Page 1

Page 2

Accuracy

● Highest accuracy to support certification of all low DP critical process pressure sensors

● True low range dual reference pressure sensors with NIST traceability

● Dual reference design provides maximum accuracy, repeatability and resolution

Pressure Generation

■ User selectable automated pressure generation profiles with up to 101 calibration points

■ NASA patented low pressure generating technology achieves ±0.0002 in. W.C. low

pressure regulation - micro in. of W.C. per step resolution

■ True differential pressure generation - both high and low pressure ports connect to the

unit under test, providing isolation from process background disturbances

■ True zero pressure generation - high and low pressure ports shorted to produce stable,

noise-free zero pressure input - outperforms competitive active zero pressure systems

e

REVOLUTIONARY PERFORMANCE

Calibration Capabilities

■ Analog Pressure Transducers

■ Pressure Switches

■ Analog Dial Gauges

■ Setra Digital Auto-Cal™ Products 269 & RPM

Measurement

Accuracy.................................... .................... ±0.04% FS

Precision..................................................... 0.000 2” W.C.

Calibration Stability (Pressure Span)....................0.2% Rdg./yr

Calibra tion Stability (mA and Voltage)..............0.01% FS/yr

Cali b r a t ion A djustme n t . ........ . . . ....... . . . ........ . . ze ro ta r e

Compens ated Temperature Range ........ ...... 40oF to 120oF

Storage Temperature Range....................... 40oF to 16 0oF

Temper a t u r e Effect ( Zero)..... . . . . ........ none, zero t are

Temp e rature Eff e ct ( S pan).. . ...... . ...... . ...... . .... 0. 0 1%/oF

Certif i c a t i o n. .. .. .. .. .. . N I ST tracea b l e certif i c a t i o n for

r e f e re n ce p r e s su r e se n s o rs a nd v ol t ag e / c ur r en t

meters

Control

Controlled Pressure Stability................. 0.0002” W.C., typical

Minimum Controlled Pressure..................... 0.00005” W.C.

Dual Reference Pressure Ranges................ see order info.

Pres s u re Typ e s . ........ . . ........ . . . .. gauge a n d diff e r e ntial

Overpressure Limit............ ..... ....................... ..... ... 5 psid

Control Time.............................................. user selectable

General Specifications

Pressure Units (Selectable)........... in. W.C., Pa, kPa, mbar, cm W.C.

Warmup............................................................................. 1 Hour

Reading Rate......................................20 readings/second, typical

Gravity/Orientation......................................................... negligible

Shock and Vibration..................................................5g, maximum

Communications............................................................... RS 232

Display............. 3.5” transflective type TFT color, QVGA, 64-k color

Keypad......................................................... pocket PC touch pad

Size........................ 11” x 14” x 6” (27.9 cm x 35.6cm x 15.2 cm)

Weight.................................................................... 16 lbs. (8.2kg)

Pressure Media............................. clean, dry. non-corrosive gases

Power..... 120/240 AC, 50/60Hz, battery Li Ion - 8 hours operation,

integrated charger

Pressure Transducer Interface

Pressure Fittings....... barbed, plug-in o-ring quick connects

Electrical ................................................ banana plug jacks

Voltage Meter ......................... ±0.005% FSO at ±10.5 VDC

Current Meter ............................. ±0.005% FSO at 4-20mA

Excitation ........................ 24 VDC nominal for 4-20 mA output,

adjustable 5 to 24 VDC for voltage output

Page 3

Key Features

SIMPLE STEP-BY-STEP INTERFACE

• Easy step-by-step user interface process

• Designed with built-in leak test function

• Provides accuracy and stability plots

Simple Pocket PC

User Interface

Step 1

UUT (Unit Under Test) Setup

- Select transducer profi le

- Select accuracy specifi cation

- Select output (VDC or mA)

Step 2

Real Time

- View current pressure and out put for testing and calibration

- Apply selected pressure to per form adjustment (zero, span or

linearity)

• Handles multiple engineering units

• Both pressure generation and monitoring

modes to verify system performance

Calibration management database

• Store and retrieve transducer profi les

• Generate as found and as left calibration data

• Print calibration certifi cates

Step 3

Test Unit

- Return to screen to perform

calibration test sequence

- Review and record results

- Copy and save data into

your calibration database

Portability & Versatility

■ AC or battery operation - eight hours of operation on full battery

■ Rugged, compact carrying case - great for cramped and

remote locations

■ Calibrate diffi cult-to-reach devices in-situ (ceilings,

ducts, etc.) with electro-pneumatic harness

assembly - for analog tranducers, 2, 3 and 4-wire,

confi gurable length

Page 4

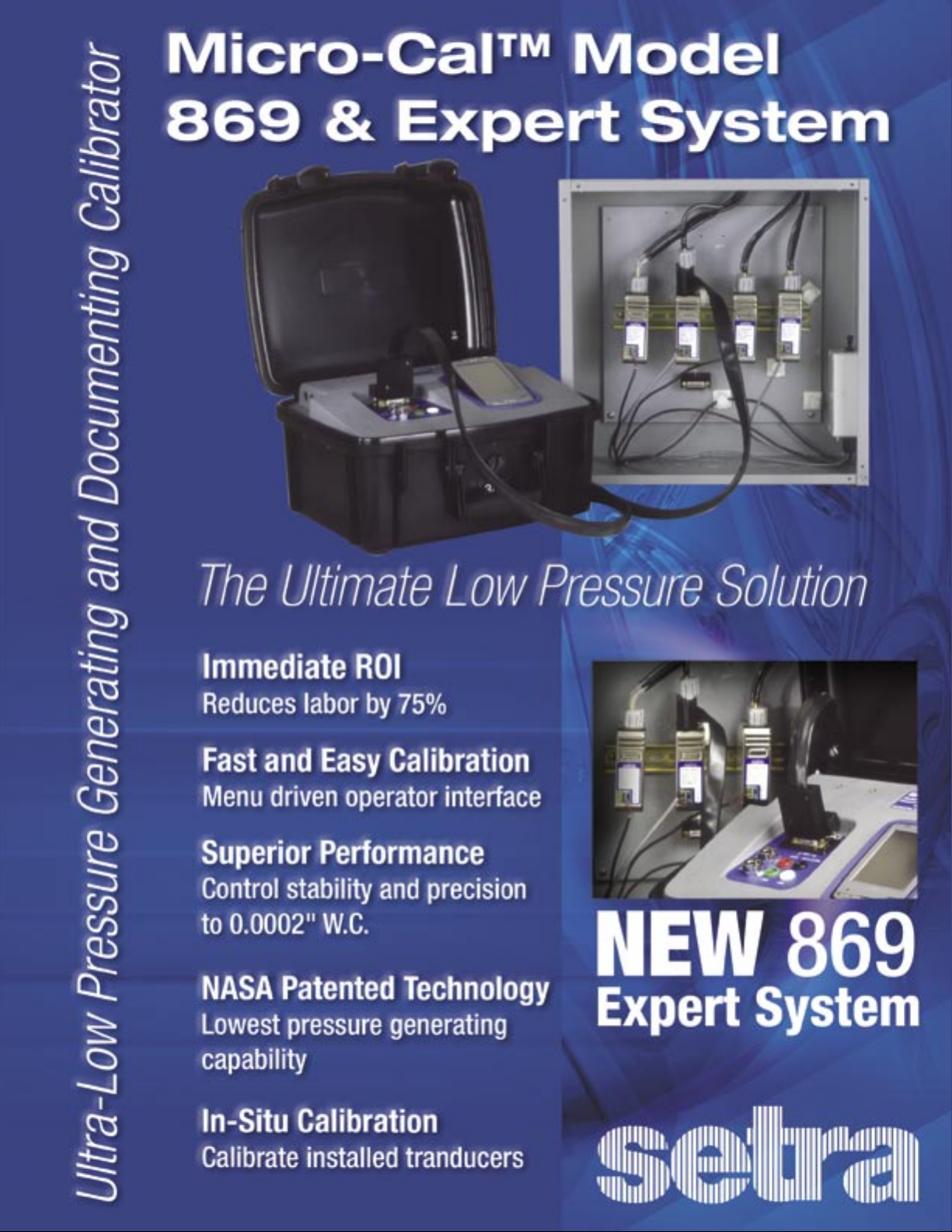

869 Expert System

For even greater savings and security, upgrade to

the 869 ‘Expert’ Automatic Calibration System*

Features

Fully Automated, Hands-Off Calibration reduces

●

calibration times by 2/3 or more. No tube cutting or wire

removal is required.

●

Easy-to-Use, Smart Communication Software pro-

vides transducer detection and automated calibration with

Setra’s digital transducers and room pressure monitors.

●

Electropneumatic Interface Cable (EPIC) allows the

869 to simultaneously pressurize a 269 or SRPM under test

and automatically transmit ID and calibration data between

the two units.

●

Two EPIC Cable Lengths Offered: 6ft (standard) & 12ft

(optional), providing easy access to units located in remote,

difficult to access areas.

Expert System: EPIC, SRPM, 269 & 869

Calibration Time

Time Needed (in minutes)

5 10 15 20 25 30 35 40 45 50

869 E.S.

w/ 269

●

Easily Upgrade Original 869 - simply send in your unit

and it will be returned with the installed Expert System.

This is especially convenient if performed when your 869 is in

the factory for it’s annual recertification.

869 w/ analog

transducer

Competitive calibrator

w/ analog transducer

Smart, Secure, Cost Effective Calibration

* Expert System can only be used with Setra 269 and SRPM products.

Ordering Information

Code all blocks in table

Example: Part No. 86910R5WD015WDPN for a 869 Calibrator, 0 to 0.5 in. WC (Range One) to 0 to 15 in. WC (Range Two), PDA Included,

with a Standard Pharmaceutical User Interface.

8 6 9 1

Model

8691 = 869

Range - One

Inches W.C. Pascal

0R5WD = 0 to 0.5 in. WC 050LB = ±50 Pa

001WD = 0 to 1 in. WC 100LD = 0 to 100 Pa

005WD = 0 to 5 in. WC 100LB = ±100 Pa

2R5WD = 0 to 2.5 in. WC 250LD = 0 to 250 Pa

015WD = 0 to 15 in. WC 250LB = ±250 Pa

R25WB = ±0.25 in. WC 500LD = 0 to 500 Pa

0R5WB = ±0.5 in. WC 500LB = ±500 Pa

001WB = ±1 in. WC 10CLD = 0 to 1000 Pa

2R5WB = ±2.5 in. WC 10CLB = ±1000 Pa

005WB = ±5 in. WC 35CLD = 0 to 3500 Pa

015WB = ±15 in. WC 35CLB = ±3500 Pa

Range - Two

PDA

P = Includes PDA

For calibrating hard-to-reach

analog transducers, a 2-wire

and 4-wire configurable length,

electropneumatic assembly is

available from 6 to 15 feet.

User Interface

N = Standard User Interface

E = Expert System

SSP869 Rev. B 12/07

While we provide application assistance on all Setra products, both

personally and through our literature, it is the customer’s responsibility

to determine the suitability of the product in the application.

159 Swanson Road, Boxborough, Massachusetts 01719/Tel: 800-257-3872;

Fax: 978-264-0292; Email: sales@setra.com; Web: www.setra.com

Loading...

Loading...