AccuSense™

Model ASM

High Accuracy

Pressure Transducer

Setra’s Model ASM is the highest accuracy transducer for

measuring gauge, absolute, compound and vacuum pressure in the AccuSense™ product line. Its ±0.05% FS accuracy

is calibrated using the “End Point Method”, which improves

linearity when compared to competitive transducers which

use the “Best Fit Straight Line Method” of calibration. The

ASM’s calibration is tamper proof by utilizing a SecureCal™

calibration key, which eliminates inadvertent adjustments,

while allowing authorized users to adjust the sensor’s calibration coecients for a true sensor calibration. The design

of the ASM oers class leading overpressure capability and

multiple pressure and electrical ttings for a wide range of

applications.

n Reliable Testing Data

High Accuracy For Demanding Applications

The Model ASM pressure transducer uses a resonant variable

capacitance sensor. This sensor is linearized and thermally

compensated through a computerized curve tting algorithm that optimizes the sensor’s linearity for maximum accuracy in demanding applications.

Robust Design & Construction for Reliable Service

The Model ASM is designed and built to withstand demanding applications. The laser welded sensor construction, designed with a positive overpressure stop, enables the sensor

to resist overpressure conditions up to 10X in all pressure

ranges.

Secure and Fast Calibration & Service

The Model ASM is ideal for the Test & Measurement industry

because it adheres to the stringent accuracy requirements.

In order to make adjustments, the ASM utilizes the SecureCal™ calibration key, providing secure calibration. The SecureCal™ provides the ability to calibrate zero and span coecients through a simple push button and rotary adjustment

dial. The SecureCal™ also oers the option to restore factory

defaults for fail-safe sensor calibration.

n Minimize Downtime

n Reduce Calibration Time

Model ASM Features:

• High Accuracy: ±0.05% FS

• End Point Method Linearity

• Low Dierential Pressure Ranges

• High Overpressure Capability: >10X Range

• Low Thermal Error

• Excellent Stability: <0.15% FS/YR

• Calibrate Using SecureCal™ Calibration Key

• High Line Pressure Capability

• Unidirectional & Bidirectional Models Available

Applications:

• Engine Test Stands

• Particle Test & Analysis

• Industrial (High Accuracy)

• Manifold Pressure

• Refrigeration Testing

AccuSense™ Model ASM

High Accuracy Pressure Transducer

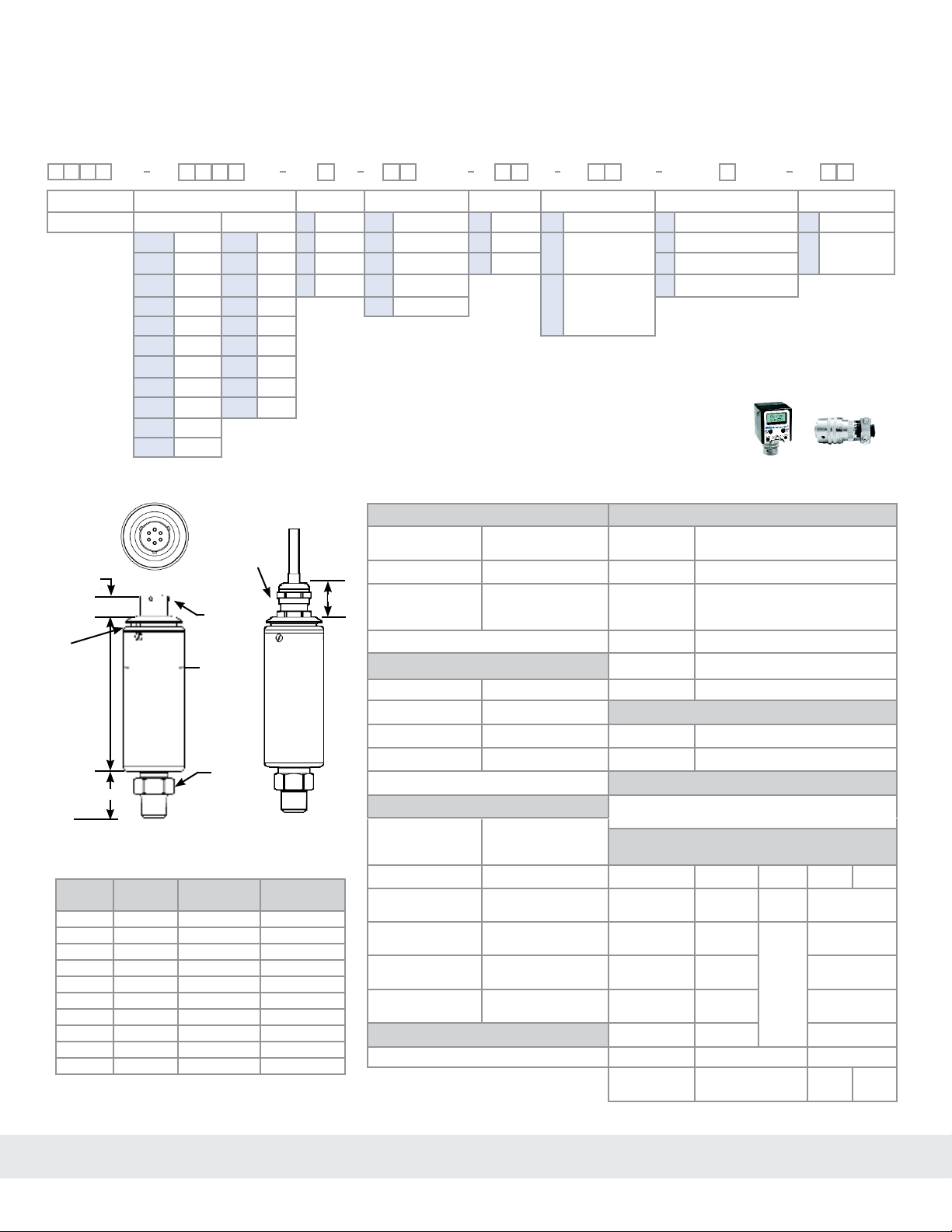

ORDERING INFORMATION

A S M 1

Model Pressure Ranges Type Pressure Port Output Elec. Termination Accuracy Option

ASM1= Model ASM PSI BAR G Gauge 1F 1/8” NPT Female 2B 0 to 5 VDC 03 3 ft, 1m Std Cable

Z01P 0 to -14.7 Z01B -1 C Compound 1M 1/8” NPT Male 2C 0 to 10 VDC

015P 0 to 15 001B 1 A Absolute 2F 1/4” NPT Female 11 4 to 20 mA

025P 0 to 25 002B 2 V Vacuum

050P 0 to 50 005B 5

100P 0 to 100 010B 10

150P 0 to 150 020B 20

250P 0 to 250 040B 40

300P 0 to 300 050B 50

500P 0 to 500 068B 68

750P 0 to 750

10CP 0 to 1000

1

2M 1/4” NPT Male B4

1

Z01 Range Only

Example: Part No. ASM1015PG1F2B03A00= ASM Transducer, 0 to 15 PSI pressure range, Gauge, 1/8” NPT Female Pressure Port, 0 to 5 VDC Output, 3ft Cable, ±0.05% FS accuracy, No options

J7 7/16-20 SAE Male

ACCESSORIES:

See data sheet for more information on Setra’s SecureCal™ Calibration Key.

6-Pin Bayonet Connector Assembly w/ Strain Relief. Order Separately: Part No. 600751

Std 6-Pin Male Bayonet

B3

Connector, Std Wiring

6-Pin Male Bayonet

B5

Connector, Optional

B6

Wiring

B7

(See Op Instructions)

A <±0.05% FS RSS <0.25% TEB

B <±0.10% Reading <0.25% TEB

C <±0.1% FS RSS <0.5% TEB

D <±0.1% FS RSS <1.5% TEB

See data sheet for more information on Setra’s SecureCal™ Calibration Key .

DIMENSIONS GENERAL SPECIFICATIONS

Performance Data Physical Description

Cable Strain

0.45/11.4

Relief

6-Pin

Vent

Porous Teon,

Recessed

3.29/83.4

Bayonet

Connector

1.3/32.9

in./mm

3/4” Hex

1.0/25.4

Shown w/Bayonet Connector Shown w/Cable Connector

PROOF PRESSURE

Full Scale

Range (PSI)

0 to 15 3,000 30 (2x) 150 (10x)

0 to 25 3,000 50 (2x) 250 (10x)

0 to 50 8,000 100 (2x) 500 (10x)

0 to 100 10,000 200 (2x) 1,000 (10x)

0 to 150 10,000 300 (2x) 1,200 (8x)

0 to 200 10,000 400 (2x) 1,200 (6x)

0 to 300 10,000 600 (2x) 1,500 (5x)

0 to 500 10,000 800 (1.5x) 2,000 (4x)

0 to 750 10,000 1,200 (1.5x) 2,250 (3x)

0 to 1000 10,000 1,500 (1.5x) 3,000 (3x)

1

Burst Pressure: The maximum pressure that may be applied to the positive pressure port without

rupturing the sensing element.

2

Proof Pressure: The maximum recoverable pressure that may be applied without changing

performance beyond specication:

±0.5% Zero Shift, Typical

Burst

Pressure1 (PSI)

Std Proof Pressure

Option Code “00”

2

High Proof Pressure

Option Code “01”

Zero Oset Position Eect <0.05%/G (Ranges ≥100 psi)

Long-term Stability <0.10% FS/Year, Typical Dimensions See reverse side

Response Time to Pressure

0.8/20

Input (From 100% to 10% of

pressure range)

Unit factory calibrated in vertical position (pressure port downward) Weight 9 oz. (254 g)

<0.1%/G (Ranges ≤50 psi)

<10 ms for Voltage Output

<80 ms for Current Output

Environmental Data

Temperature Calibrated ºF (ºC) -4 to +140 (-20 to +60) Case Materials Stainless Steel

Operating -40 to +185 (-40 to +85)

Storage -40 to +185 (-40 to +85) Wetted Materials 17-4 PH Stainless Steel

Vibration 10g from 1 kHz to 2kHz Life Cycle Rating >10^6 Pressure Cycles

Higher or lower limits available (consult factory).

Electrical Data

Excitation Range 9 to 30VDC (5VDC & 4-20 mA

Current Consumption <23 mA A B C D

Warm-up, Environmental Within ±0.02% FS after 15 min

Miswiring Reverse Excitation Protection Non-Linearity: End-

Signal Output Ranges 0 to 5 VDC, 0 to 10VDC (4-wire),

Regulatory Data CE Compliant & RoHS Compliant Non-Repeatability <±0.02%

output) 15 to 30VDC (10VDC

output)

warm-up time

4-20mA (2-wire)

Approvals

CE, RoHS Zero Oset Tol. <±0.05% FS Typ. <±0.01% FS

1

RSS of Non-Linearity, Hystereis, and Non-Repeatability.

2

Units calibrated at nominal 70oF. Max thermal error computer from this datum.

3

Operating temperature limits of the electronics only.

4

Calibrated into a 50K ohm load, operable into a 5000 ohm load or greater

US Patents # 6,532,834; 6,718,827

Electrical

Terminations

Moisture/Splash

Resistance

Pressure Fittings See Ordering Information

6-Conductor Cable, Pigtail

6-Pin Bayonet Connector

NEMA 4X (IP65)

Sensor Description

Pressure Media

Gases or liquids compatible with17-4 pH stainless steel. Note: Hydrogen not

recommended for use with 17-4 PH stainless steel.

Accuracy Data

Accuracy RSS*: EndPoint Typ. (BFSL)

Point Typ. (BFSL)

Hysteresis <0.03% FS

Span Setting Tol. <±0.05% FS <±0.01% FS

Thermal Total Error

Band (-20°C to 60°C)

<±0.05% FS

(<±0.04% FS)

<±0.025% FS

(±0.015% FS)

Typ.

FS Typ.

<±0.25% FS Typ. <±0.5% FS<±1.5%

<±0.1%

Reading**

00 None, Standard

High Overpressure

01

(See Table)

<±0.1% FS

(<±0.07% FS)

<±0.05% FS

(<±0.03% FS)

<±0.03% FS Typ.

<±0.02% FS Typ.

FS

SSASM REV. F 02/15

Loading...

Loading...