Page 1

Model MRG

Multi-Range General

Pressure Transducer

The Setra Model MRG is Setra’s newest dierential pressure

transducer. The Setra MRG is the ideal product for any contractor, combining the exibility of a multi-range with the performance of a single range transducer. The MRG has 8 selectable

ranges and 3 selectable outputs, easily adjustable on the job

with a ip of a switch or jumper. The MRG uses an IP67 rated

housing and has a conduit tting for easy wiring, making the

MRG an ideal solution for any general HVAC application.

Universal Design

The Setra MRG utilizes a universal design that gives the user

total exibility to make changes on the job site. The user has

the option to choose the eld congurable range, mounting

(DIN Rail, wall mount and duct mount), output (mA or Volt) and

engineering unit (W.C. or Pascals). This exibility means that

the contractor can use the MRG for all of their needs.

n Universal Design

n IP67 Rated Housing

8 Field Selectable Ranges

The Setra MRG provides 8 eld selectable ranges (0.5, 1.0, 2.5

and 5.0”W.C.). These ranges can be selected on site by ipping

the jumper to the desired range. Setra chose these ranges

from analyzing 30 years worth of customer data that proved

up to 90% of all dierential pressure transducers ordered from

Setra that require 1.0% accuracy are between 0.5 and 5.0”W.C.

IP67 Rated Housing

The MRG housing is a robust IP67 rated design and is sealed

with a gasket to make it wash-down capable for dicult applications. The MRG also has a conduit tting that make installa-

tion and wiring easier.

Capacitive Sensing Technology

Only Setra can claim ownership to the stainless steel capacitive

design used in all of our HVAC/R sensors. Our advanced capacitive element provides excellent stability and linearity, while

standing above the competitors in our ability to measure low

pressure (<0.001”W.C.) at high accuracy. Our technology has

been used in over 8 million installations and has the highest

eld acceptance rate in the industry.

n Field Selectable

Model MRG Features:

• Field Congurable Duct Probe

• 4 Digit LCD

• Field Selectable Range

• Field Selectable Output

• Simple 5-Step Setup

• Field Accessible Push-Button Zero & Span

• External Mounting Tabs & Optional DIN Rail

• Unregulated AC/DC Operation

Target Uses:

• Sub-Contractors- Quick Installation

• Flexible for Building Specication Changes

• Service/Retrot Friendly

• Service Technicians- Quick & Accurate

Reconguration

Phone: 800-257-3872 • Fax: 978-264-0292 • setra.com © Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc.

Page 2

Model MRG

Mutli-Range General Pressure Transducer

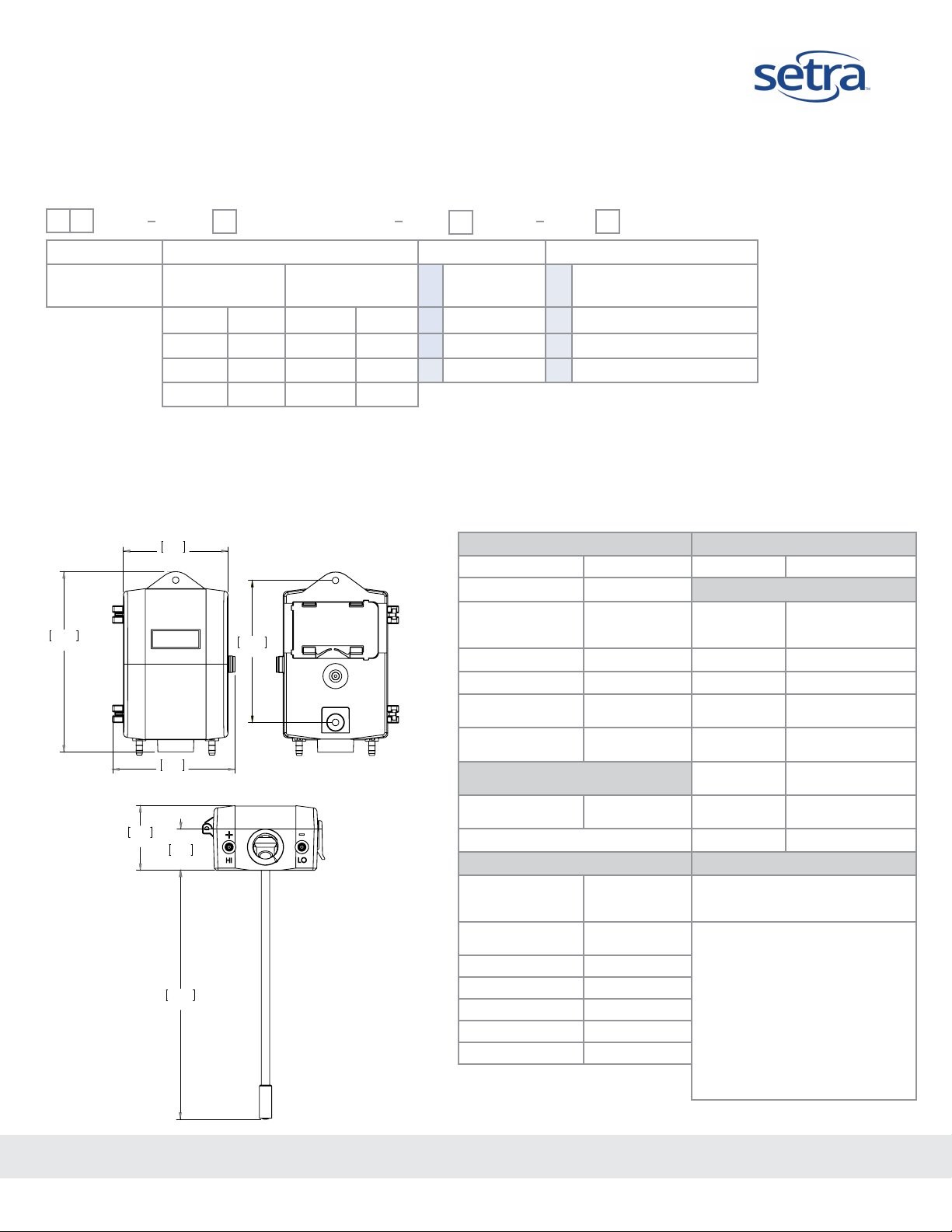

ORDERING INFORMATION

M R

G

Model Field Selectable Ranges Conguration Options

MRG Unidirectional

Pressure Ranges

0.5”W.C. 100 Pa ±0.5”W.C ±100Pa U Universal

1.0”W.C. 250 Pa ±1.0”W.C. ±250 Pa D DIN Rail C 1/2” Conduit W/ Cal Certication

2.5”W.C. 500 Pa ±2.5”W.C ±500Pa P Duct Probe D PG9 W/ Cal Certication

Bidirectional

Pressure Ranges

S Standard (Base

Mount)

1

A 1/2” Conduit

P PG9

2

2

5.0”W.C. 1,000 Pa ±5.0”W.C. ±1,000Pa

1

Code U, Universal unit includes Duct Probe and DIN Rail options.

2

Calibration is performed at highest range.

Ordering Example: MRGSA = Model MRG, Standard Conguration, with 1/2” Conduit.

DIMENSIONS GENERAL SPECIFICATIONS

Performance Data Environmental Data

Standard

1

(at constant temp) ±1.0% FS

Accuracy RSS

Compensated Range ºF (ºC) 32 to 122°F (0 to 50°C)

Thermal Eects2 %FS/ºF(ºC) 0.03 (0.054)

Maximum Line Pressure 10 PSI

Overpressure

Long Term Stability (max.) 2.0% FS/YR

Up to 10 PSI

(range dependent)

Position Eect

Zero Oset %FS/G 0.5% Loop Resistance

(Unit is factory calibrated at 0g eect in the vertical position) Approval CE & RoHS Compliant

Operating Temperature

Electrical Data

Excitation Range 13 to 30 VDC/18 to 24 VAC (Voltage

Current Consumption 30mA (max)

Mis-Wiring Reverse Excitation Protection

Field Selectable Output

Output Resistance

(Voltage Output)

Load Resistance

(Voltage Output)

(4-20mA)

3

32 to 122°F (0 to 50°C)

Output) 13 to 30 VDC (4 to 20mA

output at terminals)

4

0 to 5 V, 0 to 10V (3-wire), 4 to

20mA (2-wire)

10 Ohms (max)

10 K-Ohms (min)

0 to 800 Ohms

Physical Description Pressure Media

Case Fire-Retardant Polycarbon-

ate (UL 94 V-0 Approved),

Hinged Lid

Mounting Two Screw Holes Vertical

Position

Electrical Connection Block Removable Screw Terminal

Pressure Fitting 3/16” O.D. Barbed Brass

Zero Push Button

Span Push Button

Weight (approx.) 8 Ounces

Typically air or similar non-conducting gases.

1

RSS of Non-Linearity, Hysteresis, and Non-Repeatability.

2

Units calibrated at nominal 70˚F. Maximum thermal error

computed from this datum.

3

Operating temperature limits of the electronics only. Pressure

media temperatures may be considerably higher.

4

Calibrated into a 50K ohm load, operable into a 10K ohm load

or greater.

5

Span (Full Scale) output factory set to within 1%.

6

Calibrated at factory with a 24 VDC loop supply voltage and

a 250 ohm load.

7

Span (Full Scale) output factory set to within ±0.16mA.

Specications subject to change without notice.

138.5

5.45

80.4

3.17

94.1

3.71

49.7

1.96

31.8

1.25

191.4

7.5

109.1

4.30

1/2" CONDUIT

OR

PG9

STATIC PRESSURE

PROBE

DIN RAIL

BACKPLATE

Phone: 800-257-3872 • Fax: 978-264-0292 • setra.com © Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc.

SSP-MRG Rev A 4/2015

Loading...

Loading...