Page 1

AccuSense™ Model ASM

High Accuracy Pressure Transducer

AccuSense™ Model ASM with

SecureCal™ Accessory

DESCRIPTION

The AccuSense™ Model ASM is a high performance pressure

transducer designed for industrial applications requiring high

accuracy. The all stainless steel construction, groove design,

and hydrophobic porous plug protect the recessed air vent

from contaminents in industrial environments. The patented

resonant variable capacitance sensor is laser welded, providing

high accuracy and stability.

TEST & MEASUREMENT

FEATURES

High Accuracy: ±0.05% FS (End-Point)

Low Thermal Error Over Wide Temperature

Compact Design (1.3” Diameter)

Optional Overpressure Protection up to 10x

Proof Pressure

Low Thermal Error

Secure & Simple Field Calibration

Rugged Stainless Steel Construction

Multiple Congurations Available

CE Mark & EU RoHS Compliant

APPLICATIONS

Engine Test Stands

Particle Test & Analysis

Industrial (High Accuracy)

Dynamometers

Research & Development

Refrigeration Testing

The electronics platform enables outstanding performance

over environmental temperature ranges.

As part of the AccuSense™ product family, Model ASM’s zero

and span settings are securely set through use of SecureCal™

accessory making for secure and stable calibration settings.

Excellent stability, and secure calibration makes it ideal for high

performance industrial, laboratory, and test cell applications.

SPECIFICATIONS

Performance Data Physical Description Electrical Data

Zero Oset Position Eect <0.05%/G (Ranges ≥100 psi)

Long-term Stability <0.10% FS/Year, Typical Dimensions See reverse side Current Consumption <23 mA

Response Time to Pressure Input

(From 100% to 10% of pressure range)

Unit factory calibrated in vertical position (pressure port downward) Weight 9 oz. (254 g) Miswiring Reverse Excitation Protection

<0.1%/G (Ranges ≤50 psi)

<10 ms for Voltage Output

<80 ms for Current Output

Environmental Data

Temperature Calibrated ºF (ºC) -4 to +140 (-20 to +60) Case Materials Stainless Steel Regulatory Data CE Compliant & RoHS Compliant

Operating -40 to +185 (-40 to +85)

Storage -40 to +185 (-40 to +85) Wetted Materials 17-4 PH Stainless Steel Clean, dry gases compatible with17-4 pH stainless steel.

Vibration 10g from 1 kHz to 2kHz Life Cycle Rating >10^6 Pressure Cycles

Higher or lower limits available (consult factory).

US Patents # 6,532,834; 6,718,827

Electrical Terminations 6-Conductor Cable, Pigtail

Moisture/Splash

Resistance

Pressure Fittings See Ordering Information Signal Output Ranges 0 to 5 VDC, 0 to 10VDC (4-wire), 4-20mA (2-wire)

6-Pin Bayonet Connector

NEMA 4X (IP65) Warm-up,

Sensor Description

Excitation Range 9 to 30VDC (5VDC & 4-20 mA output)

15 to 30VDC (10VDC output)

Within ±0.02% FS after 15 min warm-up time

Environmental

Pressure Media

Note: Hydrogen not recommended for use with 17-4 PH stainless steel.

Specications subject to change without notice

Phone: 800-257-3872 • Fax: 978-264-0292 • www.setra.com ©2013 Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc.

Page 2

AccuSense™ Model ASM

High Accuracy Pressure Transducer

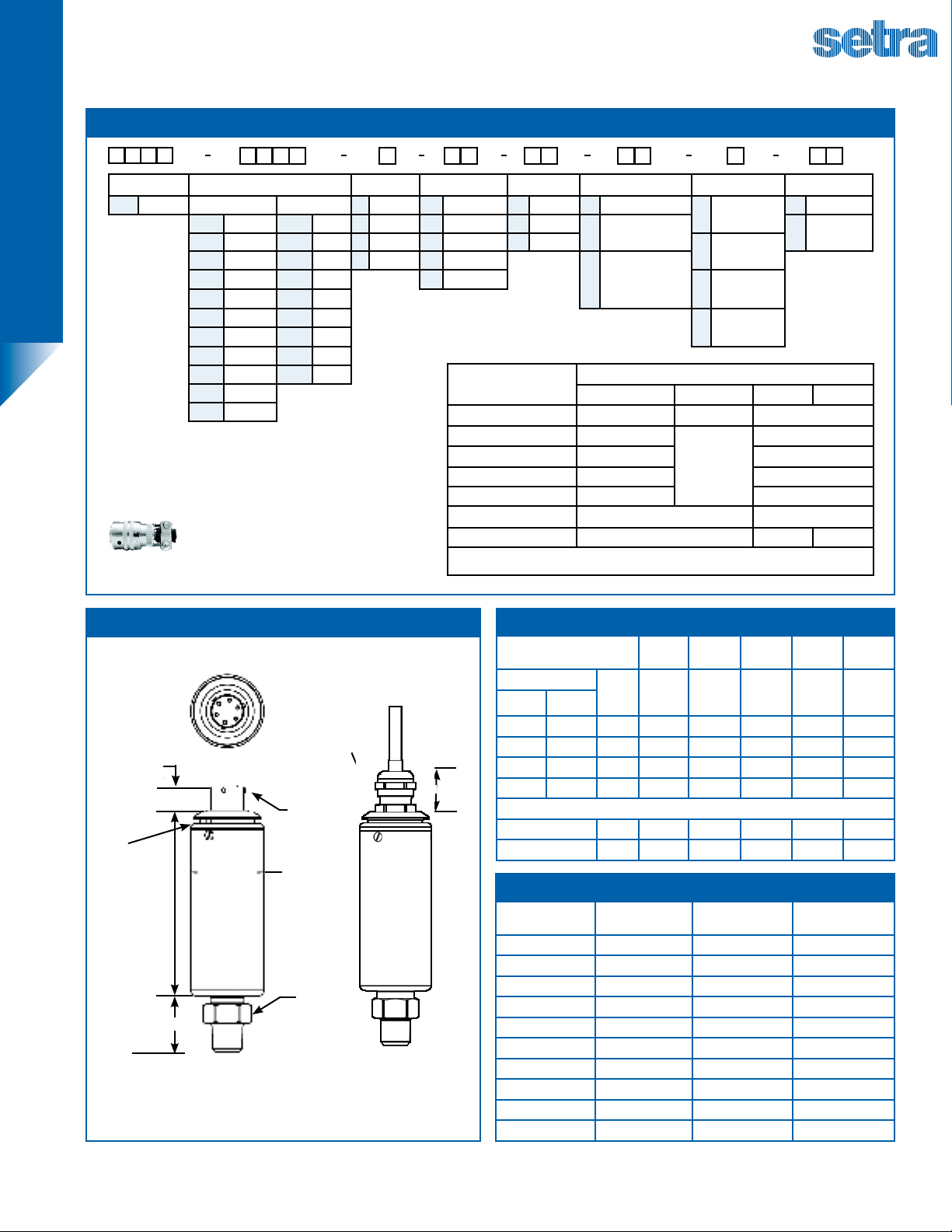

ORDERING INFORMATION

A S M 1

Model Pressure Ranges Type Pressure Port Output Elec. Termination Accuracy Option

ASM1 ASM PSI BAR G Gauge 1F 1/8” NPT Female 2B 0 to 5 VDC 03 3 ft, 1m Std Cable

Z01P 0 to -14.7 PSI Z01B -1 BAR C Compound 1M 1/8” NPT Male 2C 0 to 10 VDC

015P 0 to 15 PSI 001B 1 BAR A Absolute 2F 1/4” NPT Female 11 4 to 20 mA

025P 0 to 25 PSI 002B 2 BAR V Vacuum*

TEST & MEASUREMENT

Example: Part No. ASM1015PG1F2B03A00= ASM Transducer, 0 to 15 PSI

pressure range, Gauge, 1/8” NPT Female Pressure Port, 0 to 5 VDC Output,

3ft Cable, ±0.05% FS accuracy, No options

050P 0 to 50 PSI 005B 5 BAR *Z01 Range Only

100P 0 to 100 PSI 010B 10 BAR

150P 0 to 150 PSI 020B 20 BAR

250P 0 to 250 PSI 040B 40 BAR

300P 0 to 300 PSI 050B 50 BAR

500P 0 to 500 PSI 070B 70 BAR

750P 0 to 750 PSI

10CP 0 to 1000 PSI

6-Pin Bayonet Connector

Assembly w/Strain Relief

Order Separately:

Part No: 600751

<±0.05% FS RSS

A

Std 6-Pin Male Bayonet

B3

Connector, Std Wiring

2M 1/4” NPT Male

J7 7/16-20 SAE Male

ACCURACY DATA

Accuracy RSS*: End-Point Typ. (BFSL) <±0.05% FS (<±0.04% FS) <±0.1% Reading** <±0.1% FS (<±0.07% FS)

Non-Linearity: End-Point Typ. (BFSL) <±0.025% FS (±0.015% FS) <±0.05% FS (<±0.03% FS)

Hysteresis <0.03% FS Typ. <±0.03% FS Typ.

Non-Repeatability <±0.02% FS Typ. <±0.02% FS Typ.

Span Setting Tol. <±0.05% FS <±0.01% FS

Zero Oset Tol. <±0.05% FS Typ. <±0.01% FS

Thermal Total Error Band (-20°C to 60°C) <±0.25% FS Typ. <±0.5% FS <±1.5% FS

*RSS: Root Sum Square of endpoint linearity, Hysteresis and Non-repeatability at constant temperature.

** % of Reading accuracy achieved down to 20% of pressure range when zero oset is removed. Below 20% of pressure range uncertainty is ±0.03% FS.

B4

6-Pin Male Bayonet Con-

B5

nector, Optional Wiring

B6

(See Wiring Code Table)

B7

A B C D

<0.25% TEB

<±0.10% Reading

B

<0.25% TEB

<±0.1% FS RSS

C

<0.5% TEB

<±0.1% FS RSS

D

<1.5% TEB

Accuracy Code

00 None, Standard

01

High Overpressure

(See Table)

DIMENSIONS

0.45/11.4

Vent

Porous Teon,

Recessed

1.0/25.4

Shown w/Bayonet Connector Shown w/Cable Connector

SSPASM RevD 5/2013

3.29/83.4

Cable Strain Relief

6-Pin

Bayonet

Connector

1.3/32.9

3/4” Hex

in./mm

0.8/20

WIRING CODES

Code B3*

(Standard)

Electrical Connection

Current Voltage

+ EXC + EXC Red A A A C A

- EXC - EXC Black D B B D C

NA + Sig Out Green B C D A F

NA - Sig Out White C D C B E

Reserved for communication with SecureCal

SecureCal™ Blue E E E E B

SecureCal™ Brown F F F F C

Wire

Color

Bayonet

Connector

Pinout

Code B4

Option

Bayonet

Connector

Pinout

Code B5

Option

Bayonet

Connector

Pinout

TM

calibration module

Code B6

Option

Bayonet

Connector

Pinout

Code B7

Option

Bayonet

Connector

Pinout

PRESSURE RANGES

Full Scale Range

(PSI)

0 to 15 3,000 30 (2x) 150 (10x)

0 to 25 3,000 50 (2x) 250 (10x)

0 to 50 8,000 100 (2x) 500 (10x)

0 to 100 10,000 200 (2x) 1,000 (10x)

0 to 150 10,000 300 (2x) 1,200 (8x)

0 to 200 10,000 400 (2x) 1,200 (6x)

0 to 300 10,000 600 (2x) 1,500 (5x)

0 to 500 10,000 800 (1.5x) 2,000 (4x)

0 to 750 10,000 1,200 (1.5x) 2,250 (3x)

0 to 1000 10,000 1,500 (1.5x) 3,000 (3x)

* Burst Pressure: The maximum pressure that may be applied to the positive pressure port without rupturing the sensing element.

** Proof Pressure: The maximum recoverable pressure that may be applied without changing performance beyond specication:

±0.5% Zero Shift, Typic al

Burst Pressure*

(PSI)

Std Proof Pressure*

Option Code “00”

High Proof Pressure

Option Code “01”

©2013 Setra Systems, Inc. All rights reserved. The Setra Systems name and logo are registered trademarks of Setra Systems, Inc. Phone: 800-257-3872 • Fax: 978-264-0292 • www.setra.com

Loading...

Loading...