Congure/edit alarm type, setpoint, deadband, delay,

LED indication, relay trigger for conditions that

require notication

8. Installation report

Generate record of installation with snapshot of live

data in a pdf

50

Page 51

18.0 Setup menu help legend

Throughout the web portal there are icons and coloring to help the user know the state of

the conguration and if further action might be needed. These legends are accessible

by clicking the encircled question mark icon and opening the relevant legend on the page.

Within the setup menu, the legend is below:

If the section has this symbol to the right of title, it requires no further action from

user.

Note: When rst logging into the web portal, the user will see the green checkmark

since the defaults are loading at the time of manufacturing.

If the section has this symbol to the right of title the user is required to click the

Upload to Meter button in the Meter communication bar.

Note: The upload to meter button only appears when there is something to upload.

If the section has this symbol to the right of title, it serves as a warning that there may

or may not be more work to do to fully congure the meter.

Note: This will not prevent you from uploading the conguration to the meter,

(warning only).

If the section has this symbol to the right of title, the conguration has a fundamental

error and cannot be uploaded to the meter.

51

Page 52

19.0 General settings

The General Settings menu is where the user can nd general device information, set unit

default parameters, and enter any detailed information about the site where the meter is being

installed. The general settings conguration/data window can be accessed by clicking the

Setup section (if minimized) and then clicking the General Settings menu.

Once in the General settings menu, the user can access three sub menus: Device general, Unit

defaults, and Site information.

19.1 Device general

Within the Device general section, the Product, Model, and Serial no. will automatically be

pulled from the stored values on the meter. The date and time can be set following the

procedures below.

The date can be set by:

1. Click the calender icon

2. Use the left & right arrow to scroll to the correct month/year

3. Click the correct day within the month

4. Click out of the window and your date should be changed

5. To upload changes to the meter, click Upload to Meter in the

communication bar

The time can be set by:

6. Click the clock icon

7. With the hour highlighted in white, click the number that

needs to be set

8. With the Minute highlighted in white, click the number that

needs to be set

9. Click out of the window and your time should be changed

10. To upload changes to the meter, click Upload to Meter in the

communication bar

Note: The date & time set will be used for time stamping during

data collection. The unit will not adjust for daylight savings

time.

52

Page 53

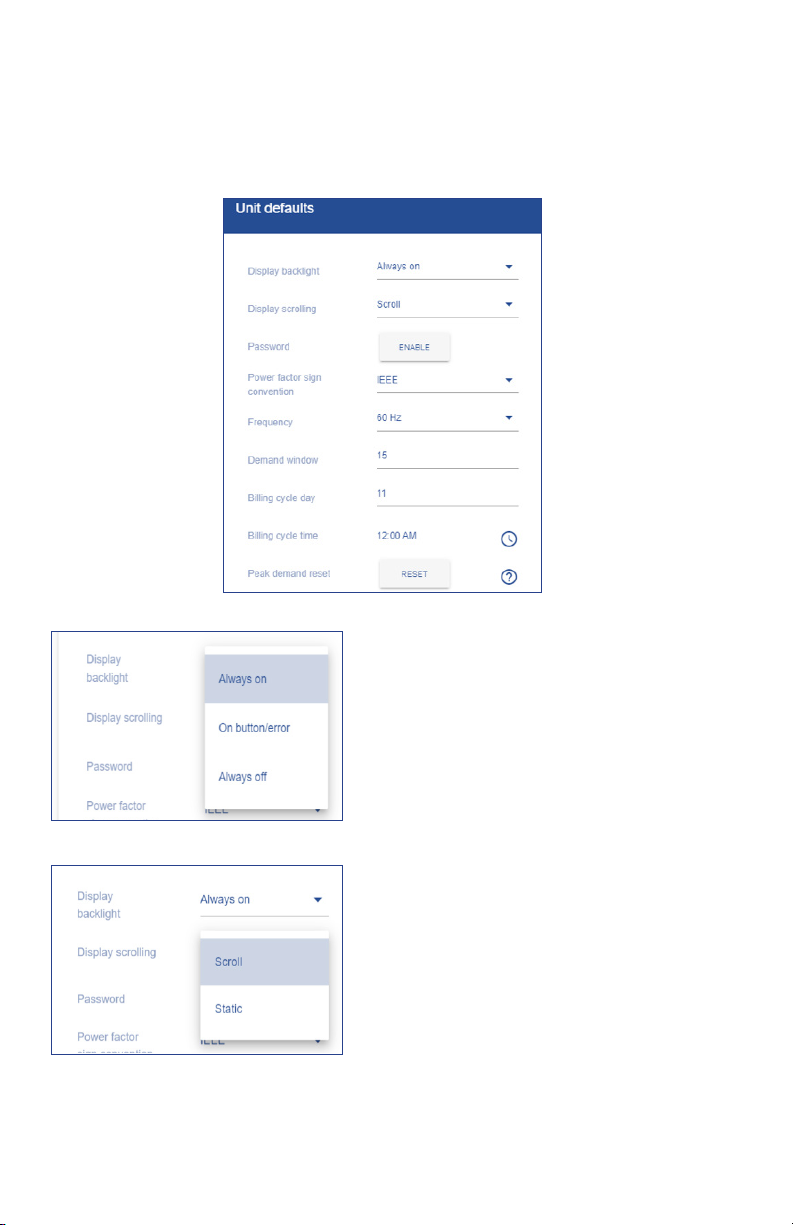

19.2 Unit defaults

Within the Unit defaults section, the user can change global settings that will apply to all

measurements and/or operation of the power meter. Within the Unit defaults menu, the

user can edit: Display backlight, Display scrolling, Password enablement, Power factor sign

convention, frequency, and demand window.

Display backlight

This setting changes the backlight behavior on the physical meter

1. Click the drop down arrow

2. Select Always on (stays on all the time), On

button/error (display will be backlit after a

button press or if there is an error, or always off

(back light is never on)

3. To upload changes to the meter, click Upload to

Meter in the communication bar if conguration

is complete

Display scrolling

This setting changes the behavior of the data on LCD screen

1. Click the drop down arrow

2. Select scroll (real-time data will scroll from load

to load), or Static (real-time data will remain

static until user clicks left/right arrow)

3. To upload changes to the meter, click Upload to

Meter in the communication bar if conguration

is complete

53

Page 54

Password/Pin code

This setting enables/disables pin code access to the mete

1. Click Enabled or Disables

2. Type 4 digit pin code

3. Conrm 4 digit pin code

4. Click save

5. To upload changes to the meter, click Upload to

Meter in the communication bar if conguration

is complete

6. Unit will go to login screen. Enter pin and circle

login button.

Note: Some version of the software require a pin

code. Disabling is not an option.

Power factor sign convention

This setting changes the convention for the power factor sign

1. Click the drop down arrow

2. Select IEC or IEE

3. To upload changes to the meter, click Upload to

Meter in the communication bar if conguration

is complete

Frequency

This setting changes the frequency setting, based on region

1. Click the drop down arrow

2. Select 50 or 60 Hz

3. To upload changes to the meter, click Upload to

Meter in the communication bar if conguration

is complete

54

Page 55

Demand window

This setting changes the time interval for peak demand window

1. Click into the eld

2. Enter desired time interval (1 to 120 minutes)

3. To upload changes to the meter, click Upload to

Meter in the communication bar if conguration

is complete

Billing cycle day

This setting changes day of the month, the peak demand value

in the meter is reset, and is also used to see the last month date

window in the odometer

1. Click into the Billing Cycle day eld

2. Enter day of the month for the peak demand

and odometer the user wants the change

to occur (i.e. if the user enters a value, every

th

11

day of the month the peak demand and

odometer would reset)

3. To upload changes to the meter, click Upload to

Meter in the communication bar if conguration

is complete

55

Page 56

Billing cycle time

This setting changes time of day on the billing cycle day the peak

value in the meter is reset and is also used to set the last month

date window in the odometer

1. Click on the clock symbol to the right of the

current time setting

2. Select new time for reset to occur

3. Click into the grayed out area, new time will

show in the billing cycle time eld

4. To upload changes to the meter, click Upload to

Meter in the communication bar if conguration

is complete

Note: The unit will not adjust for daylight savings

time

Peak demand reset

The peak demand is reset automatically every month on the day

and time as congured in the billing cycle. Pressing the 'Reset'

button resets the peak demand directly once.

1. Click Reset

2. Click OK or CANCEL to continue/not continue

with reset of the current peak demand value

56

Page 57

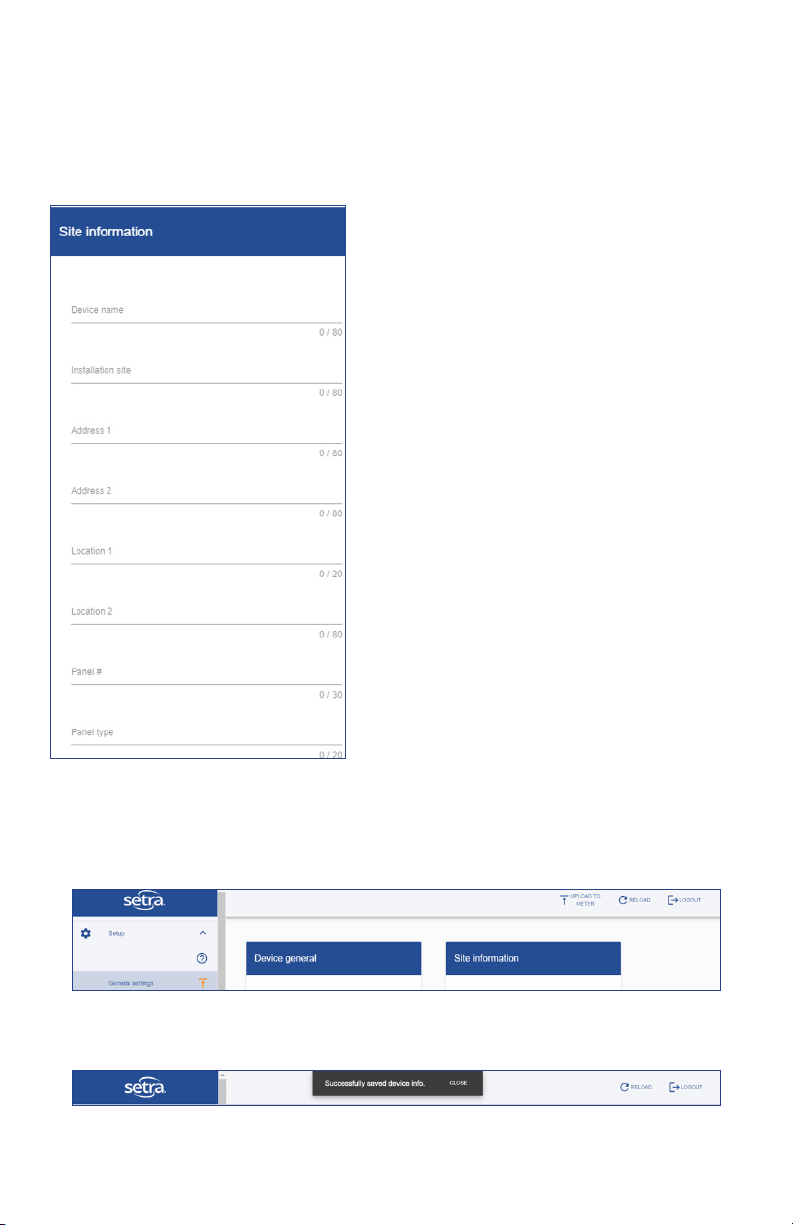

19.3 Site information

The Site information section allows the user to store pertinent information about the job site

directly on the meter. While optional, this information gives the user detailed information

about the site that can be accessed through BACnet, transferred directly to the installation

report, and stored in a job le.

Site information

This is a repository for pertinent job sire information

1. User lls out elds that are pertinent to the job

Note: Each eld has a character limit that is noted

in grey.

19.4 Uploading to meter

With the General settings menu complete, the user can click Upload to meter to load settings