Page 1

TM

Quickstart Guide

1.Intended Use

Thank you for purchasing the Setra FLEX, the industry’s most advanced and flexible room environmental monitor.

Setra FLEX is designed for indoor use only to monitor critical environments by providing differential pressure indication and additional

parameters such as temperature, relative humidity, air changes per hour, and user-dened information. Typically this is between a monitored

room and a reference space such as a corridor or ante room. The unit also provides monitoring, control, alarm, and communications

functions.

Typical Applications:

1. Hospitals – patient isolation and protection rooms, operating suites, intensive care and emergency rooms.

2. Pharmaceutical, semiconductor, precision manufacturing and clean rooms

3. Laboratories – medical research, BSL (bio safety labs), radiation, vivarium, toxic metals and chemicals.

Included in the box

a) FLEX unit

b) FLEX unit mounting screws

c) Tubing

d) Room pressure snubber (RPS, if ordered)

and mounting screws

e) Electrical connector kit

a

d

Quantity of box contents may vary.

b

e

c

(photos not to scale)

Parts required and to be supplied by installer

To mount and install properly, the following components are required.

NOT INCLUDED and required for each FLEX unit:

• Triple Gang Double Deep Metal Electrical Box, RACO 697 or Appleton M3-350 or equivalent: 1

(a single-deep box may be used if no on-board pressure sensor was ordered)

• Green grounding screw: 1

• Power and signal wiring, as needed

• ¼” pressure tubing to run from the room(s) to the FLEX unit

• Transformer, 24 VAC

• Door Switch SPDT or SPST, N.O., as needed

• Remote Pressure Transducers, as needed

• Remote Annunciators, as needed

Setra Systems, Inc.

159 Swanson Road, Boxborough, MA 01719

800.257.3872 • www.setra.com

Page 2

B+

GND

+24V

L1

L2

+24V

AI

VDC

COM

SERIAL

(PROPRIETARY)

+24V

UI1

COM

+24V

UI2

COM

UI3

COM

B

A

Z

Y

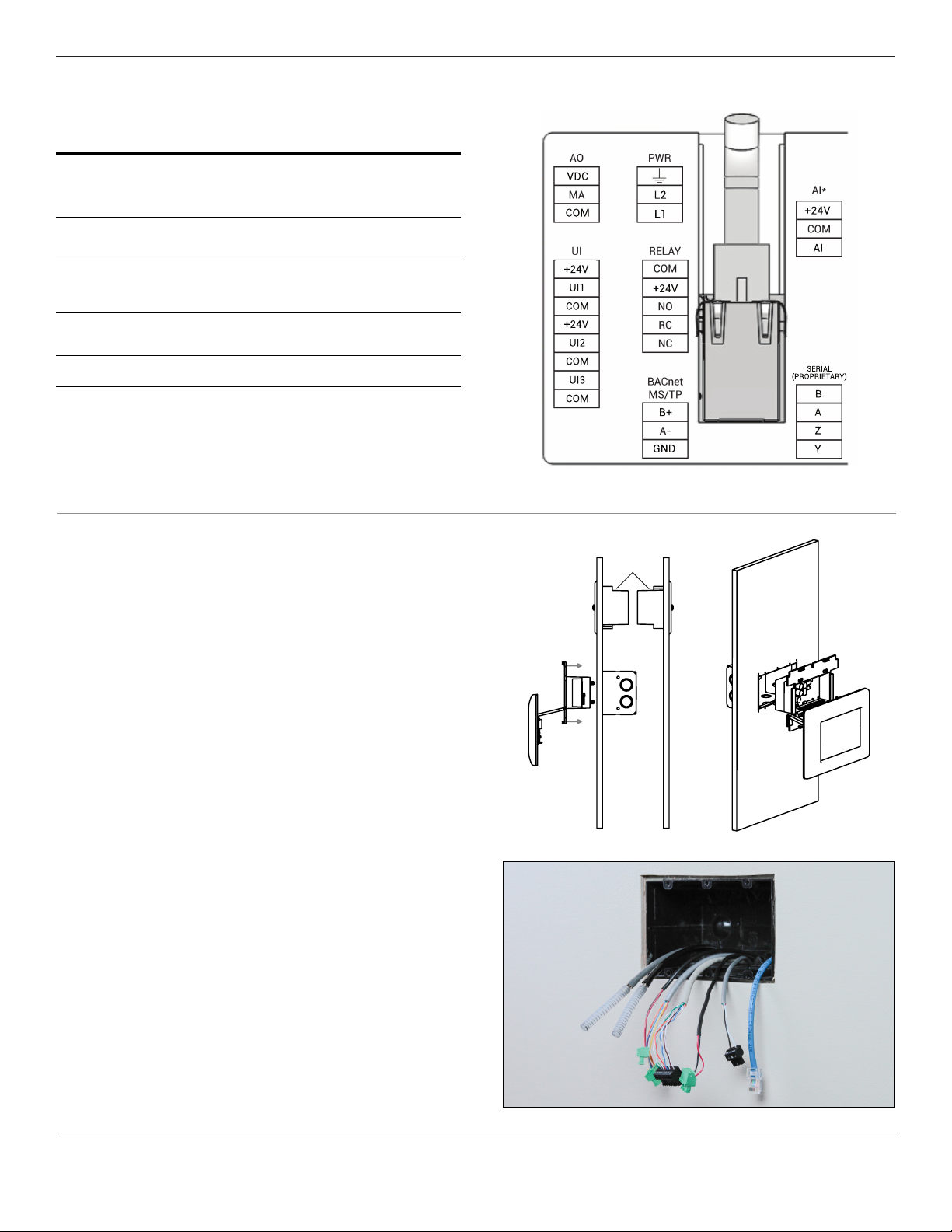

2. Wiring

Inputs & Outputs

Universal inputs (3)

Analog input (1)

Analog output (1)

Relay output (1)

Wire

0-5 VDC, 0-10 VDC, or 4-20 mA input signal*

Congurable for either Analog or Digital signals. Use

external sensors for pressure, temperature, humidity, or

any suitable application. Use as digital input for door, HVAC

Dedicated for use as input for either on-board pressure

0-5 VDC, 0-10 VDC, or 4-20 mA output signal. Use as PI

control loop to modulate reheat valves or other analog

driven devices, pressure output signal, or mirror an input

annunciator or other NO/NC applications. Contact rating

Stranded shielded twisted pair, 16-24 AWG .14-1.5 mm2

lter DP, or duct static DP pressure switch.

transducer, or general AI input. Used only when no

signal. Can be assigned to any room parameter.

24 VDC SPDT NO/NC Relay. Use as remote alarm

transducer is purchased on unit.

2.0A @ 30 VDC

cross sectional area

Expansion I/O module

*Installer provided 250Ω resistor required for 4-20mA signal

8 Universal Inputs, 4 Analog Outputs, 4 Relay Outputs

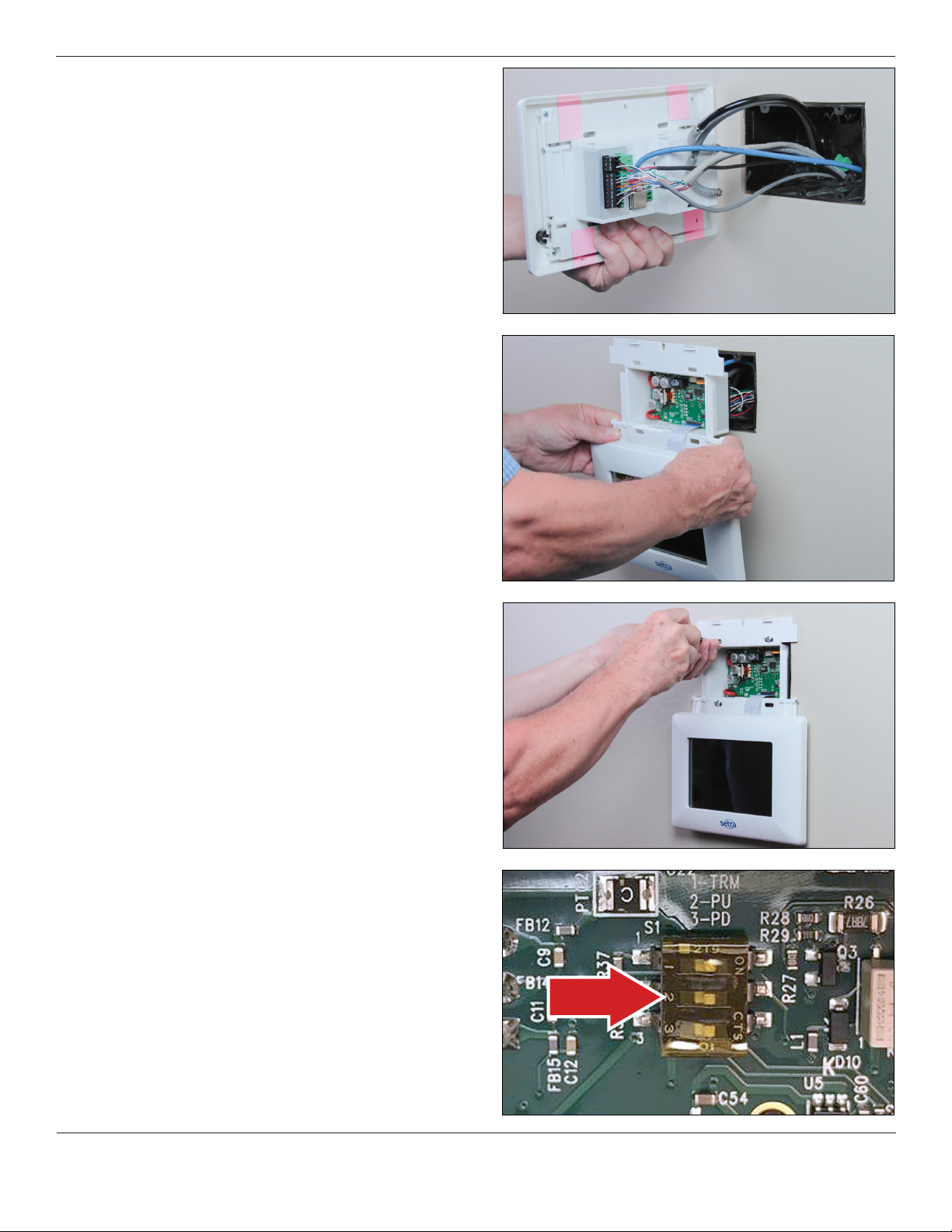

3. Rough-In

• Ensure rough-in box is ready to receive the RPS

a) Setra RPS Reference Pressure Side

b) 1-Gang Electric Box

c) Setra RPS Room Pressure Side

d) Setra FLEX Unit (Display hinges down during installation then

snaps in place when mounting is complete)

e) Setra FLEX Unit (may be mounted inside or outside room)

f) Wall cavity

g) Electrical Box (3-Gang double-deep if using on-board sensor,

single deep if no on-board sensor)

• Ensure rough-in box is ready to receive the FLEX unit

b

a

e

c

g

d

f

Phone: (800) 257-3872 | Fax: (978) 264-0292 | www.setra.com

Page 3

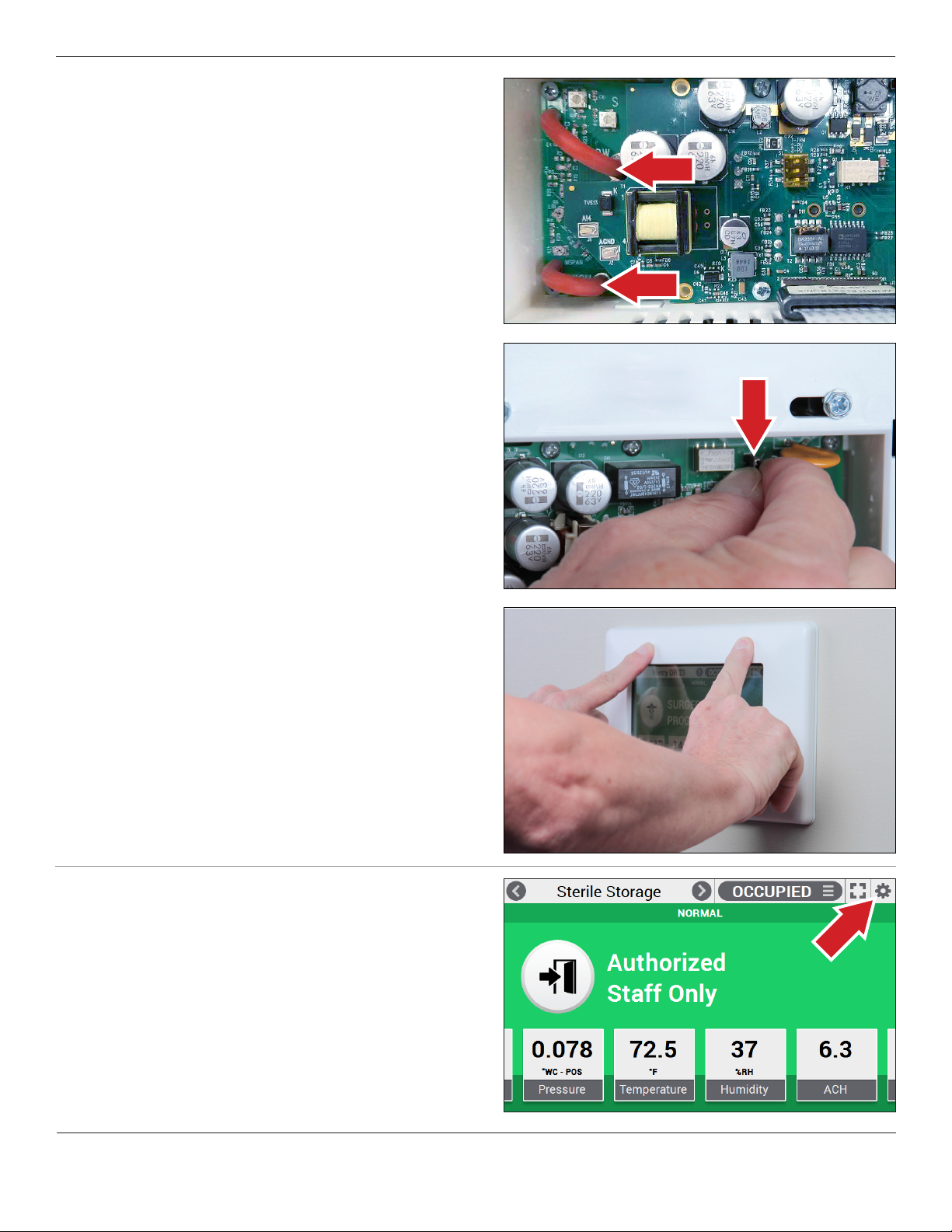

4. Installation

• Make the nal connections by pushing the removable

connectors and wires into the back of the FLEX unit. If

connecting BACnet/IP, insert the RJ-45 cable into the Ethernet

port. If connecting pressure tubing, align HIGH and LOW ports

to their appropriate pressure sensor connections with anti-

kink tubing and secure in place.

• Slide the FLEX unit back into the wall, taking care to not crimp

tubing or damage wires.

• Secure the FLEX base unit into the electrical box with the four

(4) mounting screws provided. Allow the FLEX display to hang

below the mounting box, taking care so that the display does

not get damaged by tools.

• BACnet MS/TP hardware is implemented as isolated RS485.

Wire to Connector COMM, labeled BACNET. Connect TX line

to B (+), RX to A (-) and ground wires to GND. Connect shields

together with wire nut. Hardware conguration is done using a

three position dip switch located in the upper center section of

the rear PCB. Use a small flat blade screwdriver or pen to push

the switch to the right to turn the function on, or to the left to

turn the function off. If the unit will be at the end of the line,

the terminating resistor can be enabled by pushing position

1 to on.

© Setra Systems, Inc. All Rights Reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc.

Page 4

• With the FLEX display hanging open and unit powered, re-zero

the sensor to ensure accurate operation:

1. Remove one end of each pressure tube (shown here)

2. Access “Settings” > “Maintenance” > “Pressure Calibration”

3. With tubes disconnected, press “Adjust Zero”

4. Reconnect tubes

• The unit is now ready for nal mounting

• If live power is already turning on FLEX, power can be cycled on

FLEX by removing the J6 jumper on the unit. This can be done

by hand, or carefully with non-conductive pliers. Normally,

FLEX is continuously powered and this jumper does not need

to be accessed.

• Swivel up the FLEX display, and push rmly at the frame just

above and just below the touch screen. The display will snap

into place and seal against the wall surface.

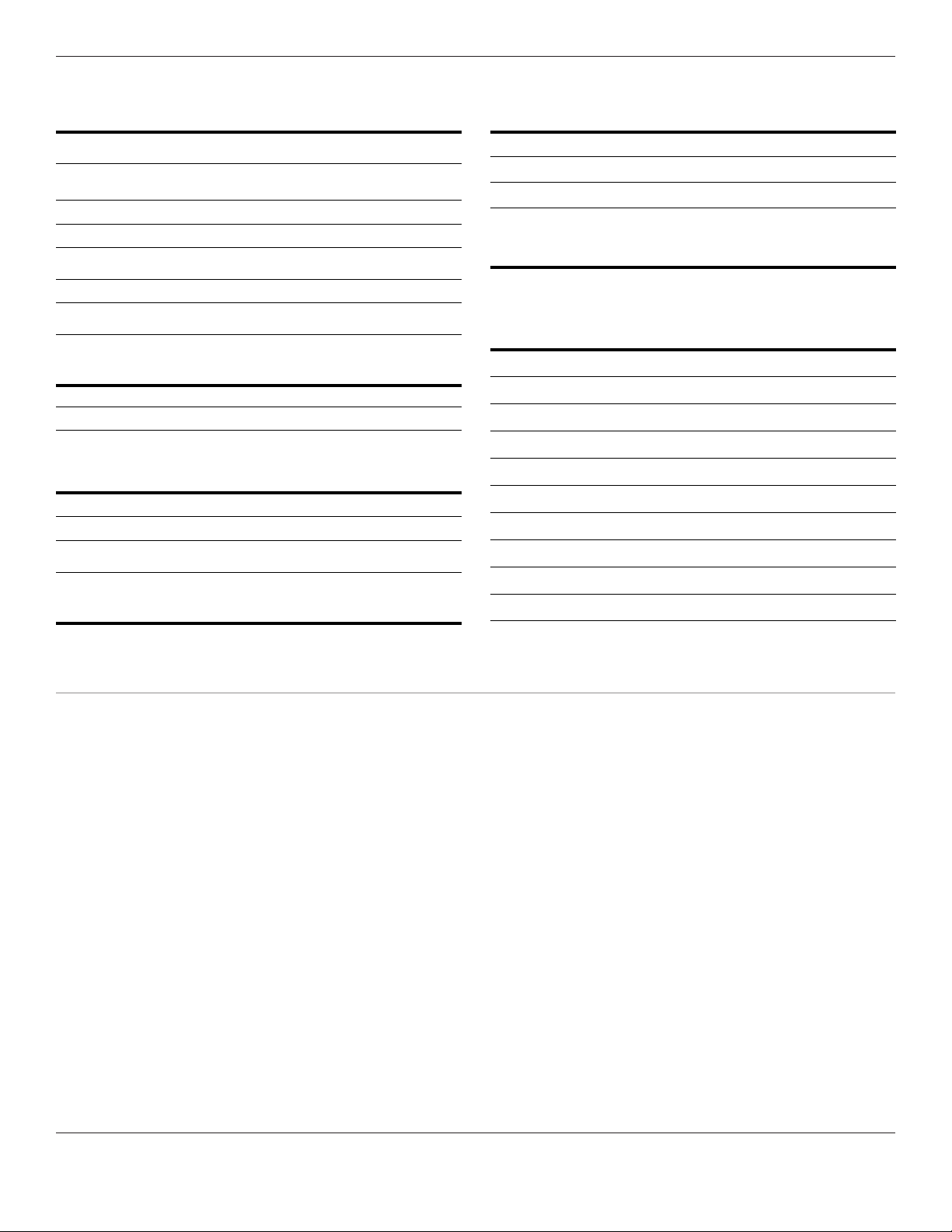

5. Power Up Conguration

• Access the “cog wheel” on the top-right of the FLEX display to

congure the unit.

Phone: (800) 257-3872 | Fax: (978) 264-0292 | www.setra.com

Page 5

• Use “Device Conguration” for initial setup.

• The next seven menus (three tiles over four) permit complete

conguration of your FLEX unit. Detailed instructions for each

menu can be found in the FLEX Installation & Operations Guide.

6. FLEX Home Screen

Room name

(Up to 3 congured))

Two lines of text

provide notices to

staff, or none

Select from 32 icons

to represent room

use or none

Badges show room

parameters, values,

units, and state

Room navigation,

to view home screen of

rooms 2 and 3

Full screen mode

Pull-down room

proles, user-dened,

to set new monitor

and control setpoints

in effect

Set up unit

Banner indicates room

condition: NORMAL,

WARNING, ALARM,

or STANDBY

Two icons enable alarm

silencing. latch alarm

reset, or door indicator

Badges 5 and 6

(if congured) appear

off-screen and can be

accessed by swiping

left of right

© Setra Systems, Inc. All Rights Reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc.

Page 6

7. Specications

Physical Description

Dimensions

Mounting

Case

Weight

Display

Display brightness

USB port

Audible alarm

(215.0mm x 160.0mm x 16.51mm)

Triple-gang, double deep electrical box. RACO 697,

7” Projected Capacitive (PCAP) multitouch. 800 x 480

Micro-USB port for conguration cloning between units

Dual piezo with 3 volume levels (0-75 dB max.)

pixels. Usable with medical gloves.

9.25” W x 6.3” H x 0.65”D

Appleton M3-350, or equivalent

Fire-retardant plastic UL94 V-0

and software upgrades.

Communications

Protocols (BACnet objects can be found at setra.com) BTL- Compliant

BACnet/IP using IPv4, Ethernet CAT5 cables with RJ45

BACnet MS/TP up to 76.8 kbps, 3-conductor, twisted,

shielded 16-24 AWG cable

Electrical

Power

Power draw

Wire

Connections

24 VAC (18-30 VAC operational), 50-60 HZ

13 W max, 10 W typical

2 or 3-conductor (depending on application)

stranded unshielded twisted pair, 16-24 AWG

Removable Terminal Blocks

Regulatory Compliance

CSA, CE, RoHS, WEEE

Specications subject to change without notice.

2 lbs

1-7

Environmental Data

Operating temp. °F (°C)

Storage temp. °F (°C)

Operating humidity

Ingress Protection (IP) rating

5 to 95% RH (non-condensing)

32 to 120 (0 to 50)

-40 to 185 (-40 to 85)

IP54

Chemical Resistance

Exposed surfaces are chemically resistant to vaporized hydrogen peroxide (VHP),

formaldehyde, chlorine dioxide (clidox), perchloric acid, sodium hypochlorite 3-6%

(bleach), quaternary ammonium 7% in 1:128 tap water (ammonia).

Performance

Accuracy RSS

Non-linearity (BFSL)

Hysteresis

Non-repeatability

Span setting tol.

Zero/span shift % FS

Overpressure

Pressure media

Pressure ttings

Altitude

Position

± 0.03% PSI (±0.05% FS)

±1 PSI (15” WC for ≤0.10” WC FS)

Air or non-conductive, non-explosive gases

3/16” barbed ttings

6562 ft. (2000 m) max.

Housing to be 90° in reference to level surface, ±5°

±0.25%

±0.24%

±0.05%

±0.05%

±0.5% Rdg

8. Maintenance

• The FLEX is designed to operate in an indoor environment, monitoring clean, dry air.

• Upon nal installation of the FLEX Environmental Monitor, no routine maintenance is required. An annual check of system calibration is

recommended. FLEX is not eld serviceable and should be returned if repair is needed (eld repair should not be attempted and may void

warranty). Be sure to include a brief description of the problem plus any relevant application notes. Contact customer service to receive

a return goods authorization number before shipping.

• WARNING: Do not blow into the pressure tubing or ttings with mouth, compressed air, or canned air. Such actions may permanently

damage the pressure sensor. Do not clean or wash-down FLEX with industrial cleaners or solvents other than those approved in

specications. Do not immerse unit.

Phone: (800) 257-3872 | Fax: (978) 264-0292 | www.setra.com

Page 7

9. Returns

When returning a product to Setra Systems, the material should be carefully packaged and shipped prepaid to:

Setra Systems, Inc.

159 Swanson Road

Boxborough, MA 01719-1304

Attn.: Repair Department

To assure prompt handling, please refer to return instructions at the following URL:

http://www.setra.com/tra/repairs/cal_rep.htm.

10. Warranty and limitation of liability

SETRA warrants its products to be free from defects in materials and workmanship, subject to the following terms and conditions: Without charge, SETRA

will repair or replace products found to be defective in materials or workmanship within the warranty period; provided that:

a) the product has not been subjected to abuse, neglect, accident, incorrect wiring not our own, improper installation or servicing, or use

in violation of instructions furnished by SETRA;

b) the product has not been repaired or altered by anyone except SETRA or its authorized service agencies;

c) the serial number or date code has not been removed, defaced, or otherwise changed; and

d) examination discloses, in the judgment of SETRA, the defect in materials or workmanship developed under normal installation, use

and service;

e) SETRA is notied in advance of and the product is returned to SETRA transportation prepaid.

Unless otherwise specied in a manual or warranty card, or agreed to in writing and signed by a SETRA ofcer, SETRA pressure, humidity, and acceleration

products shall be warranted for one year from date of sale.

The foregoing warranty is in lieu of all warranties, express, implied or statutory, including but not limited to, any implied warranty of merchantability for a

particular purpose.

SETRA’s liability for breach of warranty is limited to repair or replacement, or if the goods cannot be repaired or replaced, to a refund of the purchase price. In

no instance shall SETRA be liable for incidental or consequential damages arising from a breach of warranty, or from the use or installation of its products.

No representative or person is authorized to give any warranty other than as set out above or to assume for SETRA any other liability in connection with the

sale of its products.

For all CE technical questions, contact Setra Systems, USA. EU customers may contact our EU representative Hengstler GmbH, Uhlandstr 49, 78554 Aldingen,

Germany (Tel: +49-7424-890; Fax: +49-7424-89500).

Safety Precautions

This product conforms to UL 61010-1/61010-2-201 and CSA CSA22.2 No. 61010-1/61010-2-201 safety standards

Pollution Degree 2, and Measurement Category 2.

To ensure the safe operation and service of the device, follow these instructions closely. Failure to observe warnings can

result in severe personal injury or permanent damage to the device.

• This product is for indoors use only

• Use a Class-2 transformer of the appropriate size to supply power to the device

• Relay shall only be used to switch load up to 30VDC 2A

• Temperature inside enclosure may exceed 60˚C under normal operation. Select appropriate cable or wire rating for

connection. Avoid touching electronics components with bare hands to prevent personal injury

• All wiring must conform to national and local codes and regulations

• Observe ESD general practice. Wear ESD wrist strap to install and service the device

© Setra Systems, Inc. All Rights Reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc.

Page 8

11. Support

Setra FLEX

Installation & Operation Guide

Technical Support

Setra FLEX

Data Sheet

SS-FLEX Quickstart Rev. E 05/2019

www.setra.com800.257.3872 techsupport@setra.com

Setra Systems, Inc.

159 Swanson Road, Boxborough, MA 01719

800.257.3872 • www.setra.com

Loading...

Loading...