Page 1

User Manual

User Manual

Micro-Cal™

Micro-Cal™

Model 869

Model 869

1-800-257-3872 Toll Free

1-978-264-0292 FAX

www.setra.com Web Site

Page 2

Table of Contents

1.0 SAFETY INSTRUCTIONS………………………………………….……

2.0 INTRODUCTIONS……….…………………………………….…………

3.0 STANDARD EQUIPMENT………………………………………………

4.0 OPERATING FEATURES

4.1 Pocket PC……………………………………………………..

4.2 Portability……………………………………………………..

5.0 CALIBRATION SETUP

5.1 Battery Charging…………………………………...………..

5.2 Pocket PC Charging…………………………….…………..

5.3 User Interface Panel………………………………………...

5.4 Getting Started……………………………………………….

5.5 Backup/Restore Data………………………………………..

6.0 POCKET PC INTERFACE SCREENS

6.1 Real Time……….…………………………………...………..

6.2 Test…………………..…………………………….…………..

6.3 Profile………………..………………………………………...

6.4 Unit Under Test (UUT)….…………………………………...

6.5 Reference……………………………………………………..

6.6 System………………………………………………………...

1

1

2

2

2

3

3

3

4

4

5

5

6

6

7

7

7.0 UNIT UNDER TEST SETUP

7.1 Wiring Setup……….…………………………………...……

8.0 CALIBRATING/TESTING A TRANSDUCER…………………………..

9.0 POCKET PC TO PC USER INTERFACE……………………………....

9.1 Setup…………….…………………………………...………..

9.2 Graphic User Interface………………………….…………..

9.3 Test Results Data………………….………………………...

10.0 GLOSSY OF TERMS & SPECIFICATION DERIVATIONS……..…

9

9

10

10

13

15

Page 3

1.0 SAFETY INSTRUCTIONS

Use the calibrator only as specified in the manual, otherwise the protection provided may be impaired.

Do not operate the calibrator in explosive gas, vapor or dust environments.

The calibrator is designed to operate from 24 VDC internal battery source or from the AC adapter that is

Included. Additionally, a smart battery charging system is supplied for charging the internal Nickel Metal

Hydride (NiMH) battery. Do not use AC adapters or chargers other than those supplied with the unit.

When charging the battery from the included battery charger the AC adapter must be plugged into the 24

VDC port on the left side of the unit to enable charging.

If supply external excitation to the Unit Under Test is a measure mode, do not exceed 30 VDC.

There are no user serviceable parts internally, removing the internal cover will void warranty. Return the unit

to the factory for re-certification or repair.

BEST PRACTICES FOR CALIBRATOR OPERATION:

Use the shortest length of tubing from the calibrator to the Unit Under Test, during pressure testing avoid

vibration of the tubing.

Avoid movement of the calibrator during operation, avoid locating in a high vibration environment.

Allow the calibrator to warm-up for one (1) hour before use. The calibrator can be turned on during transport.

2.0 INTRODUCTION

DOCUMENTING PROCESS CALIBRATOR:

The Setra Micro-Cal Model 869 is a pressure generating, very low pressure documenting calibrator. The calibrator has been designed and optimized to meet the needs of our customers for a capable system for the

calibration, troubleshooting and documentation of very low pressure measuring information.

The design of the Model 869 exploits years of experience in the calibration of Setra transducers, as well as

NASA patented and Setra exclusive licensed technology. The Pocket PC user interface provides a familiar

“state-of-the-art” application of computer technology and an upgrade path for future developments.

Major Features:

-Pocket PC user interface, capable of storing thousands of Units Under Test (UUT) data files.

-Portable, battery powered system, capable of full operation for eight (8) hours.

-Closed loop pressure control which is immune to the effects of ambient pressure perturbations, (doors

closing, people moving around).

-Very low internal reference pressure standards, which are matched to the UUT, pressure ranges.

-Auto zero pressure “tare” function.

-Ability to source power to the UUT, or external power supply.

-Strip chart capability for troubleshooting leak and drift conditions.

-Micro-stepping pressure control capable of precise generation and

pressure control in the micro inch of water column pressure ranges.

-Leak testing

-Volume measurement

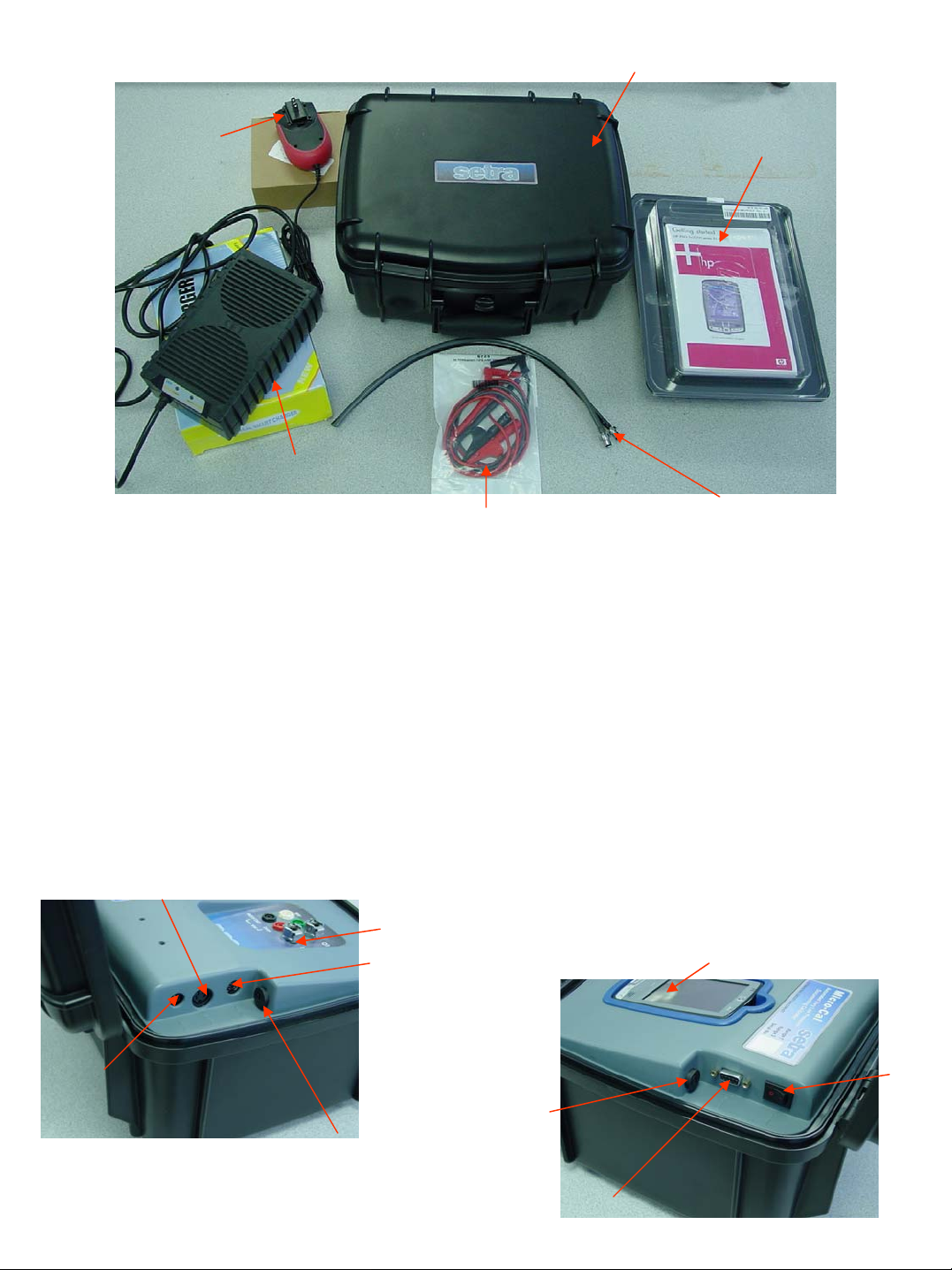

Diagram 1

Standard Equipment

Page 4

3.0 STANDARD EQUIPMENT BREAKOUT

THE ITEMS BELOW ARE INCLUDED IN YOUR CALIBRATOR:

Calibrator

AC Power

Adapter

Battery Charger

Pocket PC Document

Diagram 2

Electronic Test Lead Kit

Pneumatic Fittings & Tubing

4.0 OPERATING FEATURES

4.1 THE POCKET PC PERFORMS THE FOLLOWING MAJOR FUNCTIONS:

-User interface for setups, display and storage.

-External communications

-Communications with internal data acquisition and control microprocessor board.

-Monitors battery voltage

-Stores data for UUT, test profiles and test results.

and cables

4.2 PORTABILITY – CALIBRATOR IS FULLY PORTABLE AND POWERED BY:

-120/240 VDC to 24 VDC power adapter.

-Using the internal 24 VDC battery which has been designed for eight (8) hours of continuous operation after

a full charging cycle. The NiHM battery is rated at 24 VDC, 4 Amp hour (AH). See Diagrams 3 and 4.

Battery Charger

User Interface

Panel

Pocket PC

On/Off

Switch

120V/

24VDC

Input

Diagram 3

Keyboard

Input

Power

Fuse (4A)

Current Loop

Fuse (63mA)

Serial

Port

Diagram 4

Page 5

5.0 CALIBRATION SETUP

5.1 BATTERY CHARGING:

The calibrator is assembled, calibrated and tested at the factory.

The battery, as received, will be in a partially charged state. Before operation please be sure to fully charge

the battery to get maximum portable use of the device.

TO CHARGE THE BATTERY:

-Connect the AC power adapter to AC supply and the 24 VDC connector to the input labeled 24 VDC on the

left side of the calibrator.

-Connect the AC end of the Smart Charger to an AC power source, connect the other end (4 pin circular DIN

connector) of the charger to the battery charger input of the calibrator.

-Initial battery charging will take approximately 2-4 hours. If the battery is discharged below 20 VDC charging

overnight will be required.

5.2 POCKET PC CHARGING

TO CHARGE THE POCKET PC:

-If calibrator is not in use for extended periods of time, Pocket PC should be plugged into HP supplied power

cable.

-Pocket PC will only charge from calibrator when battery is charged or A/C adapter is plugged in. The main

power switch must be in the ON position.

-Pocket PC must remain charged.

-Should the battery on the Pocket PC become drained to the point that the device resets itself, please see the

Pocket PC Backup/Restore information on Page 6 of this manual.

5.3 USER INTERFACE PANEL

The user interface panel includes the pressure and electrical connections to the Unit Under Test.

See Diagram 5.

Optional UUT Mounting

8-32 UNF Threaded Inserts (2)

Power Switch

Pocket PC

Power Switch

High Pressure Port

Low Pressure Port

Diagram 5

Page 6

5.4 GETTING STARTED

-Open calibrator top.

-Turn on calibrator power (power switch on right side of the calibrator).

-Once calibrator is powered up, re-zero function begins automatically,

Please wait for completion. (User will hear operation of solenoid valves

and stepper motor).

-Look for orange light (flashing or solid) on PDA (if light does not come

on, see section on battery charging.

-Turn on PDA power (button in upper right-hand corner of the PDA).

-After powering up, tap the icon labeled

programs folder and

CALIBRATOR icon).

-Software will start up with Real Time page. Tap

CALIBRATOR, (tap START MENU icon,

VENT button (diagram 6)

to leave the calibrator in a ready to “hook-up” state.

Diagram 6

5.5 POCKET PC BACKUP/RESTORE

Vent Function

-Once calibrator is received, install Microsoft® ActiveSync ®. (Disc provided with Pocket PC equipment).

-After installation, connect Pocket PC to PC using USB cable provided.

-ActiveSync should start automatically, if not, please follow instructions for usage provided by Microsoft.

-ActiveSync will ask which type of partnership to setup. ActiveSync will recognize standard setup and the

required actions without automatic synchronization running. If backup/restore and interfacing the database

through a PC are the only actions required, select

-Once the partnership type has been selected, the ActiveSync main screen should appear.

GUEST.

CONNECTED

Should be displayed. If not, please refer to the usage instructions provided by Microsoft.

-To backup:

-Select

-From drop-down menu, choose

TOOLS menu

BACKUP/RESTORE

-Select BACKUP tab

-Press

BACKUP NOW button

-Wait for status bar to fill and status page to close

-To restore:

-Select

-From drop-down menu, choose

TOOLS menu

BACKUP/RESTORE

-Select RESTORE tab

-Press

RESTORE button

-A box will pop up requesting which Pocket PC to restore

-Press

-Press

OK button

RESTORE button on confirmation page and wait for status page completion

-To restore the file shortcut:

-Use the FILE EXPLORER PROGRAM on the Pocket PC to copy the shortcut from MYDEVICE/IPAQFILESTORE to

MYDEVICE/WINDOWS/STARTMENU/PROGRAMS.

-Press START button

-Select

-Select

-Select

PROGRAM from list

FILE EXPLORER from list of available programs

ROOT DIRECTORY by pressing down arrow next to CURRENT DIRECTORY

-A list with drop down showing the path, select MYDEVICE.

-Select

IFAQ file store directory

-Press and hold stylus to CALIBRATOR file (should be 36B for file size).

-A list of options will pop up, select

-Start

WINDOWS directory

-Select

-Select

START MENU directory (scroll down using slide bar to right if necessary).

PROGRAMS directory

COPY and return to root directory

-Scroll to bottom of list (using slide bar on right).

-Press and hold stylus to white area beneath last item in list.

-Select

PASTE from pop up list

Page 7

-To restore button shortcut:

-On Pocket PC, press

Highlight desired button (

Calibrator program is not available, press

START and select SETTINGS from drop down list. Select buttons from PERSONAL tab.

BUTTON 4 is factory default). Select PROGRAM to assign from drop down list. If

OK, please be sure file shortcut has been restored.

6.0 POCKET INTERFACE SCREENS

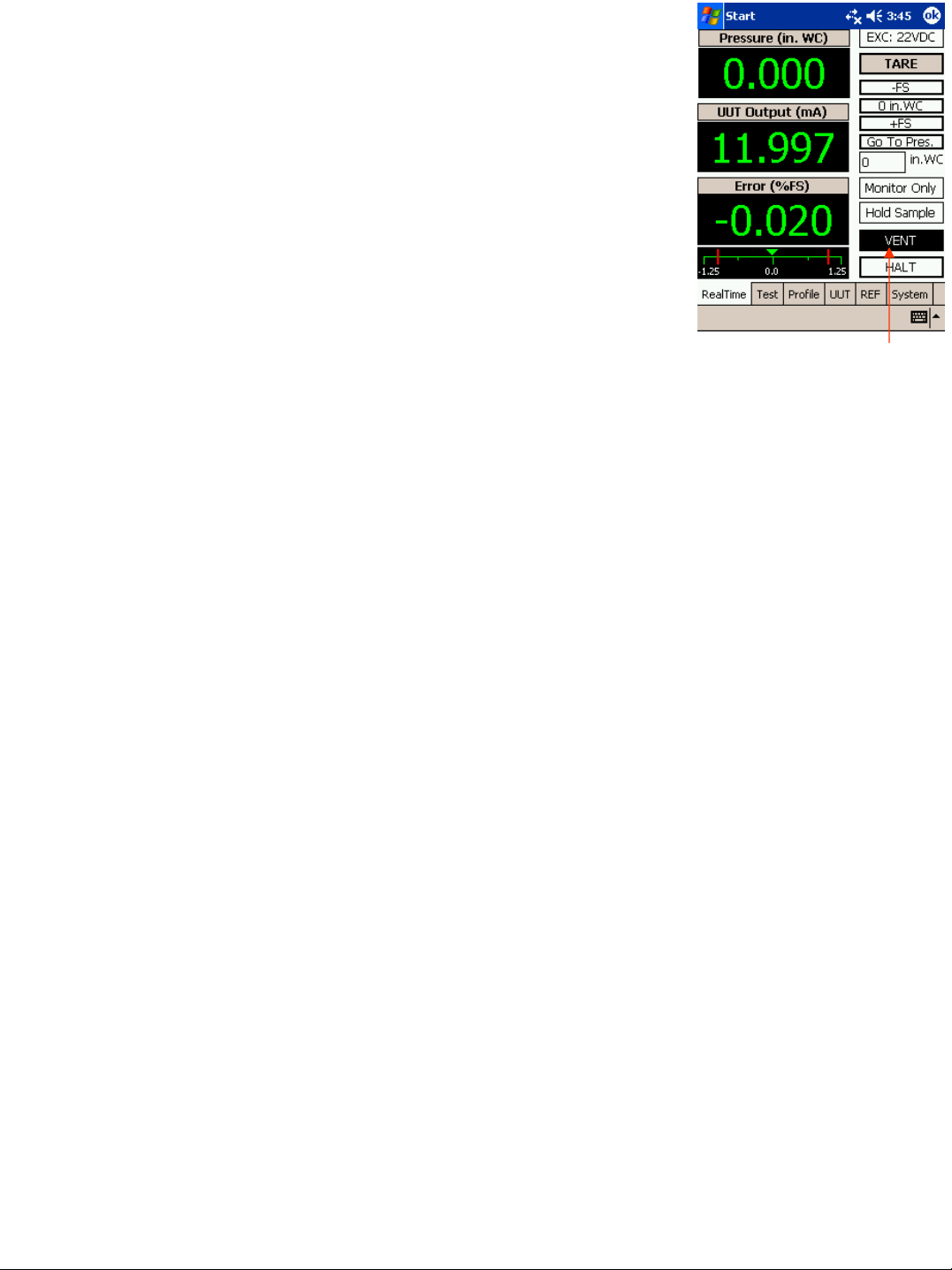

6.1 REAL TIME – Screen instructions on Diagram 7.

-Real Time output is constantly updating and is used to see the existing output and existing pressure being

applied for calibration purposes and test purposes, (acts as a digital indicator).

-The

HOLD SAMPLE button will take a filtered reading and freeze the display with that reading. To release,

Press the same button – release display hold.

-The

–FS, +FS button enters the selected UUT’s lowest

and highest pressure input into pressure target box, and

call

GO TO PRESSURE function.

-

Vent: Opens both positive and negative pressure

ports to each other and atmosphere.

Tare: Tares reference and re-zero’s mechanical

components in the controller.

-

Go to pressure: Calls controller to generate

pressure point set in pressure target box.

Terminal Based Error

(%FS) Includes Zero

and Span Errors

-Halt: Stops process in action.

-

Monitor/Control: Switches pressure generating

Bar Graph of

Error (%FS)

mode into monitoring mode. Allows calibrator to

be used as pressure measurement device.

Applied

Pressure

UUT Output

Excitation to UUT

Tares Internal

Pressure Standard

Sets Pressure at -FS

Range in UUT Profile

0 In. of W.C. (True Zero)

Sets Pressure at +FS

Range in UUT Profile

Sets Pressure to 0

Current Pressure Target

Monitor/Control Mode

Snapshot of Any

Displayed Condition - Release

Vents Pressure to

Atmosphere

Halts Operation

Diagram 7

6.2 TEST – Screen instructions on Diagram 8.

-Tap the

TEST tab at the bottom of the page.

-Select desired UUT serial number ID from the drop

down box at the bottom of the page. If desired UUT

is not there, see section on creating a new UUT.

-View the PROFILE ID drop down box and confirm

that profile selected is the desired profile, if not,

select desired profile from drop down list.

-Select

-Tap

-Tap

-To stop a test in process, tap the

AS FOUND or AS LEFT radio button.

RE-ZERO and wait until completed.

DO TEST button

STOP button.

Unit Under Test

(UUT) Identity

Profile ID

Do Test

Record Data

Review Date

This will stop and cancel the test.

-Target pressure will be generated and data will be

Test

Screen

automatically recorded at each pressure point.

Note: If the

DISPLAY TEST RESULTS IN GRAPH OPTION is selected

– a graph will appear displaying pressure vs. error

after the pressure sequence has been completed.

-To record data – Tap

a text file (.txt) – Selecting

RECORD TEST RESULTS button – a dialog box will appear and ask if you wish to save as

YES will save data as an encrypted file and as a (.txt) file. Selecting NO will only

save it as an encrypted file. (Note: Text file is required to review data offline).

-To review data – tap

REVIEW TEST RESULTS button.

Stop

Re-Zero

As Found/As Left

Test Selection

Target Pressure

Diagram 8

Page 8

6.3 PROFILE – Screen instructions on Diagram 9.

-Program has capability of creating additional test profiles besides the default test profiles that come with it.

-If new profile setup is required tap the

-Select

-Select

NEW button and type new profile ID in box.

PROFILE to copy, (if desired) from drop down list.

-Once you’ve entered your new profile ID, select the

number of data points box and highlight the number

and change it.

-Go to

PROFILE TYPE drop down window and press down

arrow and select from the list of ascending, descending

or both – this is the direction of pressure application.

Note: when using

BOTH, the number of data points must be

PROFILE tab.

Profile ID

Number of

Test Points

Pressure

Point

Target

Pressure

Profile Type

Perform Leak

Test

Target

Output

odd, it can not be even.

-If leak test is required, check

-To save, press

SAVE button.

-To delete a profile, select

push DELETE button.

PERFORM LEAK TEST box.

PROFILE from list and

Diagram 9

6.4 UUT (UNIT UNDER TEST) SETUP – Screen instructions on Diagram 10.

UUT setup screen is used for inputting units into the UUT database.

The calibrator is supplied with many default instrument templates which may be copied, modified and saved

as new UUT.

-Select an existing profile – Go to the

UUT ID drop down box, click the down arrow and select your unit from

the list.

-Create a new profile – Tap

NEW button at bottom of page, a dialog box will appear prompting user to enter

new UUT ID#. Enter number in the box and select UUT to copy if desired from drop down list below. Press

OK to create new or CANCEL to cancel action. Note: If you don’t want to copy an existing UUT you may select

DEFAULT from the drop down menu.

-Enter the transducers lowest and highest pressure in the –FS and +FS boxes in the

-Enter the transducers lowest and highest output in the –FS and +FS boxes in the

-Select

DEFAULT TEST PROFILE (many defaults are already

INPUT column.

OUTPUT column.

listed) select which one you want or create a new one.

(Save UUT, go to

to UUT and select newly created profile for default

profile and press

-Enter the required pressure set time at target

(in milliseconds, 99,999 max. and 0 min. – 5,000

recommended). Pressure set time is time allowed

at pressure point before data is acquired.

-Enter

CONTROL STABILITY (in in ches of water column,

0.0003” min. and default). Required control stability

is the maximum allowable deviation from a pressure

point when data is to be acquired. Pop up box will

appear asking if you want to save. Press

-Enter maximum

PROFILE page and create NEW, return

SAVE).

YES.

LEAK RATE in box. This is PASS/FAIL

UUT ID

Box

Accuracy

Setting Time

For Data

Acquisition

Pressure Stability

Required for

Data Acquisition

Excitation

Level

New UUT

ID Setup

Profile Template

ID

UUT Input/Output

Specs (Ideal)

Max. Leak Rate

Allowable for

Pass/Fail

Delete UUT ID

Save New

UUT ID

criteria for leak check function, measured in change

of pressure second.

Save – Once all parameters have been changed,

tap the

Delete a UUT – Select UUT from list of available UUT ID’s at the top of the screen. Tap DELETE button at

-

SAVE button at the bottom.

Diagram 10

the bottom of the page.

-Select

EXCITATION LEVEL from drop down list.

-Select UUT TYPE from drop down list, (See 8.1 for UUT Type details).

Page 9

6.5 VIEW A REFERENCE SETUP – Screen instructions on Diagram 11.

-Tap the

REF tab to view the different reference data – Tap on REF 1 or REF 2 radio button.

-Reference Setup – The Model 869 is shipped with either one or two internal reference transducers that

are referred to as

If only one reference is installed, it will be located in

The box at the top called

REF 1 or REF 2 respectively. REF 1 is the lowest range and REF 2 is the highest range.

REF 1.

REF ID is the serial number of the

reference unit.

-Input/Output Parameters – This section tells you the

pressure range and the output of the reference transducer.

-Tare Button – Allows the user to “zero” the reference unit.

-Reference Locations – Shows the high and low ranges of

the reference unit, (the Model 869 automatically selects the

proper reference sensor according to the full scale range of

the UUT).

REF Input/

Output

Specs

Select Reference

Number

6.5 SYSTEM –

Screen instructions on Diagram 12.

-Software Version – Version of software on Pocket PC.

-Firmware Version – Version of firmware on calibration

microprocessor board.

-Serial Number – Serial number of device.

-Next Calibration Due Date – Calibration date set at

factory when calibrated.

-Current Date – System date/time display – This must

Be set through Pocket PC settings. Date should be set

accurately to notify operators of calibration due date.

-Filter Length – The number of samples taken when a

data point is collected during an automated test. It is

also the number of sample taken when

HOLD SAMPLE

Button is pressed on Real Time page. The software

will read these numbers of samples and return the

average as the data value.

-System Volume – This variable cannot be set by the

user. The value shown is retrieved through the

MEASURE VOLUME button.

-Excitation – This value is the current excitation being

provided to +EXC.

-Battery Level – This value is the current battery voltage

level and shows the adapter power level when 24V

adapter is connected,

Select Reference

Tab

Diagram 11

Software Version

Firmware Version

Serial Number

Filter Length

System Volume

Edit Defaults

Set Engineering

Units

Excitation

Battery Level

Diagram 12

Next

Calibration

Due Date

Current

Date

Measure

Volume

Leak Test

System

Page 10

-EDIT DEFAULTS button brings up default settings page. See diagram 13.

-DISPLAY TREND GRAPH ON UUT WARM-UP box will make a graph

appear when the test page is opened, or the UUT ID is

changed on test page. The graph will show UUT output

vs. time to allow the operator to see if the UUT has a warmup drift, and output has been stabilized. (This feature is not

likely to be required if the units to be tested are normally

connected to a power supply).

-DISPLAY TESTS RESULTS IN GRAPH will make a graph appear at the

Display Trend Graph on

UUT Warm-Up

Display Test Results

Excitation Setting

Warning

Miswire Warning

Manual Step Throug h Test

Add Extra Digit

end of the automated test. Graph will show the UUT output

error seen during test vs. applied pressure.

-TURN ON EXCITATION BOX WARNING SETTING will make a dialog box

appear on screen anytime the excitation is about to be changed

at a higher level. (This is used to help prevent damage to unit.

If all units to be tested can accept 24VDC excitation, feature

Diagram 13

will not likely be required).

-TURN ON MISWIRING WARNING will make a dialog box appear on screen if the UUT pressure range appears

to be set incorrectly.

-

EDIT DEFAULT UUT SETTINGS button will bring up a screen allowing the user to enter the default values for a

UUT profile. These values are entered into the data fields of the UUT when the

New button is pressed, and

The copy from file is set to default. See Diagram 14.

-Engineering Units - opens the Engineering Units Selection

page. See Diagram 15.

-Measure Volume – Initiates the System Volume Measurement

function. This function should only be performed in a closed-loop

system. Opens Pressure Selection page used to test system at

highest pressure possible without overpressurizing any devices

connected. See Diagram 16.

-Leak Test System – Initiates leak test (pressure decay test)

function. This function should only be performed in a closed-loop

system. The number returned is a rate of pressure decay.

-Change/Recover User Password – Allows operator to enter into

a screen that allows changes/recovery of user password. The user

password is required to change UUT default values.

Pressure

Selections

Diagram 15

Diagram 14

Maximum UUT

Pressure

Maximum Reference

Pressure

Diagram 16

Page 11

7.0 UNIT UNDER TEST SETUP

7.1 WIRING – ELECTRICAL See Diagram 17.

-Attach the unit in a secure location. Two (2) 8-32 threaded inserts are provided in the area above the User

Interface Panel to install the UUT. A custom bracket may be created to mount to these inserts for testing the

UUT in a desired location.

-Hook up the pneumatic lines – attaching the

high port

on the UUT and the low port

(HI) on the calibrator to the high port

(LO) on the

calibrator to the low port on the UUT.

-Hook up electrical – See Diagram 18.

UUT UUT UUT UUT

Unit Under

Test

(Model 260)

Electrical Lines

Pneumatic Lines

Diagram 17

+ -

EXC

24VDC

SIG

(+)

869

Current Internal

Source (CSOU)

COM

SIG

(-)

External

Power

Supply

+ -

+

-

EXC

24VDC

SIG

(+)

Current External

Source (CSIM)

COM

SIG

(-)

EXC COM SIG EXC COM +SIG -SIG

EXC

24VDC

SIG

(+)

COM

SIG

(-)

EXC

24VDC

SIG

(+)

869869869

Diagram 18

COM

SIG

8.0 CALIBRATING AND TESTING TRANSDUCER/TRANSMITTER

MANUAL CALIBRATION:

-Setup unit to perform and select

-Select

-Press the

REAL TIME tab

-FS button (will be updated in the target pressure window) it will generate the lowest pressure

of the UUT range, wait until pressure is achieved.

-At this point, you may adjust the zero adjustment on the UUT until the output is within desired tolerance.

-Once zero is adjusted, press the

is achieved. You may adjust the span potentiometer until within desired specification.

-Unit should be calibrated at this point. To verify, select

AUTOMATED TEST:

-Select

-Select

TEST tab

UUT from list, (if not available, follow instructions for creating new).

-If test profile is not desired, select

-Press

DO TEST button and wait for completion.

UUT tab. Select UUT ID from list and verify.

+FS button (target pressure will again update in window) wait until pressure

TEST tab.

NEW from list.

(-)

Page 12

9.0 POCKET PC TO PC USER INTERFACE

The Pocket PC provides a central location for all data

within a given facility, database management and easy

data entry and manipulation.

9.1 SETUP FOR POCKET PC CONNECTION

-Install Microsoft ActiveSync. (Please follow ActiveSync

setup instructions.)

-Connect Pocket PC using USB cable, or other preferred

method. IE Bluetooth, IRD, etc.

-Select

-Verify device is connected on Microsoft ActiveSync.

CONNECTED should now appear in ActiveSync wi ndow.

-Run Pocket PC to PC interface software.

GUEST partnership

-Press CONNECT button – See Diagram 20.

-Screen will update with data from both PC and

Pocket PC.

Diagram 19

9.2 GRAPHICAL USER INTERFACE SETUP

The interface is divided into sections corresponding

to the pages on the Pocket PC software.

DATA SETS

UUT (Unit Under Test) Profiles. These define a

transducer so the 869 knows what it’s working with.

See Diagram 21 – Portion outlined in red.

Test Profiles - Determines how a test is performed.

See Diagram 21 – Portion outlined in blue.

Test Results - Actual data files created when a test

is recorded on the Pocket PC. See Diagram 21 –

Portion outlined in green.

Diagram 20

Diagram 21

COMMON FUNCTIONS FOR UUT AND

TEST PROFILES - See Diagram 22

Upload Data - This function is performed during the

connect process performed when

pressed.

-To update with any changes made on the

Pocket PC while connected, press

button.

CONNECT button is

UPLOAD DATA

Diagram 22

Page 13

Download Data - This function is used to download

changes to the DB made with the software.

This process is not performed automatically!

See Diagram 23.

Profile selection - With each profile set, there are

two list windows for existing profiles. One is labeled

PC Database, the other Pocket PC Database.

See Diagram 24.

Diagram 23

Diagram 24

After upload, the Pocket PC database list will show

what is currently on the Pocket PC. Once changes

are made, the list will show what the Pocket PC

database will contain once the download button is

pressed. See Diagram 25.

-To select a profile, simply click on the ID in the list.

-Only one profile can be selected at a time for each type of profile.

IE Only one UUT profile can be selected at a time from both PC and Pocket PC database lists.

Profile quick display - Below the database lists

is a window, which will display the properties of the

selected profile. Once a profile is selected, form

either database, it is loaded from its database, and

the data is then displayed in this window.

See Diagram 26.

Diagram 25

Diagram 26

Page 14

Transfer buttons (Æ & Å) - These buttons will copy a selected profile from the database it currently exists

within, to the other remaining database. IE If a profile is selected in the PC database, and

TRANSFERÆ button

is pressed, the profile will now be copied to the Pocket PC database.

-When transferring profiles, if a profile of the same ID exists in the Copy To database, the profile will be

overwritten on the Copy To database. See Diagram 27.

Diagram 27

Edit button - This button opens a dialog box containing the information for the selected profile. At this point,

the data may be manipulated and saved. ID cannot be changed with this function. To change ID, copy the

profile (see

NEW BUTTON section below), giving it a new ID, then delete the old version. See Diagram 28.

New button - This button opens a dialog box to

create a new unique profile. Profile ID must be

entered Into the ID box on the dialog.

-To copy a profile, simply highlight the desired

profile within the list window, and then press

NEW.

The data from the selected profile will appear in

the edit window.

-The new profile will be copied to the database

from which the profile to be copied was selected.

See Diagram 29.

Diagram 28

Diagram 29

Page 15

Delete button - This button will delete a profile

from the database it exists within. Data cannot be

recovered, so a verification dialog box will pop up

asking operator to verify that delete is really desired.

See Diagram 30.

Diagram 30

9.3 TEST RESULTS DATA

-At bottom of screen, there is a list box showing all

the test results data files stored in memory.

-On connect, all the data files from the Pocket PC

are copied to the main PC database. If a file already

exists with the same name, the file will not be copied.

-If a new data file is created while connected, the new

files can be uploaded by pressing the

RESULTS

button. This will repeat the file upload

procedure performed on connect. See Diagram 31.

REFRESH TEST

Diagram 31

Diagram 32

Once a UUT ID is selected, the test results list

will update to display only the test results from

that UUT. See Diagram 33.

-To review a particular test – See Diagram 32.

-Select the ID of the Unit Under Test from the dropdown list above the test results list. (Just below

REFRESH TEST RESULTS button.)

-Press dropdown arrow at the right of the ID box.

-Click on ID in box.

The test results for each UUT can be

distinguished using date/time of test and As

Left/As Found status.

Diagram 33

Page 16

To print As Left or As Found data only.

-Select any profile desired from the list of test

results.

-Press

PRINT button.

See Diagram 34

Diagram 34

This will bring up a printer selection dialog.

Select printer from here and press

PRINT button.

See Diagram 35.

Diagram 35

To print an As Left/As Found pair, the test results must be selected manually.

-Select As Found file, then holding

-Press

PRINT button.

See Diagram 36.

Before data can be sent to the printer, the 2

selected files must be verified as a valid pair.

Data is validated as follows:

-Only two files being requested for print

operation.

-Only one As Found and one As Left file.

-As Left data file’s date/time stamp comes

after As Found date/time stamp.

-UUT Profiles for each test results data file

match.

-Test Profiles for each test results data file

match.

-As Left data file date/time stamp is within 24

hours after As Found data file date/time stamp.

CTRL key, select As Left file.

Diagram 36

Page 17

10.0 GLOSSY OF TERMS

Atmospheric Pressure – Pressure of the

atmosphere at the earth’s surface. NIST

standard atmospheric pressure = 1.01325 bar.

P/I – Term common to process industries

meaning pressure-in/current-out. (3-15 PSIG

Input to 4-20 mA DC Output).

Bar – Unit of pressure (or stress). 1 bar =

750.07 mm of mercury at 0°C, lat. 45°.

Burst Pressure – The maximum pressure that

may be applied to the positive pressure port

without rupturing the sensing element.

Capacitive Sensing – Detection and measurement of pressure through the change in voltage

across a capacitor, one plate of which is a

diaphragm which deflects slightly with changes

in applied pressure.

Differential Pressure – Pressure measurement

relative to a reference pressure. Referred to as

pounds per square inch differential (PSID).

FS (Full Span or Full Scale) – The range of

measured values over which a transducer is

intended to measure, specified by the upper

and lower limits. Ex: 0 to 100 PSIG, FS is 100

PSIG/0 to 5 VDC, FS is 5 VDC, 800-1100 MB,

FS is 300 MB.

Pressure Transducer – An electromechanical

device for translating fluid pressure valves into

voltages across a high-impedance (5k ohms or

greater) load.

Pressure Transmitter – An electromechanical

device for translating fluid pressure values into

Currents (generally 4-20 mA) into a low-impedance

load.

Proof Pressure – The maximum pressure that

may be applied without changing performance

beyond specifications (typically 0.5% FS zero shift).

Range – The spread between the maximum and

minimum pressures between which the transducer

has been designed to operate.

Span – The algebraic difference between the limits

of the range. Ex: .1 to 5.1 Volts DC; span is 5 VDC.

Sometimes used to designate full scale output;

i.e. 5 VDC.

SPECIFICATION DERIVATIONS

Accuracy Non-Linearity

Relationship of a calibration curve to a specified

straight line.

Expressed in %FS at constant temperature.

Best Fit

Accuracy as RSS non-linearity, hysteresis and

non-repeatability.

Root Sum Squares (RSS)

Non-linearity: (±0.1%)

Hysteresis: (±0.05%)

2

2

Non-Repeatability: (±0.05%)

= 0.01%

= 0.0025%

2

= 0.0004%

0.0129%

√0.0129% = ±0.11% FS at constant temperature

*Charts do not reflect calibrator measurements.

Straight Line

(BFSL)

Method

Example: ±0.1% FS

Relationship of a calibration curve to a specified

straight line with end points at zero and full scale.

Terminal

Method

Example: ±0.12%

FS

5.1 VDC

S

F

%

1

.

0

+

0.1 VDC

0 PSI 100 PSI

1

0

.

0

-

RS232 OUTPUT

0 PSI 100 PSI

F

%

2

1

0

.

0

+

S

F

%

1

.

0

-

%

2

Page 18

Hysteresis Non-Repeatability

The maximum difference in output at any

pressure value within the specified range, when

the value is approached with increasing and

decreasing pressure.

5 VDC

>

>

<0.05%FS

0 VDC

0 PSI 100 PSI

The ability of a transducer to reproduce output

readings when the same pressure value is

applied to it consecutively, under the same

conditions, and from the same direction.

5 VDC

0 VDC

Long-Term Stability Zero Offset

The ability of a transducer to reproduce output

readings obtained during its original calibration

at room conditions for a specified period of time.

5 VDC

Example: ±0.1% FS

Over 6 Months at

70°F (21°C)

0 VDC

0 PSI 100 PSI

S

F

%

1

.

0

+

S

F

%

1

.

0

-

Original Calibration

After 6 Months

Zero output is factory-set to within a certain %

of full scale. Results

in a shift up or down

of the calibration

curve. Does

not affect

linearity or

accuracy.

.2% FS

(10 mv)

>

>

<0.02%FS

0 PSI 100 PSI

Zero shift +0.2%FS

No span shift

Linearity still ±0.1% FS

1

0

.

0

%

1

0

.

0

+

%

1

0

.

0

+

0 PSI 100 PSI

-

No zero or span shift

Linearity ±0.1% FS

%

%

1

0

.

0

-

Span Offset Total Error Band

Span output is factory-set to within a certain % of

full scale. Results in a change in the slope of the

curve. Does not

affect linearity

or accuracy.

1

.

0

+

0

S

F

%

S

F

%

1

.

0

+

Span shift +0.2%FS

Linearity still ±0.1%FS

S

F

%

1

.

0

-

No span shift

Linearity ±0.1% FS

0.2%%FS

(10 mv)

S

F

%

1

.

0

-

(Worst case) over a temperature range of

-10°F to +130°F

Non Linearity: ±0.1% FS

Hysteresis: ±0.05% FS

Non-Repeatability: ±0.02% FS

Thermal Zero Shift: < ±0.32% FS

Thermal Span Shift: < ±0.24% FS

Zero Offset: ±0.2% FS

Span Offset: ±0.2% FS

Thermal Effects

The change in the zero and span output that

occurs due to temperature changes.

Thermal Zero Shift: < ±0.4% FS/100°F

Thermal Span Shift: < ±0.3% FS/100°F

Example: Temp. Range -10°F to +130°F

Max. Temp. Change from 70°F = 80°F

80°F x .4% = .32% FS DZ/DT, 80°F x .3% = .24% FS DZ/DT

Z Shift = <±0.32% FS, S Shift = <±0.24% FS

Microsoft® and ActiveSync® are registered trademarks of the Microsoft Corporation.

Long-term stability error not included.

159 Swanson Road, Boxborough, MA 01719-1304

±1.13% FS

Tel: 800-257-3872/978-263-1400

SS869 2/24/06 Rev. 6

Loading...

Loading...