Page 1

Industrial Sensing

Product Selection Guide

Page 2

Setra Systems, Inc. was founded in 1967 by brothers Dr.Y.T.

Li and Dr. S.Y. Lee, both professors of engineering at the

Massachusetts Institute of Technology and co-developers

of the variable capacitance transduction principle.

Building on this heritage of innovation, we continue to

design and deliver premium sensing devices for many

diverse applications and industries — innovating solutions

for HVAC & building automation, industrial OEM, test &

measurement, and critical environments.

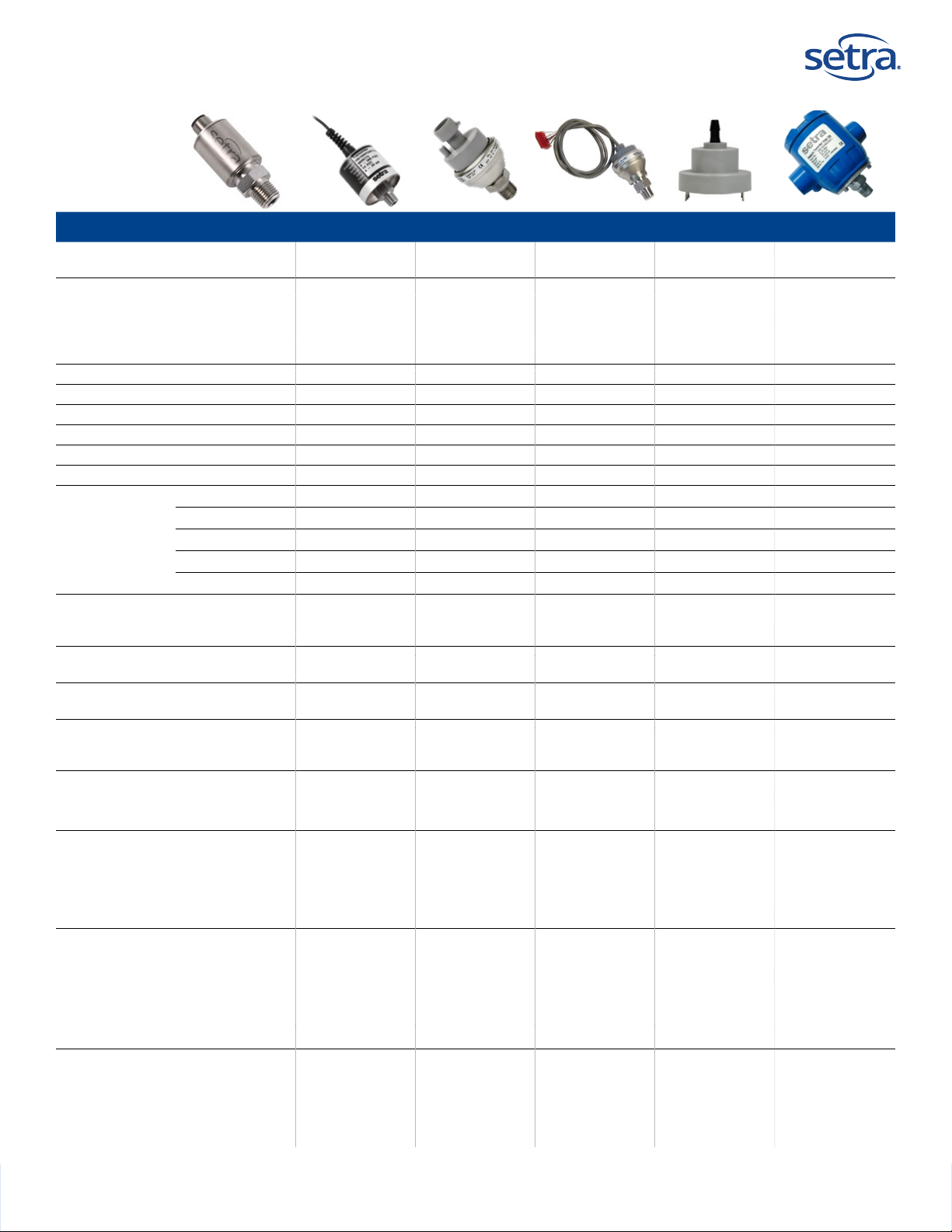

Setra’s technology

Gold plated surface

Ceramic wafer

Air dialectic

Diaphragm

(conductive surface)

Setra is part of the Fortive group of companies, a diversied

industrial growth organization with 24,000 employees

worldwide. The Fortive Business System (FBS) is the

cornerstone of our culture and our ultimate competitive

advantage. It drives every aspect of our work, our strategy

and our performance. We use FBS to guide our decisions,

measure how well we execute and develop innovative ways

to do even better.

Variable capacitance

In a typical Setra conguration, a compact housing contains two closely

spaced, parallel, electrically isolated metallic surfaces, one of which is

a diaphragm capable of slight flexing under pressure. The diaphragm

is constructed of a low-hysteresis material such as 17-4 PH SS or a

proprietary compound of fused glass and ceramic (Setraceram).

Sensor body

Advantage of

capacitive

sensors

These rmly secured surfaces (or plates) are mounted so that a slight

mechanical flexing of the assembly, caused by a minute change in applied

pressure, alters the gap between them (creating, in effect, a variable

capacitor).The resulting change in capacitance is detected by a sensitive

linear comparator circuit (employing proprietary custom designed ASICs),

which amplies and outputs a proportional, high level signal.

Better for applications that are susceptible to over-pressurization

—

Very good hysteresis, linearity, stability, and repeatability, in

addition to static pressure measurement capability

—

Excellent accuracy in low pressure ranges – as low as 1 PSI.

Page 3

Providing you the right solution for any application

Capacitance technology

Thin lm strain gauge technology

-14.7 0 15 75 250 1k 10k 32k 250k PSI

Sensor type Measuring principle Best avail. accuracy Pressure ranges Max. temperature ranges

Variable capacitance

Thin lm

Fixed electrode with moving diaphragm

linearized over temperature through ASIC

Wheatstone bridge with integrated temperature

compensation; resistors in compression or

tension, then linearized through ASIC

±0.05% FS

±0.25% FS

Thin lm strain gauge

Thin lm pressure transducers are made by vapor deposition or sputtering

of insulation and strain gauge elements directly on a polished pressure

sensing diaphragm or beam. The desired strain gauge pattern is deposited

either by masking the non-conductive areas or by etching away unwanted

conductive material.

Through a sputtering process, a small circuit is created that contains on

it a Wheatstone-bridge resistance network. As pressure is applied to the

diaphragm and unbalances (or strains) the bridge, its electrical resistance

is changed and results in a voltage output.

1 to 15,000 PSI

G, C, S, V, A

75 to 32,000 PSI

G, C, S, A

Temperature

compensation

resistor

Wheatstone

bridge resistors

-40°C to 125°C

-40°C to 125°C

Excellent resistance to shock, vibration, and dynamic pressure changes

—

Measurement cell is hermetically sealed and does not

require additional sealing materials

—

Like variable capacitance technology, does not exhibit position effect

Advantage of

thin lm

strain gauge

sensors

Page 4

General OEM pressure sensing

Model AXD 206 209 209H 210 256 526 550 3100 3200 31CS 32CS Model

Description

Low & high range OEM

pressure transducer

Field calibration-enabled

OEM pressure transducer

General purpose OEM

pressure transducer

OEM pressure transducer

for harsh applications

Circuit board-mountable

pressure transducer

NEMA4/IP65 rated

pressure transducer

Sample

Applications

Sensing technology

Gauge (PSIG)

Sealed Gauge (PSIS)

Compound (PSIC)

Absolute (PSIA)

Vacuum (PSIV)

Ranges

(PSI)

Accuracy

FS (RSS) or

% of reading

Operating

temperature

Compensated

temperature range

Thermal effect

% FS/100°F

(% FS/50°C)

Media

compatibility

Fuel cell OEM,

Industrial OEM,

CNG/LNG,

Hydraulic systems,

Compressor control,

HVAC/R equipment

Variable capacitance Variable capacitance Variable capacitance Variable capacitance Variable capacitance Variable capacitance Thin lm strain gauge Variable capacitance Thin lm strain gauge Thin lm strain gauge Thin lm strain gauge Thin lm strain gauge

Hydraulic systems,

Compressor control,

HVAC/R equipment,

Tank level

Hydraulic systems,

Compressor control,

HVAC/R equipment,

Tank level

Fuel cell OEM,

CNG & LNG,

Hydrogen production,

Water & wastewater,

Natural gas distribution.

Analytical measurement

& control,

OEM Medical Systems

Process control,

Chemical processing,

Agricultural irrigation,

Nat. gas pipeline mon-

itoring,

Grain processing

• • • • • • • • • • • •

• • • • • • •

• • • • • • •

• • •

• •

1 to 10,000 PSIG 25 to 10,000 PSIG 1 to 10,000 PSIG 15 to 1,000 PSIG 1 to 1,000 PSIG 1 to 10,000 15 to 6,000 PSIG 1 to 15 PSIG 75 to 32,000 PSIG 50 to 25,000 PSIG 75 to 32,000 PSIG 75 to 32,000 PSIG

200 to 10,000 PSIS - 200 to 10,000 PSIS 250 to 1,000 PSIS - - - - 2,300 to 32,000 PSIS 2,300 to 25,000 PSIS 1,500 to 32,000 PSIS 1,500 to 32,000 PSIS

5 to 10,000 PSIC 25 to 10,000 PSIC 1 to 10,000 PSIC 15 to 1,000 PSIC - - -14.7 to 300 PSIC - 75 to 32,000 PSIC 50 to 25,000 PSIC - -

25 to 5,000 PSIA 25 to 10,000 PSIA - - - - 15 to 300 PSIA - - - - -

ATM to 14.7 PSIV - ATM to 14.7 PSIV - - - - - - - - -

±0.25% FS ±0.13% FS ±0.25% FS ±0.25% FS

-40° to 257°F

(-40° to 125°C)

-4° to 176°F

(-20 to 80°C)

<1% (TEB avail.)

Gases or liquid

compatible with

17-4 or 316L stainless

steel

-40° to 185°F

(-40° to 85°C)

-4° to 176°F

(-20 to 80°C)

Zero: ±1 (0.9)

Span: ±1.5 (1.4)

Gases or liquid

compatible with 17-4

stainless steel

-40° to 185°F

(-40° to 85°C)

-4° to 176°F

(-20 to 80°C)

Zero: ±2.0 (1.8)

Span: ±1.5 (1.3)

Gases or liquid

compatible with

17-4 or 17-7 stainless

steel

compatible with 316L

-40° to 185°F

(-40° to 85°C)

-4° to 176°F

(-20 to 80°C)

Zero: ±0.03 (0.05)

Span: ±0.015 (0.03)

Gases or liquid

stainless steel

Standard: ±1.0% FS

Opt.: ±0.5%, ±0.25%

-4° to 176°F

(-20 to 80°C)

NA

Zero: <±2.0 (1.8)

Span: <±1.5 (1.4)

Gases compatible with

304 or 17-7 stainless

steel, nylon, polyester, or

silicone

≥25 PSI: ±0.13% FS

<25 PSI: ±0.25% FS

-40° to 185°F

(-40° to 85°C)

-4° to 176°F

(-20 to 80°C)

Please view

data sheet

Gases or liquid

compatible with 17-4

stainless steel

Output

Electrical

terminations

Pressure

ttings

4 to 20 mA

0.5 to 5.5 VDC

0.5 to 10.5 VDC

(13.5 VDC Exc. Min)

0.5 to 4.5 VDC

(5 VDC Exc.)

Cable,

3-pin Packard,

M12 4-pin,

1/2” conduit

1/4” NPT Ext.,

1/4” NPT Int.,

1/8” NPT Ext.,

1/8” NPT Int.,

7/16” SAE,

1/4“ Int. SAE

w/ Schraeder

4 to 20 mA

0.1 to 5.1 VDC

1 to 5 VDC

1 to 6 VDC

0.1 to 10.1 VDC

Cable,

Hirschmann,

1/2” conduit w/ cable,

Terminal strip

1/4” NPT Ext.,

1/8” NPT Ext.,

7/16” SAE

4 to 20 mA

0.5 to 5.5 VDC

1 to 5 VDC

1 to 6 VDC

0.5 to 4.5 VDC

(5 VDC Exc.)

Cable,

3-pin Packard,

4-pin Packard,

“Mini” Hirschmann,

Terminal strip

1/4” NPT Ext.

7/16” SAE Ext.

1/8” NPT Ext.,

1/4 Int. SAE internal 7/16”-

20 w/ Schrader,

1/2” A Ext.,

1/8” NPT Int. bulkhead

4 to 20 mA

0.5 to 5.5 VDC

0.2 to 5.2 VDC

Cable,

3-pin Packard,

4-pin Packard,

“Mini” Hirschmann,

Terminal strip

1/4”-18 NPT Ext.,

7/16”-20 SAE Ext.,

1/8”-27 NPT Ext.

1 to 6 VDC

0.5 to 4.5 VDC

0.5 to 5.5 VDC

PC board

mountable pins

Straight barbed,

Right angled barbed

4 to 20 mA

0.1 to 5.1 VDC

Two (2) 1/2” Int. conduit

ports

1/4” NPT Ext.,

1/8” NPT Ext.,

1/2” NPT Ext.,

1.4” NPT Int.

Page 5

Product images

are not shown

to scale

Submersible pressure

transducer

General purpose,

OHV,

Nat. gas equipment,

Power plants,

HVAC compressors,

Refrigeration,

Robotics

Standard: ±0.25% FS

Opt.: ±0.15% FS

Please view data sheet Please view data sheet

-4° to 176°F

(-20 to 80°C)

Standard: ±0.8 (1.5)

Opt.: ±0.5 (1.0)

Gases or liquid

compatible with 17-4

stainless steel

100 mV

4 to 20 mA

1 to 6 VDC

1 to 5 VDC

0.5 to 5.5 VDC

0 to 5 VDC

0 to 10 VDC

(and more)

10-6 bayonet conn.,

Immersible cable,

8-4 bayonet conn.,

1/2” conduit,

Large DIN 43650

1/8”-27 NPT Ext.,

1/8”-27 NPT Int.,

1/4-18 NPT Ext.,

7/16”-20 UNF Ext.,

G 1/4” Ext.,

G 1/4” Int.,

Plastic nose cone,

SS nose cone

Low range submersible

pressure transducer

Tank level,

Reservoir level,

River level,

Hydro-power,

Open channel flow,

Flood warning,

Waste water

±0.25% FS ±0.25% FS ±0.5% FS ±0.25% FS ±0.5% FS

-5° to 140°F

(-20 to 60°C)

±1.0 (2.0) ±0.83 (1.5) ±0.94 (2.0) ±0.83 (1.5) ±0.94 (2.0)

Water or viscous fluids

compatible with 316

stainless steel, ceramic,

or nitrile

4 to 20 mA

1 to 6 VDC

0 to 5 VDC

0.5 to 5.5 VDC

1 to 5 VDC

0.1 to 5.1 VDC

Large DIN 43650,

Immersible cable

G 1/4” Int.,

1/4”-18 NPT Ext.,

1/2”-14 NPT Ext.,

G 1/4” Ext.,

KF25 flange

Rugged OEM pressure

transducer

Power generation,

Hydraulic systems,

Booster pump systems,

Irrigation systems,

OHV

-40° to 257°F

(-40° to 125°C)

-40° to 257°F

(-40° to 125°C)

Gases or liquid

compatible with 17-4

stainless steel

4 to 20 mA

1 to 6 VDC

1 to 5 VDC

0.5 to 4.5 VDC

0 to 5 VDC

0 to 10 VDC

0.5 to 4.5 ratiometric

Industrial DIN,

3-pin Deutsch,

M12xP 4-pin,

AMP Superseal

1.5 Series,

Deutsch DT04-4P,

Packard Metri Pack

Please view

data sheet

Heavy-duty OEM

pressure transducer

Power generation,

Hydraulic systems,

Booster pump systems,

Irrigation systems,

OHV

-40° to 257°F

(-40° to 125°C)

-40° to 257°F

(-40° to 125°C)

Gases or liquid

compatible with 17-4

stainless steel

4 to 20 mA

1 to 6 VDC

1 to 5 VDC

0.5 to 4.5 VDC

0 to 5 VDC

0 to 10 VDC

0.5 to 4.5 ratiometric

Industrial DIN,

3-pin Deutsch,

M12xP 4-pin,

AMP Superseal

1.5 Series,

Deutsch DT04-4P,

Packard Metri Pack

Please view

data sheet

Intrinsically safe

CSA rated pressure

transducer

Industrial processes,

Chemical,

HVAC/R equipment,

Water management

-40° to 176°F

(-40 to 80°C)

-4° to 176°F

(-20 to 80°C)

Gases or liquid

compatible with 17-4

stainless steel

4 to 20 mA

1 to 6 VDC

0.1 to 5.1 VDC

1 to 5 VDC

1 to 10 VDC

0 to 5 VDC

0 to 10 VDC

(and more)

EN175301

(DIN43650 A),

M12xP 4-pin,

AMP Superseal

1.5 Series,

Deutsch DT04-4P,

Packard Metri Pack,

Industry Standard

Form C,

Integrated cable

Please view

data sheet

Heavy-duty Intrinsically

safe CSA rated pressure

transducer

Natural gas test equip-

ment,

Gas bottle lling,

Petroleum processing,

Oil & gas drilling

-40° to 176°F

(-40 to 80°C)

-4° to 176°F

(-20 to 80°C)

Gases or liquid

compatible with 17-4

stainless steel

4 to 20 mA

1 to 6 VDC

0.1 to 5.1 VDC

1 to 5 VDC

1 to 10 VDC

0 to 5 VDC

0 to 10 VDC

(and more)

EN175301

(DIN43650 A),

M12xP 4-pin,

AMP Superseal

1.5 Series,

Deutsch DT04-4P,

Packard Metri Pack,

Industry Standard

Form C,

Integrated cable

Please view

data sheet

Description

Sample

Applications

Sensing technology

Gauge (PSIG)

Sealed Gauge (PSIS)

Compound (PSIC)

Absolute (PSIA)

Vacuum (PSIV)

Ranges

(PSI)

Accuracy

FS (RSS) or

% of reading

Operating

temperature

Compensated

temperature range

Thermal effect

% FS/100°F

(% FS/50°C)

Media

compatibility

Output

Electrical

terminations

Pressure

ttings

Page 6

Test & measurement pressure sensing

Model ASL ASM 201 204 239 270 276 278 370 470 Model

Description

Sample

Applications

Sensing technology

Gauge (PSIG)

Compound (PSIC)

Absolute (PSIA)

Vacuum (PSIV)

Differential (PSID)

Ranges

Accuracy

FS (RSS) or

% of reading

Test stand-grade low

differential pressure transducer

Filter pressure,

Leak detection systems,

Exhaust pressure,

Medical instrumentation,

Part integrity testing,

Test stands,

Wind tunnels

Variable capacitance Variable capacitance Variable capacitance Variable capacitance Variable capacitance Variable capacitance Variable capacitance Variable capacitance Variable capacitance Variable capacitance

• • •

- 15 to 1,000 PSIG 5” W.C. to 20 PSIG 25 to 10,000 PSIG - 5 to 100 PSIG - - - -

- 15 to 1,000 PSIC - - - - - - - -

- 15 to 1,000 PSIA - 25 to 5,000 PSIA -

- 0 to 14.7 PSIV - 0 to 14.7 PSIV - - - - - -

2 to 40” W.C. Unidirectional,

±1 to ±15” W.C. Bidirectional

<±0.07% FS ±0.05% FS

Test stand-grade

pressure transducer

Engine test stands,

Particle test & analysis,

Manifold pressure,

Refrigeration testing,

High accuracy industrial

• • • •

•

• • • • • • •

• •

-

Very low differential/gauge

pressure transducer

Vapor recovery systems,

Exhaust gas control systems,

Industrial scrubbers

5 to 50” W.C. Unidirectional,

±2.5” to ±25” W.C.

Bidirectional

Standard: ±0.5% FS

Opt.: ±0.25% FS

High accuracy

pressure transducer

Research & development,

Vacuum systems,

Dynamometers,

Engine test cells,

General purpose

-

±0.11% FS,

±0.073% FS

High accuracy low differential

pressure transducer

Filter pressure,

Leak detection systems,

Exhaust pressure,

Medical instrumentation,

Part integrity testing,

Cleanrooms

0.5 to 30” W.C. Unidirectional,

±0.25 to ±15” W.C.

Bidirectional

Standard: ±1.0% FS

Opt.: ±0.5%, ±0.25%

Operating

temperature

Compensated

temperature range

Thermal effect

% FS/100°F

(% FS/50°C)

Media

compatibility

Output

Electrical

terminations

Pressure

ttings

-40° to 185°F

(-40° to 85°C)

-5° to 140°F

(-20 to 60°C)

<0.25% (total error band) <0.25% (total error band)

Clean, dry gases compatible

with 300 series and 17-4 PH

stainless steel

0 to 5 VDC,

0 to 10 VDC,

4 to 20 mA

3 ft (1 m) standard cable,

Standard 6-pin ext. bayonet

connection

1/8” NPT Int., Barb;

1/8” NPT Int., 1/8” NPT Int.;

1/8” NPT Ext., Barb;

7/16”-20 SAE Ext., Barb

-40° to 185°F

(-40° to 85°C)

-5° to 140°F

(-20 to 60°C)

Gases or liquid compatible with

17-4 stainless steel

0 to 5 VDC,

0 to 10 VDC,

4 to 20 mA

3 ft (1 m) standard cable,

Standard 6-pin ext. bayonet

connection

1/8” NPT Ext.,

1/8” NPT Int.,

1/4” NPT Ext.,

1/4” NPT Int.,

7/16”-20 SAE Ext.

-40° to 176°F

(-40 to 80°C)

-20° to 175°F

(-29° to 80°C)

Zero: ±2.0 (1.8)

Span: ±1.5 (1.4)

Gases or liquid compatible with

stainless steel and Inconel

4 to 20 mA

Cable,

1/2” NPT Ext. conduit,

4-pin bayonet connector,

Hirschmann w/ large ext. tting,

Terminal strip

1/4”-18 NPT Ext.,

1/4” Tube stub,

1/4”-18 NPT Int.,

7/16” SAE 37° flare

0 to 176°F

(-18° to 80°C)

NA

Zero: <±0.4 (0.36)

Span: <±0.3 (0.27)

Gases or liquid compatible with

17-4 stainless steel

4 to 20 mA,

0 to 5 VDC,

0 to 2.5 VDC,

1 to 5 VDC,

1 to 6 VDC,

0 to 10 VDC,

1 to 10 VDC

Cable,

30 AWG 9-conductor cable

1/4” NPT Int. 1/8” NPT Int. 1/8” NPT Int.

0 to 176°F

(-18° to 80°C)

30° to 150°

(-1 to 65° C)

<±1.0 (0.9)

Gases compatible with

stainless steel, hard adonized

6061 aluminum

(Buna-N O-ring)

4 to 20 mA,

±2.5 VDC,

0 to 5 VDC,

1 to 5 VDC,

1 to 6 VDC,

0 to 10 VDC

Cable,

30 AWG 9-conductor cable

Page 7

Barometric pressure sensing

Product images

are not shown

to scale

Premium barometric

pressure sensor

High accuracy barometric

pressure measurement,

Data buoys,

Remote weather stations,

Engine test cells

600/800 to 1,100 mb/hPa,

5 to 100 PSIA

- - - - -

±0.03% FS,

±0.05% FS

0 to 176°F

(-18° to 80°C)

Low-cost barometric

pressure transducer

Environmental monitoring

systems,

Wind measurement systems,

Weather & environmental data

logging,

600/800 to 1,100 mb/hPa,

20 PSIA

±0.25% FS

0 to 176°F

(-18° to 80°C)

Low power barometric

pressure transducer

AWS,

Data buoys and ships,

Agriculture metrology,

AWOS/ASOS systems

500/600/800 to 1,100 mb/hPa

Between

±0.3 and ±2.5

mb/hPa

(range dependent)

-40 to 140°F

(-40 to 60°C)

Digital barometric

pressure standard

Automatic weather

reporting systems,

Pressure transfer standard,

Altimeter calibration,

lab process monitoring,

altitude chambers

600/800 to 1,100 mb/hPa,

10 to 100 PSIA

±0.02% FS

at 70°F (21°C)

32° to 110°F

(0 to 45°C)

OEM digital

barometric transducer

Automatic weather

reporting systems,

Pressure transfer standard,

Altimeter calibration,

lab process monitoring,

altitude chambers

600/800 to 1,100 mb/hPa,

10 to 100 PSIA

±0.02% FS

at 70°F (21°C)

32° to 110°F

(0 to 45°C)

Description

Sample

Applications

Sensing technology

Gauge (PSIG)

Compound (PSIC)

Absolute (PSIA)

Vacuum (PSIV)

Differential (PSID)

Ranges

(PSI)

Accuracy

FS (RSS) or

% of reading

Operating

temperature

30° to 120°

(-1 to 49° C)

Barometric: ±0.2 (0.18)

Other: ±0.1 (0.09)

Non-condensing air or gas

compatible with hard adonized

aluminum, alumina ceramics,

gold, flourocarbon elastomer

sealant & Buna-N O-ring

0 to 5 VDC (24 VDC Exc.),

0 to 5 VDC (12 VDC Exc.)

Cable Cable 5-pin terminal block 25-pin D-Sub

30° to 130°

(-1 to 55° C)

±1% FS

Non-condensing air or gas

compatible with stainless steel,

alumina ceramics, gold, and

elastomer

0.1 to 5.1 VDC

(24 VDC Exc.),

0.1 to 5.1 VDC

(12 VDC Exc.),

0.5 to 4.5 VDC

(5 VDC Exc.)

1/8” push tube tting,

1/8” NPT Ext.

NA

Please view

data sheet

Non-condensing

air or gas

0 to 2.5 VDC

(9.5 to 28 VDC Exc.),

0 to 5 VDC

(9.5 to 28 VDC Exc.)

1/8” barbed tting 1/8” NPT Int. 1/8” barbed tting

32° to 110°F

(0 to 45°C)

Zero: ±0.002 (0.004)

Span: ±0.001 (0.002)

Non-condensing

air or gas

Bidirectional RS-232

6 digit LCD display

32° to 110°F

(0 to 45°C)

Zero: ±0.002 (0.004)

Span: ±0.001 (0.002)

Non-condensing

air or gas

Bidirectional RS-232

EIA-232 connector

DB-9P

Compensated

temperature range

Thermal effect

% FS/100°F

(% FS/50°C)

Media

compatibility

Output

Electrical

terminations

Pressure

ttings

Page 8

More solutions from Setra

Environmental monitoring

• Hospitals — ASHRAE Standard 170

• Pharmacies — USP 797 & USP 800

• Bio-safety laboratories & vivariums

• Pharmaceutical manufacturing

Particle counting & indoor air quality

• Compounding pharmacy cleanrooms

• Hospital operating and patient isolation rooms

• Construction sites near critical environments

• Industrial manufacturing cleanrooms

Power monitoring & energy management

• Tenant submetering

• Energy cost allocation

• Demand response

• Equipment efciency tracking

Low differential pressure sensing

• Building automation systems

• HVAC/R & energy management

• Cleanrooms & other critical environments

• Variable air volume (VAV) and fan control

Humidity & temperature sensing

• Hospital operating and patient isolation rooms

• Compounding pharmacy cleanrooms

• Bio-safety laboratories & vivariums

• Pharmaceutical manufacturing

Sanitary pressure sensing

• Food processing

• Dairy & beverage processing

• Sanitary pipelines

• Liquid level control

Loading...

Loading...